Metal Fabrication Online Demystified: From Upload To Doorstep

Understanding Metal Fabrication in the Digital Age

Imagine needing a custom metal bracket for a vintage motorcycle restoration, a unique signage piece for your business, or precision components for a robotics project. A decade ago, you'd spend hours searching for local machine shops, waiting days for quotes, and navigating complex negotiations. Today? You upload a design file, receive an instant quote, and have professionally manufactured parts delivered to your doorstep—often within days.

This is metal fabrication online, and it's fundamentally changing how individuals and businesses access professional metalworking services. At its core, this digital approach transforms traditional manufacturing into an accessible, streamlined process where anyone with a design can become a maker.

From Blueprint to Browser: The Digital Fabrication Revolution

Metal fabrication online refers to the complete digitization of the custom parts ordering process. Instead of physically visiting a fabrication shop, you interact entirely through web-based platforms. The workflow is surprisingly straightforward: you create or obtain a digital design file, upload it to a fabrication platform, select your material and specifications, receive automated pricing, and place your order—all without a single phone call or in-person meeting.

What makes this revolution possible? Advanced manufacturing equipment combined with sophisticated software that can automatically analyze designs, calculate material requirements, and generate accurate quotes in seconds. Platforms like Send Cut Send have pioneered this approach, allowing customers to get instant pricing for everything from simple flat parts to complex bent assemblies.

The beauty of online fabrication lies in its accessibility. Whether you're a hobbyist creating one-off art projects, an engineer prototyping production parts, or an entrepreneur launching a product line, the same professional-grade equipment and processes are available to you. There's no minimum order requirement intimidation, no need to understand industry jargon during quote negotiations, and no guesswork about pricing.

What Makes Online Metal Fabrication Different

Traditional custom fabrication often meant relationship-based business—you needed to know the right shop, understand manufacturing terminology, and commit to larger quantities to get reasonable pricing. Online metals services have democratized this process entirely.

The scope of services available through digital platforms is comprehensive. Most online fabrication providers offer:

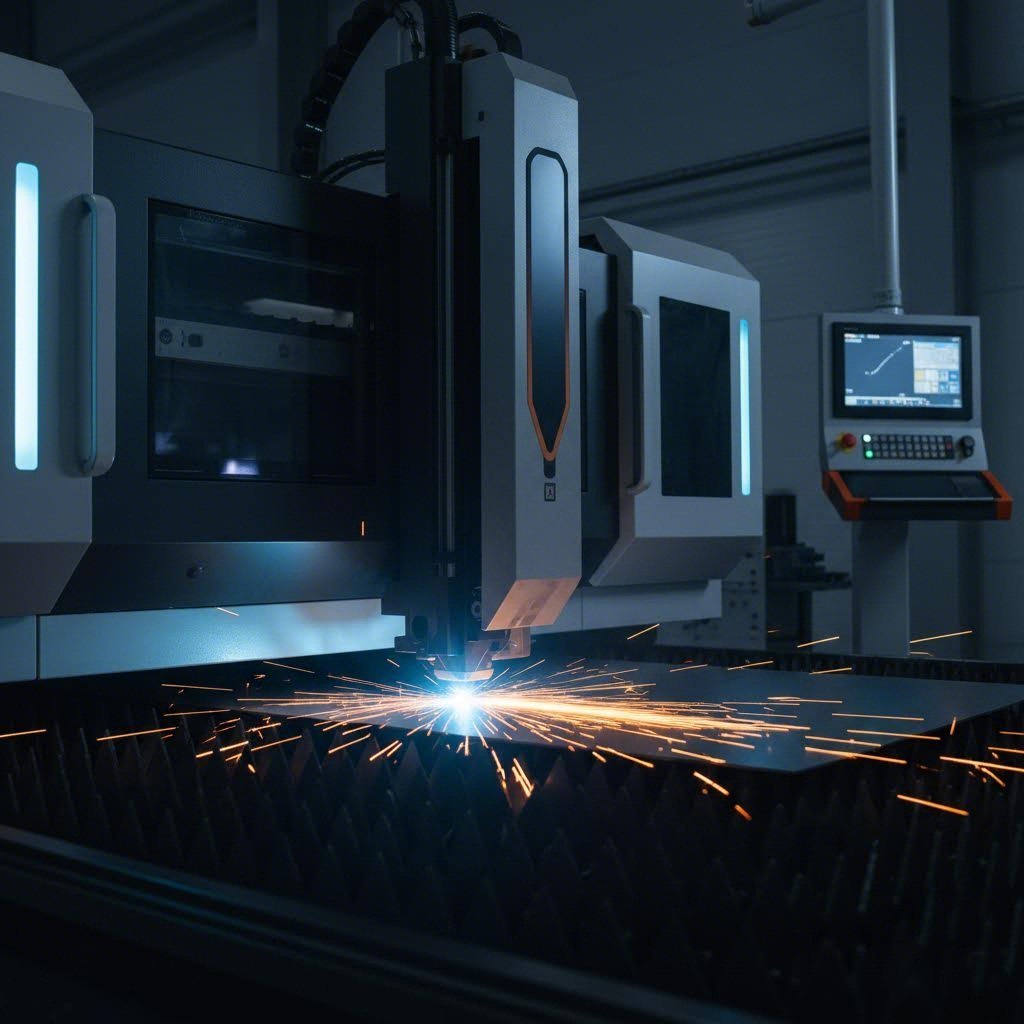

- Laser Cutting – Using high-intensity focused light beams to cut precise shapes from sheet metal and plate materials

- Waterjet Cutting – Employing high-pressure water jets with fine abrasives to cut through even thick materials

- CNC Routing – Utilizing computer-controlled spinning cutting tools for specific material applications

- Bending and Forming – Transforming flat parts into three-dimensional shapes using press brakes

- Tapping and Hardware Insertion – Adding threaded holes and installing fasteners like nuts and standoffs

- Finishing Services – Applying protective and aesthetic treatments including powder coating, anodizing, and zinc plating

- Deburring and Tumbling – Removing sharp edges and providing smooth, professional finishes

This comprehensive service offering means you can receive fully finished, assembly-ready parts rather than raw components requiring additional processing. For makers and manufacturers alike, online fabrication eliminates the complexity of coordinating multiple vendors—one upload, one order, one delivery.

The target audience for these services spans an impressive spectrum. Hobbyists use them for custom signage, decorative pieces, and DIY projects. Engineers leverage rapid turnaround times for prototyping and iteration. Small manufacturers source production parts without maintaining expensive equipment. Even large companies use custom fabrication services for specialized components that don't justify in-house production.

Throughout this guide, you'll gain the knowledge to navigate this digital manufacturing landscape confidently—from understanding specific processes to selecting the right materials and optimizing your designs for cost and quality.

How Online Metal Fabrication Ordering Actually Works

So you've decided to explore custom metal fabrication online—but what actually happens when you click that "upload" button? The process might seem mysterious if you've never done it before, but understanding each step transforms uncertainty into confidence. Let's walk through the complete journey from design file to delivered parts.

Step-by-Step: Your First Online Fabrication Order

Think of online sheet metal fabrication as a streamlined conversation between your design and sophisticated manufacturing software. Unlike traditional methods where you'd email files back and forth, wait days for responses, and negotiate pricing over multiple phone calls, digital platforms compress this entire process into minutes.

Here's exactly what happens when you place an order:

- Prepare Your Design File – Create or obtain a digital design in an accepted format. Most platforms require 3D CAD files for sheet metal parts, with STEP files (.step, .stp) being the universal standard. If your design includes special requirements like threading, welding, or tight tolerances, you'll also need a 2D drawing (PDF, DWG, or DXF) with clear annotations.

- Upload to the Platform – Navigate to the fabrication service's quote page and upload your file. The system immediately begins analyzing your design geometry, calculating material requirements, and identifying any potential manufacturing issues.

- Configure Your Specifications – Select your desired material (aluminum, steel, stainless, etc.), thickness, quantity, and any finishing options like powder coating or anodizing. This is where you customize the order to match your project needs.

- Review the Instant Quote – Within seconds, the system generates pricing based on your selections. You'll see breakdowns for material costs, processing, finishing, and estimated shipping.

- Submit for Manual Review – After placing your order, human engineers review your design to verify manufacturability. According to JLCCNC's ordering guidelines, this review typically completes within 10 minutes to 4 hours on working days.

- Complete Payment – Once approved, you'll receive notification to finalize payment. Most platforms accept PayPal, credit cards, and platform-specific balance systems.

- Track Production and Delivery – Your order enters the production queue. You can monitor status through your account dashboard until parts ship to your address.

File Formats and Design Requirements Explained

Sounds complex? It's actually simpler than you might expect—but file preparation is where many first-time users stumble. Understanding format requirements upfront saves frustration and rejected orders.

For sheet metal parts, a 3D STEP file is essential. This format preserves precise geometry that manufacturing software needs to calculate bend lines, material deformation, and cutting paths. If you're working with flat laser-cut parts only, DXF files work perfectly—they're essentially digital blueprints containing the exact cutting geometry.

When should you include a 2D drawing alongside your 3D model? Whenever your part has specifications that geometry alone can't communicate:

- Thread specifications (tap sizes, thread depth)

- Critical tolerances tighter than standard manufacturing precision

- Surface finish requirements for specific areas

- Welding locations and specifications

- Silkscreen or marking requirements

The magic behind a laser cutting instant quote lies in automated analysis software. When you upload a file, algorithms instantly calculate the total cutting path length, identify the number of pierces required, assess material nesting efficiency, and factor in setup time. This happens in seconds—a task that would take a human estimator 30 minutes or more.

Traditional Request for Quote (RFQ) processes worked differently. You'd email files to multiple shops, wait 2-5 business days per response, receive quotes with varying formats and assumptions, then spend time clarifying discrepancies. The sheet metal online quote revolution eliminates this friction entirely.

Here's an important note for beginners: the automated quote you initially receive is typically preliminary. As JLCCNC notes, "the automatic quotation generated by the system is for reference only. The final price shall be subject to the approval of our manual review." This review catches design issues that software might miss—features too close to bend lines, material selections that won't work for specific geometries, or specifications that require clarification.

For custom metal fabrication online success, approach your first order with a simple design. A straightforward flat part with basic material selection teaches you the platform workflow without complexity. Once comfortable, you can tackle assemblies with multiple bends, hardware insertion, and finishing—knowing exactly what to expect at each stage of the online sheet metal quote process.

Fabrication Processes Explained for Every Project

Now that you understand how to place an order, let's explore what actually happens to your material once production begins. Each fabrication process has distinct characteristics that affect your design decisions, material choices, and final part quality. Understanding these processes transforms you from a passive customer into an informed maker who can optimize designs for better results.

Laser Cutting: Precision at the Speed of Light

When your design enters a laser cutter, something remarkable happens. A high-energy beam of coherent light—generated through a process called stimulated emission—focuses onto a spot smaller than a pencil tip. This concentrated energy rapidly heats the material until it melts, chars, or vaporizes completely. Gas assist (typically nitrogen or oxygen) blows the molten material clear, creating a clean cut path as the machine traces your design.

According to Xometry's technical guide, laser cutting has evolved dramatically since Western Electric developed the first commercial machines around 1975. Today's systems can cut through hardened steel and complex composites up to 100mm thick when properly optimized.

But here's what most platforms won't explain: the kerf. This term refers to the width of material actually removed by the cutting process. Think of it like a saw blade—the blade itself has thickness, so the cut is slightly wider than the blade path. For laser cutting, kerf typically ranges from 0.1mm to 0.4mm depending on material type, thickness, and laser power settings.

Why does kerf matter for your designs? Imagine you're cutting a gear that needs to mesh precisely with another component. If you design the teeth exactly to specification without accounting for kerf, your actual part will be slightly smaller than intended—the laser removes material on both sides of the cut line. Professional fabrication platforms compensate for this automatically, but understanding the concept helps you interpret tolerances and design mating parts correctly.

The metal cutting process involves several optimizable parameters that affect your final part:

- Laser Power – Higher power enables faster cutting and thicker materials but may increase the heat-affected zone (HAZ)

- Cutting Speed – Faster speeds reduce HAZ but may leave rougher edges; slower speeds produce cleaner cuts

- Focal Point Position – Adjusting focus depth controls kerf shape and cut quality through thick materials

- Gas Assist Type – Oxygen creates faster cuts in steel through oxidation; nitrogen produces cleaner edges without discoloration

When should you choose waterjet over a laser cutter? Waterjet excels with heat-sensitive materials that would warp or discolor under laser heat. It also handles reflective materials like copper and brass more reliably, and cuts extremely thick stock that exceeds laser capacity. However, waterjet is generally slower and produces a slightly rougher edge finish.

CNC Routing, Bending, and Beyond

Flat cutting is just the beginning. Once your parts are cut, additional processes transform them into three-dimensional components ready for assembly.

CNC Brake Bending takes flat sheet metal and creates precise angles using a punch and die system. The process works by pressing material between matched tooling until it deforms to the desired angle. According to Metal Works of High Point, achieving accurate bends requires understanding several key concepts:

- Bend Radius – The distance between the bend axis and interior surface; should generally equal or exceed material thickness to prevent cracking

- Springback – Material's tendency to partially return toward its original shape after bending, requiring slight overbending to achieve target angles

- K-Factor – A value (typically 0.25-0.5) defining where the neutral axis sits within the material during bending

- Bend Allowance – The arc length of the neutral axis through the bend, essential for calculating correct flat pattern dimensions

Sheet metal bending services transform your flat designs into enclosures, brackets, channels, and complex formed shapes. The minimum bend height must be at least four times the material thickness plus the bend radius—otherwise, the part will deform unpredictably.

Tapping and Hardware Insertion adds functionality to your parts. Tapping creates internal threads in holes, allowing you to fasten components with machine screws. Hardware insertion presses nuts, standoffs, and studs directly into the sheet metal, creating permanent fastening points. Both processes require proper hole sizing—too small and the tap breaks, too large and threads won't hold.

Here's a comparison of the primary fabrication processes available through most online platforms:

| Process | Materials Supported | Typical Thickness Range | Precision Tolerance | Best Applications |

|---|---|---|---|---|

| Fiber Laser Cutting | Steel, stainless, aluminum, brass, copper | 0.5mm – 25mm | ±0.1mm – ±0.25mm | Intricate shapes, fine details, high volume |

| CO2 Laser Cutting | Steel, stainless, aluminum, wood, acrylic | 0.5mm – 25mm | ±0.1mm – ±0.3mm | Mixed materials, engraving, thicker organics |

| Waterjet Cutting | Nearly all materials including glass, stone | 0.5mm – 150mm+ | ±0.1mm – ±0.5mm | Heat-sensitive materials, very thick stock |

| CNC Routing | Aluminum, plastics, wood, composites | 1mm – 75mm | ±0.05mm – ±0.15mm | 3D profiles, pocketing, soft materials |

| CNC Brake Bending | Steel, stainless, aluminum | 0.5mm – 12mm | ±0.5° angle, ±0.25mm position | Enclosures, brackets, formed components |

Each metal cutter and forming process has minimum feature size requirements that affect your design. Laser-cut holes should generally be at least equal to material thickness in diameter. Bend reliefs—small notches at the ends of bend lines—prevent tearing and must be deeper than the bend radius plus material thickness. Features too close to bend lines will distort during forming.

Understanding these technical specifications empowers you to design parts that manufacture efficiently on the first attempt. With process knowledge established, the next critical decision is selecting the right material for your specific application requirements.

Choosing the Right Metal for Your Application

You've mastered the ordering process and understand how different fabrication methods work. Now comes a decision that will define your project's success: which metal should you actually use? This choice affects everything from structural integrity to long-term durability, manufacturing cost, and final appearance.

Selecting materials doesn't have to feel overwhelming. By understanding a few key properties and how they relate to your specific application, you'll make confident decisions that balance performance with budget.

Aluminum vs Steel vs Stainless: Making the Right Choice

Walk through any fabrication platform's material options, and you'll encounter three dominant categories: aluminum, mild steel, and stainless steel. Each brings distinct advantages—and limitations—to your project.

Aluminum Alloys are the go-to choice when weight matters. According to Clickmetal's material comparison, aluminum's strength-to-weight ratio is approximately 1/8, compared to stainless steel's 1/16. What does this mean practically? An aluminum sheet metal structure supporting the same load as a steel equivalent will be larger but weigh roughly half as much.

Aluminum naturally forms a protective oxide layer when exposed to air, providing excellent corrosion resistance without additional treatment. This makes aluminum sheet ideal for outdoor signage, marine applications, and electronics enclosures where moisture exposure is inevitable. It's also highly conductive—which explains why power transmission lines use aluminum rather than steel.

The trade-off? Raw strength. When comparing steel and stainless to aluminum, steel wins on absolute strength every time. Its higher carbon content creates a stronger, more rigid material that resists deformation under heavy loads.

Mild Steel offers the best value proposition for structural applications. It's significantly less expensive than stainless or aluminum, easy to weld, and readily available in virtually any thickness. Fabrication shops love working with mild steel because it machines predictably and accepts finishing treatments well.

The catch? Mild steel rusts. Without protective coatings like galvanizing, powder coating, or paint, exposed mild steel will corrode when moisture contacts the surface. This isn't necessarily a deal-breaker—many applications allow for protective finishing—but it's a critical consideration for outdoor or humid environments.

Stainless Steel bridges the gap between strength and corrosion resistance. By adding chromium (typically 10.5% or more), stainless steel gains remarkable resistance to rust and oxidation while maintaining excellent structural properties. 316 stainless steel takes this further by incorporating molybdenum, creating superior resistance to chlorides and harsh chemical environments.

When should you specify 316 stainless steel specifically? Marine environments, chemical processing, food preparation surfaces, and medical equipment all benefit from its enhanced corrosion resistance. Standard 304 stainless handles most general-purpose applications at lower cost.

Specialty Materials like brass and copper serve niche applications. Brass offers attractive appearance and antimicrobial properties—perfect for decorative fixtures and touch surfaces. Copper provides exceptional electrical and thermal conductivity, making it essential for heat sinks and electrical components.

Material Properties That Matter for Your Project

Beyond the broad categories, specific properties determine whether a material will perform in your application. Here's what to evaluate:

Tensile Strength measures how much pulling force a material can withstand before breaking. Steel typically offers tensile strength around 400-550 MPa for mild grades, while aluminum alloys range from 70-700 MPa depending on the specific alloy. Higher tensile strength means thinner material can support equivalent loads—potentially reducing weight and cost.

Formability describes how easily material bends without cracking. Aluminum excels here—it's highly ductile and can stretch into complex shapes without fracturing. Steel is more rigid and will break if pushed beyond its forming limits. This matters significantly if your design includes tight bends or complex geometry.

Weldability affects assembly options. Mild steel welds beautifully with common processes. Aluminum requires specialized TIG welding and careful technique to prevent porosity. Stainless steel welds well but requires attention to heat management to prevent warping and carbide precipitation.

Corrosion Resistance determines long-term durability. Aluminum's natural oxide layer protects it indefinitely. Stainless steel resists rust through its chromium content. Mild steel requires protective coatings for any exposure to moisture or humidity.

Use this comparison table to match material properties with your application requirements:

| Material | Relative Weight | Relative Strength | Relative Cost | Corrosion Resistance | Best Applications |

|---|---|---|---|---|---|

| Aluminum (6061) | Low | Medium | Medium | Excellent (natural oxide) | Aerospace, electronics, signage, marine |

| Mild Steel | High | High | Low | Poor (requires coating) | Structural, automotive, general fabrication |

| 304 Stainless Steel | High | High | High | Very Good | Food equipment, architectural, general industrial |

| 316 Stainless Steel | High | High | Very High | Excellent (chloride resistant) | Marine, chemical, medical, pharmaceutical |

| Brass | High | Medium | High | Good | Decorative, plumbing, electrical contacts |

| Copper | High | Low-Medium | Very High | Good (develops patina) | Electrical, thermal management, decorative |

Understanding Gauge Thickness Standards

When browsing material options, you'll encounter gauge numbers that seem counterintuitive—higher numbers mean thinner material. A 14 gauge steel thickness measures approximately 0.0747 inches (1.9mm), while 16 gauge measures 0.0598 inches (1.5mm). The gauge size chart exists because of historical manufacturing conventions, not logical progression.

Here's where it gets tricky: gauge measurements differ between ferrous and non-ferrous metals. According to All Metals Fabrication's thickness guide, "Ferrous and non-ferrous metals, classified by the same gauge, actually have different thicknesses." Most fabrication professionals measure steel and stainless by gauge while specifying aluminum, copper, and brass by decimal thickness to avoid confusion.

Common gauge thicknesses you'll encounter:

- 24 gauge – Approximately 0.024" (0.6mm) – Thin sheet for light-duty enclosures and decorative applications

- 20 gauge – Approximately 0.036" (0.9mm) – Standard for HVAC ductwork and light brackets

- 16 gauge – Approximately 0.060" (1.5mm) – Common for structural brackets and medium-duty enclosures

- 14 gauge – Approximately 0.075" (1.9mm) – Heavy-duty brackets, automotive components

- 11 gauge – Approximately 0.120" (3mm) – Structural applications requiring significant strength

Material thicker than 7 gauge (approximately 0.188" or 4.8mm) transitions from "sheet metal" to "plate metal" territory, requiring different handling equipment and manufacturing approaches.

When Material Certification Matters

For hobbyist projects and general prototyping, standard commercial-grade materials work perfectly. But certain applications demand documented material traceability.

Request material certification when your parts will be used in:

- Aerospace applications requiring traceable material origin

- Medical devices subject to regulatory compliance

- Automotive safety components

- Pressure vessels or structural applications with code requirements

- Government or military contracts specifying material documentation

Material certifications (often called "mill certs" or "MTRs") document the exact chemical composition, mechanical properties, and manufacturing origin of your material. This documentation adds cost but provides essential traceability for regulated industries.

With material selection clarified, you're ready to focus on designing parts that manufacture efficiently—avoiding common mistakes that lead to costly revisions and delays.

Design Guidelines for Fabrication-Ready Parts

You've selected your material and understand the fabrication processes available. Now comes the step that separates successful orders from costly revisions: designing parts that actually work with manufacturing equipment. The difference between a smooth production run and multiple back-and-forth corrections often comes down to a few critical design choices made before you ever click "upload."

Think of these guidelines as the language of sheet metal fabrication. When your design speaks this language fluently, fabricators can produce exactly what you envision—on time and on budget.

Design Rules That Save Time and Money

Every fabrication process has physical limitations. Ignoring them doesn't make them disappear—it creates rejected parts, costly rework, and frustrating delays. Let's break down the essential rules that keep your projects running smoothly.

Minimum Hole Diameters

Here's a simple rule that prevents broken tools and deformed features: your hole diameter should equal or exceed the material thickness. According to Blackstone Advanced Technologies, punching small holes in thick material puts excessive stress on cutting tools. A 1mm hole in 2mm steel? That's asking for trouble. Design that same hole at 2mm diameter, and production runs smoothly.

Bend Radius Requirements

When you fold a piece of paper sharply, the outer edge creases or tears. Metal behaves similarly. The inside bend radius should at least match your material thickness—bend 1.5mm aluminum with at least a 1.5mm inside radius. This prevents cracking on the outer surface where the material stretches during forming.

But don't go too far the other direction. Blackstone's engineering team notes that excessively large bend radii create their own problems: increased springback, difficulty achieving precise bend angles, and inconsistent results. Keep radii reasonable—typically 1x to 2x material thickness for most applications.

Feature Spacing and Hole-to-Bend Distance

Imagine cutting a hole right next to where metal will bend. During forming, that hole stretches into an oval—rendering it useless for fasteners or precise fits. According to Norck's DFM guidelines, holes must stay at least two times the material thickness away from any bend line.

For custom size sheet metal parts with multiple features, maintain consistent spacing between holes, slots, and edges. A general rule: feature-to-feature and feature-to-edge distances should be at least 2x material thickness. This ensures clean metal sheet cutting and prevents distortion during subsequent operations.

Minimum Flange Width

The flange—the portion of material that bends upward—needs enough surface area for the brake tooling to grip properly. As Blackstone explains, "the flange width should not go under four times the thickness of the metal." Designing a 1mm thick bracket? Your flanges need to be at least 4mm wide. Shorter flanges require custom tooling that dramatically increases costs.

Avoiding the Most Common Fabrication Errors

Even experienced designers make mistakes that trigger manufacturing friction. Here's what to watch for—and how to fix it:

- Missing Bend Reliefs – When a bend line meets a flat edge, material tears at the junction. Solution: Add small rectangular or semicircular cutouts (at least material thickness wide and bend radius plus material thickness deep) at bend-line endpoints.

- Ignoring Grain Direction – Sheet metal has a "grain" from the rolling process. Bending parallel to this grain causes cracking. Solution: Orient your part so bends occur perpendicular to the grain direction—your sheet metal bending service provider can advise on material orientation.

- Overly Narrow Cutouts – Thin slots or fingers warp from laser heat concentration. Solution: Keep narrow features at least 1.5x material thickness wide to prevent thermal distortion.

- Forgetting Bend Allowance – Metal stretches during bending, making bent parts longer than the sum of their flat segments. Solution: Use bend allowance calculations (or let your fabricator's software handle it) to ensure correct final dimensions.

- Specifying Unnecessary Tolerances – Demanding ±0.05mm when ±0.25mm works fine for your application increases inspection time and cost. Solution: Only specify tight tolerances on critical mating surfaces.

- Non-Standard Hole Sizes – A 5.123mm hole requires custom tooling. Solution: Use standard drill sizes (5mm, 6mm, 1/4") that fabricators stock and can punch instantly.

Understanding Bend Allowances

When you bend sheet metal, the outer surface stretches while the inner surface compresses. The neutral axis—the theoretical plane where material neither stretches nor compresses—shifts during this process. This means your flat pattern dimensions must account for material deformation.

Consider a simple L-bracket with two 50mm legs and a 90° bend. The flat pattern isn't simply 100mm wide. The bend allowance formula incorporates material thickness, bend angle, inside radius, and the K-factor (typically 0.3-0.5 for most materials). Modern CAD software and fabrication platforms calculate this automatically, but understanding the concept helps you verify that your designs will produce correctly dimensioned parts.

Designing for Assembly

If your custom cut sheet metal parts will join together, think beyond individual components. Successful assemblies require:

- Consistent Tolerances – Parts that mate together need compatible tolerances. A ±0.25mm tolerance on both mating edges creates up to 0.5mm potential gap or interference.

- Alignment Features – Adding tabs, slots, or locating holes simplifies assembly and ensures repeatable positioning.

- Hardware Access – Can you actually reach the fasteners once parts are positioned? Ensure adequate clearance for tools and fingers.

- Weld Preparation – If parts will be welded, design appropriate joint configurations and access for welding equipment.

The Value of DFM Support

Design for Manufacturability (DFM) support transforms potential problems into solved problems—before production begins. When you upload files to a quality sheet metal fabrication platform, engineering review catches issues that automated systems miss.

What does effective DFM support provide?

- Identification of features that violate manufacturing constraints

- Suggestions for design modifications that reduce cost without compromising function

- Verification that your material selection suits your geometry

- Confirmation that tolerances are achievable with specified processes

According to Norck's DFM guide, "If a design is too complex or ignores the physical limits of metal, it leads to 'manufacturing friction': higher prices, longer wait times, and a higher risk of errors." Investing time in DFM review upfront prevents expensive corrections downstream.

Typical tolerances achievable through standard sheet metal cutting and forming processes range from ±0.1mm for laser-cut features to ±0.5° for bend angles. Tighter tolerances require additional inspection steps and increase cost—specify them only where your application genuinely demands precision.

With these design guidelines in your toolkit, you're equipped to submit fabrication-ready files that manufacture correctly on the first attempt. Next, let's explore how pricing works—so you can optimize your designs not just for manufacturability, but for budget efficiency as well.

Understanding Pricing and Optimizing Your Budget

You've designed a fabrication-ready part, selected the perfect material, and you're ready to order. Then the quote appears—and you wonder: is this price reasonable? What exactly am I paying for? Understanding the anatomy of a sheet metal fabrication quote transforms you from passive price-taker to informed buyer who can optimize costs strategically.

Unlike commodity purchases where price comparison is straightforward, sheet metal quotes reflect dozens of interconnected variables. Let's break them down so you can evaluate quotes intelligently and make design decisions that respect your budget.

What Drives Your Fabrication Quote

Every online metal fabrication service builds quotes from the same fundamental components—though the proportions vary dramatically based on your specific project. Here's what you're actually paying for:

Material Costs

Raw material typically represents 30-50% of your total quote. According to TZR Metal's cost analysis, several factors determine material expense:

- Material Type – Carbon steel costs significantly less than stainless steel or aluminum alloys. Specialty metals like copper, brass, and titanium command premium prices.

- Thickness – Thicker materials cost more per unit area and require more powerful machinery or slower processing speeds.

- Quantity – Larger orders allow fabricators to purchase material at volume discounts and optimize sheet utilization.

- Market Fluctuations – Global commodity prices shift constantly, affecting raw material costs month to month.

Processing Costs

Every cut, bend, and hole adds processing time—and cost. TZR Metal estimates laser or plasma cutting at $1.50-$6.00 per linear foot depending on material and complexity. Basic bends might add $1-$5 each, increasing with material thickness and tolerance requirements. The more operations your part requires, the higher the processing component of your quote.

Design complexity multiplies processing costs through several mechanisms:

- Cutting Path Length – Intricate designs with many curves and features require longer cutting time

- Number of Operations – Each bend, tap, or hardware insertion adds setup and cycle time

- Tolerance Requirements – Tighter specifications demand slower processing and additional inspection

- Nested Cutting Efficiency – Complex shapes may not pack efficiently on material sheets, increasing waste

Finishing and Secondary Operations

Surface treatments like powder coating, anodizing, or plating add both material and labor costs. According to TZR Metal, basic powder coating or painting runs approximately $2-$5 per square foot of surface area, while specialized plating may reach $5-$15+ per square foot. Deburring, assembly, and hardware insertion each contribute additional charges.

Shipping and Packaging

Don't overlook logistics. Weight, volume, destination, and shipping speed all affect final cost. Sensitive parts may require custom packaging with foam inserts or VCI bags to prevent damage during transit—adding expense but protecting your investment.

Why "No MOQ" Matters—And When It Doesn't

Many online platforms advertise "no minimum order quantity" as a key benefit. For prototyping and one-off projects, this flexibility is genuinely valuable. You can order a single part without committing to hundreds.

However, understanding production economics reveals why volume still matters for your wallet. Setup costs—programming, tooling configuration, first-article inspection—get amortized across your order quantity. Order one part, and you absorb 100% of setup costs. Order one hundred parts, and each piece carries just 1% of that overhead.

According to Zintilon's fabrication cost guide, this explains the dramatic price-per-piece difference between prototype pricing and volume production pricing. A laser cutting online quote for a single prototype might show $50 per part, while the same design at 500 units drops to $8 each. Neither price is "wrong"—they reflect different economic realities.

Smart Strategies to Optimize Costs

Armed with understanding of cost drivers, you can make intentional choices that reduce expenses without sacrificing functionality. Here's your optimization playbook:

- Simplify Your Design – Every feature costs money. Eliminate unnecessary curves, reduce bend count, and question whether complex cutouts serve a genuine purpose. As Zintilon notes, "Simple angle bends with inside radii equal to 1x the material thickness can help cut fabrication costs."

- Choose Cost-Effective Materials – Don't over-specify. If standard mild steel meets your requirements, specifying stainless or aluminum adds cost without benefit. Match material to actual application needs.

- Optimize for Nesting Efficiency – Can you adjust part dimensions slightly to fit more pieces per sheet? Consult with your fabricator about optimal sizing for their standard stock.

- Batch Similar Orders – Combining multiple parts into a single order shares setup costs. If you need brackets today and panels next month, consider ordering together.

- Relax Non-Critical Tolerances – Tight tolerances require slower processing and additional inspection. Specify precision only where function demands it.

- Reconsider Finishing Requirements – Do you need powder coating for a part that lives inside an enclosure? Sometimes raw or minimally finished parts work perfectly.

- Use Standard Features – Standard hole sizes, common bend radii, and off-the-shelf hardware reduce tooling requirements and setup time.

Evaluating Your Sheet Metal Quote

When you receive sheet metal fabrication quotes, don't simply accept the number. Develop a framework for evaluation:

Compare Apples to Apples

Ensure quotes cover identical specifications. A lower price might exclude finishing, use different material grades, or assume looser tolerances. Request itemized breakdowns when possible.

Consider Total Cost of Ownership

The cheapest quote isn't always the best value. Factor in:

- Lead time costs (delays have real business impact)

- Quality consistency (rework and scrap add hidden expense)

- Communication efficiency (unclear specifications cost revision cycles)

- Shipping and handling fees

Ask About Volume Breaks

Even if you're ordering small quantities now, understanding volume pricing helps you plan for scale. Some fabricators offer significant discounts at surprisingly low thresholds.

Request DFM Feedback

Quality fabricators will identify cost-saving design modifications during review. This collaborative approach—which TZR Metal notes can "identify potential cost drivers and suggest modifications before designs are finalized"—often yields savings that exceed any price difference between vendors.

The price for sheet metal varies widely based on factors within your control. By understanding what drives costs and applying strategic optimization, you transform fabrication from an unpredictable expense into a manageable, optimizable investment. With pricing demystified, let's explore how finishing options and quality standards complete the manufacturing picture.

Finishing Options and Quality Assurance Standards

Your parts have been cut, bent, and formed to specification. But raw fabricated metal rarely represents the final product. The finishing stage transforms functional components into professional, durable parts ready for their intended application. Understanding these options—and when they matter—separates adequate results from exceptional outcomes.

Finishing Options That Transform Raw Parts

Why finish metal parts at all? Raw fabricated surfaces show cutting marks, oxidation potential, and sharp edges that can compromise both function and appearance. The right finishing treatment addresses these issues while adding properties your application demands.

Here are the most common finishing options available through online fabrication platforms:

- Powder Coating – A dry finishing process where electrostatically charged powder particles adhere to grounded metal parts, then cure in an oven to form a durable, uniform coating. According to Gabrian's finishing comparison, powder coating excels at providing "vibrant colors or unique textures that will last, even when exposed to the elements." Typical applications include outdoor equipment, architectural components, and consumer products requiring both protection and aesthetics.

- Anodizing – An electrochemical process that thickens aluminum's natural oxide layer. As Gabrian explains, technicians "submerge [the aluminum piece] into an electrolytic bath, and run an electric current through it," creating enhanced wear resistance, corrosion protection, and improved heat dissipation. Anodized aluminum maintains a metallic appearance while accepting dyes for color options.

- Plating (Zinc, Nickel, Chrome) – Electroplating deposits thin metal layers onto base materials, providing corrosion resistance, wear protection, or decorative finishes. Zinc plating offers economical corrosion protection for steel; nickel and chrome plating add hardness and aesthetic appeal.

- Deburring and Tumbling – Mechanical processes that remove sharp edges and smooth surfaces. Essential for parts that will be handled, assembled, or used in applications where burrs could cause injury or interference.

- Passivation – Chemical treatment for stainless steel that removes surface contaminants and enhances the protective chromium oxide layer, maximizing corrosion resistance.

When Is Finishing Essential Versus Optional?

Not every part needs finishing—but knowing when it matters prevents both unnecessary expense and premature failure.

Finishing is essential when:

- Parts will be exposed to moisture, chemicals, or outdoor environments (corrosion protection)

- Components will be handled frequently (smooth edges, attractive appearance)

- Your application requires specific electrical properties (anodized surfaces are non-conductive)

- Parts must meet food-contact or medical-grade standards (appropriate coatings and passivation)

- Color matching or branding is required (powder coat or anodizing with dyes)

Finishing may be optional when:

- Parts remain inside sealed enclosures, protected from environmental exposure

- Components will receive additional finishing during later assembly stages

- Cost constraints outweigh appearance considerations for internal prototypes

- Material already provides adequate corrosion resistance (stainless steel in mild environments)

When choosing between anodizing and powder coating for aluminum parts, consider that anodizing maintains tighter dimensional tolerances—the oxide layer is extremely thin—while powder coat adds measurable thickness. If your parts have precision fits, anodized finishes preserve critical dimensions better.

Quality Standards Worth Demanding

Finishing quality depends heavily on the fabricator's quality management systems. For critical applications, certifications provide documented assurance of consistent results.

According to Xometry's certification guide, IATF 16949 certification represents the automotive industry's quality standard, ensuring "consistency, safety, and quality across automotive products." While developed for automotive applications, this certification signals manufacturing discipline applicable to any precision-critical project.

What does IATF 16949 certification actually mean for your parts? Certified facilities maintain:

- Documented quality management systems with traceable processes

- Rigorous internal and external audit programs

- Commitment to defect reduction and waste minimization

- Consistent training and competency verification for personnel

For parts destined for automotive chassis, suspension components, or other safety-critical assemblies, working with IATF 16949-certified suppliers isn't optional—it's essential.

Inspection and Documentation

Quality assurance extends beyond certifications to actual inspection practices. Professional metal bending service providers and fabricators should offer:

- First Article Inspection (FAI) – Detailed measurement verification of initial production samples against your specifications

- Dimensional Reports – Documentation confirming critical dimensions meet tolerance requirements

- Material Certifications – Mill test reports tracing material origin and properties (when specified)

- Finish Verification – Coating thickness measurements, adhesion testing, or salt spray results for corrosion-resistant finishes

When ordering multiple parts designed to fit together, request assembly verification. Having the fabricator confirm that mating parts actually assemble correctly—before shipping—catches tolerance stack-up issues that individual part inspections might miss.

With finishing options and quality standards clarified, you're equipped to specify complete, production-ready parts. The final piece of the puzzle? Knowing how to evaluate and select the right fabrication partner for your specific needs.

Evaluating Online Fabrication Services for Your Needs

You've mastered design principles, understand material options, and know what finishing treatments your parts require. Now comes a decision that can make or break your project: choosing the right fabrication partner. With dozens of sheet metal fabricators competing for your business, how do you separate exceptional service from mediocre execution?

Whether you're searching for fabrication shops near me or exploring nationwide online platforms, the evaluation criteria remain consistent. Let's build a framework that matches your specific needs—whether you're a weekend hobbyist, a professional engineer, or a procurement specialist managing production volumes.

Key Factors When Comparing Fabrication Services

Not all fabrication services are created equal. According to Prince Manufacturing's selection guide, "Selecting the right metal fabrication service provider is crucial for achieving your desired outcome." The quality of your fabrication partner directly impacts project success—from prototype accuracy to production consistency.

Here's what to evaluate systematically:

Turnaround Time Options

Your timeline requirements should match vendor capabilities. Some projects demand rapid prototyping measured in days; others can accommodate standard production schedules spanning weeks. The best steel fabricators offer tiered options:

- Rush/Rapid Prototyping – Parts shipped within 3-7 days for design validation and testing

- Standard Production – 2-3 week lead times balancing cost efficiency with reasonable speed

- Volume Production – Extended timelines optimized for maximum cost savings on large orders

For automotive and precision applications, manufacturers like Shaoyi Metal Technology demonstrate how rapid prototyping (as fast as 5 days) combined with production scalability serves the full project lifecycle—from initial concept validation through mass production.

Material Selection Breadth

Your fabricator's material inventory directly limits your design options. Evaluate whether they stock:

- Common grades of aluminum, mild steel, and stainless steel in multiple thicknesses

- Specialty alloys for demanding applications (316 stainless, 6061-T6 aluminum)

- Non-ferrous options like brass, copper, and bronze when required

- Various surface finishes and pre-treatments

Finishing Capabilities

Can the fabricator complete your parts in-house, or will finishing require coordination with third-party vendors? In-house capabilities for powder coating, anodizing, plating, and hardware insertion streamline your supply chain and reduce handling damage risks.

Quality Certifications

As Prince Manufacturing notes, "Quality assurance is essential in metal fabrication. Look for a provider that adheres to industry standards and certifications, such as ISO 9001." For automotive components, IATF 16949 certification signals manufacturing discipline specifically designed for safety-critical applications. Services like those offered by Shaoyi Metal Technology—delivering IATF 16949-certified quality for chassis, suspension, and structural components—demonstrate what quality indicators to look for when sourcing precision parts.

Customer Support Accessibility

When questions arise—and they will—can you reach knowledgeable support quickly? Evaluate response times, communication channels, and whether technical staff can address design or manufacturing questions directly.

Instant-Quote Platforms vs. Traditional RFQ Processes

Online fabrication services generally fall into two categories, each suited to different use cases:

Instant-Quote Platforms

These automated systems analyze your uploaded files and generate pricing immediately. Benefits include 24/7 accessibility, transparent pricing, and elimination of quote-waiting time. They excel for straightforward parts with standard materials and processes.

However, complex assemblies, unusual materials, or parts requiring extensive DFM consultation may not fit automated quoting systems. Some platforms flag these orders for manual review, which can extend response times.

Traditional RFQ (Request for Quote) Processes

Traditional quoting involves human engineers reviewing your specifications before providing pricing. This approach accommodates complex requirements, allows for detailed technical discussion, and often identifies cost-saving opportunities automated systems miss.

The trade-off? Longer response times—typically 1-5 business days versus seconds. For high-stakes production orders or parts requiring close collaboration, this investment in human review often pays dividends. Shaoyi Metal Technology, for example, combines the speed of 12-hour quote turnaround with comprehensive DFM support—bridging the gap between automated convenience and engineering expertise.

Red Flags and Green Lights in Vendor Selection

Experience teaches which signals predict success—and which warn of trouble ahead. Here's what to watch for:

Green Lights (Positive Indicators)

- Transparent Pricing – Itemized quotes showing material, processing, finishing, and shipping costs separately

- Proactive DFM Feedback – Engineers who identify potential issues and suggest improvements before production

- Clear Communication – Responsive support with direct access to technical staff when needed

- Documented Quality Systems – Certifications backed by actual inspection protocols and quality records

- Reference Availability – Willingness to provide case studies or connect you with previous customers

Red Flags (Warning Signs)

- Unusually Low Quotes – As Prince Manufacturing cautions, "Be cautious of quotes that seem too low, which may indicate compromised quality or hidden costs"

- Vague Specifications – Quotes that don't clearly state material grades, tolerances, or included services

- Poor Communication – Slow responses, unclear answers, or difficulty reaching decision-makers

- No Quality Documentation – Inability to provide inspection reports, material certifications, or process documentation

- Inflexibility – Unwillingness to accommodate reasonable design modifications or specification clarifications

Matching Vendors to Buyer Types

Different buyers have different priorities. Use this framework to focus your evaluation on what matters most for your situation:

| Buyer Type | Primary Priorities | Key Evaluation Criteria | Recommended Approach |

|---|---|---|---|

| Hobbyists/Makers | Ease of use, no minimum orders, reasonable pricing | Intuitive upload process, clear pricing, helpful tutorials | Start with instant-quote platforms; prioritize user experience |

| Engineers/Designers | Technical accuracy, DFM support, material options | Engineering review quality, tolerance capabilities, technical support access | Value DFM feedback over lowest price; test with prototype orders first |

| Procurement Teams | Documentation, certifications, supply chain reliability | Quality certifications, inspection reports, production capacity, on-time delivery history | Request references; verify certifications; establish qualification process |

| Automotive/Aerospace | IATF 16949 or AS9100 certification, traceability, zero-defect quality | Certified quality systems, first-article inspection protocols, material traceability | Require certification documentation upfront; conduct supplier audits when possible |

When searching for metal fab near me or sheet metal fabrication near me, remember that geographic proximity offers advantages for large or heavy parts where shipping costs dominate—but capabilities and quality should drive selection for precision components where a few extra shipping days matter less than manufacturing excellence.

Building Your Vendor Evaluation Checklist

Before committing to any fabrication partner, work through this evaluation framework:

- Verify Capabilities Match Requirements – Confirm they handle your specific materials, thicknesses, and processes

- Request Sample or Test Order – A small prototype order reveals actual quality and communication effectiveness

- Review Quality Documentation – Ask for sample inspection reports and verify certification validity

- Test Communication Responsiveness – Submit technical questions and evaluate response quality and speed

- Compare Total Cost – Factor in shipping, potential rework, and timeline impacts—not just quoted prices

- Check References – As Prince Manufacturing recommends, "Speaking directly with previous customers can offer a clearer picture of the fabricator's performance"

The right fabrication partner becomes a competitive advantage—delivering consistent quality, responsive support, and reliable timelines that let you focus on your core business rather than manufacturing headaches. With evaluation criteria established, you're ready to take action on your next project with confidence.

Moving Forward With Your Metal Fabrication Projects

You've journeyed from understanding what sheet metal fabrication online actually means to mastering design guidelines, material selection, and vendor evaluation. That's a significant transformation—from someone wondering how digital fabrication works to someone equipped to order custom parts with confidence.

But knowledge without action remains theoretical. Let's synthesize everything into actionable next steps tailored to wherever you are in your metal fab journey.

Your Path Forward in Online Metal Fabrication

Every successful fabrication project navigates the same critical decision points. Before uploading your first file—or your hundredth—run through this mental checklist:

- Process Selection – Does your design require laser cutting, waterjet, bending, or a combination? Match your geometry and material to the right manufacturing method.

- Material Choice – Have you balanced performance requirements against cost? Remember: specify what you need, not what sounds impressive.

- Design for Manufacturability – Do your hole sizes, bend radii, and feature spacing respect physical manufacturing constraints? Violations here create delays and cost overruns.

- Vendor Alignment – Does your chosen fabricator's capabilities, certifications, and communication style match your project requirements?

These four pillars—process, material, design, and vendor—determine whether your project runs smoothly or stumbles through revisions.

Online platforms have democratized access to professional metal parts fabrication. The same precision equipment and processes that once required industry connections and volume commitments are now available to anyone with a design file and an idea worth building.

Taking Action on Your Next Project

Where you start depends on where you are. Here's tailored guidance for different stages of your fabrication journey:

First-Time Users: Start Simple

Your goal isn't perfection—it's learning the workflow. Choose a straightforward flat part: a simple bracket, a decorative sign, or a basic enclosure panel. Keep it to one material, minimal bends, and standard finishes. This approach teaches you the upload-quote-order-receive cycle without overwhelming complexity.

Apply the design guidelines from earlier sections before uploading. Check hole diameters against material thickness. Verify feature spacing meets minimum requirements. A clean first order builds confidence for more ambitious projects.

Experienced Engineers: Leverage DFM Support

You understand manufacturing constraints, but fresh perspectives catch blind spots. When tackling complex assemblies with multiple bent components, tight tolerances, or novel geometries, engage fabricators who offer comprehensive DFM review.

According to UPTIVE's prototype-to-production guide, working with experienced manufacturing partners helps "refine your product design faster" while making "long-term, large-volume production more cost-effective." Don't view DFM feedback as criticism—view it as free engineering consultation that prevents expensive downstream corrections.

Production Buyers: Prioritize Certified Suppliers

When parts affect safety, reliability, or regulatory compliance, vendor selection transcends price comparison. Prioritize fabricators with documented quality systems, traceable processes, and relevant certifications for your industry.

For automotive chassis, suspension, and structural components, IATF 16949 certification isn't optional—it's essential. Manufacturers like Shaoyi Metal Technology demonstrate the combination of rapid 12-hour quote turnaround, 5-day prototyping capability, and IATF 16949-certified production that bridges initial development through mass manufacturing seamlessly.

Steel fabrication for production volumes demands suppliers who can scale consistently. Verify on-time delivery history, inspect sample parts before committing to large orders, and establish clear quality specifications upfront.

Applying What You've Learned

Whether you're searching for metal fabrication near me or exploring nationwide online services, the evaluation framework from earlier sections serves as your roadmap. Before committing to any vendor:

- Submit a test file to evaluate their quoting process and DFM feedback quality

- Request sample inspection reports to verify quality documentation practices

- Confirm turnaround time options align with your project timeline

- Verify material availability for your specific requirements

- Test communication responsiveness with technical questions

Custom metal cutting and forming have never been more accessible. The barriers that once separated makers from manufacturing—minimum orders, insider knowledge, relationship-based pricing—have largely dissolved. What remains is your willingness to take the first step.

Upload that design. Get that quote. Build something real. The digital fabrication revolution isn't coming—it's here, and it's waiting for your next project.

Frequently Asked Questions About Metal Fabrication Online

1. What is custom sheet metal fabrication and how does it work online?

Custom sheet metal fabrication online is a digital manufacturing process where you upload design files (typically STEP, DXF, or DWG formats) to a web-based platform, configure material and thickness options, receive an instant quote, and have professionally manufactured parts delivered to your location. The process includes automated design analysis, human engineering review for manufacturability, and production using laser cutting, CNC bending, and finishing services—all without visiting a physical shop.

2. What file formats are accepted for online metal fabrication orders?

Most online fabrication platforms require 3D CAD files for sheet metal parts, with STEP files (.step, .stp) being the universal standard. For flat laser-cut parts only, DXF files work well as they contain exact cutting geometry. If your design includes threading, welding, or tight tolerances, you should also provide a 2D drawing (PDF, DWG, or DXF) with clear annotations to communicate specifications that geometry alone cannot convey.

3. How do I choose between aluminum, steel, and stainless steel for my project?

Choose aluminum when weight matters and corrosion resistance is needed—it's ideal for aerospace, electronics, and marine applications. Select mild steel for cost-effective structural applications requiring high strength, though it needs protective coatings against rust. Opt for stainless steel (304 for general use, 316 for harsh environments) when you need both strength and corrosion resistance without additional finishing. Consider your application's exposure to moisture, required strength, weight constraints, and budget when making this decision.

4. What are the key design rules to follow for sheet metal fabrication?

Critical design rules include: hole diameters should equal or exceed material thickness; inside bend radius should match material thickness minimum; holes must stay at least 2x material thickness away from bend lines; flange width needs to be at least 4x material thickness; and always include bend reliefs at bend-line endpoints. Following these guidelines prevents manufacturing issues like cracking, distortion, and tool breakage while reducing costs and production delays.

5. How can I reduce costs when ordering custom fabricated metal parts?

Optimize costs by simplifying designs to eliminate unnecessary features, choosing cost-effective materials that meet requirements without over-specifying, batching similar orders to share setup costs, relaxing non-critical tolerances, using standard hole sizes and bend radii, and reconsidering finishing requirements for parts that don't need them. Volume orders also significantly reduce per-piece costs since setup expenses are distributed across more parts. Requesting DFM feedback from fabricators often reveals additional cost-saving design modifications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —