Process Of Stamping Demystified: From Raw Sheet To Finished Part

What Metal Stamping Actually Means in Modern Manufacturing

Ever wondered how manufacturers produce millions of identical metal parts with incredible precision? The answer lies in a process that has shaped industries for over a century. Understanding what is metal stamping opens the door to appreciating one of the most efficient manufacturing methods available today.

The Core Definition of Metal Stamping

So, what is stamping exactly? At its core, the stamping meaning refers to a cold-forming manufacturing process that transforms flat sheet metal into precise, three-dimensional shapes. Unlike machining operations that cut away material, metal stamping applies controlled force to deform metal without removing any of it. This fundamental principle makes the process incredibly efficient, with minimal waste and maximum material utilization.

Metal stamping—also called pressing—involves placing flat sheet metal, in either coil or blank form, into a stamping press where a tool and die surface form the metal into the desired shape through techniques such as punching, blanking, bending, coining, embossing, and flanging.

When you think about stamping means in practical terms, imagine pressing a cookie cutter into dough—except the "dough" is steel, aluminum, or copper, and the forces involved can reach thousands of tons. The metal flows and stretches into the die cavity, permanently taking on the new shape while maintaining its structural integrity.

Why Stamping Dominates Modern Manufacturing

Why has this method become the backbone of high-volume production? The answer comes down to three critical advantages: speed, consistency, and cost-effectiveness.

Consider the automotive industry, where a single vehicle contains hundreds of stamped metal components. From body panels to brackets, manufacturers rely on this process because it delivers:

- Exceptional speed: Modern presses can complete anywhere from 20 to 1,500 strokes per minute

- Remarkable consistency: Each part matches the previous one with precision measured in fractions of a millimeter

- Economic efficiency: Once tooling is established, per-unit costs drop dramatically at high volumes

Beyond automotive applications, stamped metal parts appear in aerospace components, electronic devices, medical equipment, and everyday consumer goods. The process has evolved significantly since its early adoption in the 1880s for bicycle parts, eventually forcing even Henry Ford to embrace it when die forging couldn't meet production demands.

Three Essential Components Every Stamping Operation Requires

What is a stamping operation without its foundational elements? Every successful stamping process relies on three interconnected components working in harmony:

- Sheet Metal (The Workpiece): The raw material—typically steel, aluminum, copper, or brass—arrives as flat coils or pre-cut blanks. Material properties like ductility and tensile strength directly influence what shapes can be achieved.

- Die (The Tooling): This precision-engineered tool contains the negative image of the final part. Dies can range from simple single-operation designs to complex progressive systems with dozens of stations.

- Press (The Power Source): Whether mechanical, hydraulic, or servo-driven, the press delivers the controlled force needed to push metal into the die cavity. Press selection depends on factors like required tonnage, stroke speed, and part complexity.

These three elements form the foundation you'll need to understand as we explore each stage of this manufacturing method in detail. The interplay between material selection, die design, and press capabilities ultimately determines whether a project succeeds or fails.

Complete Step-by-Step Stamping Workflow Explained

Now that you understand the foundational components, how does an idea actually become a finished stamped part? The metal stamping process follows a carefully orchestrated sequence where each stage builds upon the previous one. Skip a step or rush through it, and you'll face costly rework downstream. Let's walk through the complete manufacturing stamping process from concept to final inspection.

From Blueprint to Finished Part

Think of the stamping process like building a house—you wouldn't pour the foundation before finalizing architectural drawings. Similarly, successful stamping projects move through distinct phases in a specific order:

- Concept and Design Development: Engineers work with clients to understand functional requirements, tolerances, and production volumes. Using CAD software, they create detailed 3D models and technical drawings that define every dimension.

- Material Selection: Based on the part's end-use requirements, engineers select the optimal metal—considering factors like strength, formability, corrosion resistance, and cost.

- Tooling and Die Design: Precision dies are engineered to match exact specifications. This stage determines whether the part can actually be manufactured as designed.

- Die Fabrication: Skilled toolmakers build the dies using high-quality tool steels, often incorporating CNC machining and EDM processes for accuracy.

- Prototyping and Validation: Before full production, sample parts are created to test the die and verify that outputs meet specifications.

- Press Setup and Programming: Operators configure the stamping press with optimal parameters—stroke length, speed, pressure, and feed rate.

- Production Run: Metal sheets or coils are fed into the press, where dies transform raw material into finished components at high speed.

- Quality Inspection: Each part undergoes dimensional checks, visual assessment, and functional testing to ensure consistency.

- Secondary Operations and Finishing: Parts may require additional processes like deburring, heat treatment, plating, or assembly.

Why does this sequence matter so much? Because decisions made in early stages ripple through the entire sheet metal stamping process. Selecting the wrong material affects die wear. Poor die design leads to defects during production. Inadequate setup causes inconsistent parts. Each phase connects directly to the next.

The Critical Design and Engineering Phase

Imagine trying to build furniture without measurements—that's what rushing past the design phase looks like. According to RCO Engineering, product development starts with conceptualizing the end product, requiring design teams and engineers to collaborate on intricate designs based on specifications.

During this phase, engineers focus on several critical elements:

- Design for Manufacturability (DFM): Parts are optimized so they can actually be stamped efficiently, avoiding impossible geometries or excessive complexity.

- Tolerance Analysis: Engineers determine acceptable dimensional variations based on functional requirements.

- Material Specification: Strength, flexibility, and cost all factor into choosing between steel, aluminum, brass, or copper.

- Volume Considerations: Production quantities influence whether progressive dies or simpler compound dies make economic sense.

The stamping metal process truly begins here—not when the press starts running. As noted by Sinoway Industry, using state-of-the-art CAD software to create detailed blueprints and 3D models ensures the product design is optimized for both functionality and manufacturability.

Production Workflow That Ensures Consistency

Once tooling is validated and the press is configured, the production phase transforms raw material into finished components. But what actually happens during a typical stamping cycle?

A standard production workflow includes these steps:

- Material Loading: Coiled metal or pre-cut blanks are fed into the press, either manually or through automated feeding systems.

- Positioning: The material advances to precise locations using pilot pins or sensor-guided systems.

- Stamping Action: The press ram descends, forcing material into the die cavity where it's cut, bent, or formed.

- Part Ejection: Completed parts are stripped from the die and collected for inspection.

- Cycle Repeat: The process continues at speeds ranging from 20 to over 1,000 strokes per minute, depending on part complexity.

Engineers use lubricants throughout the stamping manufacturing process to reduce friction and extend tool life. Cooling systems help disperse heat, particularly during high-speed operations where friction can affect part quality.

Quality control doesn't wait until the end. Operators monitor parameters in real-time, and statistical sampling catches deviations before they become widespread problems. As Aranda Tooling emphasizes, the ideal metal pressing service provider combines equipment, custom capabilities, and extensive expertise to achieve project goals.

Understanding this complete workflow reveals why stamping excels at high-volume production—once the system is dialed in, it delivers remarkable consistency part after part. But what type of press should you use for your specific application? That's exactly what we'll explore next.

Stamping Press Types and Their Ideal Applications

So you've designed your part and mapped out the workflow—but which stamping press should actually form your metal? This question trips up many manufacturers because the answer directly affects production speed, part quality, and long-term costs. Let's break down the three primary press types so you can match the right machine to your specific needs.

What is a stamping press at its core? It's the powerhouse that delivers controlled force to push metal into die cavities. But not all stamping presses operate the same way. Each type—mechanical, hydraulic, and servo—uses different mechanisms to generate and control that force. Understanding these differences helps you avoid costly mismatches between equipment and application.

Mechanical Presses for High-Speed Production

If speed is your priority, mechanical presses are often the best choice. These machines use an electric motor to generate energy, which is transferred and stored in a massive flywheel. That flywheel powers the punch-press system through a crankshaft mechanism, converting rotational energy into the linear motion that drives the ram.

Why do manufacturers love mechanical metal stamping presses for high-volume work? The answer lies in their operating principle. The flywheel stores rotational energy and releases controlled portions to drive rapid, consistent strokes. According to Sangiacomo Presses, mechanical presses excel at operating at higher speeds than servo press machines, making them particularly advantageous for large-scale operations where every second of production matters.

Key advantages of mechanical stamping presses include:

- Exceptional speed: Continuous rapid cycles ensure high output for repetitive production tasks

- Reliability and durability: Decades of proven technology with sturdy construction that minimizes unexpected breakdowns

- Raw power: Ratings typically range from 20 tons up to 6,000 tons, handling heavy-duty tasks with ease

- Cost-effectiveness: Lower upfront investment and straightforward maintenance compared to servo alternatives

However, mechanical presses have limitations. They offer reduced flexibility in stroke length and profile. The flywheel runs continuously throughout the press cycle, leading to higher energy consumption. They also tend to operate at higher noise levels, potentially requiring additional workplace safety measures.

Hydraulic Press Advantages in Complex Forming

When your application demands variable force and deep drawing capability, hydraulic presses step into the spotlight. These machines operate on a completely different principle—using pressurized hydraulic fluid instead of a kinetic flywheel to generate force.

The basic configuration involves two interconnected cylinders: a large high-volume cylinder called the "ram" and a smaller low-volume cylinder called the "plunger." As hydraulic fluid moves from the ram to the plunger, internal pressure ramps up dramatically. According to SPI, this system can deliver up to approximately 10,000 tons of metal stamping force.

What makes a steel stamping press using hydraulic power ideal for complex forming? Consider these advantages:

- Full force throughout stroke: Unlike mechanical presses that peak at specific points, hydraulic systems maintain consistent pressure

- Superior deep drawing capability: The controlled, variable force excels at forming complex cross-sections

- Flexibility with heavy materials: Preferred for working with thicker or high-tensile metals

- Adjustable force application: Operators can fine-tune pressure based on material requirements

The tradeoff? Hydraulic presses operate slower than mechanical counterparts. But for applications requiring intricate stamped metal parts or significant material deformation, that consistency and adaptability often outweighs speed considerations.

Servo Press Technology and Programmable Control

Imagine combining mechanical speed with hydraulic precision—that's essentially what servo press technology delivers. These advanced machines use high-capacity servo motors instead of flywheels, offering unprecedented control over the stamping process.

What sets a metal stamping press machine with servo technology apart? The servo motor directly controls ram movement, allowing real-time adjustments to stroke and speed based on the task at hand. Software controls the motor, enabling on-the-fly modifications that mechanical systems simply cannot match.

According to Eigen Engineering, servo presses are excellent for jobs requiring extreme accuracy, such as electronics, medical items, or high-end stamped metal parts. They also allow quick setup adjustments, making them ideal for job shops with changing requirements.

The standout benefits include:

- Precision and control: Highly programmable stroke profiles with adjustable motion, speed, and position at any point

- Energy efficiency: Power consumption occurs only during the actual stamping process, not continuously

- Versatility: Adapts to different materials, thicknesses, and forming requirements without physical adjustments

- Reduced setup times: Stored programs can be recalled instantly for high-mix production environments

- Maximum force flexibility: Able to output maximum pressing force at any point within the operation

The downsides? Higher initial investment and more complex maintenance requirements. These machines demand operators with greater technical expertise and specialized knowledge for both mechanical and software components.

Press Type Comparison at a Glance

Choosing between these options requires weighing multiple factors against your specific production needs. The following comparison helps clarify which press type aligns with different operational priorities:

| Factor | Mechanical Press | Hydraulic Press | Servo Press |

|---|---|---|---|

| Speed Capability | Highest (rapid continuous cycles) | Slowest (controlled, steady) | Moderate to High (programmable) |

| Force Range | 20 to 6,000 tons | Up to 10,000 tons | Varies by model; full force at any stroke point |

| Precision Level | Consistent but fixed profile | Good with variable control | Exceptional (fully programmable) |

| Energy Consumption | Higher (continuous flywheel operation) | Moderate | Lower (on-demand power usage) |

| Best Applications | High-volume, repetitive production; progressive and transfer operations | Deep drawing; heavy materials; complex forming | High-mix production; precision parts; electronics and medical components |

| Initial Cost | Lower | Moderate | Higher |

| Maintenance Complexity | Straightforward | Moderate | Complex (requires specialized expertise) |

How does press selection affect part quality? The relationship is direct. Mechanical presses deliver consistent results for simple, repetitive operations but lack flexibility for complex geometries. Hydraulic systems excel when parts require sustained pressure or significant material flow. Servo presses offer the precision needed for tight tolerances and intricate features.

Tonnage requirements also influence your choice. Undersize the press, and you'll struggle with incomplete forming or excessive die wear. Oversize it, and you're wasting capital on unused capacity. Matching press capability to your specific part requirements ensures optimal results without unnecessary expense.

With press selection clarified, the next logical question becomes: what stamping techniques will these machines perform? Let's explore the nine essential methods that transform flat metal into functional components.

Nine Essential Stamping Techniques and When to Use Each

You've selected your press and mapped your workflow—but which stamping technique actually shapes your part? The answer depends on what you're trying to achieve. Each method applies force differently, creating distinct outcomes ranging from simple cutouts to complex three-dimensional forms. Let's explore the nine core techniques that manufacturers rely on daily, along with the engineering principles that make each one work.

Before diving into specifics, here's a quick overview of the techniques we'll cover:

- Blanking: Cutting flat shapes from sheet metal to create workpieces

- Piercing: Punching holes and internal features into metal sheets

- Bending: Forming angles and curves along a linear axis

- Coining: Applying extreme pressure to create fine details and precise dimensions

- Embossing: Raising or recessing patterns on metal surfaces

- Flanging: Bending edges at angles for assembly or reinforcement

- Drawing: Pulling metal into deep cavities to form hollow shapes

- Progressive Die Stamping: Performing multiple operations in sequence as material advances through stations

- Transfer Die Stamping: Moving separated parts between independent workstations

Understanding when to apply each technique—and recognizing their limitations—separates successful projects from costly failures. Let's examine each method in detail.

Blanking and Piercing for Precision Cutouts

What happens first when raw sheet metal enters a stamping operation? Typically, it gets cut. Blanking and piercing represent the two primary cutting techniques, and while they seem similar, they serve opposite purposes.

Blanking involves cutting a flat shape from a larger sheet—the removed piece becomes your workpiece. Think of it like using a cookie cutter where you keep the cookie and discard the surrounding dough. According to Tuling Metal, blanking is the first step in metal stamping operations, where the outer profile of the stamped metal component is cut for convenience. This example of stamping creates the foundation for all subsequent forming operations.

When you're blank stamping metal, the engineering principle relies on shear force. A punch descends into a matching die cavity, and the metal fractures cleanly along the cutting edge. The gap between punch and die—called clearance—critically affects edge quality. Too little clearance causes excessive tool wear; too much creates rough, burred edges.

Piercing flips the script. Here, you punch holes or slots into the sheet, and the removed slugs become scrap. The workpiece remains the sheet with holes in it. Piercing tools typically use high-carbon steel and require regular maintenance to maintain precision cutting. Variations include lancing (cutting partial outlines), shaving (improving edge finish), and nibbling (creating complex shapes through overlapping cuts).

Key considerations for cutting operations:

- Minimum hole diameter should equal at least 1.2x material thickness for ductile materials like aluminum

- For high-tensile materials like stainless steel, increase minimum diameter to 2x thickness

- Edge-to-feature spacing should maintain at least 2x material thickness to prevent distortion

- Blanking produces rough edges requiring deburring or secondary finishing

Bending and Forming Techniques Compared

Once your blank is cut, bending transforms flat metal into three-dimensional shapes. But bending isn't one technique—it's a family of related methods, each suited to specific applications.

Standard bending places metal over a die while a ram pushes against the blank to produce desired angles. You'll encounter L-bends, U-bends, and V-bends depending on the die geometry. The engineering challenge? Springback. Metal has an elastic component that causes it to partially return toward its original shape after the load is released. Experienced engineers compensate by over-bending slightly.

Air bending offers an economical alternative. The punch doesn't fully bottom out against the die, leaving an air gap beneath the material. This approach requires lower tonnage and eliminates the need for matched tooling, but achieving tight tolerances becomes more difficult. Angle accuracy depends on precise clearance control.

Bottoming (also called coining bending) drives the sheet fully into a fitted V-die under strong pressure. Unlike air bending, bottoming produces permanent, precise bends with minimal springback. The tradeoff? It only supports V-shaped bends and requires significantly higher press force.

Flanging specializes in bending small workpiece edges at curved angles. These flanged edges create connection points for fastening assemblies together. Manufacturers rely on flanging when high accuracy along curved surfaces is required.

Critical bending considerations:

- Bending stiff metals with low plasticity risks cracking—especially when bends run parallel to grain direction

- Perform bending after drawing operations to avoid stress concentration defects

- Maintain minimum bend radius of at least 0.5x material thickness for sharp corners

- Allow 1-degree tolerance variation when stamping 90-degree angles

Coining and Embossing for Surface Detail

Need fine details, precise dimensions, or decorative patterns? Coining and embossing deliver surface modifications that other techniques cannot achieve.

Coining represents cold-forming at its most precise. Two dies compress the sheet metal from both sides simultaneously, applying extreme pressure that causes material to flow into every die detail. When coining sheet metal, the process produces fine features with minimal material displacement. The resulting surfaces exhibit enhanced resistance against impact and abrasion—which explains why actual coin production uses this method. Coining steel or other metals typically occurs as a finishing operation after primary forming is complete.

Embossing creates raised or recessed patterns on metal surfaces. A blank sheet presses against a die containing desired patterns, transferring those designs onto the workpiece. The result? A three-dimensional effect that adds visual interest or functional features like grip patterns. Aluminum excels in embossing applications due to its excellent ductility and machinability.

The key difference? Coining involves compression from both sides with significant material flow, while embossing typically works from one side to create surface relief.

Drawing for Hollow and Deep Shapes

How do manufacturers create hollow parts like cups, cans, or enclosures? Drawing operations pull sheet metal into die cavities, forming three-dimensional shapes from flat stock.

Standard drawing uses a punch matching the die's cross-section. As the punch descends, it pulls sheet metal into the die's depth, shaping the material around the punch profile. This stamping and pressing technique produces components with thin walls and irregular shapes, though accuracy remains lower than deep drawing alternatives.

Deep drawing takes this further. Here, the depth of the drawn part exceeds its diameter—achieving height-to-width ratios of 2:1 or even 3:1. This technique manufactures versatile components with complex detailing and exceptional accuracy. Deep drawing serves as a cost-effective alternative to turning processes for hollow cylindrical parts.

Drawing operations require careful attention to:

- Blank holder force—insufficient pressure causes wrinkling as material flows unevenly

- Lubrication—reduces friction between die surfaces and material

- Material selection—ductile metals like aluminum and low-carbon steel draw more easily

- Multiple reduction stages for extreme depth ratios

Progressive Die Stamping for Complex Parts

What if your part requires multiple operations—blanking, piercing, bending, and forming? Running separate passes through different dies wastes time and introduces alignment errors. Progressive die and stamping solves this by combining operations into a single automated sequence.

In progressive stamping, a metal coil feeds through a series of stations within one die set. Each station performs a specific operation as the strip advances. According to Larson Tool, progressive dies are designed for high-volume production of complex parts, operating through sequential stations where each performs a specific operation on the workpiece as it moves through the press.

The engineering brilliance? Guide posts align each operation precisely, ensuring accuracy as the metal strip progresses. The finished part separates from the carrier strip at the final station, while a new section immediately enters the first station. No breaks, no repositioning—just continuous production.

Progressive die advantages include:

- Automated continuous operation without manual intervention

- Precise alignment through guide posts and pilot pins

- High-speed production suitable for large orders of repeatable parts

- Reduced handling and associated quality risks

The limitation? Higher upfront tooling costs due to the complex, multi-station die design. Progressive dies demand meticulous planning and precision engineering, but per-part costs decrease significantly with volume.

Transfer Die Stamping for Large Components

Progressive stamping works brilliantly—until your parts are too large or require operations that can't sequence linearly. Transfer die stamping addresses these challenges by separating the workpiece from the metal strip at the beginning rather than the end.

In transfer operations, mechanical systems move individual parts between independent workstations. Unlike progressive dies where the strip carries parts forward, transfer systems physically relocate each piece. This approach dramatically reduces metal waste since no carrier strip connects the stations.

Transfer die stamping excels at producing:

- Large or intricate parts that won't fit progressive die constraints

- Components requiring operations from multiple angles

- Tube and deep-drawing applications

- Parts with threads, knurls, or knobs

Because transfer systems allow one or more independent dies, tooling costs can actually decrease compared to complex progressive setups. However, the sophisticated transfer mechanisms require regular maintenance to prevent misalignment or part defects.

Cold Forming vs. Hot Forming: Practical Implications

Most stamping operations occur at room temperature—this is cold forming. But when should you consider hot stamping instead?

Cold stamping represents standard practice. The metal's mechanical profile remains constant throughout processing. Benefits include simpler equipment, lower energy costs, and excellent surface finish. However, cold forming requires higher press force since room-temperature metal resists deformation more strongly.

Hot stamping heats metal before forming, changing its microstructure. At low temperatures, metal crystals exist in harder, more brittle orientations. Heating transforms them into softer, more ductile phases—reducing the pressure needed for deformation. After forming, quenching the hot part creates a martensitic structure that adds hardness and strength.

Practical implications:

| Factor | Cold Stamping | Hot Stamping |

|---|---|---|

| Required Force | Higher | Lower |

| Surface Finish | Excellent | May require secondary finishing |

| Material Thickness | Up to approximately 3 inches with special dies | Better suited for thicker materials |

| Part Strength | Consistent with base material | Can be enhanced through heat treatment |

| Energy Consumption | Lower | Higher (heating required) |

| Complexity | Simpler process control | Requires temperature management |

Hot stamping produces parts that absorb high-impact energy without fracturing—making it ideal for automotive safety components. Cold forming remains the default for most applications due to its simplicity and cost-effectiveness.

Selecting the right technique—or combination of techniques—depends on your part geometry, material properties, and production requirements. But even perfect technique selection won't overcome poor material choices. That's why understanding stampability factors matters just as much as mastering the methods themselves.

Material Selection and Stampability Factors

You've mastered the techniques—but can your chosen material actually handle them? This question separates successful stamping projects from costly failures. Selecting the wrong metal stamping materials leads to cracked parts, excessive die wear, and production delays that erode profit margins. Let's explore how material properties directly influence what you can achieve in the stamping process.

Think of stampability as a material's "willingness" to be formed. Some metals flow easily into complex shapes while others resist deformation or crack under stress. Understanding these characteristics helps you match metal for stamping to your specific application requirements—balancing formability, strength, cost, and end-use performance.

Steel Grades and Their Stamping Characteristics

Steel remains the workhorse of metal stamping, but not all steel grades perform equally. The key differentiator? Carbon content and alloying elements.

Low carbon steel (0.05% to 0.3% carbon) offers excellent formability and cost-effectiveness. According to Pans CNC, low carbon steels provide good weldability, ductility, and tensile strength while maintaining cost efficiency. Common grades like 1008, 1010, and 1018 handle deep drawing, bending, and progressive die operations without cracking. The tradeoff? Lower hardness and susceptibility to corrosion require protective coatings for many applications.

Stainless steel metal stamping introduces chromium, nickel, and molybdenum to create corrosion-resistant alloys. The 300 series (austenitic) offers superior corrosion resistance and ductility but exhibits high work-hardening rates—meaning the material becomes harder and more resistant to deformation as you work it. The 400 series (ferritic) provides good formability with lower work-hardening, making it suitable for applications where corrosion resistance matters but extreme ductility isn't required.

Key stainless steel stamping considerations:

- 304 stainless delivers tensile strength ≥515MPa with excellent salt spray resistance (≥48 hours)

- Higher forming forces required compared to carbon steel—expect 50% to 100% more tonnage

- Work hardening accelerates die wear, requiring harder tooling materials

- Ideal for medical equipment, food processing, and automotive charging terminals

Galvanized steel combines carbon steel's formability with zinc coating protection. With zinc layer thickness ≥8μm, these materials offer basic rust prevention at lower cost than stainless alternatives. According to Tenral, galvanized steel suits structural parts with cost sensitivity and short-term rust prevention needs, such as chassis brackets for new energy vehicles and appliance control panels.

Aluminum Stamping Considerations

When weight reduction matters, aluminum stamping delivers. At just 2.7 g/cm³ density—roughly one-third of steel—stamped aluminum components significantly reduce product weight without sacrificing structural integrity.

But aluminum isn't a single material—it's a family of alloys with varying characteristics:

- 1100 series (pure aluminum): Excellent ductility for deep-drawn components; lowest strength

- 3003 and 5052: Good balance of strength and stampability for general applications

- 5083: Higher strength with good corrosion resistance for marine and structural uses

- 6061: Heat-treatable for structural stamped parts requiring higher strength

According to LS Rapid Prototyping, aluminum provides high mechanical strength and good electrical conductivity while being corrosion-resistant and non-toxic. It requires no additional coatings during precision machining, though anodizing enhances appearance and further improves corrosion resistance.

Aluminum stamping does present challenges. The material's lower tensile strength (110-500 MPa depending on alloy) means careful attention to forming limits. Galling—where aluminum sticks to die surfaces—requires specialized lubricants and sometimes surface treatments on tooling.

Copper and Brass: Conductivity Champions

When electrical or thermal conductivity drives your design, copper stamping and brass alternatives deserve consideration.

Copper offers conductivity up to 98%, making it irreplaceable for electrical contacts, busbars, and heat transfer components. Grades like C101 and C110 provide excellent formability for cold forming techniques. According to Tenral, copper is easy to punch into micro-contacts, making it suitable for SIM card shrapnel and industrial sensor wiring terminals.

Copper's natural antimicrobial properties add value for medical and food-processing applications. However, at 8.9 g/cm³ density, weight becomes a consideration for portable products.

Brass (copper-zinc alloy) provides a cost-effective alternative when pure copper's conductivity isn't essential. H62 brass delivers hardness of HB≥80 with excellent machinability—often requiring no secondary processing after stamping. Its ductility allows forming into complex bends and tight radii that would challenge other materials.

Brass stampings commonly appear in:

- Smart door lock mechanisms

- Automotive air conditioning joints

- Electrical terminals and connectors

- Decorative hardware and architectural elements

How Material Properties Affect Die Design

Your material choice ripples directly into tooling requirements. Understanding this connection prevents expensive mismatches between dies and metals.

Ductility measures how much a material can stretch before fracturing. High-ductility materials like aluminum and brass tolerate aggressive forming operations. Low-ductility metals require larger bend radii and gentler forming sequences to prevent cracking.

Tensile strength indicates resistance to being pulled apart. Higher strength materials demand more press tonnage and harder die materials. Stainless steel's elevated tensile strength (≥515 MPa) explains why it requires substantially more forming force than mild steel.

Work hardening describes how materials strengthen during deformation. Austenitic stainless steels work-harden rapidly—the first forming pass makes subsequent passes more difficult. Dies must account for this progressive strengthening through proper clearances and forming sequences.

Thickness affects nearly every aspect of die design. Thicker materials require wider die clearances, higher tonnage, and more robust tooling construction. Minimum feature sizes scale proportionally—a hole suitable for 0.5mm aluminum won't work in 2mm steel without modifications.

Material Comparison at a Glance

Selecting the optimal material requires balancing multiple factors against your application requirements. This comparison summarizes key characteristics to guide your decision:

| Material Type | Tensile Strength (MPa) | Density (g/cm³) | Stampability Rating | Typical Applications | Key Considerations |

|---|---|---|---|---|---|

| Low Carbon Steel | ≥375 | 7.8 | Excellent | Automotive brackets, appliance panels, structural components | Requires coating for corrosion protection; lowest cost option |

| Stainless Steel | ≥515 | 7.9 | Good to Moderate | Medical equipment, food processing, charging terminals | High work hardening; requires 50-100% more forming force |

| Aluminum | 110-500 | 2.7 | Excellent | 5G heat sinks, electronics enclosures, lightweight structural parts | Galling risk; specialized lubricants recommended |

| Copper | 200-450 | 8.9 | Good | Electrical contacts, busbars, heat exchangers | Highest conductivity; higher material cost |

| Brass | 300-600 | 8.5 | Excellent | Connectors, decorative hardware, lock mechanisms | Cost-effective copper alternative; easy to form complex shapes |

| Galvanized Steel | ≥375 | 7.8 | Excellent | Chassis brackets, control panels, structural parts | Basic rust prevention; coating may flake during severe forming |

The right material isn't always the strongest or most expensive—it's the one that matches your forming requirements, end-use environment, and budget constraints. A real-world example illustrates this perfectly: when a communications company needed lightweight 5G base station heat sinks with thermal conductivity ≥150W/(m·K), pure copper would have exceeded weight limits. By selecting 6061-T6 aluminum and precision stamping, they achieved weight targets while increasing heat dissipation efficiency by 25% and reducing costs by 18%.

Material selection establishes the foundation—but even perfect material choices won't compensate for poor tooling. Understanding die design fundamentals ensures your selected material transforms into quality parts consistently.

Die Design Fundamentals and Tooling Essentials

You've selected the perfect material and chosen your stamping technique—but what actually shapes that metal into precision parts? The answer lies in the die. This precision-engineered tool determines everything from edge quality to dimensional accuracy, yet many manufacturers overlook its critical importance. Understanding steel stamping dies and their design principles separates consistently successful operations from those plagued by quality issues and unexpected downtime.

Think of a stamping die as the DNA of your finished part. Every feature, every tolerance, every surface finish traces back to how that die was designed, built, and maintained. A poorly engineered die produces scrap. A well-designed die running on proper maintenance schedules delivers millions of identical parts. Let's explore what makes the difference.

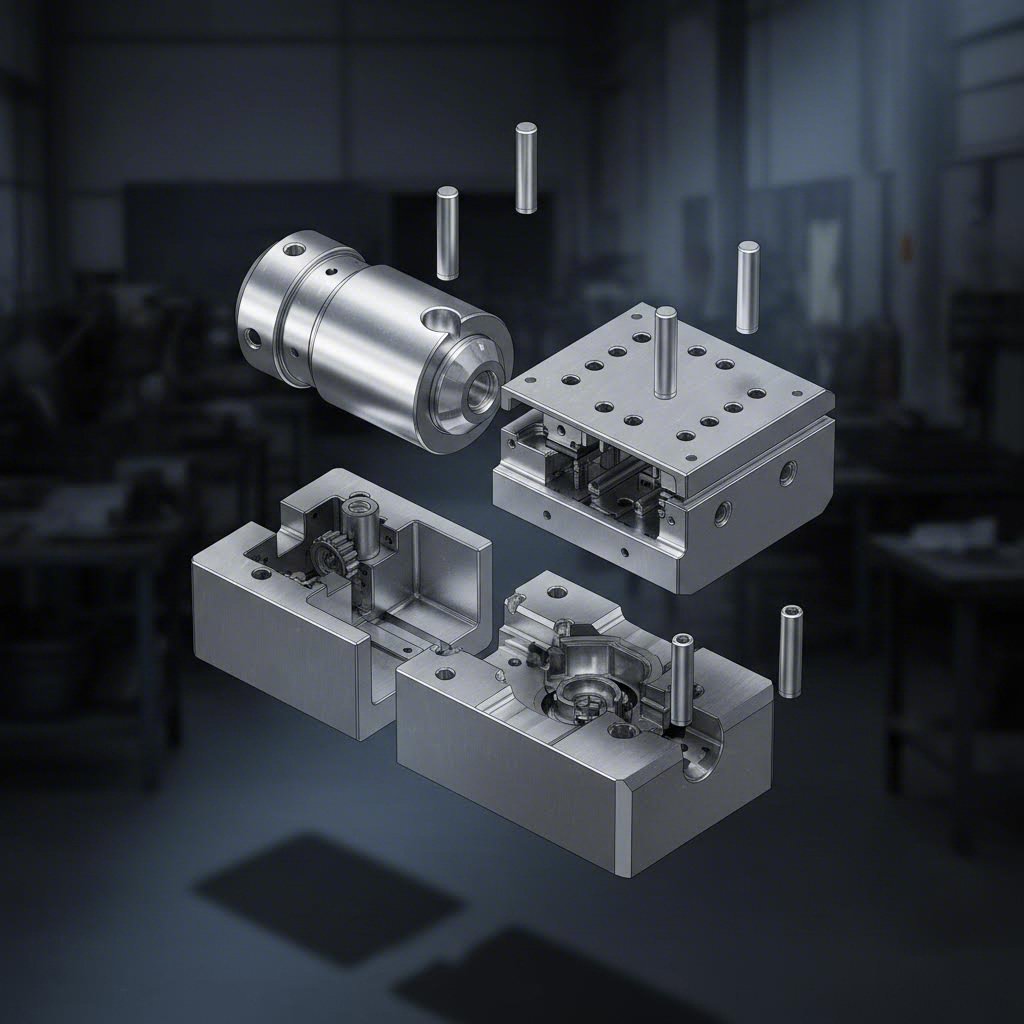

Essential Die Components and Their Functions

What's actually inside a stamping machine for metal? Every die assembly—whether simple or complex—shares fundamental components that work together to transform flat sheet into finished parts. According to Dynamic Die Supply, these components each serve specific functions within the overall assembly:

- Die Block: The female portion of the die, situated at the bottom of the assembly. It houses the holes and protrusions necessary for material forming—essentially the cavity that defines your part's shape.

- Die Holder: Supports the die block and remains clamped by a bolster plate. This component ensures the die block stays precisely positioned during high-force operations.

- Punch: The male portion of the die that applies force to cut or form the workpiece. Usually made of hardened steel or tungsten carbide, the punch descends into the die block cavity to create the desired shape.

- Punch Plate: Where the punching component attaches, driven by hydraulic or mechanical means. This plate transfers press force directly to the punch.

- Stripper Plate: Ejects formed or trimmed parts from the punch after each stroke. Without proper stripping action, parts would stick to tooling and jam production.

- Guide Pins: Align the two halves of the die with extreme precision. Misalignment—even by fractions of a millimeter—causes uneven wear and dimensional errors.

- Pressure Pads: Hold the workpiece securely during cutting or forming operations. Proper blank holder pressure prevents wrinkling while allowing controlled material flow.

- Pressure Plates: Distribute the force exerted by the punch evenly across the die assembly, preventing localized stress concentrations.

How does sheet metal stamping design account for these components working together? The relationship between punch and die block clearance—the gap between cutting edges—directly affects edge quality. According to Fictiv, proper clearance prevents excessive burrs and ensures clean cuts, while incorrect clearance leads to rough edges and accelerated tool wear.

Standard practice sets die clearance at approximately 5% to 10% of material thickness for most metals. Thinner materials and softer alloys use tighter clearances; thicker or harder materials require wider gaps. Getting this balance wrong creates immediate quality problems—too tight causes excessive tool wear, while too loose produces burred, inconsistent edges.

Die Materials That Maximize Tool Life

Your stamping machine runs only as long as your dies hold up. Selecting appropriate die materials determines whether tooling lasts for thousands of parts or millions. The steel stamping machine you invest in deserves dies engineered for the job.

According to Gunna Engineering, tool grade steel used for punches and dies must be harder and more deform-resistant than the workpiece it contacts. More than this, components must last for hundreds—perhaps thousands—of impact-stressed operations without cracking, deforming, or chipping.

Tool steels undergo specific heat treatment processes to achieve these properties. The base material—a coarse-grained alloy—transforms through heating and quenching into hardened martensite. Carbon diffuses through the grain structure, forming carbides that resist wear. Finally, tempering adds the resilience needed to prevent brittleness during repeated impact loading.

Common tool steel grades for stamping machinery include:

| Grade | Key Properties | Best Applications | Relative Cost |

|---|---|---|---|

| D-2 | High wear resistance, good toughness, air hardening | Blanking dies, piercing punches, long-run production | Moderate |

| A-2 | Excellent toughness, moderate wear resistance, air hardening | General-purpose dies, forming operations | Moderate |

| O-1 | Good machinability, oil hardening, economical | Short-run tooling, prototype dies | Lower |

| S-7 | Exceptional shock resistance, high toughness | Heavy blanking, impact-intensive operations | Higher |

| M-2 (High-Speed) | Extreme hardness, heat resistance | High-speed progressive dies, abrasive materials | Higher |

Carbide inserts take wear resistance further. Tungsten carbide—significantly harder than tool steel—extends die life dramatically when stamping abrasive materials or running extremely high volumes. According to Fictiv, carbide inserts are preferred for abrasive or extended production runs where tool steel would wear prematurely.

Alloying elements within tool steels provide specific performance benefits:

- Tungsten and vanadium: Enhance wear resistance and edge retention

- Chromium: Improves hardenability and corrosion resistance

- Molybdenum: Increases toughness and high-temperature strength

- Carbon content: Determines achievable hardness levels

Maintenance Practices for Consistent Quality

Even the best-designed dies using premium materials require systematic maintenance. What separates operations achieving millions of consistent parts from those facing constant quality issues? Proactive maintenance protocols.

Die life expectancy depends on multiple interacting factors:

- Material being stamped: Abrasive materials like stainless steel wear dies faster than mild steel or aluminum

- Production volume and speed: Higher stroke rates generate more heat and accelerate wear

- Lubrication practices: Proper lubrication reduces friction, heat, and galling

- Press alignment: Misaligned presses create uneven wear patterns and premature failure

- Clearance maintenance: As dies wear, clearances change—affecting edge quality and dimensional accuracy

Effective maintenance programs include these essential practices:

Regular inspection intervals: Scheduled die inspections catch wear before it affects part quality. Visual checks identify chipping, galling, or surface damage. Dimensional measurements verify that critical clearances remain within specification.

Sharpening and regrinding: Cutting edges dull over time. Planned regrinding restores sharp edges before burrs become problematic. Most dies can be reground multiple times before requiring replacement components.

Component replacement schedules: Wear items like stripper plates, guide pins, and springs have predictable life cycles. Replacing these components on schedule prevents unexpected failures during production runs.

Proper storage protocols: Dies not in active use require protection from corrosion and physical damage. Climate-controlled storage with rust-preventive coatings extends the life of idle tooling.

Documentation and tracking: Recording stroke counts, maintenance activities, and quality observations creates data for predicting future maintenance needs. This systematic approach transforms reactive repairs into planned interventions.

The relationship between die maintenance and part quality is direct and measurable. As clearances wear beyond specification, edge quality degrades—first with slight burr increases, then with dimensional drift. Catching these changes early through regular measurement prevents shipping nonconforming parts.

Understanding die types adds another dimension to stamping design decisions. According to Dynamic Die Supply, dies fall into three primary categories:

- Simple dies: Perform one task per stroke, ideal for low-volume processes with few steps

- Compound dies: Execute multiple cutting operations per stroke, suitable for intricate designs

- Combination dies: Perform both cutting and forming operations in a single stroke, accelerating production

Each type requires different maintenance approaches. Progressive dies with multiple stations need individual attention to each workstation. Transfer dies require verification of mechanical handling systems alongside tooling condition.

Proper die design and maintenance creates a foundation for quality—but even excellent tooling produces defects when process parameters drift. Recognizing common stamping problems and their root causes ensures your investment in quality tooling delivers consistent results.

Common Stamping Defects and How to Prevent Them

Your dies are perfectly designed and your materials carefully selected—so why are parts still failing inspection? Even the most sophisticated stamping operations encounter defects that can derail production schedules and inflate costs. Understanding what causes these problems—and how to prevent them—separates efficient operations from those constantly fighting quality issues.

Here's the reality: defects in stamped parts rarely appear randomly. Each problem traces back to specific root causes involving material properties, tooling conditions, or process parameters. When you understand these connections, troubleshooting becomes systematic rather than guesswork. Let's examine the most common issues affecting stamped steel parts and metal stamped parts, along with proven strategies for prevention.

Identifying Wrinkling and Tearing Causes

Wrinkling and tearing represent opposite ends of the forming spectrum—yet both stem from improper force balance during the stamping process.

Wrinkling occurs when material compresses unevenly, creating unwanted folds or waves in the finished part. According to Leeline Pack, several factors contribute to this defect:

- Insufficient blank holder force: When pressure pads don't grip the workpiece firmly enough, material flows uncontrollably into the die cavity

- Incorrect die design: Improper geometry or inadequate draw beads fail to control material flow

- Excessive material thickness: Thicker sheets resist bending and may buckle rather than stretch

- Poor lubrication: Uneven lubricant distribution creates inconsistent friction zones

Prevention strategies focus on controlling material flow. Increasing blank holder pressure restrains excess material movement. Adding draw beads to die surfaces creates friction barriers that regulate how metal enters the cavity. Optimizing die geometry ensures uniform stress distribution throughout the forming process.

Tearing happens when material stretches beyond its forming limits, causing fractures in precision stamping parts. The primary causes include:

- Excessive strain: Material deformation exceeds the metal's ductility limits

- Sharp die radii: Tight corners concentrate stress, creating failure points

- Insufficient lubrication: High friction prevents smooth material flow

- Improper material selection: Low-ductility metals crack during aggressive forming

Preventing tears requires balancing force application with material capabilities. Selecting metals with appropriate elongation properties—higher ductility for complex shapes—reduces fracture risk. Increasing die and punch fillet radii distributes stress over larger areas. Proper lubrication allows material to flow smoothly without binding.

Controlling Springback in Formed Parts

Ever bent a piece of metal only to watch it partially return toward its original shape? That's springback—and it's one of the most challenging defects to control in precision stamping operations.

Springback occurs because metals have an elastic component alongside their plastic deformation. When forming pressure releases, the elastic portion recovers, causing the part to deviate from the intended geometry. According to Leeline Pack, high-strength materials show significant springback because they have a smaller difference between yield strength and tensile strength compared to lower-strength steels.

Factors influencing springback severity include:

- Material properties: Higher-strength metals exhibit greater elastic recovery

- Bend radius: Tighter bends create more residual stress and greater springback

- Material thickness: Thicker sheets store more elastic energy

- Forming speed: Faster operations may not allow complete plastic deformation

Effective springback compensation strategies:

- Over-bending: Design dies to bend material past the target angle, allowing springback to reach the desired position

- Bottoming: Apply additional force at the bottom of the stroke to maximize plastic deformation

- Stress relief features: Incorporate stiffening ribs or flanges that reduce elastic recovery

- Material substitution: When possible, select alloys with lower yield-to-tensile strength ratios

Modern CAE simulation tools predict springback behavior before production tooling is built—allowing engineers to compensate during the die design phase rather than through costly trial-and-error adjustments.

Preventing Surface Defects and Burrs

Surface quality problems—burrs, scratches, and edge deformation—directly impact both aesthetics and functionality of stamped metal parts. Understanding their origins enables targeted prevention.

Burrs are raised edges or small metal fragments remaining on cut surfaces. According to Leeline Pack, burrs typically result from:

- Excessive tool wear: Dull cutting edges tear rather than shear material cleanly

- Improper die clearance: Gaps that are too wide allow material to flow between punch and die

- Misaligned tooling: Uneven gaps create inconsistent cutting conditions

- Incorrect press speed: Inappropriate stroke rates affect shear quality

Burr prevention requires systematic attention to tooling condition. Regular inspection catches wear before edges dull excessively. Maintaining proper clearances—typically 5% to 10% of material thickness—ensures clean cuts. According to DGMF Mold Clamps, using alignment mandrels to regularly check and adjust die positioning prevents uneven wear patterns.

Surface scratches typically originate from:

- Contaminated die surfaces: Metal chips or debris trapped between tooling and workpiece

- Inadequate lubrication: Metal-to-metal contact during forming creates friction marks

- Rough die finish: Surface imperfections transfer to parts during forming

- Improper material handling: Scratches before or after stamping from careless transport

Deformed edges result from forces acting unevenly on part perimeters. Prevention involves ensuring uniform blank holder pressure, proper die alignment, and appropriate clearances around the entire cutting profile.

Defect-Cause-Solution Reference Chart

When production issues arise, quick diagnosis saves time and material. This reference chart summarizes the most common defects affecting precision stamping parts, their root causes, and proven solutions:

| Defect Type | Primary Causes | Prevention Strategies |

|---|---|---|

| Wrinkling | Insufficient blank holder force; poor die geometry; excessive material thickness; uneven lubrication | Increase blank holder pressure; add draw beads; optimize die design; ensure uniform lubricant application |

| Tearing | Excessive strain; sharp die radii; insufficient lubrication; low material ductility | Select higher-ductility materials; increase fillet radii; improve lubrication; reduce forming severity |

| Springback | Elastic recovery in high-strength materials; tight bend radii; thick materials | Over-bend compensation; bottoming technique; add stress-relief features; consider material substitution |

| Burrs | Worn cutting edges; improper clearance; misaligned tooling; incorrect press speed | Regular tool sharpening; maintain proper clearances (5-10% of thickness); verify alignment; optimize stroke rate |

| Surface Scratches | Die contamination; inadequate lubrication; rough die surfaces; poor material handling | Clean dies regularly; apply proper lubricants; polish die surfaces; implement careful handling procedures |

| Deformed Edges | Uneven blank holder pressure; die misalignment; improper clearances | Balance pressure distribution; check and adjust alignment; verify clearances around entire perimeter |

| Dimensional Inaccuracy | Die wear; thermal expansion; springback; material variation | Regular dimensional verification; temperature monitoring; springback compensation; incoming material inspection |

How Proper Process Control Prevents Quality Issues

Defect prevention isn't about addressing problems individually—it's about creating systems where problems rarely occur. Three interconnected factors determine whether your stamped parts meet specifications consistently:

Die design establishes the foundation. Proper clearances, appropriate radii, effective blank holders, and quality die materials prevent many defects before they start. Investing in well-engineered tooling pays dividends throughout production runs.

Material selection must match forming requirements. Choosing metals with appropriate ductility, consistent thickness, and suitable surface quality reduces the likelihood of tears, wrinkles, and surface defects. Incoming material inspection catches variations before they enter production.

Process parameters tie everything together. Press speed, blank holder force, lubrication systems, and temperature control all influence part quality. Documenting optimal settings—and monitoring for drift—catches problems before they produce scrap.

The most effective operations combine these elements with systematic quality monitoring. Statistical process control tracks key dimensions over time, identifying trends before parts fall out of specification. First-article inspection validates that each production run starts correctly. In-process checks catch issues while they're still correctable.

Understanding defects and their prevention prepares you for production—but how do you verify that parts actually meet requirements? Quality control measures throughout the stamping process provide the answer.

Quality Control Measures Throughout the Stamping Process

You've designed the tooling, selected the material, and optimized your process parameters—but how do you actually know your parts meet specifications? Quality control isn't an afterthought in production stamping; it's the system that transforms good intentions into verified results. Without rigorous inspection protocols, even the most sophisticated stamping technology produces uncertainty instead of confidence.

Think about it: a single defective component in an automotive braking system or medical device could have serious consequences. That's why production metal stamping operations invest heavily in quality systems that catch problems early—ideally before they become problems at all. Let's explore the inspection methods, statistical tools, and industry certifications that separate world-class stamping operations from the rest.

Dimensional Inspection Methods

How do you verify that a stamped part matches its blueprint? Dimensional inspection provides the answer through increasingly sophisticated measurement technologies.

Traditional measurement tools remain foundational. Calipers, micrometers, and height gauges verify critical dimensions with precision measured in thousandths of an inch. Coordinate measuring machines (CMMs) take this further, probing multiple points across complex geometries to build complete dimensional profiles. These contact-based methods deliver reliable results for most metal stamping components.

But what about complex curved surfaces or features that contact probes can't reach? According to Keneng Hardware, 3D scanning technology represents one of the most significant breakthroughs in metal stamping inspection. Traditional methods frequently used 2D measurements, which could miss minor alterations in complicated geometries. 3D scanners create detailed three-dimensional representations of stamped parts, allowing for comprehensive analysis of shape and dimensions with unparalleled accuracy.

Modern inspection methods used in stamping operations include:

- Coordinate Measuring Machines (CMMs): Programmable systems that probe multiple points for complete dimensional verification

- 3D Laser Scanning: Non-contact technology capturing precise surface data rapidly for real-time inspection

- Optical Comparators: Project magnified part profiles against reference overlays for visual verification

- Vision Systems with AI: Automated cameras that identify surface defects, color variations, and minute imperfections that may escape human observation

- Computer-Aided Inspection (CAI): Automated measurement comparison against digital design models for rapid deviation detection

Tolerances in automotive stamping often reach demanding levels. According to The Fabricator, what used to be ±0.005 inches is now commonly ±0.002 inches—and sometimes as tight as ±0.001 inches. On top of that, customers require capability indices (Cpk) of 1.33, which essentially cuts working tolerance in half. Achieving these specifications demands robust die construction, controlled strip progression, and tooling that doesn't flex during stamping.

Non-destructive testing (NDT) methods verify internal integrity without damaging parts. These techniques detect hidden defects that surface inspection cannot reveal:

- Ultrasonic Testing: Sound waves identify subsurface flaws and material inconsistencies

- Eddy Current Testing: Electromagnetic induction detects cracks, voids, or composition variations in conductive materials

- Magnetic Particle Inspection: Reveals surface and near-surface discontinuities in ferromagnetic materials

Statistical Process Control in Stamping

Catching a defective part is good. Preventing defective parts from ever being made is better. Statistical Process Control (SPC) shifts quality focus from detection to prevention by monitoring process behavior in real time.

According to Keneng Hardware, implementing SPC methodologies allows manufacturers to monitor and control the metal stamping process more effectively. SPC involves collecting and analyzing data throughout production to ensure the process remains within specified tolerances. By continuously monitoring key process parameters, manufacturers can proactively address potential issues and maintain high quality levels.

How does SPC work in practice? Operators sample parts at regular intervals, measuring critical dimensions and plotting results on control charts. These charts establish upper and lower control limits based on natural process variation. When measurements trend toward limits—or show non-random patterns—operators intervene before parts fall out of specification.

Key SPC concepts for stamping operations:

- Control Charts: Visual displays tracking dimension measurements over time, showing process stability

- Process Capability (Cp/Cpk): Indices measuring how well the process performs relative to specification limits

- Run Rules: Statistical triggers indicating non-random variation requiring investigation

- Sampling Plans: Systematic approaches determining inspection frequency and sample sizes

First-article inspection (FAI) validates production readiness before full runs begin. This comprehensive evaluation verifies that initial parts meet all dimensional and functional requirements—confirming that tooling setup, material properties, and process parameters align correctly. FAI catches setup issues before they produce batches of nonconforming parts, saving material and time.

In-line inspection systems take monitoring further by integrating directly into stamping machinery. These systems enable real-time quality verification during production, identifying deviations immediately and enabling prompt adjustments to maintain consistency.

Industry Certifications That Signal Quality

How do you evaluate a potential stamping supplier's quality commitment? Industry certifications provide objective evidence that operations meet recognized standards—particularly important for automotive metal stamping applications where failure consequences are severe.

According to NSF International, IATF 16949 is the international standard for automotive quality management systems. It provides a standardized Quality Management System (QMS) that focuses on driving continuous improvement, with emphasis on defect prevention and reduction of variation and waste in the automotive supply chain and assembly process.

What makes IATF 16949 particularly rigorous? The standard requires:

- Defect prevention focus: Systems designed to prevent problems rather than just detect them

- Variation reduction: Statistical approaches minimizing process inconsistency

- Continuous improvement: Ongoing enhancement of quality systems and outcomes

- Supply chain management: Quality expectations extending to suppliers and subcontractors

- Risk-based thinking: Proactive identification and mitigation of potential quality issues

IATF 16949 certification demonstrates commitment to these principles. According to NSF, most major automotive Original Equipment Manufacturers (OEMs) mandate certification to IATF 16949 for their supply chain. Organizations cite benefits including improved customer satisfaction, increased efficiency, better risk management, and enhanced market access.

IATF 16949 certified suppliers like Shaoyi demonstrate this quality commitment through rigorous systems that achieve high first-pass approval rates—Shaoyi reports 93% first-pass approval through their comprehensive quality protocols. Their use of CAE simulation technology enables defect prediction before production tooling is even built, catching potential issues during the design phase rather than on the production floor.

Beyond IATF 16949, other relevant certifications include:

- ISO 9001: Foundation quality management system applicable across industries

- ISO 14001: Environmental management systems—increasingly required by automotive OEMs

- ISO 45001: Occupational health and safety management

These standards share a common High Level Structure, facilitating integration. Operations certified to multiple standards demonstrate comprehensive management system maturity.

Precision Specifications and Tolerance Achievement

What tolerances can modern automotive stamping actually achieve? The answer depends on part geometry, material, and process sophistication—but capabilities continue advancing.

Achieving tight tolerances requires attention across multiple factors. According to The Fabricator, minimizing dimensional variation depends on three big factors: die shoe thickness preventing flex during stamping, oversized die stops controlling hit consistency, and robust guide pins ensuring precise alignment.

Practical tolerance guidelines for stamped metal parts:

| Feature Type | Standard Tolerance | Precision Tolerance | Key Factors |

|---|---|---|---|

| Hole Diameter | ±0.005 in | ±0.001 in | Punch/die clearance, material thickness |

| Hole Location | ±0.010 in | ±0.002 in | Pilot pin accuracy, strip control |

| Bend Angle | ±1° | ±0.5° | Springback compensation, material consistency |

| Overall Dimensions | ±0.010 in | ±0.002 in | Die stability, thermal control |

| Flatness | 0.010 in per inch | 0.003 in per inch | Blank holder pressure, forming sequence |

Advanced stamping technology increasingly enables precision levels previously achievable only through machining—at stamping's characteristic speed and cost advantages. CAE simulation predicts forming behavior before physical tooling exists, allowing engineers to optimize designs for dimensional stability. Servo press technology provides programmable motion control that adapts to material variations in real time.

The combination of rigorous quality systems, advanced inspection technology, and precision-focused process control enables stamping operations to consistently meet demanding specifications. But how does stamping compare to alternative manufacturing methods when precision, volume, and cost all matter? That comparison reveals when stamping truly shines—and when other approaches make more sense.

Stamping Compared to Alternative Manufacturing Methods

You've mastered the stamping process—but is it actually the right choice for your project? That question deserves honest analysis. While stamping manufacturing excels in many scenarios, alternative methods sometimes deliver better results depending on your specific requirements. Understanding these tradeoffs helps you make informed decisions that balance cost, quality, and timeline.

Think of manufacturing method selection like choosing transportation. Cars work great for most trips, but you wouldn't drive across an ocean or use one to move a piano. Similarly, metal stamping manufacturing dominates certain applications while other processes shine elsewhere. Let's compare the options so you can match the right method to your needs.

Stamping vs CNC Machining Cost Analysis

The stamping versus CNC machining decision often comes down to one factor: volume. Both methods produce precision metal parts, but their cost structures differ dramatically.

CNC machining removes material from solid blocks using computer-controlled cutting tools. There's minimal setup investment—you upload a CAD file and start cutting. This makes machining ideal for prototypes and small batches. According to Neway Precision, CNC machining typically costs $5 to $50 per unit at low-to-mid volumes, with low-to-medium setup costs.

Metal stamping and forming requires significant upfront tooling investment—typically $5,000 to $50,000 depending on part complexity. However, once dies are built, per-part costs plummet. According to the same source, stamped sheet metal parts can drop to under $0.50 for simple geometries at high volumes, with average unit costs ranging from $0.30 to $1.50.

Where's the crossover point? The math depends on your specific part, but general guidelines apply:

- Under 1,000 parts: CNC machining typically wins on total cost

- 1,000 to 10,000 parts: Analysis required—complexity and material drive the decision

- Over 10,000 parts: Stamping almost always delivers lower total cost

Speed matters too. High-speed stamping achieves cycle times as low as 0.06 seconds per part—CNC machining can't approach that throughput. For steel stamping at scale, nothing else competes.

Volume Thresholds for Stamping ROI

When does the sheet metal process investment pay off? Understanding volume thresholds helps you plan projects economically.

According to Neway Precision, stamping becomes exponentially more cost-effective at higher volumes due to amortization of tooling and automation. Automotive OEMs save 20-30% in unit cost using progressive stamping versus CNC machining for structural brackets.

The economics work like this: spread $20,000 in tooling costs across 1,000 parts, and each part carries $20 in tooling burden. Spread that same investment across 100,000 parts, and tooling adds just $0.20 per piece. Combined with stamping's inherently low per-cycle costs, high volumes deliver dramatic savings.

Additional efficiency factors compound these advantages:

- Material utilization: Up to 85-95% yield with optimized nesting, especially using carbon steel and stainless steel

- Labor efficiency: One operator can oversee multiple press lines simultaneously

- Consistency: Low reject rates (under 2%) with automated stamping systems reduce waste and rework

When Alternative Methods Make More Sense

Honesty matters here: stamping isn't always the answer. Several scenarios favor alternative manufacturing approaches.

Laser cutting plus forming suits low-to-medium volumes with moderate complexity. Setup costs are minimal, and changes require only CAD updates rather than new tooling. According to Neway Precision, this approach works well for prototyping with average unit costs of $2 to $10.

3D printing (DMLS/SLS) excels at complex geometries impossible to stamp. Need internal channels, lattice structures, or organic shapes? Additive manufacturing creates them directly. The tradeoff? Very high unit costs ($15 to $100+) and slow production speeds limit 3D printing to prototypes, tooling, or low-volume specialty parts.

Casting handles complex three-dimensional shapes that would require multiple stamping operations and assembly. For medium-to-high volumes of intricate housings or brackets, casting may prove more economical than stamped and welded assemblies.

According to Veco Precision, stamping offers limited flexibility for design modifications, which can lead to additional tooling expenses when changes occur. Processes like electroforming provide greater design flexibility without incurring extra costs since modifications can be implemented without new tooling.

Manufacturing Method Comparison

Choosing the right approach requires weighing multiple factors against your specific requirements. This comparison summarizes key decision criteria:

| Factor | Sheet Metal Stamping | CNC Machining | Laser Cutting + Forming | 3D Printing |

|---|---|---|---|---|

| Ideal Volume Range | High (10,000+) | Low to Medium | Low to Medium | Prototyping to Low |

| Setup/Tooling Cost | High ($5,000-$50,000) | Low to Medium | Low | None to Low |

| Unit Cost at Volume | Very Low ($0.30-$1.50) | High ($5-$50) | Medium ($2-$10) | Very High ($15-$100+) |

| Production Speed | Very Fast (up to 1,000 strokes/min) | Slow | Moderate | Very Slow |

| Part Complexity | Good (2D profiles, bends, draws) | Excellent (any machinable geometry) | Moderate | Excellent (internal features) |

| Design Change Flexibility | Low (requires new tooling) | High (CAD update only) | High | Very High |

| Lead Time for First Parts | Weeks (tooling build) | Days | Days | Hours to Days |

| Best Applications | High-volume brackets, panels, housings | Prototypes, complex machined features | Short-run sheet metal parts | Complex prototypes, tooling |

Decision Framework for Method Selection

When evaluating your project, work through these questions systematically:

- What's your production volume? Under 1,000 parts often favors machining or laser cutting. Over 10,000 typically justifies stamping tooling investment.

- How stable is your design? Frequent changes favor flexible methods. Locked designs benefit from dedicated tooling.

- What's your timeline? Need parts in days? Machining or printing wins. Planning for months-long production? Invest in stamping tooling.

- What geometry do you need? Flat patterns with bends and cutouts suit stamping. Complex 3D shapes may require alternative approaches.

- What's your budget structure? Capital-constrained projects may prefer low-setup methods despite higher unit costs.

The most cost-effective approach often combines methods. Prototype with machining or printing, validate designs through short laser-cut runs, then transition to stamping for production volumes. This staged approach minimizes risk while capturing stamping's volume economics when appropriate.

Understanding where stamping fits in your manufacturing toolkit—and where alternatives make more sense—prepares you to implement projects successfully from the start.

Implementing Your Stamping Project Successfully

You've journeyed through the complete process of stamping—from understanding the fundamentals to comparing manufacturing alternatives. Now comes the practical question: how do you actually bring a stamping project to life? Success doesn't happen by accident. It requires systematic planning, informed decision-making, and strategic partnerships that carry your project from concept through production.

Think of your stamping project like building a house. You wouldn't start construction without architectural plans, vetted contractors, and a clear understanding of building codes. Similarly, successful metal pressing operations demand careful preparation across multiple fronts before the first press stroke occurs.

Key Factors for Stamping Project Success

Every successful stamping project shares common foundations. Whether you're producing automotive brackets or electronic enclosures, these decision factors determine outcomes:

- Material Selection Alignment: Match metal properties to forming requirements and end-use performance. Consider ductility for complex shapes, strength for structural applications, and corrosion resistance for harsh environments.

- Process Type Matching: Progressive die stamping suits high-volume complex parts. Transfer operations handle larger components. Simple dies work for basic geometries at lower volumes. Choose based on your part geometry and production quantities.

- Press Requirements: Tonnage, speed, and control capabilities must match your application. Mechanical presses deliver speed; hydraulic systems provide force control; servo technology offers programmable precision.

- Quality Standards Compliance: Define tolerance requirements upfront. Specify inspection methods. Establish acceptance criteria before tooling design begins—not during production troubleshooting.

- Volume and Timeline Planning: Tooling investment only makes sense at appropriate volumes. Rush timelines require suppliers with proven rapid prototyping capabilities and available capacity.

According to Eigen Engineering, the right metal stamping parts supplier will ensure your product quality and timely delivery in any manufacturing project. With many suppliers available, identifying a custom metal stamping supplier with the necessary expertise and quality standards becomes a critical success factor.

Selecting the Right Tooling Partner

Your metal stamping equipment and metal stamping machines are only as effective as the dies they run. That's why tooling partner selection often determines project success or failure.

What should you look for in a die supplier? According to Eigen Engineering, key evaluation criteria include:

- Industry-Specific Experience: Suppliers familiar with your industry understand specific tolerances and safety standards. Aerospace and automotive expertise signals capability for demanding applications.

- Certifications: IATF 16949 for automotive, ISO 9001 for general quality management, and AS9100 for aerospace indicate standardized, audited processes.

- In-House Tooling Capabilities: Suppliers with internal die design and fabrication can update adjustments and reduce costs compared to outsourcing tooling.

- Engineering Support: Design-for-manufacturability guidance and CAE simulation capabilities catch problems before expensive tooling is built.

- Prototyping Speed: Rapid prototyping capabilities—some suppliers deliver samples in as little as 5 days—accelerate design validation and reduce time-to-market.

- Scalable Production Capacity: Partners should accommodate different order sizes and adjust to your project growth without delays.

Comprehensive tooling partners like Shaoyi demonstrate these capabilities through IATF 16949 certification, advanced CAE simulation for defect prediction, and rapid prototyping turnaround as fast as 5 days. Their 93% first-pass approval rate reflects rigorous quality systems that prevent problems before they occur—exactly what demanding applications require.

Communication matters too. According to Eigen Engineering, open communication is important for smooth collaboration, especially for complex projects with tight deadlines. Select suppliers who maintain regular updates, communicate production timelines, and remain transparent about potential challenges.

Your Next Steps in Stamping Implementation