Metal Forming Dies Exposed: From Raw Steel To Flawless Parts

Understanding Metal Forming Dies and Their Manufacturing Impact

Ever wondered how a flat sheet of steel transforms into a precisely curved automotive panel or an intricate electronic housing? The answer lies in metal forming dies - specialized tools that serve as the backbone of modern manufacturing. These precision-engineered instruments shape metal through controlled force and carefully designed geometry, enabling the mass production of complex components we rely on daily.

A die is used to cut, form, or shape material into precise geometries, often achieving micrometer-level tolerances. Unlike simple cutting tools, metal forming dies work by deforming materials like sheet metal using compression, tension, or both forces simultaneously. They rely on the material's mechanical properties to create permanent changes in shape without removing material.

The Foundation of Precision Metal Shaping

At its core, a die tool consists of matched components - typically a punch and a die block - that work together during each press stroke. The punch performs stretching, bending, or blanking operations, while the die block securely clamps the workpiece and provides complementary forming action. This partnership between components is what makes sheet metal forming so remarkably precise and repeatable.

Dies are not just tools - they are the DNA of production quality. A single precision die can produce millions of identical parts, each matching the original design specifications within microns.

Metal forming operations span a wide range of techniques, from simple bending and blanking to complex deep drawing and coining. Each operation requires dies specifically engineered for that purpose, with careful consideration given to material flow, clearances, and the mechanical properties of the workpiece.

Why Dies Matter in Modern Manufacturing

The investment value of quality dies extends far beyond initial tooling costs. Properly designed and maintained dies directly impact part quality, production uptime, and overall manufacturing efficiency. When you understand how these tools function, you gain a decision-making framework that helps evaluate suppliers, anticipate maintenance needs, and optimize production outcomes.

Throughout this article, you'll journey from foundational concepts through material selection, design principles, and lifecycle management. Whether you're specifying tooling for automotive body panels, electronic connector housings, or precision brackets, the knowledge ahead bridges the gap between basic introductions and technical product catalogs - giving you practical insights for real-world manufacturing decisions.

Types of Forming Dies and Their Applications

Now that you understand what metal forming dies are and why they matter, let's explore the different types available. Choosing the right die type can mean the difference between a streamlined production process and costly inefficiencies. Each category excels at specific forming operations - from simple blanking to intricate coining bending sequences - and understanding these distinctions helps you match tooling to your exact manufacturing requirements.

Progressive Dies for High-Volume Production

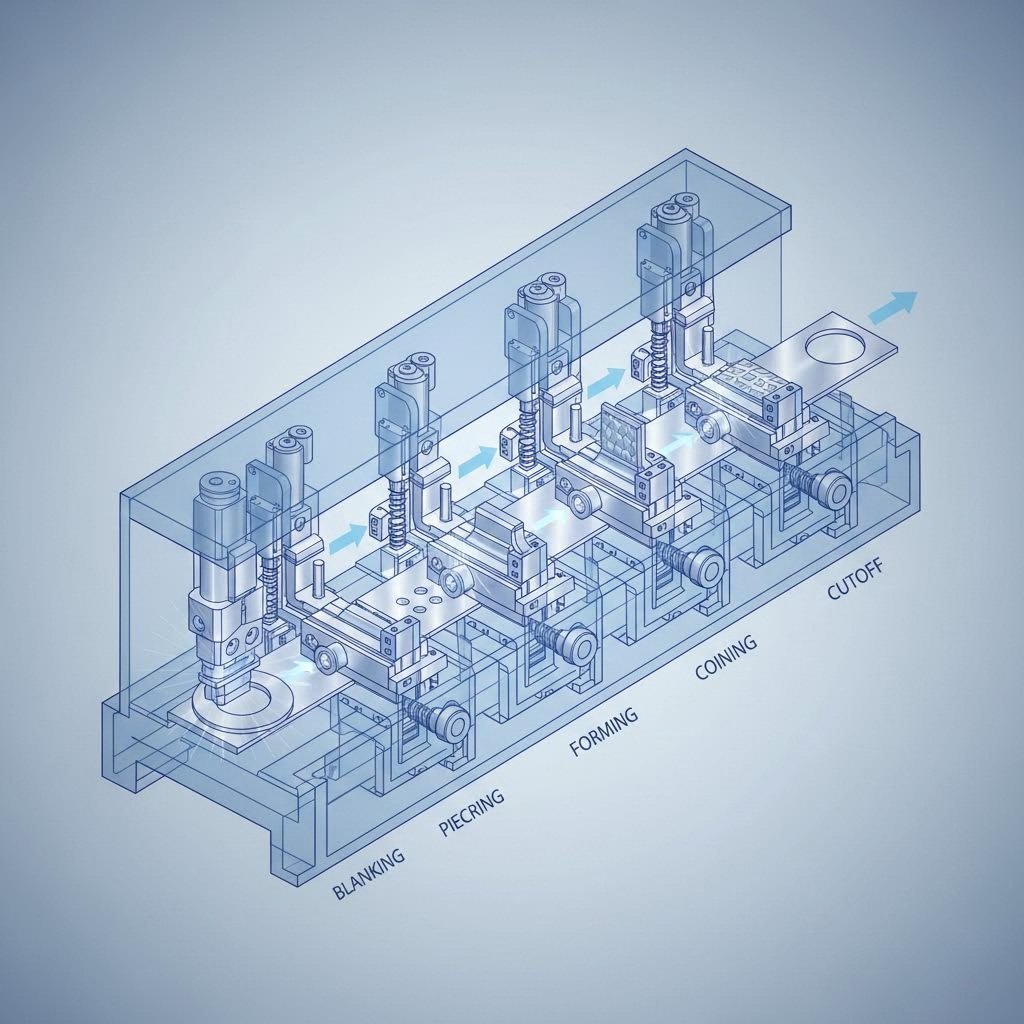

Imagine a strip of sheet metal moving through a series of stations, each performing a different operation until a finished part drops off the end. That's the beauty of progressive dies. These sophisticated tools arrange multiple stations in sequence, with the metal advancing through each stage during every press stroke.

Progressive dies handle different types of forming operations simultaneously - blanking at one station, piercing at the next, bending further along, and final trimming at the end. This die process eliminates manual handling between operations, dramatically increasing throughput while maintaining exceptional consistency.

Why do automotive manufacturers love progressive dies? They produce components like brackets, clips, and electrical connectors at speeds exceeding 1,000 parts per minute. Electronics companies rely on them for intricate connector housings requiring multiple precise features. When your production volume justifies the initial investment, progressive dies deliver unmatched efficiency and repeatability.

Transfer and Compound Die Applications

What happens when your parts are too large or complex for progressive dies? Transfer dies step in to solve this challenge. Unlike progressive dies where parts remain attached to the strip, transfer dies separate the workpiece early and mechanically move it between stations. This approach handles larger components and more complex assemblies that would be impractical to produce any other way.

Transfer dies shine in aerospace and heavy machinery applications. Think fuel tank shells, structural panels, or deep-drawn housings. The controlled transfer process maintains tight tolerances even on substantial components, making these dies indispensable for demanding forming operation requirements.

Compound dies take a different approach - they perform multiple operations in a single stroke. Need to blank a shape while simultaneously piercing holes? A compound die accomplishes both instantly. This efficiency makes them ideal for medium-volume production of moderately complex parts, particularly in medical device and consumer goods manufacturing.

For simpler requirements, single-station dies (also called simple dies) perform one operation per stroke. They're cost-effective, easy to maintain, and perfect for low to medium production volumes or straightforward tasks like basic cutting or bending.

Understanding Metal Forming and Coining Operations

Each die type excels at specific forming operations. Blanking dies cut flat shapes from sheet stock. Piercing dies punch precise holes. Forming dies reshape metal through bending, curling, or stretching. Drawing dies pull sheet metal into cavities for hollow shapes like cups or deep enclosures.

Then there's metal forming coining - a specialized high-precision operation. Coining dies apply extreme pressure to create detailed features with exceptional surface finish. Jewelry components, medical devices, and decorative elements often require this level of precision. The process produces sharp edges, fine details, and dimensionally accurate features that other methods simply cannot achieve.

| Die Type | Best Application | Production Volume | Complexity Level | Typical Industries |

|---|---|---|---|---|

| Progressive Dies | Multi-step parts from continuous strip | High (100,000+ parts) | High | Automotive, Electronics, Appliances |

| Transfer Dies | Large or deep-drawn components | High | Very High | Aerospace, Heavy Machinery, Automotive |

| Compound Dies | Multiple simultaneous operations | Medium to High | Medium | Medical Devices, Consumer Goods |

| Simple Dies | Single operations (cut, bend, punch) | Low to Medium | Low | General Manufacturing, Prototyping |

| Coining Dies | High-precision detailed features | Varies | High | Jewelry, Medical, Decorative Parts |

Matching Die Types to Your Requirements

So how do you choose? Start by evaluating three key factors: part complexity, production volume, and material type. Intricate components with multiple features often point toward progressive or transfer dies. Simpler geometries might only need compound or single-station solutions.

Production volume heavily influences economics. Progressive dies require significant upfront investment but deliver the lowest per-part cost at high volumes. For prototype runs or low-volume specialty parts, simpler forming dies make more financial sense despite higher unit costs.

Material considerations matter too. Different metals behave differently under stress. Aluminum flows easily but springs back more. High-strength steels require robust tooling and precise clearances. Your die selection must account for these material-specific behaviors to achieve consistent results.

With this foundation in die types established, the next critical decision involves selecting appropriate materials and coatings for the dies themselves - factors that directly determine tool longevity and performance under demanding production conditions.

Die Materials and Coatings for Extended Tool Life

Selecting the right die type is only half the equation. The materials and surface treatments you choose for your tooling dies directly determine how long they'll perform - and how consistently they'll produce quality parts. Think of it this way: even the most brilliantly designed die will fail prematurely if built from inadequate materials or left unprotected against the harsh realities of high-volume metal operation.

Die steel selection isn't just about picking the hardest material available. It's a careful balance between competing properties - hardness versus toughness, wear resistance versus machinability. Understanding these trade-offs helps you specify tooling that delivers optimal performance for your specific forming metal applications.

Tool Steel Grades for Demanding Applications

Three tool steel grades dominate the die tooling landscape, each engineered for distinct operating conditions. Your choice depends on the failures you're most likely to encounter - whether that's abrasive wear, impact cracking, or thermal fatigue.

D2 Tool Steel stands as the workhorse of cold work applications. This high-carbon, high-chromium steel offers exceptional wear resistance thanks to its abundant chromium carbides. With a typical working hardness of 58-62 HRC, D2 excels at blanking, piercing, and forming operations where abrasive wear dominates. According to The Fabricator, D2 is commonly chosen for forming stainless steel grades like 409 and 439 - though the high chromium content can cause adhesive bonding issues requiring additional coatings.

A2 Tool Steel provides a middle ground between wear resistance and toughness. Its air-hardening characteristics make it dimensionally stable during heat treatment, reducing distortion in complex die components. A2 typically achieves 57-62 HRC and works well for precision blanking dies, forming dies, and applications requiring tight tolerances after hardening.

S7 Tool Steel prioritizes toughness above all else. When your die components face shock loading - think heavy-duty stamping or operations with significant impact forces - S7 absorbs energy without cracking or chipping. Its working hardness ranges from 54-58 HRC, slightly lower than D2, but the trade-off delivers dramatically improved resistance to catastrophic failure.

- Hardness Ratings: D2 achieves 58-62 HRC; A2 reaches 57-62 HRC; S7 operates at 54-58 HRC

- Wear Resistance: D2 offers superior abrasive wear resistance; A2 provides good overall wear properties; S7 sacrifices some wear resistance for impact strength

- Toughness: S7 leads significantly; A2 offers moderate toughness; D2 is more brittle under shock loading

- Machinability: A2 machines most easily in annealed state; S7 follows closely; D2 presents the greatest machining challenge due to carbide content

When Carbide Components Make Sense

Sometimes even premium steel dies can't handle the punishment. Tungsten carbide components step in when production volumes climb into the millions or when forming abrasive materials like high-strength steels. Carbide inserts typically achieve hardness values of 85-92 HRA - dramatically harder than any tool steel.

The trade-off? Carbide is brittle and expensive. It excels at resisting abrasive wear but can crack under impact loading. Smart die design uses carbide strategically - inserting it at high-wear points like punch tips and cutting edges while using tougher steel dies for structural components. This hybrid approach maximizes tool life without the full cost of solid carbide construction.

For high-volume automotive stamping where dies might produce 500,000+ parts before maintenance, carbide-tipped punches often outperform solid steel alternatives by factors of two to one or more.

Material Selection Based on Workpiece Properties

What you're forming matters as much as how many parts you need. Different workpiece materials create distinct challenges for your die components.

Forming Steel: Carbon and mild steels respond well to D2 or A2 die components. Higher-strength steels demand harder die surfaces - consider carbide inserts or advanced coatings to combat accelerated wear.

Forming Aluminum: Aluminum's softness seems like it would be gentle on dies, but adhesive wear becomes the real enemy. Aluminum tends to gall and stick to tool surfaces, requiring polished dies with specialized coatings to prevent material transfer.

Forming Copper Alloys: Brass and bronze alloys can cause adhesive wear similar to aluminum. High-polish die surfaces and appropriate coatings minimize sticking while maintaining part quality.

Surface Treatments That Extend Tool Life

Raw tool steel rarely goes directly into production. Surface treatments dramatically extend die life by adding protective layers that resist wear, reduce friction, or both.

Nitriding produces a hard iron-nitride layer that penetrates into the steel surface. Research from the Auto/Steel Partnership confirms that nitriding performs better than chrome plating for high-load wear resistance because the thicker nitride layer better absorbs both vertical and tangential sliding loads. This treatment works particularly well on die components facing heavy stamping forces.

Chrome Plating creates a thin, hard surface coating that lowers friction and improves low-load wear resistance. However, chrome alone can chip, peel, or deform under high loads. The same research found that combining nitriding with chrome plating - called duplex chroming - significantly outperforms either treatment alone. Specifically, thin chrome over a nitrided substrate without a white layer delivered the best wear resistance across extended testing cycles.

PVD Coatings (Physical Vapor Deposition) deposit ultra-hard materials like titanium nitride or chromium nitride onto die surfaces. These coatings excel at preventing adhesive wear and material pickup, making them ideal for aluminum or stainless steel forming. Note that some PVD processes require high temperatures during application - tool steels with low tempering temperatures may soften during coating, potentially requiring rehardening.

Hardness Requirements by Production Volume

Your production expectations should guide hardness specifications. Low-volume runs might tolerate softer, tougher die materials that are easier to modify or repair. High-volume production demands maximum hardness and wear resistance to minimize maintenance interruptions.

For prototype and short runs under 10,000 parts, flame-hardened 4140 steel often suffices at lower cost. Medium volumes between 10,000-100,000 parts typically justify D2 or A2 with appropriate heat treatment. High-volume production exceeding 100,000 parts often requires premium steels with advanced coatings or carbide inserts at critical wear points.

Cost considerations extend beyond initial material prices. As industry experts note, the cost of downtime with lower-quality tool steel typically exceeds the premium paid for higher-quality materials. Some tool grades outperform traditional steels by margins of two-to-one, making the investment worthwhile for demanding applications.

With the right materials and coatings selected for your die components, the next step involves applying sound design principles that prevent manufacturing defects before they occur - principles that govern everything from punch clearances to springback compensation.

Die Design Principles That Prevent Manufacturing Defects

You've selected premium materials and coatings for your tooling. Now comes the real challenge - designing dies that consistently produce defect-free parts. Poor design decisions at this stage can undermine even the best materials, leading to splits, wrinkles, dimensional errors, and costly production delays. The good news? Proven design principles exist that prevent these problems before they start.

Die making combines engineering science with practical experience. What is die making at its core? It's the art of translating part requirements into tooling geometry that controls material flow, compensates for springback, and maintains tight tolerances across thousands or millions of production cycles. Let's break down the principles that separate successful dies from problematic ones.

Critical Clearances and Tolerances

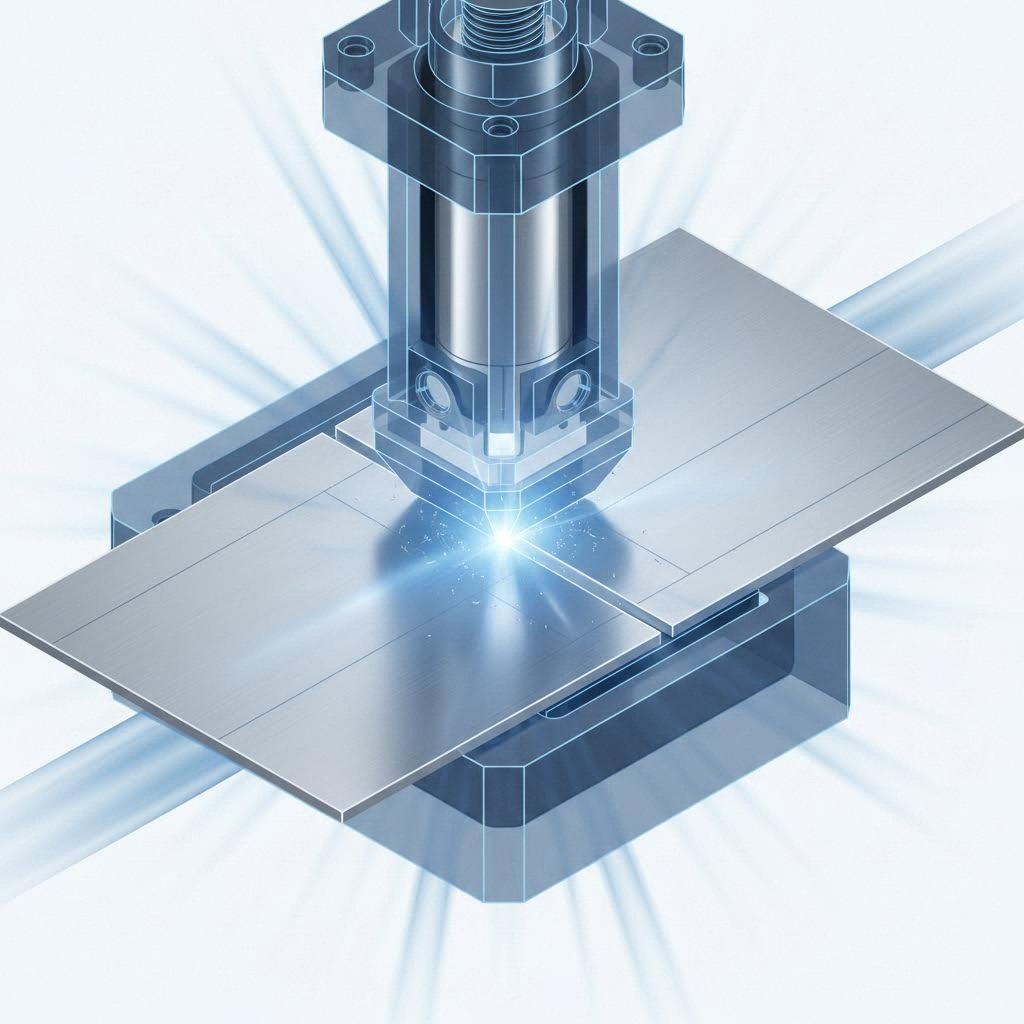

Punch-to-die clearance might seem like a minor detail, but it's actually one of the most consequential decisions in the entire metal forming process. Too little clearance causes excessive wear, galling, and premature tool failure. Too much clearance produces burrs, rough edges, and dimensional variation.

For blanking and piercing operations, optimal clearance typically ranges from 5% to 10% of material thickness per side - though this varies significantly based on material type. Soft aluminum might require clearances closer to 3-5%, while high-strength steel often needs 8-12%. Getting this right means understanding your specific workpiece properties, not just applying generic rules.

Material flow considerations extend beyond simple clearances. When metal flows through a forming process, it follows paths of least resistance. Sharp corners create stress concentrations that cause splits. Insufficient radii restrict flow and thin the material excessively. Experienced die designers anticipate these flow patterns and incorporate generous radii, smooth transitions, and strategically placed draw beads to control material movement.

Springback compensation presents another critical challenge. As industry research confirms, springback occurs due to the elastic recovery of material after bending force is removed. High-strength steels and aluminum alloys exhibit particularly significant springback, sometimes rebounding 5° or more from the intended angle. Successful forming processes must account for this elastic recovery through over-bending, optimized tooling geometry, or multi-stage forming sequences.

Designing for Manufacturability and Longevity

Effective die design follows a logical sequence that builds understanding systematically. Skipping steps leads to expensive corrections later. Here's the proven approach:

- Part Analysis: Examine the finished component thoroughly. Identify critical dimensions, surface quality requirements, and material specifications. Understand how the part functions in its final assembly and which features matter most.

- Process Planning: Determine which forming processes best achieve the required geometry. Will the part require drawing, bending, blanking, piercing, or combinations? Establish the sequence of operations and identify potential problem areas.

- Strip Layout: For progressive dies, optimize how parts nest within the strip. Maximize material utilization while ensuring adequate carrier strips and pilot locations. According to Keysight's forming simulation research, simulation software allows optimization of the initial flat blank contour to maximize material utilization.

- Die Construction Design: Specify the overall die architecture - die shoes, guide systems, stripper mechanisms, and station arrangements. Ensure adequate strength and rigidity to withstand production forces without deflection.

- Component Specification: Detail individual components including punches, die inserts, pilots, and springs. Select appropriate materials and coatings for each based on the loads and wear conditions they'll face.

Advanced Considerations for Complex Parts

Grain direction effects become significant when forming high-strength materials. Sheet metal exhibits different mechanical properties parallel versus perpendicular to the rolling direction. Bending across the grain typically produces better results with less springback, while bending along the grain can cause edge cracking. Your sheet metal forming process must account for these directional properties during blank layout and process planning.

Draw ratios determine whether deep-drawn parts will form successfully or split during production. The ratio compares blank diameter to punch diameter - exceeding material-specific limits causes failure. For mild steel, maximum draw ratios typically range from 1.8 to 2.0 for first draws, decreasing for subsequent redraws. Aluminum and stainless steel have more restrictive limits.

Blank holder pressure controls material flow during drawing operations. Too little pressure allows wrinkles to form as excess material bunches up. Too much pressure restricts flow, causing splits and excessive thinning. Finding the optimal pressure window requires understanding your specific material's behavior - another area where simulation proves valuable.

CAE Simulation: Preventing Defects Before Physical Tooling

Modern forming processes rely heavily on Computer-Aided Engineering simulation to predict problems before cutting steel. As Keysight's research explains, sheet metal forming simulation leverages advanced computational techniques like finite element analysis to predict and analyze metal behavior during forming.

What can simulation reveal? The technology predicts:

- Formability issues including cracks, wrinkles, and excessive thinning

- Springback magnitude and direction, enabling semi-automatic tool compensation

- Cosmetic defects visible through digital stoning or virtual lightroom analysis

- Minimum required press force for complete forming

- Contact pressures and material flow patterns affecting die wear

Virtual die tryouts reduce the time and cost traditionally spent on physical iterations. By simulating the manufacturing die behavior before production begins, engineers can optimize tool geometry, adjust clearances, and refine process parameters digitally. This proactive approach proves particularly beneficial when working with challenging materials or complex geometries where trial-and-error would be prohibitively expensive.

The integration of accurate physics-based simulation helps manufacturers predict springback in high-strength steels and aluminum where control is difficult due to large variations in magnitude. For the sheet metal forming process, this capability transforms tooling development from reactive problem-solving to proactive optimization.

With sound design principles established and validated through simulation, the next critical step involves understanding the physical die components themselves - the shoes, plates, guides, and precision elements that translate design intent into production reality.

Essential Die Components and Their Functions

You've mastered design principles and simulation techniques. But what actually makes up the physical die assembly sitting in your press? Understanding individual components - and how they work together - separates reactive maintenance from proactive tooling management. Each element in a set of die components plays a specific role, and weakness in any single part can cascade into quality problems across your entire production run.

Think of die equipment as a precision system where every piece contributes to the final result. The die shoe provides the foundation. Guide pins ensure alignment. Strippers remove parts cleanly. Pilots position material precisely. When you understand these relationships, setting die maintenance priorities becomes straightforward rather than guesswork.

Upper and Lower Die Shoe Assemblies

The die shoe serves as the structural foundation of the entire assembly. According to Langdi Precision, the die set holds the die block and punch in alignment, consisting of a top (upper shoe) and bottom (lower shoe) plate connected by guide pins. These heavy steel plates mount to the press - the lower shoe attaches to the press bed or bolster while the upper shoe connects to the ram.

Why does this matter for your production? Die shoes must resist deflection under enormous stamping forces. Any flex or movement translates directly into dimensional variation in your parts. Premium die sets for press applications use precision-ground surfaces and adequate thickness to maintain rigidity throughout millions of cycles.

The die plate (sometimes called the die block) mounts to the lower shoe and contains the cutting or forming cavities. This is where material actually transforms - the shape of your finished parts begins here. Material selection for die plates typically follows the guidelines discussed earlier: D2 for high-wear applications, carbide inserts for extreme production volumes.

Punch holders secure the working punches to the upper shoe. These components must position punches with extreme accuracy while withstanding repeated impact forces. Backing plates sit behind punches and die buttons, preventing the softer shoe material from deforming under high pressure. As U-Need's component guide explains, backing plates are hardened plates that protect against concentrated loads that would otherwise damage the die structure.

Precision Components That Enable Accuracy

Guide pins and bushings might seem simple, but they're manufactured to tolerances within .0001" - about one-fourth the thickness of a human hair. According to Moeller Precision Tool, these components work together to align upper and lower die plates with exceptional accuracy.

Two main types dominate the industry:

- Friction (straight) guide pins: Slightly smaller than bushing inner diameter, providing accurate guidance but requiring more force to separate die halves

- Ball-bearing guide pins: Glide on rotating ball bearings within aluminum cages, making die separation easier - now industry standard due to ease of use

Stripper plates serve a critical dual purpose. First, they hold the workpiece flat during forming or cutting operations. Second, they strip material off the punch as it retracts - without this function, material elasticity would keep parts stuck to punches, jamming production. Die springs (either mechanical coil or nitrogen gas) provide the force that powers stripper action.

Pilots are the unsung heroes of progressive die accuracy. These precision pins align the material strip at each station, ensuring every operation hits exactly the right location. Even slight misalignment compounds across multiple stations, turning acceptable tolerances into scrap parts. In high-speed operations exceeding hundreds of strokes per minute, pilots must engage reliably every single cycle.

| Component Name | Primary Function | Material Typically Used | Maintenance Priority |

|---|---|---|---|

| Die Shoe (Upper/Lower) | Structural foundation; mounts to press | Steel or aluminum alloy | Low - inspect for cracks/wear |

| Die Plate | Contains forming/cutting cavities | D2, A2 tool steel; carbide inserts | High - regular sharpening/inspection |

| Punch Holder | Secures and positions punches | Hardened tool steel | Medium - check alignment |

| Guide Pins & Bushings | Aligns upper/lower die halves | Hardened, precision-ground steel | Medium - lubrication critical |

| Stripper Plate | Holds material; strips parts from punch | Tool steel, sometimes hardened | High - wear affects part quality |

| Pilots | Aligns strip material at each station | Hardened tool steel; carbide tips | High - critical for accuracy |

| Backing Plates | Prevents shoe deformation under load | Hardened steel | Low - inspect periodically |

| Die Springs | Provides stripping/pressure force | Chrome silicon wire; nitrogen gas | Medium - replace on schedule |

How Component Quality Affects Production Consistency

In high-volume environments producing hundreds of thousands or millions of parts, component quality directly translates to production consistency. Consider this: a guide pin worn just 0.001" can cause the entire upper die assembly to shift slightly with each stroke. That shift might produce parts within tolerance initially - but across a million cycles, wear accelerates exponentially.

Die tools from reputable suppliers are manufactured using CNC machining centers, wire EDM, and precision grinding to achieve the required tolerances. As industry sources confirm, these components require specialized equipment including 3-axis and 5-axis CNC milling, surface grinding, profile grinding, and EDM machines.

The relationship between component quality and part consistency follows a predictable pattern. Premium components with tighter tolerances maintain accuracy longer, reducing the frequency of adjustments and rework. Lower-quality components may cost less initially but require more frequent replacement and cause more production interruptions.

Understanding these die tools and their functions prepares you for the next evolution in stamping technology - where CNC machining and automation are transforming how dies are manufactured, operated, and monitored in real time.

Modern CNC and Automated Die Systems

What if your die could tell you when it's about to fail - before producing a single defective part? That's not science fiction. Modern forming manufacturing processes now integrate sophisticated CNC machining, automation, and sensor technology that fundamentally changes how dies are built, operated, and maintained. These advances aren't just incremental improvements - they're reshaping the economics of precision stamping.

The transition from manual to automated systems represents one of the most significant shifts in the forming manufacturing process over the past two decades. Understanding these technologies helps you evaluate suppliers, specify equipment, and optimize your production strategy.

CNC Machining in Die Production

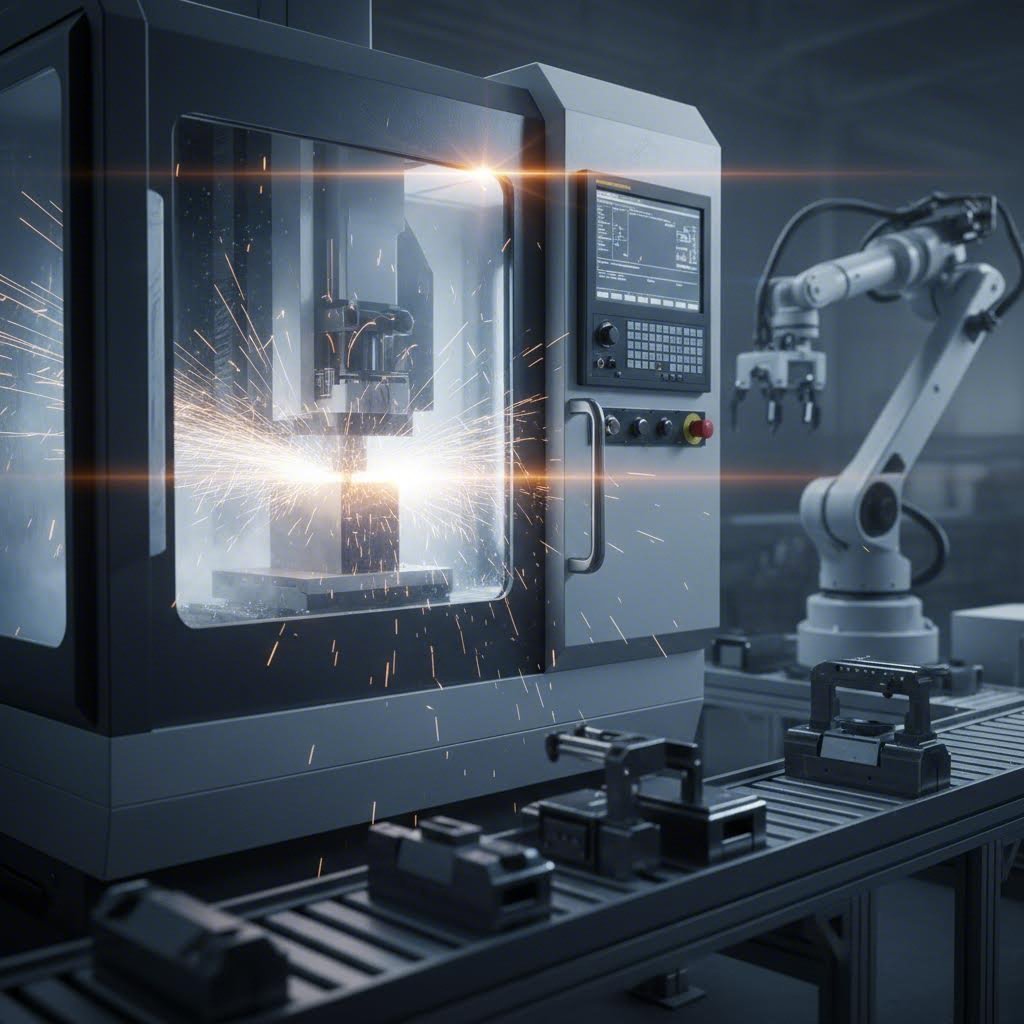

How do modern die shops achieve micron-level precision across complex geometries? The answer lies in advanced CNC machining centers working in concert with specialized processes like wire EDM and precision grinding.

Multi-axis CNC milling machines - typically 3-axis or 5-axis configurations - rough and finish machine die components from tool steel blanks. Five-axis machines prove particularly valuable for machining die because they can approach complex surfaces from virtually any angle, eliminating multiple setups and the accumulated errors that come with repositioning workpieces.

Wire Electrical Discharge Machining (wire EDM) handles operations that conventional machining simply cannot. When you need to cut hardened D2 tool steel into intricate punch profiles or create sharp internal corners, wire EDM delivers. The process uses electrical discharges to erode material regardless of hardness, achieving tolerances within 0.0001" on features that would destroy conventional cutting tools.

Precision grinding provides the final surface finish on critical machine dies components. Surface grinders flatten die plates and backing plates to exacting specifications. Profile grinders shape punch contours and die openings. Cylindrical grinders finish guide pins and bushings to the tolerances that enable smooth, accurate die operation.

The integration of these technologies means modern die shops produce tooling faster and more accurately than ever before. CAD/CAM software translates design intent directly into machine instructions, reducing interpretation errors and enabling rapid iterations when design changes occur.

Automation Integration for Consistent Results

Automation extends beyond machining die components - it's transforming press operations themselves. Automated die changing systems represent a significant advancement, allowing production cells to switch between different dies in minutes rather than hours.

Quick die change (QDC) systems use standardized die's mounting interfaces, hydraulic clamping, and automated transfer carts to minimize changeover time. What once required skilled technicians working for two or three hours can now happen in under ten minutes. For manufacturers running multiple part numbers through the same press line, this flexibility translates directly into increased capacity and responsiveness.

Robotic part handling further amplifies automation benefits. Articulated robots load blanks, transfer parts between stations, and unload finished components without human intervention. This eliminates operator fatigue effects that cause quality variation across shifts while enabling continuous operation.

The real game-changer, however, is sensor integration for real-time die monitoring. Modern forming systems embed sensors directly into die assemblies, continuously measuring force, position, temperature, and vibration. According to research published in Applied Sciences, force data analysis can identify fault indicators representative of quality deterioration, die damage, and non-die component damage - often hours before actual failure occurs.

Predictive Maintenance Through Sensor Technology

Imagine receiving an alert that your fourth-station punch will crack in approximately eight hours - giving you time to schedule maintenance during a planned break rather than suffering an unplanned shutdown. That capability exists today.

The research from Taiwan's six-die nut manufacturing study demonstrated that force sensor correlation analysis provided warning periods of 2-8 hours before die failures, depending on fault severity. The study established health thresholds below which deviations indicated faulty performance, enabling condition-based maintenance rather than reactive repair or overly conservative scheduled replacement.

Force Shock Response Spectrum (SRS) analysis proved particularly effective, detecting faults earlier than simple force profile monitoring because it measures instantaneous impact against natural frequency. This sensitivity catches subtle changes - like developing cracks in internal die structures - long before they manifest as part defects or catastrophic tool failure.

- Reduced Setup Time: Automated die changing systems cut changeover from hours to minutes, increasing available production time and enabling economical short runs

- Consistent Quality: Robotic handling eliminates operator variation while automated process control maintains optimal parameters stroke after stroke

- Real-Time Monitoring: Embedded sensors track force, position, and vibration continuously, catching deviations before they affect part quality

- Predictive Maintenance Capabilities: Advanced analytics identify developing problems hours before failure, enabling scheduled intervention rather than emergency repairs

The ROI Impact of Modern Automation

How do these technologies affect your bottom line? The economic case builds on multiple factors working together.

As American Micro Industries notes, automation reduces errors, minimizes manual intervention, and ensures consistency. These operational improvements translate directly into cost savings while expanding profit margins. The precision and efficiency of automated systems help streamline workflows, ensuring optimal resource use.

Reduced scrap rates compound savings across high-volume production. When every part meets specification, material waste drops and rework disappears. Consistent quality means fewer customer returns and warranty claims - costs that often hide in overhead but significantly impact profitability.

Predictive maintenance reduces both unplanned downtime and unnecessary preventive replacement. The Taiwan study highlighted that traditional run-to-failure maintenance causes hours or days of machine downtime based on damage severity, plus substandard products. Condition-based approaches maintain product quality, reduce maintenance costs, and keep production schedules on track.

Perhaps most importantly, automation enables scalability. As demand fluctuates or increases, automated systems adapt seamlessly, maintaining high productivity without sacrificing quality. This adaptability positions manufacturers to capture growth opportunities that rigid manual operations cannot pursue.

With CNC precision and automation establishing new performance baselines, the question becomes: how do you maintain these sophisticated systems to preserve their advantages? The next section addresses practical maintenance strategies and troubleshooting approaches that keep modern die systems operating at peak performance.

Die Maintenance and Troubleshooting Best Practices

Your die formed parts only stay consistent when your tooling stays healthy. All those CNC precision components and sensor technologies we discussed? They require systematic care to deliver their full potential. Neglecting maintenance transforms expensive precision tooling into expensive scrap generators - often gradually enough that you don't notice until quality metrics tank or an unplanned shutdown halts production.

Understanding what is a die is used for helps frame maintenance priorities. Dies in manufacturing endure tremendous forces, abrasive material contact, and thermal cycling with every stroke. This punishment accumulates invisibly until something fails. The difference between reactive and proactive maintenance often determines whether your forming die remains a reliable production asset or becomes a recurring headache.

Preventive Maintenance Schedules That Extend Die Life

How often should you sharpen cutting edges? When do guide pins need replacement? These questions have answers - but they depend on your specific production conditions.

Sharpening intervals vary dramatically based on material being formed, production volume, and die material. For blanking and piercing operations on mild steel, expect to sharpen every 50,000 to 150,000 hits with D2 tool steel punches. High-strength steels or abrasive materials accelerate wear significantly - some applications require sharpening every 20,000 strokes. Carbide-tipped components last longer but cost more to resharpen, so tracking actual wear patterns matters more than following generic schedules.

Component replacement criteria should be established before problems occur. Guide pins showing visible wear marks or increased play need replacement - not adjustment. Die springs losing force (typically after 1-2 million cycles) should be replaced as sets, not individually. Stripper plates with grooves worn deeper than 0.005" risk inconsistent stripping and part damage.

Storage best practices prevent damage between production runs. Clean dies thoroughly, removing all debris and lubricant residue. Apply rust preventive to exposed steel surfaces. Store in climate-controlled areas when possible - humidity fluctuations cause corrosion that pits precision surfaces. Support dies properly to prevent warping of die shoes, and never stack dies directly on top of each other.

Anyone learning how to make a die quickly discovers that maintenance documentation proves just as important as fabrication records. Track every sharpening, component replacement, and repair. This history reveals wear patterns and helps predict future maintenance needs before they become emergencies.

Troubleshooting Common Forming Defects

When parts start failing inspection, systematic troubleshooting isolates root causes faster than random adjustments. Most forming defects trace back to identifiable die conditions:

- Burrs: Excessive burrs typically indicate worn or dull cutting edges. Check punch-to-die clearances - excessive clearance from wear produces larger burrs. Sharpening or replacing affected components usually resolves the issue.

- Wrinkles: Wrinkling during drawing operations suggests insufficient blank holder pressure or improper material flow. Inspect blank holder surfaces for wear and verify spring force meets specifications. Draw beads may need adjustment or replacement.

- Splits and Cracks: Material splitting indicates excessive stress - often from worn radii that have become too sharp. Check all forming radii for wear or damage. Also verify die alignment, as misalignment concentrates stress at unexpected locations.

- Dimensional Variations: Parts drifting out of tolerance usually trace to worn guide components or loosened die elements. Check guide pin and bushing clearances. Verify all bolted connections remain tight. Inspect pilots for wear that allows strip misalignment.

- Surface Defects: Scratches, galling, or surface marks indicate die surface problems. Polish affected areas and verify adequate lubrication. For persistent issues, consider surface coating treatments.

Repair Versus Replace: A Cost-Conscious Framework

When forging dies or forming die components wear, the repair-versus-replace decision impacts both immediate costs and long-term reliability. Here's a practical framework:

Favor repair when: Damage is localized and repairable to original specifications. The component has significant remaining life after repair. Repair costs stay below 40-50% of replacement cost. Lead time for replacement would cause unacceptable production delays.

Favor replacement when: Wear exceeds safe rework limits (punches worn too short, die openings too large). Multiple repairs have accumulated, compromising dimensional stability. Upgraded materials or designs offer significant performance improvements. Die supplies are readily available at reasonable cost.

Production volume influences this calculation significantly. High-volume dies justify premium replacement components that maximize time between maintenance. Low-volume tooling might tolerate more frequent repairs using less expensive approaches.

Maintenance Investments Based on Production Criticality

Not all dies deserve equal maintenance investment. A decision-making framework considers both volume and part criticality:

High-volume, critical parts: Invest in premium spare components kept on-site. Implement sensor-based monitoring for predictive maintenance. Schedule proactive refurbishment during planned downtime rather than waiting for degradation.

High-volume, non-critical parts: Maintain adequate die supplies for routine replacement. Follow standard preventive schedules. Accept some reactive maintenance when economics favor it.

Low-volume, critical parts: Prioritize careful storage between runs. Inspect thoroughly before each production campaign. Budget for complete refurbishment when needed rather than incremental repairs.

Low-volume, non-critical parts: Basic maintenance suffices. Repair when practical, replace when repair costs approach replacement costs.

Proper maintenance directly impacts both part quality and production uptime. Every hour spent on planned maintenance typically saves multiple hours of unplanned downtime plus the scrap, rework, and expediting costs that accompany unexpected failures.

With maintenance strategies established for preserving die performance, the final consideration becomes selecting the right die partner - a supplier whose capabilities, quality systems, and support services align with your production requirements and long-term goals.

Selecting the Right Die Partner for Your Production Needs

You've invested time understanding die types, materials, design principles, and maintenance strategies. Now comes perhaps the most consequential decision: choosing the right metal die supplier. This choice shapes everything that follows - from initial tooling quality to long-term production consistency and total cost of ownership. The wrong partner creates headaches that persist for years; the right one becomes a competitive advantage.

Selecting a tool die supplier goes far beyond comparing price quotes. According to industry experts at KY Hardware, the ideal partner does more than just produce parts - they offer engineering expertise, ensure rigorous quality control, and function as an extension of your team. This comprehensive approach matters especially for sheet metal forming operations where precision directly impacts product performance.

Evaluating Die Suppliers for Your Requirements

Before contacting potential suppliers, clarify your own needs first. What materials will you form? What tolerances must you hold? What volumes do you anticipate - both initially and as demand grows? Rushing this internal assessment often leads to selecting a supplier who's a poor fit for your project's complexity or scale.

Once you understand your requirements, evaluate suppliers systematically using these criteria:

- Technical Capabilities: Does the supplier have the right equipment for your parts? Look beyond just the number of presses. The type and tonnage of their presses determine the size, thickness, and complexity of components they can produce. A supplier with 600-ton press capacity handles demanding automotive structural components; a shop limited to 100-ton presses cannot. Similarly, verify they have the CNC machining, wire EDM, and precision grinding capabilities needed for quality sheet metal die fabrication.

- Quality Certifications: A robust quality management system is non-negotiable. Certifications provide third-party validation of a supplier's commitment to quality processes. For general manufacturing, ISO 9001 establishes baseline quality standards. For automotive applications, IATF 16949 certification is essential - this automotive-specific framework ensures suppliers meet the rigorous requirements OEMs demand.

- Lead Time Flexibility: Can the supplier meet your timeline for prototyping and production? Some projects require rapid turnaround for development phases, while others prioritize steady high-volume delivery. Discuss your timeline openly - first article samples, production ramp-up, and ongoing delivery expectations.

- Engineering Support: The best suppliers provide Design for Manufacturability (DFM) expertise, not just manufacturing capacity. Their early involvement can identify cost savings and improve part robustness before tooling is cut. Ask about their CAE simulation capabilities - suppliers using advanced forming simulation can predict and prevent defects virtually, reducing physical tryout iterations.

- Production Capacity: Can the supplier meet your volume demands today and scale with future growth? Assess their current capacity and ask how they manage production scheduling. Also consider logistics - do they offer inventory management programs like Kanban or Just-in-Time delivery that can reduce your on-hand stock and improve cash flow?

Why IATF 16949 Certification Matters

If you're manufacturing automotive components, IATF 16949 certification deserves special attention. As Xometry explains, this framework distills the ISO 9001 standard into guidelines specifically useful for automotive manufacturers, emphasizing consistency, safety, and quality across products.

What makes this certification significant for sheet metal dies? IATF 16949 ensures your supplier maintains documented processes for every critical operation. It mandates traceability, defect prevention systems, and continuous improvement initiatives. When problems occur - and in high-volume manufacturing, problems eventually occur - certified suppliers have established protocols for root cause analysis and corrective action.

The certification process involves rigorous internal and external audits covering context of the organization, leadership commitment, planning, support systems, operational processes, performance evaluation, and improvement mechanisms. Suppliers who achieve and maintain certification demonstrate commitment to the discipline automotive production requires.

Balancing Quality, Speed, and Cost in Tooling Decisions

Here's a truth many buyers learn the hard way: the lowest price per part is rarely the best value. True value comes from a supplier who acts as a strategic partner, helping you optimize total cost of ownership rather than just minimizing the initial quote.

According to Shaoyi's cost estimation analysis, tooling investments ranging from $5,000 for simple blanking dies to over $100,000 for complex progressive dies must be amortized across production volume. A die guaranteed for 1 million strikes effectively caps your tooling spend for the project lifecycle - making the initial investment worthwhile for high-volume runs.

Consider these hidden cost factors when comparing suppliers:

- First-pass approval rates: Suppliers with high first-pass rates (90%+ is excellent) minimize costly iterations during development. Each round of modifications adds weeks and thousands of dollars.

- Scrap rates during production: Quality tooling produces consistent parts with minimal waste. Even 1-2% scrap rate differences compound significantly over hundreds of thousands of parts.

- Downtime for maintenance: Dies built from premium materials with proper heat treatment require less frequent sharpening and component replacement.

- Engineering change responsiveness: When designs evolve mid-project, suppliers with strong engineering teams adapt quickly without derailing schedules.

Evaluating Supplier Partnership Potential

Beyond technical capabilities, assess the less tangible aspects of the relationship. How responsive is their communication? Do they proactively identify potential issues or wait until problems emerge? Will they invest time understanding your application requirements rather than just processing orders?

Experience within your industry matters significantly. A company serving the automotive sector understands rigorous PPAP (Production Part Approval Process) requirements. One focused on medical devices knows cleanliness and traceability expectations. Ask for case studies, testimonials, or references from companies with similar requirements.

For automotive stamping applications specifically, Shaoyi Metal Technology exemplifies the supplier characteristics discussed throughout this evaluation framework. Their IATF 16949 certification validates automotive-grade quality systems. CAE simulation capabilities enable defect-free results through virtual validation before physical tooling. Rapid prototyping in as little as 5 days accelerates development timelines, while a 93% first-pass approval rate minimizes iteration costs. Their press capabilities up to 600 tons handle demanding structural components like control arms and subframes. For readers exploring automotive sheet metal die press options, their comprehensive mold design and fabrication capabilities provide a strong reference point for what qualified suppliers offer.

Making the Final Decision

After gathering information from multiple potential partners, create a weighted scorecard. Assign importance levels to each criterion based on your priorities - perhaps Quality Systems at 30%, Engineering Support at 25%, Price at 20%, Lead Time at 15%, and Capacity at 10%. Score each supplier objectively against these weighted factors.

This structured approach removes personal bias and clearly identifies the supplier best aligned with your most critical needs. The final decision should reflect a holistic view of capabilities, quality systems, support services, and total cost of ownership - not just the piece price on the initial quote.

Remember that selecting a metal stamping die sets supplier is an investment in your product's success. The right partner brings engineering expertise that improves your designs, quality systems that ensure consistency, and production flexibility that adapts to your evolving needs. When you find that partner, you gain more than a vendor - you gain a competitive advantage that compounds across every project you undertake together.

Frequently Asked Questions About Metal Forming Dies

1. What is a die in metal forming?

A metal forming die is a precision-engineered tool that shapes metal through controlled force and carefully designed geometry. It consists of matched components—typically a punch and die block—that work together during each press stroke to cut, form, or shape material into precise geometries. Dies can perform four essential functions: locating, clamping, working, and releasing, often achieving micrometer-level tolerances for mass production of complex components.

2. What is the best steel for forming dies?

The best steel depends on your application. D2 tool steel (58-62 HRC) offers exceptional wear resistance for blanking and piercing operations on stainless steel. A2 tool steel provides a balance between wear resistance and toughness with excellent dimensional stability. S7 tool steel prioritizes toughness for shock-loading applications. For extreme production volumes exceeding 500,000 parts, tungsten carbide inserts (85-92 HRA) outperform steel alternatives at high-wear points.

3. How much does a metal stamping die cost?

Metal stamping die costs range from $500 to over $100,000 depending on complexity. Simple blanking dies start around $5,000, while complex progressive dies for automotive applications can exceed $100,000. The investment should be evaluated against production volume—a die guaranteed for 1 million strikes effectively caps tooling spend for high-volume projects. Suppliers like Shaoyi offer cost-effective solutions with 93% first-pass approval rates, minimizing expensive iterations.

4. How are metal forming dies made?

Modern die manufacturing combines CNC machining centers, wire EDM, and precision grinding. Multi-axis CNC machines rough and finish die components from tool steel blanks. Wire EDM cuts hardened steel into intricate profiles with tolerances within 0.0001 inches. Precision grinding provides final surface finishes on critical components. CAE simulation validates designs virtually before physical tooling, reducing tryout iterations and accelerating production readiness.

5. How often should metal forming dies be maintained?

Maintenance intervals depend on material, volume, and die material. For blanking operations on mild steel with D2 punches, expect sharpening every 50,000-150,000 hits. High-strength steels may require sharpening every 20,000 strokes. Guide pins need replacement when showing visible wear. Die springs typically require replacement after 1-2 million cycles. Implementing sensor-based monitoring enables predictive maintenance, providing 2-8 hours warning before failures occur.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —