Laser Cutting For Steel: Fiber Vs CO2 Power Secrets Fabricators Hide

Understanding Laser Cutting Technology for Steel Fabrication

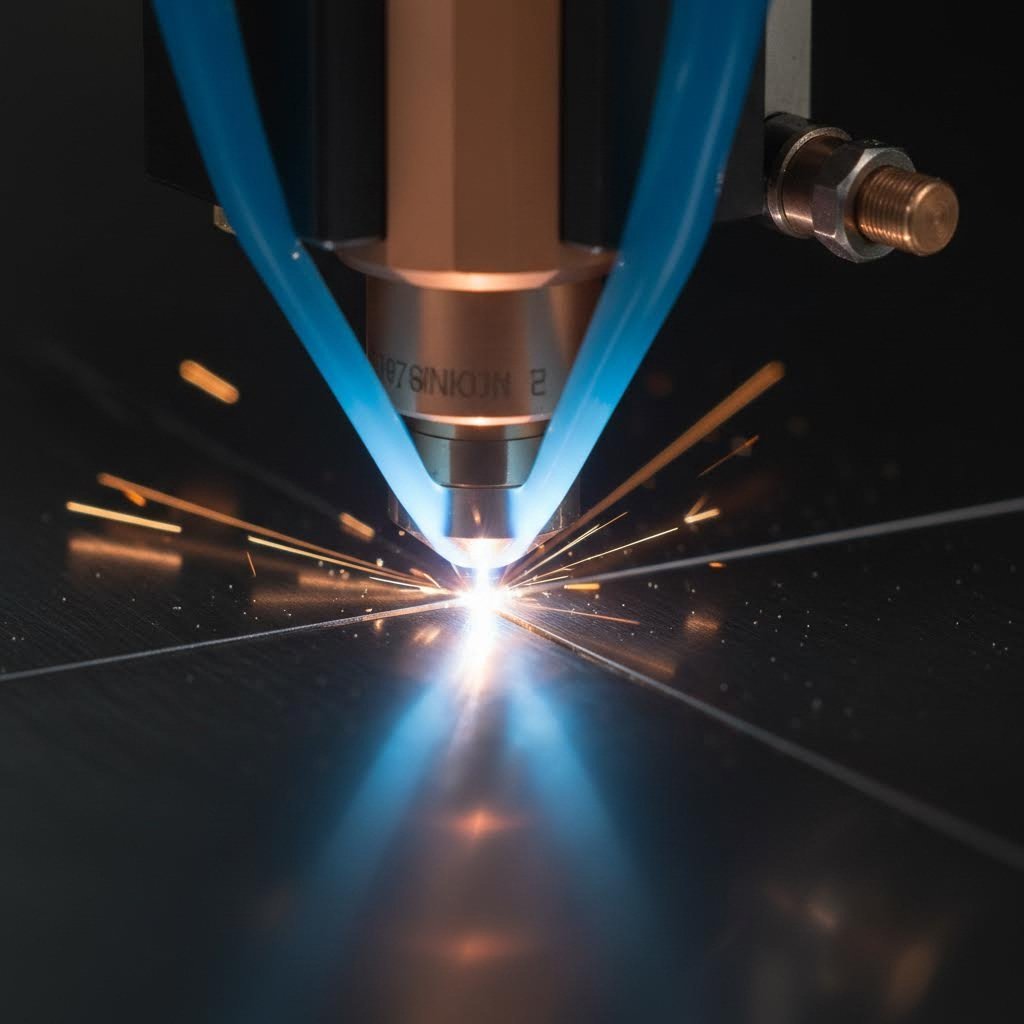

Imagine a beam of light so precise it can slice through steel with kerf widths as small as 0.004 inches. That's the reality of laser cutting for steel - a technology that has transformed from an industrial novelty into the dominant precision method for modern metal fabrication. Whether you're producing automotive chassis components or intricate architectural panels, this process delivers unmatched accuracy with tolerances often within 0.001 inch (0.025 mm).

At its core, laser cutting steel involves directing a highly focused beam of light energy along programmed paths to melt, vaporize, or burn through metal with surgical precision. The laser beam, typically focused to a spot size of approximately 0.001 inches (0.025 mm), concentrates enough thermal energy to cut through steel plates while maintaining exceptional edge quality.

Why Steel Fabricators Choose Laser Technology

You might wonder what makes a metal cutting laser superior to traditional methods. The answer lies in three key advantages:

- Precision without contact - Unlike mechanical cutting, there's no physical tool wear or contamination risk

- Minimal heat-affected zones - Reduced warping means better dimensional stability in finished parts

- Versatility across thicknesses - Modern industrial laser cutting machines handle everything from thin sheet metal to plates exceeding 13mm

Industrial laser cutting has evolved dramatically since Western Electric Engineering Research Center introduced the first production laser cutting machine in 1965. By the 1970s, CO2 lasers became the industry standard, and today's fiber laser systems operate at speeds that would have seemed impossible just decades ago.

The Precision Revolution in Metal Processing

What sets a laser metal cutting machine apart from plasma or waterjet alternatives? When you need precision combined with speed, laser technology consistently outperforms. Standard roughness values decrease with higher laser power and cutting speeds, while industrial laser cutting machine capabilities now extend to 6kW systems and beyond - approaching plasma's thickness capacity while maintaining superior edge quality.

In the sections ahead, you'll discover the secrets fabricators use to select between fiber and CO2 systems, optimize parameters for different steel grades, and troubleshoot common cutting challenges. Whether you're evaluating your first metal laser cutting investment or fine-tuning an existing operation, this guide delivers the practical knowledge you need to achieve professional results.

Fiber Laser vs CO2 Laser Systems for Steel

So you're ready to invest in laser cutting technology - but which system actually delivers the best results for steel? This is where many fabricators encounter conflicting advice. The truth is, both fiber laser cutting machines and CO2 systems have legitimate applications, but understanding their fundamental differences reveals why modern steel fabricators increasingly favor one over the other.

The core distinction starts at the wavelength. A fiber laser cutter operates at approximately 1.064 micrometers, while CO2 laser metal cutting systems produce beams at 10.6 micrometers. This tenfold difference dramatically affects how each technology interacts with steel surfaces - and ultimately determines cutting speed, edge quality, and operating costs.

Fiber Laser Advantages for Steel Processing

Here's what fabricators don't always advertise: fiber laser cutting machines can achieve cutting speeds up to three times faster than CO2 lasers when processing thin steel materials. A fiberlaser system cutting stainless steel can reach speeds of up to 20 meters per minute on thin sheets - performance that translates directly to higher throughput and shorter lead times.

Why does this happen? The shorter wavelength of laser fiber laser technology focuses into an exceptionally small spot size, concentrating thermal energy more efficiently on the steel surface. This concentrated beam creates:

- Superior absorption on reflective metals - Stainless steel, aluminum, and copper respond exceptionally well to fiber wavelengths

- Minimal thermal distortion - Less heat spread means cleaner cuts with reduced warping

- Higher electrical efficiency - Fiber systems convert approximately 35% of electrical energy into laser light, compared to just 10-20% for CO2

- Reduced maintenance demands - Solid-state technology eliminates gas tubes and mirror alignment requirements

The efficiency advantage alone changes the economics of steel fabrication. When your fiber laser cutting machine consumes roughly one-third the operating power of a comparable CO2 system, those savings compound across every production hour. Add the extended lifespan of up to 100,000 hours for fiber systems versus 20,000-30,000 hours for CO2 tubes, and the total cost of ownership shifts significantly.

When CO2 Lasers Still Make Sense

Despite fiber's advantages, dismissing CO2 laser cut metal machine technology entirely would be a mistake. CO2 lasers maintain specific strengths that matter for certain steel applications:

Thicker materials present a different equation. While fiber laser cutters excel on materials up to approximately 5mm, a CO2 laser metal cutting system can efficiently process steel plates exceeding 20mm. The longer wavelength distributes heat more evenly through thicker cross-sections, often producing smoother edge finishes on heavy plate work.

Edge quality requirements also influence the decision. CO2 lasers typically deliver slightly smoother surface finishes on thicker cuts, which can reduce secondary processing requirements for applications where edge aesthetics matter.

| Comparison Factor | Fiber Laser | CO2 Laser |

|---|---|---|

| Wavelength | 1.064 micrometers | 10.6 micrometers |

| Cutting Speed (Thin Steel) | Up to 20 m/min; 2-3x faster than CO2 | Standard baseline speed |

| Electrical Efficiency | ~35% conversion rate | ~10-20% conversion rate |

| Operating Power Consumption | Approximately 1/3 of CO2 | Higher electricity requirements |

| Maintenance Requirements | Minimal; no gas tubes or mirror alignment | Regular tube replacement and optical alignment |

| Expected Lifespan | Up to 100,000 hours | 20,000-30,000 hours |

| Optimal Steel Thickness | Excellent up to 5mm; capable to ~25mm | Superior performance on 20mm+ plates |

| Reflective Metal Handling | Excellent (stainless, aluminum, copper) | Limited; risk of back reflection damage |

| Edge Quality - Thin Materials | Exceptional; burr-free finishes | Good |

| Edge Quality - Thick Materials | May require finishing | Smoother cut edges |

The decision framework becomes clearer when you match technology to application. For high-volume production of thin to medium steel components - particularly stainless steel - a fiber laser cutter delivers compelling speed and cost advantages. For specialized thick-plate work or mixed-material operations including non-metals, CO2 technology retains relevance.

Now that you understand the core technology differences, the next critical question is: how do these systems perform across different steel grades? The answer requires examining specific cutting parameters for mild steel, stainless steel, and carbon steel varieties.

Steel Grade Selection and Cutting Parameters

Here's a secret many fabricators learn the hard way: the same laser settings that produce flawless cuts on mild steel can create excessive dross, rough edges, or incomplete penetration on stainless steel. Why? Because material composition fundamentally changes how steel absorbs and responds to laser energy. Understanding these differences is the key to consistent, professional-quality results when laser cutting steel sheet of any grade.

Each steel type presents unique thermal properties, reflectivity characteristics, and melting behaviors. When you're setting up for sheet metal laser cutting, these variables determine everything from power requirements to optimal focus position. Let's break down the specific parameters that matter for each steel grade.

Mild Steel Cutting Parameters

Mild steel laser cutting represents the most forgiving application for most fabricators. With its low carbon content (typically 0.05-0.25%) and minimal alloying elements, mild steel absorbs laser energy efficiently and responds predictably to parameter adjustments.

When cutting mild steel, you'll typically use oxygen as your assist gas. This creates an exothermic reaction that actually adds energy to the cutting process - the oxygen reacts with iron in the steel, releasing heat that helps the laser penetrate thicker materials. For thin sheets under 3mm, you can achieve cutting speeds exceeding 10 meters per minute with moderate power settings.

The key variables affecting your mild steel laser cutting results include:

- Material thickness - Directly determines minimum power requirements and maximum achievable speed

- Desired edge quality - Higher speeds may sacrifice edge smoothness; slower speeds improve finish but increase heat input

- Production speed requirements - Balancing throughput against quality often means finding the sweet spot where both are acceptable

- Heat sensitivity - Thin materials warp more easily, requiring faster speeds and optimized cooling strategies

Focus position plays a critical role here. For mild steel with oxygen assist, a positive focus position - where the focal point sits slightly above the material surface - produces enhanced oxygen reaction and improved cutting efficiency. This setup creates a slightly wider kerf but delivers faster penetration through thicker sections.

Stainless and Carbon Steel Considerations

Laser cutting stainless steel introduces an entirely different set of challenges. The chromium content (typically 10.5% or higher) that makes stainless steel corrosion-resistant also changes its thermal behavior during cutting. Chromium forms a protective oxide layer that affects laser absorption and can influence edge quality if parameters aren't properly adjusted.

Unlike mild steel, stainless steel's chromium content allows the surface to oxidize naturally, protecting the metal from weathering. However, during laser metal sheet cutting, this same property means you'll typically switch to nitrogen assist gas to prevent oxidation and achieve those clean, bright edges that stainless applications demand.

Carbon steel falls between mild and stainless in terms of cutting complexity. Higher carbon content (0.6-1.0% in high-carbon grades) increases hardness and affects heat distribution during cutting. Tool steel, with its additional alloying elements like tungsten, chromium, and vanadium, requires even more careful parameter selection to prevent cracking from thermal stress.

| Steel Grade | Thickness Range | Recommended Power | Cutting Speed Range | Focus Position | Primary Assist Gas |

|---|---|---|---|---|---|

| Mild Steel (A36/1008) | 1-3mm | 1-2 kW | 8-15 m/min | Positive (+1 to +2mm) | Oxygen |

| Mild Steel (A36/1008) | 4-10mm | 3-6 kW | 2-6 m/min | Positive (+2 to +3mm) | Oxygen |

| Stainless Steel (304/316) | 1-3mm | 2-3 kW | 6-12 m/min | Negative (-1 to -2mm) | Nitrogen |

| Stainless Steel (304/316) | 4-8mm | 4-6 kW | 1.5-4 m/min | Negative (-2 to -3mm) | Nitrogen |

| Carbon Steel (1045/1095) | 1-3mm | 1.5-2.5 kW | 6-12 m/min | Zero to Positive | Oxygen |

| Carbon Steel (1045/1095) | 4-10mm | 3-6 kW | 1.5-5 m/min | Positive (+1 to +2mm) | Oxygen |

| Tool Steel (D2/A2/O1) | 1-3mm | 2-3 kW | 4-8 m/min | Negative (-1mm) | Nitrogen |

| Tool Steel (D2/A2/O1) | 4-6mm | 4-6 kW | 1-3 m/min | Negative (-1 to -2mm) | Nitrogen |

Notice how stainless and tool steel require negative focus positions? This places the focal point below the workpiece surface, increasing the internal melting effect and enabling deeper penetration with smoother cross-sections. It's particularly effective for materials resistant to oxidation where you want to avoid surface burning.

When you laser cut metal sheets of different grades, remember that surface preparation matters just as much as machine settings. Steel must be as clean as possible before cutting - any oil, rust, or mill scale will interfere with consistent laser absorption. Wiping with acetone or degreaser, followed by compressed air, addresses most contamination issues.

The interplay between steel composition and cutting parameters becomes intuitive with experience. Start with the recommended settings in the table above, then fine-tune based on your specific material lot and edge quality requirements. Watch the spark patterns during cutting - consistent downward flow indicates optimal speed, while angled sparks suggest you're moving too fast.

With your steel grade parameters dialed in, the next critical factor is selecting the right assist gas. The choice between oxygen, nitrogen, and compressed air affects not just edge quality but also cutting speed and operating costs in ways that might surprise you.

Assist Gas Selection for Optimal Edge Quality

Ever wonder why two identical steel laser cutter setups can produce drastically different edge finishes? The answer often lies in what's flowing through that cutting nozzle alongside the laser beam. Assist gas selection is one of the most overlooked factors in steel laser cutting - yet it directly controls whether your finished parts come out with clean, oxide-free edges or require costly secondary processing.

When you laser cut steel, the assist gas performs two critical functions: it blows molten metal away from the kerf and either reacts chemically with the material or shields it from atmospheric contamination. Understanding this distinction transforms your approach to every cutting job.

Oxygen Assist for Carbon Steel

Here's the chemistry that makes oxygen so effective for carbon steel: when oxygen contacts heated iron at cutting temperatures, it triggers an exothermic reaction - meaning it releases additional heat energy. This oxidation process essentially turns your laser cutter steel operation into a combination thermal-chemical cutting system.

The practical result? Oxygen does approximately 60 percent of the cutting work on carbon steel, according to industry testing. This supplemental energy allows you to:

- Cut thicker materials - The added thermal energy enables penetration through plates that would otherwise exceed your laser's capacity

- Increase processing speed - Exothermic assistance means faster cutting on mild and carbon steel grades

- Reduce power requirements - Lower wattage settings can achieve equivalent penetration compared to inert gas cutting

However, oxygen cutting comes with a tradeoff. The same chemical reaction that boosts cutting efficiency also generates oxidation along the cutting edge, producing a slightly grey appearance. For applications requiring painting, welding, or aesthetic finishes, this oxidized edge may need brushing, grinding, or chemical treatment before further processing.

Oxygen pressure requirements stay relatively modest - typically around 2 bars with consumption of approximately 10 cubic meters per hour. This lower pressure demand translates to reduced gas costs compared to high-pressure nitrogen cutting.

Nitrogen for Clean Stainless Edges

When your laser cutting ss applications demand pristine edge quality, nitrogen becomes the essential choice. Unlike oxygen's reactive approach, nitrogen cutting is purely mechanical - the high-pressure inert gas simply blows molten material away without any chemical interaction.

This inert behavior creates what fabricators call "clean cutting" - edges emerge oxide-free with no discoloration or scale deposits. For stainless steel applications where corrosion resistance and appearance matter, nitrogen preserves the material's inherent properties right to the cut edge.

The key specifications for nitrogen-assisted cutting include:

- Gas purity requirements - Standard quality of 4.5 (99.995% pure) provides sufficient performance; harmful impurities like hydrocarbons and moisture are the real concerns rather than achieving ultra-high purity

- Pressure settings - High-pressure operation at 22-30 bars is essential for effective material ejection and clean cuts

- Consumption rates - Expect approximately 40-120 cubic meters per hour depending on material thickness and cutting speed

- Edge finish outcomes - Bright, oxidation-free surfaces ready for welding, painting, or visible applications without secondary processing

The cost consideration is significant: nitrogen consumption runs roughly 4-6 times higher than oxygen due to elevated pressure requirements. Additionally, nitrogen laser cutting speed runs approximately 30% slower than oxygen cutting since there's no exothermic energy contribution. However, when you factor in eliminated finishing labor and preserved material properties, nitrogen often delivers better overall value for stainless steel and aluminum work.

The market trend is toward a single multipurpose gas source using nitrogen. Of course, in specific cases - such as companies that only cut steel with thickness greater than 2 or 3 mm - oxygen remains the best solution.

When Compressed Air Makes Sense

Sounds expensive to choose between specialized gases? Compressed air offers an alternative worth considering - though "free" shop air isn't as cost-free as it might seem.

Air cutting cuts galvanized or aluminized steel twice as fast as other methods. It also handles thin steel and aluminum effectively for non-critical applications. The approximately 20% oxygen content in compressed air provides partial exothermic benefit while being more economical than pure oxygen supply.

However, air quality requirements are strict:

- Water content - Must be reduced to less than 2,000 ppm minimum; ideally below 100 ppm with proper drying equipment

- Oil contamination - Total hydrocarbons must stay under 2 ppm with zero droplets to prevent lens fouling

- Edge quality tradeoffs - Expect partially blackened surfaces and potential burrs requiring secondary machining

- Lens wear - Contamination risks mean more frequent lens replacement compared to pure gas systems

When calculating true air cutting costs, include electricity for compression (ranging from $0.06 to $0.20 per kW across different regions), filtration and drying equipment maintenance, and accelerated lens replacement. For high-volume operations, these hidden costs can exceed specialized gas expenses.

Matching Gas to Your Application

The optimal assist gas depends on matching your material, thickness, and quality requirements. Use this decision framework to guide your selection for any laser cutter for steel application:

| Steel Type | Thickness Range | Desired Finish | Optimal Gas | Pressure (bars) | Key Considerations |

|---|---|---|---|---|---|

| Mild/Carbon Steel | 1-6mm | Standard (oxidized OK) | Oxygen | 1-2 | Fastest cutting; lowest gas cost |

| Mild/Carbon Steel | 6-25mm | Standard (oxidized OK) | Oxygen | 2-4 | Exothermic reaction essential for thick plates |

| Mild/Carbon Steel | 1-6mm | Clean (oxide-free) | Nitrogen | 18-25 | Higher cost but eliminates finishing |

| Stainless Steel | 1-4mm | Clean (oxide-free) | Nitrogen | 18-22 | Preserves corrosion resistance |

| Stainless Steel | 5-12mm | Clean (oxide-free) | Nitrogen | 22-30 | High pressure critical for thick SS |

| Galvanized Steel | 1-4mm | Standard | Compressed Air | 8-12 | 2x faster than oxygen; cost-effective |

| Thin Steel (any) | Under 2mm | Non-critical | Compressed Air | 6-10 | Budget option for high-volume simple parts |

Remember that gas supply logistics matter too. Operations consuming over 800-1,000 cubic meters of nitrogen monthly should evaluate bulk tank storage versus cylinder racks. Tank storage offers lower per-unit costs but requires sufficient consumption volume to offset evaporation losses during idle periods.

With your assist gas strategy optimized, the next critical question becomes: how much laser power do you actually need for your steel thickness range? The answer involves more than just raw wattage - beam quality, focus optimization, and cutting head technology all influence real-world capability.

Laser Power Requirements for Steel Thickness Ranges

How much laser power do you actually need? It's the question every fabricator asks when investing in a steel laser cutting machine - and the answer is more nuanced than simply buying the most powerful unit available. Selecting the right wattage involves balancing capability against cost, because both underpowered and overpowered systems create problems that eat into your bottom line.

Here's the reality: a laser steel cutting machine that struggles to penetrate your material thickness produces rough edges, excessive dross, and incomplete cuts requiring rework. But a system with far more power than necessary wastes electricity, increases consumable wear, and ties up capital that could be deployed elsewhere. Finding the sweet spot means understanding exactly how power translates to cutting capability.

Matching Laser Power to Steel Thickness

The relationship between laser power and cutting thickness isn't linear. According to industry testing data, doubling your wattage doesn't double your thickness capacity - physical limitations in beam penetration, heat dissipation, and material ejection create diminishing returns at higher power levels.

For mild steel, the numbers tell a clear story. A 3kW system handles up to 15mm with good quality cuts, stretching to 18mm with reduced speed and edge finish. Jump to 6kW and you're processing up to 25mm with excellent results. The 12kW systems that have become increasingly common in production environments cut through 35mm mild steel at production-worthy quality levels.

Stainless steel demands more power for equivalent thicknesses due to its higher chromium content and thermal properties. That same 3kW laser maxes out at approximately 12mm for stainless, while 6kW reaches 20mm with high-pressure nitrogen assist. For heavy stainless plate work exceeding 30mm, you'll need the 12kW class machines.

| Laser Power | Mild Steel - Quality Cut | Mild Steel - Maximum | Stainless Steel - Quality Cut | Stainless Steel - Maximum |

|---|---|---|---|---|

| 1kW | 6mm | 10mm | 3mm | 5mm |

| 2kW | 10mm | 16mm | 6mm | 8mm |

| 3kW | 15mm | 20mm | 10mm | 12mm |

| 4kW | 18mm | 22mm | 12mm | 16mm |

| 6kW | 22mm | 30mm | 18mm | 20mm |

| 10kW | 30mm | 40mm | 25mm | 30mm |

| 12kW+ | 35mm | 50mm | 30mm | 40mm |

Notice the distinction between "quality cut" and "maximum" thickness. A cnc laser cutter for steel can technically penetrate material at its maximum rating, but edge finish degrades significantly. For production parts requiring minimal secondary processing, stay within the quality cut range. Reserve maximum capacity for roughing operations or parts destined for heavy machining anyway.

Understanding Wattage Requirements

Raw power tells only part of the story. When evaluating a laser cutting table for steel, several factors beyond wattage determine actual cutting performance:

- Beam quality (BPP) - Lower beam parameter product values indicate better focus capability and deeper penetration at equivalent power levels; high-quality beams maintain energy density through thick materials

- Focus optimization - Modern cutting heads with dynamic focus control adjust focal position through the cut, maintaining optimal energy concentration even in thick sections

- Cutting head technology - Auto-focus heads, anti-collision sensors, and high-pressure nozzle designs all influence real-world capability beyond nameplate wattage

- Beam brightness - Power divided by BPP squared determines cutting capability; higher brightness enables better results at lower power levels

This explains why a well-engineered 6kW cnc steel cutting laser from a premium manufacturer can outperform a poorly-designed 10kW system. The beam quality factor affects how tightly energy concentrates at the focal point - and concentrated energy cuts deeper and cleaner than diffuse power.

Speed also varies dramatically with power selection. According to comparative testing, when cutting 8mm stainless steel, a 6kW machine runs nearly 400% faster than a 3kW system. For 20mm thick stainless, 12kW delivers 114% higher speeds than 10kW. These speed differences compound across production runs, affecting your per-part costs and delivery capability.

The economic calculation becomes clearer when you consider that a 10kW cnc laser cutter steel system costs less than 40% more than a 6kW machine while delivering over twice the output efficiency per hour. For operations cutting significant volumes of medium-to-thick steel, the higher power investment pays back rapidly through throughput gains.

However, reserve some margin in your power selection. Laser sources experience gradual output decline over their service life, and cutting parameters that work perfectly with a new tube may fall short after 30,000 operating hours. Selecting a system with 20-30% headroom above your typical requirements ensures consistent quality throughout the equipment's lifespan.

With power requirements understood, the next challenge is maintaining cut quality in production. Even perfectly matched power and thickness combinations can produce disappointing results when common cutting problems emerge - dross formation, heat-affected zones, and edge roughness all require specific troubleshooting approaches.

Troubleshooting Common Steel Cutting Challenges

You've dialed in your power settings, selected the right assist gas, and programmed your cut paths - yet the finished parts still don't meet specifications. Sounds familiar? Even experienced fabricators encounter persistent quality issues when laser cutting metal, and the causes aren't always obvious. The difference between a good shop and a great one lies in systematic troubleshooting that addresses root causes rather than symptoms.

When cutting metal with a laser, five problems account for the majority of quality rejections: dross accumulation, excessive heat-affected zones, edge roughness, incomplete cuts, and material warping. Each has distinct causes and solutions - and understanding this troubleshooting framework will save you countless hours of trial-and-error adjustment.

Solving Dross Formation Problems

Dross - that stubborn molten material clinging to the underside of your cuts - represents one of the most common complaints in laser cut metal operations. According to industry analysis, dross formation typically stems from three primary causes:

- Assist gas pressure too low - Insufficient gas flow fails to eject molten metal before it re-solidifies on the cut edge

- Nozzle height or focus misalignment - Improper standoff distance disrupts the gas flow pattern needed for clean material ejection

- Parameters mismatched to material thickness - Settings optimized for thinner stock create incomplete melting on heavier plates

The solutions follow logically from these causes. Start by adjusting your cutting head standoff distance - even 0.5mm changes can dramatically affect dross behavior. Boost assist gas pressure incrementally until you see clean ejection without excessive turbulence. For persistent issues, elevated cutting supports using slats or grids allow dross to fall away cleanly rather than accumulating on the workpiece.

Watch your spark patterns during cutting. Consistent downward sparks indicate optimal parameters, while sparks angling backward suggest excessive speed that doesn't allow complete material ejection.

Minimizing Heat-Affected Zones

The heat-affected zone (HAZ) surrounding every laser cut presents a subtler but equally important quality concern. This is the area where the metal's microstructure has been altered by thermal exposure - potentially reducing strength or creating brittleness that affects part performance.

According to thermal management research, HAZ formation depends on several interacting factors:

- Cutting speed - Slower speeds increase heat input and expand the affected zone

- Laser power settings - Excess power relative to material thickness creates unnecessary thermal spread

- Assist gas selection and pressure - Proper gas flow provides cooling that limits heat penetration into surrounding material

- Material thermal conductivity - Metals like aluminum dissipate heat quickly, reducing HAZ; stainless steel retains heat longer

Calibrating power, speed, and focus to balance cut quality with minimal heat input is the key strategy. For heat-sensitive applications, consider pulsed laser cutting modes that reduce continuous heat input, or switch to high-pressure nitrogen assist for its additional cooling effect.

Addressing Edge Roughness and Incomplete Cuts

Rough edges and visible striations indicate parameter imbalances that require systematic diagnosis. The laser that cuts metal precisely one day may produce unacceptable surface finish the next - often due to overlooked maintenance issues rather than setting errors.

Common causes of edge roughness include:

- Dirty optics - Contaminated lenses and mirrors scatter beam energy, reducing cut precision

- Mechanical vibration - Gantry movement issues create visible patterns in the cut surface

- Worn nozzles - Damaged nozzle tips disrupt gas flow symmetry

- Incorrect feed rate - Too fast creates incomplete penetration; too slow causes excessive melting

For incomplete cuts where the laser fails to penetrate fully, the troubleshooting path differs slightly. Technical analysis indicates these primary causes: laser power too low for material thickness, cutting speed too high for complete penetration, focus position too far below optimal, or nozzle diameter mismatched to cutting requirements.

Controlling Material Warping and Thermal Distortion

Thin sheets curling like potato chips after cutting? Material warping from laser cutting sheet metal operations stems from uneven heat distribution causing localized expansion and contraction. This challenge intensifies with thin gauge stock, tight corner geometries, and high-volume nested layouts.

Effective mitigation strategies include:

- Proper fixturing - Secure materials flat using vacuum tables, clamps, or jigs to prevent movement during cutting

- Cutting sequence optimization - Program cut paths to distribute heat evenly across the sheet rather than concentrating thermal input in one area

- Parameter adjustment - Use pulsed cutting modes or multiple low-power passes to minimize heat buildup

- Adequate support - Apply sacrificial backing plates for thin materials prone to deflection

Different metals react uniquely to thermal stress. Material-specific considerations show that aluminum requires faster cutting speeds to prevent heat buildup, while stainless steel's lower thermal conductivity means heat concentrates near the cut zone and dissipates slowly. Tailoring parameters to each material's thermal characteristics prevents distortion before it occurs.

Maintaining Dimensional Accuracy

Tolerance specifications in laser cutting metal typically range from ±0.001 to ±0.005 inches depending on material, thickness, and machine capability. When parts fall outside these specifications, the causes often trace to:

- Thermal expansion effects - Heat buildup during extended cutting sequences causes progressive dimensional drift

- Kerf compensation errors - CAM software settings that don't match actual cut width create undersized or oversized parts

- Material clamping issues - Poor fixturing allows sheet movement during cutting

- Machine calibration drift - Backlash in drive systems accumulates positioning errors

Compensating for kerf width in your CAD/CAM software addresses the most common dimensional issue. Measure actual kerf on test cuts with your specific material and settings, then apply that offset consistently. For thermally-sensitive precision work, slow cutting speeds and allow cooling between nested parts.

The fundamental principle of laser cutting quality: optimal results emerge from balancing cutting speed against heat input. Push too fast and you sacrifice edge finish and penetration. Cut too slowly and thermal distortion, HAZ expansion, and productivity losses compound. Finding your specific sweet spot for each material and thickness combination transforms troubleshooting from reactive problem-solving into proactive quality control.

Regular machine maintenance prevents many quality issues before they appear. Clean optics weekly for high-volume operations, check nozzle condition before each job, and verify beam alignment monthly. These preventive steps cost minutes but save hours of troubleshooting and rework.

With quality challenges under control, the next consideration is ensuring consistent results from the start of your workflow. Proper material preparation and handling practices set the foundation for everything that follows in the cutting process.

Material Preparation and Workflow Optimization

Ever started a cutting job only to discover mysterious quality issues that seem to have no logical cause? Before blaming your machine settings, consider this: many laser cutting problems trace back to what happened before the steel ever reached your cutting bed. Material preparation isn't glamorous, but it's the foundation that determines whether your carefully optimized parameters actually deliver consistent results.

When you're working with a laser sheet metal operation, surface contamination and material condition create invisible barriers to quality. Oil residue changes laser absorption characteristics. Mill scale reflects energy unpredictably. Moisture introduces variables that no parameter adjustment can overcome. Understanding and controlling these factors separates professional fabricators from those constantly chasing inconsistent results.

Pre-Cutting Surface Preparation

Surface cleanliness requirements for laser cutting of metal sheets are more demanding than many operators realize. According to industry guidelines, workpieces must be properly prepped to ensure precise cuts - and that prep starts with understanding what contaminants actually affect the process.

The primary surface contaminants requiring removal include:

- Oil and lubricants - Residual cutting fluids, handling oils, and protective coatings interfere with consistent laser absorption and can create smoke that deposits on optics

- Rust and oxidation - Corroded surfaces absorb laser energy erratically, causing inconsistent penetration and edge quality variations

- Mill scale - This oxide layer formed during steel production reflects laser energy unpredictably and prevents clean, consistent cuts

- Protective films - While sometimes left intentionally to protect surfaces, plastic films can melt, ignite, or create fumes during cutting

Effective cleaning methods depend on contamination type. For oil and grease, wiping with acetone or commercial degreaser followed by compressed air removes most residues. Rust requires mechanical removal through wire brushing or sandblasting for severe cases. Mill scale on hot-rolled steel often needs grinding or pickling for complete removal - though some operations cut through light scale with adjusted parameters.

As technical guidance confirms, surface contamination such as oil or protective film can affect laser absorption and gas flow, especially on stainless steel and aluminum. The few minutes spent on proper cleaning prevent hours of troubleshooting mysterious quality variations.

Material Handling Best Practices

How you store and handle steel before cutting matters as much as how you clean it. Moisture absorption, physical damage, and contamination from improper storage create problems that surface preparation alone cannot solve.

Proper material storage prevents issues before they develop:

- Climate control - Store steel in dry environments with stable temperatures to prevent condensation and flash rusting

- Elevated storage - Keep sheets off concrete floors using racks or pallets to avoid moisture wicking

- Protective covering - Use breathable covers that prevent dust accumulation while allowing moisture to escape

- First-in-first-out rotation - Use older stock before newer deliveries to prevent extended storage deterioration

Material flatness directly affects cutting quality in ways that become more pronounced with thinner gauges. Technical documentation emphasizes that warped or uneven sheets can cause focus position variations, incomplete cutting, and inconsistent edge quality. If a sheet is visibly warped, it should be leveled or replaced before cutting begins.

When does leveling become necessary? Sheets with visible bowing exceeding 3mm per meter typically require flattening through roller leveling equipment. Thinner materials under 2mm are particularly susceptible to handling damage and may need leveling even with careful storage. The investment in proper leveling equipment pays dividends through reduced scrap and consistent part quality.

Complete Workflow from Material to Finished Part

Professional laser cutting metal sheet operations follow a systematic workflow that eliminates quality variations. Each step builds on the previous one, creating a foundation for consistent results:

- Receiving inspection - Verify material certifications match order specifications, inspect for shipping damage, measure actual thickness against nominal values, and document any surface condition issues before accepting delivery

- Surface preparation - Clean contaminants using appropriate methods for the specific contamination type, verify flatness and level if necessary, remove protective films if cutting will generate excessive heat

- Programming - Import validated design files with correct units and scale, verify geometry for open contours or duplicate lines, organize cutting layers for optimal sequence, nest parts efficiently to minimize waste

- Fixturing - Position material securely on the cutting bed with proper support, verify sheet alignment with machine coordinate system, secure material using clamps, vacuum, or weight as appropriate for thickness

- Cutting - Confirm assist gas selection and pressure, verify focus position and nozzle condition, monitor first pierce and initial cuts for parameter validation, maintain observation throughout production run

- Post-processing - Allow adequate cooling before handling, remove parts from skeleton carefully to prevent scratching, inspect cut edges for quality verification, deburr or clean as required for application

This structured approach transforms laser cutter sheet metal operations from reactive problem-solving into proactive quality management. Each checkpoint catches potential issues before they propagate through the entire production run.

Handling Different Steel Thicknesses and Sizes

Material handling requirements vary significantly based on sheet thickness and overall dimensions. Thin materials demand gentler handling to prevent bending and surface damage, while heavy plates require mechanical assistance and careful positioning.

For thin gauge materials under 3mm:

- Use vacuum lifting equipment rather than clamps that can create edge damage

- Support sheets fully during transport to prevent permanent deformation

- Consider interleaving paper between stacked sheets to prevent scratching

- Handle edges carefully - thin materials bend easily if gripped improperly

For heavy plates exceeding 10mm:

- Use appropriate lifting equipment rated for actual sheet weight

- Position carefully on cutting bed to avoid slamming that can damage support slats

- Verify table capacity before loading oversized or particularly heavy sheets

- Allow settling time after positioning before beginning cuts on very heavy plates

Large format sheets present additional challenges regardless of thickness. As operational guidelines note, for larger sheets, ensure that the material is positioned evenly to avoid stress or bending during cutting. Uneven support creates internal stresses that release during cutting, causing dimensional drift and part distortion.

Temperature considerations also matter for precision work. Steel expands approximately 0.012mm per meter per degree Celsius. Sheets brought directly from cold storage into warm shop environments should stabilize to ambient temperature before precision cutting - a process that can take several hours for thick plates.

With materials properly prepared and handled, you've eliminated the hidden variables that sabotage even perfect machine settings. The next consideration becomes economic: understanding the true costs of laser cutting and how this technology compares against alternative methods for different applications and volumes.

Cost Analysis Framework for Steel Laser Cutting

What does it actually cost to laser cut a steel part? If you've ever received quotes that varied by 300% for identical work, you understand why this question matters. The truth is, laser cutting charges depend on far more than machine time alone - and understanding the complete cost picture helps you make informed decisions about equipment investments, outsourcing choices, and competitive pricing strategies.

A metal laser cutter represents a significant capital investment, but operating costs determine whether that investment generates profit or drains resources. When you break down true per-part costs, hidden factors often outweigh the obvious ones. Let's examine the complete framework for calculating what laser cutting for steel actually costs.

Calculating True Cutting Costs

Every part cut on a laser cutting machine for metal accumulates costs across multiple categories. Professional cost estimation requires tracking each component:

- Machine time - The foundation of any calculation; includes actual cutting duration plus setup, positioning, and idle time between parts

- Consumables - Assist gas consumption, lens replacement, nozzle wear, and protective window changes add up quickly on production runs

- Electricity - Power consumption varies dramatically between technologies; fiber lasers consume roughly one-third the electricity of equivalent CO2 systems

- Labor - Operator wages, programming time, material handling, and quality inspection all contribute to per-part costs

- Maintenance allocation - Spreading preventive maintenance and repair costs across production hours reveals true equipment expense

Consider a practical example: cutting 100 identical brackets from 6mm mild steel. Direct machine time might total 45 minutes, but setup adds 15 minutes, gas consumption runs approximately $12, electricity costs $8, and allocated labor approaches $35. That $55 in "obvious" costs actually totals closer to $85 when consumables and maintenance allocation are included.

The fiber laser cutting machine price premium over CO2 systems often recovers within 18-24 months through reduced operating costs - particularly electricity savings and lower maintenance requirements. However, this calculation depends heavily on utilization rates. A machine running single shifts at 60% efficiency shows vastly different economics than one operating three shifts at 85% utilization.

Laser vs Alternative Methods

How does a metal laser cutting machine compare against plasma, waterjet, and mechanical alternatives? Each technology occupies a distinct economic niche based on material thickness, precision requirements, and production volumes. According to comparative industry analysis, the right choice depends on matching technology to application rather than defaulting to any single solution.

| Cutting Method | Equipment Cost Range | Best Steel Thickness | Precision Capability | Operating Cost/Hour | Ideal Application |

|---|---|---|---|---|---|

| Fiber Laser | $150,000 - $500,000+ | 0.5mm - 25mm | ±0.001" - ±0.005" | $15 - $35 | Precision parts, thin-medium gauge, high volume |

| CO2 Laser | $80,000 - $300,000 | 1mm - 25mm+ | ±0.002" - ±0.008" | $25 - $50 | Thick plate, mixed materials |

| Plasma | $60,000 - $150,000 | 6mm - 50mm+ | ±0.015" - ±0.030" | $20 - $40 | Heavy plate, structural steel |

| Waterjet | $100,000 - $300,000 | Any thickness | ±0.003" - ±0.010" | $30 - $60 | Heat-sensitive, mixed materials |

| Mechanical Shearing | $20,000 - $80,000 | 0.5mm - 12mm | ±0.010" - ±0.030" | $8 - $15 | Simple shapes, high volume |

The data reveals clear patterns. Plasma cutting dominates when working with thick conductive metals while keeping costs manageable - testing shows plasma cutting 1-inch steel runs 3-4 times faster than waterjet at roughly half the operating cost per foot. For structural fabrication and heavy equipment manufacturing, plasma often delivers the best return on investment.

Laser cutter for metal applications excel where precision matters most. When parts require clean edges, small holes, or intricate shapes, laser technology justifies its higher hourly rates through reduced secondary processing. Electronics, medical devices, and precision parts manufacturing consistently favor laser cutting despite higher per-hour costs.

Waterjet becomes the clear choice when heat damage must be avoided or when cutting non-metals alongside steel. The waterjet market is projected to reach over $2.39 billion by 2034, reflecting growing demand for cold-cutting capability in aerospace and sensitive applications.

Worth noting for shops considering diversification: a laser cutting machine aluminum capability often comes standard with fiber systems, expanding your addressable market without additional equipment investment. This versatility improves overall equipment utilization and spreads fixed costs across more revenue-generating applications.

Production Volume and Cost-Effectiveness

The relationship between volume and per-part cost follows predictable patterns that should guide your technology decisions. Setup time, programming, and first-article inspection costs remain relatively fixed regardless of quantity - meaning these expenses drop dramatically on a per-part basis as quantities increase.

For prototype quantities of 1-10 parts, setup costs often exceed cutting costs. A job requiring 30 minutes of programming and 15 minutes of setup might involve only 10 minutes of actual cutting. Those fixed 45 minutes spread across 10 parts adds $4-5 each; spread across 100 parts, the allocation drops below $0.50.

High-volume production reveals laser cutting's true economic advantage. Automated loading systems, optimized nesting, and continuous operation minimize non-cutting time. At volumes exceeding 1,000 parts monthly, per-piece costs for appropriate applications often undercut alternatives that appear cheaper at low volumes.

The breakeven calculation for in-house versus outsourced cutting depends on your utilization rate. A $200,000 metal laser cutting machine carrying $40,000 annual costs (financing, maintenance, facility allocation) requires approximately 2,000 productive hours yearly just to break even on ownership - before counting labor or consumables. Operations that can't achieve this utilization often find outsourcing more economical.

Material Utilization and Nesting Economics

Here's a factor that can dwarf all other cost considerations: how efficiently you use raw material. According to nesting optimization research, professional software typically recovers its cost within 1-6 months through material savings alone.

Consider the math on a high-volume operation spending $50,000 monthly on steel. A modest 5% utilization improvement from better nesting generates $30,000 in annual savings - paying back a $10,000 software investment in approximately 4 months. For operations processing expensive alloys like stainless steel, the returns compound even faster.

Effective nesting strategies include:

- Common-line cutting - Adjacent parts share cut paths, eliminating inter-part kerf waste and saving 8-12% material plus 15-25% cutting time

- True-shape nesting - Parts rotated and mirrored for optimal fit, requiring software investment but delivering measurable ROI

- Remnant management - Systematic tracking and reuse of off-cuts reduces scrap costs by 30-60% on expensive materials

- Dynamic nesting - Advanced algorithms testing thousands of arrangements approach theoretical maximum utilization

The ROI calculation for nesting software becomes compelling at any significant volume: a shop cutting 100 identical brackets daily using common-line nesting reduces 200 cut operations to 100 (mirrored pairs), saving 4 hours daily in cutting time worth $80-150 plus 10-12% material savings.

Edge margins and part spacing also affect utilization. Standard practice maintains 3-5mm from sheet edges and 1-3mm between parts. Reflective materials like aluminum require 2-4mm spacing due to heat dissipation concerns. These small allowances compound across thousands of parts into significant material differences.

When evaluating laser cutting economics, remember that the cheapest hourly rate rarely delivers the lowest per-part cost. Total cost analysis including material utilization, secondary processing requirements, and quality consistency often reveals that premium laser cutting services outperform apparently cheaper alternatives. Understanding this complete framework empowers better decisions about equipment investment, service provider selection, and competitive pricing strategy.

With cost fundamentals established, the practical question becomes: where does laser-cut steel actually go? The applications spanning automotive, construction, and precision manufacturing reveal why this technology has become indispensable across modern industry.

Industry Applications for Precision Steel Components

Where does all this precision-cut steel actually end up? Understanding real-world applications reveals why laser cutting has become the dominant fabrication method across industries requiring tight tolerances and consistent quality. From the chassis beneath your vehicle to the structural beams supporting modern architecture, a laser metal cutter shapes the components that define modern manufacturing.

The versatility of an industrial laser cutter extends far beyond simple sheet processing. Today's metal cutting laser machine technology produces everything from intricate decorative panels to heavy structural assemblies - each application demanding specific material grades, thicknesses, and edge quality specifications. Let's explore how different industries leverage this technology to solve real manufacturing challenges.

Automotive and Transportation Applications

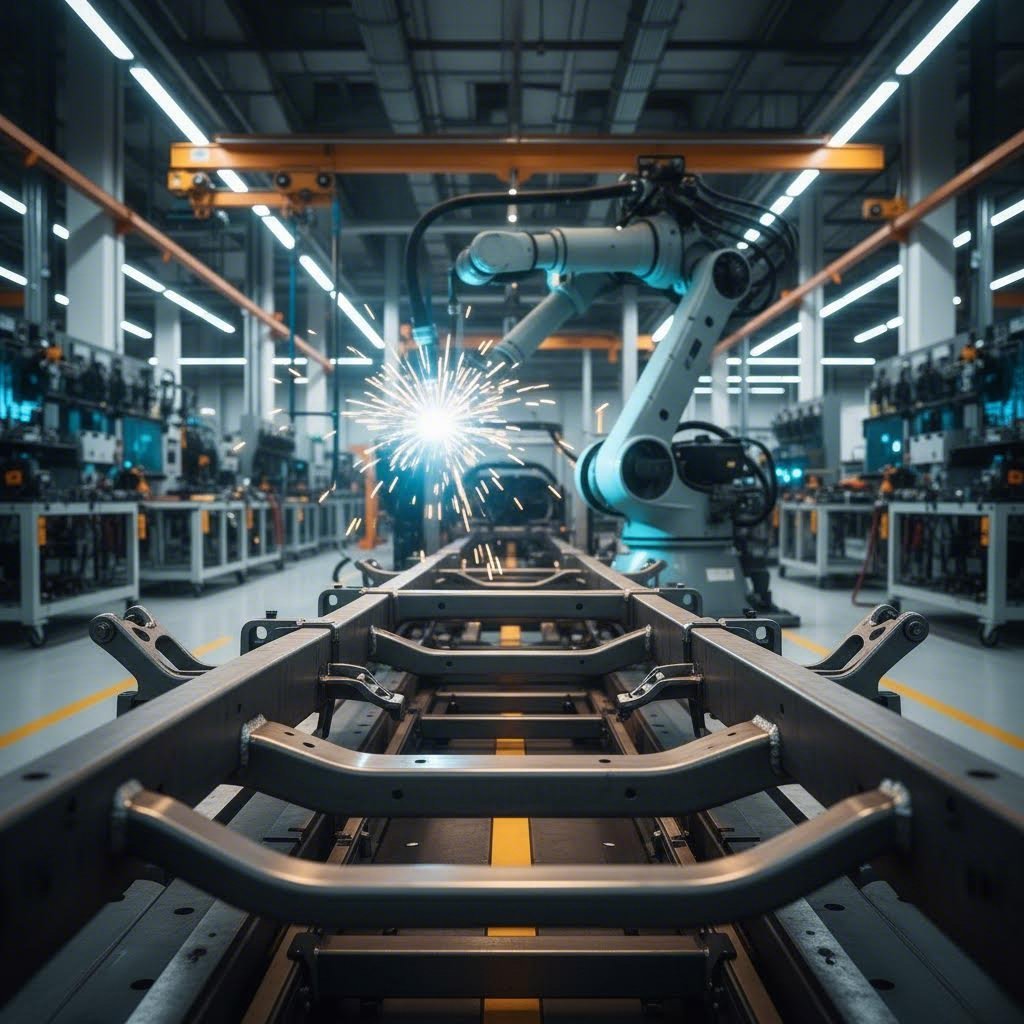

The automotive sector represents one of the most demanding environments for laser cutting machine metal technology. When you're producing chassis components, suspension brackets, and structural assemblies, precision isn't optional - it's the difference between vehicles that perform safely and those that fail under stress.

Consider roll cage fabrication for motorsport applications. Traditional methods involving manual tube notching, grinding, and repeated fitting consume enormous labor hours while producing inconsistent results. Modern 3D tube laser systems cut perfect coping curves in approximately 3 seconds compared to 5 minutes for manual processes - with puzzle-piece fitments that self-align during assembly.

Automotive steel applications include:

- Chassis rails and cross-members - 4130 Chromoly tubing cut with slot-and-tab features that fixture themselves during welding

- Suspension mounting brackets - Precision holes positioned within ±0.05mm for proper alignment geometry

- Custom gussets and reinforcements - Complex organic shapes that distribute stress better than simple triangular designs

- Body panels and structural components - Laser cut metal panels with clean edges ready for finishing without secondary grinding

The advantage extends beyond cutting speed. When suspension mounting holes are laser-cut to exact bolt diameters, bolts slide in with zero slop - preventing the "ovalizing" that occurs under racing vibration when clearances are excessive. This precision directly affects vehicle handling and safety.

For automotive manufacturers requiring both laser cutting and subsequent forming operations, integrated manufacturing partners deliver significant advantages. Companies like Shaoyi (Ningbo) Metal Technology combine laser cutting capabilities with metal stamping to produce complete chassis and suspension solutions. Their IATF 16949 certification - the automotive industry's quality management standard - ensures that precision steel components meet the stringent requirements of major OEMs. With 5-day rapid prototyping capabilities, development cycles that once took months can compress into weeks.

Structural and Architectural Steel Components

The construction industry has embraced laser cutting technology for both structural and decorative applications. According to industry analysis, laser cutting offers unparalleled precision for creating intricate designs with minimal tolerances - capabilities that manual methods simply cannot match.

Structural engineering applications demand absolute accuracy:

- Steel beams and trusses - Precision cuts ensure structural integrity where load-bearing components require exact specifications

- Connection plates and gussets - Bolt hole patterns positioned accurately across multiple mating surfaces

- Curtain wall components - Complex profiles that integrate with building envelope systems

- Decorative facades - Intricate patterns and filigree work accurately replicated on various materials

The architectural possibilities expand dramatically with laser technology. Laser cut metal signs and ornamental elements that were once prohibitively expensive to produce manually now emerge from CNC systems at production-worthy speeds. Complex patterns, custom logos, and detailed artwork translate directly from design files to finished steel components.

What makes laser cutting particularly valuable for structural applications is the minimal heat-affected zone compared to plasma cutting. When you weld to a plasma-cut edge, the hardened, brittle zone created by excessive heat input can compromise joint integrity. Laser-cut edges remain metallurgically sound right to the cut surface, enabling full-strength welds without extensive edge preparation.

Heavy Machinery and Equipment Manufacturing

Industrial equipment manufacturers rely on laser cutting for components ranging from precision housings to heavy structural frames. The technology handles the full thickness range these applications demand - from thin gauge enclosures to plate steel exceeding 25mm.

Key machinery applications include:

- Agricultural equipment - Spreader components, chassis frames, and grain handling systems requiring durability in harsh environments

- Construction machinery - Boom tube sections for cranes, excavator components, and structural assemblies

- Material handling systems - Conveyor frames, mounting brackets, and safety guards with consistent hole patterns

- Power generation equipment - Housings, brackets, and structural supports meeting strict dimensional requirements

The repeatability advantage proves particularly valuable for equipment manufacturers. If you hand-cut a chassis, no two are exactly the same. When a customer needs replacement parts years later, you're essentially starting from scratch. With laser cutting, digital files ensure every component matches the original - enabling parts kits, field replacements, and production scaling without quality variation.

Consumer Products and Precision Components

Beyond heavy industry, laser cutting serves applications requiring aesthetic quality alongside functional precision. Consumer-facing products demand clean edges, consistent finishes, and tight tolerances that justify laser technology's precision advantage.

Consumer and precision applications include:

- Electronics enclosures - Thin gauge housings with precise cutouts for connectors, displays, and ventilation

- Furniture components - Decorative steel elements, structural frames, and hardware with visible edges

- Signage and displays - Laser cut metal signs requiring intricate detail and clean presentation

- Medical equipment - Stainless steel components meeting stringent hygiene and dimensional requirements

- Military applications - Components meeting unique specifications and stringent government regulations

The contract manufacturing sector particularly benefits from laser cutting's versatility. The ability to quickly produce prototype parts with production-identical quality accelerates development cycles. When prototypes cut on the same equipment as production runs, validation testing actually reflects manufacturing reality rather than prototype-specific characteristics.

From Prototype to Production Scale

One of laser cutting's most valuable characteristics is scalability. The same process that produces a single prototype part can run unchanged for production quantities in the thousands. This consistency eliminates the quality gaps that often emerge when transitioning from prototype methods to production tooling.

For automotive applications specifically, this scalability matters enormously. A suspension bracket validated during prototype testing needs to perform identically at production volumes. When manufacturers like Shaoyi offer comprehensive DFM (Design for Manufacturing) support alongside rapid prototyping, development teams can optimize designs for both performance and manufacturability before committing to production volumes. Their 12-hour quote turnaround enables fast iteration cycles that keep development projects on schedule.

The bridge between "one-off" custom work and production manufacturing has never been shorter. Digital inventory - maintaining DXF files rather than physical stock - means any part can be reproduced on demand. Whether you need one replacement bracket or one thousand production units, the quality remains consistent.

Understanding these diverse applications clarifies why laser cutting technology has achieved such widespread adoption. The combination of precision, speed, and scalability addresses manufacturing challenges across virtually every industry working with steel. But leveraging these capabilities effectively requires strategic planning - from technology selection through production partnership choices. The final section addresses how to build a comprehensive steel cutting strategy that delivers consistent results.

Strategic Recommendations for Steel Fabrication Success

You've absorbed the technical details - fiber versus CO2 systems, steel grade parameters, assist gas chemistry, power requirements, and troubleshooting strategies. Now comes the practical question: how do you transform this knowledge into a coherent steel cutting strategy that delivers consistent results and competitive advantage?

Whether you're evaluating your first sheet metal laser cutter investment or optimizing an existing operation, success depends on synthesizing these factors into actionable decisions. The fabricators who thrive aren't necessarily those with the most expensive equipment - they're the ones who match technology, processes, and partnerships to their specific production requirements.

Building Your Steel Cutting Strategy

Every successful steel fabrication operation rests on four interconnected pillars. Weakness in any area undermines results regardless of strength elsewhere:

- Proper technology selection - Match laser type (fiber or CO2), power level, and bed size to your primary material types and thickness ranges. Remember that a well-configured 6kW fiber system often outperforms a poorly-matched 10kW machine. Consider future growth, not just current requirements

- Parameter optimization - Develop documented cutting parameters for each material grade and thickness you process regularly. Create standardized recipes that operators can execute consistently, then refine based on actual production results rather than theoretical calculations

- Material preparation - Establish receiving inspection criteria, storage protocols, and surface preparation procedures that eliminate contamination variables before they reach the cutting bed. This unsexy foundation prevents countless quality problems

- Quality control systems - Implement inspection checkpoints at critical stages: incoming material verification, first-article approval, in-process monitoring, and final inspection. Document everything to enable continuous improvement

These elements compound together. Superior technology delivers inconsistent results without proper parameters. Perfect parameters fail on contaminated material. Excellent preparation wastes resources without quality verification. The strategic advantage emerges from systematic integration across all four areas.

In-House Versus Outsourcing: The Decision Framework

Not every operation benefits from owning a laser sheet metal cutter. The economics depend on volume, complexity, and strategic priorities. According to industry research, companies with annual laser cutting requirements below 2,000 hours typically achieve better economics through outsourcing, while those exceeding 4,000 hours may justify internal equipment investments.

Consider in-house capability when:

- Production volumes justify equipment utilization above 60-70% of available capacity

- Quick turnaround for design changes provides competitive advantage

- Proprietary designs require protection from external exposure

- Integration with other internal processes (welding, forming, finishing) creates workflow efficiencies

- Quality control requirements demand direct oversight of every production step

Outsourcing often makes more sense when:

- Volume fluctuates significantly, making equipment utilization unpredictable

- Capital is better deployed in core competencies like design, sales, or assembly

- Multiple material types and thicknesses require equipment flexibility beyond any single machine

- Specialized certifications (aerospace, medical, automotive) require investments beyond cutting capability

- Geographic distribution of customers benefits from regionally-located suppliers

The hybrid approach works for many operations: maintain in-house capability for core production while outsourcing overflow, specialized materials, or extremely thick plate work requiring higher-power equipment.

Taking the Next Step in Precision Manufacturing

Whether building internal capability or selecting outsourcing partners, evaluation criteria remain consistent. According to industry guidance on partner selection, the best fabrication partners demonstrate excellence across certifications, capabilities, and responsiveness.

Certification requirements matter enormously. For automotive applications, IATF 16949 certification indicates a quality management system specifically designed for the sector's demanding requirements. ISO 9001 certification demonstrates structured, repeatable quality systems that deliver consistent results. When cutting stainless steel for food or pharmaceutical applications, look for partners meeting FDA requirements and hygienic fabrication standards.

Capability evaluation goes beyond equipment lists. A shop might own a 12kW laser for cutting machine operations, but can they actually process your specific materials at required tolerances? Request sample cuts on your actual material grades. Review documented parameter libraries. Ask about operator training and certification programs. The machine cutter metal capability only matters if operational expertise matches equipment potential.

Turnaround time reflects operational efficiency. When evaluating manufacturing partners for precision steel components, response time indicates overall capability. Partners offering comprehensive DFM (Design for Manufacturing) support and rapid quote turnaround - such as the 12-hour quote capability offered by specialists like Shaoyi (Ningbo) Metal Technology - demonstrate the process maturity and customer focus that translate to reliable production performance. This responsiveness matters particularly during development phases when iteration speed determines project success.

Look for integrated capabilities. The best manufacturing partners combine laser cutting with complementary processes - stamping, forming, welding, and finishing - to deliver complete solutions rather than just cut parts. This integration reduces your supplier management burden while ensuring accountability for final component quality.

Your Action Plan

Transform this knowledge into results with these immediate steps:

- Audit your current state - Document your material mix, thickness ranges, volume requirements, and quality specifications. This baseline determines whether technology investments or partnership changes make sense

- Calculate true costs - Apply the cost framework from earlier sections to understand your actual per-part expenses including hidden factors. Many operations discover outsourcing costs less than they assumed when all variables are included

- Evaluate technology fit - If considering equipment investment, match fiber versus CO2 selection, power level, and automation features to your documented requirements. Leave headroom for growth

- Develop parameter libraries - Whether in-house or working with partners, create documented cutting specifications for each material and thickness combination you use regularly

- Establish quality metrics - Define acceptable tolerance ranges, edge quality standards, and inspection protocols that ensure consistent results

The fabricators who dominate their markets approach laser cutting strategically rather than tactically. They invest in understanding the technology, optimizing their processes, and building partnerships that extend their capabilities. Whether you're producing chassis components, architectural elements, or precision assemblies, this systematic approach delivers the competitive advantage that distinguishes industry leaders from followers.

Laser cutting for steel has evolved from specialized technology to manufacturing essential. The secrets aren't really secrets - they're disciplined application of the principles covered throughout this guide. Your next step is implementing them in your specific context, one optimized cut at a time.

Frequently Asked Questions About Laser Cutting for Steel

1. How much does it cost to get steel laser cut?

Steel laser cutting costs typically range from $15-30 for setup fees plus hourly rates of $15-50 depending on laser type and material thickness. Per-part costs include machine time, consumables (gas, lenses, nozzles), electricity, and labor. Fiber lasers generally offer lower operating costs than CO2 systems due to higher electrical efficiency and reduced maintenance. For high-volume production, costs decrease significantly as setup expenses spread across more parts. Material utilization through optimized nesting can reduce overall project costs by 5-12%.

2. How thick of steel can a laser cut?

Modern fiber lasers cut mild steel up to 50mm and stainless steel up to 40mm with high-power 12kW+ systems. For quality cuts with clean edges, 6kW systems handle up to 22mm mild steel and 18mm stainless steel. Lower power options like 3kW machines effectively process up to 15mm mild steel and 10mm stainless. CO2 lasers excel at thicker materials exceeding 20mm due to their wavelength characteristics. The practical thickness limit depends on your power level, required edge quality, and cutting speed needs.

3. What is the difference between fiber laser and CO2 laser for cutting steel?

Fiber lasers operate at 1.064 micrometers wavelength, cutting thin steel up to 3x faster than CO2 systems while consuming roughly one-third the electricity. They excel at reflective metals like stainless steel and aluminum with minimal maintenance requirements and 100,000-hour lifespans. CO2 lasers at 10.6 micrometers deliver smoother edge finishes on thick plates exceeding 20mm and handle mixed-material operations including non-metals. Fiber technology dominates modern steel fabrication for thin-to-medium gauge work, while CO2 retains advantages for specialized thick-plate applications.

4. What assist gas should I use for laser cutting steel?

Use oxygen for carbon and mild steel when oxidized edges are acceptable - it creates an exothermic reaction that increases cutting speed and enables thicker penetration at 1-4 bars pressure. Choose nitrogen at 18-30 bars for stainless steel requiring clean, oxide-free edges suitable for welding or visible applications. Compressed air works cost-effectively for galvanized steel and thin non-critical parts, cutting galvanized materials twice as fast as other methods. The optimal choice depends on your steel type, thickness, and required edge finish quality.

5. What causes dross and rough edges in steel laser cutting?

Dross formation typically results from insufficient assist gas pressure failing to eject molten metal, improper nozzle height disrupting gas flow, or parameters mismatched to material thickness. Rough edges stem from dirty optics scattering beam energy, mechanical vibration in the gantry system, worn nozzles, or incorrect feed rates. Solutions include adjusting standoff distance, incrementally increasing gas pressure, cleaning optics weekly, and verifying focus position. Consistent downward spark patterns during cutting indicate optimal parameters, while angled sparks suggest excessive speed.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —