Metal Stamping Tooling Secrets: What Die Makers Won't Tell You

Understanding Metal Stamping Tooling Fundamentals

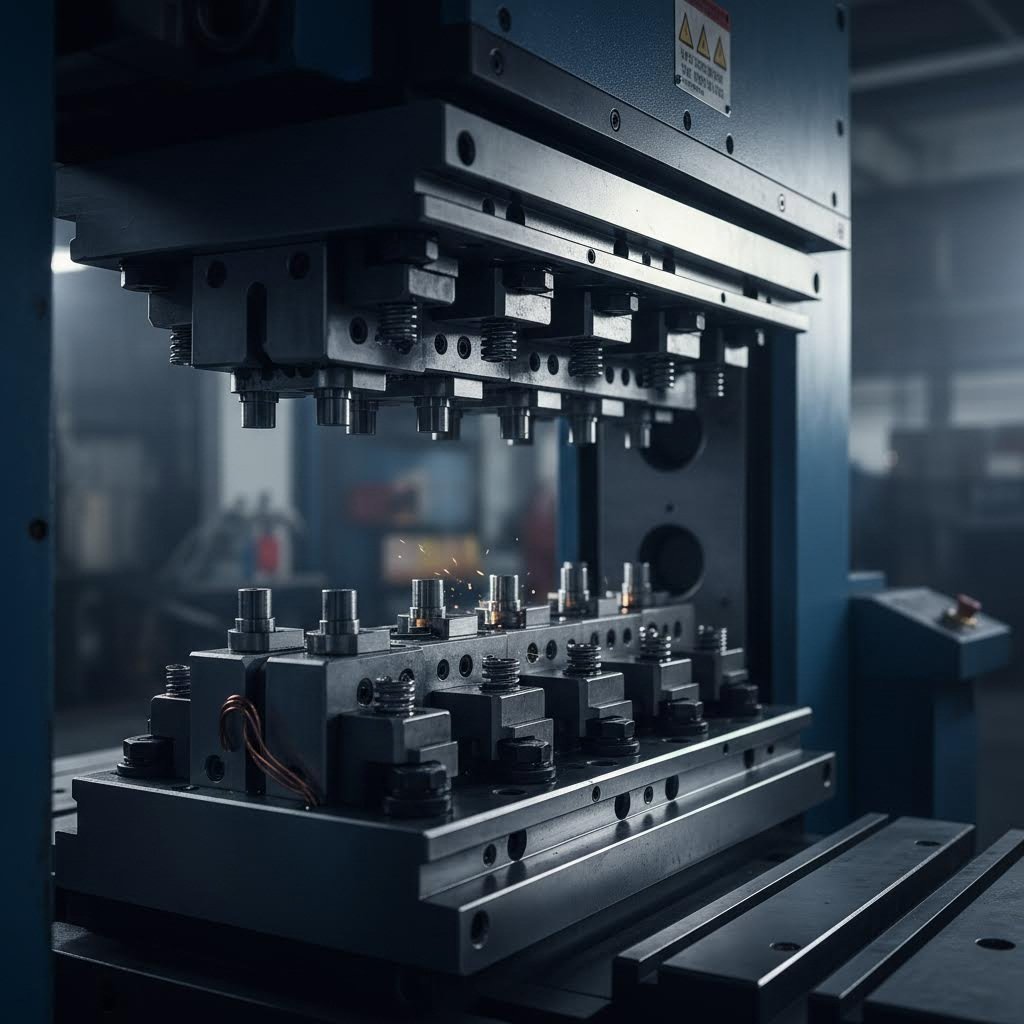

Ever wonder what separates a flawless stamped component from one riddled with defects? The answer lies in what happens before the stamping machine metal press ever cycles. Metal stamping tooling—the dies, punches, and forming components that shape raw sheet metal into precision parts—is the invisible foundation behind every successful manufacturing operation.

Think of tooling as the DNA of your stamped parts. Every cut, bend, and form your components take is determined by the quality and design of these specialized tools. Without precision-built tooling, even the most advanced metal stamping equipment becomes little more than expensive machinery producing inconsistent results.

What Metal Stamping Tooling Actually Does

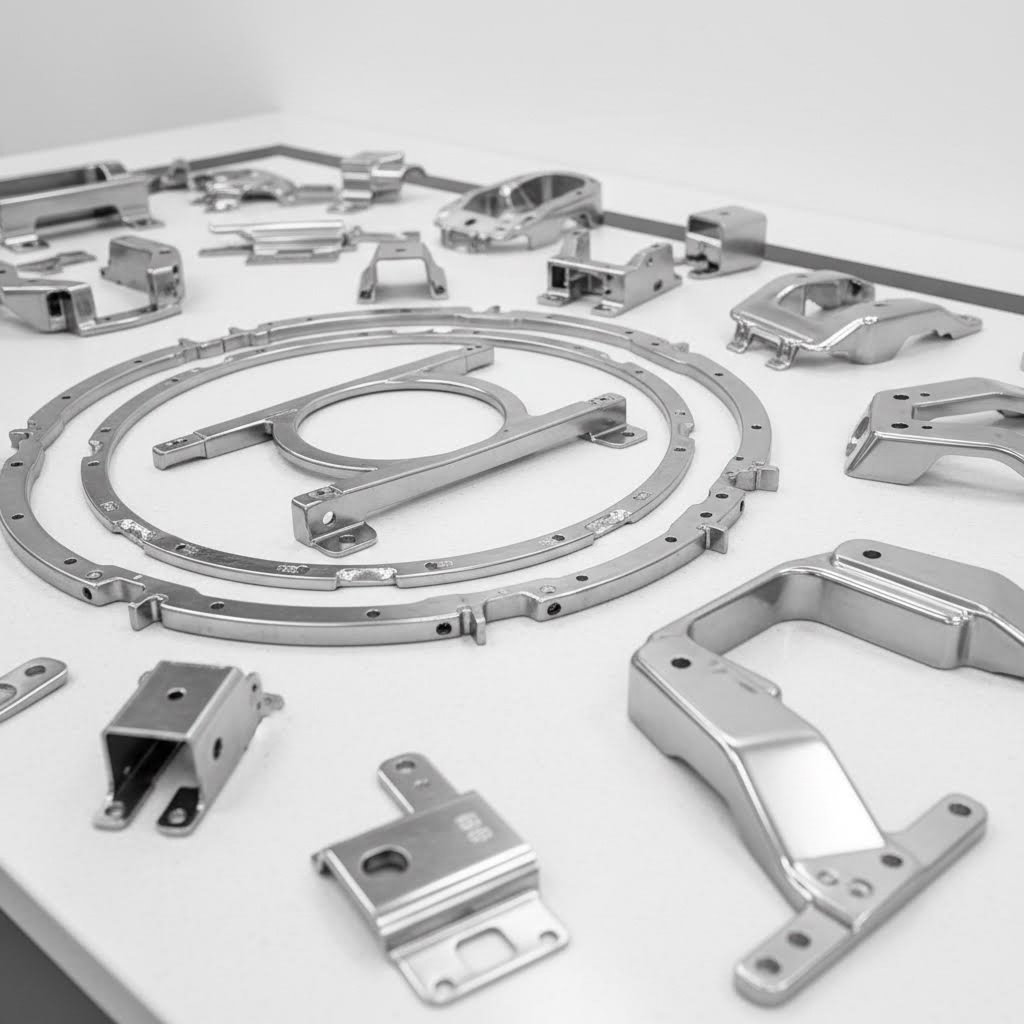

At its core, metal stamping tooling encompasses the complete system of components that transform flat sheet metal into finished parts. This includes die sets that provide the cutting and forming surfaces, punches that apply force to shape material, and inserts that handle specialized operations. Each stamping tool works in coordination with your press to execute specific operations—whether that's blanking, piercing, bending, or deep drawing.

When you tool stamp a part, you're essentially creating a repeatable manufacturing recipe. The die geometry determines your part's final shape, the punch configuration controls how force is applied, and the clearances between components dictate edge quality and dimensional accuracy. Get these elements right, and you'll produce thousands of identical parts with minimal variation.

The precision of a die directly affects the quality and repeatability of the stamped part. Poor tooling design or craftsmanship can introduce inconsistencies, increase scrap rates, and cause unplanned downtime.

The Foundation of Precision Manufacturing

Why does tooling matter so much? Consider these real manufacturing outcomes:

- Part Quality: Well-built tooling ensures each metal stamping component comes off the press dimensionally accurate and burr-free, ready for downstream operations without additional finishing

- Production Speed: Properly designed dies minimize cycle times and reduce changeover frequency, maximizing your throughput

- Cost Efficiency: Smart die design from experienced toolmakers can minimize material waste while supporting high-speed coil-fed production

- Consistency: Precision tooling eliminates the part-to-part variation that leads to assembly issues and customer complaints

In high-stakes industries like automotive and aerospace, minor deviations caused by inadequate tooling can lead to assembly failures or component rejection. The right stamping tool, however, often eliminates the need for secondary machining or finishing—saving significant time and cost across your production program.

Understanding these fundamentals is your first step toward making smarter tooling decisions. In the sections ahead, you'll discover the specific die types, material choices, and design principles that separate average tooling from exceptional manufacturing results.

Types of Stamping Dies and Their Applications

Now that you understand the fundamentals, here's where things get interesting. Not all stamping dies are created equal—and choosing the wrong type can cost you thousands in wasted material, extended lead times, and production headaches. The secret most die makers won't volunteer? The right die configuration for your project depends on factors that go far beyond basic part geometry.

When evaluating different types of tooling for your stamping operation, you'll encounter four primary die configurations: progressive, compound, transfer, and combination dies. Each serves distinct manufacturing needs, and understanding their strengths helps you make decisions that directly impact your bottom line.

Progressive Dies for High-Volume Efficiency

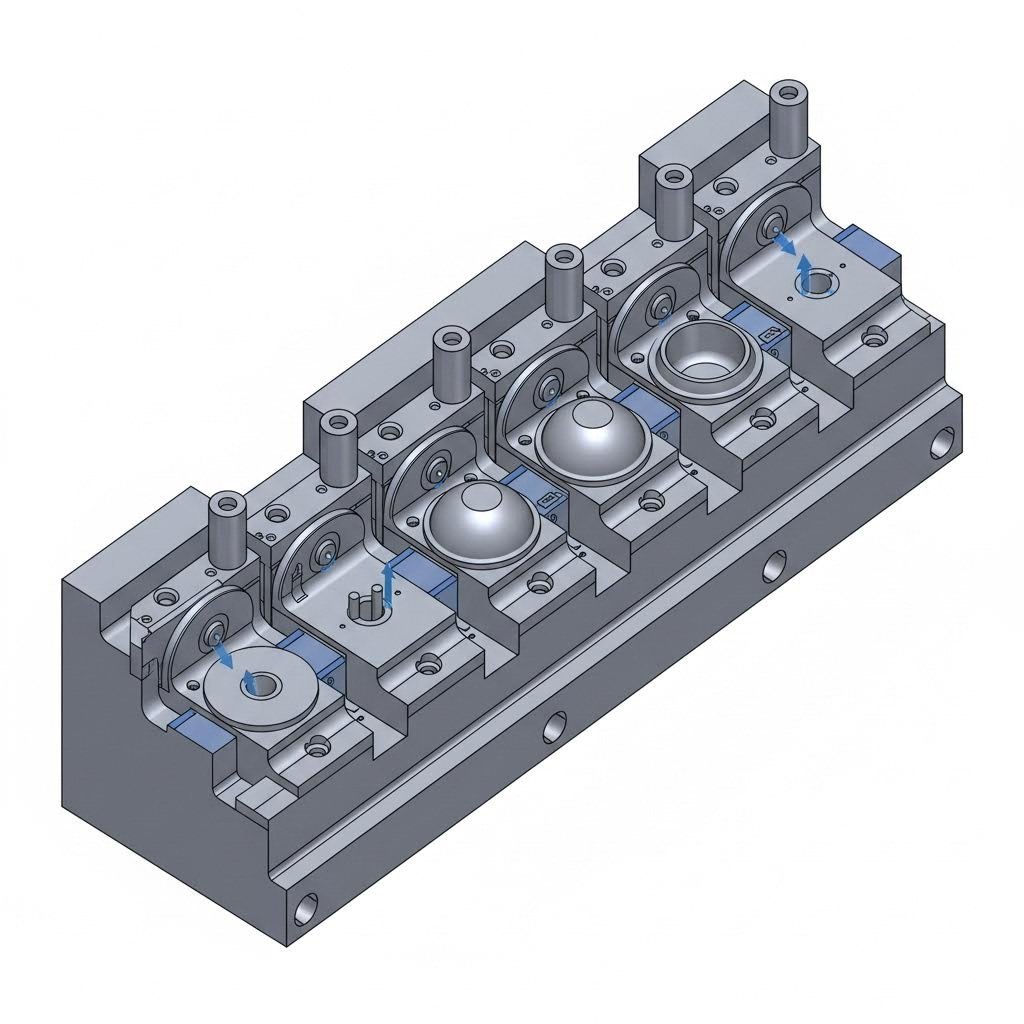

Imagine an assembly line compressed into a single tool. That's essentially what progressive dies deliver. A coil of metal feeds through multiple stations within the die, with each station performing a specific operation—punching, bending, forming, or cutting—as the material advances with each press stroke.

Here's what makes progressive dies the workhorse of high-volume production:

- Speed: Parts remain attached to the carrier strip throughout the process, enabling rapid cycling without manual handling between operations

- Consistency: Once dialed in, progressive dies deliver exceptional repeatability across millions of parts

- Efficiency: Multiple operations happen simultaneously, reducing per-part labor costs significantly

- Material versatility: Steel, aluminum, copper, stainless steel, brass, and even titanium or Inconel can be processed through progressive tooling

The trade-off? Progressive dies require substantial upfront investment in tool stamping metal design and fabrication. This makes them most cost-effective when your production volumes justify the initial tooling expense—typically runs of 100,000 parts or more. They're also less suitable for parts requiring deep drawing, since the workpiece stays connected to the strip throughout the process.

Compound Dies: Precision in a Single Stroke

When your application calls for simple, flat parts with tight tolerances, compound dies often deliver the best results. Unlike progressive setups that perform operations sequentially, compound stamping tool and die configurations execute multiple cuts, punches, and forms in one press stroke.

Think washers, gaskets, or flat brackets. Compound dies excel at these applications because:

- Single-stroke operation produces highly consistent parts with excellent flatness

- Material utilization is typically superior, reducing scrap costs

- Tooling costs are lower than progressive dies for simpler geometries

- Setup and changeover times are generally faster

The limitation here is complexity. Compound dies work best for parts without intricate bends, deep forms, or multiple sequential operations. When part designs get more elaborate, you'll need to look elsewhere.

Choosing Between Compound and Transfer Configurations

Transfer die stamping takes a fundamentally different approach. Instead of keeping the workpiece attached to a strip, the first operation separates each blank from the coil. Mechanical "fingers" then transport individual parts through multiple stations, each performing separate operations.

This configuration shines in scenarios where progressive and compound dies fall short:

- Deep drawing: Without a carrier strip restricting movement, transfer dies can form parts with significant depth

- Complex geometries: Intricate features like knurls, ribs, and threading become feasible

- Large parts: Components too big for progressive die handling can be manufactured efficiently

- Tube applications: Transfer dies are often the preferred method for tubular component manufacturing

According to industry analysis, transfer die stamping requires higher operational costs due to complex setups and the need for skilled labor. Setup times run longer, particularly for intricate parts. However, the flexibility this method offers makes it indispensable for precision die & stamping applications involving complex designs that other configurations simply cannot achieve.

Combination Dies: The Hybrid Approach

Sometimes your project doesn't fit neatly into one category. Combination dies merge elements from multiple configurations—integrating compound operations within a progressive framework, or combining cut and form operations that would typically require separate tooling. These hybrid solutions address specific manufacturing challenges where standard approaches fall short.

Die Type Comparison at a Glance

Selecting the right die type requires balancing multiple factors. This comparison breaks down the key decision criteria:

| Die Type | Best Applications | Volume Suitability | Complexity Level | Typical Part Examples |

|---|---|---|---|---|

| Progressive | Multi-operation parts requiring speed and consistency | High volume (100K+ parts) | Simple to moderate geometries | Electrical contacts, brackets, clips, terminals |

| Compound | Simple flat parts with tight tolerances | Medium to high volume | Low complexity | Washers, gaskets, flat blanks, shims |

| Transfer | Large or intricate parts requiring multiple operations | Medium to high volume | High complexity | Deep-drawn cups, tube components, structural housings |

| Combination | Specialized applications combining multiple die functions | Varies by design | Moderate to high | Custom parts with unique forming requirements |

How Die Selection Impacts Production Efficiency

Here's something experienced manufacturers understand but rarely discuss openly: die selection directly determines your production economics. Choose a progressive die for a 5,000-piece run, and your per-part tooling amortization makes the project uneconomical. Select a compound die for a complex multi-bend component, and you'll need costly secondary operations to complete each part.

The right tool stamping metal configuration aligns with your:

- Production volume: Higher volumes justify greater tooling investment

- Part complexity: Intricate designs demand appropriate die capabilities

- Material characteristics: Different metals respond differently to various die configurations

- Quality requirements: Precision die & stamping applications may require specific die types to achieve required tolerances

- Timeline constraints: Some die types offer faster development cycles than others

Understanding these relationships helps you have informed conversations with your tooling partners—and ensures your stamping operation delivers the results your business needs. With die types clarified, the next critical decision involves the materials your tooling is made from, which directly affects tool life, precision, and long-term performance.

Tool Steel Selection and Material Considerations

You've selected the right die configuration for your project. Now comes a decision that separates tooling that lasts from tooling that fails prematurely: material selection. Here's what many die makers won't tell you upfront—the steel grade you choose affects everything from dimensional accuracy on part number one million to how often you'll be replacing punches mid-run.

Different stamping operations place vastly different demands on tool steels. A hardened punch blanking 0.5mm aluminum faces entirely different stresses than one piercing 3mm high-strength steel. Understanding these distinctions helps you specify tooling that performs—and keeps performing—throughout your production program.

Tool Steel Grades and Their Performance Characteristics

When suppliers from Arizona tool steel distributors to specialty metallurgical houses discuss stamping applications, four steel categories dominate the conversation: D2, A2, S7, and carbide materials. Each brings distinct advantages depending on your workpiece material, production volume, and precision requirements.

D2 Tool Steel has earned its reputation as the workhorse of steel stamping tools. With approximately 12% chromium content, D2 delivers exceptional wear resistance and edge retention. According to Dayton Lamina's technical research, the carbides formed when alloys like chromium combine with carbon during solidification provide the particles that resist abrasive and adhesive wear damage. However, that same high alloy content makes D2 more brittle than alternatives—a critical consideration for applications involving impact or shock loading.

A2 Tool Steel offers a different balance. While it sacrifices some wear resistance compared to D2, A2 provides superior toughness and dimensional stability during heat treatment. This makes it ideal for precision stamping applications where maintaining tight tolerances matters more than maximum edge life. Many manufacturers choose A2 for steel tooling applications involving moderate production runs where occasional resharpening is acceptable.

S7 Tool Steel represents the toughness end of the spectrum. When your application involves shock loading, S7 resists chipping and cracking better than D-series grades. Think heavy blanking operations or stamping thick materials where each press stroke delivers significant impact to the cutting edge. The trade-off? S7 wears faster than D2, so you'll need more frequent maintenance intervals.

Carbide Tooling (tungsten carbide grades like K10, K20, K30) delivers exceptional hardness—far beyond any tool steel. Industry analysis confirms carbide's exceptional hardness makes it ideal for precise cutting edges and shearing segments. The limitation? Carbides are brittle and typically used as inserts within a tougher steel body rather than for entire die components.

Key Properties That Drive Performance

When evaluating tool steels for your stamping operation, four properties determine real-world performance:

- Hardness (HRC ratings): Measured on the Rockwell C scale, hardness indicates resistance to deformation. D2 typically achieves 58-62 HRC; A2 reaches 57-62 HRC; S7 runs 54-58 HRC. Higher hardness generally means better wear resistance but reduced toughness

- Toughness: The steel's ability to resist breakage, chipping, or cracking under impact. S7 leads this category, followed by A2, with D2 trailing. According to metallurgical research, tool steel toughness decreases as alloy content increases

- Wear resistance: How well the steel resists abrasion from contact with workpiece materials, other tools, or contaminants like scale and grit. Increased alloy content typically means increased wear resistance because more carbides are present in the steel

- Machinability: How easily the steel can be machined before hardening. This affects tooling lead times and modification costs. A2 machines more easily than D2, which becomes significantly harder to work once heat-treated

Matching Tooling Materials to Production Demands

Sounds complex? Here's how experienced toolmakers approach material selection in practice:

When stamping aluminum and aluminum alloys, the challenge isn't hardness—it's adhesion. Aluminum tends to stick to tooling surfaces, increasing friction and degrading part quality. Recommendations include A2 or M2 steels with PVD coatings like TiCN that reduce the friction coefficient.

For high-strength steels (DP, CP grades), the demands escalate. These materials require D2, PM M4, or ASP 23 powder steels to withstand the increased stamping pressures. Surface coatings become essential rather than optional.

When working with ultra-high-strength steels (TRIP, PHS, martensitic grades), conventional tool steels often fail prematurely. Powder metallurgy steels like ASP 30 or CPM 10V, carbide inserts, or hybrid tools combining hard surfaces with tough cores become necessary for acceptable tool life.

How Material Selection Affects Dimensional Accuracy

Here's what competitors rarely discuss: your tool steel choice directly impacts how well your stamped parts hold tolerances over extended production runs. Consider compressive strength—a measurement of the maximum load tooling can withstand before deforming. According to technical research, alloy elements like molybdenum and tungsten contribute to compressive strength, while higher hardness also improves this property.

When a hardened punch begins deforming under load, your part dimensions drift. This happens gradually—often imperceptibly at first—until quality inspections start flagging out-of-tolerance conditions. Selecting a tool steel with adequate compressive strength for your specific application prevents this dimensional creep.

Proper heat treatment is equally critical. Each grade of tool steel has specific heat treating guidelines that must be followed to achieve optimum results for stamping applications—which differ significantly from cutting tool applications. The heat treatment process transforms the steel's microstructure, achieving the hardness and toughness balance your application demands.

Understanding these material considerations positions you to specify tooling that delivers consistent quality throughout its service life. But even the best steel requires proper maintenance to perform—which brings us to the often-overlooked topic of tooling lifecycle management.

Design Principles for Effective Stamping Tooling

You've selected the right die type and specified quality tool steels. Now comes the engineering discipline that separates functional tooling from truly exceptional manufacturing performance: design parameters. Here's what experienced metal stamping die manufacturers understand that rarely appears in basic tutorials—the geometric relationships within your tooling determine whether you produce clean, dimensionally accurate parts or spend production time fighting burrs, cracks, and dimensional drift.

Think of die design as a physics problem with real consequences. Every clearance dimension, every punch angle, every radius you specify creates stress patterns in the workpiece material. Get these relationships right, and the metal flows predictably into your desired shape. Get them wrong, and you'll see the evidence in every reject bin.

Clearance Calculations That Prevent Defects

Die clearance—the gap between punch cutting edge and die opening—ranks as the single most critical parameter in metal stamping tool design. According to Mate Precision Technologies' technical documentation, proper die clearance directly affects tool life, stripping performance, burr height, hole quality, and punching force requirements.

Here's what happens at the microscopic level during a punch stroke: as the punch penetrates the material, shear cracks propagate from both the punch edge and die edge. When clearance is correct, these fracture lines meet cleanly, producing a part with minimal burr and consistent edge quality. When clearance is wrong, everything goes sideways.

Too Tight Clearance creates secondary shear cracks because the material lacks space to fracture naturally. The consequences cascade:

- Punching force increases dramatically, accelerating tool wear

- Excessive heat builds up, potentially softening cutting edges

- Galling occurs as material adheres to punch surfaces

- Tool life decreases by 30-50% compared to optimal clearance

- Parts exhibit work-hardened burrs that resist secondary finishing

Excessive Clearance eliminates controlled shearing, turning the process into uncontrolled tearing:

- Large rollover forms on the punch side of the hole

- Increased burr height and thickness on die side edges

- Slug pulling problems as oversized slugs resist ejection

- Dimensional inconsistency as material distorts during cutting

- Poor hole quality with rough, irregular fracture zones

So what's the right clearance? It depends on your material type and thickness. Industry guidelines provide starting points:

| Material Type | Thickness Range | Total Clearance (% of Thickness) |

|---|---|---|

| Aluminum | Less than 0.098" (2.50mm) | 15% |

| Aluminum | 0.098" to 0.197" (2.50-5.00mm) | 20% |

| Mild Steel | Less than 0.118" (3.00mm) | 20% |

| Mild Steel | 0.118" to 0.237" (3.00-6.00mm) | 25% |

| Stainless Steel | Less than 0.059" (1.50mm) | 20% |

| Stainless Steel | 0.059" to 0.157" (1.50-4.00mm) | 25-30% |

These percentages represent total clearance—the sum of gaps on both sides of the punch. Experienced metal stamping design engineers refine these starting values based on specific material grades, surface finish requirements, and production volume expectations.

Geometry Optimization for Clean Cuts and Forms

Beyond clearance, punch and die geometry directly influences part quality and tool longevity. Understanding how these elements interact with your workpiece material prevents defects before they occur.

Punch-to-Material Thickness Ratios establish limits for what's physically achievable. As technical guidelines indicate, standard tooling in aluminum can punch holes with diameters as small as 0.75 times material thickness. In mild steel, that ratio increases to 1:1. For stainless steel, you'll need punch diameters at least twice the material thickness. Pushing beyond these limits causes punch deflection, accelerated wear, and eventual breakage.

Corner Radii deserve careful attention. Sharp corners concentrate stress, wear faster than straight edges, and produce parts with crack-prone features. Adding minimum radii of 0.010" (0.25mm) on angles under 45 degrees helps overcome rapid wear while improving part integrity. For metal stamping and forming applications, generous radii also allow material to flow more smoothly during bending operations.

Understanding Cold-Forming Process Dynamics

Cold forming—deforming metal at room temperature through force rather than heat—follows predictable physical principles that inform good stamping design. According to Luvata's engineering guidance, the process maintains and enhances grain flow in the metal, producing parts with excellent strength and fatigue characteristics.

However, the cold-forming process has distinct requirements:

- Symmetry matters: Rotational features like shafts and pins form more reliably than asymmetric geometries

- Gradual transitions work best: Fillets instead of sharp corners, tapers instead of abrupt steps allow material to flow smoothly and protect tooling

- Wall thickness has limits: Each material has minimum and maximum wall thickness capabilities before rupture or irregular flow occurs

- Grain orientation affects strength: Load-bearing features should align with grain flow patterns created during forming

For metal stamping techniques involving bends and forms, the material's ductility becomes critical. Mild steel cold forms well because of excellent ductility combined with sheet strength. Stainless steel works but requires more force. Aluminum forms easily but may need design accommodations due to lower tensile strength.

Design Sequence for Optimal Results

Professional tooling design follows a structured sequence that addresses each parameter in logical order. Following this progression prevents costly redesigns and ensures all factors receive appropriate consideration:

- Material Analysis: Document the workpiece material's shear strength, ductility, thickness tolerance, and grain direction. These properties establish the boundaries for all subsequent decisions

- Feature Assessment: Identify critical dimensions versus non-critical features. Apply tight tolerances only where functionality demands—tightening dimensions everywhere just adds cost without value

- Clearance Specification: Calculate die clearances based on material type and thickness using established guidelines, then adjust for specific quality requirements

- Geometry Definition: Specify punch and die profiles including corner radii, draft angles, and surface finishes. Avoid sharp corners and sudden thickness changes that create stress concentrations

- Force Calculation: Determine required tonnage to ensure press capacity accommodates the design. Include safety margins for tool dulling, which increases required force over time

- Strip Layout Optimization: For progressive dies, engineer the strip layout to balance material utilization against station spacing and pilot requirements

- Simulation Validation: Before cutting steel, validate designs using FEA software to identify potential springback issues, material flow problems, or stress concentrations

Preventing Common Quality Problems

Proper design anticipates and prevents the defects that plague poorly engineered tooling. Here's how design choices connect to specific quality outcomes:

Excessive Burrs typically trace back to incorrect clearance, dull tools, or misaligned stations. Design solutions include specifying appropriate clearances for your material, incorporating "clearance corners" on rectangular dies to maintain uniform gaps, and planning maintenance access for easy resharpening.

Part Cracking often results from sharp corners, insufficient bend radii, or forming operations that exceed material ductility. Incorporate generous radii at all transition points, orient critical bends perpendicular to grain direction when possible, and specify forming lubricants for challenging operations.

Dimensional Drift over production runs indicates tool wear, thermal expansion, or insufficient material clamping. Design features that address these issues include specifying tool steels with adequate wear resistance for your volume, incorporating cooling channels for high-speed operations, and ensuring positive material location throughout each operation sequence.

According to comprehensive tooling research, achieving consistent, reliable stamping results requires understanding both the science driving material behavior and the engineering principles that control it. Elite tooling designers balance all these parameters simultaneously—recognizing that a change in one area ripples through the entire system.

With solid design principles established, the next critical factor in tooling success involves maintaining that precision over time. Proper lifecycle management determines whether your investment continues delivering quality parts or gradually degrades into a source of production problems.

Tooling Maintenance and Lifecycle Management

You've invested in quality tooling with proper design and premium materials. Now here's the uncomfortable truth most die makers won't volunteer: even the best stamping dies become expensive scrap metal without disciplined maintenance. The difference between tooling that delivers millions of consistent parts and tooling that creates production nightmares often comes down to what happens between press runs.

Think of tooling maintenance like vehicle service. Skip oil changes long enough, and that precision-engineered engine fails catastrophically. The same principle applies to your stamping dies—except the consequences include rejected parts, missed shipments, and emergency repair costs that dwarf what preventive maintenance would have required.

Extending Tool Life Through Proactive Maintenance

Preventive maintenance transforms tooling from a depreciating asset into a reliable production resource. According to industry research, well-maintained equipment reduces unexpected breakdowns while preventing costly production halts. The key lies in addressing minor issues during planned downtimes rather than discovering problems mid-run.

What does an effective maintenance program look like in practice? Here's what quality tool and stamping operations implement:

- Visual Inspections (After Every Production Run): Check cutting edges for chips, cracks, or unusual wear patterns. Examine working surfaces for galling, scoring, or material buildup that indicates lubrication issues

- Sharpening Intervals (Based on Hit Count): Establish resharpening schedules tied to actual production counts rather than calendar time. Most operations track hits per tool and trigger maintenance at predetermined thresholds—typically before edge degradation affects part quality

- Alignment Verification (Weekly or Bi-Weekly): Measure and document die alignment to catch drift before it creates dimensional problems. Small misalignments compound over time, eventually causing uneven wear and part defects

- Lubrication Checks (Daily During Production): Verify proper lubricant delivery to all critical surfaces. Inadequate lubrication accelerates wear exponentially and generates heat that can soften cutting edges

- Clearance Measurement (Monthly or Quarterly): Track die clearances at critical stations. As tools wear, clearances increase—eventually producing burrs and edge quality issues

Beyond surface inspections, advanced techniques catch problems invisible to the naked eye. Technical analysis recommends ultrasonic testing and magnetic particle inspection for identifying subsurface flaws that could lead to sudden tool failure. These methods matter especially for high-volume operations where unexpected die breakage halts entire production lines.

Recognizing Early Warning Signs of Tool Wear

Experienced operators develop almost intuitive abilities to spot trouble before quality reports confirm it. Here's what to watch for:

- Increased Burr Height: Burrs growing beyond established limits indicate cutting edges have dulled or clearances have opened beyond specification

- Dimensional Drift: Parts gradually trending toward tolerance limits suggest progressive wear requiring intervention

- Surface Finish Changes: Scratches, galling marks, or inconsistent textures signal lubrication problems or material buildup on forming surfaces

- Increased Press Force: Rising tonnage readings for the same operation indicate dull tools requiring more force to cut or form material

- Unusual Sounds: Changes in the acoustic signature during stamping—grinding, squealing, or irregular impacts—often precede visible quality problems

- Slug Behavior: Slugs sticking, tilting, or ejecting inconsistently point to punch wear or die clearance issues

The critical insight? Address these warning signs immediately. Continuing production with degraded tooling doesn't just create scrap—it accelerates wear on components that might otherwise have survived with timely maintenance.

Tooling Inventory Management Best Practices

Imagine discovering your critical die needs a replacement punch—and the spare you thought existed is actually sitting in another facility or was consumed months ago without documentation. Poor tooling inventory management creates exactly these scenarios, transforming minor maintenance needs into major production delays.

According to inventory management research, effective tool crib management delivers measurable benefits: reduced tool-related downtime, lower procurement costs, and improved resource allocation. The foundation involves several interconnected practices:

- Comprehensive Cataloging: Document every tool and spare component with unique identifiers, current condition, location, and usage history. This baseline enables everything else

- Real-Time Tracking: Implement barcode or RFID systems for monitoring tool movements. Tool crib software solutions provide instant visibility into what's available, what's in use, and what's out for maintenance

- Maintenance Integration: Link inventory systems to maintenance schedules so resharpening, reconditioning, and replacement activities update records automatically

- Reorder Triggers: Configure alerts when spare inventory drops below minimum thresholds. Automated notifications prevent the "we're out of punches" emergencies that halt production

- Usage Analytics: Track consumption patterns to optimize spare inventory levels. Data reveals which components wear fastest and where backup investments deliver the greatest production protection

Modern tool crib software platforms extend these capabilities with cloud-based access, mobile apps for floor-level updates, and integration with ERP systems. For operations managing tooling across multiple facilities or production lines, centralized visibility prevents the inventory blind spots that cause delays.

Connecting Maintenance to Bottom-Line Results

Here's the business case for disciplined maintenance: industry data confirms that regular inspections, timely sharpening, and proper lubrication extend tooling lifespan significantly while enhancing operational durability. This proactive approach avoids the financial burden of emergency repairs and unplanned downtime.

Consider the true cost comparison. Emergency die repair typically involves premium expedite charges, production line stoppage, potential missed customer shipments, and overtime labor to recover schedule. Contrast this with scheduled maintenance performed during planned downtimes, using stocked spare components, with production impact measured in hours rather than days.

Effective tooling inventory management amplifies these savings. When spare punches, die inserts, and wear components are tracked and stocked appropriately, maintenance happens on your schedule—not when failures force your hand. The small investment in proper tracking systems and safety stock pays dividends through predictable operations and consistent part quality.

With maintenance fundamentals established, the next logical question becomes: how do you evaluate whether your tooling investments actually deliver adequate returns? Understanding the true cost structure of stamping tooling helps you make smarter decisions about initial purchases, maintenance intensity, and upgrade timing.

Cost Analysis and ROI for Tooling Investments

Here's what separates manufacturers who thrive from those who struggle with stamping economics: understanding that tooling costs follow an asymptotic curve, not a straight line. The cheapest die rarely delivers the lowest total cost—and the most expensive option doesn't guarantee the best returns. Getting this calculation right determines whether your stamping tooling becomes a competitive advantage or a financial burden.

Most cost discussions focus narrowly on the initial purchase price. That's like evaluating a car based solely on the sticker without considering fuel economy, maintenance, or resale value. Smart manufacturers evaluate the complete financial picture across the entire production lifecycle.

Calculating True Tooling Costs Beyond Initial Investment

According to automotive stamping cost analysis, the fundamental estimation formula is: Total Cost = Fixed Costs (Design + Tooling + Setup) + (Variable Cost/Unit × Volume). This straightforward equation conceals significant complexity when applied to real manufacturing decisions.

Fixed costs represent your "sunk" investment before the first production part runs. These include:

- Tooling fabrication: Custom die costs range dramatically—from approximately $5,000 for simple blanking dies to over $100,000 for complex progressive dies with multiple forming stations

- Engineering design: CAD development, FEA simulation, and design validation hours add to upfront investment

- Tryout and calibration: The initial phase where tooling is adjusted to produce parts within specification

- Quality documentation: For automotive applications, PPAP (Production Part Approval Process) requirements add inspection fixtures, CMM time, and engineering hours

Variable costs accumulate with every part produced. Material often accounts for 60-70% of the variable piece price, followed by machine hourly rates (determined by press tonnage and energy consumption), labor, and overhead. For precision stamping products, these ongoing costs determine long-term profitability.

Here's the critical insight: spreading fixed costs over larger volumes fundamentally changes your economics. A progressive die costing $80,000 that produces 500,000 parts adds just $0.16 per part. That same die producing only 5,000 parts adds $16.00 per part—often making the project unviable regardless of how efficiently variable costs are managed.

Volume Thresholds That Justify Tooling Upgrades

When does investing in more sophisticated stamping tooling make financial sense? Industry analysis breaks this into clear volume tiers:

Low Volume (Under 10,000 parts): For low volume metal stamping applications, high-quality hardened tooling often doesn't pencil out. Consider soft tooling using zinc-based alloys or non-heat-treated steel. These alternatives cost less, produce faster, and work adequately for prototypes or limited runs. The trade-off—shorter tool life and reduced precision—matters less when you're not amortizing costs across millions of parts.

Mid Volume (10,000 to 100,000 parts): At this threshold, durable hardened steel tooling becomes justifiable. The cost per part decreases meaningfully, and the quality improvements from precision tooling start delivering value. Progressive and transfer dies become viable options, offering efficiency gains that offset their higher initial investment.

High Volume (Over 100,000 parts): Here, advanced tooling investments pay substantial dividends. The focus shifts to maximizing production efficiency and maintaining consistent quality over extended runs. Automation integration, premium tool steels, and complex multi-station dies deliver the lowest total cost of ownership despite commanding the highest upfront prices.

Comparing Tooling Investment Tiers

Understanding how different tooling approaches compare across key cost factors helps you make informed investment decisions. This breakdown illustrates the trade-offs across stamping applications:

| Tooling Tier | Initial Investment | Per-Part Cost Impact | Maintenance Requirements | Expected Lifespan |

|---|---|---|---|---|

| Soft Tooling (Prototype) | $1,000 - $5,000 | High ($2.00 - $10.00+) | Frequent resharpening; limited repair options | 1,000 - 10,000 hits |

| Standard Hardened Dies | $5,000 - $25,000 | Moderate ($0.50 - $2.00) | Regular maintenance; annual reconditioning | 100,000 - 500,000 hits |

| Progressive Dies | $25,000 - $100,000+ | Low ($0.05 - $0.50) | Scheduled maintenance; 2-5% annual die maintenance budget | 500,000 - 2,000,000+ hits |

| Premium/Carbide Tooling | $50,000 - $150,000+ | Very Low ($0.02 - $0.20) | Minimal frequency; specialized service required | 1,000,000+ hits guaranteed |

Notice how the relationship between initial investment and per-part cost inverts as you move up the tiers. A "1 million strike" guarantee—common with premium tooling—means the die is built from high-grade hardened steel engineered to produce one million parts before requiring major refurbishment. This effectively caps your tooling cost per unit at negligible levels for high-volume programs.

Decision Framework for Tooling Selection

Making smart tooling investments requires evaluating multiple factors simultaneously. Work through this sequence when assessing your options:

- Calculate break-even volumes: Determine the production quantity where higher-tier tooling costs less per part than simpler alternatives. For most stamping applications, this occurs between 10,000 and 20,000 parts

- Assess lifetime production needs: Consider not just initial orders but anticipated reorders, engineering changes, and program duration. A three-year program with steady demand justifies different tooling than a one-time prototype run

- Factor quality requirements: Precision stamping products for automotive or medical applications may demand tooling precision that eliminates lower-tier options regardless of volume

- Include hidden costs: Secondary operations, scrap rates, inspection requirements, and rework all affect true per-part costs. Superior tooling often eliminates these expenses entirely

- Budget for maintenance: Plan for 2-5% of tooling cost annually for die maintenance. This preserves your investment and maintains part quality throughout the production lifecycle

The strategic goal isn't minimizing initial spending—it's optimizing Total Cost of Ownership across your program's full duration. Sometimes that means paying more upfront; sometimes it means accepting simpler tooling for limited runs. The key is matching your investment level to your actual production reality.

With cost fundamentals established, the next consideration involves how different industries impose unique requirements on tooling decisions. Automotive, aerospace, electronics, and medical applications each demand distinct approaches to precision, certification, and material selection.

Industry-Specific Tooling Requirements

Here's something generic tooling guides won't tell you: a stamping die that performs flawlessly for consumer electronics could fail catastrophically in an automotive application—even if the parts look nearly identical on paper. Different industries impose radically different demands on metal stamping tooling, from certification requirements that add months to your development timeline to tolerance specifications that push the boundaries of what's physically achievable.

Understanding these industry-specific requirements helps you specify tooling that actually meets your customer's expectations—not just the dimensions on the print. Whether you're producing steel stamping parts for vehicle structures or aluminium stamping parts for aerospace assemblies, the sector you're serving shapes every tooling decision.

Automotive Stamping Demands and Certification Requirements

Automotive applications represent the most demanding segment for stamping components, combining extreme precision requirements with rigorous quality management certification. When you supply a metal stamped part to an OEM or Tier 1 supplier, you're entering a world where documentation matters as much as the part itself.

The foundation of automotive tooling requirements is IATF 16949 certification—the global quality management standard established by the International Automotive Task Force to ensure consistent quality throughout the supply chain. This isn't optional for serious automotive suppliers; it's table stakes for even being considered for production programs.

What does IATF 16949 mean for your tooling decisions?

- Process Validation: Every stamping die must demonstrate capability through documented tryout procedures, dimensional studies, and production trials before volume manufacturing begins

- Measurement System Analysis: Your inspection fixtures and gauging systems require validation to confirm they can reliably detect part variation

- Statistical Process Control: Tooling must produce parts with sufficient capability margins (typically Cpk ≥ 1.33) to maintain quality throughout production runs

- Traceability: Complete documentation linking each die to its design specifications, material certifications, heat treatment records, and maintenance history

- Continuous Improvement: Systematic processes for identifying and eliminating sources of variation in your stamping operation

Beyond certification, automotive stamping presents unique technical challenges. High-strength steels (DP, TRIP, and press-hardened grades) now dominate structural applications, requiring tooling materials and designs that withstand significantly higher stamping forces. Springback compensation becomes critical—parts that look perfect in the die can distort unpredictably after forming.

This is where advanced CAE (Computer-Aided Engineering) simulation proves essential. Modern forming simulation software predicts material behavior, identifies potential defects before cutting steel, and optimizes die geometry for consistent results. Companies like Shaoyi leverage CAE simulation capabilities alongside IATF 16949 certification to deliver precision stamping die solutions with first-pass approval rates exceeding 93%—a significant advantage when development timelines are compressed.

Aerospace: Where Tolerances Push Physical Limits

If automotive requirements seem demanding, aerospace applications raise the bar further. When a stamping component goes into aircraft structures, the tolerance expectations and material challenges intensify dramatically.

- Tolerance Specifications: Aerospace drawings routinely specify tolerances of ±0.001" (0.025mm) or tighter on critical features—dimensions that approach the limits of what stamping processes can reliably achieve

- Material Complexity: Aluminum stamping tools must handle high-strength aerospace alloys (2024-T3, 7075-T6) that work-harden aggressively and demand precise forming parameters

- Exotic Alloys: Titanium, Inconel, and other specialty materials require tooling with extreme wear resistance—often carbide or specially coated surfaces

- Surface Integrity: Fatigue-critical parts cannot tolerate surface defects, requiring tooling that produces consistently smooth surfaces without scratches, tool marks, or micro-cracks

- First Article Inspection: Comprehensive dimensional verification of initial production parts, often requiring 100% inspection of all features

Aerospace certification (typically AS9100) adds documentation requirements comparable to IATF 16949, with particular emphasis on material traceability and special process controls. For stamping operations, this means maintaining complete records linking each lot of aluminium stamping parts back to specific material heat lots and processing parameters.

Electronics: Miniaturization and Material Variety

Electronics stamping operates at a different scale than automotive or aerospace applications. Here, the challenges center on miniaturization, high-speed production, and the diversity of materials processed.

- Micro-Features: Lead frames, connector terminals, and shielding components often require features smaller than 0.005" (0.127mm)—demanding specialized tooling with extreme precision

- Material Diversity: A single electronics supplier might stamp copper alloys, phosphor bronze, beryllium copper, nickel silver, and various stainless grades—each requiring different clearances and tool steels

- High-Speed Production: Progressive dies running at 400+ strokes per minute demand tooling designed for thermal management and minimal lubrication

- Plating Compatibility: Many electronics parts receive subsequent plating operations, requiring stamped surfaces free from contamination that could interfere with coating adhesion

- ESD Considerations: For sensitive electronic components, tooling and handling systems may need electrostatic discharge protection

Electronics manufacturers also increasingly require labeling services for metal stamping to support component traceability throughout complex supply chains. This integration of identification marking into the stamping process adds another dimension to tooling requirements.

Industry-Specific Tolerances and Material Challenges

Medical device stamping combines elements from multiple sectors while adding unique regulatory dimensions. When stamping components go into implants, surgical instruments, or diagnostic equipment, the stakes—and requirements—escalate accordingly.

- Biocompatibility: Materials must meet ISO 10993 biocompatibility requirements, limiting options to specific stainless steel grades, titanium, and specialty alloys

- Surface Finish: Implant components often require mirror-polished surfaces (Ra < 0.1 μm) that start with exceptional as-stamped quality

- Burr-Free Edges: Medical parts typically cannot tolerate any burrs that might damage tissue or harbor bacteria—requiring tooling that produces essentially burr-free edges consistently

- Dimensional Precision: Tolerances comparable to aerospace, with particular attention to features that interface with other surgical components

- Clean Room Compatibility: Some medical stamping operations occur in controlled environments, requiring tooling designed for minimal particulate generation

- Validation Requirements: FDA regulations demand process validation demonstrating consistent capability—tooling must perform identically across production lots

The medical sector also imposes unique documentation requirements through 21 CFR Part 820 (Quality System Regulation) and ISO 13485 certification. These standards mandate rigorous design controls, risk analysis, and validation protocols that affect tooling development from initial concept through production release.

Matching Tooling Approach to Industry Demands

What does this industry analysis mean for your tooling decisions? Each sector requires a calibrated approach:

- Automotive: Prioritize certification compliance and simulation-validated designs. Partner with toolmakers who understand IATF 16949 requirements and can deliver documented processes. For rapid development cycles, seek suppliers offering rapid prototyping capabilities—some deliver functional samples in as little as 5 days

- Aerospace: Invest in premium tool steels and carbide components for exotic material applications. Build extended tryout time into schedules to achieve the tight tolerances these applications demand

- Electronics: Focus on tooling precision and multi-material capability. High-speed production requirements favor progressive dies with robust thermal management

- Medical: Emphasize surface quality and burr-free performance from initial design. Build validation protocols into your tooling development process from the start

Understanding these industry-specific demands helps you communicate effectively with tooling partners and specify dies that actually meet your application requirements. The next step? Building a practical framework for evaluating your own tooling needs and making smart decisions for your specific operation.

Making Smart Tooling Decisions for Your Operation

You've absorbed the technical fundamentals—die types, material science, design principles, maintenance protocols, cost analysis, and industry-specific requirements. Now comes the practical question every manufacturing professional faces: how do you translate this knowledge into actionable decisions for your specific operation? Whether you're launching a new product line, optimizing existing processes, or evaluating potential tooling partners, a systematic approach prevents costly missteps.

Here's the reality most metal stamping manufacturers won't advertise: the "best" tooling solution doesn't exist in isolation. What works brilliantly for one operation becomes a financial disaster for another. The secret lies in matching your tooling investment to your actual production reality—not theoretical ideals or what worked for someone else's project.

Building Your Tooling Strategy

Before requesting quotes or reviewing die designs, work through this evaluation sequence. Each step builds on the previous, creating a foundation for informed decision-making:

- Define Your Volume Reality: Calculate total lifetime production requirements, not just initial orders. Include anticipated reorders, engineering change volumes, and program duration. A custom metal stamping tool justified for 500,000 parts becomes questionable at 50,000—and vice versa

- Establish Critical Quality Parameters: Identify which dimensions and features are truly critical versus which carry standard tolerances. Tightening everything adds cost without value; focusing precision where it matters delivers quality tool & stamping results economically

- Map Your Material Requirements: Document workpiece materials, thickness ranges, and any special characteristics (high-strength grades, surface finish requirements, coating compatibility). Material properties constrain tooling options and influence cost

- Assess Timeline Constraints: Determine whether your schedule prioritizes fast prototyping or optimized production ramp-up. According to manufacturing research, CNC machining typically enables faster initial production, while stamping requires longer tooling development but offers superior production speeds once established

- Calculate Budget Boundaries: Establish both upfront investment limits and target per-part costs. Remember that tooling decisions affect total program economics—not just the line item for die purchases

- Evaluate Design Stability: Consider how likely engineering changes are during production. Stable, mature designs justify higher tooling investments; evolving products may benefit from more flexible (though potentially costlier per-part) approaches

- Identify Certification Requirements: Determine whether your application demands specific quality certifications (IATF 16949 for automotive, AS9100 for aerospace, ISO 13485 for medical). These requirements shape partner selection and add development timeline

Working through this sequence before engaging suppliers positions you to have substantive conversations about your actual needs—not generic discussions about capabilities you may not require.

Selecting the Right Tooling Partner

Your tooling supplier becomes an extension of your engineering team. According to industry guidance, the distinction between a supplier and a true partner matters significantly. A supplier fulfills orders; a partner assists with design optimization, manufacturing solutions, and ongoing support.

When evaluating potential metal stamping manufacturers, assess these critical capabilities:

- Design Engineering Support: Partners with in-house tooling design teams can optimize your parts for manufacturability before committing to production tooling—preventing costly redesigns later

- Prototyping Capabilities: Rapid prototyping services validate designs before full tooling investment. Some suppliers deliver functional prototypes in as little as 5 days, accelerating your development cycle

- Production Flexibility: Evaluate whether the partner can scale from prototype quantities through high-volume manufacturing. Maintaining supplier continuity through production phases simplifies quality management

- Secondary Services: In-house heat treatment, finishing, assembly, and packaging reduce supply chain complexity and lead times

- Industry Experience: Partners familiar with your specific industry understand relevant requirements and restrictions without requiring education from your team

Next Steps for Your Stamping Operation

Ready to apply these principles to your specific situation? Consider this practical action sequence:

For New Projects: Begin with a thorough production requirements analysis using the seven-step framework above. Engage potential partners early—before finalizing designs—to leverage their manufacturing expertise during the optimization phase. Request case studies demonstrating experience with similar applications.

For Existing Operations: Audit current tooling performance against the maintenance and lifecycle management principles covered earlier. Identify opportunities to upgrade worn dies or consolidate operations into more efficient configurations. Calculate whether volume changes justify tooling tier adjustments.

For Quality Improvements: If current tooling produces parts that require secondary finishing or generate excessive scrap, the root cause often traces back to design parameters or maintenance practices. Review clearances, material selections, and inspection protocols before assuming replacement is necessary.

For operations serving automotive markets specifically, the combination of IATF 16949 certification, advanced CAE simulation for forming analysis, and rapid prototyping capabilities creates significant competitive advantages. Companies like Shaoyi exemplify this integrated approach—delivering precision stamping die solutions with a 93% first-pass approval rate through engineering expertise that spans design optimization through high-volume manufacturing. Their ability to provide rapid prototyping in as little as 5 days while maintaining OEM-level quality standards demonstrates what experienced sheet metal stamping equipment partners can deliver.

The tooling decisions you make today determine your manufacturing performance for years to come. Invest the time to evaluate your requirements systematically, select partners who understand both design and production realities, and maintain your tooling investments with the discipline they deserve. The manufacturers who master these fundamentals don't just produce parts—they build sustainable competitive advantages that compound over time.

Frequently Asked Questions About Metal Stamping Tooling

1. Which tool is used for stamping?

Metal stamping uses specialized tooling including punch presses, dies, and forming components. The primary tools are stamping dies (progressive, compound, transfer, or combination types) paired with punches that apply force to shape sheet metal. Progressive dies are most common for high-volume production, featuring multiple stations that perform sequential operations as material advances through the tool. The specific tooling configuration depends on your part complexity, production volume, and precision requirements.

2. What are the different types of stamping tools?

The four main stamping die types are progressive dies (for high-volume, multi-operation parts), compound dies (for simple flat parts in a single stroke), transfer dies (for large or deep-drawn components), and combination dies (hybrid configurations for specialized needs). Each type serves distinct manufacturing requirements. Progressive dies excel at speed and consistency for 100K+ parts, while transfer dies handle complex geometries and deep drawing operations that other configurations cannot achieve.

3. What are the four types of metal stamping?

The four primary metal stamping types are progressive die stamping (parts remain on carrier strip through multiple stations), transfer die stamping (individual blanks moved between stations by mechanical fingers), deep draw stamping (forming parts with significant depth like cups and housings), and compound die stamping (multiple operations in a single press stroke). Selection depends on part geometry, volume requirements, and complexity level. High-volume automotive applications often use progressive dies, while deep-drawn components require transfer or specialized deep draw tooling.

4. How do I choose the right tool steel for stamping dies?

Tool steel selection depends on your workpiece material, production volume, and precision requirements. D2 tool steel offers excellent wear resistance for high-volume applications, A2 provides superior toughness and dimensional stability for precision work, S7 excels in shock-loading situations, and carbide tooling delivers maximum hardness for exotic materials. For aluminum stamping, A2 or M2 with PVD coatings work well. High-strength steels require D2 or powder metallurgy grades. Match hardness ratings (HRC), toughness, and wear resistance to your specific application demands.

5. What maintenance extends stamping tooling life?

Effective tooling maintenance includes visual inspections after every production run, sharpening intervals based on hit counts (not calendar time), weekly alignment verification, daily lubrication checks, and monthly clearance measurements. Watch for warning signs like increased burr height, dimensional drift, surface finish changes, and increased press force. Implementing tool crib software for inventory tracking prevents production delays from missing spare components. Regular maintenance can extend tooling lifespan significantly while reducing emergency repair costs and unplanned downtime.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —