Metal Cutting Service Secrets: From Raw Steel To Flawless Parts

Understanding Metal Cutting Services and Their Manufacturing Impact

Ever wondered how a raw slab of steel transforms into the precision components inside your car, smartphone, or medical device? The answer lies in metal cutting service expertise—a cornerstone of modern manufacturing that powers virtually every industry you can imagine.

Metal cutting is a subtractive metalworking process that divides metal workpieces into precise shapes using force, thermal energy, or erosion techniques. Whether through blades, electrical discharges, laser beams, or high-pressure water jets, these processes transform raw metal fabrication materials into components that meet exact specifications.

What Metal Cutting Services Actually Deliver

When you partner with a professional metal cutter provider, you're gaining access to industrial capabilities that go far beyond simple slicing. These services encompass the complete journey from design consultation to finished parts. Steel fabrication shops handle everything from thin-gauge sheet metal to thick structural plates, adapting their approach based on your project's unique demands.

The scope is impressive. Modern fabrication shops near me—and across global manufacturing hubs—utilize four primary cutting categories: mechanical cutting, abrasive cutting, thermal cutting, and electrochemical methods. Each brings distinct advantages for specific materials and applications.

From Raw Stock to Precision Components

Understanding CNC meaning (Computer Numerical Control) helps explain why today's cutting processes achieve such remarkable accuracy. CNC technology automates metal cutting operations, enabling tolerances as tight as +/- 0.001 inches in methods like waterjet cutting. This precision wasn't possible just decades ago.

Selecting the right cutting method can reduce project costs by minimizing material waste, eliminating secondary finishing operations, and preventing heat-affected zones that compromise part integrity.

Throughout this comprehensive guide, you'll discover how different cutting technologies work, which materials pair best with each method, and what criteria matter most when evaluating metal fabrication near me options. You'll learn the complete workflow from design submission to delivery, understand industry-specific quality requirements, and gain practical insights into pricing factors and timeline planning.

Whether you're sourcing precision components for aerospace applications or general fabrication parts for everyday products, this resource bridges the knowledge gap between service providers and buyers—helping you make informed decisions that improve part quality while optimizing your manufacturing budget.

How Different Metal Cutting Technologies Work

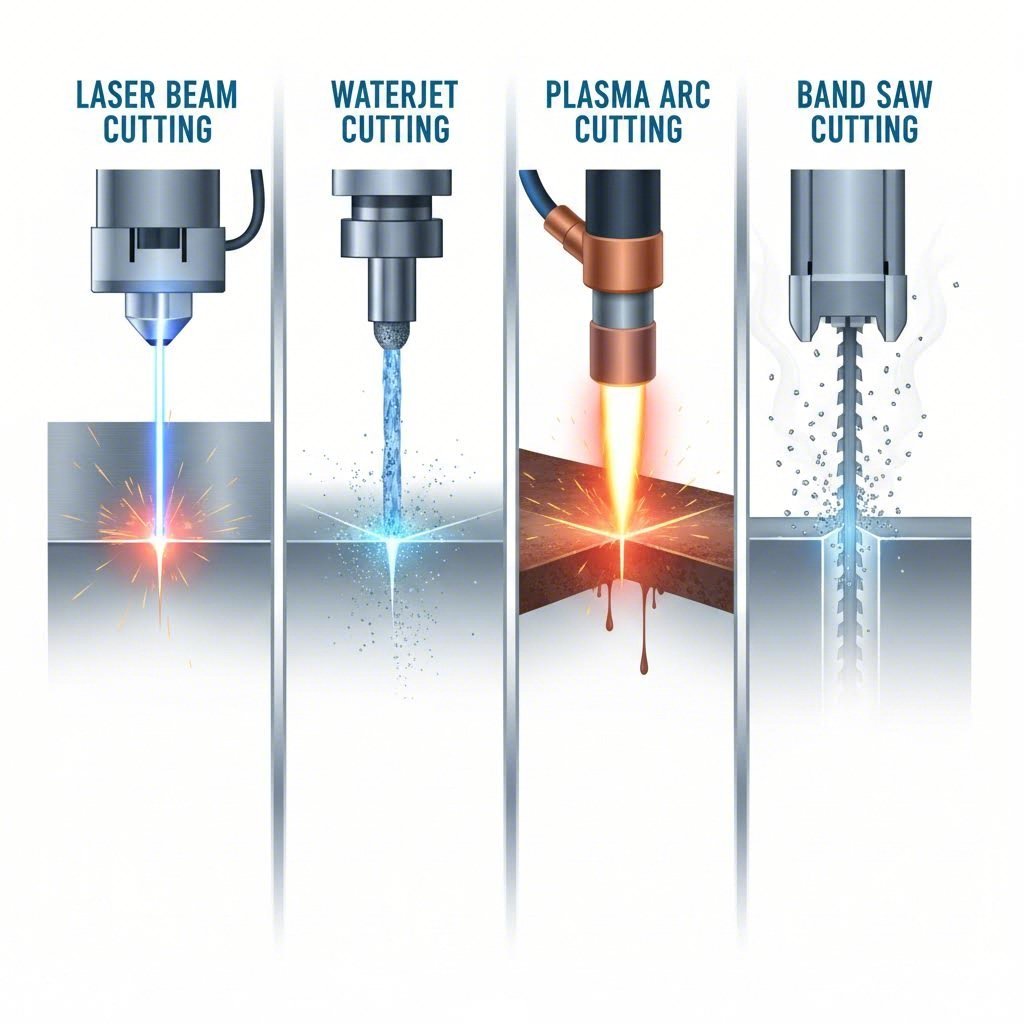

Imagine standing in a fabrication shop watching four completely different machines tackle the same steel plate. One uses an invisible beam of light, another shoots water mixed with sand, a third creates an arc of superheated plasma, and the fourth relies on good old-fashioned teeth. Each approach seems radically different—yet all achieve the same goal. Understanding how these technologies work helps you choose the right method for your project.

The physics behind each metal laser cutting method determines everything from precision capabilities to operating costs. Let's break down what's actually happening inside these machines.

How Laser Cutting Achieves Micron-Level Precision

A laser cutter focuses an intense beam of light onto a pinpoint area, generating temperatures exceeding 20,000°F. This concentrated energy melts, burns, or vaporizes the material along a programmed path. The result? Cuts so precise they're measured in microns rather than millimeters.

But here's where it gets interesting—not all laser metal cutters are created equal. Two dominant technologies compete in today's market:

- Fiber Lasers: Use solid-state technology with fiber optic cables doped with rare-earth elements. Operating at a wavelength of 1.064 micrometers, they achieve cutting speeds up to 20 meters per minute on thin stainless steel. Their efficiency reaches approximately 35%, translating to lower electricity bills and lifespans exceeding 100,000 hours.

- CO2 Lasers: Generate laser light by electrically stimulating a gas-filled tube containing carbon dioxide. Their longer wavelength of 10.6 micrometers makes them better suited for non-metallic materials like wood, acrylic, and textiles. Efficiency hovers around 10-20%, with typical lifespans of 20,000-30,000 hours.

For metal laser cutting applications, fiber technology dominates. The shorter wavelength focuses into a smaller spot size, enabling sharper cuts on reflective metals like aluminum and copper that can damage CO2 systems through back reflection.

Waterjet vs Plasma Technology Explained

Sounds complex? Think of waterjet cutting as erosion on hyperdrive. Pressurized water—often mixed with abrasive particles like garnet—blasts through material at pressures exceeding 60,000 PSI. This cold-cutting process creates zero heat-affected zone, making it ideal for heat-sensitive alloys and materials where thermal distortion means scrapped parts.

Plasma cutting takes the opposite approach. An electrical arc superheats compressed gas into plasma—the fourth state of matter—reaching temperatures around 40,000°F. This ionized gas stream melts and blasts away material simultaneously. When you're cutting conductive metals like steel, aluminum, or copper at thicknesses exceeding half an inch, plasma offers the best speed and cost efficiency.

The key distinction? Waterjet handles virtually anything—metals, stone, glass, composites—without heat effects. Plasma excels specifically on thick conductive metals where raw cutting speed matters most.

Mechanical Sawing: The Workhorse Method

Don't overlook traditional saw cutting for certain applications. Circular and band saws use sharp metal teeth to shear through material mechanically. This method offers several underappreciated advantages:

- Close tolerance cutting reduces material waste

- Fast speeds on thick bars, tubes, and structural sections

- High cut quality often eliminates secondary finishing

- Lower equipment costs compared to thermal processes

Sawing works best for materials with greater thickness or varying cross-sections—think structural steel beams, solid bars, and heavy plate where a laser cutting machine for metal would struggle with penetration or a waterjet would take excessive time.

Complete Technology Comparison

When evaluating which cutting method fits your project, these specifications matter most:

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | Mechanical Sawing |

|---|---|---|---|---|

| Precision Tolerance | ±0.001" to ±0.005" | ±0.001" to ±0.005" | ±0.015" to ±0.030" | ±0.005" to ±0.015" |

| Material Thickness Range | Up to 1" (steel) | Up to 6" | Up to 6"+ (conductive metals) | Unlimited (bar/plate stock) |

| Heat-Affected Zone | Small to moderate | None (cold process) | Large | None (mechanical) |

| Edge Quality | Excellent (burr-free) | Excellent (smooth) | Good (may need finishing) | Good to excellent |

| Best Applications | Thin sheet metal, intricate patterns, electronics | Heat-sensitive alloys, composites, thick materials | Structural steel, heavy plate, shipbuilding | Bars, tubes, structural sections |

| Relative Speed (thick material) | Slow | Moderate | Fast | Moderate to fast |

| Relative Speed (thin material) | Very fast | Slow | Moderate | Moderate |

Notice how no single technology wins across all categories. A metal cutting laser delivers unmatched precision on thin sheets but struggles with thick plate. Plasma slices through heavy steel quickly but can't match laser tolerances. Waterjet handles anything without heat effects but operates slower than thermal processes. Understanding these trade-offs helps you match technology to your specific requirements.

Now that you understand how each cutting method works, the next critical question becomes: which materials work best with each technology? Material properties dramatically influence method selection—and getting this wrong can mean scrapped parts, blown budgets, or production delays.

Material Specifications and Thickness Considerations

Here's a reality check: choosing the wrong cutting method for your material doesn't just affect quality—it can double your costs or render parts unusable. Every metal behaves differently under laser beams, water jets, and plasma arcs. Understanding these material-specific behaviors transforms you from a buyer placing orders into a partner who specifies exactly what your project needs.

Material selection and cutting method are inseparable decisions. A stainless steel sheet that cuts beautifully with fiber laser technology might require completely different parameters than aluminum sheet metal of identical thickness. Let's explore why.

Thickness Ranges and Tolerance Capabilities by Material

When you're reviewing a sheet metal gauge chart, you're looking at standardized thickness measurements that determine which cutting technologies apply. Gauge sizes work inversely—higher numbers mean thinner material. For example, 14 gauge steel thickness measures approximately 0.0747 inches (1.9mm), while 22 gauge drops to just 0.0299 inches.

This thickness directly impacts your options:

- Thin gauge sheet metal (up to 3mm): Laser cutting dominates here, achieving tolerances of ±0.1–0.2mm (±0.004–0.008 inches) with fiber lasers. Cutting speeds can reach 1,000–3,000 mm/min depending on laser power.

- Medium thickness (3–6mm): Both laser and plasma become viable. Laser cutting tolerances widen slightly to ±0.25mm, while plasma offers faster throughput at ±0.4–0.8mm tolerance.

- Heavy steel plate (above 6mm): Plasma and waterjet take over. Laser cutting aluminum or steel at these thicknesses requires 3,000–8,000 watts or more, with cutting speeds dropping to 200–800 mm/min.

Material thickness also affects kerf width—the material removed during cutting. Fiber laser kerf typically runs 0.1–0.3mm, meaning small internal features will effectively shrink by this amount. When designing tabs to fit into slots, sizing for the thick end of material tolerance (adding 0.2–0.4mm clearance) prevents assembly headaches.

Why Material Properties Dictate Your Cutting Choice

Beyond thickness, inherent material characteristics create specific cutting challenges. Ignoring these properties leads to quality problems, equipment damage, or both.

Steel and Carbon Steel

Steel plate remains the most forgiving material for cutting operations. Its consistent thermal properties and moderate reflectivity work well with laser, plasma, and mechanical methods. Standard tolerances of ±0.1–0.2mm are achievable on thin-to-medium steel sheet with properly calibrated equipment. Mill tolerances can vary ±0.1–0.3mm depending on gauge and specification, so designing clearance into mating features prevents fit issues.

Stainless Steel Sheet

Stainless offers excellent corrosion resistance but introduces cutting complications. Higher chromium content increases hardness, accelerating tool wear in mechanical cutting. Fiber lasers handle stainless effectively, though cutting speeds decrease approximately 20-30% compared to carbon steel at equivalent thickness. Heat-affected zones require attention—excessive heat input can compromise the corrosion-resistant properties that made you choose stainless initially.

Aluminum Sheet Metal

Aluminum presents unique challenges that trip up inexperienced fabricators. Consider these critical factors:

- High reflectivity: Aluminum reflects laser energy, particularly at CO2 wavelengths (10.6 µm). This can damage laser optics through back reflection. Fiber lasers at 1.064 µm wavelength handle aluminum more effectively.

- Thermal conductivity: Aluminum dissipates heat rapidly, requiring higher power levels—at least 500W for 3mm aluminum sheet, scaling to 3,000W+ for material above 6mm.

- Oxide layer: Surface oxidation affects cut initiation and edge quality. Proper assist gas selection (typically nitrogen) helps manage this.

- Grade selection: Common grades like 5052 and 6061 laser cut well, while high-strength 7075 requires slower speeds and higher power due to increased hardness.

Brass and Copper

These highly reflective metals share aluminum's laser cutting challenges but with added intensity. Copper's thermal conductivity—the highest of common metals—demands substantial power to overcome heat dissipation. Both metals work better with fiber lasers than CO2 systems, though waterjet cutting eliminates reflectivity concerns entirely while preserving material properties.

Material-Specific Cutting Considerations Summary

- Reflectivity issues: Aluminum, brass, and copper reflect laser energy back toward optics. Fiber lasers mitigate this better than CO2 systems; waterjet avoids the problem completely.

- Heat sensitivity: Certain alloys lose temper or corrosion resistance when overheated. Waterjet's cold-cutting process preserves metallurgical properties that thermal methods can compromise.

- Hardness factors: Hard materials like tool steels and hardened stainless accelerate saw blade wear and reduce cutting speeds. Abrasive waterjet handles hardness without tool wear concerns.

- Material thickness variations: Metal sheet can vary ±5-10% from nominal thickness. A 12 gauge steel (approximately 2.66mm nominal) might actually measure anywhere in that range—design clearances accordingly.

Understanding how material properties interact with cutting technology prevents costly mistakes. But knowing the right method is only half the equation. The next step involves translating your design into manufacturable parts—a process where file preparation and design-for-manufacturability reviews determine whether your project succeeds or stumbles.

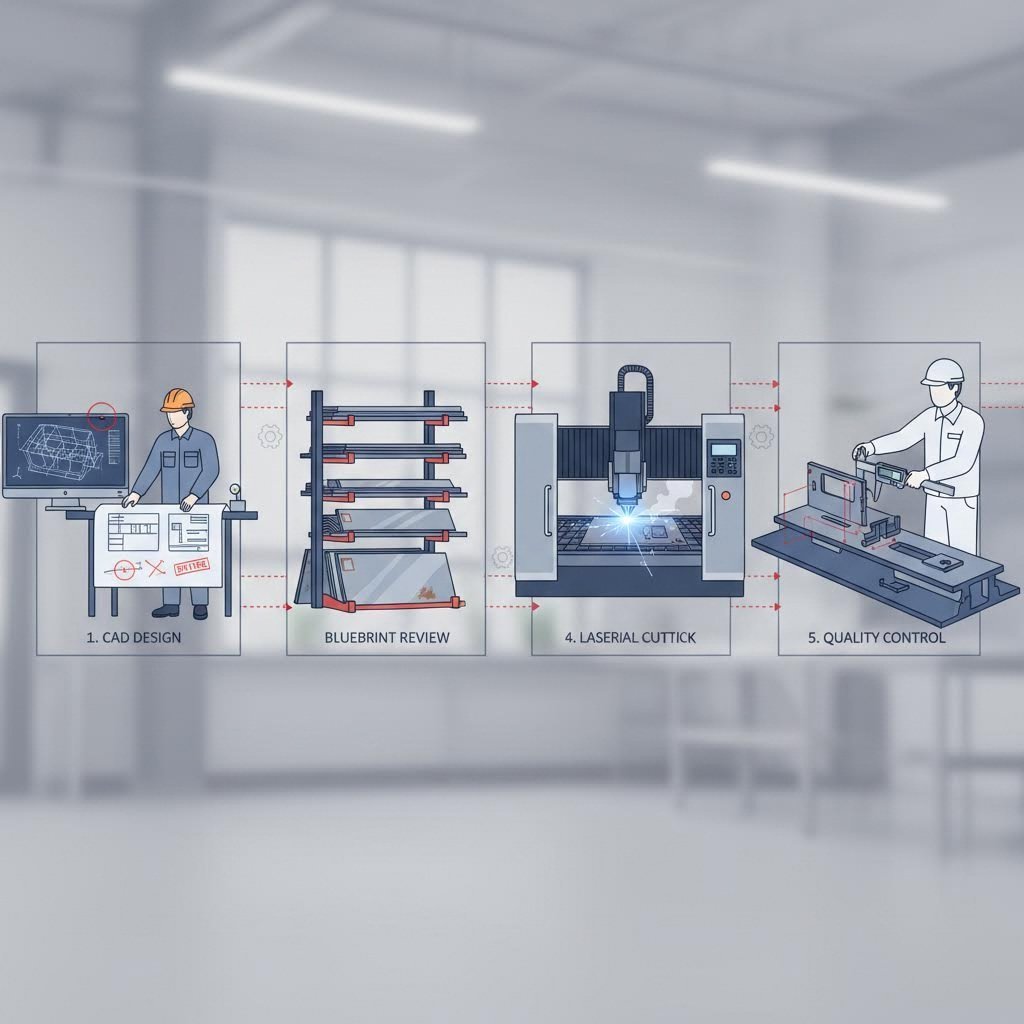

The Complete Fabrication Workflow from Design to Delivery

You've selected your cutting method and specified your material. Now what? The journey from CAD file to finished laser cut parts involves multiple checkpoints where small decisions create big impacts on cost, quality, and timeline. Understanding this workflow helps you avoid the surprises that derail projects and inflate budgets.

Professional sheet metal fabrication follows a structured sequence designed to catch problems early—when they're cheapest to fix. Let's walk through exactly what happens after you click "submit."

The Design-to-Delivery Process Explained

The complete metal fab workflow moves through distinct phases, each building on the previous step. Here's the sequential process your project follows:

- Design Submission: You provide technical files—typically a 2D drawing (PDF format) paired with 3D CAD data (.STEP or .IGES files). These documents communicate geometric complexity, tolerance specifications, and technical requirements. Steel fabricators review these for part symmetry, machinability, and wall thickness before proceeding.

- DFM Review: Experienced engineers conduct a Design for Manufacturability analysis to identify potential risk factors. This includes evaluating undercuts, thin sections, overly tight tolerances, and features that complicate cutting or increase scrap rates. Recommendations at this stage minimize machining time and cost.

- Material Selection and Procurement: Certified raw materials are sourced and inspected against mechanical specifications. Stock is cut to rough dimensions and labeled with job tracking codes for traceability throughout production.

- Cutting Operation: Your parts move to sheet metal laser cutting, waterjet, plasma, or mechanical processing based on prior specifications. CAM programmers generate optimized toolpaths that minimize idle time, reduce material waste, and ensure consistent quality across the production run.

- Quality Inspection: Dimensional verification using micrometers, calipers, or CMM (coordinate measuring machines) confirms parts meet specifications. Critical applications may require first-article inspection reports with full traceability documentation.

- Finishing Options: Based on your requirements, parts proceed to secondary operations—anodizing, powder coating, thermal treatments, or electropolishing. Each treatment addresses specific aesthetic or functional needs.

This structured approach applies whether you're ordering five prototype pieces or five thousand production parts. The difference lies in setup allocation and timeline expectations.

What Happens After You Submit Your CAD File

When you engage a custom laser cutting provider, file format matters more than you might expect. Native CAD files from programs like SolidWorks or Fusion 360 aren't universally readable. Instead, export neutral formats:

- .STEP files: The industry standard for 3D geometry exchange, preserving accurate surface data

- .IGES files: Older but widely compatible format for complex curved surfaces

- .DXF/.DWG files: Essential for 2D cutting profiles and flat patterns

- PDF drawings: Communicate dimensions, tolerances, and special requirements

Incomplete submissions create delays. Missing tolerance callouts, undefined material specifications, or ambiguous finishing requirements force back-and-forth communication that extends timelines by days or weeks.

The DFM review represents your biggest opportunity for cost reduction. According to industry research on DFM practices, addressing manufacturability issues during the design phase costs far less than fixing problems during production. This review examines factors like raw material form, dimensional tolerances, and secondary processing requirements—making adjustments that improve yield without compromising function.

When laser cut sheet metal requires additional features beyond flat cutting—threaded holes, chamfers, precise bore diameters—secondary CNC machining services enter the workflow. Understanding this relationship helps you design parts that minimize handling between operations, reducing both cost and potential quality issues.

Common Design Mistakes That Increase Costs

Certain design decisions consistently trigger production delays or budget overruns. Avoid these frequent missteps:

- Tolerances tighter than necessary: Specifying ±0.001" when ±0.005" meets functional requirements forces slower cutting speeds and additional inspection steps

- Ignoring kerf width: Designing tabs and slots without accounting for material removed during cutting creates assembly fit problems

- Inadequate bend relief: Parts destined for forming require relief cuts near bend lines—omitting these causes tearing

- Text and logos too small: Fine details below 0.5mm become unreadable or structurally weak after cutting

- Material thickness mismatches: Specifying standard gauge without confirming availability extends lead times for special orders

A thorough DFM review catches these issues before metal ever touches a cutting table. The result? Fewer revisions, faster delivery, and parts that work the first time.

With your design optimized and workflow clear, the next consideration becomes industry-specific: what quality standards and certifications does your application demand? The answer varies dramatically between decorative components and safety-critical aerospace parts.

Industry Requirements and Quality Certifications

Here's something that catches many buyers off guard: a part that's perfectly acceptable for one industry might be completely rejected in another—even when dimensions match exactly. The difference? Certification requirements, documentation standards, and tolerance expectations that vary dramatically across sectors.

Understanding these industry-specific demands helps you communicate effectively with service providers and avoid costly mismatches between what you need and what gets delivered.

Aerospace Tolerances vs General Fabrication Standards

Consider the gap between structural steel beams and aircraft components. A construction beam might allow tolerances of ±0.030 inches without compromising safety—the structure accounts for this variation. An aerospace component operating at 30,000 feet under extreme stress? That same tolerance could mean catastrophic failure.

Aerospace manufacturing demands what engineers call "razor-thin tolerances"—often measured in thousandths of an inch. Even slight deviations affect aerodynamics, structural integrity, and component fit within precision assemblies. Precision laser cutting services targeting this sector invest heavily in equipment calibration, environmental controls, and inspection protocols that general fabrication shops simply don't need.

General fabrication standards, by contrast, balance precision against practical cost considerations. Structural components, enclosures, and non-critical brackets can tolerate wider variation because their function doesn't demand micron-level accuracy. The key question becomes: what level of precision does your application actually require?

Certification Requirements by Industry

Quality certifications function as shorthand—they tell you a provider has documented systems meeting specific standards. But not all certifications carry equal weight across industries.

ISO 9001 serves as the foundational quality management standard. According to industry certification guidelines, ISO 9001-certified organizations demonstrate their ability to deliver high-quality products consistently while meeting customer and regulatory requirements. This certification applies across virtually all manufacturing sectors and signals baseline quality management competence.

IATF 16949 builds on ISO 9001 with automotive-specific requirements. Developed by the International Automotive Task Force, this certification addresses the unique demands of automotive supply chains—including chassis, suspension, and structural components where failure creates safety risks. Automotive suppliers must comply with both IATF 16949 and ISO 9001 requirements to achieve certification.

AS9100D represents the aerospace equivalent, adding stringent requirements for traceability, risk management, and configuration control. Manufacturers certified to AS9100D 2016 standards demonstrate capabilities specifically aligned with aerospace and defense requirements.

ISO 13485 governs medical device manufacturing, ensuring quality management practices protect consumers from devices that don't meet safety and performance standards. When laser cut stainless steel components end up in surgical instruments or implantable devices, this certification becomes non-negotiable.

Industry-Specific Considerations

Each sector brings unique documentation, traceability, and inspection requirements:

- Automotive: Full material traceability from raw stock through finished parts; PPAP (Production Part Approval Process) documentation; statistical process control for production runs; aluminum laser cutting for lightweight chassis components demands consistent quality across high volumes

- Aerospace: First-article inspection reports with dimensional verification; material certifications with heat lot traceability; non-destructive testing for critical components; configuration management for design changes

- Medical Devices: Validated cleaning and passivation processes for stainless steel sheet metal; biocompatibility documentation for patient-contact surfaces; lot traceability enabling recalls if quality issues emerge

- Electronics: ESD (electrostatic discharge) handling protocols; precision tolerances for enclosures and heat sinks; surface finish specifications affecting thermal management

- General Industrial: Standard inspection reports; material test reports; dimensional verification against drawings

The difference between decorative components and safety-critical parts extends beyond tolerances. A 316 stainless steel bracket holding a sign might need only visual inspection and basic dimensional checks. That same material formed into a medical implant requires validated processes, documented cleaning protocols, and complete traceability from mill certification through final packaging.

Why Certifications Matter for Your Project

Certifications aren't just bureaucratic checkboxes—they indicate operational maturity. A provider maintaining IATF 16949 certification has invested in documented procedures, trained personnel, calibrated equipment, and continuous improvement systems. This infrastructure benefits all customers, not just automotive programs.

When evaluating precision laser cutting services, consider which certifications align with your industry requirements. Overpaying for aerospace-grade quality on decorative parts wastes budget. Underspecifying quality requirements on safety-critical components creates liability exposure.

Quality isn't just about meeting specifications—it's about consistency. The right certification signals that a provider can deliver the same results on part one thousand as on part one. With quality requirements defined, the next practical question becomes: what will this actually cost, and how long will it take?

Pricing Factors and Project Timeline Planning

You've defined your material, selected your cutting method, and confirmed quality requirements. Now comes the question every project manager asks: what will this cost, and when will I receive parts? The answers depend on variables that interact in ways many buyers don't anticipate—and understanding these dynamics puts you in a stronger negotiating position.

Pricing for metal cutting services isn't arbitrary. Every line item on your quote reflects real operational costs, from machine time to material handling. Let's decode what drives those numbers and how timeline choices affect your bottom line.

What Drives Metal Cutting Service Costs

When you request a laser cutting quote, fabricators evaluate several interconnected factors before generating pricing. Missing any of these considerations leads to unexpected charges or revised estimates mid-project.

Material Type and Availability

Different metals carry vastly different costs—both for raw stock and processing. According to industry pricing research, selecting an in-stock material prevents minimum order charges that inflate quotes significantly. Special-order alloys or non-standard thicknesses require procurement lead time and often carry premium pricing.

Material properties also affect processing costs. Highly reflective metals like aluminum and copper demand more machine time and specialized parameters. Hardened steels accelerate consumable wear. These factors translate directly into laser cutting charges beyond base material costs.

Thickness Impact

The thicker the material, the longer cutting takes—and time equals money. A 1/4" steel plate requires substantially more machine time than 16-gauge sheet metal. Fabrication experts note that considering whether a thinner material might work equally well for your application represents one of the most effective cost-reduction strategies.

Design Complexity

Complex geometries with intricate cutouts, tight radii, and numerous features extend cutting time dramatically. Every direction change, pierce point, and small feature adds seconds that accumulate across production runs. According to precision fabrication specialists, components with multiple bends, intricate cutouts, or tight tolerances require more programming, setup, and inspection time.

Simplifying complex features that aren't strictly necessary—particularly those added primarily for aesthetics rather than function—can make a significant difference on tight budgets.

Tolerance Requirements

Tighter tolerances increase costs through multiple mechanisms:

- Slower cutting speeds to maintain precision

- Higher scrap rates from parts falling outside specification

- Additional inspection steps and documentation

- Potential secondary machining operations when cutting alone can't achieve requirements

Before specifying ±0.005" tolerances, evaluate whether ±0.010" or ±0.015" would meet functional requirements without impacting performance.

Finishing and Secondary Operations

Surface treatments add both cost and time. Powder coating, anodizing, polishing, and heat treatments each carry distinct pricing based on surface area, coating type, and durability requirements. Integrated fabricators who perform finishing in-house typically offer better cost control and faster turnaround than operations requiring external vendors.

Balancing Speed, Quality, and Budget

Every project navigates the classic manufacturing triangle: fast, good, or cheap—pick two. Understanding how these trade-offs work helps you make informed decisions rather than simply accepting whatever a provider offers.

Setup Costs and Quantity Economics

Initial setup—programming CNC paths, configuring machines, loading materials—carries fixed costs regardless of whether you're cutting ten parts or ten thousand. This setup investment gets distributed across your order quantity, creating significant per-piece price differences.

A prototype run of five pieces might cost $50 each when setup represents the majority of expenses. That same part at 500-piece volume might drop to $8 each as setup amortizes across the larger run. At 5,000 pieces, automated production further reduces per-unit costs.

Prototype vs. Production Timelines

Rapid prototyping and mass production operate on fundamentally different schedules. Tooling and process experts explain that prototype operations prioritize speed and flexibility—making a few physical copies to test concepts and work out problems before committing to production investment. Production runs prioritize efficiency and consistency across thousands of identical parts.

| Production Type | Typical Turnaround | Quantity Range | Per-Piece Cost | Best For |

|---|---|---|---|---|

| Rapid Prototyping | 1-5 business days | 1-50 pieces | Highest (setup-dominated) | Design validation, fit testing, investor samples |

| Standard Production | 1-3 weeks | 50-1,000 pieces | Moderate (balanced) | Initial market launch, replacement parts inventory |

| High-Volume Runs | 3-6 weeks | 1,000+ pieces | Lowest (volume efficiency) | Ongoing production, multi-year contracts |

| Rush/Expedited | 24-72 hours | Any quantity | Premium (overtime, priority scheduling) | Emergency replacements, deadline-critical projects |

Notice how turnaround expectations and per-piece economics shift across these categories. When searching for laser cutting near me or laser cutting services near me, clarify which category your project falls into—it affects both pricing and provider selection.

Quote Turnaround as a Quality Indicator

Here's an insight many buyers overlook: how quickly a provider returns your quote indicates operational efficiency and customer service quality. A laser cutting service near me that responds within hours demonstrates streamlined quoting systems and adequate engineering capacity. Providers taking weeks to generate simple quotes often struggle with production scheduling too.

Online laser cutting platforms have compressed quote turnaround dramatically—some offering instant pricing for standard materials and geometries. While these automated systems work well for straightforward parts, complex projects with tube laser cutting services, unusual materials, or tight tolerances still benefit from engineering review and human expertise.

Planning for Success

Effective project planning means aligning budget, timeline, and quality expectations before requesting quotes. Consider these strategies:

- Batch similar parts: Combining multiple part numbers into single orders improves material utilization and reduces setup frequency

- Plan ahead: Rush charges for expedited delivery often add 25-50% to standard pricing—building adequate lead time into schedules eliminates this premium

- Communicate volumes: Sharing anticipated annual quantities helps providers optimize pricing for long-term partnerships

- Request DFM feedback: Design modifications suggested during quoting often reduce costs more than negotiating margins

Pricing and timeline represent quantifiable factors you can plan around. But what about quality itself? Knowing what to look for when parts arrive—and what questions to ask before they ship—protects your investment and prevents costly rework.

Quality Considerations and Common Cutting Challenges

Your parts have shipped. The boxes arrive, you open them—and something looks off. Maybe the edges feel rough, dimensions don't quite match your drawings, or there's discoloration along cut lines you weren't expecting. These quality issues cost real money: scrapped parts, delayed assemblies, and frustrated customers downstream.

Understanding what quality problems look like—and why they occur—transforms you from a passive recipient into an informed buyer who catches issues before they cascade into bigger problems. Let's examine the most common cutting defects and what they reveal about process control.

Identifying Quality Problems Before They Become Costly

Quality issues in metal cutting fall into predictable categories. Recognizing these patterns helps you evaluate incoming parts and communicate effectively with providers when problems arise.

Dross Formation

So what exactly is dross? Define dross as the resolidified molten metal that adheres to the bottom edge of laser or plasma cuts. It appears as rough, bead-like deposits that require secondary grinding or deburring to remove. According to cutting process experts, minimal dross indicates properly tuned laser power, speed, and assist gas settings.

When dross becomes excessive, it signals process problems: incorrect cutting speed, insufficient assist gas pressure, or worn nozzles. Parts arriving with heavy dross formation suggest the provider either lacks proper equipment calibration or rushed production without adequate quality checks.

Heat-Affected Zones (HAZ)

Thermal cutting processes—laser and plasma—generate intense heat that can alter material properties near the cut edge. This heat-affected zone exhibits changed hardness, altered microstructure, and sometimes visible discoloration. For most applications, a narrow HAZ causes no functional problems. But when you're working with heat-treated alloys or materials where edge hardness matters, excessive HAZ compromises part performance.

A sheet metal laser cutter operating at optimal parameters minimizes HAZ by moving quickly enough that heat doesn't conduct deeply into surrounding material. Slow cutting speeds or excessive power settings expand this zone—sometimes visibly, always measurably.

Burr Development

Burrs are raised edges or small metal fragments remaining attached after cutting. Unlike dross (which forms from molten metal), burrs result from mechanical deformation during the cutting process. They're common in mechanical sawing and can occur in thermal cutting when parameters drift from optimal settings.

When evaluating laser cut aluminum parts, pay particular attention to burr formation. Aluminum's softness and high thermal conductivity make it prone to edge irregularities if cutting parameters aren't precisely controlled. Industry testing shows that highly reflective materials like aluminum and brass require specific assist gas and power combinations to achieve clean edges.

Dimensional Accuracy Issues

Parts that don't match dimensional specifications create assembly nightmares. Common causes include:

- Thermal expansion during cutting that isn't compensated in programming

- Material movement or vibration during processing

- Worn machine components affecting positioning accuracy

- Incorrect kerf compensation in CAM programming

Stainless steel laser cutting demands particular attention to thermal management. The material's lower thermal conductivity compared to aluminum means heat concentrates near the cut, potentially causing localized warping in thin sheets or parts with narrow features.

Edge Quality and Tolerance Verification

Edge quality tells a story about the entire cutting operation. When you're evaluating parts from a laser sheet metal cutter or any other cutting process, systematic inspection reveals whether the provider maintains proper process control.

Understanding Kerf Width Impact

Kerf—the material removed during cutting—directly affects both individual part dimensions and how efficiently parts nest on sheet stock. According to fabrication guidelines, kerf width typically ranges from 0.1mm to 1.0mm depending on material and cutting parameters.

Why does this matter for your designs? Consider a tab-and-slot assembly where the slot is designed exactly to theoretical tab width. The laser cutting of metal sheets removes material from both the tab and slot edges—effectively making tabs narrower and slots wider than drawn dimensions. Without proper kerf compensation, parts won't fit correctly.

Efficient part nesting also depends on kerf considerations. Spacing cutting geometry at least two times the sheet thickness prevents thermal distortion between adjacent parts. Crowding parts too closely—attempting to maximize material utilization—often backfires through distortion and edge quality degradation.

Quality Inspection Checklist

When parts arrive from your sheet metal laser cutter provider, evaluate these critical factors:

- Edge smoothness: Run your finger along cut edges (carefully). Properly cut parts feel smooth with minimal roughness. Excessive texture indicates suboptimal parameters or worn equipment.

- Dimensional accuracy: Measure critical dimensions against drawing specifications using calibrated instruments. Quality control protocols recommend measuring devices calibrated to at least one decimal place beyond the required tolerance.

- Surface finish: Examine surfaces for scratches, gouges, or handling damage. Professional providers protect material surfaces during processing and handling.

- Material integrity: Check for warping, especially on thin materials or parts with asymmetric geometries. Excessive heat input causes distortion that may not be recoverable.

- Edge squareness: Cut edges should be perpendicular to material surfaces. Angled edges indicate worn focusing optics, incorrect focal distance, or beam alignment issues.

- Consistent cut quality: Compare multiple parts from the same batch. Variation between pieces signals unstable process control.

Questions to Ask Your Service Provider

Before quality problems occur, proactive communication establishes expectations and reveals provider capabilities. Consider asking these questions when evaluating metal cutting partners:

- What inspection equipment do you use, and how frequently is it calibrated?

- What sampling plan do you follow for production runs?

- How do you document and handle non-conforming parts?

- Can you provide first-article inspection reports for critical dimensions?

- What process controls prevent parameter drift during extended cutting runs?

- How do you verify material certifications match specifications?

Providers maintaining robust quality management systems welcome these questions—they've invested in answering them systematically. Evasive responses or vague assurances suggest gaps in quality infrastructure that may surface as defects in your parts.

Quality problems caught early cost far less than those discovered during assembly or—worse—in the field. With a clear understanding of what to look for and what questions to ask, you're equipped to evaluate not just individual parts but the overall capability of potential manufacturing partners.

Selecting the Right Metal Cutting Service Provider

You've mastered cutting technologies, understand material behaviors, know what quality looks like, and can interpret pricing structures. Now comes the decision that determines whether all that knowledge translates into successful parts: choosing the right manufacturing partner. This selection impacts not just your current project but potentially years of production runs, design iterations, and supply chain reliability.

Finding metal fabricators near me through a quick search returns dozens of options. But how do you distinguish between providers who merely cut metal and those who become genuine partners in your manufacturing success? The answer lies in systematic evaluation against criteria that matter most for your specific needs.

Matching Your Project Requirements to Provider Capabilities

Not every metal cutting services provider excels at every application. A shop optimized for high-volume automotive production operates differently than one specializing in aerospace prototypes. Matching your requirements to provider strengths prevents the frustration of forcing a square peg into a round hole.

Equipment and Technology Assessment

Start with the fundamentals: does the provider own equipment capable of executing your specifications? According to industry evaluation guidelines, modern, well-maintained equipment often translates to higher precision and faster turnaround times. When evaluating metal laser cutting services or cnc laser cutting services capabilities, consider:

- Machine age and technology generation: Fiber lasers manufactured in the last five years outperform older CO2 systems on reflective metals

- Power capacity: Higher wattage enables thicker material processing and faster cutting speeds

- Bed size limitations: Confirm maximum sheet dimensions accommodate your largest parts

- Multi-process capabilities: Providers offering laser fabrication alongside forming, welding, and finishing simplify your supply chain

Ask about equipment redundancy too. A single-machine shop means your project stops when that machine needs maintenance. Providers with multiple cutting systems offer production continuity even during equipment service periods.

Material Expertise Verification

Cutting steel differs fundamentally from processing aluminum, titanium, or exotic alloys. Fabrication specialists emphasize that metals like aluminum, steel, and copper each have unique properties affecting how they're processed. A provider with deep experience in your specific materials understands the parameter adjustments, tooling requirements, and quality considerations that ensure consistent results.

Request examples of similar material projects. Ask about challenges they've encountered with your alloy and how they resolved them. Knowledgeable providers discuss thermal management strategies, assist gas selection, and surface finish optimization with confidence. Those unfamiliar with your material offer vague generalities or promise capabilities they haven't demonstrated.

Evaluating Service Partners for Long-Term Success

Transactional relationships work for one-off projects. But if you're developing products requiring ongoing production, design iterations, or multi-year supply agreements, evaluate partners through a different lens—one focused on capability depth and operational maturity.

Certification Status as Capability Indicator

Quality certifications reveal more than compliance with standards—they indicate systematic operational discipline. As discussed earlier, IATF 16949 certification signals automotive-grade quality management including PPAP documentation, statistical process control, and continuous improvement systems. Providers maintaining this certification have invested substantially in infrastructure that benefits all customers.

For example, manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate how IATF 16949 certification translates into practical capabilities: 5-day rapid prototyping for design validation, automated mass production for volume efficiency, and comprehensive DFM support that catches manufacturing issues before they become expensive problems. Their 12-hour quote turnaround exemplifies the operational responsiveness that certified manufacturers maintain.

Communication Responsiveness

How a provider handles your initial inquiry predicts how they'll handle production challenges. Industry experience shows that responsive communication, willingness to address concerns, and proactive problem-solving are hallmarks of excellent customer support.

Evaluate these communication indicators:

- Quote turnaround time: Custom metal cutting quotes returned within hours indicate adequate engineering capacity and streamlined processes

- Technical question responsiveness: Knowledgeable answers to material or process questions signal deep expertise

- Proactive DFM feedback: Providers who suggest design improvements demonstrate genuine partnership interest

- Clear documentation: Detailed quotes with transparent pricing breakdown indicate organized operations

The Value of Comprehensive DFM Support

Design for Manufacturability review represents perhaps the highest-value service a metal laser cutting service provider offers—yet many buyers underappreciate it. Thorough DFM analysis identifies cost reduction opportunities, prevents production problems, and optimizes designs for cutting efficiency before metal ever touches a cutting table.

According to fabrication service evaluation criteria, you should ask: Can they assist with design and engineering to optimize your product? Are they equipped to handle prototypes and small-batch production? Providers offering robust DFM support function as extensions of your engineering team rather than mere order-takers.

Provider Evaluation Criteria Checklist

When comparing potential metal cutting partners, systematic evaluation prevents overlooking critical factors. Use this comprehensive checklist adapted from job shop selection research:

- Experience and expertise: Years in business, industry-specific experience, technician qualifications and certifications

- Facilities and equipment: Modern machinery, organized facilities, capacity for both prototype and production volumes

- Quality control systems: Documented processes, industry certifications (ISO 9001, IATF 16949, AS9100), regular inspection and calibration protocols

- Material capabilities: Variety of metals and alloys handled, reliable supply chain, knowledge of material properties and specifications

- Customization and design support: DFM assistance, prototype capabilities, engineering collaboration willingness

- Pricing transparency: Detailed quotes, competitive rates without quality compromise, value-added services that optimize total cost

- Lead time reliability: On-time delivery track record, capacity for rush orders, realistic timeline commitments

- Customer service quality: Responsive communication, regular project updates, effective complaint resolution

- References and reputation: Verifiable customer testimonials, industry peer reviews, case studies demonstrating similar project success

The Benchmark Standard

Certified manufacturers with comprehensive capabilities set the benchmark against which other providers should be measured. When a provider combines IATF 16949-certified quality systems with rapid prototyping speed, automated production efficiency, and responsive DFM support, they demonstrate the operational maturity that translates into reliable parts and predictable timelines.

This combination—certification-backed quality, prototyping agility, production scalability, and engineering partnership—represents what serious manufacturing programs require. Whether you're sourcing chassis components, precision assemblies, or structural parts, providers meeting these standards deliver confidence that extends beyond individual purchase orders.

Making Your Decision

Choosing a metal cutting partner isn't about finding the lowest price or fastest promise. It's about identifying providers whose capabilities, quality systems, and communication style align with your project requirements and long-term manufacturing strategy.

The knowledge you've gained throughout this guide—understanding cutting technologies, material behaviors, quality indicators, and pricing dynamics—equips you to evaluate providers from an informed position. You can ask the right questions, interpret the answers accurately, and recognize when capabilities match your needs versus when they fall short.

Your next step? Apply this evaluation framework to your current project. Request quotes from multiple providers, assess their DFM feedback quality, verify their certification status, and compare not just pricing but the complete value proposition they offer. The right partner transforms metal cutting from a transactional commodity into a strategic manufacturing advantage.

Frequently Asked Questions About Metal Cutting Services

1. How much does metal cutting cost?

Metal cutting costs typically range from $0.50 to $2 per linear inch for sheet or bar cutting, or $20 to $30 per hour depending on the method used. Key factors affecting pricing include material type and thickness, design complexity, tolerance requirements, order quantity, and finishing needs. Setup costs are distributed across your order—a 5-piece prototype run might cost $50 per piece, while 500 pieces of the same part could drop to $8 each. Requesting quotes from IATF 16949-certified providers often yields competitive pricing with guaranteed quality standards.

2. How much does it cost to cut sheet metal?

Sheet metal fabrication averages $1,581 per project, ranging from $418 to $3,018 depending on complexity. Per-square-foot costs range from $4 to $48 based on material selection and customization level. Laser cutting thin gauge materials offers the most cost-effective solution for intricate patterns, while plasma cutting provides better value for thick steel plates. Choosing in-stock materials, simplifying complex features, and batching similar parts together are proven strategies to reduce overall costs.

3. What is the difference between laser cutting and plasma cutting?

Laser cutting uses a focused light beam achieving tolerances of ±0.001" to ±0.005", ideal for thin sheet metal up to 1 inch with excellent edge quality and minimal burrs. Plasma cutting uses superheated ionized gas reaching 40,000°F, offering tolerances of ±0.015" to ±0.030" but excelling on thick conductive metals above 6 inches at faster speeds and lower cost. Laser produces smaller heat-affected zones and cleaner edges, while plasma handles heavy structural steel more economically. Your choice depends on material thickness, precision requirements, and budget.

4. What materials can be processed with metal cutting services?

Professional metal cutting services process a wide range of materials including carbon steel, stainless steel (304, 316), aluminum alloys (5052, 6061, 7075), brass, copper, titanium, and specialty alloys. Each material requires specific cutting parameters—aluminum's high reflectivity demands fiber lasers, while stainless steel's hardness affects cutting speed. Material thickness from thin gauge sheet metal (22 gauge at 0.03 inches) to heavy plate (6+ inches) can be accommodated using the appropriate cutting method—laser, waterjet, plasma, or mechanical sawing.

5. How do I choose the right metal cutting service provider?

Evaluate providers based on equipment capabilities (modern fiber lasers, adequate power capacity), material expertise with your specific alloys, relevant certifications (ISO 9001, IATF 16949 for automotive, AS9100 for aerospace), and communication responsiveness. Request sample work similar to your project, verify inspection and quality control processes, and assess their DFM (Design for Manufacturability) support. Providers offering 12-hour quote turnaround and comprehensive engineering feedback typically demonstrate operational maturity that translates into reliable parts and on-time delivery.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —