Laser Cut Metal Designs: From First Sketch To Flawless Delivery

Understanding Laser Cut Metal Design Fundamentals

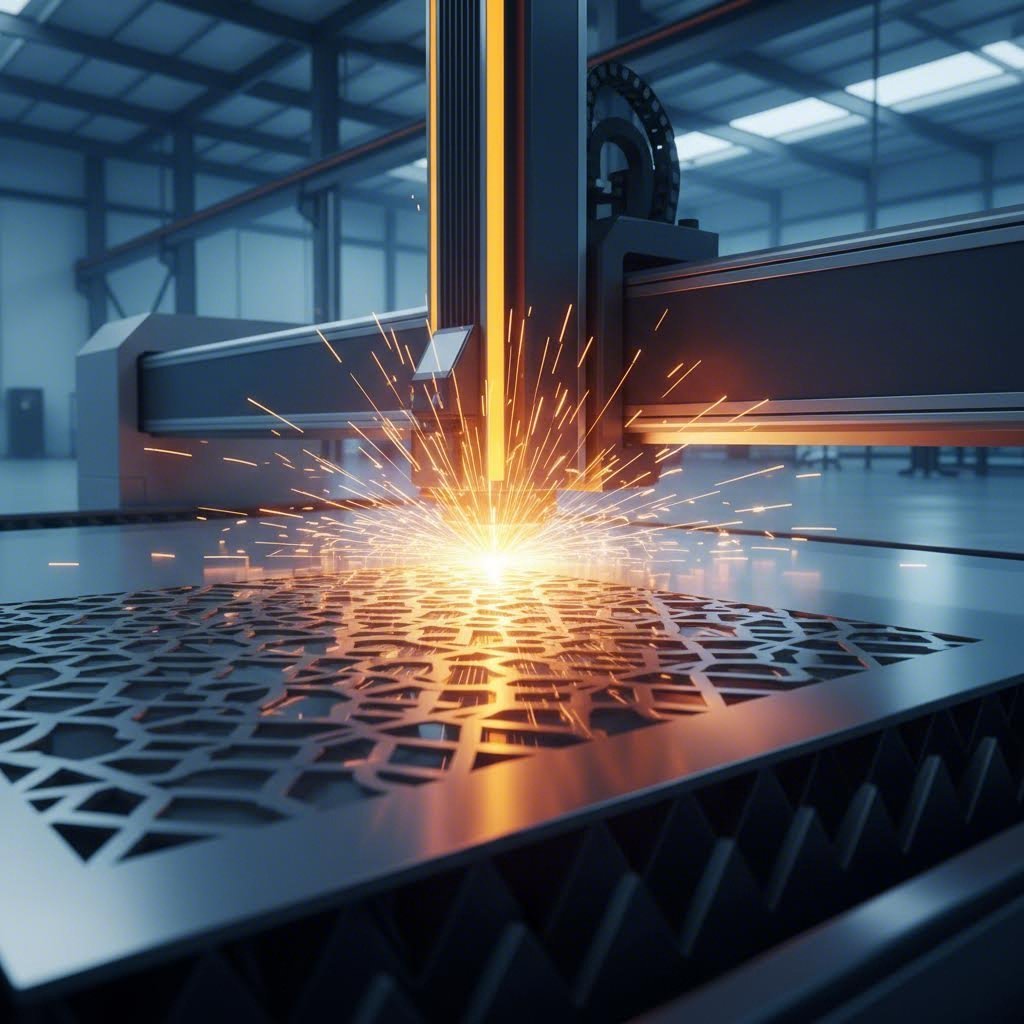

Have you ever wondered how intricate metal signs, stunning architectural facades, and decorative wall panels achieve such flawless detail? The answer lies in laser cut metal designs—a technology that has revolutionized how we shape, create, and express ideas through metal. From bold business signage to delicate artistic screens, this precision manufacturing method has transformed raw metal sheets into works of functional art.

Whether you're an architect specifying building cladding, a business owner seeking eye-catching signage, or a homeowner dreaming of custom decorative pieces, understanding the fundamentals of laser cutting empowers you to make informed decisions. Let's explore the technology that makes microscopic accuracy not just possible, but standard.

What Makes Laser Cutting the Precision Standard for Metal Design

Imagine focusing sunlight through a magnifying glass to burn a leaf—now multiply that intensity by thousands. That's the basic principle behind a laser that cuts metal. A metal cutting laser generates a highly concentrated beam of light energy, focusing it through specialized optics to a spot as small as 0.001 inches (0.025 mm). When this intense beam contacts metal, it doesn't simply cut—it vaporizes material with surgical precision.

The focused beam heats the metal surface to its flashpoint almost instantaneously. High-pressure gas, typically oxygen or nitrogen, then blows the molten material away from the cut path. This process, known as "melt and blow" cutting, allows for kerf widths (the width of material removed) as small as 0.004 inches (0.10 mm)—thinner than a human hair.

Modern fiber lasers achieve positioning accuracy of 10 micrometers and repeatability of 5 micrometers, with tolerances as tight as ±0.001 inches on stainless steel—precision that traditional mechanical cutting simply cannot match.

This exceptional accuracy means your laser cut metal designs translate from digital files to finished products with remarkable fidelity. Complex geometric patterns, flowing organic shapes, and fine text all emerge exactly as designed.

From Industrial Tool to Creative Medium

The journey of laser cutting from industrial necessity to creative medium is fascinating. When searching for "laser metal cutting near me," you're tapping into technology that began in aerospace manufacturing during the early 1970s. Back then, lasers cut titanium for aircraft components. Today, that same precision serves artists, designers, and businesses seeking custom metal creations.

Two primary laser types dominate the metal fabrication landscape, each suited to different applications:

- CO2 Lasers: Operating at a wavelength of approximately 10.6 µm, these versatile systems excel at cutting wood, plastics, and textiles while also handling light-gauge metals. They've been the industry workhorse for decades and remain popular for mixed-material applications.

- Fiber Lasers: With a wavelength of around 1,064 nanometers, fiber lasers produce spot sizes up to 100 times smaller than CO2 systems. This makes them ideal for cutting reflective metals like aluminum, copper, brass, and stainless steel. According to Kern Lasers, fiber technology delivers high power in a compact package with minimal maintenance requirements.

For most laser cut metal applications—signs, panels, decorative screens—fiber lasers have become the preferred choice. Their efficiency with metals, combined with maintenance-free operation and lower running costs, makes them particularly well-suited for precision metal work. A quality laser cutter for metal can process stainless steel, mild steel, aluminum, copper, and brass with consistent results across thousands of parts.

Understanding these fundamentals gives you the vocabulary and knowledge to discuss your project confidently with fabricators—and to appreciate just how your vision transforms into flawless laser cut metal reality.

Metal Material Selection Guide for Laser Cutting

Now that you understand how laser cutting technology works, here's the critical question: which metal should you choose for your project? The material you select influences everything—from how cleanly the laser cuts your design to how your finished piece weathers outdoor exposure. Yet most guides simply list available metals without explaining why one might suit your needs better than another.

Let's change that. Whether you're creating aluminum metal signs for a coastal business, steel signs for industrial applications, or decorative copper panels for interior design, matching metal properties to your specific requirements ensures your laser cut metal designs perform beautifully for years.

Aluminum vs Steel vs Brass vs Copper Performance Breakdown

Each metal brings distinct advantages and limitations to laser cutting. Understanding these differences helps you make confident material decisions rather than guessing or simply accepting whatever a fabricator suggests.

| Metal Type | Laser Cutting Compatibility | Corrosion Resistance | Weight (Relative) | Cost Range | Ideal Applications |

|---|---|---|---|---|---|

| Aluminum | Excellent with fiber lasers; highly reflective surface requires proper setup | Excellent; naturally forms protective oxide layer | Very Light (⅓ weight of steel) | Low to Moderate | Outdoor signage, architectural panels, lightweight decorative pieces |

| Mild Steel | Excellent; cuts cleanly with both CO2 and fiber lasers | Poor; requires protective finish for outdoor use | Heavy | Low | Industrial signage, structural components, steel metal signs with powder coating |

| Stainless Steel | Excellent; produces clean cuts with minimal burring | Excellent; chromium content prevents rust | Heavy | Moderate to High | Marine environments, food service signage, architectural facades, medical applications |

| Brass | Good with fiber lasers; requires careful parameter control | Good; develops attractive patina over time | Heavy | Moderate to High | Decorative plaques, interior signage, architectural hardware, artistic installations |

| Copper | Challenging; high reflectivity and thermal conductivity require specialized settings | Excellent; develops distinctive green patina | Heavy | High | Roofing accents, decorative art, electrical applications, premium architectural details |

Sounds complex? Here's the practical takeaway: laser cut aluminum offers the best combination of affordability, corrosion resistance, and weight savings for most outdoor applications. Stainless steel signs deliver unmatched durability in harsh environments but at higher cost and weight. Brass and copper excel when aesthetics matter more than budget—their warm tones and natural patina create distinctive character impossible to replicate with other materials.

Matching Metal Properties to Project Requirements

Beyond the comparison table, understanding how aluminium laser cutting differs from cutting steel helps you appreciate why fabricators might recommend specific materials for your project.

When working with laser cut metal sheets, each metal responds differently to the cutting process:

- Aluminum: Cuts quickly and cleanly with fiber lasers. Its lightweight nature (approximately 2.7 g/cm³ density) makes it ideal for large panels that require mounting. However, its softness means thin gauges can bend during handling—something to consider for intricate designs.

- Mild and Carbon Steel: The workhorse of metal fabrication. According to New Mexico Metals LLC, carbon steel's high use in construction and machinery makes laser cutting essential for timely availability of precisely cut components. Expect clean cuts but plan for protective finishing in outdoor applications.

- Stainless Steel: Known for producing exceptionally clean cuts with minimal burring. Its corrosion resistance and strength make stainless steel signs the premium choice for lasting outdoor installations, particularly in coastal or industrial environments where salt or chemicals challenge lesser materials.

- Brass and Copper: Both metals are softer and easier to work with than steel, but their high reflectivity and thermal conductivity demand experienced operators. These materials reward that extra effort with stunning visual warmth—perfect for decorative and artistic applications where visual impact justifies higher material costs.

Understanding Thickness Options and Gauge Specifications

When you order laser cut metal sheets, you'll encounter thickness specifications in two formats: gauge numbers and decimal inches. This can get confusing because—counterintuitively—lower gauge numbers mean thicker metal.

According to Cut2SizeMetals, gauge is a traditional measurement system where the same gauge number can represent slightly different actual thicknesses depending on the metal type. Here's what you need to know:

- Stainless steel sheets: Available from 26 gauge (0.018") to 7 gauge (0.1874") in standard grades like 304, 316, and 430

- Aluminum sheets: Typically listed in decimal form, ranging from 0.016" to 0.19" in common alloys like 3003 and 6061

- Copper sheets: Range from 26 gauge (0.0216") to 11 gauge (0.125"), often specified by ounces per square foot in architectural applications

- Brass sheets: Available from 0.020" to 0.125" in decimal thickness, with 260 alloy being standard for general use

How does thickness affect your laser cut metal designs? Thinner materials (higher gauge numbers) allow more intricate detail and tighter curves but may not provide adequate rigidity for large unsupported panels. Thicker materials offer structural strength but increase weight and cost while limiting how fine your design details can be.

For most signage and decorative applications, 16 to 14 gauge (approximately 0.060" to 0.075") provides an excellent balance of detail capability, structural rigidity, and cost efficiency. Larger architectural panels often require 11 to 7 gauge material to prevent warping and ensure lasting flatness.

With your material options clearly defined, the next consideration is equally important: understanding the design constraints and technical limitations that govern what's actually possible to cut—regardless of which metal you choose.

Design Constraints and Technical Limitations

You've selected your metal and envisioned your design—but here's where many projects stumble. Your beautiful concept might look flawless on screen, yet become impossible to cut cleanly. Why? Because laser cutting metal sheet involves physical realities that digital design software simply doesn't warn you about.

Understanding these constraints before you finalize your design saves costly revisions and disappointing results. Think of it this way: knowing the rules helps you push creative boundaries without crossing into the impossible. Let's explore the technical limitations that separate successful laser cut sheet metal projects from frustrating failures.

Minimum Feature Sizes and Kerf Width Considerations

Remember that focused laser beam vaporizing metal? That process removes a thin strip of material—called the kerf—along every cut path. According to SendCutSend, fiber laser kerf ranges from 0.006" to 0.040" (0.152mm to 1mm) depending on material thickness, while CO2 laser kerf typically falls between 0.010" and 0.020" (0.254mm to 0.508mm).

What does this mean for your design? Any feature smaller than the kerf width simply disappears during cutting. That intricate filigree detail you spent hours perfecting? If the lines are thinner than 0.040", they'll vanish completely on thicker materials.

Here's the practical impact:

- Small geometry gets lost: Features or cutouts smaller than the kerf width (0.008" to 0.040" depending on process and material) won't survive the cut

- Bridge widths matter critically: The thin metal strips connecting parts of your design need adequate width to maintain structural integrity after cutting

- Hole diameters have minimums: A general rule—minimum hole diameter should equal or exceed the material thickness for clean, consistent results

The good news? Professional fabricators typically compensate for kerf automatically, offsetting the laser path so your final dimensions match your design specifications. However, you still need to avoid features too small to survive the cutting process.

Material-Specific Design Rules You Must Follow

Different metals behave differently under laser cutting. Heat-affected zones (HAZ)—areas where metal properties change due to cutting heat—vary significantly between materials. Aluminum dissipates heat quickly, while stainless steel retains it longer, affecting how closely you can space cuts.

| Material | Thickness | Min. Hole Diameter | Min. Bridge Width | Min. Feature Size |

|---|---|---|---|---|

| Aluminum | 0.040" (1mm) | 0.040" | 0.030" | 0.020" |

| Aluminum | 0.125" (3mm) | 0.125" | 0.060" | 0.040" |

| Mild Steel | 0.060" (1.5mm) | 0.060" | 0.045" | 0.030" |

| Mild Steel | 0.125" (3mm) | 0.125" | 0.080" | 0.050" |

| Stainless Steel | 0.048" (1.2mm) | 0.048" | 0.040" | 0.025" |

| Stainless Steel | 0.125" (3mm) | 0.125" | 0.075" | 0.045" |

| Brass/Copper | 0.040" (1mm) | 0.050" | 0.040" | 0.030" |

According to MakerVerse, spacing cutting geometry at least two times the sheet thickness helps avoid distortion. Placing holes too close to edges increases the risk of tearing or deforming—especially if the part undergoes forming later.

Common Design Mistakes and How to Avoid Them

When working with a sheet metal laser cutter, these errors appear repeatedly—even from experienced designers:

- Overlapping lines: Duplicate paths cause the laser to cut the same area twice, creating burned edges and wasted time. Always check for and remove overlapping geometry before submitting files.

- Open shapes: Unclosed paths confuse cutting software. Every shape intended as a cutout must form a completely closed loop.

- Text too small: Letters under 0.25" height often lose detail, especially in serif fonts. Sans-serif typefaces like Arial or Helvetica cut more reliably at smaller sizes.

- Ignoring kerf on tight tolerances: If your design requires precise interlocking parts, account for kerf width in your dimensional planning.

- Excessive detail density: Cramming too many small features into one area creates heat buildup, potentially warping the metal or degrading cut quality.

File Preparation for Flawless Custom Cut Sheet Metal

Your design file bridges imagination and reality. According to Kirin Laser, DXF format stands as the universal standard—it's vector-based, loads quickly, and processes efficiently on cutting machines. AI (Adobe Illustrator) files work well for design flexibility but should be converted to DXF for production.

Before submitting your file for laser cutting of metal sheets:

- Convert all text to outlines/paths: This prevents font substitution issues that could distort your typography

- Set units consistently: Match your file units (inches or millimeters) to your material specifications

- Clean up stray lines: Remove construction lines, guidelines, and any geometry not intended for cutting

- Verify scale: Confirm your design dimensions match actual intended size—scaling errors are surprisingly common

- Simplify complex paths: Reduce unnecessary anchor points on curves to improve processing speed without affecting visual quality

One Kirin Laser case study found that fixing a file with 50 stray lines reduced cut time by 30%. Proper file preparation doesn't just prevent errors—it accelerates production and often reduces costs.

Understanding these technical constraints might seem limiting, but they actually liberate your creativity. When you know exactly what's achievable, you can design confidently within those boundaries—or strategically push them for dramatic effect. With your design optimized for production success, it's time to explore the exciting range of applications where laser cut metal designs truly shine.

Popular Applications for Laser Cut Metal Designs

Now that you understand the technical foundations—materials, constraints, and design principles—where exactly do laser cut metal designs make their greatest impact? From towering architectural facades to intimate garden accents, this precision technology transforms functional requirements into visual statements. The key lies in matching design approaches and material choices to each application's unique demands.

Whether you're specifying metal signs for business visibility, selecting laser cut metal panels for a building facade, or choosing decorative screens for residential privacy, understanding application-specific considerations ensures your project delivers lasting value—not just immediate appeal.

Architectural Panels and Building Facades

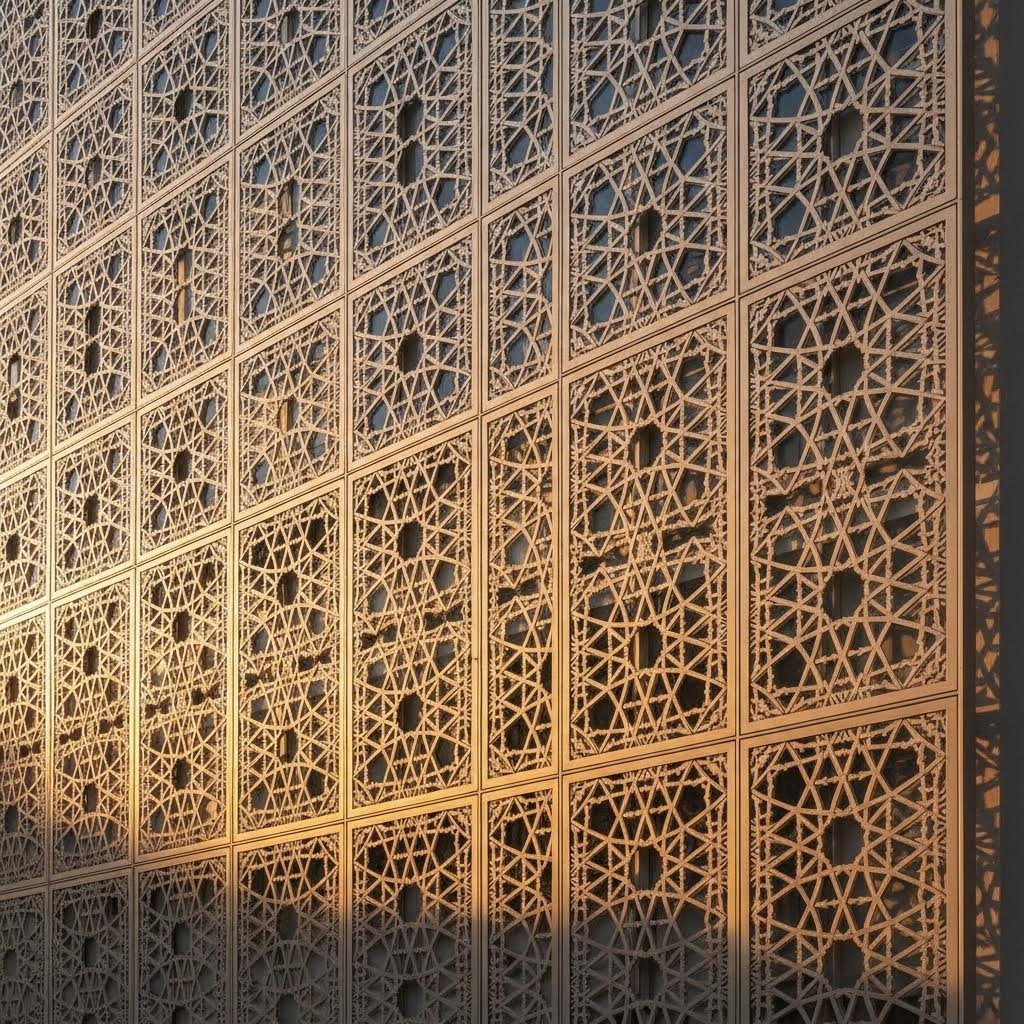

Imagine walking past a building where sunlight filters through intricate geometric patterns, casting ever-changing shadows across the entrance. That's the magic of architectural laser cut panels—they transform static structures into dynamic visual experiences.

According to KF Laser, custom laser cut metal panels are widely used in architectural design, from facades and exterior walls to decorative screens and room dividers. The precision cutting allows for designs that play with light and shadows, adding depth and character impossible to achieve with traditional construction methods.

Here's what makes architectural applications unique:

- Exterior Cladding: Large metal signs and panels covering building exteriors require materials that withstand decades of weather exposure. Aluminum offers lightweight durability with natural corrosion resistance, while stainless steel delivers unmatched longevity in harsh environments. Design considerations include panel weight (affects structural requirements), thermal expansion (requires proper mounting allowances), and pattern density (impacts wind load calculations).

- Privacy Screens: Outdoor screening panels balance visibility control with airflow and light transmission. Pattern openness typically ranges from 30% to 60%—lower percentages provide more privacy but reduce natural light. For patios, gardens, and courtyards, aluminum screens resist corrosion while remaining lightweight enough for residential mounting.

- Sunshading Systems: Perforated or patterned panels positioned as brise-soleil reduce solar heat gain while maintaining views. Pattern orientation and hole size directly affect shading performance—horizontal slots work differently than circular perforations for controlling different sun angles.

The Metrix Group notes that scale and proportion matter critically for architectural panels—large screens can overpower small spaces, while undersized panels get lost on vast facades. When selecting patterns, consider how designs interact with building geometry and surrounding landscape elements.

Signage Solutions from Business to Residential

What separates forgettable signage from signs that stop people in their tracks? Beyond design creativity, material selection and finishing determine whether your sign commands attention for years or fades into obscurity within months.

Metal signs custom designed for specific environments dramatically outperform generic alternatives. Here's how to match signage approaches to different settings:

- Commercial Storefront Signs: Custom metal signs outdoor installations face UV exposure, temperature swings, and precipitation. According to SmartSign, properly maintained metal aluminum signs can last a decade or more, offering the best longevity among common sign materials. For maximum impact, consider dimensional lettering where individual laser-cut letters mount slightly off the wall, creating shadow depth.

- Metal Signs for Business Identification: Permanent facility signage benefits from heavier gauge materials (11-14 gauge) that resist vandalism and accidental damage. Stainless steel provides a professional appearance that communicates permanence and authority—particularly effective for professional offices, medical facilities, and financial institutions.

- Metal Yard Signs and Address Markers: Residential applications often prioritize aesthetics over maximum durability. Powder-coated aluminum handles typical yard conditions beautifully while offering extensive color options. Decorative metal sign designs incorporating house numbers, family names, or artistic motifs add curb appeal while serving practical wayfinding functions.

- Wayfinding and Directional Signage: Campus environments, parks, and large facilities require consistent sign families where multiple pieces share design DNA. Laser cutting enables precise reproduction across dozens or hundreds of signs, maintaining brand consistency that reinforces professional identity.

Decorative Wall Art and Interior Applications

Inside buildings, laser cut metal designs serve purposes ranging from purely decorative to subtly functional. The controlled indoor environment allows material choices focused on aesthetics rather than weather resistance.

- Metal Decorative Signs and Wall Art: Interior pieces can utilize copper, brass, and patinated finishes that would deteriorate outdoors. Thinner gauge materials (18-22 gauge) work beautifully for wall-mounted art since structural rigidity matters less than visual delicacy. Backlighting transforms flat panels into dramatic light features—consider LED strip placement when designing pieces intended for illumination.

- Room Dividers and Screens: As the Metrix Group explains, decorative screens allow light to filter through while creating distinct areas within larger spaces, making them ideal for open-plan living. Unlike solid walls, perforated panels maintain visual connection and airflow between zones.

- Ceiling Panels and Light Fixtures: Suspended laser cut panels create stunning overhead features that interact with both natural and artificial lighting. Pattern design directly controls shadow effects—geometric patterns produce crisp shadows while organic patterns create softer, more diffuse effects.

- Cabinet Inserts and Furniture Details: Decorative metal sign panels scaled for furniture applications add custom character to built-ins, cabinet doors, and custom furniture pieces. Thinner materials (20-24 gauge) integrate seamlessly into woodworking projects.

Functional Grilles, Vents, and Practical Elements

Not every laser cut application prioritizes decoration—many serve essential functional purposes while adding aesthetic value:

- HVAC Grilles and Vent Covers: Custom covers transform utilitarian openings into design features. Open area percentage must maintain adequate airflow—typically 50% or greater for supply vents, potentially lower for return vents. Pattern selection balances visual appeal with practical airflow requirements.

- Radiator Covers: Laser cut panels conceal heating elements while ensuring heat distribution. Perforated designs allow thermal convection while adding period-appropriate or contemporary styling to any room.

- Security Screens and Gates: Pattern density and material gauge determine security level. Heavier gauges (7-11) with smaller openings provide physical barrier properties, while lighter materials with larger openings prioritize visual deterrence and privacy.

- Drain Covers and Grates: Exterior applications require corrosion-resistant materials like stainless steel or galvanized steel. Pattern design must prevent debris accumulation while maintaining drainage capacity—radiating patterns often outperform grid patterns for this purpose.

Connecting Design Choices to Real-World Outcomes

Each application category demands different priorities. Here's a quick reference connecting project types to key decision factors:

| Application Type | Primary Material Choice | Typical Gauge | Key Durability Concern | Maintenance Level |

|---|---|---|---|---|

| Exterior Architectural Panels | Aluminum or Stainless Steel | 11-14 gauge | Corrosion, UV fading | Low (periodic cleaning) |

| Custom Metal Signs Outdoor | Powder-coated Aluminum | 14-16 gauge | Weather, UV exposure | Low to Moderate |

| Interior Decorative Panels | Steel, Brass, or Copper | 18-22 gauge | Fingerprints, dust | Moderate (dusting) |

| Privacy Screens (Outdoor) | Aluminum | 14-16 gauge | Wind load, corrosion | Low |

| Functional Grilles | Steel or Stainless Steel | 16-20 gauge | Heat exposure, debris | Moderate |

Notice how outdoor applications consistently favor aluminum and stainless steel for corrosion resistance, while interior pieces can explore the full material palette including brass and copper. Heavier gauges serve structural and security purposes, while thinner materials enable finer decorative detail.

Understanding these application-specific considerations helps you specify projects that perform as beautifully five years from installation as they do on day one. Of course, material and design choices represent only part of the equation—budgeting accurately requires understanding the cost factors that influence final project pricing.

Cost Factors and Budget Considerations

You've selected your material, refined your design within technical constraints, and identified the perfect application. Now comes the question everyone asks but few resources answer clearly: what will this actually cost? Unlike commodity products with fixed pricing, laser cut metal designs involve multiple variables that combine to determine your final investment.

Understanding these cost drivers empowers you to make informed trade-offs—perhaps simplifying one design element to upgrade material quality, or adjusting quantity to unlock volume pricing. Let's break down exactly what influences laser cutting costs and how to plan your custom metal sign or panel project budget realistically.

What Drives Laser Cutting Pricing

According to Komacut, the primary factors affecting laser cutting costs include material type, thickness, design complexity, cutting time, labor costs, and finishing processes. Each element impacts efficiency and resources required for the cutting process. Here's how these factors translate to your project budget:

| Cost Factor | Impact Level | How It Affects Pricing | Budget Optimization Tips |

|---|---|---|---|

| Material Type | High | Raw material costs vary significantly—aluminum costs less than stainless steel, which costs less than copper or brass | Match material to actual requirements; don't over-specify |

| Material Thickness | High | Thicker materials require slower cutting speeds and more energy, increasing machine time | Use minimum thickness that meets structural needs |

| Design Complexity | High | More cutouts mean more pierce points and longer cutting paths; intricate details demand greater precision | Simplify geometry where detail won't be visible |

| Total Cut Length | Medium-High | Longer cutting paths directly increase machine time and energy consumption | Optimize paths; combine multiple parts on single sheets |

| Order Quantity | Medium | Setup costs spread across more units; bulk orders often qualify for material discounts | Consider ordering extras for future needs |

| Finishing Requirements | Medium | Powder coating, anodizing, and other finishes add labor, materials, and production time | Evaluate if finish is necessary or purely aesthetic |

Why does material thickness matter so much? According to Shixinproto's fabrication cost guide, thicker materials require more energy and slower cutting speeds to achieve clean cuts. This increases cutting time and energy consumption, leading to higher overall costs. A custom metal sign in 1/8" aluminum cuts significantly faster than the same design in 1/4" stainless steel.

Budget Planning for Custom Metal Projects

When planning your budget for customized metal signs or decorative panels, ranking cost factors by impact helps you prioritize where to focus optimization efforts:

- Material selection and thickness — The single biggest cost driver. Choosing aluminum over stainless steel can reduce material costs by 40-60% for equivalent dimensions. Stepping down one gauge thickness often yields 15-25% savings with minimal structural compromise.

- Design complexity and cut length — Each pierce point where the laser initiates a cut adds time and energy. A design with 50 small cutouts costs more than one with 10 larger openings covering the same open area. Longer cutting paths also increase wear on equipment.

- Order quantity — Fixed setup costs (programming, material loading, machine calibration) distribute across all pieces. Ordering 10 metal custom signs instead of 5 rarely doubles your cost—per-unit pricing drops significantly with volume.

- Secondary processes — Finishing, deburring, chamfering, and threading each add labor and specialized equipment time. According to Komacut, these processes increase manufacturing cycle complexity and duration.

- Nesting efficiency — How efficiently parts fit together on a sheet affects material waste. According to Komacut, efficient nesting maximizes material usage by arranging parts closely together, minimizing waste and reducing raw material needs.

Custom Designs vs Standard Patterns: Making the Right Investment

Here's a question many buyers face: does a fully custom metal sign design justify its premium over adapting standard patterns? The answer depends on your specific situation.

When custom designs justify the investment:

- Brand identity requires unique visual elements that standard patterns can't deliver

- Architectural integration demands designs that complement specific building features

- Functional requirements (specific open areas, mounting points, or dimensions) don't match available standards

- Volume is high enough that custom design costs amortize across many pieces

- The installation is highly visible, making distinctive design a competitive advantage

When standard patterns make sense:

- Budget constraints limit options, and standard designs meet functional needs

- Timeline pressure makes custom design development impractical

- The application is utilitarian rather than brand-defining

- Testing concepts before committing to full custom development

Many fabricators offer semi-custom options—standard patterns with customizable elements like dimensions, mounting provisions, or incorporated text. This middle ground often delivers 70% of custom design impact at 30% of the design development cost.

The most effective budget planning considers total project cost, not just cutting price. A lower-cost material requiring expensive finishing may ultimately cost more than a pricier material with natural corrosion resistance. Similarly, investing in proper design optimization upfront often pays dividends through reduced cutting time and material waste.

With your budget framework established, one major cost variable deserves deeper exploration: finishing options. The right surface treatment protects your investment for decades—while the wrong choice can lead to premature failure regardless of how much you spent on cutting.

Finishing Options and Surface Treatments

Your laser cut metal design emerges from the cutting machine with precision edges and perfect geometry—but it's not ready for installation. Without proper surface treatment, that beautiful metalwork faces an invisible enemy: corrosion. The right finish transforms vulnerable raw metal into weather-defying artwork. The wrong choice? Your investment deteriorates within months.

Finishing isn't merely cosmetic. According to SendCutSend's coating comparison testing, different finishes perform dramatically differently under real-world conditions—some excel at abrasion resistance while others provide superior corrosion protection. Understanding these trade-offs helps you specify the perfect finish for your metal sign outdoor installation, architectural panel, or decorative piece.

Powder Coating vs Anodizing vs Hot Dip Galvanizing

Three finishing methods dominate the laser cut metal industry, each with distinct advantages and limitations. Here's how they compare across the factors that matter most for long-term performance:

| Finish Type | Compatible Metals | Durability Rating | Relative Cost | Color Options | Recommended Environments |

|---|---|---|---|---|---|

| Powder Coating | Steel, Aluminum, Stainless Steel | Excellent (abrasion, impact) | Low to Moderate | Virtually unlimited RAL colors, metallics, textures | Indoor, Outdoor, Light Industrial |

| Type 2 Anodizing | Aluminum only | Good (thin but hard surface) | Moderate | Limited—clear, black, bronze, gold, red, blue | Indoor, Outdoor, Architectural |

| Type 3 Anodizing (Hardcoat) | Aluminum only | Excellent (very hard, wear-resistant) | High | Limited—typically dark gray to black | Industrial, High-Wear, Marine |

| Zinc Plating | Steel only | Good (sacrificial corrosion protection) | Low to Moderate | Silver/gray metallic appearance | Industrial, Moderate Outdoor |

| Hot Dip Galvanizing | Steel only | Excellent (thick zinc layer) | Moderate | Metallic gray only | Outdoor, Marine, Industrial, Agricultural |

What do these ratings mean in practice? SendCutSend's abrasion testing revealed that powder coated steel outperformed all other finishes dramatically—lasting nearly 10 times longer than the runner-up before the coating wore through. However, once scratched, powder coating offers no underlying protection, while zinc-based finishes continue protecting even when damaged.

Understanding Each Finish's Strengths

Let's explore when each finish makes the most sense for your project:

Powder Coating: Applied electrostatically and cured under heat, powder coating creates a thick, durable layer that bonds mechanically and chemically to metal surfaces. According to Palm City Iron Works, this process creates a bond much thicker and harder than paint, explaining why powder-coated metalwork outlasts painted pieces significantly. The finish prevents oxidation—the root cause of rust—while offering unmatched color options.

- Best for: Metal outdoor signs, decorative panels, architectural elements requiring specific brand colors

- Expected lifespan: 15-20+ years with proper preparation and quality powder

- Maintenance: Periodic cleaning with mild soap; inspect annually for chips or damage

Type 2 Anodizing: This electrochemical process converts the aluminum surface into a hard aluminum oxide layer. Unlike coatings that sit on top, anodizing actually becomes part of the metal. SendCutSend testing confirmed type 2 anodizing offers the thinnest coating with minimal dimensional impact while providing decent durability.

- Best for: Personalized outdoor metal signs, architectural trim, applications requiring tight tolerances

- Expected lifespan: 10-20 years depending on environment and color

- Maintenance: Simple cleaning; extremely low maintenance

Type 3 Anodizing (Hardcoat): A thicker, harder version of standard anodizing, type 3 creates exceptional wear resistance. Testing showed it as the runner-up for abrasion resistance while adding minimal thickness. The finish performed very well across all durability tests, making it a safe choice for demanding applications.

- Best for: High-traffic exterior metal signs, industrial components, marine environments

- Expected lifespan: 20+ years in typical conditions

- Maintenance: Minimal; occasional cleaning

Zinc Plating and Hot Dip Galvanizing: Both processes apply zinc to steel surfaces, but through different methods with very different results. Zinc plating creates a thin, consistent layer ideal for indoor or sheltered applications. Hot dip galvanizing submerges steel in molten zinc, creating a much thicker coating. As McLean Company notes, zinc coatings serve as sacrificial protection—the zinc corrodes instead of the steel beneath, continuing to protect even when scratched.

- Best for: Structural components, metal outside signs in harsh environments, agricultural equipment

- Expected lifespan: 25-50+ years for hot dip galvanizing; 5-15 years for zinc plating

- Maintenance: Inspect for white rust (zinc oxide); generally low maintenance

Matching Finishes to Environmental Conditions

Where will your laser cut metal design live? Environmental conditions should drive your finish selection more than aesthetic preference. Here's how to match finishes to specific exposure conditions:

- Indoor environments: Nearly any finish works. Choose based on aesthetics and budget. Consider clear coats to preserve natural metal appearance, or powder coating for color. Brass and copper can remain unfinished to develop natural patina.

- Standard outdoor exposure: Powder coated aluminum or anodized aluminum handles typical weather beautifully. For steel, powder coating over properly prepared surfaces provides excellent protection. Metal signs outdoor installations should specify UV-stable powder formulations to prevent color fading.

- Coastal and marine environments: Salt spray accelerates corrosion dramatically. Type 3 anodized aluminum or marine-grade stainless steel perform best. For steel, hot dip galvanizing with a powder coat topcoat provides maximum protection. Standard zinc plating fails relatively quickly in salt environments.

- Industrial settings: Chemical exposure, abrasion, and high temperatures demand specialized solutions. Type 3 anodizing resists chemical attack while powder coating handles physical abuse. Consult with finishers about specific chemical exposures—some environments require specialty coatings.

Finish Selection Criteria by Application

When specifying finishes for your laser cut metal project, evaluate these criteria in order of importance for your specific application:

- Environmental exposure: Indoor, outdoor, marine, or industrial? This single factor eliminates many options immediately.

- Substrate compatibility: Anodizing works only on aluminum; galvanizing only on steel. Material choice may dictate finishing options.

- Color requirements: Need brand-specific colors? Powder coating offers unlimited options. Can you work with metallic or limited tones? Anodizing or galvanizing may suffice.

- Dimensional tolerance: Type 2 anodizing adds minimal thickness (approximately 0.0007" per side). Powder coating adds more—typically 0.002" to 0.004". Hot dip galvanizing adds the most, potentially affecting fit for precision parts.

- Budget constraints: Powder coating typically offers the best value for most applications. Type 3 anodizing commands premium pricing but delivers exceptional performance.

- Expected lifespan: How long must the finish perform? Specify accordingly—over-engineering wastes budget while under-engineering creates premature failures.

Testing by SendCutSend demonstrated that no single finish excels at everything. Powder coating leads for abrasion and impact resistance. Zinc plating provides sacrificial corrosion protection that continues working even when damaged. Type 3 anodizing offers the best all-around performance for aluminum—a safe choice that performs well across all tests.

The finish you select directly impacts how long your metal outdoor signs, architectural panels, and decorative elements maintain their intended appearance. Investing in proper finishing during fabrication costs far less than premature replacement or extensive restoration later. With finishing considerations addressed, understanding the complete project journey—from initial concept through final delivery—helps you navigate the fabrication process with confidence.

The Complete Project Journey from Concept to Delivery

You've researched materials, understood design constraints, and specified the perfect finish. But what actually happens between submitting your design and receiving your finished laser cut metal signs? For many first-time buyers, this production journey feels like a black box—files go in, parts come out, and the magic in between remains mysterious.

That mystery ends now. Understanding each stage of the fabrication process helps you set realistic expectations, catch potential issues early, and evaluate whether your fabricator delivers the quality your project deserves. Whether you're ordering custom laser cut metal signs for a new business or personalized laser cut metal signs for a special gift, knowing the journey builds confidence in your investment.

From Initial Concept to Production-Ready Files

Every laser cut metal signage project begins with an idea—but transforming that vision into a manufacturable design involves several critical steps. Here's what the complete process looks like from your first sketch to final delivery:

- Concept Development: Your journey starts with defining what you need. Are you creating laser cut signs metal pieces for outdoor branding? Decorative interior panels? Functional architectural screens? Clarifying purpose, dimensions, installation requirements, and aesthetic goals shapes every subsequent decision. Many fabricators offer design consultation at this stage—take advantage of it. Experienced fabricators have seen thousands of projects and can suggest approaches you might not consider.

- Design Creation and File Preparation: Once your concept solidifies, someone needs to create production-ready files. This might be your designer, the fabricator's team, or a specialized service. According to Steelway Laser Cutting, modern commercial laser cutters use computer numerical control (CNC) systems that follow precise digital patterns. Your design must translate into vector files—typically DXF format—with clean geometry, proper scaling, and no overlapping lines. This stage often involves multiple revisions as design intent meets manufacturing reality.

- Design Review and DFM Analysis: Before cutting begins, quality fabricators review your files for manufacturability. This Design for Manufacturing (DFM) analysis identifies potential problems: features too small to cut cleanly, bridge widths too narrow for structural integrity, or geometry that might warp during processing. According to MakerVerse, kerf width typically ranges from 0.1mm to 1.0mm depending on material and cutting parameters—your fabricator should verify your design accounts for these realities.

- Material Selection and Procurement: With your design finalized, your fabricator sources the specified material. Lead times vary significantly—common aluminum and steel gauges typically ship within days, while specialty alloys or unusual thicknesses may require weeks. Quality fabricators verify incoming material specifications, checking thickness, alloy composition, and surface condition before processing.

- Laser Cutting Production: The actual cutting happens remarkably fast compared to preparation time. As Steelway notes, once instructions feed into the laser cutter, the focused beam follows all specifications without human intervention—the cutting head moves automatically as needed. This hands-off precision means your custom metal signs laser cut pieces emerge exactly as programmed, whether you order five pieces or five hundred.

- Secondary Processing and Finishing: Raw cut parts typically require additional work. Deburring removes sharp edges. Bending or forming shapes flat pieces into three-dimensional forms. Surface preparation—cleaning, etching, or blasting—readies parts for finishing. Then comes your specified finish: powder coating, anodizing, plating, or other treatments that protect and beautify your work.

- Quality Inspection: Before shipping, reputable fabricators inspect finished pieces against specifications. This includes dimensional verification, finish quality assessment, and visual inspection for defects. According to West River Welding, quality control measures typically include comprehensive inspection and testing procedures performed throughout various production stages.

- Packaging and Delivery: Proper packaging prevents shipping damage that could ruin weeks of careful work. Finished laser cut metal signs and panels require protection from scratches, dents, and moisture during transit. Your fabricator should explain their packaging approach and shipping options during quoting.

Quality Checkpoints Throughout Manufacturing

How do you know if your fabricator delivers quality work? Look for these indicators at each production stage:

Pre-Production Quality Indicators:

- They ask clarifying questions about your application, not just your dimensions

- They provide DFM feedback identifying potential issues before cutting

- They confirm material specifications in writing, including alloy and temper

- They offer samples or references for similar previous projects

Production Quality Indicators:

- Cut edges appear clean and consistent—no excessive dross, burrs, or discoloration

- Dimensional accuracy matches specifications within stated tolerances

- Complex geometry reproduces faithfully without distortion

- Material shows no warping, especially on large panels or thin gauges

Finishing Quality Indicators:

- Coating coverage appears uniform with no thin spots, drips, or bare areas

- Color matches approved samples or specified RAL/Pantone standards

- Surface texture remains consistent across all pieces in your order

- Hardware holes and edges receive complete coverage without buildup

Essential Questions to Ask Potential Fabricators

Before committing to any fabricator for your laser cut metal signs project, these questions reveal their capabilities, processes, and commitment to quality:

- What are your capabilities and equipment? According to West River Welding, understanding the types of materials they're proficient with—such as steel, aluminum, or specialty alloys—helps ensure they can meet your project's unique requirements. Ask about laser types (fiber vs. CO2), bed sizes, and thickness capacities.

- Can you provide references or case studies? Past client experiences attest to reliability and work quality. Request examples of projects similar to yours—if they've successfully delivered comparable work, they'll likely succeed with your project too.

- How do you ensure quality control? Quality fabricators describe specific inspection and testing procedures performed throughout production stages. Vague answers suggest inconsistent processes.

- What are your typical lead times? Understanding turnaround times provides an initial gauge of efficiency and workload management. Ask specifically about your project scope and current backlog.

- What tolerances do you guarantee? Professional fabricators state specific dimensional tolerances—typically ±0.005" to ±0.010" for laser cutting. Avoid fabricators who can't or won't commit to measurable standards.

- How do you handle files that need modification? Their answer reveals whether they'll simply reject problematic files or work with you to achieve your vision within manufacturing constraints.

- What finishing options do you offer in-house vs. outsource? In-house finishing typically means faster turnaround and better quality control. Outsourced finishing adds lead time and potential communication gaps.

- How do you package and ship finished pieces? This often-overlooked question reveals attention to detail. Quality fabricators describe specific packaging methods appropriate to your material and finish.

The fabrication journey may seem complex, but each stage serves a purpose—transforming your concept into durable, beautiful reality. Fabricators who explain their process transparently demonstrate confidence in their work and respect for your investment. Those who treat production as a mystery may be hiding inconsistent quality or outdated capabilities.

Armed with process knowledge and the right questions, you're prepared to evaluate potential partners effectively. But understanding the journey is just one part of project success—applying design best practices specific to your application type ensures your laser cut metal designs achieve maximum impact.

Design Best Practices by Application Type

You've navigated material selection, understood technical constraints, and mapped the complete fabrication journey. Now comes the creative part—designing laser cut metal pieces that actually work. But here's what most guides miss: design best practices aren't universal. What makes a stunning decorative metal sign fails miserably as business signage. The pattern that creates beautiful privacy screening may compromise structural integrity on large architectural panels.

Let's fix that gap. Whether you're creating laser cut steel signs for a storefront, metal art signs for a gallery, or functional grilles for HVAC applications, these application-specific principles help you design with intention—not guesswork.

Signage Design Principles for Maximum Impact

Your metal signage serves one primary purpose: communication. Every design decision should support legibility, brand recognition, and visual impact from the intended viewing distance. Sounds simple? You'd be surprised how often these fundamentals get sacrificed for aesthetic flourishes that undermine the sign's core function.

Best practices for business and commercial laser cut signs:

- Size lettering for viewing distance: A general rule—every inch of letter height provides approximately 10 feet of readable distance. A sign intended for 50-foot visibility needs 5-inch minimum letter height. Decorative fonts may require even larger sizing to maintain clarity.

- Prioritize contrast over complexity: According to Stealth Industry, clarity is essential when creating custom metal signage. Excessively complex or ornate fonts may appear attractive up close but obstruct readability from a distance. Choose suitable text sizes, clear font styles, and contrasting color combinations.

- Consider dimensional mounting: Laser cut letters mounted with standoffs create shadow depth that dramatically increases visibility. This simple technique transforms flat signage into eye-catching dimensional displays without increasing material costs significantly.

- Design for lighting integration: If your sign will be illuminated, plan for it from the start. LED backlighting, edge lighting, and halo effects each require different design considerations—cutout sizes, mounting provisions, and material transparency all factor into the final effect.

- Match material weight to mounting: A heavy stainless steel sign requires robust mounting provisions. Designing an oversized sign without considering installation realities leads to expensive engineering solutions or, worse, safety hazards.

Common mistakes with decorative metal sign projects:

- Using serif fonts at small sizes—fine details disappear during cutting

- Forgetting that negative space (cutouts) defines the design as much as solid areas

- Ignoring how powder coating adds thickness, potentially filling fine details

- Designing without considering how shadows will appear on the mounting surface

Laser engraved signs offer an alternative when your design requires fine detail that cutting can't achieve. Surface engraving preserves intricate patterns while maintaining structural integrity—ideal for detailed logos, QR codes, or decorative borders surrounding cut typography.

Architectural Panel Patterns That Perform

Large-scale architectural applications demand more than aesthetic appeal—they require structural engineering sensibility. A beautiful pattern that works at desktop scale may buckle, warp, or fail entirely when scaled to building facades.

Best practices for architectural panels and privacy screens:

- Maintain consistent bridge widths: The solid metal between cutouts (bridges) provides structural integrity. Varying bridge widths across a panel creates uneven stress distribution and potential warping. Keep bridges consistent, and don't go narrower than recommended minimums for your material and gauge.

- Account for thermal expansion: Large metal panels expand and contract with temperature changes. Mounting systems must accommodate this movement—rigid mounting causes buckling. Design mounting provisions that allow controlled movement.

- Calculate open area percentage: Pattern openness affects wind load, light transmission, and privacy. Document your design's open area percentage and verify it meets project requirements before production.

- Consider pattern orientation: Horizontal patterns behave differently than vertical ones under gravity and wind load. Panel orientation during installation should match your design intent.

- Specify appropriate gauge: According to MakerVerse, spacing cutting geometry at least two times the sheet thickness helps avoid distortion. Larger panels typically require heavier gauges to maintain flatness—don't underestimate structural requirements.

Best practices for decorative wall art and interior pieces:

- Design for the viewing angle: Wall-mounted pieces are typically viewed straight-on, while ceiling installations are seen from below. Pattern density and detail scale should match the primary viewing perspective.

- Plan for backlighting effects: Interior panels often incorporate lighting. Consider how light will pass through openings—smaller, denser perforations create diffused glow while larger openings project distinct shadow patterns.

- Balance positive and negative space: The most compelling metal art signs achieve visual harmony between solid metal and cut areas. Neither should overwhelm the other unless that imbalance serves a specific design purpose.

- Consider material patina: Interior applications can showcase materials like copper and brass that develop character over time. Design with this evolution in mind—initial appearance differs from aged beauty.

Best practices for functional grilles and ventilation covers:

- Prioritize open area for airflow: Decorative patterns must maintain adequate open area—typically 50% or greater for supply vents. Beautiful patterns that restrict airflow compromise HVAC performance.

- Avoid debris-catching geometry: Horizontal slots accumulate dust faster than vertical openings. Radiating or diagonal patterns often balance aesthetics with practical maintenance considerations.

- Design for removability: Grilles require periodic cleaning or access to systems behind them. Include mounting provisions that allow easy removal without tools or damage.

Avoiding Common Mistakes and Misconceptions

After reviewing thousands of laser cut metal projects, certain errors appear repeatedly. Understanding these pitfalls helps you avoid costly revisions:

Misconception: More detail equals better design.

Reality: Excessive detail increases cutting time, raises costs, and often degrades faster during finishing. Strategic simplification frequently improves both aesthetics and durability. Remember that laser cut metal designs are viewed at distance—micro-details visible in CAD software disappear in real-world installation.

Misconception: Any vector file is production-ready.

Reality: Design files require specific preparation for laser cutting. Overlapping lines cause double-cuts. Open paths confuse cutting software. Text must convert to outlines. According to MakerVerse, proper file preparation isn't optional—it directly impacts cut quality and production efficiency.

Misconception: Material choice is purely aesthetic.

Reality: Different metals respond differently to identical designs. A pattern that cuts beautifully in aluminum may distort in copper due to thermal conductivity differences. Material selection and design development should happen together, not sequentially.

Misconception: Finishing covers design flaws.

Reality: Powder coating and other finishes actually emphasize imperfections. Sharp edges become more prominent. Warped panels remain warped. Quality finishing enhances quality cutting—it cannot compensate for poor fabrication.

Working with Designers vs DIY Approaches

When should you hire professional design help, and when can you confidently handle design yourself? Project complexity provides the clearest guidance:

DIY-appropriate projects:

- Simple geometric patterns with consistent features

- Text-based signage using standard fonts

- Adaptations of existing designs to new dimensions

- Single pieces with clear reference examples

- Personal projects where learning matters more than perfection

Professional design recommended:

- Brand identity work requiring distinctive visual language

- Large-scale architectural installations with structural requirements

- Complex patterns requiring engineering analysis

- High-volume production where optimization significantly impacts costs

- Projects with specific performance requirements (airflow, light transmission, load bearing)

The investment in professional design often pays for itself through optimized material usage, reduced revisions, and superior final results. When evaluating designers, look for experience specifically with laser cut metal—skills in graphic design don't automatically translate to understanding manufacturing constraints.

For precision metal fabrication projects requiring comprehensive Design for Manufacturing support, manufacturers like Shaoyi provide DFM guidance that helps optimize designs for production efficiency. This type of expert input proves invaluable when your design must balance aesthetic goals with manufacturing realities—experienced fabricators understand material constraints that purely visual designers may overlook.

Design Checklist Before Submitting Files

Before sending your design for production, verify these critical elements:

- All text converted to outlines/paths

- No overlapping or duplicate lines

- All shapes completely closed

- Minimum feature sizes meet material requirements

- Bridge widths adequate for structural integrity

- File units match intended dimensions

- Design scaled to actual production size

- Mounting provisions included where needed

- Open area percentage documented (for functional applications)

- Material and finish specified in accompanying documentation

This systematic approach catches issues that cause production delays and cost overruns. Taking an extra hour for thorough file review often saves days of revision cycles.

With design best practices mastered for your specific application, one critical decision remains: selecting the right fabrication partner to transform your optimized design into flawless reality. The criteria for that evaluation—and the questions that reveal true capability—deserve focused attention.

Choosing the Right Fabrication Partner

You've mastered materials, understood constraints, optimized your design, and mapped the production journey. Now comes the decision that determines whether all that preparation translates into stunning results or frustrating disappointment: selecting your fabrication partner. This choice matters more than most buyers realize—the same design file yields dramatically different outcomes depending on who cuts, finishes, and delivers your work.

Think of it this way: a skilled fabricator transforms good designs into exceptional metal signs and panels. A mediocre one diminishes even brilliant concepts. Whether you're creating personalized metal signs for a special occasion or outdoor custom metal signs for lasting brand visibility, your partner selection directly impacts quality, timeline, and overall project success.

Evaluating Laser Cutting Service Providers

Not all fabricators deserve your business. These evaluation criteria help you distinguish true partners from order-takers who may compromise your project:

- Industry Certifications and Quality Systems: Certifications reveal commitment to consistent quality. According to Xometry, ISO 9001 certification demonstrates adherence to standardized quality management systems that ensure traceability, documentation, and process excellence. For precision metal components requiring automotive-grade quality standards, manufacturers like Shaoyi offer IATF 16949 certification—the automotive industry's rigorous quality framework that limits defects and reduces waste. Look for fabricators who can document their quality processes, not just claim them.

- Turnaround Times and Responsiveness: How quickly can they quote your project? How fast do they deliver finished pieces? According to TMCO, understanding turnaround times provides an initial gauge of efficiency and workload management. Quality fabricators offer 5-day rapid prototyping capabilities and maintain transparent communication throughout production. Shaoyi, for example, provides 12-hour quote turnaround—demonstrating the responsiveness you should expect from serious partners.

- Material Options and Inventory: Does the fabricator stock the materials you need, or will procurement add weeks to your timeline? Comprehensive material offerings indicate manufacturing depth. Verify they handle your specific metal type, thickness range, and quantity requirements before committing.

- Finishing Capabilities: In-house finishing streamlines production and maintains quality control. According to TMCO, each step managed under one roof minimizes delays, improves consistency, and ensures accountability throughout the process. Ask specifically whether powder coating, anodizing, or plating happens on-site or gets outsourced.

- Design Support Services: The best fabrication partners offer more than cutting—they provide Design for Manufacturing (DFM) analysis that optimizes your design for production. TMCO notes that effective turnkey partners don't just follow blueprints—they collaborate from the start, offering CAD/CAM modeling, prototyping capabilities, and engineering consultations to improve performance and reduce waste.

- Equipment and Technology: Modern fiber lasers, advanced CNC systems, and robotic automation indicate investment in quality and efficiency. According to TMCO, precision manufacturing depends heavily on the right equipment—advanced technology enables faster production cycles, tighter tolerances, and improved repeatability.

- Scalability: Can they handle a single prototype and later scale to production quantities? TMCO emphasizes that the best partners maintain robust supply chain networks and flexible production capacity to meet evolving demands—whether you need one piece or thousands.

- Communication and Project Transparency: Clear communication often determines project success. Look for dedicated project managers, regular progress updates, and proactive problem-solving. Fabricators who treat your project as a black box may be hiding inconsistent processes.

Starting Your Custom Metal Design Project

Throughout this guide, you've built a comprehensive decision-making framework. Here's how it all connects:

Your Decision Framework Summary:

- Material selection balances corrosion resistance, weight, cost, and aesthetic goals against your specific application requirements

- Design constraints establish what's physically achievable—minimum feature sizes, bridge widths, and kerf considerations that transform creative concepts into manufacturable reality

- Application-specific best practices ensure your design performs its intended function, whether that's brand communication, privacy screening, or architectural impact

- Finishing selection protects your investment for years or decades, matched to environmental exposure and maintenance expectations

- Partner evaluation identifies fabricators with the certifications, capabilities, and commitment to deliver your vision flawlessly

Your Next Steps Based on Project Stage:

If you're still exploring possibilities:

- Gather inspiration images showing styles, materials, and applications that appeal to you

- Define your project requirements: dimensions, environment, budget range, and timeline

- Review the material comparison and finishing tables to narrow your options

- Consider whether you need professional design assistance or can prepare files yourself

If you have a design concept ready:

- Verify your design meets the technical constraints outlined in this guide

- Prepare production-ready files in DXF format with clean geometry

- Document your specifications: material, thickness, finish, and quantity

- Identify three to five potential fabricators matching your project requirements

If you're ready to request quotes:

- Submit identical specifications to multiple fabricators for accurate comparison

- Ask the evaluation questions outlined earlier—responses reveal true capability

- Request samples or references for similar previous work

- Evaluate total value—not just price—including quality assurance, turnaround, and communication

- Confirm all specifications in writing before production begins

Your laser cut metal design journey doesn't end with fabrication—it begins there. The metal sign, architectural panel, or decorative piece you create today becomes part of buildings, brands, and spaces for years to come. By applying the knowledge in this guide, you ensure that investment delivers lasting value: precision that honors your design vision, durability that withstands real-world conditions, and beauty that commands attention from day one through decade ten.

The path from first sketch to flawless delivery is now clear. Your next step? Take it.

Frequently Asked Questions About Laser Cut Metal Designs

1. What materials can be laser cut for metal signs and panels?

Laser cutting works excellently with aluminum, mild steel, stainless steel, brass, and copper. Aluminum offers lightweight durability and natural corrosion resistance, making it ideal for outdoor signage. Stainless steel provides unmatched longevity in harsh environments. Brass and copper deliver warm aesthetics with natural patina development, perfect for decorative applications. Fiber lasers handle reflective metals like aluminum and copper particularly well, while both CO2 and fiber lasers produce clean cuts on steel. Material selection should match your project's environmental exposure, weight requirements, and budget constraints.

2. How do I find laser cut metal signs near me?

When searching for local laser cutting services, evaluate fabricators based on their certifications (ISO 9001 or IATF 16949 for precision work), equipment capabilities (fiber vs CO2 lasers), material options, and finishing services. Request samples of previous work similar to your project. Quality fabricators offer DFM (Design for Manufacturing) analysis, transparent communication, and clear turnaround timelines. For automotive-grade precision, manufacturers like Shaoyi provide IATF 16949-certified quality with 12-hour quote turnaround and comprehensive DFM support.

3. What is the minimum feature size for laser cut metal designs?

Minimum feature sizes depend on material type and thickness. Generally, minimum hole diameter should equal or exceed material thickness for clean results. For 1mm aluminum, expect minimum features around 0.020 inches; for 3mm stainless steel, approximately 0.045 inches. Bridge widths between cutouts must maintain structural integrity—typically 0.030 to 0.080 inches depending on gauge. Kerf width (material removed by the laser) ranges from 0.006 to 0.040 inches, meaning any feature smaller than kerf width will disappear during cutting.

4. How much do custom laser cut metal signs cost?

Laser cutting costs depend on material type and thickness (aluminum costs less than stainless steel), design complexity (more cutouts increase cutting time), total cut length, order quantity, and finishing requirements. Thicker materials require slower cutting speeds, increasing machine time. Volume orders reduce per-unit costs as setup expenses distribute across more pieces. Efficient nesting maximizes material usage, reducing waste. Custom designs justify higher costs when brand identity requires unique visual elements or architectural integration demands specific patterns.

5. What finishing options protect laser cut metal outdoors?

Powder coating offers excellent abrasion and impact resistance with unlimited color options, lasting 15-20+ years outdoors. Type 2 anodizing (aluminum only) creates a thin, hard surface ideal for architectural applications. Type 3 hardcoat anodizing provides exceptional wear resistance for high-traffic or marine environments. Hot dip galvanizing protects steel with thick zinc layers lasting 25-50+ years through sacrificial corrosion protection. For coastal environments, combine hot dip galvanizing with powder coat topcoat for maximum protection against salt spray.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —