Progressive Metal Stamping Demystified: From Raw Coil To Finished Part

What Is Progressive Metal Stamping and How Does It Work

Imagine transforming a simple coil of metal into thousands of precision components—all without human hands touching a single piece. That's exactly what progressive metal stamping accomplishes every day in manufacturing facilities worldwide.

Progressive metal stamping is a high-speed sheet metal forming process where a continuous strip of metal advances through multiple stations within a single die, with each station performing a specific operation—such as cutting, bending, punching, or shaping—until a finished part emerges with every stroke of the press.

This definition captures why progressive die stamping has become the backbone of high-volume manufacturing. But understanding the "what" is only half the story. Let's explore exactly how this process turns raw material into precision parts.

How Progressive Dies Transform Sheet Metal Step by Step

The journey begins with a coil of sheet metal mounted on an uncoiler. A feeder mechanism pulls the metal strip and advances it into the progressive die at precise intervals. Here's where the magic happens: with each stroke of the press, the strip moves forward a fixed distance—called the pitch—positioning fresh material at every station simultaneously.

What keeps everything perfectly aligned? Pilot holes. These small reference holes are punched in the strip during the first station and serve as registration points throughout the entire process. Pilot pins in subsequent stations engage these holes, ensuring the strip maintains exact positioning as it advances. Without this alignment system, tolerances would quickly drift out of specification.

Throughout the progressive stamping process, the parts remain connected to a carrier strip—the skeletal framework of material that transports components through each station. This carrier strip maintains part orientation and simplifies material handling. Only at the final station does a cutoff operation separate the finished component from the strip.

The Anatomy of a Progressive Stamping Operation

Think of a progressive die as a manufacturing assembly line compressed into a single tool. The progressive punch and die work together at each station to perform operations in a carefully planned sequence:

- Station 1: Pilot holes are pierced for alignment

- Intermediate stations: Various operations like blanking, piercing, forming, and bending occur

- Final station: The finished part is separated from the carrier strip

The beauty of this system? Multiple operations happen simultaneously. While one section of the strip undergoes bending, another receives piercing, and yet another gets its final cutoff—all in a single press stroke. This simultaneous processing is what makes sheet metal pressings produced through progressive die stamping so remarkably efficient.

According to industry sources, this sequential approach enables the creation of complex parts with tight tolerances and minimal waste—a combination that's difficult to achieve with other forming methods.

Why does progressive stamping dominate high-volume manufacturing? Three reasons stand out:

- Speed: Cycle times measured in fractions of a second mean thousands of parts per hour

- Consistency: Each part receives identical operations under identical conditions

- Cost efficiency: Per-unit costs drop dramatically as production volumes increase

These advantages explain why industries from automotive to electronics rely on this process for their most demanding production requirements. With the fundamentals in place, you're now ready to explore the specific components that make progressive dies work—and how each one contributes to manufacturing precision.

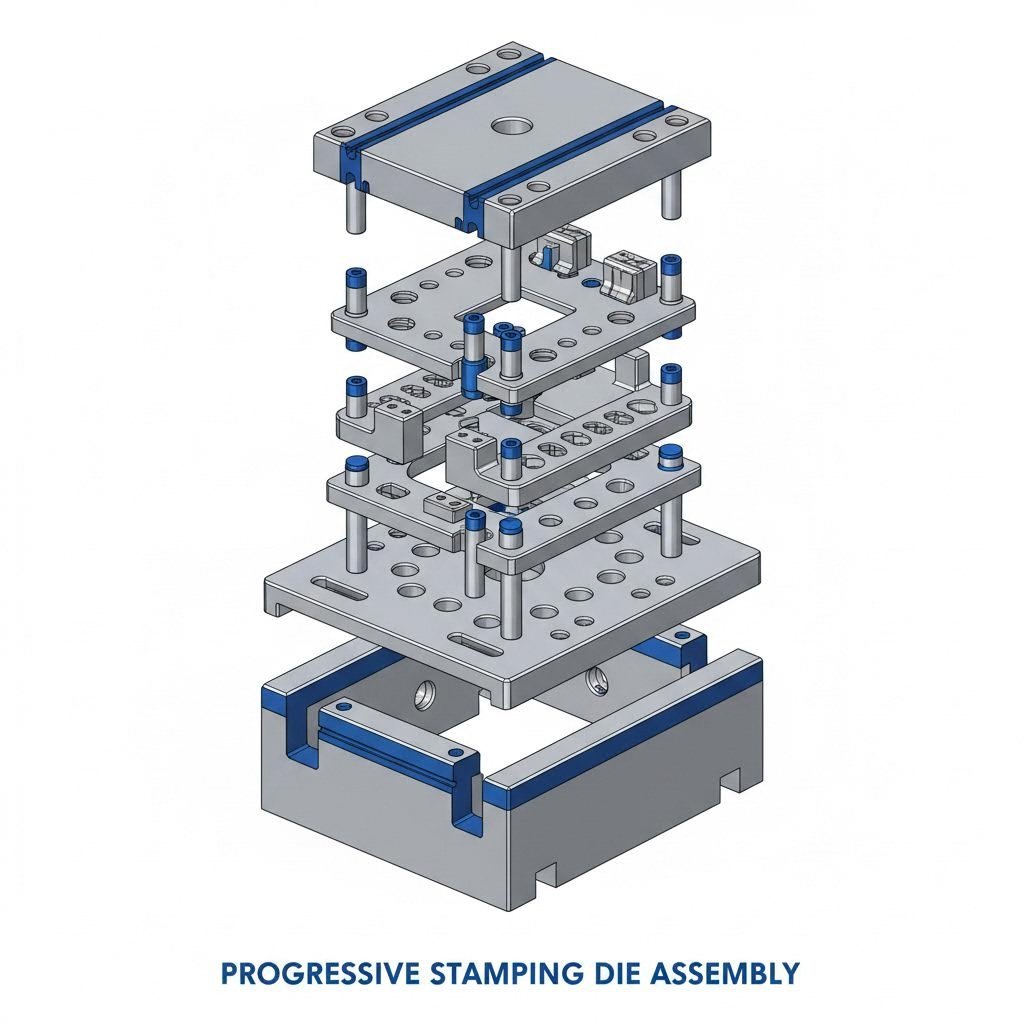

Essential Progressive Die Components and Their Functions

Ever wonder what's actually inside a progressive die that makes it capable of producing thousands of identical parts? The answer lies in understanding the individual components—each one engineered for a specific purpose. When you examine a stamp die set closely, you'll discover a sophisticated assembly where every element plays a critical role in transforming flat sheet metal into precision components.

Let's break down the anatomy of progressive dies so you can appreciate how these tools achieve such remarkable consistency.

Critical Die Components That Drive Precision

A complete sheet metal die consists of numerous interconnected parts working in harmony. Here are the essential progressive die components you'll find in virtually every stamping operation:

- Die Shoes (Upper and Lower): These heavy steel plates form the foundation of the entire assembly. The lower die shoe mounts to the press bed while the upper die shoe attaches to the ram. They provide rigidity and maintain alignment between all other components during operation.

- Punch Plates: Mounted to the upper die shoe, these plates hold and position the punches that perform cutting and forming operations. The punch plate ensures each punch remains perfectly perpendicular to the strip during every press stroke.

- Die Blocks: These precision-ground steel blocks contain the cavities that receive the punches. Located in the lower die assembly, die blocks must be hardened to withstand millions of cycles while maintaining tight tolerances.

- Stripper Plates: Positioned between the punch plate and the strip material, stripper plates serve two functions—they hold the material flat during operations and strip the material off the punches as they retract. Spring-loaded strippers provide consistent pressure throughout the cycle.

- Pilots: These precision pins extend from the upper die and engage the pilot holes punched in the strip. Pilots guarantee accurate positioning at each station, typically achieving alignment within 0.001 inches or better.

- Punches: The actual cutting and forming tools that contact the material. Punches come in countless shapes depending on the required operation—round punches for piercing, irregular profiles for complex geometries, and forming punches for bending operations.

- Forming Stations: These specialized sections of the die contain matched punch and die sets designed for bending, drawing, or coining operations. Unlike cutting stations, forming stations reshape material without removing it.

- Guide Pins and Bushings: These components ensure the upper and lower die assemblies align precisely every time the press closes. Worn guides lead to misalignment and premature tool failure.

Understanding Punch and Die Interactions

Sounds complex? It is—but the interaction between punches and die blocks is where the real precision happens. When the press closes, each punch descends into its corresponding die opening with clearance measured in thousandths of an inch. This clearance varies based on material type and thickness, typically ranging from 5% to 10% of material thickness per side for steel stamping tools.

Here's what happens during a cutting operation: the punch contacts the material first, applying pressure until the metal's shear strength is exceeded. The material fractures, and the slug passes through the die opening. The quality of this cut—smooth edges versus excessive burrs—depends directly on proper clearance and tool sharpness.

For forming operations, the interaction differs significantly. The punch forces material into a cavity or over a radius, plastically deforming it into a new shape. Spring-back compensation must be built into the tooling because metals partially return toward their original form after pressure releases.

Why does component quality matter so much? Consider this: a progressive die might cycle 600 times per minute, accumulating millions of strokes over its service life. Metal stamping dies constructed from premium tool steels with proper heat treatment can produce parts for years. Inferior materials or heat treatment shortcuts lead to rapid wear, dimensional drift, and costly downtime.

The relationship between stamping die components and part quality is direct and measurable:

- Die block hardness: Affects edge wear rates and hole diameter consistency

- Stripper pressure: Influences material flatness and prevents distortion

- Pilot fit: Determines positioning accuracy between stations

- Guide system condition: Controls upper-to-lower alignment throughout the stroke

Understanding these components gives you a foundation for evaluating die quality and anticipating maintenance needs. But components alone don't tell the whole story—next, you'll see how these elements work together as material progresses through each station, transforming flat stock into finished parts in seconds.

The Progressive Stamping Process Explained Station by Station

Now that you understand the components inside a progressive die, let's follow a strip of metal through its complete transformation. The progressive die stamping process operates like a choreographed sequence—each station performs its role at precisely the right moment, building upon the previous operation until a finished part emerges.

What makes this stamping technology so effective? Every station adds value while multiple operations happen simultaneously across the strip. Let's walk through each stage.

From Flat Stock to Finished Part in Seconds

The progressive die metal stamping sequence follows a logical order where each operation prepares the material for the next. Here's a typical example of stamping progression:

- Pilot Hole Piercing: The first station punches small reference holes that will guide the strip through all subsequent operations. These holes engage pilot pins at every downstream station, ensuring positioning accuracy within thousandths of an inch.

- Blanking: This operation removes the outer perimeter material or creates the basic part outline. Blanking establishes the overall shape while the part remains attached to the carrier strip through small tabs or bridges.

- Piercing: Internal holes, slots, and cutouts are punched into the blank. Piercing stations can create multiple holes simultaneously—round, square, or complex geometries—depending on the part requirements.

- Forming: The flat blank begins taking three-dimensional shape. Forming operations create features like embosses, ribs, or shallow draws that add structural rigidity or functional characteristics.

- Bending: Flanges, tabs, and angular features are created by folding material along precise lines. Bending stations must account for spring-back—the tendency of metal to partially return toward its original flat state.

- Coining: This precision operation compresses material to achieve exact dimensions, flatten surfaces, or create fine details. Coining applies higher tonnage than other operations to plastically deform the metal into its final form.

- Cutoff: The final station separates the completed part from the carrier strip. The finished component drops through the die or is ejected onto a conveyor for collection.

According to Die-Matic's process guide, this entire sequence can happen in fractions of a second, with cycle times enabling production rates of hundreds or even thousands of parts per hour.

Station Sequencing for Optimal Part Quality

Why does the order of operations matter so much? Consider what happens if you bend material before piercing nearby holes—the bending operation would distort hole positions. Or imagine attempting to coin a feature after cutoff when there's no carrier strip to maintain part orientation. Proper sequencing prevents these problems.

Here's how experienced die designers approach station sequencing:

- Piercing before forming: Holes are easier to punch in flat material and maintain better dimensional accuracy

- Forming before bending: Three-dimensional features should be created while the part is still relatively flat for tool access

- Critical dimensions last: Features requiring the tightest tolerances are formed in later stations to minimize cumulative error

- Progressive complexity: Simple operations occur first, with more complex forming happening as the part develops

The progressive stamping die must also account for material flow and stress patterns. When metal is stretched, compressed, or bent, it work-hardens and becomes less formable. Strategic sequencing distributes these stresses to prevent cracking or tearing.

What about secondary operations? Many manufacturers integrate processes like in-die tapping directly into the progressive die stampings sequence. As noted by Clairon Metals, in-die tapping eliminates secondary operations by threading holes during the stamping cycle itself. This integration guarantees that tapped holes align perfectly with other part features while reducing handling and processing time.

Other secondary operations that can be built into progressive dies include:

- Hardware insertion: Press-fit nuts, studs, or fasteners installed during stamping

- Assembly operations: Multiple components joined together before cutoff

- Marking: Part numbers or identification marks applied within the die

The integration of secondary operations demonstrates why the progressive die stamping process delivers such compelling efficiency—what might require multiple machines and handling steps happens in a single automated sequence. This simultaneous processing across all stations means that while one section of strip receives its pilot holes, another undergoes bending, and yet another gets its final cutoff—all in the same press stroke.

Understanding this station-by-station progression helps you appreciate why progressive stamping dominates high-volume production. But how does it compare to alternative methods? That's exactly what we'll explore next—giving you the decision criteria to determine which approach fits your specific requirements.

Progressive Stamping vs Alternative Metal Forming Methods

You've seen how progressive stamping works—but is it always the right choice? The honest answer: it depends. Selecting the optimal die stamping method requires matching your specific requirements to each process's strengths and limitations. Let's compare the major alternatives so you can make an informed decision.

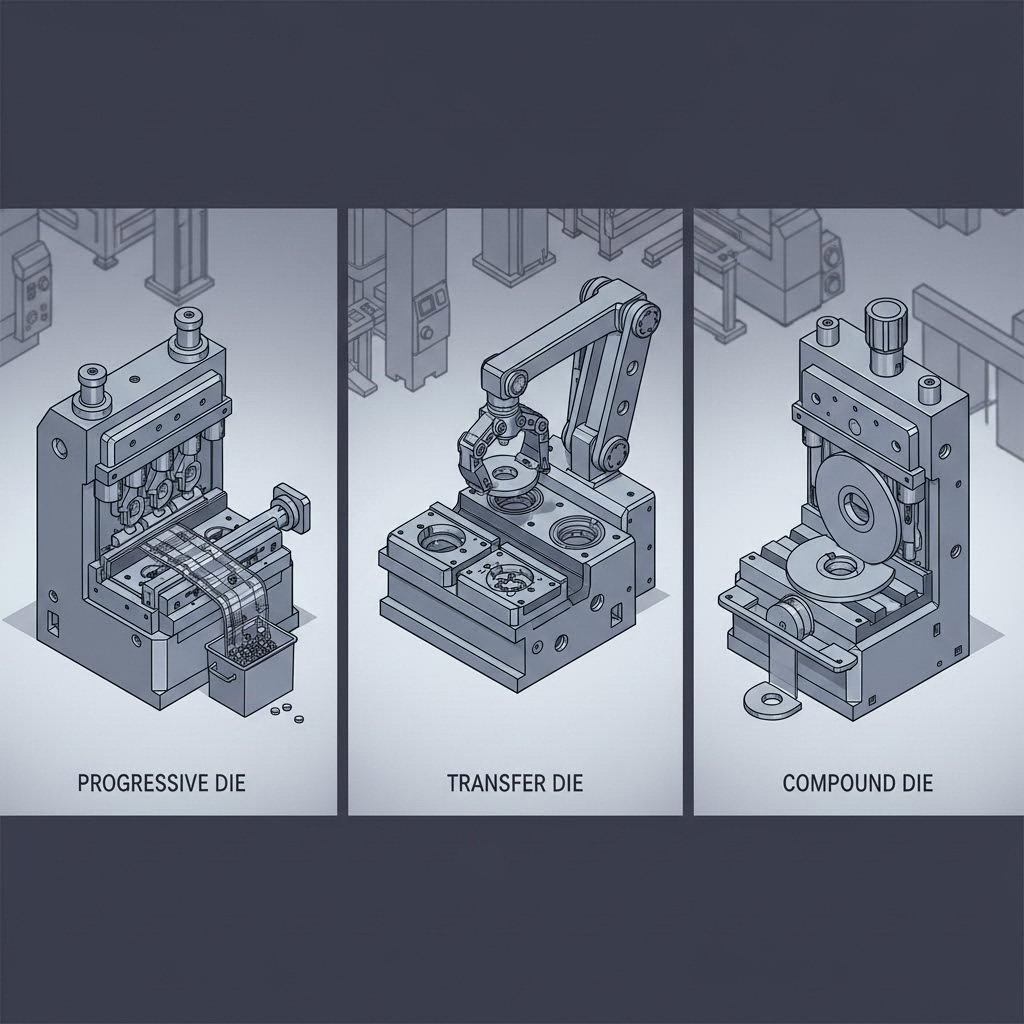

Progressive vs Transfer Die Stamping Decision Factors

Transfer die stamping operates differently from progressive stamping in one fundamental way: parts are physically moved between stations rather than remaining connected to a carrier strip. According to Worthy Hardware's comparison, this approach allows more flexibility in part handling and orientation, making it suitable for intricate designs and shapes.

When would you choose transfer stamping over progressive? Consider these scenarios:

- Larger part sizes: Transfer dies handle components too big to remain on a carrier strip

- Complex geometries: Parts requiring operations from multiple angles benefit from independent part movement

- Deep draws: Transfer press stamping excels at forming deeper three-dimensional shapes

However, the transfer die approach comes with trade-offs. Setup times run longer, operational costs increase due to more complex mechanisms, and you'll need skilled technicians for maintenance. The mechanical transfer systems require precise calibration—any misalignment affects every part produced.

When Compound Dies Outperform Progressive Tooling

Compound die stamping takes a completely different approach: multiple operations occur simultaneously in a single press stroke rather than sequentially. As Larson Tool explains, compound dies are generally less expensive to design and produce compared to progressive dies, making them attractive for specific applications.

Compound dies shine when you need:

- Simple, flat parts with precise edge quality

- Lower production volumes that don't justify progressive tooling investment

- Parts where all features can be created in one stroke

The limitation? Compound dies struggle with complex shapes or parts requiring forming operations. They're essentially specialists—excellent at what they do, but with a narrower application range.

Complete Method Comparison

Understanding the relationships between these methods becomes clearer when you see them side by side. Here's how each approach compares across critical decision factors:

| Factor | Progressive Die | Transfer Die | Compound Die | Single-Stage | Fine Blanking |

|---|---|---|---|---|---|

| Part Complexity | High—multiple operations in sequence | Very high—complex 3D shapes possible | Low to moderate—flat parts only | Low—one operation per stroke | Moderate—precision flat parts |

| Volume Requirements | High volume (100,000+ parts) | Medium to high volume | Low to medium volume | Prototypes to low volume | Medium to high volume |

| Cycle Time | Fastest—fractions of a second | Moderate—transfer time adds overhead | Fast—single stroke completion | Slow—one operation at a time | Moderate—higher tonnage required |

| Tooling Costs | High upfront, low per-part | Very high—complex mechanisms | Lower—simpler construction | Lowest—simple tooling | High—precision requirements |

| Ideal Applications | Automotive brackets, electrical contacts, connectors | Large body panels, structural components | Washers, simple blanks, gaskets | Prototyping, short runs | Gears, precision blanks, safety parts |

| Edge Quality | Good—standard tolerances | Good—depends on operation | Excellent—simultaneous cutting | Variable—operator dependent | Exceptional—smooth, burr-free |

Making Your Selection Decision

How do you determine which method fits your project? Start with these questions:

- What's your annual volume? Progressive dies become cost-effective above 100,000 parts annually. Below that threshold, compound or single-stage approaches may prove more economical.

- How complex is your part geometry? Parts requiring operations from multiple angles or deep forming often favor transfer stamping. Simpler flat parts work well with compound dies.

- What tolerances do you need? Fine blanking delivers the tightest tolerances and best edge quality—but at higher cost. Standard progressive stamping handles most commercial tolerance requirements.

- What's your timeline? Single-stage tooling can be ready in weeks; complex progressive dies may require months of development.

The relationship between these factors isn't always straightforward. A high-volume project with simple geometry might still favor compound dies if edge quality is critical. Conversely, a medium-volume project with complex features might justify progressive tooling if the alternative requires multiple secondary operations.

Remember: the "best" method depends entirely on your specific combination of volume, complexity, tolerance, and budget requirements. What works perfectly for automotive brackets might be entirely wrong for medical device components—even if both use sheet metal as the starting point.

With a clear understanding of how progressive stamping compares to alternatives, you're ready to explore another critical decision factor: which materials work best with this process and why material selection matters for both part quality and die longevity.

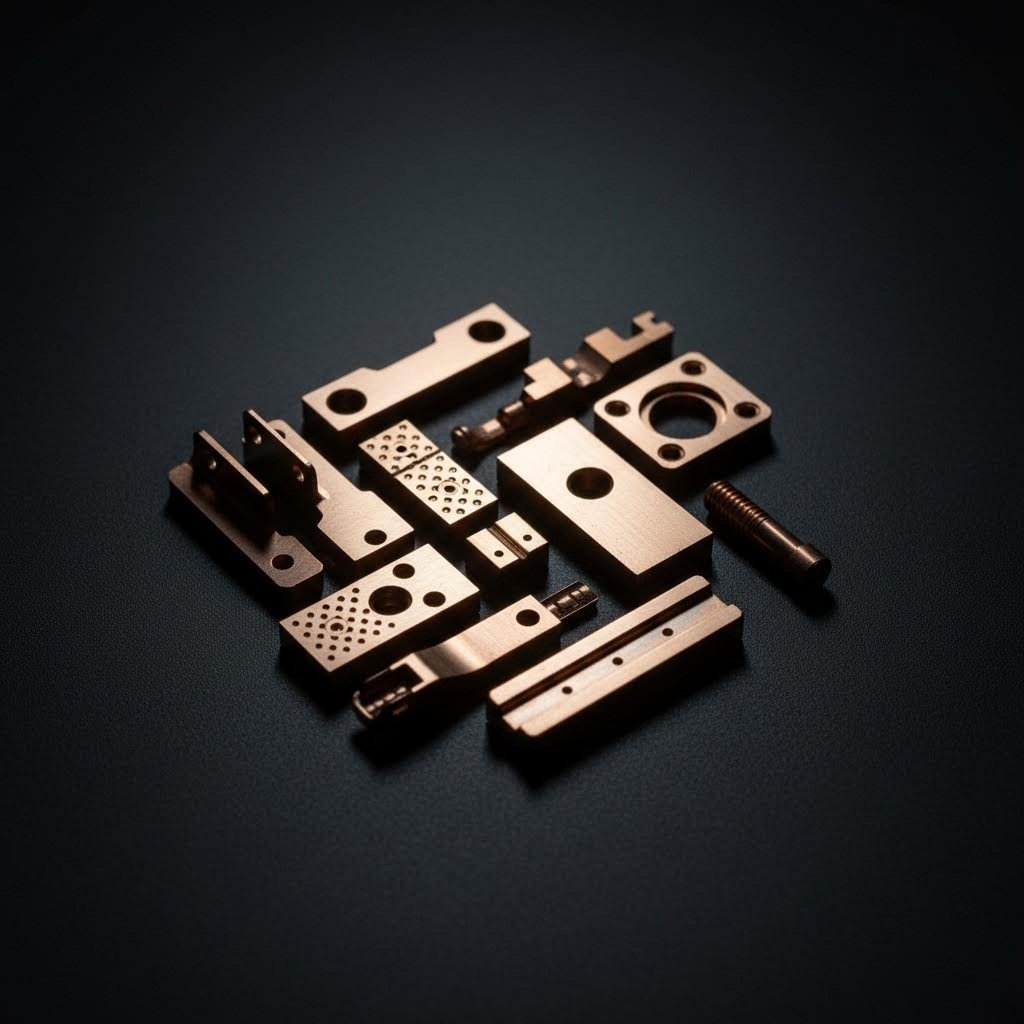

Material Selection Guide for Progressive Stamping Success

Choosing the right material isn't just a procurement decision—it directly impacts part performance, die longevity, and production costs. While competitors often list compatible metals without explanation, understanding why certain materials behave differently in sheet metal stamping dies gives you a significant advantage when planning your next project.

Here's the reality: not all metals stamp equally. The forces involved in progressive stamping interact differently with each material's unique properties, affecting everything from tool wear to dimensional accuracy.

Matching Material Properties to Progressive Die Capabilities

When evaluating materials for progressive stamping, four characteristics matter most:

- Ductility and Formability: According to Ulbrich's material guide, forming occurs somewhere between the yield strength and tensile strength of the material. If yield isn't exceeded, forming doesn't happen—but exceeding tensile strength causes fractures. Higher-strength materials have a narrower window between these limits, making them more challenging to form.

- Tensile Strength: This measures how much pulling force a material can withstand before breaking. Stronger metals resist deformation better in service but require higher press tonnage during stamping.

- Work Hardening Rate: As metal is stamped, its crystalline structure changes—making it harder and more brittle. Materials with high work-hardening rates may require intermediate annealing to prevent cracking during complex forming sequences.

- Machinability: How easily can the material be cut and shaped? As noted by American Industrial Company, metals that are easy to cut typically cost less to process, while those with poor machinability may require specialty steel stamping tools or additional finishing operations.

Material thickness also plays a critical role. Most progressive stamping operations handle material from 0.005" to 0.250" thick, though this range varies based on press capacity and part requirements. Thinner materials require more precise handling to prevent wrinkling, while thicker stock demands higher tonnage and more robust tooling.

Common Materials Compared

Here's how the most frequently used materials stack up for copper progressive stamping and other common applications:

| Material | Formability | Relative Cost | Key Properties | Typical Applications |

|---|---|---|---|---|

| Carbon Steel | Good | Low | High strength, design flexibility, accepts coatings for corrosion protection | Automotive brackets, structural components, general hardware |

| Stainless Steel | Moderate | Medium-High | Corrosion resistance, attractive finish, higher work-hardening rate | Medical devices, food handling equipment, marine components |

| Aluminum | Excellent | Medium | Lightweight, high strength-to-weight ratio, good thermal and electrical conductivity | Electronics enclosures, heat sinks, aerospace components |

| Copper | Excellent | Medium-High | Superior electrical/thermal conductivity, soft, malleable, corrosion resistant | Electrical contacts, bus bars, heat exchangers |

| Brass | Good to Excellent | Medium | Varying hardness based on zinc content, decorative appeal, low friction | Bearings, locks, gears, decorative hardware |

| Beryllium Copper | Moderate | High | High fatigue strength, non-sparking, stress relaxation resistance | Springs, aircraft engine parts, high-stress connectors |

How Metal Selection Impacts Die Design and Longevity

Your material choice directly affects metal stamping die sets in several ways:

Clearance requirements change with material type. According to Xometry's design standards, ductile materials like aluminum require minimum hole diameters of at least 1.2x material thickness, while higher-tensile materials like stainless steel need 2x material thickness. These requirements influence punch and die block dimensions throughout your steel stamping dies.

Harder materials accelerate tool wear. Stainless steel and high-strength alloys wear die components faster than softer materials. This wear pattern affects maintenance schedules and may require:

- Hardened tool steel inserts in high-wear areas

- Specialized coatings like titanium nitride (TiN) or diamond-like carbon (DLC)

- More frequent sharpening intervals

Work-hardening materials demand careful sequencing. Austenitic stainless steels present particular challenges. Ulbrich notes that these materials transform during deformation, inducing a brittle martensitic phase that increases residual stress and cracking risk. Progressive dies working with these alloys often require additional forming stations with smaller incremental deformations.

Surface treatments extend die life. When stamping abrasive or adhesive materials, die coatings become essential. Aluminum tends to gall—sticking to tooling surfaces—while stainless steel can cause adhesive wear. Appropriate surface treatments prevent material buildup that degrades part quality and accelerates die deterioration.

The bottom line? Material selection isn't just about what works—it's about optimizing the relationship between your part requirements, production volumes, and tooling investment. A material that seems economical upfront may cost more overall if it dramatically shortens die life or requires frequent maintenance. Understanding these trade-offs positions you to make decisions that balance performance with total production economics.

With material fundamentals covered, you're ready to explore how different industries leverage progressive stamping—and why each sector demands specific capabilities from this versatile process.

Industry Applications Where Progressive Stamping Excels

Why do certain industries rely so heavily on progressive stamping while others rarely use it? The answer comes down to matching process capabilities with sector-specific demands. When you need millions of identical parts with tight tolerances delivered on aggressive timelines, progressive stamping becomes not just an option—but often the only viable solution.

Let's explore how different industries leverage this process and why their unique requirements align perfectly with what progressive stamping delivers.

Automotive Components That Rely on Progressive Stamping

The automotive industry represents the largest consumer of progressive stamped automotive parts—and for good reason. According to Wedge Products, automotive component manufacturers rely on high-volume stamping partners who can meet demanding schedules and strict tolerances. This sector's requirements create an ideal match with progressive die capabilities:

- Volume demands: A single vehicle contains hundreds of stamped components. Multiply that by production runs reaching millions of units annually, and you understand why speed matters

- Tight tolerances: Safety-critical components must fit precisely every time—no exceptions

- Cost pressure: Competitive pricing requires minimizing per-part costs through efficient production

- Consistency: Parts produced today must match parts produced years from now for service and replacement needs

Typical progressive stamped automotive parts include:

- Brackets and mounting hardware

- Electrical connectors and terminals

- Seat frame components

- Brake system parts

- Transmission components

- Sensor housings and shields

- Clips, retainers, and fastener hardware

The automotive stamping die must withstand millions of cycles while maintaining dimensional accuracy. This explains why automotive applications often use the most robust tooling designs with premium materials and advanced coatings. When a single die produces parts for multiple vehicle platforms over a decade or longer, upfront tooling investment pays dividends through extended service life.

Electronics and Electrical Applications

Imagine stamping components smaller than your fingernail with features measured in thousandths of an inch—that's the reality of electronics manufacturing. This sector demands miniaturization that pushes progressive stamping to its precision limits:

- Micro-scale features: Connector pins, contact springs, and terminals often require tolerances below ±0.001"

- Material conductivity: Copper and copper alloys dominate for their electrical properties

- Surface finish requirements: Contact surfaces need consistent finish quality for reliable electrical connections

- High-speed production: Consumer electronics volumes demand the fastest possible cycle times

Common electronics components produced through progressive stamping:

- USB and connector terminals

- Battery contacts and springs

- RF shielding components

- Lead frames for semiconductors

- Heat sink fins and thermal management parts

- Switch contacts and actuators

The challenge intensifies when you consider that many electronic components require plating or surface treatments applied after stamping. Progressive die design must account for these downstream processes, maintaining dimensional stability through additional handling and thermal cycles.

Medical Device Manufacturing

Medical progressive stamping operates under a different set of pressures. Here, precision isn't just about fit and function—it's about patient safety. Regulatory requirements add layers of complexity that shape every aspect of production:

- Material traceability: Every lot of material must be documented and traceable back to its source

- Process validation: Stamping parameters must be validated and controlled within tight limits

- Cleanliness standards: Many medical components require contamination-free production environments

- Biocompatibility: Material selection must consider long-term contact with human tissue

Medical device components commonly produced through progressive stamping:

- Surgical instrument components

- Implantable device housings and frames

- Diagnostic equipment parts

- Drug delivery system components

- Monitoring device contacts and connectors

- Catheter and cannula components

The documentation requirements alone distinguish medical manufacturing. Each production run generates records linking raw materials, process parameters, and inspection results to specific part lots. This traceability enables recalls if problems emerge and demonstrates regulatory compliance during audits.

Aerospace Applications

Aerospace stamping combines the volume requirements of automotive with tolerance demands exceeding medical devices. Weight savings drive material selection toward aluminum and specialty alloys, while safety requirements mandate exceptional consistency:

- Weight optimization: Every gram matters when fuel efficiency determines operating costs

- Fatigue resistance: Components must survive millions of stress cycles without failure

- Extreme environments: Temperature swings from -65°F to 300°F+ challenge material stability

- Long service life: Aircraft remain in service for decades, requiring parts that maintain performance throughout

Aerospace components produced through progressive stamping:

- Structural brackets and mounting hardware

- Electrical system connectors

- Ventilation and ducting components

- Control system linkages

- Interior hardware and fasteners

- Sensor mounting brackets

Precision Requirements Across Industry Applications

What connects these diverse applications? Each industry demands specific capabilities that progressive stamping delivers better than alternatives:

| Industry | Primary Driver | Critical Capability | Typical Tolerance |

|---|---|---|---|

| Automotive | Volume and cost | High-speed production with consistency | ±0.005" to ±0.010" |

| Electronics | Miniaturization | Micro-feature precision | ±0.001" to ±0.003" |

| Medical | Regulatory compliance | Traceability and process control | ±0.002" to ±0.005" |

| Aerospace | Weight and reliability | Material expertise and documentation | ±0.002" to ±0.005" |

Notice how the process capabilities we discussed earlier—simultaneous operations, precise positioning through pilot systems, and controlled forming sequences—directly address these industry requirements. The same progressive die principles apply whether you're stamping automotive brackets or medical implant components; the difference lies in material selection, tolerance specifications, and documentation requirements.

Understanding these application-specific demands helps you evaluate whether progressive stamping fits your project. But even the best-designed process encounters problems. What happens when parts don't meet specifications? That's where troubleshooting expertise becomes essential—and it's exactly what we'll cover next.

Troubleshooting Common Progressive Stamping Defects

Even the most precisely engineered progressive die will eventually produce defective parts. The difference between struggling manufacturers and industry leaders? Knowing how to identify problems quickly, trace them to root causes, and implement lasting solutions. This troubleshooting knowledge—often learned through years of hands-on experience—separates competent operators from true stamping tooling experts.

Let's examine the most common defects you'll encounter and the systematic approaches to eliminate them.

Identifying Root Causes of Stamping Defects

When parts start failing inspection, resist the urge to make random adjustments. According to DR Solenoid's quality guide, successful troubleshooting starts with understanding that every defect has a specific cause—and often, multiple contributing factors. Here's what you're likely to encounter:

Burrs represent perhaps the most frequent quality issue. These raised edges along cut features affect fit, function, and safety. What causes them? The gap between punch and die tells most of the story. When clearance exceeds optimal ranges (typically 8% to 12% of material thickness for mild steel), material doesn't shear cleanly—it tears, leaving ragged edges. Worn cutting edges compound the problem, as dull tooling can no longer produce the clean fracture that precision stamp operations require.

Springback frustrates manufacturers working with high-strength materials. You bend the material to a precise angle, release pressure, and watch it partially return toward its original shape. This behavior stems from the elastic recovery inherent in all metals—the portion of deformation that isn't permanent. Higher-strength steels and stainless alloys exhibit more pronounced springback, sometimes requiring over-bending by several degrees to achieve target dimensions.

Misalignment manifests as features that drift from their nominal positions—holes that don't match mating parts, bends that occur in wrong locations, or progressive accumulation of positioning errors. Root causes typically trace back to worn pilot pins, damaged locating holes in the strip, or guide system deterioration. When pilots can no longer precisely engage their corresponding holes, every downstream station produces parts with compounding inaccuracies.

Slug pulling occurs when the material slug cut from a piercing operation doesn't cleanly exit through the die—instead, it gets pulled back up with the punch and redeposited on the strip or die surface. This phenomenon causes surface damage, jams, and tool breakage. Insufficient vacuum or ejection force, worn punch surfaces that create suction, or inadequate die clearance all contribute to this frustrating issue.

Die wear patterns reveal themselves through gradual dimensional drift rather than sudden failure. Cutting edges round over, forming surfaces develop galling marks, and critical dimensions creep outside tolerance. Recognizing wear patterns early—through statistical process control and regular inspection—prevents the catastrophic failures that occur when worn tooling finally breaks.

Defect-Cause-Solution Quick Reference

When production problems arise, quick diagnosis saves time and reduces scrap. Use this matrix for systematic troubleshooting:

| Defect | Common Causes | Solutions |

|---|---|---|

| Excessive Burrs | Punch-die clearance too large; worn cutting edges; improper material hardness | Adjust clearance to 8-12% of material thickness; sharpen or replace cutting components; verify incoming material specifications |

| Springback | Insufficient overbend compensation; material properties variation; inconsistent forming pressure | Increase overbend angle (use CAE simulation for optimization); implement incoming material testing; verify press tonnage consistency |

| Hole/Feature Misalignment | Worn pilot pins; damaged pilot holes; guide bushing wear; improper feed length | Replace pilots on schedule; inspect strip for pilot hole damage; check and replace guide components; recalibrate feeder |

| Slug Pulling | Insufficient slug ejection; punch surface suction; inadequate die clearance | Add vacuum assist or positive ejection; polish punch faces; verify and adjust die opening dimensions |

| Surface Scratches | Die surface contamination; rough tooling finish; insufficient lubrication | Clean die surfaces regularly; polish to Ra 0.2μm or better; optimize lubricant application |

| Cracking/Tearing | Drawing ratio too aggressive; insufficient material ductility; die radius too small | Add intermediate forming stations; select more formable material grade; increase die corner radius (R≥4x material thickness) |

| Wrinkling | Insufficient blank holder pressure; material too thin for draw depth; improper material flow | Increase blank holder force; redesign draw sequence; add draw beads to control material movement |

| Dimensional Drift | Progressive tool wear; thermal expansion during production; material lot variation | Implement statistical process control; allow thermal stabilization before production; tighten incoming material specifications |

Preventive Strategies for Consistent Part Quality

Fixing problems after they occur costs far more than preventing them. Smart manufacturers build prevention into their progressive die design and maintenance programs from the start.

Establish baseline measurements. When a die first enters production, document critical dimensions across multiple parts. These baseline measurements become your reference point for detecting wear-related drift before it causes rejections. Statistical process control charts make trend identification straightforward—you'll see gradual changes developing long before parts fail inspection.

Create maintenance schedules based on stroke counts. Different components wear at different rates. Cutting edges may need sharpening every 50,000 strokes, while guide bushings might last 500,000 strokes. Track actual wear rates for your specific materials and build preventive maintenance schedules around real data rather than arbitrary intervals.

Implement in-process monitoring. Modern stamping tooling can incorporate sensors that detect problems in real-time. Load monitoring identifies tonnage variations indicating tool wear or material changes. Proximity sensors confirm proper strip positioning. These systems catch problems within strokes rather than after thousands of defective parts accumulate.

Control your incoming materials. According to industry best practices, strict incoming material inspection—including tensile testing and thickness verification to ±0.02mm—prevents many downstream quality issues. Material lot variations that seem minor can significantly affect forming behavior and final dimensions.

Use simulation to predict problems. CAE software can model material flow, predict springback, and identify high-stress areas before cutting any tool steel. This virtual testing catches stamping die design issues that would otherwise appear only after expensive tooling is built and production begins.

Document everything. When you solve a problem, record what you found and what fixed it. Build a troubleshooting database specific to each die. Over time, this institutional knowledge accelerates problem resolution and helps new team members avoid repeating past mistakes.

The investment in prevention pays dividends through reduced scrap, fewer production interruptions, and extended die life. A well-maintained progressive die producing parts within tolerance is far more valuable than one constantly requiring intervention—even if both started from identical designs.

Understanding defects and their solutions prepares you for production realities. But before committing to progressive stamping, you need to understand the economics—when does the tooling investment make financial sense, and how do you calculate the true return? That's exactly what we'll examine next.

The Business Case for Progressive Die Investment

Here's a question that stops many projects before they start: how do you justify spending $50,000 to $100,000 on tooling before producing a single part? The answer lies in understanding progressive stamping economics—a classic trade-off where high upfront investment unlocks dramatically lower per-part costs over time. For decision-makers evaluating manufacturing options, grasping this relationship separates profitable projects from expensive mistakes.

Let's break down the numbers so you can determine when progressive die and stamping makes financial sense for your specific requirements.

Calculating ROI on Progressive Die Investments

The fundamental equation for progressive die tooling costs is straightforward:

Total Cost = Fixed Costs (Design + Tooling + Setup) + (Variable Cost per Unit × Volume)

According to automotive stamping cost analysis, fixed tooling costs range dramatically—from approximately $5,000 for simple blanking dies to over $100,000 for complex progressive dies with multiple forming stations. This upfront investment represents the largest barrier to entry, but it's also what enables the remarkable efficiency gains that follow.

Here's how the math works in practice. Imagine a progressive die costing $80,000 that produces parts over a five-year production run of 500,000 units. Your tooling cost per part drops to just $0.16. But for a run of only 5,000 parts? That same die adds $16.00 per part—likely making the project economically unviable.

The variable cost portion includes:

- Raw material costs: Often accounting for 60-70% of the piece price, material utilization and scrap recovery significantly impact economics

- Machine hourly rates: Based on press tonnage, energy consumption, and operational overhead

- Labor costs: Minimal for high volume stamping due to automation, but still a factor in setup and monitoring

- Maintenance allocation: Typically 2-5% of tooling cost annually for sharpening, repairs, and component replacement

The strategic insight? Progressive stamping follows an asymptotic cost curve. Unlike CNC machining or laser cutting where per-part costs remain relatively flat regardless of quantity, stamping costs drop precipitously as volume increases. This characteristic makes precision die and stamping the clear winner for high-volume applications—but the wrong choice for low-quantity production.

Volume Thresholds That Justify Progressive Tooling

When does progressive stamping make economic sense? The break-even calculation depends on comparing your tooling investment against the per-part savings achieved versus alternative methods.

Industry experience suggests these general thresholds:

- Below 10,000 units annually: Progressive stamping typically costs more than alternatives due to unrecovered tooling investment

- 10,000 to 20,000 units: The crossover zone—detailed analysis required based on part complexity and alternative method costs

- Above 20,000 units annually: Progressive die manufacturers generally deliver the lowest total cost of ownership

- 100,000+ units: Per-part costs become exceptionally competitive, with tooling amortization becoming negligible

But volume alone doesn't tell the complete story. Part complexity dramatically affects this equation. A component requiring twelve forming operations might cost $3.50 each using multiple single-stage operations—but only $0.45 from a progressive die running at 400 strokes per minute. Even at 15,000 units annually, the progressive approach wins despite higher tooling costs.

Cost Factors Across the Project Lifecycle

Smart financial analysis extends beyond initial tooling quotes to encompass the full production lifecycle:

- Die design and engineering: Complex geometries require more design iterations and simulation analysis, adding $5,000 to $25,000 in engineering costs

- Tooling construction: Premium tool steels, precision grinding, and heat treatment quality directly affect both initial cost and service life

- Tryout and validation: First-article inspection, process capability studies, and customer approval add time and cost before production begins

- Production efficiency: Cycle times measured in fractions of a second translate to thousands of parts per hour—labor cost per part becomes negligible

- Maintenance and refurbishment: Budget 2-5% of tooling cost annually for preventive maintenance; quality dies with million-stroke guarantees minimize this burden

- Scrap and material recovery: Efficient strip layouts and scrap metal recycling programs offset raw material costs

- Quality control: Automotive applications require PPAP documentation, inspection fixtures, and ongoing process monitoring

As noted by industry sources, once the die is made, the per-unit cost decreases significantly with higher production runs. This economic reality drives the decision-making process: accept a high initial cost to secure an extremely low piece price for the duration of a long production run.

Hidden Costs That Affect True ROI

The lowest quoted piece price isn't always the best deal. Experienced buyers evaluate Total Cost of Ownership (TCO), which includes factors often overlooked in initial comparisons:

- Quality failures: Defective parts generate scrap costs, sorting expenses, and potential line-down situations at customer facilities

- Secondary operations: A lower-cost die requiring manual deburring or additional machining may cost more overall than integrated in-die operations

- Lead time impacts: Delayed tooling affects product launch schedules, potentially costing far more than the tooling premium for faster delivery

- Die life and replacement: A $60,000 die lasting one million strokes costs less per part than a $40,000 die requiring replacement at 300,000 strokes

- Logistics considerations: Offshore tooling may appear 30% cheaper, but shipping costs, communication delays, and difficulty troubleshooting engineering changes can eliminate savings

The bottom line? Progressive die tooling represents a strategic investment, not simply a procurement expense. When annual volumes exceed threshold levels and part complexity demands multiple operations, this approach delivers the lowest total production cost—but only when you account for the complete economic picture from design through end-of-life.

With a clear understanding of the economics, your next challenge becomes finding a manufacturing partner capable of delivering on these cost projections. What capabilities should you evaluate, and how do you distinguish between vendors who merely quote low prices and those who consistently achieve them? That's precisely what we'll explore next.

Selecting the Right Progressive Stamping Partner

You've mastered the technical fundamentals—now comes the decision that determines whether your project succeeds or stumbles. Choosing the wrong stamping die manufacturers can transform a well-designed part into a production nightmare, while the right partner turns even challenging geometries into reliable, cost-effective components. How do you separate genuine capability from polished sales presentations?

The answer lies in evaluating specific competencies that directly impact your outcomes. Let's examine what distinguishes precision die stamping leaders from the crowd.

Engineering Capabilities That Separate Top-Tier Suppliers

When evaluating potential partners for progressive stamping dies, engineering expertise matters more than equipment lists or facility size. According to industry experts, an experienced supplier has tackled various design complexities and production challenges—this knowledge helps them anticipate potential issues early on.

What specific engineering capabilities should you look for?

CAE simulation for defect prevention. As demonstrated in research published by The Fabricator, integrating computer-aided engineering with experienced tool designers reduces sequence development time while predicting critical attributes such as strain distribution, stress patterns, material flow, and forming defects. Suppliers using FEM simulation can optimize punch diameters, die radii, and forming sequences before cutting tool steel—catching problems that would otherwise require expensive die modifications.

Look for partners who demonstrate:

- Virtual tryout capabilities: Simulating material flow and springback before physical prototyping

- Thickness distribution analysis: Predicting thinning and potential failure points

- Formability assessment: Identifying areas at risk of cracking or wrinkling

- Springback compensation: Calculating overbend angles through simulation rather than trial-and-error

For example, Shaoyi demonstrates this approach through advanced CAE simulation that delivers defect-free results—setting a benchmark for what you should expect from any serious oem progressive stamping supplier. Their engineering-first methodology exemplifies how simulation prevents costly mistakes before production begins.

In-house tooling design and fabrication. Suppliers with complete vertical integration—from die design through construction—maintain tighter control over quality and timelines. When design and fabrication teams work in the same facility, communication improves and modifications happen faster. As Eigen Engineering notes, in-house tooling capabilities enable faster adjustments and reduce costs compared to outsourcing.

Rapid prototyping speed. How quickly can a supplier deliver sample parts for validation? This metric reveals both engineering agility and production readiness. Industry-leading stamping die operations like Shaoyi can deliver prototypes in as little as 5 days—dramatically compressing development timelines when speed matters. You can explore their comprehensive mold design and fabrication capabilities to understand what rapid-response engineering looks like in practice.

Quality Certifications That Matter for Automotive Applications

Certifications aren't just wall decorations—they represent verified quality systems that directly affect your parts. Understanding what each certification guarantees helps you set appropriate expectations.

IATF 16949:2016 certification stands as the gold standard for automotive suppliers. According to Master Products, this certification harmonizes quality assessment systems across the global automotive industry while focusing on defect prevention and production variance minimization. The three primary aims include:

- Improving product quality and manufacturing process consistency

- Establishing suppliers as "supplier of choice" for leading automotive manufacturers

- Seamless integration with ISO certification standards

IATF 16949 demands increased attention to customer needs—your unique production requirements, expectations, and specifications. This customer-focused approach aligns perfectly with precision die stamping operations where every project presents unique challenges.

Shaoyi's IATF 16949 certification, combined with their 93% first-pass approval rate, demonstrates how rigorous quality systems translate into tangible production outcomes. When evaluating progressive precision metal stampings suppliers, these metrics indicate systematic excellence rather than occasional good results.

Additional certifications to evaluate:

- ISO 9001:2015: Foundation-level quality management applicable across industries

- AS9100: Aerospace-specific requirements for suppliers serving that sector

- ISO 14001: Environmental management systems demonstrating sustainability commitment

Partner Evaluation Checklist

Before committing to a stamping die supplier, systematically evaluate these criteria:

- Engineering expertise: Does the supplier have experience with your specific industry and material requirements?

- Simulation capabilities: Can they demonstrate CAE-based die development with documented defect prediction?

- Quality certifications: Do they hold IATF 16949 for automotive applications or industry-appropriate equivalents?

- Prototyping speed: What's their typical turnaround for first samples? (Benchmark: 5-10 days for responsive suppliers)

- First-pass approval rate: What percentage of new dies achieve production approval without modification? (Benchmark: above 90%)

- Production capacity: Can they scale from prototype quantities to high volume stamping as your needs grow?

- In-house tooling: Do they design and build progressive stamping dies internally or outsource critical steps?

- Quality control technology: What inspection equipment verifies dimensional accuracy—CMMs, optical systems, statistical process control?

- Communication transparency: Do they provide regular updates, detailed quotes, and clear timelines?

- References and track record: Can they provide client references demonstrating successful long-term partnerships?

Making the Final Decision

Selecting the right progressive stamping partner isn't about finding the lowest quote—it's about identifying a supplier whose capabilities match your requirements across the complete project lifecycle. As industry analysis confirms, while cost is important, it should not compromise quality and service. Consider the overall value the supplier offers, including their ability to reduce costs through process efficiency and improved design.

The most successful partnerships develop when both parties understand expectations from the outset. A supplier with proven engineering depth, verified quality systems, and responsive communication will contribute more to your success than one offering marginally lower piece prices but lacking the technical foundation to deliver consistently.

When you find a partner combining IATF 16949 certification, advanced simulation capabilities, rapid prototyping, and high first-pass approval rates, you've identified a supplier equipped to transform your designs into production reality—efficiently, accurately, and economically.

Frequently Asked Questions About Progressive Metal Stamping

1. What is progressive metal stamping?

Progressive metal stamping is a high-speed sheet metal forming process where a continuous strip of metal advances through multiple stations within a single die. Each station performs a specific operation—such as cutting, bending, punching, or shaping—until a finished part emerges with every stroke of the press. This method dominates high-volume manufacturing due to its exceptional speed, consistency, and cost efficiency, producing thousands of identical parts per hour.

2. How much does a progressive stamping die cost?

Progressive stamping dies typically range from $50,000 to over $100,000 depending on complexity, number of stations, and precision requirements. Simple blanking dies may cost around $5,000, while complex multi-station progressive dies with forming operations can exceed $100,000. However, this upfront investment unlocks dramatically lower per-part costs—often dropping to just cents per unit at high volumes, making it economical for production runs exceeding 20,000 units annually.

3. What is the difference between progressive and transfer stamping?

The key difference lies in how parts move through the die. In progressive stamping, parts remain connected to a carrier strip throughout all operations until final cutoff. In transfer stamping, parts are physically picked up and moved between stations independently. Progressive dies excel for smaller, intricate parts at very high volumes (1M+ parts/year), while transfer dies suit larger components requiring operations from multiple angles or deep draws that cannot remain strip-attached.

4. What are the four types of metal stamping?

The four primary types are: (1) Progressive die stamping—where strip metal advances through multiple stations for high-volume complex parts; (2) Transfer die stamping—where individual parts are mechanically moved between stations for larger components; (3) Deep draw stamping—specialized for creating deep, cup-shaped parts; and (4) Compound die stamping—where multiple cutting operations occur simultaneously in one stroke for simpler flat parts requiring precise edge quality.

5. What materials work best for progressive metal stamping?

Carbon steel, stainless steel, aluminum, copper, and brass are the most commonly used materials. Carbon steel offers excellent formability at low cost for structural components. Aluminum provides lightweight properties ideal for electronics and aerospace. Copper and brass deliver superior electrical conductivity for electrical contacts. Material selection depends on formability requirements, strength needs, corrosion resistance, and how the material properties affect die wear and tool longevity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —