যানবাহনের নিরাপত্তা উপাদানের জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রড: ইস্পাতের সাথে তুলনা

কেন অ্যালুমিনিয়াম বাইরে টিপে দেওয়া রড নিলম্বন ডিজাইন পুনর্গঠন করছে

একটি যানবাহনের নিলম্বন ব্যবস্থা কল্পনা করুন—প্রতিটি বক্রতা, ঢেউ, এবং তীক্ষ্ণ মোড় লিঙ্ক, বাহু এবং রডের একটি নেটওয়ার্ক দ্বারা নিয়ন্ত্রিত হয়। ঐতিহ্যগতভাবে, এই অংশগুলি ইস্পাত দিয়ে তৈরি করা হত, কিন্তু হালকা এবং আরও দক্ষ যানবাহনের চাহিদা বাড়ার সাথে সাথে, অ্যালুমিনিয়াম বাইরে টিপে দেওয়া রড ক্রমবর্ধমান ভাবে প্রাধান্য পাচ্ছে। কিন্তু ঠিক কী কারণে তারা যানজনিত নিলম্বন অংশগুলির জন্য এত মূল্যবান এবং প্রকৌশলীদের কী বিষয়গুলি মাথায় রাখা উচিত?

আধুনিক নিলম্বনে অ্যালুমিনিয়াম বাইরে টিপে দেওয়া রডগুলি কী করে

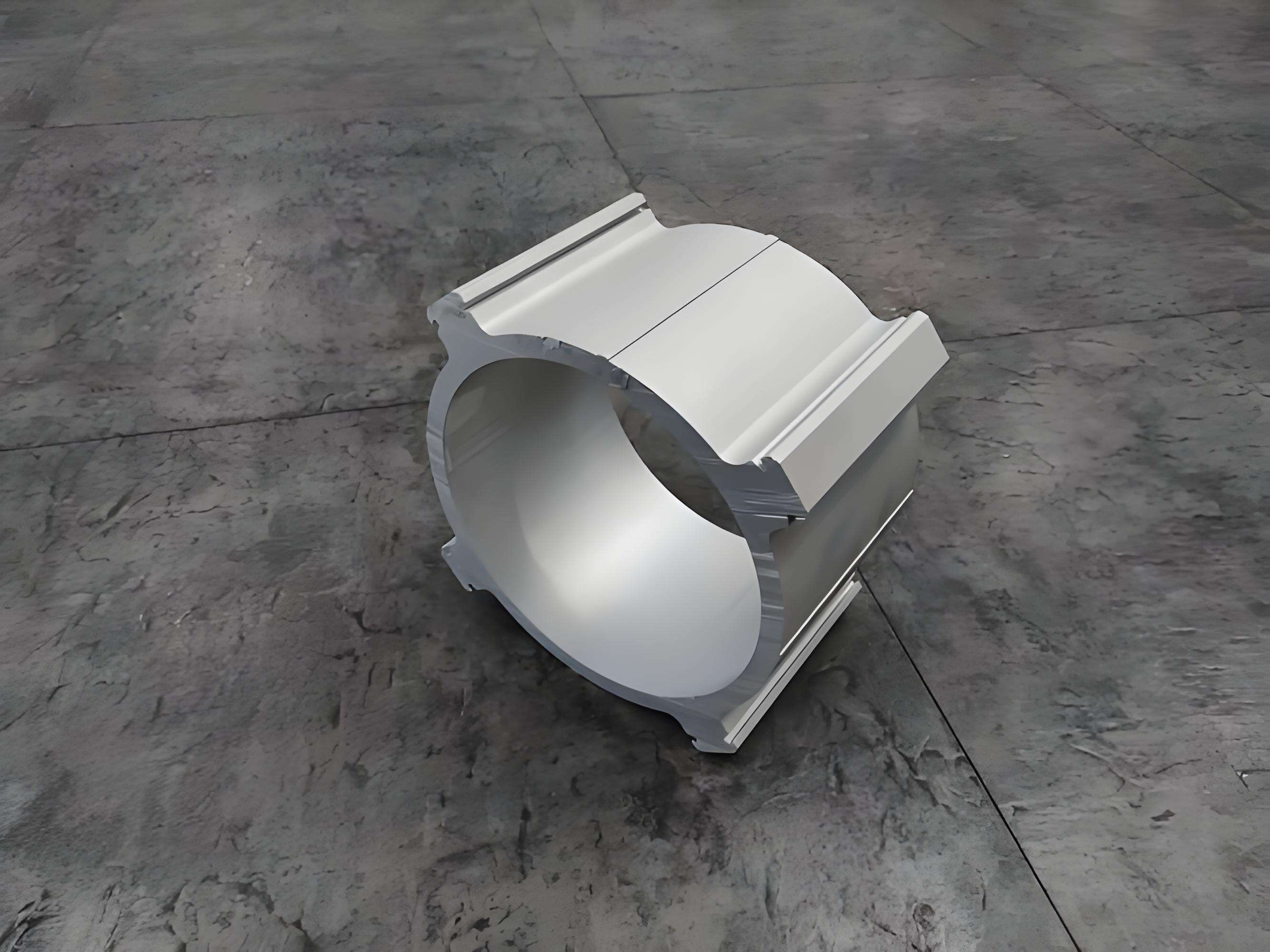

অ্যালুমিনিয়ামের বাইরের দিকে ঠেলে দেওয়া রডগুলি, যেমন অ্যালুমিনিয়াম রড, অ্যালুমিনিয়াম গোলাকার স্টক এবং অ্যালুমিনিয়াম গোলাকার বারের মতো আকৃতি, এখন নির্ণায়ক সাসপেনশন অঞ্চলগুলিতে সাধারণভাবে ব্যবহৃত হয়: নিয়ন্ত্রণ বাহু, টাই-রড, স্থিতিশীলকারী লিঙ্ক এবং সাবফ্রেম সংযোগকারীদের মধ্যে। এগুলি লোড স্থানান্তরের জন্য মেরুদন্ড হিসাবে কাজ করে, সংরেখন বজায় রাখে এবং চাকার সঠিক গতিবিধি নিশ্চিত করে। উচ্চ-কার্যকারিতা এবং বৈদ্যুতিক যানগুলিতে, এই অ্যালুমিনিয়াম বাইরের দিকে ঠেলে দেওয়া পণ্যগুলি অ-স্প্রংগ ভরকে হ্রাস করতে সাহায্য করে, সরাসরি চলার মান এবং নিয়ন্ত্রণকে উন্নত করে। আপনি তাদের উপস্থিতি স্পোর্টস গাড়ি থেকে শুরু করে ভারী ট্রাকগুলিতে লক্ষ্য করবেন, যেখানে ওজন কমানো এবং ক্ষয় প্রতিরোধ করার বিশেষ প্রয়োজন (AEC অটোমোটিভ অ্যাপ্লিকেশনস) .

প্রকৌশলীদের ভারসাম্য রক্ষা করতে হবে এমন সুবিধা এবং ত্রুটিগুলি

- ভর হ্রাস: অ্যালুমিনিয়ামের ঘনত্ব ইস্পাতের এক তৃতীয়াংশের সমান, অংশগুলির ওজন কমিয়ে জ্বালানি দক্ষতা বা ইভি পরিসর বাড়ায়।

- ক্ষয়ক্ষতি প্রতিরোধ: অ্যালুমিনিয়াম স্বাভাবিকভাবেই একটি সুরক্ষামূলক অক্সাইড স্তর তৈরি করে, যা কঠোর পরিবেশের জন্য এটিকে আদর্শ করে তোলে এবং রক্ষণাবেক্ষণের প্রয়োজনীয়তা কমায়।

- ডিজাইন নমনীয়তা: এক্সট্রুশন প্রক্রিয়া জটিল, কাস্টমাইজড প্রোফাইলগুলি তৈরি করতে সক্ষম - ফাঁপা অংশগুলি, প্লাস্তিকের খাঁজ বা মাউন্টিংয়ের বৈশিষ্ট্যগুলি চিন্তা করুন - প্রকৌশলীদের শক্তি এবং প্যাকেজিং অপ্টিমাইজ করতে দেয়।

- পুনর্ব্যবহারযোগ্যতাঃ অ্যালুমিনিয়াম এর মূল ধর্মগুলি ক্ষতি না করেই 100% পুনর্ব্যবহারযোগ্য, যা টেকসই উদ্দেশ্যগুলি সমর্থন করে।

- পারফরম্যান্স সংক্রান্ত সতর্কতা: যদিও শক্তিশালী হয়, তবু অ্যালুমিনিয়াম এক্সট্রুডেড রডগুলির নকশা সাবধানে পরিচালনা করার প্রয়োজন যাতে থ্রেডেড বা খাঁজকাটা অঞ্চলগুলিতে ক্লান্তি পরিচালনা করা যায়। প্রকৌশলীদের স্টিলের তুলনায় কম শক্ততা নিয়েও হিসাব করতে হবে, যা বিক্ষেপ এবং NVH (শব্দ, কম্পন, কঠোরতা) কে প্রভাবিত করতে পারে।

নিলাম্বন স্থাপত্যের মধ্যে এক্সট্রুডেড রডগুলি কোথায় প্রযোজ্য

বিভিন্ন ধরনের সাসপেনশন ব্যবস্থার জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রডগুলি নানাভাবে ব্যবহার করা যেতে পারে। ডবল-উইশবোন এবং মাল্টি-লিঙ্ক সেটআপে, এগুলি প্রধান বাহু এবং সংযোগকারী রড হিসাবে কাজ করে। ম্যাকফারসন স্ট্রাটের ক্ষেত্রে, এক্সট্রুডেড অ্যালুমিনিয়াম পণ্যগুলি প্রায়শই টাই-রড এবং স্থিতিশীলকারী লিঙ্ক হিসাবে কাজ করে। ভারী বাণিজ্যিক যানগুলিতেও, উচ্চ-কার্যকারিতা সম্পন্ন অ্যালুমিনিয়াম এক্সট্রুশন শিল্প প্রয়োগের দিকে ঝোঁকটি স্পষ্ট, যেখানে ভারী ওজন ছাড়াই শক্তি নিশ্চিত করতে রড এবং বারগুলি প্রকৌশলীদের দ্বারা তৈরি করা হয়।

- রড প্রোফাইলের ডিজাইন এবং অনুকরণ

- মিশ্র ধাতু নির্বাচন এবং বিলেট প্রস্তুতি

- কাস্টম ডাইয়ের মাধ্যমে নির্ভুল এক্সট্রুশন

- তাপ চিকিত্সা এবং সোজা করা

- গুরুত্বপূর্ণ বৈশিষ্ট্যগুলির জন্য সিএনসি মেশিনিং

- পৃষ্ঠতল সম্পন্নকরণ (অ্যানোডাইজিং, কোটিং)

- চূড়ান্ত পরিদর্শন এবং সমাবেশ

সবচেয়ে গুরুত্বপূর্ণ বিষয়: অ্যাপ্লিকেশনের সাথে খাপ খাওয়ানো এবং শক্তিশালী প্রক্রিয়া নিয়ন্ত্রণ ব্যবহার করে তৈরি করা অ্যালুমিনিয়াম এক্সট্রুডেড রড ডিজাইন না শুধুমাত্র ওজন কমায় তবুও আধুনিক যানবাহনের সাসপেনশনের জন্য অপরিহার্য দীর্ঘায়ু এবং নিরাপত্তা প্রদান করে।

যেহেতু অটোমোটিভ খাত হালকা ও স্থায়ী উপকরণের উপর জোর দিয়ে যাচ্ছে, অ্যালুমিনিয়াম এক্সট্রুডেড রডের ভূমিকা কেবল প্রসারিত হবে। নতুন সাসপেনশন প্রকল্প চালু করা দলগুলোর জন্য উচ্চ-কর্মদক্ষতা সম্পন্ন মিশ্র ধাতু এবং উন্নত উত্পাদন প্রযুক্তির গভীর জ্ঞান সহ বিশ্বস্ত অংশীদারদের সহায়তা নেওয়া অপরিহার্য। শাওয়ি মেটাল পার্টস সাপ্লায়ার, চীনের অগ্রণী একীভূত নির্ভুল অটো মেটাল পার্টস সমাধান সরবরাহকারী, একটি পরীক্ষিত সংস্থান হিসাবে প্রদান করে অ্যালুমিনিয়াম এক্সট্রুশন অংশ - যারা তাদের যানবাহন প্রোগ্রামে এক্সট্রুডেড অ্যালুমিনিয়াম পণ্য অন্তর্ভুক্ত করতে চান তাদের জন্য একটি ব্যবহারিক শুরুর বিন্দু।

রড পারফরম্যান্স চালিত এমন এক্সট্রুশন মৌলিক বিষয়সমূহ

নিলম্বন উপাদানগুলির প্রসঙ্গে "এল এক্সট্রুশন" শুনলে আপনি ভাবতে পারেন: কেন এই প্রক্রিয়াটি এত ব্যাপকভাবে ব্যবহৃত হয় এবং অন্যান্য ধাতু গঠনের পদ্ধতির সঙ্গে এর তুলনা কীভাবে হয়? চলুন এক্সট্রুডেড অ্যালুমিনিয়াম খাদ রডগুলি কীভাবে অনন্য তা বিশ্লেষণ করি এবং কেন তাদের কার্যকারিতা উত্পাদনের মৌলিক বিষয়গুলির উপর নির্ভর করে।

কীভাবে অ্যালুমিনিয়াম এক্সট্রুশন রডের কার্যকারিতা গঠন করে

অ্যালুমিনিয়াম এক্সট্রুশনকে একটি আকৃতি দেওয়া নল দিয়ে টুথপেস্ট চাপা দেওয়ার মতো ভাবুন—শুধুমাত্র এখানে, একটি উত্তপ্ত অ্যালুমিনিয়াম বিলেটকে একটি সুনির্দিষ্ট ঢালাইয়ের মধ্য দিয়ে ঠেলে দেওয়া হয় যাতে করে পছন্দের অনুপ্রস্থ কাটা সহ একটি অবিচ্ছিন্ন রড তৈরি হয়। দীর্ঘ, সোজা রড উৎপাদনের জন্য এই পদ্ধতিটি আদর্শ, যার সম্পত্তিগুলি একঘেয়ে থাকে, যার ফলে যানবাহনের নিলম্বন প্রয়োগের ক্ষেত্রে এটি সবচেয়ে বেশি ব্যবহৃত হয়। বিলেটের রসায়ন, ঢালাইয়ের ডিজাইন এবং সঠিক প্রক্রিয়ার অবস্থা সবকটিই ফলাফলের পৃষ্ঠতলের সমাপ্তি, শস্য প্রবাহ এবং মাত্রিক সহনশীলতার উপর প্রভাব ফেলে। এই কারকগুলি সরাসরি চূড়ান্ত অ্যালুমিনিয়াম এক্সট্রুডেড পণ্যগুলির ক্লান্তি জীবন এবং শক্তির উপর প্রভাব ফেলে।

দণ্ডের জন্য অ্যালুমিনিয়াম এক্সট্রুড করার পদক্ষেপে পদক্ষেপে ওভারভিউ

- ডাই প্রস্তুতি: মেশিনিং বা একটি গোলাকার ডাই নির্বাচন করে প্রক্রিয়াটি শুরু হয়, তারপরে সমান ধাতু প্রবাহ নিশ্চিত করতে এবং ডাইয়ের আয়ু সর্বাধিক করতে এটিকে আগেভাগেই উত্তপ্ত করা হয়।

- বিলেট প্রস্তুতি: এক্সট্রুডেড অ্যালুমিনিয়াম মিশ্র ধাতুর একটি সিলিন্ড্রিক্যাল বিলেট কাটা হয় এবং এমন একটি তাপমাত্রায় আগেভাগেই উত্তপ্ত করা হয় যা এটিকে নমনীয় করে তোলে কিন্তু গলিত করে না।

- এক্সট্রুশন: বিলেটটি প্রেসে রাখা হয়, তারপরে এটিতে ঘর্ষণহীন করণ প্রয়োগ করা হয় এবং একটি হাইড্রোলিক র্যাম দ্বারা ডাইয়ের মধ্যে দিয়ে ঠেলে দেওয়া হয়, যার ফলে অ্যালুমিনিয়ামটি দণ্ডের আকৃতি ধারণ করে।

- কোয়েঞ্চিং: নতুন তৈরি করা দণ্ডটিকে দ্রুত শীতল করা হয়—প্রায়শই বাতাস বা জল দিয়ে—যাতে পছন্দের যান্ত্রিক বৈশিষ্ট্যগুলি স্থায়ী হয়ে যায়।

- প্রসারিত করা: সামান্য মলাট বা বাঁকগুলি প্রসারিত করে সংশোধন করা হয়, সোজা রাখার নিশ্চয়তা এবং অবশিষ্ট চাপ দূর করতে।

- কাটিং এবং বার্ধক্য প্রক্রিয়া: নির্দিষ্ট টেম্পার এবং শক্তি অর্জনের জন্য রডগুলি প্রয়োজনীয় দৈর্ঘ্যে কাটা হয় এবং তাপ চিকিত্সা (বার্ধক্য প্রক্রিয়া) করা হয়।

- ফিনিশিং: আনোডাইজিং বা কনভারসন কোটিংয়ের মতো ঐচ্ছিক প্রক্রিয়া প্রয়োগ করা হয় যা ক্ষয় প্রতিরোধ এবং চেহারা উন্নত করতে সাহায্য করে।

এক্সট্রুডেড ধাতু বনাম টানা বা আঘাতজাত বার

তাহলে, বার স্টক থেকে এক্সট্রুশন, টানা, আঘাত দেওয়া বা যান্ত্রিক কর্তনের তুলনামূলক অবস্থান কেমন? যদিও সব পদ্ধতিগুলিই রড উৎপাদন করতে পারে, প্রতিটি পদ্ধতির বিভিন্ন সুবিধা রয়েছে:

- এক্সট্রুশন: দ্রুত, কম খরচে এবং জটিল বা কাস্টম প্রোফাইল তৈরি করার ক্ষমতা সম্পন্ন। সাসপেনশন লিঙ্কগুলিতে ফ্যাটিগ প্রতিরোধের জন্য দৈর্ঘ্য বরাবর স্থিতিশীল শস্য প্রবাহ তৈরি করে।

- টানা (ঠান্ডা ফিনিশিং): পৃষ্ঠের ফিনিশ উন্নত করে এবং কম মাত্রার মাত্রিক সহনশীলতা অর্জন করে, কিন্তু এটি ধীর এবং সাধারণত বেশি খরচের। টানার সময় কাজের কঠোরতা শক্তি বাড়ায়।

- ফোর্জিং: খুব উচ্চ শক্তি এবং দুর্দান্ত শস্য অভিমুখিতা তৈরি করে, কিন্তু তা ছোট, মোটা অংশগুলির জন্য উপযুক্ত—দীর্ঘ রডগুলির জন্য নয়।

- বার স্টক থেকে যান্ত্রিক কাজ: এটি নির্ভুল মাত্রা অফার করে কিন্তু এর উপকরণ এবং শ্রম তীব্র, বেশি অপচয় এবং উচ্চ খরচ সহ।

| শর্ত | বর্ণনা | গ্রহণযোগ্যতার মানদণ্ড | সাধারণ ফিনিশ |

|---|---|---|---|

| বিলেট | অ্যালুমিনিয়াম মিশ্র ধাতুর কঠিন সিলিন্ড্রিক্যাল ব্লক, এক্সট্রুশনের জন্য পূর্ব উত্তপ্ত | পরিষ্কার, ত্রুটি মুক্ত, সঠিক মিশ্র ধাতু | N/a |

| রড | দীর্ঘ, কঠিন, গোলাকার এক্সট্রুডেড অংশ | সোজা, ব্যাস, রানআউট | অ্যানোডাইজ, কনভারসন কোট |

| বার | কঠিন অংশ, প্রায়শই আয়তক্ষেত্রাকার বা বর্গক্ষেত্র, বা বৃহত্তর গোলাকার আকৃতি | মাত্রিক সহনশীলতা, পৃষ্ঠ ফিনিশ | অ্যানোডাইজ, কনভারসন কোট |

| প্রোফাইল | কাস্টম ক্রস-সেকশন, যা কঠিন, খাঁজযুক্ত বা আধা-খাঁজযুক্ত হতে পারে | প্রোফাইল সহনশীলতা, সোজা | অ্যানোডাইজ, পাউডার কোট |

অ্যালুমিনিয়াম এক্সট্রুশনের সময় বিলেট রসায়ন, ডাই ডিজাইন এবং প্রক্রিয়া সেটিংয়ের সতর্ক নিয়ন্ত্রণ হল প্রতিটি সাসপেনশন অ্যাপ্লিকেশনে ব্যবহৃত অ্যালুমিনিয়াম এক্সট্রুডেড রডের ফ্যাটিগ শক্তি এবং স্থায়িত্বের জন্য উপরের সীমা নির্ধারণ করে।

এই মৌলিক বিষয়গুলি বোঝা প্রকৌশলীদের তাদের প্রয়োজনীয়তা অনুযায়ী সঠিক প্রক্রিয়া বেছে নিতে সাহায্য করে। পরবর্তীতে, আমরা অ্যালয় এবং টেম্পার নির্বাচন কীভাবে চ্যালেঞ্জজনক সাসপেনশন পরিবেশের জন্য রডের কার্যকারিতা আরও উন্নত করে তোলে তা নিয়ে আলোচনা করব।

সাসপেনশন রডের জন্য অ্যালয় এবং টেম্পার নির্বাচন

যখন আপনাকে যানবাহনের সাসপেনশন উপাদানগুলির জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রড ডিজাইন করার দায়িত্ব দেওয়া হয়, সঠিক অ্যালয় এবং টেম্পার বেছে নেওয়া একটু রেস কার টিউন করার মতো—প্রতিটি সেটিং গুরুত্বপূর্ণ। জটিল শোনাচ্ছে? হতে পারে, কিন্তু এটিকে ব্যবহারিক মানদণ্ডে ভাগ করে নিলে প্রক্রিয়াটি আরও মসৃণ হয়ে ওঠে। চলুন দেখে নেওয়া যাক কীভাবে আপনার নির্দিষ্ট সাসপেনশন প্রয়োজনীয়তা অনুযায়ী সঠিক অ্যালুমিনিয়াম রাউন্ড বার বা অ্যালুমিনিয়াম রাউন্ড স্টক বেছে নিতে হয়।

শক্তি, ক্ষয় এবং ওয়েলডেবিলিটির জন্য খাদ নির্বাচন করা

দুটি প্রধান খাদ পরিবার বিবেচনা করে শুরু করুন: 6000-সিরিজ (যেমন 6061 অ্যালুমিনিয়াম রাউন্ড বার) এবং 7000-সিরিজ (যেমন 7075)। প্রতিটি সম্পত্তির একটি অনন্য মিশ্রণ সরবরাহ করে:

- 6061 অ্যালুমিনিয়াম রাউন্ড বার: সাসপেনশন লিঙ্কের জন্য প্রায়শই পছন্দ করা হয়, এই খাদটি মাঝারি থেকে উচ্চ শক্তি, দুর্দান্ত ক্ষয় প্রতিরোধ এবং উত্কৃষ্ট ওয়েলডেবিলিটির জন্য মূল্যবান। এর মেশিনেবিলিটি থ্রেড এবং জটিল বৈশিষ্ট্যগুলি তৈরি করা সহজ করে তোলে - টাই-রড বা নিয়ন্ত্রণ বাহুতে কাস্টম অ্যালুমিনিয়াম রাউন্ডের জন্য আদর্শ।

- ৭০৭৫ অ্যালুমিনিয়ামঃ এই 7000-সিরিজের খাদটি অনেক বেশি টেনসাইল এবং ভাড়া শক্তি দিয়ে প্যাক করা হয় - উচ্চ-ভার, ক্লান্তি-প্রবণ উপাদানগুলির জন্য একটি শীর্ষ পছন্দ হিসাবে। যাইহোক, এটি কম ক্ষয় প্রতিরোধী এবং ওয়েল্ড করা কঠিন, তাই এটি সেই অ্যাপ্লিকেশনগুলির জন্য সংরক্ষিত থাকা ভাল যেখানে শক্তি অন্যান্য সমস্ত কারককে হারিয়ে দেয়।

- অন্যান্য খাদ: 5000-সিরিজ এবং 2000-সিরিজ স্পষ্টতই বিদ্যমান, কিন্তু শক্তি, ক্ষয় বা যন্ত্রের কাজের বিনিময়ের কারণে সাসপেনশনে এগুলো কম সাধারণ। বেশিরভাগ যানবাহন সাসপেনশন প্রোগ্রামের জন্য, প্রমাণিত কর্মক্ষমতার জন্য 6061 বা 7075 এর সাথে থাকুন।

একটি খেলার গাড়ির নিম্ন নিয়ন্ত্রণ বাহু কল্পনা করুন: যদি এটি শক্তিশালী এবং কাস্টম বুশিং বা থ্রেডের জন্য মেশিন করা সহজ হতে হয়, তবে একটি 6061 অ্যালুমিনিয়াম রাউন্ড বার সাধারণত বুদ্ধিমান পছন্দ। একটি রেসিং টাই-রডের জন্য যেখানে চূড়ান্ত শক্তি অপরিহার্য, 7075 অতিরিক্ত খরচের মূল্য প্রদানের যোগ্য হতে পারে।

ক্লান্তির জন্য টেম্পার এবং তাপ চিকিত্সা কী অর্থ বহন করে

"টেম্পার" সেই খাদ কীভাবে প্রক্রিয়া করা হয় তার প্রতি ইঙ্গিত করে—আপনার উপাদানের কঠোরতা, শক্তি এবং নমনীয়তার চূড়ান্ত সমঞ্জস্য হিসাবে এটি চিন্তা করুন। সাসপেনশন রডের জন্য, সবচেয়ে প্রাসঙ্গিক টেম্পারগুলি হল:

- T6 (সমাধান তাপ-চিকিত্সা এবং কৃত্রিমভাবে বয়স্ক): 6061-T6 এবং 7075-T6 উভয়ই উচ্চ শক্তি এবং ভাল ক্লান্তি প্রতিরোধ প্রদান করে, যা পারফরম্যান্স নিয়ন্ত্রণের জন্য এদের প্রিয় পছন্দ করে তোলে। T6 টেম্পারগুলি দ্রবণ তাপ চিকিত্সা এবং কৃত্রিম বয়সের সংমিশ্রণের মাধ্যমে অর্জিত হয়, যা পিক যান্ত্রিক বৈশিষ্ট্যগুলি নিশ্চিত করে।

- ও (পুনরুদ্ধারিত): মৃদু এবং নমনীয়, কিন্তু বেশিরভাগ নিয়ন্ত্রণ লোডের জন্য খুব দুর্বল - বিরল ব্যবহার হয় ছাড়া গঠন বা প্রাক-মেশিনিং ব্লাঙ্কের জন্য।

- এইচ (স্ট্রেইন-হার্ডেনড): সাধারণত নিয়ন্ত্রণে এক্সট্রুডেড রডের জন্য ব্যবহৃত হয় না, কারণ এটি শীট বা প্লেট আকৃতিতে আরও সাধারণ।

টেম্পার কেন এত বেশি গুরুত্বপূর্ণ? কারণ ক্লান্তি ফাটলগুলি প্রায়শই থ্রেড বা সংক্রমণে শুরু হয়। T6 টেম্পার শক্তি এবং ক্লান্তি জীবন বাড়িয়ে দেয়, কিন্তু আপনাকে থ্রেডযুক্ত প্রান্তগুলিতে ওভার-হার্ডেনিং এড়াতে হবে, যা ভঙ্গুর এবং ফাটার প্রবণতা দেখাতে পারে।

প্রাধান্য দেওয়া উচিত এমন প্রমিত এবং ডেটাশীট সংকেত

আপনি কিভাবে বিকল্পগুলি তুলনা করবেন এবং সঠিক মিল নিশ্চিত করবেন? সর্বদা কর্তৃপক্ষের মান এবং ডেটাশিট (অ্যালুমিনিয়াম অ্যাসোসিয়েশন বা ASTM এর মতো উৎস থেকে) পরামর্শ করুন। এখানে সাসপেনশনে ব্যবহৃত অ্যালুমিনিয়াম রাউন্ড বারগুলির সাধারণ মিশ্র ধাতু এবং টেম্পারের একটি তুলনামূলক দৃষ্টিভঙ্গি:

| মিশ্র ধাতু/টেম্পার | ফলন শক্তি (এমপিএ) | টেনসাইল শক্তি (এমপিএ) | দৈর্ঘ্যবৃদ্ধি (%) | মডুলাস (GPa) | ক্লান্তি প্রবণতা | দুর্নীতি সম্পর্কিত নোট | সিল্ডিং ক্ষমতা | সাধারণ টেম্পার | সাসপেনশন ব্যবহারের ক্ষেত্র |

|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 | 270 | 310 | 12 | 69 | মাঝারি | চমৎকার | চমৎকার | T6, O | নিয়ন্ত্রণ বাহু, টাই-রড, স্থিতিশীলকারী লিঙ্ক |

| 7075-T6 | 490 | 570 | 11 | 71 | ভাল | মাঝারি | ভালো (বিশেষ পদ্ধতি) | T6, O | উচ্চ-ক্ষমতাসম্পন্ন টাই-রড, রেসিং লিঙ্ক |

সতর্কতামূলক লাল পতাকা

- থ্রেডযুক্ত প্রান্তে অত্যধিক শক্ত অবস্থা ফাটলের কারণ হতে পারে—স্থানীয়ভাবে আরামের ব্যবস্থা করুন অথবা কম শক্ত অবস্থা ব্যবহার করুন।

- অ্যালুমিনিয়াম রাউন্ড বারগুলি যখন ইস্পাতের সাথে যুক্ত হয় তখন গ্যালভানিক ক্ষয়ের ঝুঁকি থাকে—সর্বদা কোটিং বা বুশিং দিয়ে আলাদা করুন।

- খারাপ নথিভুক্তি বা অমীমাংসিত মিশ্র ধাতুর উৎস—সর্বদা প্রত্যয়িত মিল পরীক্ষা প্রতিবেদন দাবি করুন।

- নিম্ন-ভার অঞ্চলে অত্যধিক উচ্চ-শক্তি মিশ্র ধাতু—খরচ বাড়াতে পারে কোনও উপকারিতা ছাড়াই এবং নমনীয়তা হ্রাস করতে পারে।

স্থায়ী, নিরাপদ এবং খরচ কার্যকর সাসপেনশন রড তৈরির জন্য ভিত্তি হল সঠিক মিশ্র ধাতু এবং অবস্থা বেছে নেওয়া—এই পদক্ষেপটি সঠিকভাবে করুন, এবং পরবর্তী সমস্ত কিছু সহজ হয়ে যায়।

পরবর্তীতে, আমরা এই ধাতব নির্বাচনগুলিকে অ্যালুমিনিয়াম রড লিঙ্কের জন্য বাস্তব ডিজাইন এবং মাপের পদ্ধতিতে রূপান্তর করব যা প্রকৃত সাসপেনশনের ভার সামলাতে পারে।

অ্যালুমিনিয়াম রড লিঙ্কের জন্য ডিজাইন এবং সাইজিং পদ্ধতি

যখন আপনি যানবাহনের সাসপেনশন কম্পোনেন্টের জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রড ডিজাইন করছেন, তখন লোডের প্রয়োজনীয়তা থেকে চূড়ান্ত জ্যামিতি পর্যন্ত পথটি ভয়ঙ্কর মনে হতে পারে। আপনি কীভাবে নিশ্চিত করবেন যে আপনার 1 ইঞ্চি অ্যালুমিনিয়াম রড বা 3/4 অ্যালুমিনিয়াম রড আসলে বাস্তব পরিস্থিতিতে টিকে থাকবে? চলুন এই প্রক্রিয়াটি ভেঙে ফেলি, ক্লান্তি, বাঁকানো এবং সেই গুরুত্বপূর্ণ বিবরণগুলির উপর দৃষ্টিনিবদ্ধ করুন যা একটি শক্তিশালী ডিজাইনকে ঝুঁকিপূর্ণ ডিজাইন থেকে আলাদা করে তোলে।

লোড থেকে রডের ব্যাস এবং দৈর্ঘ্য পর্যন্ত ডিজাইন ওয়ার্কফ্লো

কল্পনা করুন আপনি একটি সাসপেনশন লিঙ্কের জন্য একটি কঠিন অ্যালুমিনিয়াম রড সাইজ করছেন। রডটি যানবাহনের ওজনের স্থিতিশীল বলগুলি সহ্য করতে হবে না শুধুমাত্র, বাম্প, কোণারক এবং ব্রেকিং থেকে গতিশীল লোডগুলিও সহ্য করতে হবে। এই লোডগুলি টেনশন, সংকোচন এবং বাঁকানোর মিশ্রণ তৈরি করে - কখনও কখনও একযোগে। এখানে অ্যালুমিনিয়াম রড লিঙ্কগুলি সাইজ এবং পরিমার্জনের জন্য প্রকৌশলীদের দ্বারা অনুসরণ করা হয় এমন একটি পদক্ষেপ পদক্ষেপ ওয়ার্কফ্লো রয়েছে:

- লোড স্পেকট্রাম সংজ্ঞায়িত করুন: পরিষেবা চলাকালীন রডটি যে সর্বোচ্চ এবং চক্রাকার লোডগুলি (অক্ষীয় এবং বাঁকানো) সহ্য করবে তা সংগ্রহ করুন। এতে গাড়ির ভর, সাসপেনশন জ্যামিতি এবং রাস্তার অবস্থা অন্তর্ভুক্ত থাকবে (IJAERS) .

- প্রাথমিক ব্যাস নির্বাচন করুন: অক্ষীয় এবং বাঁকানো লোডের জন্য প্রয়োজনীয় ন্যূনতম ব্যাস গণনা করুন মান সমূহিত শক্তি সমীকরণ ব্যবহার করে। উদাহরণ স্বরূপ, হালকা যানগুলির জন্য 1/2 অ্যালুমিনিয়াম রড বা 1/4 অ্যালুমিনিয়াম রড যথেষ্ট হতে পারে, যেখানে উচ্চ-লোড পারফরম্যান্স অ্যাপ্লিকেশনগুলির জন্য প্রায়শই 1 ইঞ্চি অ্যালুমিনিয়াম রড প্রয়োজন হয়।

- স্থিতত্ব এবং বাঁক পরীক্ষা করুন: নিশ্চিত করুন যে রডটি অত্যধিক নমনীয় হবে না (যা চাকার সামঞ্জস্য বা চলার গুণমানকে প্রভাবিত করতে পারে) এবং সংকোচনের অধীনে ভেঙে যাবে না। কার্যকর দৈর্ঘ্য এবং প্রান্তের অবস্থা বিবেচনা করে বাঁক পরীক্ষার জন্য অয়লারের সূত্র ব্যবহার করুন।

- থ্রেড শ্রেণী এবং রানআউট রিলিফ নির্বাচন করুন: উপযুক্ত অ্যালুমিনিয়াম থ্রেড (রোলড বা কাটা) নির্বাচন করুন এবং চাপের মেরুদণ্ডের স্থানে চাপ কমাতে রিলিফ প্রদান করুন।

- ফিলেট ব্যাসার্ধ পরিমার্জন করুন: উচ্চতর স্থানীয় চাপ হ্রাস করতে কাঁধের সংক্রমণে প্রচুর মাংসের টুকরা যোগ করুন এবং তীক্ষ্ণ কোণ এড়িয়ে চলুন।

- ক্লান্তি মূল্যায়নের সাথে চূড়ান্ত করুন: স্ট্রেইন-লাইফ বা স্ট্রেস-লাইফ পদ্ধতি ব্যবহার করে প্রত্যাশিত ক্লান্তি জীবন মূল্যায়ন করুন, বিশেষ করে সেই স্থানগুলিতে যেখানে ফাটলগুলি শুরু হওয়ার সম্ভাবনা সবচেয়ে বেশি থ্রেডের মূল এবং ক্রস-হোলসে।

থ্রেডযুক্ত প্রান্ত, ফিলেট এবং চাপ ঘনত্ব নিয়ন্ত্রণ

থ্রেডযুক্ত প্রান্তগুলি সহজ সংযোজন সক্ষম করে তোলে, কিন্তু এগুলি চাপ কেন্দ্রীভবন তৈরি করার জন্য খুব খারাপ নাম রয়েছে। অ্যালুমিনিয়াম রড লিঙ্কের জন্য কাটা থ্রেডের উপরে রোলড থ্রেডগুলি পছন্দ করা হয় কারণ তারা মসৃণ মূল প্রোফাইল এবং উচ্চ ক্লান্তি প্রতিরোধের প্রস্তাব দেয় (রড এন্ড ক্যালকুলেশন) . যেখানে সম্ভব, একটি মসৃণ ফিলেট দিয়ে থ্রেডযুক্ত অংশ থেকে শ্যাঙ্কে সংক্রমণ করুন এবং হঠাৎ ব্যাস পরিবর্তন এড়িয়ে চলুন। গ্রিজ ফিটিং বা মাউন্টের জন্য ক্রস-হোলস উচ্চ চাপ অঞ্চল থেকে দূরে রাখা উচিত বা অতিরিক্ত উপকরণ দিয়ে শক্তিশালী করা উচিত।

লিঙ্ক এবং টাই-রডের জন্য বাকলিং পরীক্ষা এবং নিরাপত্তা কারণগুলি

টাই-রড বা ট্রেইলিং আর্মের মতো কমপ্রেশন মেম্বারের ক্ষেত্রে, বাকলিং হল প্রাথমিক ব্যর্থতার মোড। ঝুঁকি বৃদ্ধি পায় লম্বা রডের (ব্যাসের তুলনায় দীর্ঘ দৈর্ঘ্য) ক্ষেত্রে এবং বিশেষ করে 1/4 ইঞ্চি অ্যালুমিনিয়াম রড বা 3/4 অ্যালুমিনিয়াম রড ব্যবহার করে হালকা ডিজাইনের ক্ষেত্রে এটি সমালোচনামূলক। সংরক্ষণশীল নিরাপত্তা ফ্যাক্টর ব্যবহার করুন এবং পিন করা এবং স্থির প্রান্তের শর্তাবলী বিবেচনা করে ফিনিট এলিমেন্ট এনালাইসিস (FEA) বা হ্যান্ড ক্যালকুলেশনের মাধ্যমে যাচাই করুন। উচ্চ-প্রদর্শন বিল্ডের জন্য, সামান্য ওভার-সাইজিং (উদাহরণস্বরূপ, 3/4 এর পরিবর্তে 1 ইঞ্চি অ্যালুমিনিয়াম রড ব্যবহার করে) মোট ওজনের কোনো প্রভাব না ফেলে মানসিক শান্তি দিতে পারে।

- স্ট্রেস রাইজার কমাতে রড এবং থ্রেডেড অংশের মধ্যে মসৃণ শোল্ডার ট্রানজিশন ব্যবহার করুন

- উচ্চ-চাপ অঞ্চল থেকে দূরে রেঞ্চ ফ্ল্যাটস যোগ করুন যাতে অনিচ্ছাকৃত নটচ তৈরি না হয়

- পর্যাপ্ত থ্রেড এঙ্গেজমেন্ট নিশ্চিত করুন (সাধারণত 1 থেকে 1.5 গুণ নমিনাল ব্যাস)

- সমস্ত ক্রস-হোলস চামফার বা রেডিয়াস করুন এবং সর্বোচ্চ চাপ অঞ্চলের কাছাকাছি তা রাখা এড়িয়ে চলুন

- চক্রাকার লোডিং পরিবেশে উচ্চ ফ্যাটিগ জীবনের জন্য রোলড থ্রেড নির্দিষ্ট করুন

নিলম্বনের জন্য এলুমিনিয়াম নিষ্কাশিত রডের ক্ষেত্রে, রডের আকৃতি, পৃষ্ঠের সমাপ্তি এবং স্থানীয় চাপ নিয়ন্ত্রণের মধ্যে পারস্পরিক ক্রিয়াকলাপ ঘটে, যা চূড়ান্তভাবে ক্লান্তি প্রতিরোধ এবং দীর্ঘমেয়াদী নিরাপত্তা নির্ধারণ করে।

এই ব্যবহারিক পদক্ষেপগুলি অনুসরণ করে এবং বিস্তারিত বিষয়ে যথোচিত মনোযোগ দিয়ে, আপনি এলুমিনিয়াম রড লিঙ্ক তৈরি করবেন—যেটি 1/2 এলুমিনিয়াম রড, 3/4 এলুমিনিয়াম রড বা সলিড এলুমিনিয়াম রড যাই হোক না কেন—যেগুলি হালকা, শক্তিশালী এবং নির্ভরযোগ্য। পরবর্তীতে, উত্পাদন নিয়ন্ত্রণ এবং কীভাবে উৎপাদনের প্রতিটি পর্যায়ে আপনার ডিজাইন উদ্দেশ্য রক্ষা করে তার মধ্যে সংযোগস্থলগুলি সংযুক্ত করব।

এলুমিনিয়াম রড উত্পাদনে নিয়ন্ত্রণ এবং মান নিশ্চিতকরণ যা গুরুত্বপূর্ণ

একই সংকর ধাতু দিয়ে তৈরি দুটি রড কেন পরিষেবাতে এত আলাদভাবে আচরণ করে তা কখনও ভেবে দেখেছেন? উত্তরটি হল উত্পাদন নিয়ন্ত্রণের বিস্তারিত বিবরণে। যখন আপনি গাড়ির সাসপেনশন উপাদানগুলির জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রড নির্দিষ্ট করেন, আপনার ডিজাইনটি তৈরি করা প্রক্রিয়ার চেয়ে ভালো হয় না। প্রতিটি পর্যায় কীভাবে - এক্সট্রুশন থেকে চূড়ান্ত পরিদর্শন পর্যন্ত - রডের যান্ত্রিক বৈশিষ্ট্য, নির্ভরযোগ্যতা এবং চাহিদাপূর্ণ অটোমোটিভ পরিবেশের উপযুক্ততা গঠন করে তা বিশ্লেষণ করুন।

মাইক্রোস্ট্রাকচার এবং ত্রুটিগুলি আকার দেওয়ার জন্য এক্সট্রুশন প্যারামিটার

উত্তপ্ত অ্যালুমিনিয়াম বিলেটটিকে একটি ঢালাই মডেলের মধ্যে ঠেলে দেওয়ার কথা কল্পনা করুন - সহজ শোনাচ্ছে, তাই না? বাস্তবে, ফলাফলটি কয়েকটি কঠোরভাবে নিয়ন্ত্রিত পরিবর্তনশীলের উপর নির্ভর করে:

- এক্সট্রুশন অনুপাত: উচ্চ অনুপাতগুলি শস্য কাঠামোকে পরিষ্কার করে, শক্তি বাড়ায়, কিন্তু অত্যধিক হ্রাস ত্রুটি তৈরি করতে পারে।

- প্রস্থান তাপমাত্রা: যদি তাপমাত্রা খুব বেশি হয় তবে আপনি মোটা শস্য বা পৃষ্ঠের ফাটলের ঝুঁকি নেন; খুব কম হলে, প্রবাহ রেখা বা অসম্পূর্ণ পরিপূরক ঘটতে পারে।

- ডাই ডিজাইন: ভালোভাবে প্রকৌশলীকৃত ডাই টার্বুলেন্স কমায় এবং গ্রেন প্রবাহ স্থিতিশীল রাখে— ক্লান্তি-প্রবণ এক্সট্রুডেড উপাদানগুলির জন্য এটি অত্যন্ত গুরুত্বপূর্ণ।

এই প্যারামিটারগুলি সরাসরি মাইক্রোস্ট্রাকচারকে প্রভাবিত করে, যা রডের শক্তি, নমনীয়তা এবং দীর্ঘমেয়াদী স্থায়িত্ব নিয়ন্ত্রণ করে। সামান্য প্রক্রিয়াগত পরিবর্তন হতে পারে এমন রডের মধ্যে যা ক্লান্তি পরীক্ষা পাস করে এবং যা সময়ের আগে ব্যর্থ হয়ে যায়।

কোয়েঞ্চ এবং এজিং পদ্ধতি যা শক্তি নিয়ন্ত্রণ করে

এক্সট্রুশনের পরপরই রড এখনও গরম এবং নমনীয়। দ্রুত শীতলীকরণ— বায়ু বা জলে ডুবিয়ে দেওয়ার মাধ্যমে— পছন্দের মাইক্রোস্ট্রাকচারকে "লক ইন" করে রাখে। যদি কোয়েঞ্চ খুব ধীর হয়, তবে মোটা শস্য এবং দুর্বল স্থানগুলি তৈরি হতে পারে; খুব দ্রুত হলে, অবশিষ্ট চাপ তৈরি হতে পারে।

- কোয়েঞ্চিং: দ্রুত, সমানভাবে শীতলীকরণ আকৃতি সংরক্ষণ করে এবং যান্ত্রিক বৈশিষ্ট্য সর্বাধিক করে।

- আর্টিফিশিয়াল এজিং: নিয়ন্ত্রিত তাপ চিকিত্সা (এজিং) আরও শক্তি বাড়ায় এবং মাত্রা স্থিতিশীল করে, বিশেষত সাসপেনশন লিঙ্কগুলিতে ব্যবহৃত এক্সট্রুডেড কাঠামোগত অ্যালুমিনিয়ামের জন্য এটি গুরুত্বপূর্ণ।

ঠান্ডা করার পর স্ট্রেচ-স্ট্রেইটেনিং টুইস্টগুলি সরিয়ে দেয় এবং অভ্যন্তরীণ চাপ কমিয়ে দেয়, সেবাতে রডগুলি সত্য এবং পূর্বানুমেয় রাখে।

মাত্রিক নিয়ন্ত্রণ, সোজাপনা এবং পৃষ্ঠের অখণ্ডতা

আপনি কিভাবে নিশ্চিত করবেন যে আপনার অ্যালুমিনিয়াম বার স্টকের মাপ প্রিন্টের সাথে মেলে? স্বয়ংক্রিয় স্ট্রেইটেনিং এবং নির্ভুল কাটিং কঠোর সহনশীলতা প্রদান করে, যেখানে কঠোর পৃষ্ঠ পরিদর্শন করে ডাই লাইন, ল্যাপস বা অন্তর্ভুক্তি ধরে ফেলে যা ভবিষ্যতে ক্লান্তি ব্যর্থতা ঘটাতে পারে। পৃষ্ঠের সমাপ্তি কেবলমাত্র সৌন্দর্য নয়—মসৃণ, ত্রুটিহীন রডগুলি ফাটল তৈরি করতে কম ঝোঁকপূর্ণ, বিশেষ করে উচ্চ-চাপযুক্ত সাসপেনশন জয়েন্টগুলিতে।

| প্রক্রিয়া সেটিং | সম্ভাব্য ঝুঁকি | পরিদর্শন চেকপয়েন্ট |

|---|---|---|

| এক্সট্রুশন অনুপাত | গ্রেন মোটা হওয়া, অভ্যন্তরীণ শূন্যতা | মাইক্রোস্ট্রাকচার বিশ্লেষণ (কাট নমুনা) |

| প্রস্থান তাপমাত্রা | পৃষ্ঠের ফাটল, প্রবাহ রেখা | দৃশ্যমান এবং অতিশব্দীয় পরিদর্শন |

| ডাই রক্ষণাবেক্ষণ | ডাই রেখা, মাত্রিক বিচ্যুতি | পৃষ্ঠের সমাপ্তি পরীক্ষা, প্রোফাইল গেজ |

| নির্বাতন পদ্ধতি | অবশিষ্ট চাপ, বক্রতা | সোজাপনা/ঘূর্ণন পরিমাপ |

| কৃত্রিম বার্ধক্য | অসঙ্গতিপূর্ণ কঠোরতা | কঠোরতা/টেম্পার যাচাইকরণ |

অঙ্কনে উল্লেখযোগ্য প্রযোজ্য মান সমূহ

সামঞ্জস্য নিশ্চিত করতে, আপনার প্রযুক্তিগত অঙ্কন এবং কেনার অর্ডারে সর্বদা স্বীকৃত শিল্প মানগুলি উল্লেখ করুন। অ্যালুমিনিয়াম রাউন্ড বার স্টক এবং অন্যান্য এক্সট্রুডেড উপাদানগুলির জন্য, প্রধান মানগুলির মধ্যে রয়েছে:

- ASTM B221: অ্যালুমিনিয়াম এবং অ্যালুমিনিয়াম-সংকর এক্সট্রুডেড বার, রড, তার, প্রোফাইল এবং টিউবগুলি কভার করে

- ASTM B211: অ্যালুমিনিয়াম বার, রড এবং তারের জন্য প্রয়োজনীয়তা নির্দিষ্ট করে, মাত্রিক এবং যান্ত্রিক সম্পত্তির মানদণ্ড অন্তর্ভুক্ত করে

- SAE এবং OEM উপাদান স্পেকগুলি: পরিষ্কারতা, ট্রেসেবিলিটি বা পরীক্ষা প্রতিবেদনের জন্য অতিরিক্ত প্রয়োজনীয়তা যোগ করতে পারে

- অ্যালুমিনিয়াম অ্যাসোসিয়েশন প্রকাশনা: এক্সট্রুশন এবং ফিনিশিং-এর জন্য খাদ নির্বাচন, টেম্পার এবং সেরা অনুশীলনগুলির ওপর পরামর্শ প্রদান করুন

এই মানগুলি উল্লেখ করা আপনার অ্যালুমিনিয়াম বার স্টকের আকার এবং গুণমানের প্রত্যাশাগুলি সরবরাহকারীদের কাছে পরিষ্কার করে তোলে এবং অডিট করা সহজ হয়ে ওঠে

- বিলেট থেকে শেষ করা রড-এ তাপ পরিমাণের ট্রেসেবিলিটি

- প্রতিটি ব্যাচে কঠোরতা/টেম্পার যাচাইকরণ

- সমস্ত এক্সট্রুডেড স্ট্রাকচারাল অ্যালুমিনিয়ামের জন্য সোজা এবং রানআউট পরীক্ষা

- অ্যাপ্লিকেশনের ভিত্তিতে পৃষ্ঠ-ফিনিশ গ্রহণযোগ্যতার মানদণ্ড

- পরিদর্শন সরঞ্জামগুলির নথিভুক্ত ক্যালিব্রেশন

শক্তিশালী প্রক্রিয়া নিয়ন্ত্রণ এবং ব্যাপক মান নিয়ন্ত্রণ হল আপনার প্রকৌশল উদ্দেশ্য এবং এমন একটি রডের মধ্যে সেতু, যা প্রকৃত নিলামবাজারের সাসপেনশন লোডের অধীনে নির্ভরযোগ্যভাবে কাজ করে

এই উত্পাদন নিয়ন্ত্রণগুলি বুঝতে এবং নির্দিষ্ট করতে পারলে আপনি নিশ্চিত হতে পারবেন যে আপনার এক্সট্রুডেড অ্যালুমিনিয়াম রড ডিজাইনটি ছাপার থেকে উত্পাদনের যাত্রা টিকিয়ে রাখবে। পরবর্তীতে, আমরা যেভাবে প্রত্যায়ন পরীক্ষা এবং ক্লান্তি মূল্যায়ন লুপটি সম্পূর্ণ করে, নিশ্চিত করে যে প্রতিটি রড ক্ষেত্রে তার স্থায়িত্বের লক্ষ্যগুলি পূরণ করেছে।

স্থায়িত্বের জন্য অ্যালুমিনিয়াম সাসপেনশন রডের পরীক্ষা, ক্লান্তি যাচাই এবং অ-ধ্বংসাত্মক পরীক্ষা (NDT)

যখন আপনি একটি সাসপেনশন লিঙ্কের জন্য একটি অ্যালুমিনিয়াম এক্সট্রুডেড রড নির্দিষ্ট করেন, তখন আপনি কীভাবে জানবেন যে এটি বছরের পর বছর ধরে পিথোল, তীক্ষ্ণ মোড় এবং তাপমাত্রা পরিবর্তন সহ্য করবে? এর উত্তরটি রয়েছে একটি শক্তিশালী যাচাইকরণ পরিকল্পনায়—যা মেকানিক্যাল পরীক্ষা, ক্লান্তি মূল্যায়ন, অনুকরণ এবং উন্নত অ-ধ্বংসাত্মক পরীক্ষা (NDT) এর সংমিশ্রণে তৈরি হয়। আসুন দেখি কীভাবে আপনার 5/16 অ্যালুমিনিয়াম রড বা 1/2 ইঞ্চি অ্যালুমিনিয়াম রড কেবলমাত্র ড্রয়িং বোর্ডের জন্য নয়, পথের জন্য সত্যিই উপযুক্ত করে তুলবেন।

মেকানিক্যাল পরীক্ষা এবং নমুনা প্রস্তুতির প্রয়োজনীয়তা

প্রথমত, আপনাকে নিশ্চিত করতে হবে যে উপকরণ এবং জ্যামিতি প্রয়োজনীয় শক্তি এবং নমনীয়তা প্রদান করে। এর মানে হল প্রতিনিধিত্বমূলক নমুনা প্রস্তুত করা—3/8 অ্যালুমিনিয়াম রড কুপন বা সমস্ত প্রয়োজনীয় বৈশিষ্ট্য (থ্রেড, ফিলেট, ক্রস-হোলস) সহ পূর্ণ-স্কেল প্রোটোটাইপ চিন্তা করুন। উপযুক্ত নমুনা প্রস্তুতি খুবই গুরুত্বপূর্ণ: পৃষ্ঠের সমাপ্তি, থ্রেড রোলিং বনাম কাটিং এবং কঠোর ব্যাসার্ধ নিয়ন্ত্রণ সবই ক্লান্তির ফলাফলকে প্রভাবিত করে। একটি 1/4 ইঞ্চি অ্যালুমিনিয়াম রড খুব খারাপ পৃষ্ঠের সাথে বা তীক্ষ্ণ সংক্রমণ কল্পনা করুন—এটি অনেক আগে ব্যর্থ হওয়ার সম্ভাবনা রয়েছে।

- সমস্ত পরীক্ষার পৃষ্ঠগুলি উত্পাদন সমাপ্তির সাথে মেলে পুলিশ এবং ডেবার করুন

- ক্লান্তি পরীক্ষার জন্য যেখানে সম্ভব রোলড থ্রেড ব্যবহার করুন (উচ্চতর বাস্তব জীবনের স্থায়িত্ব)

- স্ট্রেস রাইজারগুলি কমাতে কাঁধ এবং সংক্রমণগুলিতে ফিলেট ব্যাসার্ধ নিয়ন্ত্রণ করুন

- ট্রেসেবিলিটি এবং পুনরাবৃত্তিযোগ্যতার জন্য সমস্ত প্রস্তুতি পদক্ষেপ নথিভুক্ত করুন

ক্লান্তি পরীক্ষার কৌশল এবং এস-এন বক্ররেখা উন্নয়ন

ফ্যাটিগ হল একটি সাসপেনশন রডের জন্য চূড়ান্ত পরীক্ষা। আপনি আসল মিশ্র ধাতু, টেম্পার এবং জ্যামিতির জন্য S–N (চাপ বনাম চক্রের সংখ্যা) বক্ররেখা তৈরি করতে চাইবেন—বিশেষ করে 5/16 অ্যালুমিনিয়াম রড বা 1/2 ইঞ্চি অ্যালুমিনিয়াম রডের মতো গুরুত্বপূর্ণ ব্যাসের ক্ষেত্রে। পরীক্ষা প্রকৃত পরিষেবা লোডকে প্রতিফলিত করবে: পরিবর্তনশীল পরিমাণ, প্রতিনিধিত্বমূলক গড় চাপ, এবং বাস্তবিক পরিবেশ (আর্দ্রতা, লবণ, তাপমাত্রা চক্র)।

- উপাদান কুপন পরীক্ষা: বেসলাইন বৈশিষ্ট্য নির্ধারণের জন্য ছোট, পোলিশ করা নমুনা দিয়ে শুরু করুন।

- যন্ত্রাংশ পরীক্ষা কাটানো: চাপের কেন্দ্রীকরণ অধ্যয়ন করার জন্য কুপনে থ্রেড, অনুপ্রস্থ ছিদ্র বা ফিলেট যোগ করুন।

- উপ-সমাবেশ পরীক্ষা: বাস্তব বা অনুকল্পিত সাসপেনশন ফিক্সচারে রড স্থাপন করুন যাতে বাস্তব সংযোগগুলি ধরা পড়ে।

- পূর্ণ-যান সংশ্লেষ: প্রোটোটাইপ যানবাহনে রড স্থাপন করুন এবং স্থায়িত্ব চক্র বা প্রমাণ ভূমি পরীক্ষা চালান যাতে ল্যাব ফলাফলগুলি যাথার্থ্য যাচাই করা যায়।

| পরীক্ষা প্রকার | স্ট্যান্ডার্ড | নমুনা অভিমুখিকরণ | পরিবেশ | গ্রহণযোগ্যতার মানদণ্ড |

|---|---|---|---|---|

| টেনসাইল টেস্ট | ASTM E8 | লম্বা | ঘরের তাপমাত্রা | বিকৃতি, ইউটিএস, প্রসারণ |

| ফ্যাটিগ টেস্ট (এস–এন) | এএসটিএম ই৪৬৬ | দৈর্ঘ্যমূলক, থ্রেডযুক্ত | পরিবেশগত/দাহ্য | ব্যর্থতার চক্র, ফাটলের স্থান |

| সাবঅ্যাসেম্বলি স্থায়িত্ব | এসএই জে৩২৮ | যেমনটি ইনস্টল করা হয়েছে | থर্মাল সাইক্লিং | কোনও ফাটল নেই, ন্যূনতম চক্র |

| পূর্ণ-যানবাহন পরীক্ষা | ওইএম স্পেসিফিকেশন | যেমনটি ইনস্টল করা হয়েছে | রাস্তা ভার | কোনও ব্যর্থতা নেই, দৃশ্যমান পাস |

FEA সম্পর্কযুক্ততা এবং স্থায়িত্ব স্বাক্ষর অপশন ওয়ার্কফ্লো

ক্লান্তি জীবন পূর্বাভাস শুধুমাত্র ল্যাব কাজের বাইরে। নিম্ন সাসপেনশন বাহু সম্পর্কিত গবেষণায় উল্লেখ করা হয়েছে, স্ট্রেস হট স্পটগুলি অনুকরণ করতে এবং পরীক্ষা পরিকল্পনা পরিচালিত করতে প্রাথমিকভাবে পরিমিত উপাদান বিশ্লেষণ (FEA) ব্যবহার করা হয় (কোর) . এই প্রক্রিয়াটি সাধারণত এই ক্রম অনুসরণ করে:

- FEA ব্যবহার করে গুরুত্বপূর্ণ স্থানগুলি চিহ্নিত করুন (উদাহরণস্বরূপ, 1/4 রাউন্ড স্টকের থ্রেড রুট বা 1/2 ইঞ্চি অ্যালুমিনিয়াম রডের ফিলেট ট্রানজিশন)।

- এই স্থানগুলির উপর পরীক্ষার ডিজাইন করুন, লোড স্পেকট্রা এবং বাস্তব ডেটা থেকে সাইকেলগুলির সাথে মিল রেখে।

- FEA-প্রেডিক্টেড লাইফ এবং পদার্থগত পরীক্ষার ফলাফলের তুলনা করুন। যদি ফলাফলগুলি মিলে যায়, তাহলে সাইন-অফ সম্ভব। যদি না মেলে, তাহলে ডিজাইন পুনরাবৃত্তি করুন অথবা অনুকরণ মডেলগুলি আপডেট করুন।

এই বদ্ধ-লুপ পদ্ধতি নিশ্চিত করে যে আপনার যাচাই কেবল তাত্ত্বিক নয়—এটি অনুকরণ এবং বাস্তব বিশ্বের উভয় ক্ষেত্রেই প্রমাণিত।

প্রোডাকশন এবং ফিল্ড ইনস্পেকশনের জন্য NDT পদ্ধতিসমূহ

সেরা ডিজাইন এবং পরীক্ষার সত্ত্বেও, উৎপাদনের সময় ত্রুটিগুলি ঢুকে যেতে পারে। এখানেই আসে উন্নত NDT-এর দরকার—যা ব্যর্থতায় পরিণত হওয়ার আগেই ত্রুটিগুলি ধরে ফেলে। সাসপেনশনে ব্যবহৃত অ্যালুমিনিয়াম রডগুলির জন্য, প্রধান NDT পদ্ধতিগুলি হল:

- আল্ট্রাসনিক টেস্টিং (UT): অভ্যন্তরীণ শূন্যতা, অন্তর্ভুক্তি বা ফাটলগুলি সনাক্ত করে। 1/2 ইঞ্চি অ্যালুমিনিয়াম রড বা 3/8 অ্যালুমিনিয়াম রডের মতো মোটা রডগুলির ক্ষেত্রে এটি বিশেষভাবে গুরুত্বপূর্ণ। UT স্ক্যানগুলি দৃশ্যমান পরিদর্শনের দ্বারা মিস করা লুকানো ত্রুটিগুলি সনাক্ত করতে পারে।

- ইডি কারেন্ট টেস্টিং (ECT): পৃষ্ঠ এবং নিকটস্থ পৃষ্ঠের ফাটল খুঁজে পাওয়ার ক্ষেত্রে এটি সবচেয়ে ভালো—5/16 অ্যালুমিনিয়াম রড বা 3 16 অ্যালুমিনিয়াম রডের থ্রেড বা পৃষ্ঠের ত্রুটি সনাক্ত করা আদর্শ।

- ডাই পেনিট্রেন্ট ইনস্পেকশন (DPI): পৃষ্ঠের ভাঙন দেখানোর জন্য সহজ এবং কার্যকর, বিশেষ করে থ্রেডযুক্ত প্রান্ত বা মেশিন করা অংশে।

গ্রহণযোগ্যতার মানদণ্ড পরিষ্কার হওয়া উচিত: নির্দিষ্ট আকারের সীমা অতিক্রম করা যে কোনও ফাটল, ফাঁকা স্থান বা অন্তর্ভুক্তি সহ রড প্রত্যাখ্যান করুন। গুরুত্বপূর্ণ সাসপেনশন অংশের ক্ষেত্রে, ক্ষুদ্রতম ত্রুটির জন্যও প্রত্যাখ্যানের কারণ হতে পারে।

- UT: নির্ধারিত সীমা অতিক্রমকারী অভ্যন্তরীণ ত্রুটির জন্য প্রত্যাখ্যান; ট্রেসেবিলিটির জন্য ইকো প্যাটার্ন নথিভুক্ত করুন

- ECT: পৃষ্ঠের ফাটল বা পরিবাহিতা অস্বাভাবিকতার জন্য প্রত্যাখ্যান; উৎপাদন লাইনের জন্য নিরবিচ্ছিন্ন নিরীক্ষণ প্রস্তাবিত

- DPI: যে কোনও দৃশ্যমান ফাটলের সংকেতের জন্য প্রত্যাখ্যান; কসমেটিক এবং কাঠামোগত ত্রুটির মধ্যে পার্থক্য করুন

কঠোর ক্লান্তি যাচাইয়ের সাথে অ-ধ্বংসী পরীক্ষার সমন্বয় করে প্রতিটি অ্যালুমিনিয়াম রডের স্থায়িত্ব ও নিরাপত্তা নিশ্চিত করে যা আধুনিক যান নিলামের দাবি পূরণ করে—যেটি হোক না কেন 1/4 ইঞ্চি অ্যালুমিনিয়াম রড বা 1/2 ইঞ্চি অ্যালুমিনিয়াম রড।

পরীক্ষা এবং পরিদর্শনের ব্যবস্থা থাকার পর আপনার পরবর্তী ফোকাস হল সরবরাহ: কীভাবে নির্দিষ্ট করবেন, অডিট এবং সেই সব সরবরাহকারীদের নির্বাচন করবেন যারা আপনার প্রমাণিত মান ল্যাব এবং রাস্তায় নির্ভরযোগ্যভাবে সরবরাহ করতে পারবে।

অ্যালুমিনিয়াম নিলাম রডের জন্য ক্রয় টেমপ্লেট এবং সরবরাহকারী নির্বাচন ওয়ার্কফ্লো

যখন ইঞ্জিনিয়ারিং ড্রইং থেকে প্রকৃত পার্টস সংগ্রহের পর্যায়ে যেতে হয়, তখন গাড়ির সাসপেনশন কম্পোনেন্টের জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রডের ক্রয় প্রক্রিয়া অত্যন্ত জটিল মনে হতে পারে। আপনি কোথা থেকে শুরু করবেন? বিশেষ করে যখন অ্যালুমিনিয়াম বার স্টক বিক্রয়ের জন্য খুঁজছেন বা কাস্টম আকারে অ্যালুমিনিয়াম রড অর্ডার করার প্রয়োজন হয়, তখন কীভাবে মান, খরচ কার্যকারিতা এবং সময়ানুবর্তিতা নিশ্চিত করবেন? সাধারণ ভুলগুলি এড়াতে এবং আপনার প্রকল্পের জন্য সেরা সম্ভাব্য অংশীদার নির্বাচন করতে সুস্পষ্ট এবং কার্যকর পদক্ষেপগুলির মাধ্যমে ক্রয় প্রক্রিয়াটি বিশ্লেষণ করুন।

উপাদান এবং প্রক্রিয়া নির্দিষ্টকরণ টেমপ্লেট

প্রথমে যা করা দরকার: একটি সুস্পষ্ট এবং বিস্তারিত নির্দিষ্টকরণ হল ভুল বোঝার এবং ব্যয়বহুল পুনরায় কাজ করা থেকে আপনাকে রক্ষা করার সেরা উপায়। আপনার পরবর্তী RFQ বা ক্রয় অর্ডারের জন্য ব্যবহার করার জন্য এখানে একটি প্রস্তুত টেমপ্লেট রয়েছে:

- উপাদানের নির্দেশ: ASTM B221/B211 অনুযায়ী অ্যালুমিনিয়াম মিশ্র ধাতু 6061-T6, 6061-T651 বা 6061-T6511 (বিকল্প হিসাবে অঞ্চলিক সরবরাহের ক্ষেত্রে 6082-T6/T651/T6511)

- টেম্পার যাচাই: প্রতিটি লটের সাথে টেম্পার সার্টিফিকেশন প্রদান করতে হবে

- মাত্রিক সহনশীলতা: ড্রয়িং অনুযায়ী; বার/রড স্ট্রেইটনেস এবং রানআউট ASTM B221/B211 প্রয়োজনীয়তা মেলে ধরানো হবে

- পৃষ্ঠের ফিনিশ: ড্রয়িং অনুযায়ী অ্যানোডাইজড বা কনভার্সন কোটেড; থ্রেডেড হোলে ফিনিশ 2.6.2 বিভাগ অনুযায়ী হবে কার্টিস-রাইট মেকানিক্যাল ম্যাটেরিয়াল পারচেজ স্পেসিফিকেশন

- পরীক্ষা রিপোর্ট: মিল টেস্ট সার্টিফিকেট (MTC) যেখানে খাদ, টেম্পার, যান্ত্রিক বৈশিষ্ট্য এবং রাসায়নিক গঠন দেখানো হবে

- PPAP/ISIR: প্রথম নমুনা এবং যেকোনো প্রক্রিয়া পরিবর্তনের জন্য প্রোডাকশন পার্ট অ্যাপ্রুভাল প্রসেস (PPAP) বা ইনিশিয়াল স্যাম্পল ইনস্পেকশন রিপোর্ট (ISIR) প্রয়োজন

- সিরিয়ালাইজেশন/ট্রেসেবিলিটি: প্রতিটি চালানে তাপ লট এবং ব্যাচ নম্বর স্পষ্টভাবে চিহ্নিত করতে হবে

স্পষ্ট স্পেসিফিকেশন আপনাকে কোটেশন তুলনা করতে এবং নিকটস্থ আলুমিনিয়াম রাউন্ড বার স্টকের প্রতিটি ব্যাচ আপনার প্রযুক্তিগত এবং পালনের প্রয়োজনীয়তা পূরণ করছে কিনা তা নিশ্চিত করতে সাহায্য করে

সরবরাহকারী অর্হতা এবং অডিট চেকলিস্ট

আপনি কিভাবে নির্ভরযোগ্য অংশীদারদের ঝুঁকিপূর্ণ বিক্রেতাদের থেকে পৃথক করবেন? ধরুন আপনি একটি গুরুত্বপূর্ণ সাসপেনশন অ্যাপ্লিকেশনের জন্য 3 ইঞ্চি আলুমিনিয়াম রাউন্ড স্টক অর্ডার করতে যাচ্ছেন। এখানে আপনার সরবরাহকারী অডিটের জন্য একটি চেকলিস্ট রয়েছে:

- অটোমোটিভ বা এয়ারোস্পেস-গ্রেড এক্সট্রুশনের সাথে প্রমাণিত অভিজ্ঞতা

- পূর্ণ নথিপত্র সরবরাহ করার ক্ষমতা (উপাদান সাক্ষ্যপত্র, পরীক্ষা রিপোর্ট, PPAP/ISIR)

- সিএনসি মেশিনিং, ফিনিশিং (অ্যানোডাইজিং, কোটিং), এবং দ্বিতীয় অপারেশনের জন্য অভ্যন্তরীণ ক্ষমতা

- প্রত্যয়িত মান ব্যবস্থা (IATF 16949, ISO 9001, বা তুল্য)

- ন্যূনতম অর্ডার পরিমাণ (MOQ) এবং লিড সময়গুলির স্পষ্ট যোগাযোগে পারদর্শিতা

- প্রোটোটাইপিং এবং কম ভলিউম রান এবং বৃহৎ উৎপাদন সমর্থনে ইচ্ছুকতা

- সময়মতো ডেলিভারি এবং ত্রুটি মেরামতের সাথে প্রমাণিত রেকর্ড

- এক্সট্রুশন ডাইসের পরিষ্কার মালিকানা এবং ডাই রক্ষণাবেক্ষণের প্রতি প্রতিশ্রুতি

- আপনার প্রয়োজন অনুযায়ী উৎপাদন বাড়ানোর ক্ষমতা

- দক্ষ পোস্ট-সেল সমর্থন এবং ওয়ারেন্টি পরিচালনা

বিক্রয়ের জন্য অ্যালুমিনিয়াম রড বা আলুমিনিয়াম বার স্টকের প্রতি পাউন্ড মূল্য নিয়ে আলোচনার সময় অপ্রত্যাশিত ঘটনা এড়াতে এবং পথের শেষে অপ্রীতিকর অবস্থা এড়াতে সম্ভাব্য সরবরাহকারীদের যাচাই করতে এই তালিকা ব্যবহার করুন

পার্টনারদের তালিকা সংক্ষিপ্ত করার জন্য তুলনা টেবিল

আপনার বিকল্পগুলি তুলনা করতে প্রস্তুত? সরবরাহকারীদের ক্ষমতা মূল্যায়ন এবং নথিভুক্ত করার জন্য এখানে একটি ব্যবহারিক টেবিল রয়েছে। মনে রাখবেন, সঠিক পার্টনার সবসময় সবচেয়ে সস্তা হয় না - যিনি নিয়ত মানসম্পন্ন পণ্য, প্রযুক্তিগত সমর্থন এবং মানসিক শান্তি দেন

| সরবরাহকারী | ক্ষমতা | প্রত্যয়ন | ন্যূনতম সহনশীলতা | অপেক্ষাকাল | মান প্রতিবেদন | সুবিধাসমূহ | অভিব্যক্তি |

|---|---|---|---|---|---|---|---|

| শাওয়ি মেটাল পার্টস সাপ্লায়ার | ওয়ান-স্টপ: ইন-হাউস এক্সট্রুশন, সিএনসি, ফিনিশিং, দ্রুত প্রোটোটাইপিং থেকে মাস প্রোডাকশন | IATF 16949, ISO 9001 | উচ্চ (প্রতি অটোমোটিভ স্পেসিফিকেশন) | নমুনার জন্য দ্রুত, বৃহৎ উৎপাদনের জন্য স্কেলযোগ্য | 8-পদক্ষেপ কিউসি, ডিএফএম, এসপিসি/সিপিকে, পিপিএপি, পূর্ণ ট্রেসযোগ্যতা |

|

|

| সাপ্লায়ার B | স্ট্যান্ডার্ড এক্সট্রুশন, সীমিত মেশিনিং | আইএসও 9001 | মাঝারি | স্ট্যান্ডার্ড | বেসিক এমটিসি, সীমিত ট্রেসেবিলিটি | বৃহৎ ব্যাচের জন্য কম খরচ | ডিজাইন বা ছোট রানের জন্য কম সমর্থন |

| সাপ্লায়ার C | কাস্টম মেশিনিং, এক্সট্রুশন আউটসোর্স করে | কোনটি নেই/আইএসও 9001 | ভেরিএবল | দীর্ঘতর | ম্যানুয়াল রিপোর্টিং | প্রোটোটাইপের জন্য নমনীয় | ডাই মালিকানা অস্পষ্ট, অসম লিড সময় |

অ্যালুমিনিয়াম রড প্রোগ্রামের জন্য সোর্সিং চেকলিস্ট

- এক্সট্রুশন ডাই মালিকানা এবং রক্ষণাবেক্ষণের দায়িত্ব নিশ্চিত করুন

- প্রতিটি ব্যাসের জন্য MOQ এবং লিড সময় পরিষ্কার করুন (উদাহরণ: 3 ইঞ্চি অ্যালুমিনিয়াম রাউন্ড স্টক)

- সমস্ত প্রয়োজনীয় গৌণ অপারেশন (মেশিনিং, ফিনিশিং, কিটিং) নথিভুক্ত করুন

- নিরাপদ পরিবহন এবং সংরক্ষণের জন্য প্যাকেজিং এবং যানবাহন নির্দিষ্ট করুন

- সরবরাহকারীদের মধ্যে প্রতি পাউন্ড অ্যালুমিনিয়াম বার স্টক মূল্য তুলনা করতে বিস্তারিত, আইটেমাইজড কোটেশন অনুরোধ করুন

- ত্রুটি মোকাবেলা এবং ওয়ারেন্টি দাবির জন্য পোস্ট-বিক্রয় সমর্থন মূল্যায়ন করুন

সঠিক সরবরাহকারী বেছে নেওয়ার মানে মূল্যের পাশাপাশি দৃষ্টি রাখা - যারা প্রমাণিত মান, প্রায়োগিক সমর্থন এবং আপনার প্রকল্পের সাথে পরিসর বাড়ানোর ক্ষমতা সরবরাহ করেন তেমন অংশীদারদের অগ্রাধিকার দিন।

এই ক্রয় সরঞ্জাম এবং টেমপ্লেটগুলির সাথে, আপনি গাড়ির সাসপেনশন উপাদানগুলির জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রড কিনতে আত্মবিশ্বাসী হয়ে উঠেছেন - আপনি যেখানেই অ্যালুমিনিয়াম রড কিনছেন না কেন, স্থানীয়ভাবে বিক্রির জন্য বা আমার কাছাকাছি সেরা অ্যালুমিনিয়াম রাউন্ড বার স্টক খুঁজছেন। পরবর্তীতে, পরিদর্শন এবং রক্ষণাবেক্ষণের সেরা অনুশীলনগুলি অনুসন্ধান করব, নিশ্চিত করে যে আপনার সোর্সকৃত রডগুলি ক্ষেত্রে দীর্ঘমেয়াদী নির্ভরযোগ্যতা সরবরাহ করে।

অ্যালুমিনিয়াম সাসপেনশন রডগুলির জন্য পরিদর্শন, রক্ষণাবেক্ষণ এবং লাইফসাইকেল সেরা অনুশীলন

যখন আপনি গাড়ির সাসপেনশনগুলি নিরাপদ এবং নির্ভরযোগ্য রাখার দায়িত্বে থাকেন, তখন আপনি কীভাবে নিশ্চিত করবেন যে সিস্টেমের প্রতিটি অ্যালুমিনিয়াম রাউন্ড রড বা অ্যালুমিনিয়াম সলিড রড কাজ করছে? কল্পনা করুন কোনও সমস্যা ধরে ফেলছেন যা পরে ব্যয়বহুল ব্যর্থতায় পরিণত হতে পারে বা ঠিক কোন সময়ে মেরামত নিরাপদ হবে এবং কখন প্রতিস্থাপনই একমাত্র বিকল্প। আসুন সেই প্রয়োজনীয় পরিদর্শন, রক্ষণাবেক্ষণ এবং লাইফসাইকেল অনুশীলনগুলি বিশ্লেষণ করি যা কঠোর সাসপেনশন পরিবেশেও অ্যালুমিনিয়াম ধাতব রডগুলি শীর্ষ অবস্থায় রাখে।

পরিদর্শনের সময়কাল এবং কী নথিভুক্ত করা হবে

আপনার নিলামি রডগুলি কতবার পরীক্ষা করা উচিত এবং আপনি কী খুঁজছেন? উত্তরটি যানবাহনের ব্যবহার, পরিবেশ এবং প্রস্তুতকারকের নির্দেশাবলীর উপর নির্ভর করে। বেশিরভাগ অটোমোটিভ এবং ফ্লিট অ্যাপ্লিকেশনের জন্য, প্রতিটি নির্ধারিত পরিষেবা ব্যবধানে সমস্ত অ্যালুমিনিয়াম রাউন্ড রড এবং সংশ্লিষ্ট যৌথগুলির দৃশ্যমান পরিদর্শন করা হয়, অথবা কঠোর পরিবেশে (যেমন রাস্তার লবণ, অফ-রোড ব্যবহার) আরও ঘন ঘন।

- চোখের পরীক্ষা: রডের দৈর্ঘ্য বরাবর পৃষ্ঠের ফাটল, দাগ, বাঁক, বা ঘর্ষণের জন্য খুঁজুন।

- টোর্ক পরীক্ষা: নির্দিষ্ট টর্ক মানগুলি পূরণ করে সমস্ত ফাস্টেনার এবং থ্রেডযুক্ত সংযোগগুলি নিশ্চিত করুন।

- ক্ষয় মূল্যায়ন: যৌথ এবং উন্মুক্ত থ্রেডগুলিতে বিশেষত পিটিং, সাদা জারণ বা ছালা খুঁজুন।

- যৌথ সীলকরণ: দূষণ প্রবেশের প্রতিরোধের জন্য বুট, বুশিং এবং সিলগুলির অখণ্ডতা পরীক্ষা করুন।

- ডকুমেন্টেশন: রড সিরিয়াল/লট নম্বর, পরিদর্শনের তারিখ এবং যেকোনো অ-মানানসই সহ সমস্ত তথ্য রেকর্ড করুন।

সামঞ্জস্যপূর্ণ ডকুমেন্টেশন পরবর্তীকালে সমস্যা দেখা দিলে পরিধানের প্রবণতা ট্র্যাক করতে এবং মূল কারণ বিশ্লেষণকে সমর্থন করতে সাহায্য করে।

সাধারণ ব্যর্থতার মোড এবং তাদের প্রারম্ভিক পর্যায়ে কীভাবে খুঁজে পাওয়া যায়

নিলম্বন পরিষেবাতে অ্যালুমিনিয়াম ধাতব রডগুলি ব্যর্থ হওয়ার সাধারণ পদ্ধতিগুলি কী কী? আপনি লক্ষ্য করবেন যে বেশিরভাগ সমস্যাই ছোট হয়ে শুরু হয় এবং সময়ের সাথে সাথে বৃদ্ধি পায়। ক্যাটাস্ট্রোফিক ব্যর্থতা এড়ানোর জন্য সময়মতো সনাক্তকরণ খুব গুরুত্বপূর্ণ:

- ক্লান্তি ফাটল: সাঁকোর গোড়া, ক্রস-হোলগুলিতে বা কাছাকাছি স্থানে প্রায়শই শুরু হয় ফাটল। পৃষ্ঠের ক্ষীণ রেখা বা রঙ পরিবর্তন খুঁজুন।

- বাঁকানো বা বাঁকিয়ে ফেলা: একটি বাঁকা বা বিকৃত অ্যালুমিনিয়াম রড ওভারলোড বা আঘাতের নির্দেশ করতে পারে। কম বাঁকা হলেও সারিবদ্ধতা এবং নিরাপত্তা প্রভাবিত করতে পারে।

- দামা বা ক্ষয়: সক্রিয় দামা বা ক্ষয়ের লক্ষণ হল সাদা, গুঁড়ো জমা। সংযোগস্থলে বা কোটিংয়ের নিচে গর্ত রডের শক্তি কমিয়ে দিতে পারে।

- পৃষ্ঠের ক্ষয়: অন্যান্য উপাদান বা ময়লার সংস্পর্শে আসার ফলে ঘর্ষণের দাগ বা চ্যাপ্টা হয়ে যাওয়া হতে পারে।

- সাঁকোর ক্ষতি: খুলে যাওয়া বা ঘষে যাওয়া থ্রেডগুলি টর্ক ধরে রাখার ক্ষমতা এবং জয়েন্টের সামগ্রিকতা হ্রাস করে।

এই লক্ষণগুলি সময়মতো চিহ্নিত করা যাতে লক্ষ্য করে রক্ষণাবেক্ষণ করা যায়, যা হঠাৎ ব্যর্থতার ঝুঁকি কমায়।

মেরামত, পুনর্কার্যকরণ এবং প্রতিস্থাপনের সীমা

সব ত্রুটির জন্যই তাৎক্ষণিক প্রতিস্থাপনের প্রয়োজন হয় না—তাহলে কীভাবে বুঝবেন কোনটা নিরাপদে মেরামত করা যায়? শিল্পের সেরা অনুশীলন এবং উপকরণ বিজ্ঞান স্পষ্ট নির্দেশিকা প্রদান করে, বিশেষ করে সাসপেনশনে ব্যবহৃত অ্যালুমিনিয়াম খাদ সম্পর্কে (ESAB University) :

- সামান্য পৃষ্ঠতলের ক্ষতি: হালকা স্ক্র্যাচ বা পৃষ্ঠের মরিচা প্রায়শই মৃদু পলিশ করে দূর করা যায়, যদি না কোনও মূল ধাতু উল্লেখযোগ্যভাবে ক্ষয়প্রাপ্ত হয়ে থাকে।

- থ্রেড চেসিং: থ্রেডের ক্ষতি হলে নির্মাতার নির্দিষ্ট সীমার মধ্যে থ্রেড চেসিং (পরিষ্কার করা) করা যেতে পারে, কিন্তু অতিরিক্ত উপকরণ অপসারণ করলে জয়েন্ট দুর্বল হয়ে যায়—সন্দেহ হলে প্রতিস্থাপন করুন।

- ফাটল বা গভীর গর্ত: যেকোনো ফাটল, বিশেষ করে থ্রেড বা ওয়েল্ডের কাছাকাছি, তা প্রত্যাখ্যানের কারণ হিসাবে গণ্য হবে। গভীর পিটিং যা ক্রস-সেকশনাল এলাকা কমায় বা নতুন ধাতুকে প্রকাশ করে, তার জন্যও প্রতিস্থাপন করা উচিত।

- ওয়েল্ড মেরামত: কেবলমাত্র সেসব মিশ্র ধাতুর ওয়েল্ডিং মেরামত করুন যা প্রমাণিত ওয়েল্ডযোগ্য এবং সঠিক চিহ্নিতকরণ সহ (যেমন, 6061-T6)। 7075 বা 2024 এর মতো মিশ্র ধাতুগুলি সাধারণত ওয়েল্ডিং মেরামতের জন্য প্রস্তাবিত হয় না কারণ চাপ সংশ্লিষ্ট ক্রাকিংয়ের ঝুঁকি থাকে।

- গুরুতর বেঁকে যাওয়া বা বাঁকানো: যেকোনো অ্যালুমিনিয়াম রাউন্ড রড প্রতিস্থাপন করুন যেখানে স্থায়ী বিকৃতি দেখা যায়।

- ডাই পেনিট্রেন্ট ইনস্পেকশন (DPI): রড পরিষ্কার করুন, পেনিট্রেন্ট প্রয়োগ করুন, দাঁড়ানোর সময় দিন, অতিরিক্তটি মুছে ফেলুন এবং ডেভেলপার প্রয়োগ করুন। লাল বা গোলাপী সংকেত দেখুন, বিশেষ করে থ্রেড এবং ওয়েল্ডের কাছাকাছি।

- ইডি কারেন্ট টেস্টিং (ECT): একটি এডি কারেন্ট প্রোব দিয়ে রড এবং থ্রেডযুক্ত অংশগুলি স্ক্যান করুন। ক্রাক বা পরিবাহিতা অস্বাভাবিকতা নির্দেশ করে এমন সংকেত পরিবর্তনের দিকে নজর দিন।

কসমেটিক দাগ-যেমন হালকা স্ক্র্যাচ বা সামান্য ডিসকলোরেশন সাধারণত গ্রহণযোগ্য হয়, কিন্তু ফাটলের কোনও সংকেত, গভীর গর্ত বা বিকৃতি থাকলে তা কাঠামোগত হয় এবং নিরাপত্তা মার্জিন বজায় রাখতে তাৎক্ষণিক প্রতিস্থাপনের প্রয়োজন হয়।

নিরাপদ রক্ষণাবেক্ষণ মানে আপনার সীমাবদ্ধতা সম্পর্কে সচেতন থাকা। খুব বেশি উপাদান সরানোর মতো আক্রমণাত্মক গ্রাইন্ডিং বা থ্রেড চেসিং এড়িয়ে চলুন; সর্বদা OEM বা সরবরাহকারীর নির্দেশিকা মেনে চলুন। যদি আপনি নিশ্চিত না হন যে একটি মেরামত নিরাপদ কিনা, সতর্কতার পক্ষে ভুল করুন এবং অ্যালুমিনিয়াম রাউন্ড রড বা অ্যালুমিনিয়াম সলিড রড প্রতিস্থাপন করুন। এই পদ্ধতি দ্বারা আপনি যে কোনও সাসপেনশন সিস্টেমের পারফরম্যান্স এবং নিরাপত্তা উভয়ই বজায় রাখবেন।

পরবর্তীতে, আমরা অ্যালুমিনিয়াম রডের জীবনকাল এবং রক্ষণাবেক্ষণের চাহিদার তুলনা এদের স্টিলের সঙ্গীদের সাথে করব- আপনার পরবর্তী সাসপেনশন প্রকল্পের জন্য সঠিক সিদ্ধান্ত নেওয়ার জন্য এটি আপনাকে সাহায্য করবে।

ইঞ্জিনিয়ারিং ট্রেড-অফ বনাম স্টিল বিকল্প

যখন গাড়ির সাসপেনশন লিঙ্কের বিকল্পগুলি মূল্যায়ন করবেন তখন হালকা অ্যালুমিনিয়াম রাউন্ড নাকি স্টিল দিয়ে তৈরি পরীক্ষিত এবং প্রমাণিত রাউন্ড মেটাল রড কোনটি ভালো পছন্দ হবে? ধরুন আপনাকে পারফরম্যান্স এবং স্থায়িত্ব উভয়ের জন্য একটি সাসপেনশন অপ্টিমাইজ করার দায়িত্ব দেওয়া হয়েছে—আপনার সিদ্ধান্তকে কোন কোন নির্দেশিকা পরিচালিত করবে? আসুন অ্যালুমিনিয়াম এক্সট্রুডেড রড এবং স্টিলের বিকল্পগুলির মধ্যে প্রকৃত ইঞ্জিনিয়ারিং তুলনা ভেঙে ফেলি, নিরাপত্তা, খরচ এবং দীর্ঘমেয়াদী মূল্যের জন্য যে মানদণ্ডগুলি সবচেয়ে বেশি গুরুত্বপূর্ণ সেগুলি নিয়ে আলোচনা করি।

ওজন, কঠোরতা এবং প্যাকেজিং প্রভাব

একই সাসপেনশন জ্যামিতির ছবি দিয়ে শুরু করুন, কিন্তু স্টিলের জন্য একটি বার স্টক অ্যালুমিনিয়াম রড বিনিময় করুন। আপনি লক্ষ্য করবেন যে অ্যালুমিনিয়াম রডটি তার ইস্পাতের প্রতিপক্ষের প্রায় এক তৃতীয়াংশ ওজন (অ্যালুমিনিয়ামের জন্য ২.৭ গ্রাম/সেমি৩ বনাম ইস্পাতের জন্য ৭.৭৫-৮.০৫ গ্রাম/সেমি৩) । এই ওজন কমানোর ফলে সরাসরি কম ভর হয়, যার অর্থ আরো ভাল যাত্রার গুণমান, আরও ধারালো হ্যান্ডলিং এবং আধুনিক সাসপেনশন লেআউটের জন্য আরো দক্ষ প্যাকেজিং। তবে, ইস্পাত উচ্চতর অনমনীয়তা (প্রস্থের মডুলাস) সরবরাহ করে, তাই একই ব্যাসের জন্য, ইস্পাত রডগুলি লোডের অধীনে কম নমন করে। অ্যালুমিনিয়াম রডগুলির জন্য, রুট অ্যালুমিনিয়াম স্ট্যাক বা এমনকি বিশেষ প্যাকেজিংয়ের জন্য অ্যালুমিনিয়াম ত্রিভুজাকার বার, এর সাথে সামঞ্জস্যপূর্ণ কঠোরতা অর্জনের জন্য কিছুটা বড় ক্রস-সেকশনের প্রয়োজন হতে পারে, তবে সামগ্রিক ভর কম থাকে।

ক্লান্তি, ক্ষয় এবং পরিবেশগত স্থায়িত্ব

ফ্যাটিগ হল সাসপেনশন কম্পোনেন্টগুলির জন্য প্রধান উদ্বেগের বিষয়। যদিও উচ্চ-মানের ইস্পাত সাধারণত উচ্চতর ফ্যাটিগ শক্তি প্রদর্শন করে, কিছু উচ্চ-কার্যকারিতা সম্পন্ন অ্যালুমিনিয়াম সংকর (যেমন 7075) চক্রীয় লোডিংয়ে মিল্ড ইস্পাতকে ছাড়িয়ে যেতে পারে। সমস্যা হল অ্যালুমিনিয়াম নটচ-সংবেদনশীল, তাই পৃষ্ঠের ফিনিশ এবং জ্যামিতির (যেমন রেডিয়াসড ফিলেট এবং রোলড থ্রেডস) দিকে যত্ন নেওয়া অত্যন্ত গুরুত্বপূর্ণ। আরেকটি গুরুত্বপূর্ণ বিষয় হল ক্ষয়। অ্যালুমিনিয়াম স্বাভাবিকভাবেই একটি সুরক্ষামূলক অক্সাইড স্তর তৈরি করে, যা একে লবণাক্ত বা আর্দ্র পরিবেশেও মরিচা প্রতিরোধে অত্যন্ত প্রতিরোধী করে তোলে। অন্যদিকে, ইস্পাতের ক্ষয় এড়ানোর জন্য কোটিং বা নিয়মিত রক্ষণাবেক্ষণের প্রয়োজন, বিশেষ করে প্রকাশিত থ্রেড বা ওয়েল্ডে। মিশ্র-উপাদানের অ্যাসেম্বলিগুলিতে, অ্যালুমিনিয়াম রড এবং স্টিল ব্র্যাকেটের সংযোগস্থলে গ্যালভানিক ক্ষয় ঘটতে পারে, তাই বুশিং বা আইসোলেটর ব্যবহার করা আবশ্যিক।

উৎপাদনযোগ্যতা, সার্ভিসযোগ্যতা এবং পুনঃচক্রায়নযোগ্যতা

ইস্পাতের তুলনায় অ্যালুমিনিয়াম এক্সট্রুডেড রড এবং বার স্টক অ্যালুমিনিয়াম মেশিন, ড্রিল এবং আকৃতি দেওয়ার জন্য সহজতর—উৎপাদনের সময় এবং যন্ত্রপাতির ক্ষয়ক্ষতি বাঁচায়। অ্যালুমিনিয়াম ত্রিভুজ বারের মতো কাস্টম প্রোফাইলগুলি এমন প্যাকেজিং বা শক্তির প্রয়োজনীয়তা পূরণের জন্য এক্সট্রুড করা যেতে পারে যা ইস্পাতের সাথে অর্জন করা অনেক বেশি কঠিন (এবং ব্যয়বহুল)। অ্যালুমিনিয়াম ভিন্নভাবে ওয়েল্ড করা হয়: এটি ছিদ্রযুক্ত হওয়া এড়ানোর জন্য বিশেষ প্রস্তুতির প্রয়োজন এবং এটি ইস্পাতের তুলনায় বেশি দক্ষতা প্রয়োজন, কিন্তু সঠিক পদ্ধতির সাহায্যে এটি যুক্ত করা যেতে পারে। পরিষেবা সংক্রান্ত বিষয়ে, অ্যালুমিনিয়ামের রডগুলি পৃষ্ঠের ক্ষতি বা থ্রেড গ্যালিংয়ের প্রবণতা রাখে, কিন্তু সংক্ষারণের কারণে আটকে যাওয়ার সম্ভাবনা কম। উভয় উপাদানই উচ্চ পুনর্ব্যবহারযোগ্য, কিন্তু অ্যালুমিনিয়ামের উচ্চ স্ক্র্যাপ মূল্য এবং পুনর্ব্যবহারের জন্য কম শক্তি প্রয়োজনীয়তার কারণে এটি স্থিতিশীলতার দিক থেকে এগিয়ে।

জীবনকাল ব্যয় এবং স্থিতিশীলতা সংকেত

প্রাথমিক খরচের দিক থেকে সাধারণত ইস্পাত সস্তা—প্রতি পাউন্ড কাঁচামাল এবং প্রস্তুতকরণের খরচ অ্যালুমিনিয়ামের তুলনায় কম। তবে, গাড়ির আয়ুষ্কালের মধ্যে এই পরিস্থিতি পাল্টে যায়। হালকা ওজনের কারণে অ্যালুমিনিয়াম জ্বালানি খরচে বড় অর্থ সাশ্রয় করে এবং নিঃসরণ হ্রাস করে, বিশেষ করে ইলেকট্রিক বা হাইব্রিড যানগুলিতে। বেশ কয়েক বছর ব্যবহারের পর অ্যালুমিনিয়ামের মোট মালিকানা খরচ (TCO) ইস্পাতের সমান বা তার চেয়েও কম হতে পারে, বিশেষ করে এমন পরিবেশে যেখানে ক্ষয় প্রতিরোধের কারণে রক্ষণাবেক্ষণের প্রয়োজন কম হয়। অ্যালুমিনিয়ামের পুনর্ব্যবহারযোগ্যতা খুব বেশি, তাই জীবনকাল শেষে সাইকেল অর্থনীতির লক্ষ্যগুলি সমর্থন করে অ্যালুমিনিয়ামের বড় অংশ সরবরাহ চেইনে ফিরে আসে।

| ক্রিটেরিয়া | অ্যালুমিনিয়াম এক্সট্রুডেড রড | স্টিল রড |

|---|---|---|

| ঘনত্ব (জি/সেমি3) | 2.7 | 7.75–8.05 |

| মডুলাস (GPa) | 69–71 | 200–210 |

| ফ্যাটিগ স্ট্রেংথ | মধ্যম–উচ্চ (মিশ্রণ-নির্ভর, খাঁজ-সংবেদনশীল) | উচ্চ (কম খাঁজ-সংবেদনশীল) |

| দ্বারা ক্ষয় প্রতিরোধ | দুর্দান্ত (প্রাকৃতিক অক্সাইড স্তর) | কোটিং বা চিকিত্সার প্রয়োজন |

| যন্ত্রপাতি | সহজ (কম টুল ক্ষয়) | কঠিনতর (উচ্চ টুল ক্ষয়) |

| আকৃতি প্রস্তুতকরণ/নির্মাণ | ইচ্ছামতো আকৃতিতে নির্মাণযোগ্য (যেমন, অ্যালুমিনিয়াম ত্রিভুজাকার বার) | মানক আকৃতিতে সীমাবদ্ধ অথবা ব্যয়বহুল যন্ত্রে কাজ |

| ওয়েল্ডিং | প্রস্তুতি এবং বিশেষ পদ্ধতির প্রয়োজন | বেশি সহনশীল, প্রচুর ব্যবহৃত |

| পুনর্ব্যবহারযোগ্যতা | খুব বেশি, উচ্চ ওস্তাদ মূল্য | খুব বেশি, কম ওস্তাদ মূল্য |

| জীবনকাল ব্যয় | উচ্চতর প্রাথমিক বিনিয়োগ, সময়ের সাথে কম মোট মালিকানা খরচ | নিম্ন প্রাথমিক বিনিয়োগ, উচ্চ রক্ষণাবেক্ষণ খরচ |

নিলম্বন রডের জন্য সর্বোত্তম উপাদান পছন্দ শুধুমাত্র দামের বিষয়টি নয় - এটি আপনার যানবাহনের কার্যকাল, পরিবেশ এবং সেবা প্রত্যাশার সাথে রডের বৈশিষ্ট্যগুলি মেলানোর বিষয়টি নিশ্চিত করা যাতে দীর্ঘস্থায়ী নিরাপত্তা এবং মূল্য পাওয়া যায়।

এই ত্যাগ-বিনিময়গুলি বুঝতে পারলে আপনি আত্মবিশ্বাসের সাথে অ্যালুমিনিয়াম রাউন্ড এবং ইস্পাতের রডগুলির মধ্যে বা এমনকি অ্যালুমিনিয়াম ত্রিভুজাকার বারের মতো নতুন প্রোফাইলগুলি বিবেচনা করতে পারবেন - আপনার নিলম্বন প্রকল্পের অনন্য প্রয়োজনীয়তার ভিত্তিতে। পরবর্তীতে, আমরা প্রধান পয়েন্টগুলি সংক্ষেপে এবং আপনার যানবাহনের নিলম্বন উপাদানের জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রডগুলি নিয়ে আপনার প্রোগ্রামটি এগিয়ে নেওয়ার জন্য একটি ব্যবহারিক পথনির্দেশিকা সরবরাহ করব।

ব্যবহারযোগ্য সারাংশ এবং নির্ভরযোগ্য সংস্থানগুলি এগিয়ে যাওয়ার জন্য

প্রত্যেক প্রোগ্রামের পক্ষে মনে রাখার মতো প্রধান পয়েন্টগুলি

গাড়ির সাসপেনশন কম্পোনেন্টের জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রডের চূড়ান্ত সিদ্ধান্ত গ্রহণের পর্যায়ে পৌঁছালে পরবর্তী পথটি খুবই কঠিন মনে হতে পারে। কী কী করা আবশ্যিক এবং কী কী এড়ানো উচিত তা কীভাবে বুঝবেন? নতুন ইভির জন্য অ্যালুমিনিয়াম রড স্টক নির্দিষ্ট করছেন অথবা বর্তমান ফ্লিটে অ্যালুমিনিয়াম রডগুলি রক্ষণাবেক্ষণ করছেন কিনা, রড প্রোগ্রামটি সঠিক পথে রাখতে এখানে কয়েকটি গুরুত্বপূর্ণ বিষয় দেওয়া হল:

- সঠিক খাদ এবং টেম্পারের অগ্রাধিকার দিন: আপনার সাসপেনশনের বাস্তব চাপের সাথে যান্ত্রিক বৈশিষ্ট্য মেলান - ওভার-অথবা আন্ডার-স্পেসিফিকেশন করবেন না।

- প্রক্রিয়া নিয়ন্ত্রণের দাবি জানান: নির্ভরযোগ্য অ্যালুমিনিয়াম এক্সট্রুডেড পণ্যগুলির জন্য শক্তিশালী এক্সট্রুশন এবং ফিনিশিং পদ্ধতি অপরিহার্য।

- ক্লান্তি এবং ক্ষয় প্রতিরোধের জন্য ডিজাইন করুন: দীর্ঘমেয়াদী স্থায়িত্বের জন্য মসৃণ সংক্রমণ, রোলড থ্রেড এবং উপযুক্ত প্রলেপ অপরিহার্য।

- যাথার্থ্য এবং পরিদর্শন যাচাই করুন: প্রতিটি অ্যালুমিনিয়াম রডের ব্যাচের জন্য ক্লান্তি পরীক্ষা, এনডিটি এবং পরিষ্কার গ্রহণযোগ্যতা মানদণ্ড ব্যবহার করুন।

- সবকিছু নথিভুক্ত করুন: বিলেট থেকে ইনস্টলেশন পর্যন্ত ট্রেসযোগ্যতা আপনাকে সমস্যাগুলি সময়মতো খুঁজে বার করতে এবং ভবিষ্যতে মূল কারণ বিশ্লেষণকে সমর্থন করতে সাহায্য করে।

সবচেয়ে গুরুত্বপূর্ণ ঝুঁকি নিয়ন্ত্রণ নীতি: পরিষ্কার স্পেসিফিকেশন, প্রক্রিয়া শৃঙ্খলা এবং প্রতিরোধমূলক যথার্থতার উপর ভিত্তি করে তৈরি করা হয় কার্যকর অ্যালুমিনিয়াম রড প্রোগ্রামগুলি - কখনোই গুণগত মান বা ট্রেসযোগ্যতায় কোনও কোণঠাসা করবেন না, বিশেষত নিরাপত্তা-সম্পর্কিত সাসপেনশন অংশগুলির জন্য।

পরবর্তীতে পরামর্শের জন্য মান ও তথ্যসূত্র

চাকা পুনরায় আবিষ্কার করার চেষ্টা করবেন না! অ্যালুমিনিয়াম রাউন্ড বার স্টক এবং সংশ্লিষ্ট পণ্যগুলি নির্দিষ্ট করার সময় বা অডিট করার সময় প্রতিষ্ঠিত মান এবং প্রযুক্তিগত সংস্থানগুলি ব্যবহার করুন। এই তথ্যসূত্রগুলি আপনার অ্যালুমিনিয়াম এক্সট্রুডেড পণ্যগুলি যেন বিশ্বব্যাপী সেরা অনুশীলনগুলি পূরণ করে তা নিশ্চিত করতে অপরিহার্য:

- ASTM B221 - অ্যালুমিনিয়াম এবং অ্যালুমিনিয়াম-সংকর এক্সট্রুডেড বার, রড, তার, প্রোফাইল এবং টিউবস

- ASTM B211 - অ্যালুমিনিয়াম এবং অ্যালুমিনিয়াম-সংকর বার, রড এবং তার

- অ্যালুমিনিয়াম অ্যাসোসিয়েশন প্রকাশনা - খাদ নির্বাচন, টেম্পার নামকরণ এবং এক্সট্রুশন নির্দেশিকা জন্য

- OEM বা SAE উপকরণ এবং পরীক্ষা মান - গাড়ির নির্দিষ্ট প্রয়োজনীয়তা জন্য

- সরবরাহকারী প্রযুক্তিগত ডেটাশীট এবং PPAP/ISIR নথি

এই সংস্থানগুলি প্রারম্ভিক পর্যায়ে পরামর্শ করা আপনাকে ব্যয়বহুল ভুলগুলি এড়াতে সাহায্য করবে এবং নিশ্চিত করবে যে আপনার অ্যালুম রড পছন্দগুলি প্রমাণিত শিল্প মানদণ্ডের সাথে সামঞ্জস্য রাখে।

রড প্রোগ্রামটি ঝুঁকি মুক্ত করার জন্য 30-60-90 দিনের পরিকল্পনা

প্রস্তুত কার্যকর করার জন্য? এখানে একটি ব্যবহারিক সময়সূচী রয়েছে যা আপনার দলকে ধারণা থেকে পরীক্ষিত উত্পাদনে পৌঁছানোর জন্য সাহায্য করবে—প্রতিটি পদক্ষেপ মিস না করেই:

- প্রথম 30 দিন: মিশ্রধাতু/টেম্পার, জ্যামিতি এবং গুরুত্বপূর্ণ বৈশিষ্ট্যগুলি চূড়ান্ত করুন। পরিষ্কার স্পেসিফিকেশন তৈরি করুন এবং উৎপাদন ও মান দলগুলির সাথে পর্যালোচনা করুন।

- পরবর্তী 30 দিন (দিন 31–60): DFM প্রতিক্রিয়া, দ্রুত প্রোটোটাইপিং এবং প্রাথমিক ফ্যাটিগ/NDT পরীক্ষার জন্য যোগ্যতাসম্পন্ন সরবরাহকারীদের সঙ্গে যোগাযোগ করুন। পরীক্ষার ফলাফলের ভিত্তিতে ডিজাইন পরিমার্জন করুন।

- চূড়ান্ত 30 দিন (দিন 61–90): PPAP/ISIR সম্পন্ন করুন, প্রক্রিয়া নিয়ন্ত্রণগুলি চূড়ান্ত করুন এবং অ্যালুমিনিয়াম রড স্টকের পাইলট উত্পাদন শুরু করুন। ট্রেসেবিলিটি এবং পরিদর্শন পরিকল্পনা বাস্তবায়ন করুন।

এই পরিকল্পনা অনুসরণ করলে আপনার অ্যালুমিনিয়ামের রড এবং অ্যালুমিনিয়ামের রাউন্ড বার স্টক পুরোপুরি ব্যবহারের জন্য প্রস্তুত থাকবে—ঝুঁকি কমানো এবং সর্বোচ্চ কার্যকারিতা অর্জন করা।

আপনার প্রোগ্রাম দ্রুত করার জন্য একজন বিশ্বস্ত অংশীদারের প্রয়োজন? ইন্টিগ্রেটেড ডিজাইন-টু-ডেলিভারি সমর্থনের জন্য অনুসন্ধানকারী দলের জন্য, শাওয়ি মেটাল পার্টস সাপ্লায়ার dFM-এ, মিশ্র ধাতু/টেম্পার নির্বাচনে এবং অ্যালুমিনিয়াম এক্সট্রুশন পার্টসের PPAP-প্রস্তুত উত্পাদনে প্রমাণিত দক্ষতা প্রদান করে। তাদের এক ধাপে পরিষেবা এবং গাড়ির অ্যালুমিনিয়াম এক্সট্রুডেড পণ্যগুলির সঙ্গে গভীর অভিজ্ঞতা আপনার পরবর্তী সাসপেনশন প্রকল্পটি আত্মবিশ্বাসের সঙ্গে চালু করার জন্য তাদের এক শক্তিশালী সংস্থানে পরিণত করেছে।

প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

1. গাড়ির সাসপেনশন উপাদানগুলির জন্য ইস্পাতের চেয়ে অ্যালুমিনিয়াম এক্সট্রুডেড রডগুলি কেন পছন্দ করা হয়?

গাড়ির নিলামবাহী অংশে অ্যালুমিনিয়াম বার ব্যবহার করা হয় কারণ এটি ওজন কমিয়ে দেয়, যা চলার গুণমান এবং জ্বালানি দক্ষতা উন্নত করে। এটি দুর্দান্ত ক্ষয় প্রতিরোধ ক্ষমতা দেয় এবং অপটিমাইজড কর্মক্ষমতার জন্য জটিল আকৃতিতে তৈরি করা যায়। যদিও ইস্পাতের তুলনায় এটির স্থিতিস্থাপকতা বেশি, অ্যালুমিনিয়ামের কম ঘনত্ব এবং পুনঃব্যবহারযোগ্যতা এটিকে আধুনিক এবং তড়িৎচালিত যানগুলিতে ব্যবহারের জন্য শীর্ষ পছন্দ করে তোলে।

2. অটোমোটিভ নিলামবাহী অংশে অ্যালুমিনিয়াম বার ব্যবহারের প্রধান সুবিধা এবং চ্যালেঞ্জগুলি কী কী?

প্রধান সুবিধাগুলির মধ্যে রয়েছে অনস্প্রাঙ্গ ভর হ্রাস, উন্নত ক্ষয় প্রতিরোধ ক্ষমতা এবং বৈশিষ্ট্য একীভূতকরণের জন্য বৃহত্তর নকশা নমনীয়তা। চ্যালেঞ্জগুলির মধ্যে রয়েছে ইস্পাতের তুলনায় কম স্থিতিস্থাপকতা পরিচালনা করা, থ্রেডযুক্ত বা খাঁজকাটা অংশগুলিতে যথেষ্ট ক্লান্তি প্রতিরোধ নিশ্চিত করা এবং অ্যালুমিনিয়াম এবং ইস্পাতের সংযোগস্থলে গ্যালভানিক ক্ষয় রোধ করা।

3. অ্যালুমিনিয়াম নিলামবাহী রডের মান এবং স্থায়িত্ব নিশ্চিত করতে প্রস্তুতকারকরা কীভাবে কাজ করেন?

এক্সট্রুশন, তাপ চিকিত্সা এবং ফিনিশিং এর সময় কঠোর প্রক্রিয়া নিয়ন্ত্রণের মাধ্যমে মান নিশ্চিত করা হয়। প্রস্তুতকারকরা ASTM B221 এবং B211 এর মতো মান ব্যবহার করেন, ক্লান্তি এবং অ-ধ্বংসাত্মক পরীক্ষা করেন এবং বিলেট থেকে শেষ হওয়া রড পর্যন্ত ট্রেসেবিলিটি প্রয়োজন। শাওয়ি এর মতো অগ্রণী সরবরাহকারীরা উন্নত মানের সিস্টেম প্রয়োগ করে এবং প্রতিটি ব্যাচের জন্য বিস্তারিত নথি সরবরাহ করে।

4. অ্যালুমিনিয়াম সাসপেনশন রডের জন্য খাদ এবং টেম্পার নির্বাচন করার সময় প্রকৌশলীদের কী বিবেচনা করা উচিত?

প্রকৌশলীদের শক্তি, শক্তি সহনশীলতা, ক্ষয় প্রতিরোধ, ওয়েল্ডেবিলিটি এবং খরচের মধ্যে ভারসাম্য বজায় রাখতে হবে। 6061-T6 এর মতো খাদগুলি বেশিরভাগ অ্যাপ্লিকেশনের জন্য ভালো মিশ্রণ দেয়, যেখানে 7075-T6 উচ্চ-লোড, পারফরম্যান্স-সমালোচনামূলক অংশগুলির জন্য নির্বাচিত হয়। থ্রেডযুক্ত অংশগুলিতে ওভার-হার্ডেনিং এড়ানো এবং গ্যালভানিক ক্ষয় প্রতিরোধ করে এমন ফিনিশ নির্দিষ্ট করা আবশ্যিক।

5. কিভাবে ক্রেতারা সাসপেনশন অ্যাপ্লিকেশনের জন্য অ্যালুমিনিয়াম এক্সট্রুডেড রডের জন্য একটি নির্ভরযোগ্য সরবরাহকারী নির্বাচন করতে পারেন?

ক্রেতাদের প্রমাণিত অটোমোটিভ অভিজ্ঞতা, আইএটিএফ 16949 এর মতো সার্টিফিকেশন, শক্তিশালী প্রক্রিয়া নিয়ন্ত্রণ এবং সম্পূর্ণ নথি সরবরাহের ক্ষমতা সহ সরবরাহকারীদের অগ্রাধিকার দেওয়া উচিত। শাওয়ির মতো একীভূত প্রদায়করা নকশা থেকে ডেলিভারি পর্যন্ত এক স্টপ পরিষেবা সরবরাহ করে, নিরাপত্তা-সম্পর্কিত সাসপেনশন উপাদানগুলিতে প্রাবিধানিক সমর্থন এবং স্থিতিশীল মান নিশ্চিত করে।

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —