Die Casting vs. Permanent Mold: Mahalagang Pagpili para sa Mga Bahagi ng Sasakyan

TL;DR

Para sa mga aplikasyon sa automotive, ang pagpili sa pagitan ng die casting at permanent mold casting ay nakasalalay sa balanse sa pagitan ng dami, gastos, at katangian ng bahagi. Mahusay ang die casting sa paggawa ng mga kumplikadong, tumpak na bahagi na may makinis na ibabaw nang mabilis, na nagiging perpekto para sa mataas na produksyon kahit may malaking paunang gastos sa tooling. Sa kabilang banda, ang permanent mold casting ay nangangailangan ng mas mababang pamumuhunan sa tooling at nagbubunga ng mas masikip at mas matibay na bahagi, na higit na ekonomikal para sa maliit hanggang katamtamang dami ng produksyon kung saan mahalaga ang mekanikal na integridad.

Mga Pangunahing Mekanismo ng Proseso: Mataas na Presyon vs. Gravity-Fed

Ang pag-unawa sa pangunahing pagkakaiba sa pagitan ng die casting at permanent mold casting ay nagsisimula sa paraan ng pagpasok ng natunaw na metal sa mold. Ang pangunahing pagkakaibang ito ang nakakaapekto sa halos lahat ng iba pang aspeto ng proseso, mula sa bilis ng produksyon hanggang sa mga katangian ng huling bahagi. Parehong gumagamit ng muling magagamit na metal na mga mold, karaniwang gawa sa bakal, ngunit iba ang mekanismo ng pagpuno.

Ang mataas na presyong die casting (HPDC) ay isang lubhang awtomatikong proseso kung saan pinipilit ang naglalagablab na metal papasok sa isang bakal na die sa ilalim ng napakalaking presyon. Ang presyon na ito, na nasa pagitan ng 1,500 hanggang mahigit sa 20,000 PSI, ay nagagarantiya na mapupunla ang metal sa bawat detalyadong bahagi ng kavidad ng mold nang may kamangha-manghang bilis. Mabilis ang proseso, dahil mabilis na lumalamig ang metal, na nagbibigay-daan sa napakaliit na oras ng ikot. Ang bilis na ito ang pangunahing dahilan kung bakit dominante ang die casting bilang pamamaraan para sa masusbok na produksyon ng mga sangkap ng sasakyan.

Kabaligtaran nito, ang permanent mold casting ay nakasalalay higit sa lahat sa gravity. Sa pamamaraang ito, ibinubuhos ang naglalagablag na metal sa loob ng mold, na pinupunla ang kavidad mula ibaba hanggang itaas. May ilang pagkakaiba-iba na gumagamit ng mababang presyon (7 hanggang 30 PSI) o mekanismong tilt-pour upang tulungan ang pagbuhos, ngunit nananatiling mas malumanay na proseso ito kumpara sa HPDC. Mas mabagal ang rate ng paglamig, na nagbibigay-daan sa mga gas na makalabas habang lumalamig ang metal. Nagreresulta ito sa mas masigla at hindi gaanong porous na panloob na istraktura kumpara sa mga bahagi na ginawa gamit ang mataas na presyong ineksyon.

Ang mga mekanikal na pagkakaiba-iba na ito ang nagsasaad sa kumplikado ng kagamitan at sa kabuuang bilis ng proseso, gaya ng nakalista sa ibaba.

| Katangian | High-pressure die casting | Permanent mold casting |

|---|---|---|

| Paraan ng Pagpuno | Iniksyon sa Mataas na Presyon | Pinapakain ng gravity o mababang presyon |

| Karaniwang Presyon | 1,500 - 25,000+ PSI | Gravity o 3 - 20 PSI |

| Bilis ng Siklo | Napakabilis (mga segundo hanggang minuto) | Mas mabagal (mga minuto) |

| Kakomplikado ng kagamitan | Mataas (kumplikadong makinarya) | Moderado |

Pagsusuri sa Kagamitan at Gastos: Puhunan vs. Dami

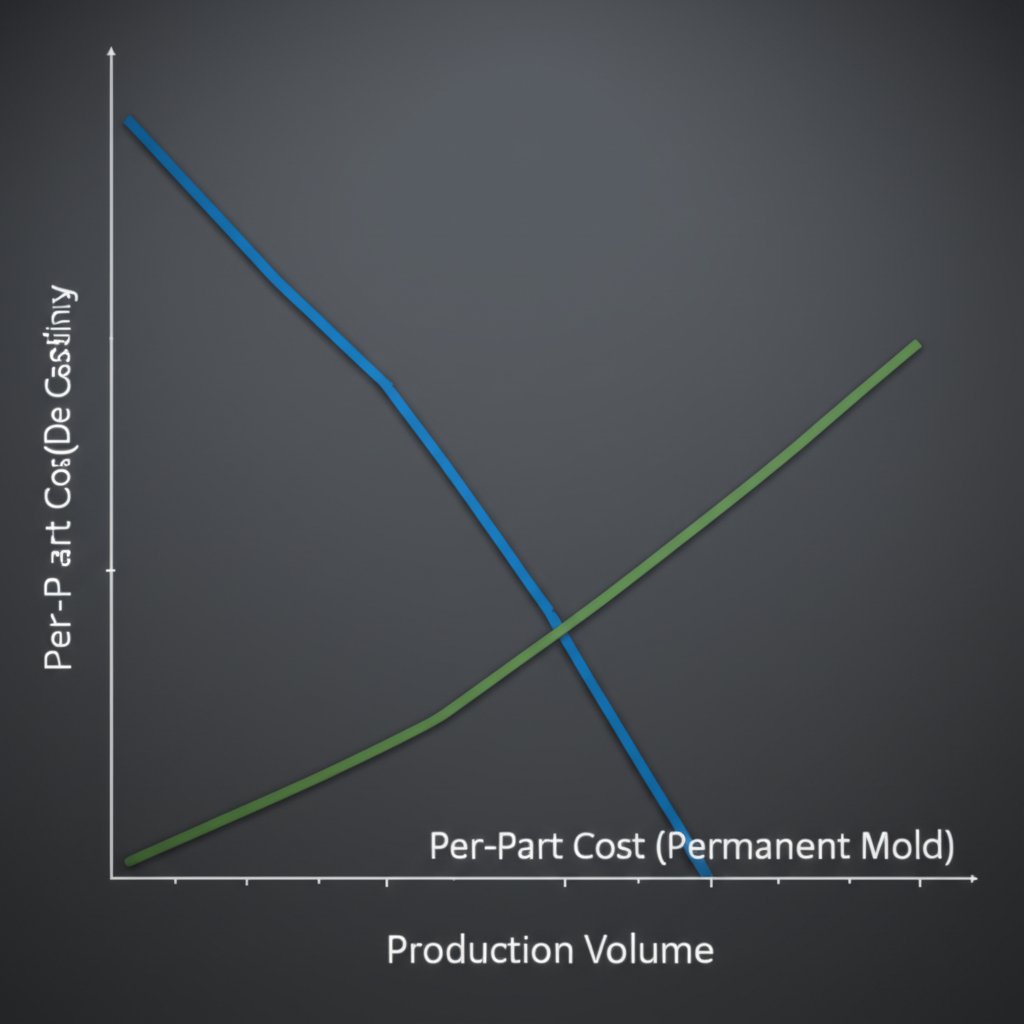

Ang pinakamalaking salik para sa maraming desisyon sa pagbili sa industriya ng automotive ay ang gastos, at dito malinaw na magkaiba ang dalawang proseso. Ang pangunahing patakaran ay simple: mataas ang paunang gastos sa tooling sa die casting ngunit mababa ang gastos bawat bahagi, samantalang katamtaman ang gastos sa tooling sa permanent mold casting ngunit mas mataas ang gastos bawat bahagi. Ang desisyon ay nakadepende sa inaasahang dami ng produksyon.

Ang mga die casting mold, o dies, ay dinisenyo upang tumagal laban sa matinding presyon at paulit-ulit na thermal shock. Gawa ito mula sa mataas na kalidad na tool steel at kumplikado ang engineering nito, na nagdudulot ng napakataas na gastos. Ayon sa mga mapagkukunan sa industriya, ang mga kagamitan sa die casting ay maaaring magkakaiba mula sa $60,000 hanggang mahigit sa $500,000 . Ang malaking pamumuhunan na ito ay nagiging makatuwiran lamang sa mataas na dami ng produksyon, karaniwang hihigit sa 10,000 yunit, kung saan maaaring i-amortize ang gastos sa daan-daang libo o kahit milyon-milyong bahagi, na nagreresulta sa napakababang gastos bawat piraso.

Ang permanenteng mold tooling ay mas murang opsyon, na may gastos na karaniwang nasa pagitan ng $10,000 at $90,000. Dahil hindi kailangang magtagal ang mga mold sa ilalim ng mataas na presyon, maaaring mas simple ang disenyo at ginawa sa mga mas magaang na materyales. Ginagawa nitong naa-access ang proseso para sa mga proyektong may mas maliit na badyet o mas mababang dami ng produksyon. Para sa mga low-to-medium volume na produksyon, na karaniwang itinuturing na mga 3,000 bahagi bawat taon, ang permanent mold casting ay halos laging mas ekonomikal na opsyon. Mahalaga ang punto ng breakeven; habang tumataas ang dami ng produksyon patungo sa sampu-sampung libo, ang mas mababang gastos bawat bahagi ng die casting ay unti-unting nagiging kompetitibo laban sa paunang gastos nito sa tooling.

Kalidad at Katangian ng Bahagi: Isang Kuwento ng Dalawang Uri ng Tapusin

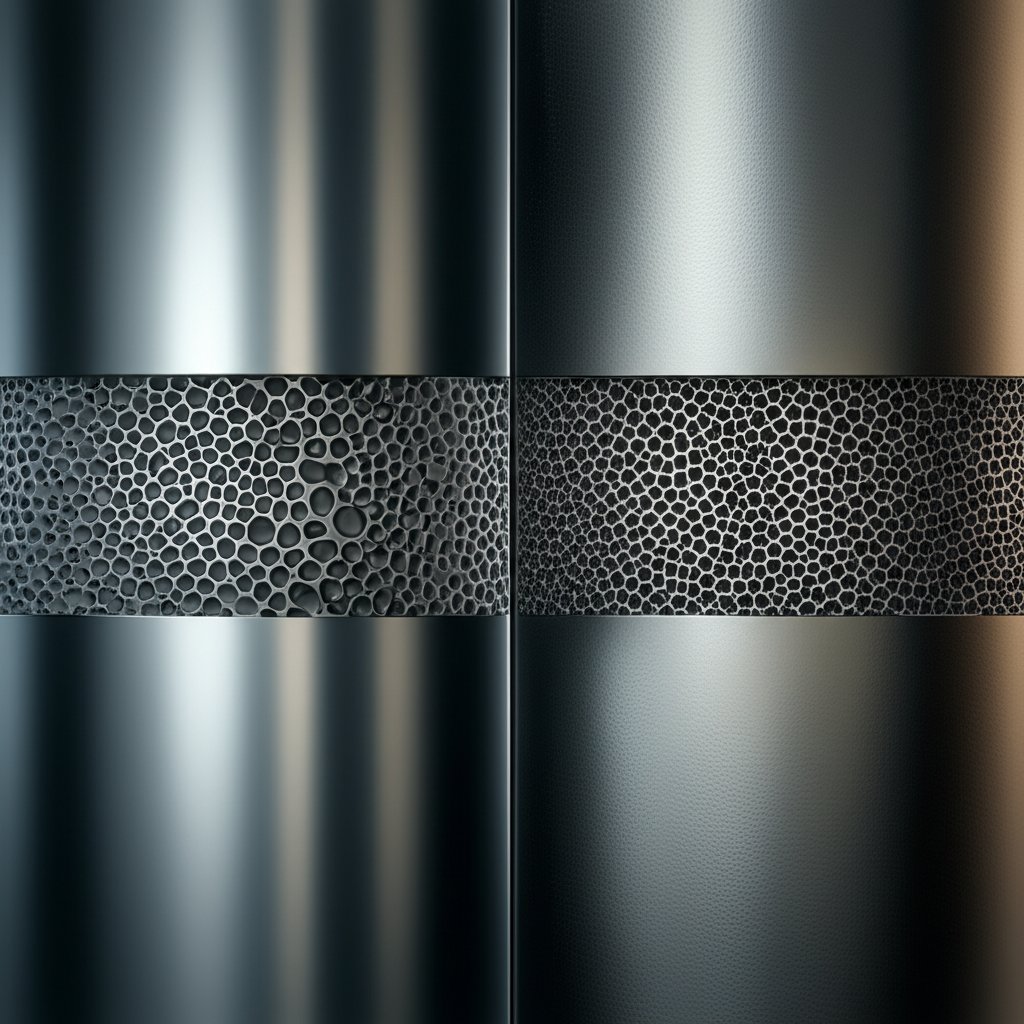

Higit sa gastos, ang pagpili ng paraan ng pag-iipon ay direktang nakakaapekto sa kalidad ng huling bahagi, mga katangiang mekanikal, at mga posibilidad sa disenyo. Ang bawat proseso ay lumilikha ng mga bahagi na may kakaibang katangian na angkop para sa iba't ibang aplikasyon sa sasakyan. Kilala ang die casting sa kanyang husay at tapusin ng ibabaw, samantalang ang permanent mold casting ay hinahalagahan dahil sa kanyang kalakasan at kahusayan sa loob.

Dahil sa mataas na presyon na nagpapahinto ng metal laban sa makinis na bakal na die, ang mga die-cast na bahagi ay may mahusay na surface finish na kung minsan ay nasa pagitan ng 32-90 RMS. Binabawasan nito ang pangangailangan para sa mga karagdagang operasyon sa pagpopondo. Pinapayagan din ng proseso ang hindi pangkaraniwang dimensional na akurado at ang paglikha ng napakakapal na pader, na kung minsan ay kasing manipis ng 0.04 pulgada, na perpekto para sa magaan at kumplikadong mga sangkap tulad ng transmission case o electronic housings. Gayunpaman, ang mabilis na iniksyon at solidipikasyon ay maaaring ikulong ang hangin at mga gas, na nagdudulot ng panloob na porosity. Ang porosity na ito ay maaaring masira ang istruktural na integridad ng bahagi at nangangahulugan na karamihan sa mga die-cast na bahagi ay hindi maaaring iwan ng heat treatment o i-weld.

Ang permanent mold casting ay naglalabas ng mga bahagi na may mas magaspang na surface finish (karaniwan 150-250 RMS) na kadalasang nangangailangan ng mas maraming post-processing. Gayunpaman, dahil sa mabagal at maayos na pagpuno, nagkakaroon ng pagkakataon ang mga gas na lumabas sa kawalang-ulo, na nagreresulta sa isang casting na mas hindi porous at mas padensidad. Ang mas mataas na kalidad ng panloob na istraktura ay nagdudulot ng mas matibay at mas maaasahang mga bahagi para sa mga aplikasyon kung saan mahalaga ang pressure tightness o mechanical strength, tulad ng mga suspension components o hydraulic cylinders. Maaari ring i-heat treat ang mga bahaging ito upang higit na mapabuti ang kanilang mechanical properties.

| Katangian | High-pressure die casting | Permanent mold casting |

|---|---|---|

| Katapusan ng ibabaw | Mahusay (32-90 RMS) | Maganda (150-250 RMS) |

| Katumpakan ng Sukat | Napakataas | Mataas |

| Kapal ng pader | Napakapino ang kapabilidad (≥0.04") | Mas makapal ang kailangan (≥0.1") |

| Antas ng Porosity | Mas mataas na potensyal para sa panloob na porosity | Mababa; karaniwang mas matibay ang mga bahagi |

| Mga mekanikal na lakas | Maganda, na may makinis na surface | Mahusay, dahil sa mababang porosity |

Pagpili ng Materyales at Mga Konsiderasyon sa Disenyo

Ang pagpili ng metal alloy ay isang mahalagang salik kung saan nagkakaiba ang dalawang proseso. Ang mataas na presyur sa die casting ay naglalagay ng malaking limitasyon sa pagpili ng materyales, samantalang ang permanent mold casting ay mas malaya sa pagpili. Maaaring ito ang naging batayan kung ang isang bahagi ng sasakyan ay nangangailangan ng tiyak na katangian ng materyal.

Ang die casting ay halos eksklusibong ginagamit kasama ang mga di-ferrous alloy na may mataas na fluidity at relatibong mababang melting point. Kabilang sa pinakakaraniwang materyales ang mga aluminum alloy (tulad ng 380 at 390), sosa, at magnesiyo. Ayon sa Casting Source , ang die casting ang pinakamaselan sa pagbabago ng mga alloy. Hindi karaniwang angkop ang ferrous metal tulad ng bakal at asero dahil ang kanilang mataas na temperatura ng pagkatunaw ay mabilis na mapapinsala sa mga steel dies. Sa aspeto ng disenyo, mahusay ang die casting sa paggawa ng mga kumplikadong bahagi na malapit sa huling hugis, na nangangailangan lamang ng kaunting machining, na tumutulong upang bawasan ang gastos sa produksyon sa malalaking dami.

Mas mapagpilian ang permanenteng paghuhulma. Bagaman ginagamit din ito para sa aluminyo, sosa, at magnesiyo, kayang-kaya rin nito ang mga haluang metal na may mas mataas na punto ng pagkatunaw, kabilang ang tanso at mga haluang metal na tanso. Ang mas malawak na pagpipilian ng materyales ay nagbibigay sa mga inhinyero ng higit pang opsyon upang matugunan ang tiyak na mga pangangailangan sa pagganap. Mas limitado naman ang kumplikadong disenyo kumpara sa die casting, dahil mahirap makamit ang napakaintrikadong mga katangian gamit ang prosesong pinapadaloy ng gravity. Gayunpaman, ang paggamit ng de-kalidad na buhangin sa isang semi-permanenteng proseso ng paghuhulma ay nagbibigay-daan sa paglikha ng kumplikadong panloob na puwang na hindi magagawa sa die casting.

Pagpili ng Tamang Opsyong Para sa Iyong Aplikasyon sa Automotive

Ang pagpili ng tamang proseso ng pag-iil cast ay isang estratehikong desisyon na nagbabalanse sa ekonomiko at inhinyeriyang mga pangangailangan. Para sa mga aplikasyon sa automotive, ang tamang pagpipilian ay nakabase sa malinaw na pag-unawa sa mga layunin ng proyekto. Ang die casting ang walang kamatayang lider para sa mataas na dami, kumplikado, at magaang mga bahagi kung saan mahalaga ang makinis na surface finish, tulad ng engine blocks, transmission housings, at panloob na cosmetic components.

Ang permanent mold casting ay nakakita ng sariling niča sa mga aplikasyon na nangangailangan ng mas mataas na mekanikal na lakas at pressure tightness sa mababang hanggang katamtamang dami. Ito ang ginustong pamamaraan para sa mga structural component tulad ng suspension parts, steering knuckles, at brake calipers, kung saan mas mahalaga ang internal soundness kaysa perpektong surface finish. Sa maingat na pagsusuri sa mga salik tulad ng production volume, badyet, at kinakailangang katangian ng materyales, ang mga inhinyero at disenyo sa automotive ay makakapili ng prosesong magbibigay ng pinakamahusay na pagganap at halaga.

Mga madalas itanong

1. ang mga tao Ano ang pangunahing pagkakaiba sa pagitan ng pagbubuhos ng mga molde sa pamamagitan ng pagbubuhos ng mga molde sa pamamagitan ng pagbubuhos ng mga molde?

Ang pangunahing pagkakaiba ay sa kung paano pinupuno ng nabubuong metal ang pagbubuo. Ang pag-iikot ng metal sa pamamagitan ng pag-iikot ay ginagawa sa ilalim ng mataas na presyon, na nagreresulta sa mabilis na paggawa, kumplikadong hugis, at makinis na ibabaw. Ang permanenteng pagbubuhos ng mga hulma ay gumagamit ng grabidad o mababang presyon upang ibuhos ang metal sa hulma, na isang mas mabagal na proseso na gumagawa ng mas mas matibay, mas malakas na mga bahagi na may mas mababang gastos sa tooling.

2. Ano ang pangunahing disbentaha ng permanenteng pagbubuhos ng mga molde?

Ang pangunahing disbentaha ng permanenteng pagbubuo ng molde ay kinabibilangan ng mas mabagal na mga siklo ng produksyon kumpara sa pagbubuo ng die, na ginagawang hindi gaanong angkop para sa napakalaking produksyon. Ang gastos sa bawat bahagi ay mas mataas din sa malalaking dami. Karagdagan pa, sa pangkalahatan ay hindi ito makakamit ng parehong antas ng komplikadong detalye o manipis na dingding tulad ng pag-cast ng high-pressure die, at ang mga bahagi ay madalas na nangangailangan ng mas pangalawang pagtatapos.

3. Ano ang pagkakaiba ng PDC at GDC?

Ang PDC ay ang maikling tawag sa Pressure Die Casting, kung saan ipinasok ang natunaw na metal sa ilalim ng mataas na presyon. Ang GDC naman ay ang maikling tawag sa Gravity Die Casting, kung saan ibinubuhos ang natunaw na metal at pinupunan ang hulma sa pamamagitan lamang ng puwersa ng gravity. Ang high-pressure die casting ay isang uri ng PDC, samantalang ang permanent mold casting ay isang anyo ng GDC.

Maliit na mga batch, mataas na pamantayan. Ang serbisyo sa paggawa ng mabilis na prototyping namin ay gumagawa ng mas mabilis at mas madali ang pagpapatunay —

Maliit na mga batch, mataas na pamantayan. Ang serbisyo sa paggawa ng mabilis na prototyping namin ay gumagawa ng mas mabilis at mas madali ang pagpapatunay —