Aluminum Stamping Process Decoded: From Raw Sheet To Finished Part

Understanding the Aluminum Stamping Process

When you think about how everyday products like laptop housings, automotive body panels, or air conditioning components are made, the aluminum stamping process plays a central role. But what exactly makes this manufacturing method so essential across industries?

Aluminum stamping is a metalworking process that uses specialized dies and high-pressure presses to shape aluminum sheets into precise, finished parts through operations such as blanking, piercing, bending, and drawing.

Unlike general metal stamping that works with steel, copper, or brass, stamping aluminum requires understanding its unique material behavior. This lightweight metal responds differently under pressure, demanding specialized tooling, adjusted press settings, and specific lubrication strategies to achieve optimal results.

What Makes Aluminum Different from Other Stamping Metals

Aluminum stands apart from other stamping metals due to several distinct material properties that directly influence how it performs during forming operations:

- Lightweight nature: Weighing only about one-third of steel, aluminum dramatically reduces component weight without sacrificing structural integrity. This characteristic proves invaluable for automotive and aerospace applications where every gram matters for fuel efficiency.

- Natural corrosion resistance: When exposed to air, aluminum forms a protective oxide layer that shields the metal from moisture and environmental degradation. This self-protecting quality eliminates the need for additional rust-prevention treatments in many applications.

- Excellent thermal conductivity: Aluminum efficiently transfers heat, making stamped components ideal for heat sinks, radiators, and electronic enclosures that require thermal management.

- Superior ductility: As the second most malleable metal available, aluminum can be pulled, stretched, and bent into complex shapes without cracking or breaking during the stamping process.

- Electrical conductivity: While not quite matching copper's performance, aluminum's conductivity combined with its lighter weight makes it a cost-effective choice for electrical components and connectors.

These properties mean that aluminum behaves quite differently than steel during forming. You'll notice that it requires tighter die clearances, experiences more pronounced springback after bending, and demands careful attention to lubrication to prevent surface galling.

Why Manufacturers Choose Aluminum Stamping

The growing preference for this metal forming method isn't accidental. Manufacturers across industries are increasingly selecting aluminum stamping over alternative methods for compelling practical reasons:

- Weight reduction goals: With automotive manufacturers pushing for lighter vehicles to meet fuel economy standards, aluminum components have become essential. Stamped parts maintain strength while significantly reducing overall vehicle weight.

- Cost-effective production: High-volume stamping operations using progressive or transfer dies deliver consistent quality with lower per-part costs compared to machining or casting alternatives.

- Design flexibility: The combination of aluminum's formability with modern die technology allows manufacturers to create complex geometries, deep-drawn shapes, and intricate details in a single production run.

- Surface treatment compatibility: Stamped aluminum readily accepts anodizing, powder coating, electroplating, and other finishing processes that enhance appearance and extend service life.

- Environmental advantages: Aluminum is highly recyclable without quality degradation. Using recycled material requires significantly less energy than processing raw ore, supporting sustainability initiatives.

The versatility of this process extends across nearly every major industry. From aerospace structural brackets to medical equipment housings, from consumer electronics enclosures to food packaging components, stamped aluminum parts deliver the performance characteristics modern products demand.

Selecting the Right Aluminum Alloy for Stamping

Choosing the correct aluminum alloy can make or break your stamping project. Pick the wrong one, and you'll face cracked parts, excessive tool wear, or components that simply don't perform as expected. But how do you navigate the seemingly endless list of alloy numbers to find the perfect match?

The key lies in understanding that aluminum alloys are organized into series based on their primary alloying elements. Each series offers distinct properties that directly influence how the material behaves during sheet metal stamping operations. Let's decode what each series brings to the table.

Aluminum Alloy Series and Their Stamping Characteristics

Aluminum alloys fall into seven main series, each with unique properties that affect stampability:

- 1XXX Series (Pure Aluminum): These alloys contain 99% or higher aluminum content. Grade 1100 offers excellent corrosion resistance and high thermal conductivity, making it ideal for heat exchangers and cooking utensils. However, its low strength limits structural applications.

- 2XXX Series (Aluminum-Copper): Known for high strength and excellent fatigue resistance, these alloys suit aerospace applications. Grade 2024 appears frequently in aircraft structures, though its reduced corrosion resistance requires protective coatings.

- 3XXX Series (Aluminum-Manganese): Grade 3003 represents the workhorse of this series. According to industry experts, it's one of the most common aluminum alloys used in stamping due to its excellent formability and good corrosion resistance. It's perfect for simple parts like decorative trim and kitchenware.

- 4XXX Series (Aluminum-Silicon): Primarily used as filler material for welding and brazing, these alloys appear in automotive heat exchangers and radiators.

- 5XXX Series (Aluminum-Magnesium): This series delivers exceptional performance for demanding applications. 5052 aluminum stamping has become a go-to choice when projects require higher strength and durability, especially in marine environments and automotive components.

- 6XXX Series (Aluminum-Magnesium-Silicon): Grade 6061 offers versatility with good mechanical properties and excellent weldability. It's the most popular and cost-efficient aluminum alloy for general-purpose structural applications.

- 7XXX Series (Aluminum-Zinc): These high-strength alloys, particularly 7075, serve aerospace and military applications. However, they're harder to form and more expensive, making them less suitable for typical stamping operations.

Matching Alloys to Your Application Requirements

When selecting an alloy for aluminum sheet metal stamping, you need to balance multiple factors. Think about your part's final use, the forming complexity involved, and your budget constraints. Asking yourself three critical questions helps narrow down your options quickly:

- What strength does your application demand? Simple brackets and decorative components can use softer, more formable alloys. Load-bearing or structural parts require higher-strength options.

- What environment will the part operate in? Marine or outdoor applications need alloys with superior corrosion resistance like 5052. Indoor electronics can use less expensive alternatives.

- How complex is your part geometry? Intricate shapes with deep draws or tight bends benefit from highly formable alloys that won't crack during forming.

The table below compares common aluminum alloys used in stamped aluminum sheet production:

| Alloy | Stampability Rating | Formability | Strength | Typical Applications |

|---|---|---|---|---|

| 1100 | Excellent | Excellent | Low | Chemical equipment, heat exchangers, cooking utensils |

| 3003 | Excellent | Excellent | Low-Medium | Roofing, siding, decorative trim, simple brackets |

| 5052 | Good | Good | Medium-High | Marine hardware, automotive components, pressure vessels |

| 6061 | Moderate | Good | High | Structural applications, pipelines, recreational equipment |

Notice that about 80% of aluminum stamping projects can be successfully completed using either 3003 or 5052 aluminum. These two alloys cover a remarkably wide range of applications, from simple electronic brackets to complex automotive panels.

Here's a practical consideration: 5052 typically costs about 20% more than 3003, but delivers significantly higher strength. For parts that don't require that extra durability, selecting 3003 keeps your project cost-effective without compromising quality.

Understanding how alloy composition affects your stamping results sets the foundation for success. With the right material selected, the next critical step involves mastering the sequential stages that transform raw sheet into finished components.

Step-by-Step Aluminum Stamping Process Breakdown

So you've selected the perfect alloy for your project. Now what? Understanding exactly how aluminum transforms from a flat sheet into a precision component gives you the insight needed to optimize quality and prevent costly defects. Let's walk through each stage of stamping aluminum from start to finish.

From Raw Sheet to Finished Part

The complete aluminum stamping process follows a logical sequence where each step builds upon the previous one. Unlike steel, aluminum's lower density and higher ductility create unique behaviors at every stage. Here's the full process broken down into manageable steps:

- Material Preparation and Inspection: The process begins with receiving aluminum sheets or coils in the specified alloy and temper. Quality technicians inspect incoming material for surface defects, thickness consistency, and proper grain direction. Since aluminum scratches more easily than steel, careful handling during storage and transport prevents cosmetic issues that could affect the final product.

- Die Design and Setup: Using CAD and CAM software, engineers create dies with the specific design required for the final part. The die must account for aluminum's pronounced springback characteristics, meaning designers often overbend angles by 2-5 degrees to achieve the target geometry after the material relaxes. The die goes into the stamping press, and operators verify precise alignment.

- Lubrication Application: Before stamping begins, technicians apply specialized lubricants to the aluminum surface. This step proves more critical with aluminum than steel because the softer material tends to gall against tooling surfaces without proper lubrication. The lubricant reduces friction, extends die life, and improves surface finish quality.

- Aluminum Blanking: The first forming operation typically involves cutting the raw sheet into appropriately sized blanks. During this stage, the stamping press shears the material against a die edge. The cut portion becomes your workpiece, while the remaining skeleton material is recycled. Aluminum blanking requires sharper die edges and tighter clearances than steel to achieve clean, burr-free edges.

- Piercing Operations: If your part design requires holes, slots, or other internal cutouts, piercing follows blanking. Sharp punches penetrate the aluminum blank while a die supports the surrounding material. The removed slugs drop away as scrap. Because aluminum is softer, piercing punches experience less wear but require more frequent sharpening to maintain edge quality.

- Forming and Bending: This stage shapes the flat blank into three-dimensional geometry through bending, flanging, or curving operations. Aluminum's work hardening properties become significant here. As you form the metal, it becomes progressively stronger and less ductile in the deformed areas. Multiple forming operations may require intermediate annealing to restore formability and prevent cracking.

- Deep Drawing (When Required): For parts requiring hollow, cup-like shapes, deep drawing forces the blank into a die cavity using a punch. Drawn aluminium components like beverage cans, cookware, and automotive panels emerge from this operation. The material experiences significant plastic deformation, and proper blank holder pressure prevents wrinkling while allowing material flow.

- Trimming and Finishing: After forming, excess material around the part perimeter gets trimmed away to final dimensions. Secondary operations like deburring, edge conditioning, and surface treatment follow. Aluminum accepts anodizing, powder coating, and various plating finishes that enhance both appearance and corrosion resistance.

- Quality Inspection: The final step verifies dimensional accuracy, surface quality, and conformance to specifications. Inspectors check critical tolerances, examine for cracks or defects, and ensure the part meets customer requirements before packaging and shipment.

Critical Stages in Aluminum Forming

Understanding how aluminum behaves differently from steel at each stage helps you anticipate challenges and optimize your process. Three factors deserve special attention:

- Springback Compensation: Aluminum exhibits more elastic recovery than steel after bending. When the forming force releases, the part "springs back" toward its original flat state. This means your tooling must overbend the material to achieve target angles. For complex parts with multiple bends, each angle may require different compensation based on material thickness, bend radius, and alloy properties.

- Work Hardening Effects: Each forming operation increases the strength and hardness of the deformed aluminum while reducing its remaining ductility. Heavily worked areas become more resistant to further forming. If your part requires multiple aggressive forming steps, you may need to anneal (heat treat) the partially formed component between operations to restore formability and prevent fractures.

- Galling Prevention: Aluminum's tendency to adhere to tooling surfaces creates a phenomenon called galling, where material transfers and builds up on dies and punches. This buildup causes surface scratches and dimensional problems. Proper lubrication, tool coating selection, and die material choices help prevent galling throughout the stamping metal operation.

The sequential nature of these stages means that problems in early operations compound downstream. A poorly prepared blank creates challenges during forming. Inadequate lubrication accelerates die wear and affects surface finish. By understanding how each step influences the next, you can identify root causes when quality issues arise.

Mastering these process stages provides the foundation, but choosing the right technique for your specific application takes your results to the next level. Different stamping methods offer distinct advantages depending on your part complexity and production volume requirements.

Aluminum Stamping Techniques and Methods

Now that you understand the sequential stages involved, how do you choose the right stamping technique for your specific aluminum project? The method you select directly impacts production efficiency, part quality, and overall cost. Let's explore the primary techniques and discover which works best for different aluminum metal stamping applications.

Each technique offers distinct advantages based on your part geometry, production volume, and complexity requirements. Understanding these differences helps you make informed decisions that optimize your manufacturing outcomes.

Progressive Die vs Transfer Die for Aluminum

These two techniques represent the workhorses of high-volume aluminum production, yet they serve distinctly different purposes.

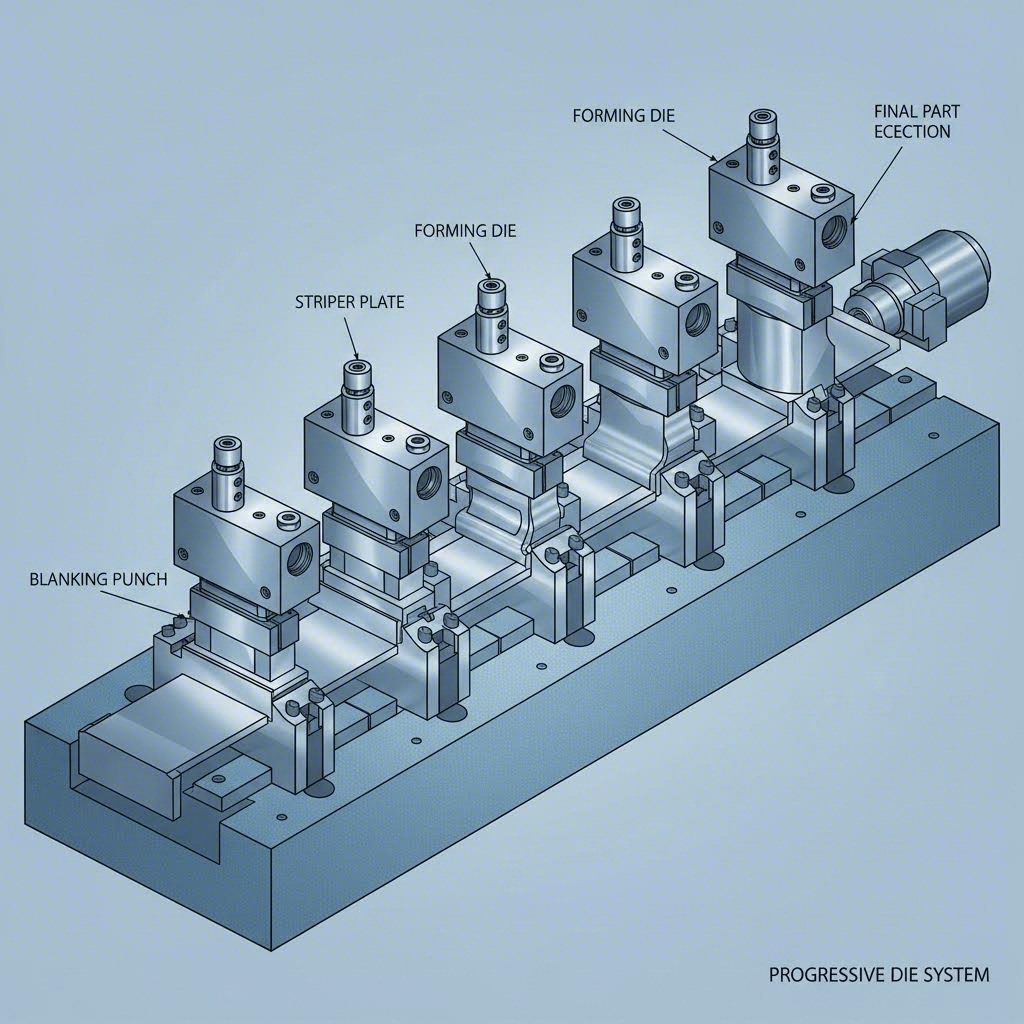

Progressive die stamping feeds aluminum sheet through a series of stations in one continuous linear motion. Each station performs a specific operation—punching, bending, or forming—until the completed part emerges at the end. The material stays connected to the carrier strip throughout the process, with the final operation typically separating the finished component.

When working with aluminum in progressive dies, you'll encounter some unique considerations:

-

Advantages for aluminum:

- Extremely fast cycle times ideal for high-volume production runs

- Consistent part-to-part quality since all operations occur in one press stroke

- Lower per-part costs when producing thousands or millions of components

- Excellent for smaller, simpler aluminum parts like brackets, connectors, and heat sinks

-

Limitations with aluminum:

- Higher upfront tooling investment compared to single-operation dies

- Requires more raw material since the carrier strip becomes scrap

- Cannot perform operations requiring the part to leave the strip, such as thread rolling or rotary stamping

- Part size limitations based on press bed dimensions and coil width

Transfer die stamping takes a different approach. The aluminum blank gets separated from the sheet early in the process, then mechanical arms or automated systems physically move it from station to station. Each die performs one specific forming operation until the part reaches completion.

-

Advantages for aluminum:

- Handles larger, more complex parts that exceed progressive die capabilities

- Allows operations requiring the part to be manipulated or rotated between stations

- Enables beading, necking, flange curling, and other specialized forming techniques

- All stations operate simultaneously, improving overall production efficiency

-

Limitations with aluminum:

- Generally slower cycle times than progressive stamping

- Higher equipment complexity with more moving parts to maintain

- Requires careful synchronization between transfer mechanisms and press operations

- Greater initial setup time and expertise needed for optimal operation

Choosing between these methods typically comes down to part size and complexity. Progressive dies excel at producing high volumes of small to medium-sized aluminum components quickly and economically. Transfer dies become necessary when parts grow larger or require forming operations that can't happen while attached to a carrier strip.

Deep Drawing Aluminum Components

When your application requires hollow, cup-shaped, or cylindrical components, the deep drawing manufacturing process becomes essential. Think beverage cans, cookware, automotive fuel tanks, and electronic enclosures—all created through this specialized forming technique.

In a deep drawing press, a punch forces the aluminum blank into a die cavity, stretching and flowing the material into three-dimensional shapes. The blank holder applies controlled pressure to prevent wrinkling while allowing sufficient material flow into the cavity.

Aluminum behaves quite differently than steel during deep drawing due to its inelastic properties. According to Toledo Metal Spinning, unlike stainless steel which can flow and redistribute its thickness under force, aluminum cannot be overstretched or excessively deformed. This means you must maintain precise control over several parameters:

- Draw ratio management: The relationship between punch diameter and blank diameter critically determines success. Aluminum's limited elongation means exceeding optimal draw ratios causes fractures or tearing.

- Blank positioning: The metal sheet must be placed precisely on the press. Even slight misalignment causes uneven stretching that leads to fractures or breaks in deep drawn aluminum parts.

- Blank holder force: Too much pressure prevents material flow and causes tearing. Too little allows wrinkling. Finding the right balance requires careful calibration for each part design.

- Specialized lubrication: Each material requires different lubricants depending on their properties. Aluminum demands lubricants specifically formulated to work with its surface characteristics.

The cold-forming nature of deep drawing actually benefits aluminum components. As the blank forms and stretches into its final shape at room temperature, the grain structure changes and the material's strength capabilities increase. This work hardening effect means your finished part emerges stronger and more durable than the original sheet.

Fine blanking deserves mention as another specialized technique. When your aluminum parts require exceptionally smooth, accurate edges without roughness or burrs, fine blanking delivers superior results. Using higher pressure and specialized tooling, this method produces clean edges suitable for gears, washers, and precision components where edge quality matters.

Here's how these techniques compare for draw aluminum applications:

| Technique | Best Aluminum Applications | Production Volume Suitability | Complexity Level |

|---|---|---|---|

| Progressive Die Stamping | Small brackets, connectors, heat sinks, electronic housings | High to very high volume (10,000+ parts) | Low to moderate |

| Transfer Die Stamping | Large frames, enclosures, structural components, panels | Medium to high volume (1,000-100,000 parts) | Moderate to high |

| Deep Drawing | Cups, cans, cookware, cylinders, tanks, deep housings | Medium to high volume | High |

| Fine Blanking | Gears, washers, precision flat parts, safety components | Medium to high volume | High |

| Multislide Stamping | Small complex parts, springs, clips, intricate connectors | High volume | Very high |

Work hardening properties significantly influence technique selection for aluminum. Each forming operation increases material strength while reducing remaining ductility. For parts requiring multiple aggressive forming steps, you may need intermediate annealing between operations to restore formability. Techniques that accomplish more forming in fewer operations—like progressive or transfer stamping—can minimize work hardening challenges.

Selecting the appropriate technique establishes your production framework, but the tooling and die design that supports these methods ultimately determines your success with aluminum components.

Tooling and Die Design for Aluminum Stamping

You've selected your technique and understand the process stages. But here's where many projects succeed or fail: the tooling itself. Aluminum stamping dies require fundamentally different design considerations than steel tooling. Get these details wrong, and you'll face slivers, excessive burrs, premature tool wear, and inconsistent part quality.

What makes aluminum stamping tools so different? The answer lies in understanding aluminum's unique mechanical behavior during cutting and forming operations.

Die Clearance and Geometry for Aluminum

Die clearance—the gap between punch and die cutting edges—dramatically affects your results when stamping sheet metal. Here's where aluminum defies conventional wisdom.

The general rule for cutting materials suggests that softer metals require smaller clearances. However, aluminum behaves differently. According to The Fabricator, insufficient clearance during cutting creates compression deformation, while excessive clearance creates tensile deformation. When clearance is too tight, the metal decompresses after fracture and grips the punch sides, dramatically increasing friction and producing slivers.

So what clearances work best? The cutting clearances for aluminum should rarely fall below 5 percent of the metal thickness per side. Often, simply increasing clearance to between 12 percent and 18 percent per side can greatly reduce sliver formation. This runs counter to instinct—you're actually opening up the gap rather than tightening it.

Why does this work? Increased clearance stretches the metal into the die slightly before fracture occurs. After the metal fractures, it pulls away from the punch rather than gripping it. The goal is causing the metal to fail in tension rather than compression.

Punch and die geometry requires equal attention:

- Cutting angle matters: Although trimming steel at 90 degrees to the part surface works well, aluminum performs better with angle cutting. Cutting on an angular surface pulls the metal downward in tension before cutting takes place, causing aluminum to pull back away from the punch. As the cutting angle increases, the clearance can decrease.

- Keep cutting sections square: Even slight angle variations can cause slivers. The upper section must be ground perfectly square to the bottom of the section. Any deviation creates uneven stress distribution that leads to quality problems.

- Sharp edges are essential: Cutting sections should have extremely sharp edges—it's not unusual for an aluminum cutting section to have only a 0.005-inch radius. As cutting angles increase, the need for razor-sharp edges becomes even more critical.

- Reduce punch entry: Minimizing how far the punch enters the die reduces friction at the interface. This simple adjustment decreases sliver formation and extends tool life.

- Precision part fitting: The part must fit the lower die very precisely, and the pressure or stripper pad must closely fit the aluminum part. Loose fits create movement that generates slivers and inconsistent cuts.

Regarding bypass notches in sheet metal forming stamping dies, these design features help control material flow and prevent wrinkling during complex forming operations. For aluminum, bypass notches must be carefully positioned and sized to account for the material's tendency toward localized straining.

Lubrication and Wear Prevention Strategies

Aluminum presents a paradox: it's softer than steel yet more abrasive to tooling. How is that possible? The oxide layer that naturally forms on aluminum surfaces is extremely hard and acts like sandpaper against tool steel. This abrasive quality can really tear up cutting sections if not properly managed.

Additionally, aluminum is described as a very "gummy" or sticky material. This stickiness causes material buildup on tool surfaces, leading to galling, surface scratches, and dimensional problems. Proper lubrication becomes your primary defense.

Effective lubrication strategies include:

- Use barrier-type lubricants: These create a physical barrier between the aluminum and tooling surfaces, preventing direct metal-to-metal contact that causes adhesion and galling.

- Apply lubricant consistently: Inconsistent lubrication leads to inconsistent results. Automated lubrication systems ensure every blank receives proper coverage.

- Match lubricant to operation: Deep drawing operations require heavier lubricants than simple piercing. Consult lubricant suppliers for aluminum-specific formulations.

- Consider dry film lubricants: For certain applications, dry film coatings applied to blanks before stamping provide excellent results without the mess of liquid lubricants.

Tool wear prevention extends beyond lubrication:

- Surface finish quality: Cutting sections should have highly polished surfaces and antifriction coatings whenever possible. Take time to linearly stone and polish sections in the cutting direction. Hand-ground surfaces perform extremely poorly for cutting aluminum.

- Tool coating selection: Modern coatings like titanium nitride (TiN), titanium carbonitride (TiCN), or diamond-like carbon (DLC) significantly extend die life when working with aluminum. These coatings reduce friction and resist the adhesive wear aluminum causes.

- Die material selection: High-speed steel and carbide tooling materials resist aluminum's abrasive oxide layer better than standard tool steels. For high-volume production, the investment in premium die materials pays dividends through longer tool life and more consistent parts.

- External pressure pads: Although sometimes costly and creating scrap removal challenges, external pressure pads help pull metal in tension toward the pad and reduce the strained area. This results in fewer slivers and smaller cutting burrs.

Tonnage requirements for aluminum stamping typically run lower than steel due to aluminum's lower tensile strength. However, don't simply reduce tonnage proportionally. The softer material requires sufficient force to achieve clean shearing without excessive deformation. Press speed recommendations vary by operation type—piercing and blanking can often run faster than deep drawing operations where material flow requires more controlled timing.

Completely eliminating slivers and burrs in aluminum cutting remains a challenging task. However, understanding that the key is causing metal to fail in tension rather than compression guides every tooling decision. When the material pulls away from the punch instead of gripping it, friction drops and quality improves.

With properly designed tooling in place, the next logical question becomes: how does aluminum's behavior during stamping compare directly to steel, and when should you choose one material over the other?

Aluminum vs Steel Stamping Comparison

You've learned the techniques, tooling requirements, and process stages for stamping aluminum. But here's a question that comes up constantly: how does aluminum actually behave compared to steel during forming? Understanding these differences isn't just academic—it directly impacts your material selection decisions and process parameters.

The two metals couldn't be more different at the molecular level. Steel presents a Body Centered Cubic (BCC) structure at ambient temperature, while aluminum presents a Face Centered Cubic (FCC) structure. According to FormingWorld, you can recognize this difference using a simple test: steel is strongly attracted by magnetic force while aluminum is not. This fundamental distinction drives seven critical behavioral differences during stamping operations.

Key Behavioral Differences During Forming

When comparing stamped aluminum to steel components, several mechanical properties create dramatically different outcomes during the forming process:

- Springback characteristics: Young's modulus measures how stiff a material is in the elastic zone. This property is inversely proportional to springback results. If you stamp identical parts from steel and aluminum using the same tooling, the final shapes will differ significantly. The aluminum component will exhibit much higher springback compared to steel, requiring tooling compensation of 2-5 degrees or more to achieve target geometries.

- Deformation capacity after necking: Here's where aluminum drawing becomes particularly challenging. Steel can hold almost double its uniform elongation (UE) limit in additional deformation after necking begins. Aluminum, however, cannot hold any meaningful additional deformation after reaching UE—typically less than 10% of the UE value. This means once aluminum starts necking, failure follows quickly.

- Material flow behavior: The Lankford coefficient (R-value) predicts how deformation distributes between surface area and thickness. Aluminum's lower R-value means deformation concentrates more on thickness changes. During drawing operations, materials with lower R-values show significant thickness increases under blankholder compression.

- Strain distribution: The strain hardening exponent (n-value) describes how well a material distributes stress throughout the sheet, avoiding local neck formation. For steel like DC05, the n-value remains relatively constant throughout plastic deformation. For aluminum 5754, the n-value drops drastically as strain approaches uniform elongation. This means aluminium stamping starts with good stress distribution capability but loses it rapidly as forming progresses.

- Extended deformation behavior: When modeling real strain-stress curves to 100% deformation, aluminum shows a much reduced slope compared to steel. This represents aluminum's diminished deformation capacity near and after uniform elongation—any additional stress causes higher strains, making tooling tryout more difficult and split avoidance more challenging.

The Forming Limit Diagram (FLD) captures these differences visually. Since aluminum presents lower R-values and declining n-values close to UE, its forming limit curve maximum is smaller compared to deep drawing steels. This directly translates to reduced strain capacity during aluminium stamping operations.

Here's a comprehensive comparison of how these materials differ across key stamping parameters:

| Parameter | Aluminum | Steel |

|---|---|---|

| Die Clearance | 12-18% per side typical; tighter clearances cause sliver formation | 5-10% per side typical; tolerates tighter clearances |

| Tonnage Requirements | Lower due to reduced tensile strength; typically 60-70% of steel | Higher force required; sets baseline for press sizing |

| Springback | Significantly higher; requires 2-5° or more overbending compensation | Lower and more predictable; easier to compensate |

| Lubrication Needs | Critical; barrier-type lubricants essential to prevent galling | Important but less sensitive; wider lubricant compatibility |

| Tool Wear Pattern | Abrasive oxide layer causes unexpected wear; adhesive galling common | Predictable abrasive wear; less material buildup |

| Surface Finish Quality | Excellent when properly lubricated; scratches easily without protection | Good; more forgiving of minor process variations |

| Material Handling | Requires vacuum systems; magnets won't work | Magnetic handling systems work effectively |

| Post-Necking Ductility | Very low (less than 10% of UE value); splits follow quickly | High (can reach nearly 2x UE); more forgiving |

When to Choose Aluminum Over Steel

Given these behavioral differences, when does aluminum stamping make sense for your application? The decision typically comes down to balancing technical requirements against practical constraints:

- Weight-critical applications: When every gram matters—automotive body panels, aerospace components, portable electronics—aluminum's one-third weight advantage justifies the additional process complexity.

- Corrosion resistance needs: For outdoor, marine, or humid environments, aluminum's natural oxide layer provides inherent protection. However, according to Tenral, untreated aluminum parts will oxidize and turn white outdoors. Anodizing treatment enables parts to resist salt spray testing for 480+ hours and remain rust-free for 5+ years.

- Thermal management: Heat sinks, radiator components, and electronic enclosures benefit from aluminum's superior thermal conductivity.

- High-volume production economics: For mass production exceeding 100,000 pieces monthly, stamped aluminum delivers per-unit costs approximately 25% lower than stainless steel after mold costs are diluted across production runs.

Steel remains the better choice when:

- Maximum strength is required: Load-bearing structural components, gears, and high-stress applications favor steel's superior absolute strength.

- Forming complexity is extreme: Steel's higher post-necking ductility and stable n-value make aggressive forming operations more forgiving.

- Small batch production: For monthly outputs below 10,000 pieces, aluminum's mold cost proportion becomes unfavorable compared to steel alternatives.

- Budget constraints are tight: Stainless steel stamping unit prices run approximately 1.5-2 times higher than aluminum, but steel's lower tooling sensitivity can reduce overall project costs for simpler parts.

The material handling differences alone require significant equipment changes. Magnetic pick-and-place systems used for steel won't work with aluminum, requiring replacement with vacuum-based robot tips. Sensing systems inside the press must also be adapted for non-magnetic material detection.

Understanding these fundamental differences between aluminum and steel behavior during stamping enables informed material selection. But producing quality parts consistently requires robust inspection methods and tolerance standards—the next critical consideration for any stamping operation.

Quality Control and Tolerance Standards

You've invested in proper tooling, selected the right alloy, and optimized your forming parameters. But how do you know your stamped aluminum parts actually meet specifications? Without rigorous quality control, even the best-designed stamping operations can produce inconsistent results that lead to costly rejections and customer complaints.

Quality verification for aluminum stamping parts presents unique challenges. The material's softer surface scratches easily during handling, springback variations can affect dimensional accuracy, and the natural oxide layer can mask underlying defects. Let's explore the inspection methods and tolerance standards that ensure your components meet demanding application requirements.

Inspection Methods for Stamped Aluminum Parts

Effective quality control begins long before the first part comes off the press. A comprehensive inspection program covers incoming materials, in-process monitoring, and final verification. Here are the critical checkpoints and techniques used throughout production:

- Incoming material inspection: Verify alloy composition, temper designation, and sheet thickness before production begins. Surface condition checks identify scratches, stains, or oxide irregularities that could affect finished part quality.

- First article inspection (FAI): The initial parts from a new production run receive comprehensive dimensional verification against engineering drawings. This establishes baseline conformance before full production proceeds.

- Coordinate measuring machines (CMM): These automated systems precisely measure complex geometries, hole positions, and critical dimensions with accuracy to 0.001 mm. CMM inspection proves essential for aluminium stamping parts with tight tolerance requirements.

- Optical measurement systems: Vision-based inspection quickly verifies 2D features like hole diameters, edge profiles, and surface patterns. These systems excel at high-speed inspection for production monitoring.

- Height gauges and calipers: Traditional hand tools remain valuable for quick in-process checks of thickness, bend angles, and overall dimensions. Operators perform these measurements at regular intervals during production runs.

- Go/no-go gauges: Custom-designed gauges verify critical features like hole sizes, slot widths, and form fits. These simple tools enable rapid pass/fail decisions without complex measurements.

- Surface roughness testers: Profilometers measure Ra (average roughness) values to verify surface finish quality meets specifications. Aluminum's tendency toward galling makes surface quality verification particularly important.

- Visual inspection: Trained inspectors examine parts for cosmetic defects including scratches, dents, burrs, and discoloration. Proper lighting and magnification tools enhance defect detection on aluminum's reflective surface.

- Statistical process control (SPC): Ongoing measurement data feeds control charts that identify process drift before parts go out of specification. This proactive approach catches problems early, reducing scrap and rework.

For automotive applications, quality requirements become even more stringent. According to Regal Metal Products, companies must adhere to IATF 16949 standards to remain competitive in the automotive supply chain. This global quality management standard, established by the International Automotive Task Force, ensures consistent quality through documented procedures, regular audits, and continuous improvement processes.

Achieving Tight Tolerances in Production

What tolerances can you realistically achieve with aluminum stamping parts? The answer depends on several factors including alloy selection, part complexity, and your supplier's capabilities.

General tolerance guidelines for stamped aluminum components include:

- Linear dimensions: Standard stamping achieves ±0.1 mm to ±0.25 mm depending on part size and complexity. Precision operations can hold ±0.05 mm or tighter with proper tooling and process control.

- Hole diameters: Punched holes typically hold ±0.05 mm to ±0.1 mm. Fine blanking operations achieve even tighter tolerances with superior edge quality.

- Bend angles: Standard bending holds ±1° to ±2° after accounting for springback. Precision applications requiring ±0.5° or better need specialized tooling and process controls.

- Flatness: Sheet flatness of 0.1 mm per 100 mm represents achievable targets for most stamped aluminum parts. Critical applications may require secondary flattening operations.

- Position tolerances: Hole-to-hole and feature-to-edge positioning typically holds ±0.1 mm with properly maintained progressive or transfer dies.

According to HLC Metal Parts, advanced stamping facilities maintain tolerances within 0.01 microns for demanding applications. This precision level requires investment in modern equipment, climate-controlled environments, and rigorous process documentation.

Several factors influence your ability to hold tight tolerances consistently:

- Tool condition: Die wear directly impacts dimensional accuracy. Regular maintenance schedules and replacement protocols prevent tolerance drift.

- Material consistency: Variations in sheet thickness, temper, and alloy composition affect forming behavior. Incoming inspection catches problematic material before it enters production.

- Press condition: Ram parallelism, shut height accuracy, and tonnage consistency all influence part quality. Preventive maintenance keeps presses performing within specifications.

- Environmental factors: Temperature variations cause thermal expansion in tooling and parts. Climate-controlled facilities minimize this variable for precision work.

- Operator training: Skilled operators recognize early signs of quality drift and take corrective action before producing scrap.

Quality certifications provide confidence that a stamping supplier maintains the systems necessary for consistent results. ISO 9001 certification establishes baseline quality management requirements. For automotive aluminum stamping parts, IATF 16949 certification demonstrates commitment to the rigorous standards the industry demands. Medical device applications may require ISO 13485 compliance.

When evaluating potential suppliers, ask about their inspection capabilities, tolerance track records, and quality certifications. A well-built tool and die foundation, combined with documented quality processes, delivers the consistent stamping parts your applications require. With quality systems in place, understanding how different industries apply these stamped components reveals the full scope of aluminum stamping's impact across manufacturing sectors.

Industry Applications for Stamped Aluminum Parts

You've mastered the technical fundamentals—alloy selection, process stages, tooling design, and quality standards. But where do all these stamped aluminum components actually end up? The answer spans nearly every major manufacturing sector, from the car you drive to the smartphone in your pocket.

Understanding real-world applications helps you recognize why manufacturers make specific material and process choices. Each industry brings unique requirements that influence everything from alloy selection to surface finishing. Let's explore how stamped aluminum sheet metal components solve critical challenges across diverse sectors.

Automotive and Aerospace Applications

These two industries drive much of the innovation in aluminum stampings, pushing the boundaries of what's possible with lightweight, high-performance components.

Automotive applications have embraced aluminum stamping as vehicle manufacturers face increasingly stringent fuel economy and emissions regulations. Every kilogram removed from a vehicle translates directly to improved efficiency. According to Eigen Engineering, common automotive aluminum stampings include brackets, heat shields, and structural frames.

- Body panels and closures: Hoods, trunk lids, and door panels increasingly use stamped aluminum to reduce body-in-white weight by 40% or more compared to steel equivalents.

- Structural brackets: Engine mounts, suspension components, and chassis reinforcements leverage aluminum's strength-to-weight ratio for critical load-bearing applications.

- Heat shields: Stamped aluminum protects sensitive components from exhaust system heat, taking advantage of the material's excellent thermal properties.

- Battery enclosures: Electric vehicle manufacturers rely on stamped aluminum housings to protect battery packs while minimizing weight penalties.

- Interior trim components: Decorative and functional interior parts benefit from aluminum's ability to accept embossed aluminum finishes and anodized surfaces.

Aerospace applications demand even higher performance standards. Weight savings translate directly to fuel efficiency and payload capacity—critical factors when every gram affects operating economics.

- Fuselage structural components: According to Winco Stamping, aircraft fuselage parts and landing gear components can be made through aluminum stamping processes.

- Interior brackets and mounting hardware: Cabin fixtures, seat frames, and overhead compartment supports use stamped aluminum for weight-critical applications.

- Avionics enclosures: Electronic equipment housings require electromagnetic shielding and thermal management that aluminum delivers effectively.

- Control surface components: Flaps, ailerons, and rudder elements incorporate stamped aluminum parts where weight reduction improves aircraft handling characteristics.

Both industries share common decision factors: certified material traceability, tight tolerance requirements, and rigorous quality documentation. Suppliers serving these sectors typically maintain IATF 16949 certification for automotive and AS9100 for aerospace applications.

Electronics and Consumer Product Components

The electronics industry presents entirely different challenges—miniaturization, thermal management, and electromagnetic compatibility drive material selection decisions here.

Electronics applications leverage aluminum's thermal conductivity and shielding properties:

- Heat sinks: Stamped aluminum heat sinks dissipate thermal energy from processors, power supplies, and LED lighting systems. The material's thermal conductivity and formability enable complex fin geometries that maximize cooling efficiency.

- Electrical housings and enclosures: According to Worthy Hardware, deep drawing creates seamless enclosures that offer excellent protection, while progressive die stamping produces the brackets and internal mounting hardware.

- RF shielding components: Stamped aluminum shields prevent electromagnetic interference between circuit sections, protecting sensitive electronics from signal degradation.

- Connector housings: Small, precisely formed housings protect electrical connections while providing mounting features. Aluminum multislide stamping excels at producing these intricate components in high volumes.

- Battery contacts and terminals: Consumer electronics rely on stamped aluminum contacts for lightweight, corrosion-resistant electrical connections.

Consumer product applications span an enormous range of everyday items where aluminum stamping delivers practical benefits:

- Kitchen products: Colanders, whisks, storage containers, and cookware components use stamped aluminum for its corrosion resistance and food-safe properties.

- Appliance housings: Washing machine drums, refrigerator panels, and small appliance enclosures benefit from aluminum's durability and surface finish quality.

- Sporting goods: Equipment frames, protective housings, and structural components in everything from camping gear to fitness equipment.

- Lighting fixtures: Reflectors, housings, and mounting brackets for residential and commercial lighting systems.

Medical device applications demand exceptional cleanliness and biocompatibility:

- Mobility aids: Winco Stamping notes that walkers, canes, wheelchair baskets, and letter writing aids utilize aluminum metal stamped parts for their lightweight durability.

- Diagnostic equipment housings: Enclosures for medical imaging and monitoring devices require precise dimensions and excellent surface finishes.

- Surgical instrument components: Handles, guards, and structural elements where weight reduction improves ergonomics during extended procedures.

- Sterilization trays: Stamped aluminum containers withstand repeated autoclave cycles while remaining lightweight for handling.

What decision factors drive manufacturers across these diverse industries to choose aluminum stamping? The answer typically comes down to five key considerations:

- Weight requirements: Applications where component mass directly affects product performance or user experience favor aluminum.

- Production volume: High-volume requirements justify tooling investments that deliver low per-part costs—progressive and transfer die stamping excel here.

- Environmental exposure: Outdoor, marine, or high-humidity applications benefit from aluminum's natural corrosion resistance.

- Thermal management needs: Products generating or sensitive to heat leverage aluminum's conductivity for passive cooling.

- Surface finish expectations: Consumer-facing products requiring anodized, powder-coated, or embossed aluminum finishes make aluminum the natural choice.

The breadth of applications demonstrates aluminum stamping's versatility across industries with vastly different requirements. Whether producing millions of small electronic clips through aluminum multislide stamping or forming large automotive panels through transfer dies, the fundamental process adapts to meet diverse manufacturing challenges.

With this understanding of where stamped aluminum components find their applications, the final consideration becomes selecting the right manufacturing partner to bring your project from concept to production.

Choosing the Right Aluminum Stamping Partner

You've explored alloy selection, process stages, tooling requirements, and quality standards. Now comes the decision that ties everything together: selecting a manufacturing partner who can actually deliver on your project requirements. The wrong choice can mean missed deadlines, quality issues, and budget overruns. The right partner becomes a strategic asset that strengthens your supply chain for years to come.

What separates exceptional aluminium stampings suppliers from average ones? The answer involves evaluating capabilities across multiple dimensions—from technical expertise and quality systems to cost competitiveness and communication. Let's break down the factors that matter most when making this critical decision.

Evaluating Stamping Partners and Capabilities

According to Talan Products, selecting a metal stamping supplier is a critical decision that directly impacts your production quality, cost, and supply chain reliability. Whether you're sourcing for automotive, industrial, or consumer applications, choosing the right partner can mean the difference between success and costly headaches.

When evaluating potential partners for your drawn aluminum projects, focus on these essential criteria:

- Proven quality and low defect rates: Quality is non-negotiable when selecting a stamping supplier. Look for a company with a low parts per million (PPM) defect rate, which strongly indicates process control and reliability. Fewer defects mean less scrap and fewer disruptions to your production schedule.

- Reliable on-time delivery: A great stamping partner delivers on time, every time. Late parts can shut down production lines, increase costs, and create massive inefficiencies. Ask potential suppliers about their delivery performance metrics before committing.

- Cost competitiveness and efficiency: The most efficient metal stamping companies offer globally competitive pricing without sacrificing quality. High production efficiency translates to lower per-part costs for your projects.

- Experience and long-term partnerships: A strong track record of customer retention signals a supplier you can trust. If a company has maintained long-term customers, it likely means they deliver consistent quality, reliability, and service.

- Skilled workforce and training commitment: Your stamping partner should invest in workforce development. Expertise translates to better quality, efficiency, and problem-solving capabilities when drawing on aluminum presents unexpected challenges.

- Workplace safety and operational stability: A safe workplace means fewer disruptions, higher productivity, and a supplier you can rely on for the long term. Ask about safety records during your evaluation.

- Advanced simulation capabilities: Partners using CAE simulation for defect prevention can identify potential issues before cutting steel on tooling. According to Keysight, simulation allows for testing different materials and designs without expensive physical prototypes, enabling faster innovation and more precise control over the final product.

- Quality certifications: ISO 9001:2015 certification ensures strict quality management processes. For automotive applications, IATF 16949 certification is essential—it demonstrates commitment to the rigorous standards the industry demands.

Optimizing Your Aluminum Stamping Project

Understanding what drives aluminum stamping costs helps you make informed decisions that balance quality requirements against budget constraints. Several interconnected factors determine your final project economics:

Material costs represent a significant portion of your project budget. According to Worthy Hardware, aluminum sits in the middle of the cost spectrum—more expensive per kilogram than basic carbon steel, but cheaper than stainless steel, brass, copper, and high-nickel alloys. However, the cost calculation isn't as simple as comparing price per kilogram:

| Cost Factor | Aluminum Advantage | Steel Advantage |

|---|---|---|

| Raw Material Price | — | Lower per-kilogram cost |

| Material Usage | More parts per kilogram due to lower density | — |

| Shipping Costs | Lower weight reduces freight expenses | — |

| Secondary Finishing | Natural corrosion resistance often eliminates plating | Requires protective coating to prevent rust |

| Tool Life | Softer material can extend die longevity | — |

When you factor in longer tool life, reduced finishing requirements, and lower shipping costs, aluminum can sometimes become the more economical choice—especially for lightweight applications where the drawing of aluminum components delivers performance advantages.

Tooling investment represents a major upfront cost that amortizes across your production volume. Complex progressive dies for high-volume production may cost significantly more than simple single-operation tooling, but they deliver dramatically lower per-part costs at scale. Partners offering rapid prototyping—some achieve turnaround in as little as 5 days—help you validate designs before committing to production tooling.

Production volume economics fundamentally shape your cost structure. High-volume runs dilute tooling costs across more parts, making the per-unit economics increasingly favorable. For production exceeding 100,000 pieces monthly, stamped aluminum delivers per-unit costs substantially lower than alternative forming methods.

Surface treatment options add functionality and aesthetics to your stamped parts while affecting overall project costs:

- Anodizing: Creates a durable oxide layer that enhances corrosion resistance and allows for color options. Type II anodizing suits decorative applications while Type III (hardcoat) provides wear resistance.

- Powder coating: Applies a thick, durable finish in virtually any color. Excellent for parts requiring impact resistance and UV stability.

- Electroplating: Deposits metallic coatings like nickel or chrome for enhanced conductivity, solderability, or decorative appearance.

- Conversion coatings: Chromate or non-chromate treatments improve paint adhesion and provide baseline corrosion protection.

- Clear coating: Preserves aluminum's natural appearance while adding scratch and corrosion resistance.

Each treatment affects part cost, lead time, and performance characteristics differently. Your partner should help you select the optimal finish for your application requirements.

The complete project lifecycle—from initial material selection through final quality verification—benefits from early partner involvement. Suppliers with high first-pass approval rates (industry leaders achieve 93% or higher) minimize costly design iterations and tooling modifications. Their engineering teams can identify potential forming challenges, recommend alloy substitutions, or suggest design modifications that improve manufacturability before you've invested in hard tooling.

For automotive applications requiring IATF 16949 compliance, partners like Shaoyi offer comprehensive mold design and fabrication capabilities that meet OEM standards. Their combination of advanced CAE simulation for defect prevention, rapid prototyping timelines, and proven quality systems demonstrates the capabilities you should expect from a qualified stamping partner.

Ultimately, the right manufacturing partner understands that your success is their success. They bring technical expertise, quality systems, and production capabilities that transform your designs into reliable, cost-effective aluminum components—delivering value that extends far beyond the stamping press.

Frequently Asked Questions About Aluminum Stamping

1. What is the process of aluminum stamping?

Aluminum stamping is a metalworking process that transforms flat aluminum sheets into precise finished parts through sequential operations. It begins with material preparation and inspection, followed by die design and setup with springback compensation. Lubrication is applied to prevent galling, then blanking cuts appropriately sized pieces. Piercing creates holes and cutouts, while forming and bending shape the three-dimensional geometry. Deep drawing creates hollow shapes when needed, and trimming removes excess material. The process concludes with finishing treatments and quality inspection to verify dimensional accuracy.

2. What are the 7 steps in the stamping method?

The seven most common metal stamping processes include blanking (cutting flat shapes from sheet metal), piercing (creating holes and internal cutouts), drawing (forming cup-like or hollow shapes), bending (creating angles and flanges), air bending (using less force for flexible angle control), bottoming and coining (achieving precise angles with high pressure), and pinch trimming (removing excess material from formed parts). For aluminum specifically, each step requires adjusted parameters including tighter die clearances, springback compensation, and specialized lubrication to account for the material's unique properties.

3. Is aluminum easy to stamp?

Aluminum is rated as a soft metal that stamps relatively easily compared to harder materials like steel. It requires moderate force—typically 60-70% of what steel needs—and can be stamped with standard equipment. However, aluminum presents unique challenges including pronounced springback after bending, tendency to gall against tooling without proper lubrication, and limited ductility after necking begins. Success requires tighter die clearances (12-18% per side), specialized barrier-type lubricants, and tooling designed specifically for aluminum's behavior. Alloys like 1100 and 3003 offer excellent stampability for most applications.

4. How thick of aluminum can you stamp?

Aluminum sheet metal typically ranges from 0.2 mm to 6 mm thick for standard stamping applications. Most production stamping works with sheets between 0.5 mm and 3 mm, where the material forms easily without requiring excessive tonnage. Thicker aluminum requires higher press forces and may need multiple forming operations with intermediate annealing to prevent cracking. Precision stamping operations can achieve tolerances of ±0.05 mm regardless of thickness. The optimal thickness depends on your specific part design, alloy selection, and forming complexity requirements.

5. What aluminum alloys work best for stamping?

The most commonly used aluminum alloys for stamping are 3003 and 5052, which handle approximately 80% of stamping projects. Alloy 3003 offers excellent formability with good corrosion resistance, making it ideal for decorative trim, brackets, and kitchenware. Alloy 5052 delivers higher strength and durability for marine hardware and automotive components, though it costs about 20% more. For pure formability, 1100 aluminum excels but has low strength. The 6061 alloy provides good mechanical properties for structural applications. Alloy selection depends on balancing strength requirements, forming complexity, environmental exposure, and budget constraints.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —