வாகனத் துறைக்கான CNC உற்பத்தி: NPI முதல் லாபகரமான உற்பத்தி அளவு வரை

ஆட்டோமொபைல் துறையில் சிஎன்சி உற்பத்தியின் அடிப்படைகள் 2025

2025 இல் CNC ஆட்டோமொபைல் துறையில் என்ன வழங்கும்

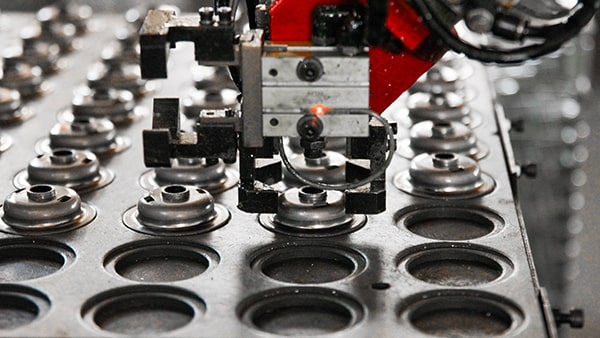

நவீன வாகனங்கள் எப்படி இத்தகைய உயர்ந்த பாதுகாப்பு, செயல்திறன், மற்றும் நம்பகத்தன்மை ஆகியவற்றின் தரங்களை அடைகின்றன என்று எப்போதாவது யோசித்திருக்கிறீர்களா? பதில் ஆட்டோமொபைல் உற்பத்தியில் CNC உற்பத்தியில் உள்ளது. ஆனால் உற்பத்தியில் CNC என்றால் என்ன? CNC என்பது கணினி எண் கட்டுப்பாடு என்று பொருள்படும். இது டிஜிட்டல் வடிவமைப்புகளை உண்மையான, இயற்பியல் பாகங்களாக மாற்றுகிறது.

2025 ஆம் ஆண்டில், சிஎன்சி ஆட்டோமொபைல் செயல்முறைகள் உலகெங்கிலும் உள்ள வாகன திட்டங்களின் முதுகெலும்பாக இருக்கும். ஏன்? ஏனென்றால் இன்றைய வாகனங்கள் உலோகங்கள், பிளாஸ்டிக் மற்றும் கலப்பு பொருட்களின் கலவையிலிருந்து செய்யப்பட்ட சிக்கலான பாகங்களைக் கோருகின்றன. இவை அனைத்தும் முன்னெப்போதையும் விட வேகமாகவும், இலகுவாகவும், மேலும் இறுக்கமான சகிப்புத்தன்மையுடன் தயாரிக்கப்படுகின்றன. இது இயந்திரத் தொகுதிகள், டிரான்ஸ்மிஷன் கீர்கள் அல்லது சஸ்பென்ஷன் கைகள் என இருந்தாலும், சிஎன்சி உற்பத்தி ஒவ்வொரு கூறுகளும் தரம் மற்றும் செயல்பாட்டிற்கான கடுமையான விவரக்குறிப்புகளை பூர்த்தி செய்கிறது.

டிஜிட்டல்-மெட்டல் துல்லியம் ஆபத்தை எவ்வாறு குறைக்கிறது

நீங்கள் ஒரு டிஜிட்டல் மாடலை ஒரு முடிக்கப்பட்ட பாகமாக மாற்றும்போது, ஒவ்வொரு விவரமும் முக்கியமானது. சிஎன்சி இயந்திரம் கைமுறை பிழைகளை நீக்கி, துல்லியமான பாகங்களை மட்டுமல்லாமல் ஆயிரக்கணக்கான அலகுகளிலும் சீரான பாகங்களை வழங்குகிறது. இந்த டிஜிட்டல்-டு-மெட்டல் பணிப்பாய்வு ஆட்டோமொபைல் எந்திரங்களுக்கு மிகவும் முக்கியமானது, ஏனென்றால் சிறிய விலகல்கள் கூட பாதுகாப்பை பாதிக்கும் அல்லது விலையுயர்ந்த திரும்பப் பெறுதல்களுக்கு வழிவகுக்கும்.

- துல்லியம்: பாதுகாப்பு-குறிப்பிட்ட அம்சங்களுக்கான மைக்ரோன் அளவிலான சகிப்புத்தன்மையை அடைதல்

- வேகம்: விரைவான முன்மாதிரி தயாரிப்பு மற்றும் உற்பத்தி சந்தைக்கு வரும் நேரத்தை துரிதப்படுத்துகிறது

- அதிர்வு: சீரான வடிவமைப்பு மாற்றங்கள் மற்றும் புதிய பொருட்களுக்கு விரைவான ஏற்பாடு

- கண்காணிப்பு திறன்ஃ தரம் மற்றும் செயல்பாடு ஆகியவற்றை உறுதிப்படுத்த ஒவ்வொரு பாகமும் இலக்கமயமாக கண்காணிக்கப்படுகிறது

“தொகுப்புகளில் தாங்கும் தன்மை கொண்ட அளவுகள் சிறிய விலகலை முக்கியமான பாதுகாப்பு ஆபத்தாக மாற்றக்கூடும். CNC இன் மீண்டும் மீண்டும் உற்பத்தி தான் தொடர்ந்தும் முக்கியமான அம்சங்களை தர வரம்பிற்குள் வைத்திருக்கிறது.”

சிஎன்சி மூலம் புரோட்டோடைப் முதல் உற்பத்தி வரை

சங்கீலமாக தெரிகிறதா? ஒரு குறிப்பு தாளிலிருந்து வரைந்த வரைபடத்திலிருந்து வெறும் நாட்களில் உற்பத்திக்கு தயாரான பாகத்தை உருவாக்குவதை கற்பனை செய்து பாருங்கள்— வாரங்கள் அல்ல. CNC உற்பத்தி வேகமான புரோட்டோடைப்பிங் முதல் முழுமையான உற்பத்தி வரை ஒவ்வொரு நிலைமையையும் ஆதரிக்கிறது. இதன் மூலம் பொறியாளர்களால் சோதிக்க, மேம்படுத்தி வேகமாக உற்பத்தியை அதிகரிக்க முடியும், தரத்தையும் செலவையும் கண்டுகொள்ள முடியும்.

லைட்வெயிட்டிங் மற்றும் உமிழ்வு செயல்பாடு ஆகியவற்றிற்கான தேவை அதிகரித்து வருவதால், ஆட்டோமோட்டிவ் உற்பத்தியாளர்கள் இப்போது சிக்கலான வடிவவியலை வழங்கவும், புதிய பொருட்களை ஒருங்கிணைக்கவும் CNC தொழில்நுட்பத்தை நாடுகின்றனர். குறைந்த நேர இடைவெளியில் வெவ்வேறு ஆட்டோ மெஷினிங் நிரல்களுக்கு மாற முடிவது உற்பத்தி அளவையும் டாக்ட் நேரத்தையும் ஒருங்கிணைப்பதில் புரட்சிகரமான மாற்றத்தை ஏற்படுத்துகிறது.

- விநியோகஸ்தர் மதிப்பீட்டிற்காக CAD/BOM கோப்புகள் தயாராக உள்ளன

- ஒவ்வொரு அம்சத்திற்கும் இலக்கு தாங்கும் தன்மை

- மதிப்பிடப்பட்ட ஆண்டு உற்பத்தி அளவுகள்

- விருப்பமான பொருட்கள் மற்றும் மேற்பரப்பு முடிக்கும் தேவைகள்

ஒரு சப்ளையரை நியமிப்பதற்கு முன் அல்லது கருவிகளைத் தேர்ந்தெடுப்பதற்கு முன், இந்த அத்தியாவசியங்களைச் சேகரிக்கவும். நீங்கள் CNC உற்பத்தியின் நெகிழ்வுத்தன்மையையும் செயல்திறனையும் முழுமையாக பயன்படுத்த தயாராக இருப்பீர்கள்.

நீங்கள் தொடர்ந்து படிக்கும்போது, ஆட்டோமொபைல் சிஎன்சி உற்பத்தியில் பயன்படுத்தப்படும் இயந்திரங்களின் வகைகள், என்பிஐ முதல் வெகுஜன உற்பத்தி வரை படிப்படியான வழிகாட்டிகள், பொருட்கள் விளையாட்டு புத்தகங்கள், கேஎம் ஆட்டோமேஷன், தரத் தரநிலைகள், ROI மாதிரிகள் மற்றும் சரியான கூட்டாளரை எவ்வாறு தேர்ந்தெ உங்கள் சொந்த வாகன இயந்திர திட்டங்களுக்கு இந்த கருத்துக்களைப் பயன்படுத்த உதவும் நடைமுறை வார்ப்புருக்கள், வேலை செய்யப்பட்ட எடுத்துக்காட்டுகள் மற்றும் நிஜ உலக வழக்கு ஆய்வுகள் எதிர்பார்க்கலாம்.

வாகனத் திட்டங்களில் இயந்திர வகைகள் மற்றும் பயன்பாடுகள்

ஒவ்வொரு அம்சத்திற்கும் சரியான இயந்திர வகையைத் தேர்ந்தெடுப்பது

ஒரு நவீன வாகனத்தை நீங்கள் பார்க்கும்போது, இயந்திரத் தொகுதியிலிருந்து டாஷ்போர்டு அலங்காரங்கள் வரை ஒவ்வொரு கூறுகளும் ஒரு CNC இயந்திரத்தில் வாழ்க்கையைத் தொடங்கியிருக்கலாம். ஆனால் எந்த சிஎன்சி இயந்திரங்களின் வகைகள் எந்த வாகன அம்சங்களுக்கு பொருந்துகிறது? பதில் பகுதி சிக்கலான தன்மை, பொருள், அனுமதிக்கக்கூடிய தன்மை மற்றும் உற்பத்தி அளவு ஆகியவற்றைப் பொறுத்தது. மிகவும் பொதுவானவற்றை உடைப்போம் சிஎன்சி இயந்திர வகைகள் நீங்கள் வாகன இயந்திரங்களில் சந்திக்கும், எனவே நீங்கள் உங்கள் குறிப்பிட்ட தேவைகளுக்கு பொருத்தமான உபகரணங்கள் பொருத்த முடியும்.

| குறியீட்டு வகை | வழக்கமான வாகன பாகங்கள் | பொதுவான சகிப்புத்தன்மை | மேற்பரப்பு முடித்தல் (Ra, μm) |

|---|---|---|---|

| 3 அச்சு செங்குத்து சுருள் | பிளேட்கள், டாஷ்போர்டு பேனல்கள், கவர் பிளேட்கள் | ±0.05 mm | 1.6–3.2 |

| 4/5-அச்சு இயந்திர மையம் | சிலிண்டர் தலைகள், இயந்திரத் தொகுதிகள், டர்போ ஹவுஸ்கள் | ±0.010.025 மிமீ | 0.8–1.6 |

| மில்-டர்ன் (CNC டார்ச் ஃப்ரீஸிங் உடன்) | ஆஷ்கள், கியர்கள், ஹப்ஸ், அச்சுகள் | ±0.02 மிமீ | 0.8–1.6 |

| பேலட் பூல் கொண்ட HMC | வால்வு உடல்கள், டிரான்ஸ்மிஷன் கேஸ்கள், பெரிய அளவிலான தொகுதிகள் | ±0.010.03 மிமீ | 1.6–3.2 |

| இரட்டை சுழல் திருப்பு மையம் | டிரைவ் ட்ரீன் பாகங்கள், லேயரிங் ரேஸ் | ±0.015 மிமீ | 0.4–1.6 |

சிக்கலான வீடுகளுக்கான 5 அச்சு நன்மைகள்

ஒரு சிலிண்டர் தலையில் ஆழமான துறைமுகங்கள் அல்லது கலப்பு கோணங்கள் போன்ற சிக்கலான அம்சங்களை இயந்திரமயமாக்க முயற்சித்தீர்களா? அதுதான் 5 அச்சு வாகன சிஎன்சி இயந்திரங்கள் ஒளிர்கிறது. அவை வெட்டு கருவியை எந்த திசையிலிருந்தும் பணிப்பொருளுக்கு நெருங்க அனுமதிக்கின்றன, அமைப்பைக் குறைத்து சிக்கலான வடிவியல் கொண்ட பகுதிகளுக்கு துல்லியத்தை மேம்படுத்துகின்றன. இது ஒளிவுச்சம் போக்குகள் மற்றும் குளிர்விப்பு அல்லது எண்ணெய் சேனல்களை நேரடியாக வீடுகளில் ஒருங்கிணைக்க முக்கியமானது.

சுழற்சி-தொழில்புறம்

தட்டையான, துளைகள் அல்லது குறுக்கு துளைகள் கொண்ட வட்ட பாகங்களை நீங்கள் தயாரிக்க வேண்டியிருக்கும்போது, இயக்கி அச்சுகள் அல்லது கீர் வெற்றுகளை நினைத்துப் பாருங்கள். இது செயல்திறனை அதிகரிக்கிறது மற்றும் கையாளுதலைக் குறைக்கிறது, இது நடுத்தர முதல் அதிக அளவு ஓட்டங்களுக்கு ஏற்றதாக அமைகிறது. இன்னும் அதிக செயல்திறனுக்காக, இரட்டை சுழல் இயந்திரங்கள் ஒரு பகுதியின் இரு முனைகளையும் ஒரே நேரத்தில் வேலை செய்ய அனுமதிக்கின்றன.

சுழல் சக்தி, திருப்பம், மற்றும் இறுக்கத்தன்மை - இவை ஏன் முக்கியம்

தொழில்நுட்ப ஒலிகள்? அது முக்கியமானதாகும். சுழல் வளைவு மற்றும் முறுக்கு வளைவு ஒரு இயந்திரம் எஃகு போன்ற கடினமான பொருட்கள் மற்றும் அலுமினியம் போன்ற மென்மையான உலோகங்களை வெட்டுவதற்கு எவ்வளவு சிறப்பாக இருக்கும் என்பதை தீர்மானிக்கிறது. எஃகு மீது அதிக சுழற்சி முறையுடன் கூடிய, இறுக்கமான இயந்திரங்கள் விரும்பப்படுகின்றன; அலுமினியத்தில் இலகுவான, அதிவேக சுழல்விளக்குகள் சிறப்பாக உள்ளன. எப்போதும் இயந்திரம் ன் வேக வரம்பில் டம்ளர் மற்றும் சக்தி வளைவுகள் சரிபார்க்கவும் நிறுத்தங்கள் அல்லது மோசமான மேற்பரப்பு முடித்த தவிர்க்க [CTE இதழ்] .

- பணிநிலை வளைவு குறைத்து மதிப்பிடுவது விவரக்குறிப்பு வெளியே பாகங்கள் வழிவகுக்கும்

- ஆழமான பைகளில் கருவி அடைய புறக்கணிப்பது சத்தம் அல்லது கருவி உடைப்பு ஏற்படலாம்

- பொருள் வகைக்கு சுழல் சக்தி பொருந்தாதது கருவி ஆயுள் மற்றும் பூச்சு குறைக்கிறது

முடிவு மரம்ஃ இயந்திரம் அம்சத்துடன் பொருந்துதல்

- அம்ச வகை மற்றும் தேவையான சகிப்புத்தன்மையுடன் தொடங்கவும்

- உற்பத்தி அளவு மதிப்பீடு (மாதிரி vs எடை)

- இயந்திர உறை (அளவு), அச்சு எண்ணிக்கை மற்றும் ஆட்டோமேஷன் (பல்லேட் / ரோபோ சேவை) தேர்ந்தெடுக்கவும்

- RFQ இல் அச்சுப் பயணம், கருவி பத்திரிகை அளவு, சோண்டிங் மற்றும் குளிர்விப்பு திரவத்தை குறிப்பிடவும்

- திட்ட சாத்தியக்கூறுகளை உறுதிப்படுத்த ஆரம்ப மோதல் மற்றும் பொருத்துதல் சோதனைகள் இயக்க

மறக்காதீர்கள்: இயந்திரக் கட்டுப்பாடுகள் மற்றும் கருவி மாற்றிகள் சுழற்சி நேரத்தின் நிலைத்தன்மையிலும் விளக்குகள் அணைக்கப்படும் உற்பத்தியிலும் பெரும் பங்கு வகிக்கின்றன. ஒவ்வொரு தேவையையும் முன்கூட்டியே ஆவணப்படுத்தி வருவது எதிர்கால கட்டுப்பாடுகள் மற்றும் தாமதங்களைத் தடுக்கிறது.

இவற்றைப் புரிந்துகொள்வதன் மூலம் சிஎன்சி இயந்திரங்களின் வகைகள் மற்றும் அவற்றின் பயன்பாடுகள், நீங்கள் முன்மாதிரி முதல் வெகுஜன உற்பத்திக்கு நகரும் போது செயல்திறன், தடமறிதல் நேரம் மற்றும் தரத்தை சமநிலைப்படுத்த சிறந்த முறையில் தயாராக இருப்பீர்கள். அடுத்து, புதிய பாகங்களை நம்பிக்கையுடன் அறிமுகப்படுத்தும் படிப்படியான விளையாட்டு புத்தகத்தில் இறங்குவோம்.

சிஎன்சி ஆட்டோ பாகங்களுக்கான நிபுணர் தொகுப்பிலிருந்து பெருமளவு உற்பத்தி வரை வழிகாட்டி

உற்பத்திக்கு வரையறுக்கப்பட்ட புரோடோடைப் பாதை முறைமை

புதிய ஆட்டோமொபைல் பாகத்தை கோட்பாட்டிலிருந்து பெருமளவு உற்பத்தி வரை கொண்டு வருமாறு உங்களுக்கு பணி வழங்கப்படும் போது, அந்த பாதை சற்று சிக்கலாக தோன்றலாம். உங்கள் பணியை எப்படி உறுதி செய்ய cNC மெஷினிங் பாகம் கடுமையான தரவரிசைகளை நிறைவேற்றவும், தடயம் தேடக்கூடியதாகவும், குறைந்த ஆபத்துடனும் வேகமாகவும் செய்ய நிரூபிக்கப்பட்ட படிப்படியான வழிமுறைகளை பின்பற்றவும். நீங்கள் காகிதத்தில் வரைந்த படத்திலிருந்து நிலையான, லாபகரமான உற்பத்தி வரை வழிகாட்டும் வகையில் APQP மற்றும் PPAP போன்ற துறை சார்ந்த சிறந்த நடைமுறைகளை ஒருங்கிணைக்கவும்.

- CAD சுத்தம் செய்தல் & துவக்க புள்ளி உத்தி: உங்கள் CAD மாடலை மேம்படுத்துவதன் மூலம் தொடங்குங்கள். தெளிவான தரவுகளை வரையறுக்கவும். இவை ஆட்டோமொபைல் பாகங்கள் இயந்திரமயமாக்கலுக்கான அனைத்து பின்வரும் அளவீடுகள் மற்றும் அமைப்புகளையும் இயக்கும் குறிப்பு புள்ளிகள்.

- DFM ஆய்வுஃ உற்பத்தித்திறனை மதிப்பீடு செய்யுங்கள்குறைந்தபட்ச சுவர் தடிமன், பிளேட் ரேடியஸ் ஆகியவற்றை சரிபார்த்து, துளை அளவுகளை தரப்படுத்தவும். ஆரம்பகால டி. எஃப். எம் (வடிவமைப்பு உற்பத்திக்கு) மதிப்புரைகள் பின்னர் விலையுயர்ந்த மறுவடிவமைப்புகளைத் தடுக்கின்றன, குறிப்பாக ஓ. எம். எஸ்ஸிற்கான சிஎன்சி எந்திரத்தில் முக்கியமானவை.

- CAM கரடுமுரடான/முடிவு மூலோபாயம்ஃ அரிதான மற்றும் முடித்த கருவிகளின் பாதைகளை உருவாக்குதல். பொருத்தமான வெட்டு கருவிகளைத் தேர்ந்தெடுத்து, நீங்கள் தேர்ந்தெடுத்த பொருளுக்கு ஏற்றவாறு ஊட்டங்களையும் வேகங்களையும் மேம்படுத்தவும்.

- பொருத்துதல் மற்றும் ஆய்வு திட்டம்ஃ ஸ்திரத்தன்மை மற்றும் மீண்டும் மீண்டும் செய்யக்கூடிய தன்மைக்கான வடிவமைப்பு பொருத்துதல். முக்கியமான அம்சங்களைத் தேடும் செயல்முறை சோதனைகளைத் திட்டமிடுதல் என்பது ஆட்டோமொபைல் சிஎன்சி பாகங்களின் தரத்தை பராமரிப்பதற்கான முக்கியமாகும்.

- FAI உடன் பைலட் ரன்: ஒரு பைலட் ரன் நடத்தி, பகுதி மற்றும் செயல்முறை இரண்டையும் சரிபார்க்க முதல் கட்டுரை ஆய்வு (FAI) செய்ய வேண்டும். அனைத்து முக்கியமான பரிமாணங்களையும் கைப்பற்றி அவற்றை அச்சுடன் ஒப்பிட்டுப் பாருங்கள்.

- திறன் ஆய்வு (Cp/Cpk): ஒரு சிறிய தொகுதி இயக்க மற்றும் செயல்முறை திறன் பகுப்பாய்வு. Cp/Cpk > 1.33 க்கு இலக்கு வைக்கவும், இது மீண்டும் மீண்டும் செய்யக்கூடிய தன்மை மற்றும் கட்டுப்பாட்டை நிரூபிக்கும்.

- PPAP தொகுப்பு உருவாக்கஃ உங்கள் முழுமையான PPAP ஆவணங்களைச் சேகரிக்கவும்FAI அறிக்கைகள், MSA (அளவீட்டு முறை பகுப்பாய்வு), கட்டுப்பாட்டு திட்டம், PFMEA மற்றும் எதிர்வினைத் திட்டம். இந்த படி குறிப்பாக OEM களுக்கான cnc எந்திரத்திற்கு முக்கியமானது, ஏனெனில் இது வாடிக்கையாளர் ஒப்புதலை உறுதிப்படுத்துகிறது.

- அடுக்கு செயல்முறை ஆடிட்டுகளுடன் ரேம்ப்ஃ நீங்கள் அளவிடுகையில், சிக்கல்களை ஆரம்பத்தில் கண்டறிந்து செயல்முறை ஒழுக்கத்தை உறுதிப்படுத்த அடுக்கு செயல்முறை தணிக்கைகளை மேற்கொள்ளுங்கள்.

- தொடர்ச்சியான மேம்பாடு: தரவுகளை திரட்டி, குறைபாடுள்ள பாகங்களையோ அல்லது நிறுத்தப்பட்ட நேரத்தையோ பகுப்பாய்வு செய்து, உங்கள் செயல்முறையை மேம்படுத்தவும். கற்றுக்கொண்டவற்றை அடிப்படையாக கொண்டு நேரத்திற்கு ஏற்ப சிறப்பான விளைவுகளையும், குறைந்த செலவினத்தையும் உறுதி செய்யவும்.

நிலைகளுக்கான முக்கிய வழங்கல்கள்: ஒவ்வொரு நிலையிலும் தயார் நிலையில் இருக்க வேண்டியவை

| தளம் | முக்கிய வழங்கல்கள் |

|---|---|

| டிஎஃப்எம் மதிப்பீடு | டிஎஃப்எம் சோதனைப்பட்டியல், புதுப்பிக்கப்பட்ட அளவீடுகளுடன் CAD |

| சோதனை இயங்கும் நிலை | FAI அறிக்கை, செயல்முறை ஓட்ட வரைபடம் |

| திறன் ஆய்வு | Cp/Cpk பகுப்பாய்வு, MSA அறிக்கை |

| பி.பி.ஏ.பி. சமர்ப்பனை | பிஎஸ்ஒ, FAI, கட்டுப்பாட்டு திட்டம், PFMEA, எதிர்வினைத் திட்டம், பொருள் சான்றிதழ்கள் |

| ராம்ப் & SOP | அடுக்கு கணக்காய்வு அறிக்கைகள், திருத்தக் கட்டுப்பாட்டு பதிவுகள் |

நம்பகமான சிஎன்சி ஆட்டோ பாகங்களுக்கான டிஎஃப்எம் விதிகள்

முதல் சிப்பை வெட்டுவதற்கு முன் ஒரு மெல்லிய சுவரை அல்லது சங்கடமான அண்டர்கட் பிடிப்பதை கற்பனை செய்து பாருங்கள். இதுவே வலுவான DFM இன் சக்தி. க்கான cnc automotive parts , எப்போதும்ஃ

- உலோகங்களின் சுவர் தடிமன் 2 மிமீக்கு மேல் இருக்க வேண்டும் (சரியாக உறுதிப்படுத்தப்படாவிட்டால்)

- எளிதாக கருவி தேர்வு செய்ய நிலையான துளை அளவுகள் மற்றும் ஆழங்கள் பயன்படுத்தவும்

- கருவி உடைப்பைக் குறைப்பதற்கும், அழுத்த உயர்வுகளைத் தவிர்ப்பதற்கும் > 1 மிமீ அளவுள்ள பிளேட் ரேடியங்களைக் குறிப்பிடவும்

- மிகவும் அவசியமில்லாமல் ஆழமான பைகளை குறைக்கவும்

இந்த வழிகாட்டுதல்களை பின்பற்றுவது முன்மாதிரி தயாரிப்பு மற்றும் உற்பத்தியை ஒழுங்கமைக்க உதவுகிறது, நேரத்தையும் செலவையும் மிச்சப்படுத்துகிறது.

கட்டுப்பாட்டுத் திட்டங்கள், திறன் மற்றும் எதிர்வினைத் திட்டங்கள்

எப்படி நீங்கள் கடை தரையில் ஆச்சரியங்கள் தடுக்க? ஒரு வலுவான கட்டுப்பாட்டு திட்டம் உங்கள் சாலை வரைபடமாகும். எதிர்வினைத் திட்டங்களுக்கான விரைவான சரிபார்ப்புப் பட்டியல் இங்கேஃ

- முக்கியமான வெட்டு இயந்திரங்களுக்கு கருவி உடைப்பு எச்சரிக்கை அமைக்கப்பட்டுள்ளது

- பாதுகாப்பு முக்கிய அம்சங்களுக்கான செயல்பாட்டு சோதனை மறுஅளவீடுகள்

- ஸ்பெக்ஸிலிருந்து வெளியேற்றப்பட்ட பாகங்கள் கண்டறியப்பட்டால் தெளிவான நிறுத்தக் கொள்கைகள்

தட மற்றும் சுழற்சி சமநிலைப்படுத்த மறக்க வேண்டாம். உங்கள் கருவி பாதை நேரத்தை கணக்கிடுங்கள், சுமை / இறக்குதல் மற்றும் ஆய்வு சுழற்சிகளை சேர்க்கவும், ரோபோ பராமரிப்பைப் பயன்படுத்தினால் நீங்கள் ஒரு இடையக மூலோபாயம் இருப்பதை உறுதிப்படுத்தவும். இந்த சீரமைப்பு உங்கள் செயல்திறனை இலக்கு வைத்து மற்றும் குறுக்கீடுகள் தடுக்கிறது [CNC சமையல் புத்தகம்] .

திருத்தக் கட்டுப்பாடு மற்றும் பொறியியல் மாற்ற அறிவிப்பு (ECN) கையாளுதல் ஆகியவை மிக முக்கியம்சோதனை ஓட்டங்களின் போது தொகுப்புகளை அல்லது காலாவதியான நிரல்களை கலப்பது இணக்கத்தன்மை பிரச்சினைகளை ஏற்படுத்தலாம் மற்றும் செலவு குறைந்த மறு வேலை செய்யலாம்

இந்த கட்டமைக்கப்பட்ட விளையாட்டு புத்தகத்தை பின்பற்றுவதன் மூலம், முன்மாதிரிக்கும் இலாபகரமான உற்பத்திக்கும் இடையிலான இடைவெளியை நீங்கள் மூடுவீர்கள், ஆபத்தை குறைத்து, உங்கள் தானியங்கி பாகங்கள் செய்வதில் தரைப்பாசி செய்முறை அடுத்த கட்டத்திற்கு திட்டங்கள் தயாராக உள்ளன. அடுத்து, உங்கள் மேற்கோள் மற்றும் செயல்முறை திட்டமிடலை மேலும் துரிதப்படுத்த, பொருள் தேர்வு மற்றும் இயந்திரமயமாக்கல் ஏமாற்றுப் பக்கங்களை ஆராய்வோம்.

பொதுவான ஆட்டோ அலாய்ஸ் பொருட்களை இயந்திரம் இயந்திரம் Cheatsheets

ஆட்டோ அலாய்ஸ் க்கான ஊட்டங்கள், வேகங்கள், கருவிகள்

நீங்கள் CNC கார் பாகங்களை மேற்கோள் காட்டும்போது அல்லது திட்டமிடும்போது, பொருள் தேர்வு எல்லாவற்றையும் வடிவமைக்கிறது சுழற்சி நேரம், கருவி ஆயுள், இறுதி பொருத்தம் மற்றும் செயல்பாடு கூட. ஒவ்வொரு அலாய்க்கும் சரியான ஊட்டங்கள், வேகங்கள், கருவிகளை எப்படி விரைவாக பொருத்துகிறீர்கள்? ஆட்டோமொபைல் துல்லியமான வேலைகளில் நீங்கள் அதிகம் காணும் அலாய்களுக்கான முக்கிய அம்சங்களை நாம் உடைப்போம், இதனால் உங்கள் மேற்கோளை விரைவுபடுத்தி செலவு குறைந்த தவறுகளை தவிர்க்கலாம்.

| பொருள் | பரிந்துரைக்கப்பட்ட வெட்டிங் | சிப்லோடு (மிமீ/பற்கள்) | SFM (மீ/நிமிடம்) | DOC/WOC (மிமீ) | குளிர்விக்கும் திரவ வகை | கருவி ஆயுள் (எதிர்பார்த்தது) | வழக்கமான Ra (μm) |

|---|---|---|---|---|---|---|---|

| அல் 6061/6082/7075 | கார்பைடு, பொலிஷ் செய்யப்பட்ட புல்லாங்குழல் | 0.05–0.15 | 150–350 | 0.5–2.0 | வெள்ளம், அதிகப்படியான வெளியேற்றங்கள் | நீண்ட | 0.8–1.6 |

| எஃகு 4140/1045 | கார்பைடு, TiAlN பூசப்பட்ட | 0.03–0.07 | 60–120 | 0.3–1.0 | உயர் அழுத்த உமிழ்நீர் | சராசரி | 1.6–3.2 |

| துருப்பிடிக்காத 304/316 | கார்பைடு, TiN/TiAlN பூசப்பட்ட | 0.02–0.06 | 40–90 | 0.3–0.7 | உயர் அழுத்த குளிர்விக்கும் திரவம் | குறுகிய நடுத்தர | 0.8–1.6 |

| Mg AZ91 | கார்பைடு, கூர்மையான விளிம்பு | 0.08–0.20 | 200–400 | 0.5–1.5 | உலர்/குறைந்த அளவு மூடுபனி, கனிம எண்ணெய் | நீண்ட | 1.6–3.2 |

| PA66 GF30 (கண்ணாடி நிரப்பப்பட்ட நைலான்) | PCD/தமர போன்ற, மெருகூட்டப்பட்ட | 0.10–0.25 | 150–250 | 0.5–2.0 | காற்று வெடிப்பு/உலர் | நீண்ட | 1.6–3.2 |

பொருள் வாரியாக மேற்பரப்பு முடித்தல் இலக்குகள்

ஏன் CNC இயந்திரம் மூலம் தயாரிக்கப்படும் பல பாகங்கள் உற்பத்தியில் மேற்பரப்பு முடித்தல் மிகவும் முக்கியமானது? இது தோற்றத்தை மட்டும் குறிக்கவில்லை, மேற்பரப்பு கடினத்தன்மை (Ra) சீல், உடை, மற்றும் பாகங்கள் ஒன்றாக எவ்வளவு நன்றாக பொருந்துகின்றன என்பதை கூட பாதிக்கிறது. பெரும்பாலான வாகனக் கலவைகளுக்கு, பயன்பாடு மற்றும் பிந்தைய செயலாக்கத்தைப் பொறுத்து, Ra இலக்குகள் 0.8 முதல் 3.2 மைக்ரோமீட்டர் வரை இருக்கும். உதாரணமாக, இயந்திர மூடிகள் மற்றும் பிளேட்கள் 1.63.2 μm இல் நன்றாக இருக்கலாம், அதே நேரத்தில் சீல் மேற்பரப்புகள் அல்லது துல்லியமான பொருத்துதல் அம்சங்கள் பெரும்பாலும் 0.81.6 μm ஐ கோருகின்றன [க்சோமெட்ரி] .

- அலுமினியம்: மெருகூட்டப்பட்ட தட்டுகள் மற்றும் அதிக வெளியேற்றம் கட்டப்பட்ட விளிம்பைக் குறைத்து சிறந்த முடிவை அடைய உதவுகின்றன.

- ஸ்டெயின்லெஸ் ஸ்டீல்: குறைந்த SFM மற்றும் உயர் அழுத்த குளிரூட்டும் திரவம் வேலை கடினப்படுத்துதலைக் குறைத்து, பூச்சு மேம்படுத்துகின்றன.

- மக்னீசியம்ஃ உலர் அல்லது குறைந்த பனி குளிர்பதனப் பொருளைப் பயன்படுத்தவும்; தீ அபாயம் காரணமாக நீர் சார்ந்த குளிர்பதனப் பொருட்களைத் தவிர்க்கவும்.

- கண்ணாடி நிரப்பப்பட்ட பிளாஸ்டிக்ஃ உராய்வு எதிர்ப்பு மற்றும் விளிம்பு தரத்தை பராமரிக்க PCD அல்லது வைர போன்ற பூச்சுகளைப் பயன்படுத்தவும்.

கருவி ஆயுள் மற்றும் குளிர்பதன உத்திகள்

கருவி வாழ்க்கை ஆட்டோமொபைல் துல்லிய இயந்திரங்களில் உங்கள் செயல்முறை பொருளாதாரத்தை உருவாக்கலாம் அல்லது உடைக்கலாம். நீங்கள் கவனிக்கலாம், நிலையான பில்ட் அல்லது மோசடி லாட் நேரடியாக கருவி உடைப்பு மற்றும் ஸ்திரத்தன்மையை பாதிக்கிறது. அலுமினியத்திற்கு, கருவி வாழ்க்கை பொதுவாக நீண்டது, ஆனால் அதிக ஊட்ட விகிதங்கள் அல்லது மோசமான சிப் வெளியேற்றம் இன்னும் முன்கூட்டிய உடைப்பை ஏற்படுத்தும் [ScienceDirect] . எஃகு மற்றும் எஃகு உலோகக் கலவைகள் வெப்பத்தை கட்டுப்படுத்தவும், கருவிகளின் ஆயுளை நீட்டிக்கவும் பூசப்பட்ட கருவிகள் மற்றும் உயர் அழுத்த குளிரூட்டும் திரவத்தை தேவைப்படுகின்றன. மெக்னீசியம் வெட்டுவது எளிதானது என்றாலும், தனித்துவமான தீ அபாயங்களைக் கொண்டுள்ளதுகலப்பு அல்லது எண்ணெய் அடிப்படையிலான குளிரூட்டும் பொருட்களை மட்டுமே பயன்படுத்தவும், சிப்ஸை நன்கு நிர்வகிக்கவும்.

மக்னீசியம் சிப்ஸ் மிகவும் எரிச்சலூட்டும் தன்மை கொண்டவை, வெடிப்பு எதிர்ப்பு வெற்றிடங்கள் மற்றும் சிறப்பு D வகுப்பு தீயணைப்பு கருவிகளுடன் கையாளப்பட வேண்டும்ஒருபோதும் மக்னீசியம் தீயை அணைக்க தண்ணீரைப் பயன்படுத்த வேண்டாம்.

- கூர்மையான கருவிகள் மற்றும் உகந்த ஊட்டங்கள், குறிப்பாக அலுமினியம் மற்றும் மக்னீசியம் உலோகக் கலவைகளுக்குப் பயன்படுத்தி, புர்ஸை கட்டுப்படுத்துதல்.

- கூடுதல் செயலாக்கத்தைத் தவிர்ப்பதற்காக தெளிவான கரைத்தல் தரங்களையும் விளிம்பு உடைப்பு விவரக்குறிப்புகளையும் அமைக்கவும்.

- அனைத்து CNC கார் பாகங்களுக்கான அச்சுகளில் ஆவண விளிம்பு முறிவுகள் (எ. கா., 0.20.5 மிமீ சம்ஃபர்).

இந்த பொருள்-குறிப்பான சுருக்குதல் வழிகாட்டிகளை அடிப்படையாகக் கொண்டு உங்கள் மதிப்பீடு மற்றும் செயல்முறை திட்டமிடலை உருவாக்குவதன் மூலம், CNC இயந்திரம் மூலம் உருவாக்கப்பட்ட மேனிஃபோல்டு பாகங்களின் உற்பத்தியிலிருந்து இறுதி ஆய்வு வரை அனைத்தையும் விரைவுபடுத்துவீர்கள். மேலும் ஒவ்வொரு ஆட்டோமொபைல் உற்பத்தியிலும் தொடர்ந்து ஒரே தரத்தை மேம்படுத்துவீர்கள். அடுத்ததாக, CAM நிரலாக்கம் மற்றும் தானியங்குத்தன்மை எவ்வாறு தரத்தையும் செயல்திறனையும் மேலும் உறுதிப்படுத்துகிறது என்பதைக் காண்போம்.

CAM நிரலாக்க தானியங்குத்தன்மை மற்றும் சோதனை சிறப்பான நடைமுறைகள்

சைக்கிள் நேரம் மற்றும் கருவி ஆயுளுக்கான CAM உத்தி

முன்னணி ஆட்டோமொபைல் கடைகள் எவ்வாறு ஒரு டிஜிட்டல் வடிவமைப்பை எடுத்து அதே ஒற்றுமை கொண்ட, அதிக துல்லியமான பாகங்களின் ஆயிரக்கணக்கானவற்றை உருவாக்குகின்றன, அதே நேரத்தில் ஒரு துடிப்பை இழக்காமல்? அதற்கான விடை ஒரு உறுதியான CAM (கம்ப்யூட்டர் உதவியுடன் உற்பத்தி) பணிவரிசையில் உள்ளது, இது நெருக்கமாக ஒருங்கிணைக்கப்பட்டுள்ளது cNC தானியங்குத்தன்மை . நீங்கள் கருவி பாதை உருவாக்கம் மற்றும் சரிபார்ப்பை தானியங்குபடுத்தும்போது, நீங்கள் நிரலாக்கத்தை துரிதப்படுத்துவது மட்டுமல்லாமல், ஒவ்வொரு ரன் க்கும் தரம் மற்றும் மீண்டும் மீண்டும் பூட்டவும்.

- CAD குணமடைதல்: நிரலாக்கத் தொடங்குவதற்கு முன்னர் வடிவமைப்பை சுத்தம் செய்து மாதிரி பிழைகளை சரிசெய்யவும்.

- பங்கு/பொருட்கள் வரையறைஃ மோதல்கள் மற்றும் அமைவு தவறுகளை தவிர்க்க மூலப்பொருள் அளவு மற்றும் பொருத்துதல்கள் இடங்களை துல்லியமாக வரையறுக்க.

- ரஃபிங் டூல்பாத்ஸ் (HPC/HSM): தொகுதி பொருளை செயல்பாடு முறையில் நீக்க உயர் செயல்திறன் அல்லது உயர் வேக இயந்திரம் பயன்பாடு முறைகளைப் பயன்படுத்தவும்

- மீதமுள்ள இயந்திரம்: முந்தைய செயல்பாடுகளிலிருந்து மீதமுள்ள பொருளை தானாக அடையாளம் காணவும் அகற்றவும்.

- நிறைவு செய்யும் நிலைகள்: இறுக்கமான மேற்பரப்பு மற்றும் பரிமாண சகிப்புத்தன்மையை அடைய உகந்த முடித்த உத்திகளைப் பயன்படுத்துங்கள்.

- டெபர்: பாதுகாப்பான கையாளுதல் மற்றும் சட்டசபை பொருத்தத்தை உறுதிப்படுத்த நிரல் deburring பாஸ்.

- துளைப்பு சுழற்சிகள்ஃ பைலட் முதல் டாப் வரை அனைத்து துளை உருவாக்கும் செயல்பாடுகளையும் ஒரே வரிசையில் ஒருங்கிணைக்கவும்.

- ஆய்வு சுழற்சிகள்: முக்கியமான அம்சங்களை உறுதிப்படுத்தவும் உண்மை உலக மாறுபாடுகளுக்கு ஏற்ப சரி செய்யவும் செயல்முறையின் போது ஆய்வைச் சேர்க்கவும்.

- தரவு உருவாக்கம்: சரக்கு, நிலையான உபகரணங்கள் மற்றும் கருவிகள் உட்பட 5-அச்சு வேலைகளுக்கு முழு மோதல் சரிபார்ப்பை இயக்கவும்.

- பின்-செயலாக்கம்: ஒவ்வொரு கட்டுப்பாட்டு வகைக்கும் பதிப்பு கட்டுப்படுத்தப்பட்ட பதிவுகளுடன் இயந்திர-குறிப்பிட்ட குறியீட்டை உருவாக்கவும்.

- அமைவு தாள்கள்ஃ ஆவணங்கள் அமைவு வழிமுறைகள், கருவி பட்டியல்கள், மற்றும் தொழிற்சாலை தரையில் ஆய்வு இடங்கள்.

இந்த பணிப்பாய்வுகளைப் பின்பற்றுவதன் மூலம், மனித பிழைகளை குறைக்கலாம், சிதைவுகளை குறைக்கலாம், மற்றும் சுழற்சி நேரங்களை கணிக்கக்கூடியதாக வைத்திருக்கலாம்.

விளக்குகளை அணைப்பதற்கான தானியங்கி கட்டிடத் தொகுதிகள்

குறைந்தபட்ச மேற்பார்வையுடன் ஒரே இரவில் உங்கள் கடையை நடத்துவதை கற்பனை செய்து பாருங்கள். வலது தானியங்கி சிஎன்சி இயந்திரங்கள் மற்றும் ரோபோட்டிக்ஸ் , நீங்கள் உற்பத்தியை அளவிடலாம், தொழிலாளர் செலவுகளைக் குறைக்கலாம், மற்றும் நிலைத்தன்மையை அதிகரிக்கலாம். உங்களுக்கு தேவையான முக்கிய கூறுகள் இங்கேஃ

- விரைவான பகுதி மாற்றத்திற்கான பேலட் பூல் அமைப்புகள்

- இயந்திரத்தில் உள்ள சோதனை உண்மையான நேர தர சோதனைகளுக்கு

- செயலிழப்பு மற்றும் திட்டமிடப்படாத வேலையில்லா நேரத்தை தடுக்க கருவிகளின் ஆயுட்காலத்தை கண்காணித்தல்

- இடைவிடாத வெட்டுக்கான தானியங்கி சிப் மேலாண்மை

- தொடர்ச்சியான பொருள் வழங்கல் பணிகளுக்கான சரக்கு உணவு வழங்குபவர்கள் அல்லது ரோபோ டெண்டர்கள்

உதாரணமாக, ஒரு ரோபோ கை ஒருங்கிணைக்கப்பட்டு, பாகங்களை ஏற்றவும் இறக்கவும் ஒரு ஆபரேட்டர் பல செல்களை மேற்பார்வையிட அனுமதிக்கிறது, இதன் மூலம் செயல்திறனை கணிசமாக அதிகரிக்கிறது. பொருந்தக்கூடிய கட்டுப்பாட்டு அமைப்புகள் கூட ஊட்டங்கள் மற்றும் வேகங்களை பறக்கையில் சரிசெய்யலாம், கருவி உடைப்பு அல்லது பொருள் மாறுபாட்டை ஈடுசெய்யலாம்.

சரிபார்ப்பு நிலையங்கள் மற்றும் கடை தள செயற்பாடுகள்

சிக்கலான ஒலி? இது அனைத்தும் ஆபத்து குறைப்பு பற்றி. சுழற்சியை துவங்குவதற்கு முன், ஒவ்வொரு கருவி பாதையையும் டிஜிட்டல் சிமுலேஷன் மூலம் சரிபார்க்கவும், குறிப்பாக 5 அச்சுகள் அல்லது பல அமைப்பு வேலைகளுக்கு. ஒவ்வொரு இயந்திரக் கட்டுப்பாட்டிற்கும் எப்போதும் தனித்தனி பிந்தைய செயலிகளைப் பயன்படுத்தவும், ஒரு கண்டிப்பான திருத்த வரலாற்றை வைத்திருக்கவும். இது ஒவ்வொரு மாற்றத்தையும் நீங்கள் கண்காணிக்க முடியும் மற்றும் துவக்கங்களுக்கு இடையில் நிரல்களை கலக்காமல் தவிர்க்க முடியும்.

(G-குறியீடு பாதுகாப்பு கோடு மாதிரி) G90 G54 G17 G21 G40 G80 T1 M6 (பொருள் மாற்றம் கருவிக்கு 1) G43 H1 Z100.0 (பொருள் நீளம் மாற்றம்) G65 P9810 Z15.0 (சோதனை சுழற்சி)இந்த பாதுகாப்பு வரி இயந்திரத்தை அமைக்கிறது, கருவியை மாற்றுகிறது, மற்றும் மோதல்கள் அல்லது சகிப்புத்தன்மையற்ற பாகங்கள் ஆபத்தை குறைக்கும் அமைப்பை சரிபார்க்க ஒரு ஆய்வு சுழற்சியை இயக்குகிறது. G-குறியீடு பாதுகாப்பு கோடுகள் பற்றி மேலும் காண்க நடைமுறை இயந்திர இயந்திரம் .

- மோதல் பாதைகளை எப்போதும் பங்கு மற்றும் பொருத்துதல் மாதிரிகள் இரண்டிலும் சரிபார்க்கவும்.

- குறிப்பாக 5 அச்சு இயந்திரங்களில், அதிகப்படியான பயணத்தைத் தவிர்க்க அச்சு வரம்புகளை சரிபார்க்கவும்.

- படிப்படியான அமைவு புகைப்படங்கள், முறுக்கு விவரக்குறிப்புகள் மற்றும் கருவி மாற்றங்களுக்குப் பிறகு மறு தகுதி சோதனை புள்ளிகளுடன் ஆவண ரன்புக்.

சோதனை அடிப்படையிலான செயல்முறை கட்டுப்பாடு குறிப்பாக பாதுகாப்பு-குறிப்பிட்ட வாகன அம்சங்களுக்கு முக்கியமானது. சுழற்சியின் நடுப்பகுதியில் முக்கிய பரிமாணங்களை அளவிடுவதன் மூலம், அது தரத்தில் உடைத்து தடுக்கப்படுவதற்கு முன்னர், கருவி உடைப்பு அல்லது டிரிஃப்ட் ஆகியவற்றை நீங்கள் கண்டறியலாம். [பொருள் பாதை] .

இவற்றை ஒருங்கிணைப்பதன் மூலம் cNC இயந்திரம் மற்றும் தானியங்கி உங்கள் கடை தற்கால தானியங்கி திட்டங்களின் தேவைகளை பூர்த்தி செய்ய நன்கு நிலைநிறுத்தப்பட்டுள்ளது - தொடர்ந்து உயர்தரமான பாகங்களை பெரிய அளவில் வழங்குதல். அடுத்து, தரக் கோட்பாடுகளும் தொடர்புடைய முறைமைகளும் ஒவ்வொரு வெற்றிகரமான CNC தொடக்கத்தையும் எவ்வாறு ஆதரிக்கின்றன என்பதை ஆராய்வோம்.

தரக் கோட்பாடுகள், GD&T, மற்றும் தொடர்புடைய முறைமைகள் தானியங்கி CNC இயந்திரங்களில்

செயல்பாடு தரைமட்டங்கள் மற்றும் பொருத்துதல் பொருத்தம் மற்றும் GD & T

நீங்கள் ஒரு நவீன வாகனத்திற்கான CNC பாகங்களின் ஆயிரக்கணக்கான கட்டமைக்கும் போது, ஒவ்வொரு பாகமும் பொருத்தமாகவும், துல்லியமாகவும் இருப்பதை எவ்வாறு உறுதிப்படுத்துவீர்கள்? இதற்கான விடை GD & T (ஜியோமெட்ரிக் டைமென்ஷனிங் மற்றும் டாலரன்சிங்) நல்ல பயன்பாடுகளில் உள்ளது. ஒரு காரின் கதவையோ அல்லது இயந்திர கூடையையோ கற்பனை செய்யுங்கள்: சிறிய பொருத்தக்குறை கூட சத்தம், சிப்பநீர் அல்லது விலை உயர்ந்த மறுபணி போன்றவற்றை உருவாக்கலாம். GD & T என்பது ஒவ்வொரு அம்சமும் மற்றவற்றுடன் எவ்வாறு தொடர்புடையதாக இருக்க வேண்டும் என்பதை வரையறுக்கும் பொதுவான மொழி ஆகும் - நிலை, சுருக்கம், சமதளம், ஓட்டம் மற்றும் பலவற்றை கட்டுப்படுத்துகிறது.

| சார்பு | வழக்கமான GD&T அழைப்பு | இது ஏன் முக்கியம் |

|---|---|---|

| வீடு (எ. கா., இயந்திர தொகுதி) | நிலை, மேற்பரப்பு விவரக்குறிப்பு | அனைத்து பொருத்துதல் துளைகள் சீரமைக்க உறுதி; ஒட்டுமொத்த வடிவம் கட்டுப்படுத்துகிறது |

| சுரங்கங்கள் | ஓட்டம், செறிவு | மென்மையான சுழற்சி மற்றும் முறையான ஏற்றல் உத்தரவாதம் |

| மூடி தட்டுகள் | சமதளத்தன்மை | கசிவுகளைத் தடுக்கிறது மற்றும் சரியான சீல் வைப்பதை உறுதி செய்கிறது |

சிக்கலான அல்லது பெரிய மேற்பரப்புகளுக்கு, நீங்கள் ஒரு நிலையான குறிப்பு கட்டத்தை நிறுவ தேர்ந்தெடுக்கப்பட்ட குறிப்பிட்ட பகுதிகளை அடிக்கடி பயன்படுத்தலாம். 3-2-1 முறை பொதுவானதுஃ முதன்மை விமானத்தில் மூன்று இலக்குகள், இரண்டாம் நிலை விமானத்தில் இரண்டு, மூன்றாம் நிலை விமானத்தில் ஒன்று. இந்த அணுகுமுறை ஆறு சுதந்திர நிலைகளையும் பூட்டுகிறது, மீண்டும் மீண்டும் அமைப்புகள் மற்றும் துல்லியமான அளவீடுகளை உறுதி செய்கிறது [FARO] .

உங்கள் இயந்திரம் தரவுகளை செயல்பாட்டு அசெம்பிளி தரவுகளுடன் எப்போதும் சீரமைக்கவும். இது ஆட்டோமொபைல் சிஎன்சி எந்திரங்களில் சகிப்புத்தன்மை அடுக்கு மற்றும் பின்புற பொருத்துதல் சிக்கல்களின் அபாயத்தைக் குறைப்பதன் மூலம் ஆய்வு மற்றும் அசெம்பிளிகளை எளிதாக்குகிறது.

FAI இலிருந்து PPAP க்கு கண்காணிப்புடன்

ஒவ்வொரு சிஎன்சி மெஷிங் கூறுகளும் ஸ்பெக்ஷனை பூர்த்தி செய்கின்றன என்பதை எப்படி நிரூபிப்பது, பல வருடங்கள் கழித்து கூட? இது முதல் கட்டுரை ஆய்வு (FAI) டன் தொடங்குகிறது, பாகங்கள் வரைபடங்கள் மற்றும் GD & T உடன் பொருந்துகின்றன என்பதற்கான உங்கள் ஆரம்ப சான்று. அடுத்து, உற்பத்தி பகுதி ஒப்புதல் செயல்முறை (PPAP) FAI, கட்டுப்பாட்டுத் திட்டங்கள், அளவீட்டு அமைப்பு பகுப்பாய்வு (MSA) மற்றும் வாடிக்கையாளர்

ஆனால் 2025ல், கண்காணிப்பு என்பது உண்மையான சிஎன்சி நன்மை. ஒவ்வொரு லாட்டிலும் தொடர்ச்சியாக, பொருள் சான்றிதழ்கள், ஆய்வு தரவு, மற்றும் NC நிரல் திருத்தங்கள் ஆகியவற்றை இணைக்கும் டிஜிட்டல் பதிவுகள் உள்ளன. பார்க் குறியீடுகள் அல்லது தட்டுகளில் நேரடி பகுதி குறித்தல் (DPM) ஒவ்வொரு பகுதியையும் அதன் தோற்றத்திற்குத் திருப்பிக் காணக்கூடியதாக ஆக்குகிறது, திரும்பப் பெறுதல், தணிக்கை மற்றும் தொடர்ச்சியான மேம்பாட்டை ஆதரிக்கிறது.

- செயல்முறை கட்டுப்பாட்டு திட்டம்ஃ ஒவ்வொரு செயல்பாட்டிற்கும் நடவடிக்கைகள், கட்டுப்பாடுகள் மற்றும் எதிர்வினைத் திட்டங்கள்

- FAI சோதனை பட்டியல்ஃ அனைத்து முக்கியமான மற்றும் முக்கிய பரிமாணங்கள், பொருள் சான்றுகள், மேற்பரப்பு பூச்சு, சிறப்பு பண்புகள்

- திறன் ஆய்வுஃ மாதிரி அளவு (எ. கா. 30 பிசிக்கள்), அளவீடுகளுக்கு Cg/Cgk, நிலையான செயல்முறைகளுக்கு Cp/Cpk > 1.33

இந்த ஆவணங்களை தயார் நிலையில் வைத்திருப்பது வாடிக்கையாளர் தேவைகளை பூர்த்தி செய்வது மட்டுமல்லாமல், சிக்கல்கள் ஏற்பட்டால் விரைவான மூல காரண திறனை உங்களுக்கு வழங்குகிறது.

சிதைவைத் தடுக்கும் செயல்பாட்டு கட்டுப்பாட்டுத் திட்டங்கள்

உங்கள் ஆட்டோமொபைல் சிஎன்சி இயந்திரங்கள் சீராக இயங்குவதை என்ன செய்கிறது, மாறி மாறி? இரகசியம் என்பது ஒழுக்கமான செயல்முறை கட்டுப்பாடு. அடுக்கு செயல்முறை ஆடிட்டுகள் (LPA) ஒவ்வொரு ஆபரேட்டரும் திட்டத்தை பின்பற்றுவதை உறுதி செய்கிறது, அதே நேரத்தில் ஷிப்ட் தொடக்கத்தில் அல்லது கருவி மாற்றங்களுக்குப் பிறகு ஆய்வு சரிபார்ப்பு சோதனைகள் சிதைவுக்கு முன்னர் டிரிஃப்டைப் பிடிக்கின்றன. புள்ளியியல் செயல்முறை கட்டுப்பாடு (SPC) வரைபடங்கள் போக்குகளை ஆரம்பத்தில் கண்டறிகின்றன, எனவே குறைபாடுகள் பெருகுவதற்கு முன்பு நீங்கள் சரிசெய்யலாம்.

- தொடர்ச்சியான பார்ட்டி கண்காணிப்பிற்கான பார்கோடு டிரேக்கள் அல்லது டிபிஎம்

- ஒவ்வொரு பார்டியுடனும் இணைக்கப்பட்ட பொருள் சான்றிதழ்கள்

- ஒவ்வொரு இயக்கத்திற்கும் NC நிரல் திருத்த வரலாறு

- முக்கியமான அம்சங்களுக்கான SPC வரைபடங்கள் மற்றும் ஆய்வு பதிவுகள்

IATF 16949 மற்றும் ISO 9001 ஆகியவை சிறப்பு பண்புகளின் ஆவணப்படுத்தப்பட்ட கட்டுப்பாட்டையும் தெளிவான எதிர்வினைத் திட்டங்களையும் தேவைப்படுத்துகின்றன. தரத்தை மட்டும் பூர்த்தி செய்யாதீர்கள், அதைப் பயன்படுத்தி உண்மையான செயல்முறை ஒழுக்கத்தை ஊக்குவிக்கவும், செலவு மிகுந்த தப்பித்தல் ஏற்படாமல் தடுக்கவும்.

இந்த தரத் தரங்களையும், கண்காணிப்பு நடைமுறைகளையும் நீங்கள் ஏற்றுக்கொள்வதன் மூலம், குறைவான ஆச்சரியங்கள், மென்மையான தணிக்கைகள் மற்றும் உயர் மதிப்புள்ள சிஎன்சி எந்திர பாகங்களை வழங்குவதில் வலுவான நற்பெயரை நீங்கள் கவனிப்பீர்கள். அடுத்து, தரத்தை அடிப்படையாகக் கொண்ட CNC உற்பத்தியின் முழு தாக்கத்தையும் அளவிட ROI மற்றும் உண்மையான உலக தரவு எவ்வாறு உதவும் என்பதைப் பார்ப்போம்.

ROI மாதிரிகள் மற்றும் தரவு சார்ந்த வழக்கு ஆய்வுகள்

பேலட் பூல்ஸ் மற்றும் ரோபோ டெண்டரிங் ஆகியவற்றிற்கான ROI மாதிரிகள்

உங்கள் வாகனத் திட்டத்திற்கான CNC ஆட்டோமேஷன் தொழில்நுட்பங்களை நீங்கள் கருத்தில் கொள்ளும்போது, பெரிய கேள்வி என்னவென்றால்ஃ முதலீடு பயனளிக்குமா? ஒரு நடைமுறை உதாரணத்துடன் எண்களை உடைப்போம். நீங்கள் ஒரு CNC செல் மேம்படுத்தலை மதிப்பீடு செய்கிறீர்கள் என்று கற்பனை செய்து பாருங்கள் ஒரு தட்டுக் குளம் மற்றும் ஒரு தானியங்கி CNC எந்திர வரிசையில் ரோபோவை கவனித்துக்கொள்வது. கணிதம் இவ்வாறு அமைகிறது:

| சூழல் | கையேடு செல் | தானியங்கி செல் |

|---|---|---|

| முதலீட்டுச் செலவு | $300,000 | $600,000 |

| OEE (மொத்த உபகரண செயல்திறன்) | 55% | 75% |

| தொழிலாளர் (FTE/இயந்திரம்) | 1.5 | 0.5 |

| வருடாந்திர தொழிலாளர் செலவு | $90,000 | $30,000 |

| ஆண்டு அறுவடை விகிதம் | 3.5% | 1.2% |

| முதலீட்டு திரும்ப பெறும் காலம் | – | ~30 மாதங்கள் |

| உணர்திறன்: 2 மற்றும் 3 வேலைநேரங்கள் | ஆபரேட்டர் கிடைக்கும் தன்மையால் OEE வரம்பு | 24/7 விளக்குகள்-அணைக்கும் போது OEE அதிகரிப்பு |

மேலே காணும் போல, ஆட்டோமேஷன் தீர்வு ஆட்டோமொபைல் துறை பயன்பாடுகளுக்கு உதவி ஊதியச் செலவுகளை மூன்றில் இரண்டு பங்காக குறைக்கலாம், OEE ஐ 20 புள்ளிகள் வரை அதிகரிக்கலாம் மற்றும் குறைக்கப்பட்ட துணை உற்பத்தியை வழங்கலாம். மீளமைப்பு காலம் பொதுவாக மூன்று ஆண்டுகளுக்குள் இருக்கும், மேலும் நீங்கள் மேலும் வேலைநேரங்களையோ அல்லது அதிக கலவை வேலைகளையோ இயக்கினால் இது மிக விரைவாகவும் இருக்கலாம் [CTE இதழ்] .

சுழற்சி நேரம் மற்றும் உதிரிபாகங்களை குறைத்தல் தொடர்பான வழக்கு ஆய்வுகள்

- வால்வு உடல் பாலேட் பூல் கொண்ட HMC: சுழற்சி நேரம் 18.5 நிமிடங்களிலிருந்து 12.7 நிமிடங்களாக குறைந்தது. பகுதிகளை சுமை மற்றும் சோதனை செய்வதை தானியங்குபடுத்திய பின்னர், இடிப்பு விகிதம் 3.8% இலிருந்து 0.9% ஆக குறைந்தது.

- பிளாஸ்டிக் 5 அச்சுகள் கொண்ட செயல்பாட்டு சோதனைஃ மறு வேலை 60% குறைக்கப்பட்டது ஏனெனில் உண்மையான நேர அளவீடுகள் கருவி உடைப்பு மற்றும் அலசல் ஆகியவற்றை கண்டறிந்தன.

- ஆஷ்ட் மில்-டிர்ன் உடன் பார் ஃபீடர்ஃ பட்டை ஊட்டல் மற்றும் விளக்குகள் அணைப்பு செயல்பாட்டைச் சேர்த்த பிறகு செயல்திறன் 32% உயர்ந்தது, திறமையான ஆபரேட்டர்கள் அதிக மதிப்புள்ள பணிகளுக்கு விடுவிக்கப்பட்டனர்.

"ஆட்டோ சிஎன்சி இயந்திரங்களில் ஆட்டோமேஷன் செய்வதன் உண்மையான ROI என்பது தொழிலாளர் சேமிப்பில் மட்டுமல்ல, இது தடமறி நேரத்துடன் இணங்குவதற்கும், உபகரண செலவுகளை குறுகியதாக மாற்றக்கூடிய தாமத அபராதங்களைத் தவிர்ப்பதற்கும் ஆகும்".

1 முதல் 10,000 தொகுதிகளுக்கு ஒரு பாகத்திற்கு செலவு

நீங்கள் அளவிடுகையில், ஒரு பாகத்திற்கு செலவுகளை ஆட்டோமேஷன் எவ்வாறு பாதிக்கிறது? ஒரு வழக்கமான வாகனக் கோப்புறைக்கான ஒரு காட்சி இங்கேஃ

| அமைப்பு அளவு | திட்டமிடல் கழிவு | பொருத்துதல்கள் செலவு/பகுதி | கருவி உடை/பகுதி | இயந்திர நேரம்/பகுதி | மொத்த செலவு/பகுதி |

|---|---|---|---|---|---|

| 100 | $5.00 | $8.00 | $3.00 | $18.00 | $34.00 |

| 1,000 | $0.50 | $0.80 | $1.00 | $8.00 | $10.30 |

| 10,000 | $0.05 | $0.08 | $0.60 | $6.00 | $6.73 |

தொகுதி அதிகரிக்கும் போது, நிகழ்ச்சி நிரல் மற்றும் பொருத்துதல்களின் செலவுகளின் தாக்கம் வியத்தகு முறையில் குறைகிறது என்பதை நீங்கள் கவனிப்பீர்கள். கருவி உடைப்பு மற்றும் இயந்திர நேரம் ஆகியவை அளவிலான முக்கிய இயக்கிகளாக மாறுகின்றன. பாதுகாப்பான கருவி ஆயுள் மாதிரிகள் மற்றும் யதார்த்தமான OEE (கருத்துப்பூர்வமாக அதிகபட்சமாக அல்ல) உங்கள் திருப்பிச் செலுத்தும் தன்மை மற்றும் ஒரு பாகத்திற்கு செலவு மதிப்பீடுகள் துல்லியமானவை என்பதை உறுதிப்படுத்துகின்றன.

நிஜ உலக தரவு மற்றும் நிரூபிக்கப்பட்ட தானியங்கி தொழில்நுட்பங்களுடன் உங்கள் வணிக வழக்கை அடிப்படையாகக் கொண்டால், நீங்கள் புத்திசாலித்தனமான முதலீட்டுத் தேர்வுகளைச் செய்து நிலையான முடிவுகளை வழங்க முடியும். அடுத்து, இந்த ஆதாயங்களை மீண்டும் மீண்டும் உற்பத்தி நன்மைகளாக மாற்றுவதற்காக சரியான சப்ளையர் மற்றும் கருவி கூட்டாளர்களைத் தேர்ந்தெடுப்பதன் மூலம் நாங்கள் உங்களுக்கு வழிகாட்டுவோம்.

உற்பத்தியை வெற்றிகரமாக நடத்துவதற்கான சப்ளையர் மற்றும் கருவிகளை எவ்வாறு தேர்வு செய்வது

ஆட்டோமொபைல் சிஎன்சி கூட்டாளரில் என்ன மதிப்பீடு செய்ய வேண்டும்

நீங்கள் ஆட்டோமொபைல் துறையில் CNC உற்பத்தியைத் தொடங்கத் தயாரானால், உங்கள் திட்டத்தை உருவாக்க அல்லது அழிக்க உங்கள் கூட்டாளரை நீங்கள் தேர்ந்தெடுப்பது முக்கியம். சிக்கலான ஒலி? அது இருக்க வேண்டியதில்லை. நீங்கள் ஒப்பிட்டு இயந்திர சப்ளையர்கள் ஒரு முன்கூட்டியே ஒரு துடிப்பை இழக்காமல் உங்களை முன்மாதிரி முதல் வெகுஜன உற்பத்தி வரை கொண்டு செல்ல முடிந்தால் என்ன? உங்கள் தேடலை எவ்வாறு கவனம் செலுத்துவது மற்றும் செலவு மிகுந்த தவறுகளை தவிர்ப்பது என்பது இங்கே.

- சீரான ஏவுதல்கள் மற்றும் வாடிக்கையாளர் ஒப்புதல்களுக்கான APQP/PPAP முதிர்வு

- பொருத்துதல்கள் வடிவமைப்பு மற்றும் செயல்முறை பொறியியல் ஆழம்

- சிக்கலான வடிவியல் வடிவங்களுக்கான 5 அச்சு மற்றும் மில்-டிர்ன் எந்திரப்படுத்தல் கவரேஜ்

- தர உறுதிப்படுத்தலுக்கான ஒருங்கிணைந்த செயல்முறை சோதனை மற்றும் SPC

- வலுவான கண்காணிப்பு அமைப்புகள்சரக்கு, பொருள் மற்றும் NC திட்ட கண்காணிப்பு

கையெழுத்திடுவதற்கு முன், சமீபத்திய வழக்கு ஆய்வுகள் மற்றும் ஒத்த விஷயங்களில் குறிப்புகளை கேட்கவும் சின்ஸ் தாங்கிய பகுதிகள் திட்டங்கள். திறன்களை மட்டும் தேடாதீர்கள், உங்கள் நீண்டகால வெற்றியில் முதலீடு செய்த, ஆட்டோமொபைல் இயந்திரங்கள் மற்றும் தர மேலாண்மை ஆகியவற்றில் நிரூபிக்கப்பட்ட சாதனைகளைக் கொண்ட ஒரு கூட்டாளரைத் தேடுங்கள்.

திறன்கள், சான்றிதழ்கள் மற்றும் துவக்க தயார்நிலை

சான்றிதழ்கள் முக்கியம், குறிப்பாக IATF 16949 ஆட்டோமொபைல். இந்த தரங்களை பூர்த்தி செய்வது மட்டுமல்லாமல், டிஜிட்டல் செயல்திறன், பொறியியல் வலிமை மற்றும் அளவிடக்கூடிய உற்பத்தி மாதிரியை நிரூபிக்கும் ஒரு சப்ளையரை நீங்கள் விரும்புவீர்கள். சில முக்கிய போட்டியாளர்களை ஒப்பிடுவோம்ஃ

| SUPPLIER | திறன்கள் | சான்றிதழ்கள் | வாகனப் பாதை பதிவு | நேர தாக்கத்தின் | பார்வைகள் | தவறுகள் |

|---|---|---|---|---|---|---|

|

ஷாய் மெட்டல் பார்ட்ஸ் சப்ளையர் சீனாவில் ஒருங்கிணைந்த துல்லியமான ஆட்டோ உலோக பாகங்கள் தீர்வுகளை வழங்குபவர். |

பல அச்சு CNC, வார்ப்பு, முத்திரை, உலை, மேற்பரப்பு சிகிச்சைகள், விரைவான முன்மாதிரி தயாரிப்பு 5,000+ அலகுகள் வரை | IATF 16949, ISO 9001 | ஆடி, பிஎம்டபிள்யூ, டொயோட்டா, டெஸ்லா மற்றும் பலவற்றிற்கான வெளியீடுகள் | 1 நாளில் முன்மாதிரி தயாரிப்பு, 1-3 வாரங்களில் உற்பத்தி | ஒரே கடை, மேம்பட்ட ஆட்டோமேஷன், வலுவான கியூசி, நெகிழ்வான அளவுகள் | சீனாவில் அமைந்துள்ளது (உலகளாவிய தளவாடத்திற்கான கருத்தில்) |

| eMachineShop | சிஎன்சி, ஷீட் மெட்டல், இன்ஜெக்ஷன் மோல்டிங், 3D பிரிண்டிங் | ISO 9001 | பல்வேறு தொழில்கள், ஆட்டோமோட்டிவ் குறைவான கவனம் | 5-20 நாட்கள் | குறைந்தபட்ச ஆர்டர் இல்லை, பயனர்-நட்பு CAD கருவிகள் | பெரிய ஆர்டர்களுக்கு தலைமை நேரம் அதிகம், ஆட்டோ-குறிப்பான நிபுணத்துவம் குறைவு |

| க்ஸோமெட்ரி | நெட்வொர்க் செய்யப்பட்ட சிஎன்சி, விரைவான முன்மாதிரி தயாரிப்பு, அதிக அளவு | ISO 9001, AS9100 | சில ஆட்டோ, வலுவான விமான / மருத்துவ | 3-4 நாட்கள் (சிறிய பாகங்கள்) | பெரிய வலையமைப்பு, விரைவான மேற்கோள்கள் | வடிவியல் சிக்கலானது செலவை அதிகரிக்கிறது, குறைந்த நேரடி வாகன வெளியீட்டு ஆதரவு |

| சிஎன்சி இயந்திர கருவிகள் விநியோகஸ்தர் | இயந்திர விற்பனை, ஆட்டோமேஷன் தீர்வுகள் | உற்பத்தியாளர்களுக்கேற்ப மாறுபடும் | இயந்திரங்கள் வழங்குபவர்கள், பாகங்கள் தயாரிப்பாளர் அல்ல | N/A | பல்வேறு இயந்திரங்கள், ஆட்டோமேஷன் நிபுணத்துவம் | சிஎன்சி இயந்திரம் மூலம் தயாரிக்கப்படும் வாகனப் பாகங்கள் நேரடி ஆதாரமாக இல்லை |

உண்மையான உலகில் உள்ள பாகங்கள் வகைகள் மற்றும் உற்பத்தி திறன்களை பார்க்க விரும்புகிறீர்களா? வருகை cnc இயந்திரம் செய்யப்பட்ட வாகன பாகங்கள் ஷாயோயின் சலுகையை விரிவாக ஆய்வு செய்து, செங்குத்தாக ஒருங்கிணைந்த சப்ளையர் ஆட்டோமொபைல் உற்பத்தியின் ஒவ்வொரு கட்டத்தையும் எவ்வாறு ஆதரிக்கிறார் என்பதைப் புரிந்துகொள்வது.

வழங்குநர்களின் குறுகிய பட்டியல் மற்றும் அவை எவ்வாறு வேறுபடுகின்றன

எனவே, எப்படி நீங்கள் முடிவு? இங்கே ஒரு விரைவான விரிவாக்கம்ஃ

- ஷாய் மெட்டல் பார்ட்ஸ் சப்ளையர்: முழு வாழ்க்கைச் சுழற்சி, உயர்தர, மற்றும் அளவிடக்கூடிய வாகனத் திட்டங்களுக்கு சிறந்தது. IATF 16949 சான்றிதழ், டிஜிட்டல் MES மற்றும் உலகளாவிய OEM களுடன் வெளியீட்டு பதிவு ஆகியவை ஆபத்து உணர்திறன் மற்றும் அதிக அளவு வேலைக்கு அவற்றை வேறுபடுத்துகின்றன.

- eMachineShop: முன்மாதிரி தயாரிப்பு அல்லது குறைந்த அளவிலான தனிப்பயன் வேலைக்கு ஏற்றது, ஆனால் ஆட்டோமொபைல் துவக்க கடுமைக்கு குறைவாக கவனம் செலுத்துகிறது.

- எக்ஸோமெட்ரிஃ விரைவான மேற்கோள்கள் மற்றும் விநியோகிக்கப்பட்ட ஆதாரங்களுக்கு சிறந்தது, ஆனால் அதே ஆட்டோமொபைல் பொறியியல் அல்லது திட்ட நிர்வாகத்தை வழங்காது.

- சிஎன்சி இயந்திர கருவிகள் விநியோகஸ்தர்ஃ நீங்கள் இயந்திரங்களை வாங்குகிறீர்கள் என்றால் சரி, பாகங்கள் அல்ல.

பார்வைகள்

- ஷாயோய்: இறுதி முதல் இறுதி சேவை, சான்றளிக்கப்பட்ட தரம், உலகளாவிய பிராண்டுகளுடன் நிரூபிக்கப்பட்டுள்ளது, விரைவான திருப்பங்கள்

- eMachineShop: குறைந்தபட்ச அளவு இல்லை, பரந்த செயல்முறை வரம்பு

- Xometry: விரைவான மேற்கோள்கள், விரிவான சப்ளையர் நெட்வொர்க்

- விநியோகஸ்தர்: இயந்திர வகைகள், ஆட்டோமேஷன் தீர்வுகள்

தவறுகள்

- ஷாயோய்: வெளிநாட்டு கப்பல் போக்குவரத்து/இலாபப் போக்குவரத்து திட்டமிடல் தேவைப்படலாம்

- eMachineShop: குறைந்த வாகனத் தொழில் சிறப்பு, அதிக அளவு

- Xometry: மாறி சப்ளையர் அனுபவம், சிக்கலான மீது பிரீமியம்

- விநியோகஸ்தர்: சிஎன்சி ஆட்டோ பாகங்களுக்கு ஒரு நிறுத்த மூலமல்ல

சரியான CNC சப்ளையர் ஒரு விற்பனையாளரை விட அதிகம்அவர்கள் உங்கள் துவக்க வெற்றியில் ஒரு கூட்டாளியாக உள்ளனர். வாகனத் துறையில் நிரூபிக்கப்பட்ட அனுபவம், சான்றளிக்கப்பட்ட தர அமைப்புகள் மற்றும் சிறந்த முடிவுகளை பெற வெளிப்படையான தகவல்தொடர்பு ஆகியவற்றுக்கு முன்னுரிமை அளிக்க வேண்டும்.

இந்த அளவுகோல்கள் மற்றும் ஒப்பீடுகள் மூலம், நீங்கள் இன்றைய தேவைகளை பூர்த்தி செய்வதோடு மட்டுமல்லாமல், எதிர்காலத்தில் உங்களுடன் அளவிடக்கூடிய ஒரு சப்ளையரைத் தேர்ந்தெடுக்க தயாராக இருப்பீர்கள். அடுத்து, படிப்படியான செயல்திட்டம் மற்றும் உங்கள் 2025 திட்டங்களுக்கான பரிந்துரைக்கப்பட்ட கூட்டாளருடன் முடிப்போம்.

செயல்திட்டம் மற்றும் 2025 திட்டங்களுக்கான பரிந்துரைக்கப்பட்ட கூட்டாளர்

உங்கள் சிஎன்சி துவக்கத்தில் ஆபத்துக்களை குறைக்க முப்பது நாள் திட்டம்

ஒரு புதிய CNC கார் பாகங்கள் திட்டத்தை துவங்குவது மிகப்பெரியதாக உணரலாம், ஆனால் ஒரு தெளிவான சாலை வரைபடம் எல்லா வித்தியாசத்தையும் உருவாக்குகிறது. நீங்கள் கடுமையான காலக்கெடு, இறுக்கமான பட்ஜெட்டுகள் மற்றும் தவறுகளுக்கு இடமில்லை என கற்பனை செய்து பாருங்கள், உங்கள் ஆதரவில் வாய்ப்புகளை எவ்வாறு அடுக்கி வைப்பது? இந்த நடைமுறை, வாரந்தோறும் திட்டத்துடன் தொடங்குங்கள், இது CNC தொழில்நுட்பத்தைப் பயன்படுத்தி வாகனப் பாகங்கள் உற்பத்தியில் செயல்திறன் மேம்பாடுகளுக்காக வடிவமைக்கப்பட்டுள்ளதுஃ

- வாரம் 1 DFM மற்றும் Datum ஒழுங்குபடுத்தல்ஃ உங்கள் CAD ஐ சுத்தம் செய்யுங்கள், தரவுகளை இறுதி செய்யுங்கள், மற்றும் உங்கள் சப்ளையருடன் வலுவான வடிவமைப்பு உற்பத்திக்கு (DFM) மதிப்பாய்விற்கு ஒத்துழைக்கவும். இங்கு ஆரம்பத்தில் ஒழுங்குபடுத்துவது பின்னர் செலவு மிகுந்த திருத்தங்களைத் தடுக்கிறது.

- வாரம் 2 CAM மூலோபாயம் மற்றும் பொருத்துதல் கருத்துஃ CAM கருவி பாதைகளை உருவாக்குதல், சுழற்சி நேரம் மற்றும் கருவி வாழ்க்கைக்கு உகந்ததாக மாற்றுதல், மற்றும் நிலைத்தன்மை மற்றும் மீண்டும் மீண்டும் வடிவமைத்தல். அனைத்து முக்கியமான அம்சங்கள் செயல்முறை சோதனை உள்ள மூடப்பட்ட உறுதிப்படுத்தவும்.

- வாரம் 3 சோதனை ஓட்டம் மற்றும் முதல் கட்டுரை ஆய்வு (FAI): குறுகிய கால சோதனை ஓட்டத்தை நடத்துங்கள், FAI தரவை சேகரித்து, அனைத்து முக்கிய பரிமாணங்களையும், மேற்பரப்பு முடிப்புகளையும், மற்றும் சட்டசபை பொருத்தத்தையும் சரிபார்க்கவும். இந்தத் தரவைப் பயன்படுத்தி உங்கள் செயல்முறையைச் சிறப்பாகச் சரிசெய்து, துவங்குவதற்கு முன்னர் சிக்கல்களைக் கண்டறியவும்.

- வாரம் 4 திறன் ஆய்வு மற்றும் PPAP தொகுப்பு வரைதல்ஃ ஒரு திறன் ஆய்வு (Cp/Cpk) நடத்தி, முடிவுகளை ஆவணப்படுத்தி, உங்கள் உற்பத்தி பகுதி ஒப்புதல் செயல்முறை (PPAP) தொகுப்பை இணைக்கவும். இது நீங்கள் வாடிக்கையாளர் மற்றும் ஒழுங்குமுறைத் தேவைகளை பூர்த்தி செய்வதை உறுதி செய்கிறது.

உங்கள் CNC சப்ளையரிடமிருந்து என்ன கோர வேண்டும்

வெற்றியை அதிகரிக்கவும், ஆச்சரியங்களை குறைக்கவும், உங்கள் சப்ளையரிடமிருந்து இந்த டெலிவரிகளை SOP (உற்பத்தி தொடங்குதல்) க்கு முன் கோருங்கள்ஃ

- மாதிரி கட்டுப்பாட்டு திட்டம் (செயல்முறை படிகள் மற்றும் எதிர்வினைத் திட்டங்கள்)

- கருவி உடைப்பு மற்றும் விவரக்குறிப்புகளுக்கு வெளியே உள்ள நிலைமைகளுக்கு எதிர்வினைத் திட்டம்

- தெளிவான புகைப்படங்கள் மற்றும் முறுக்கு விவரக்குறிப்புகள் கொண்ட அமைவு தாள்கள்

- முக்கியமான அம்சங்களுக்கான SPC (புள்ளிவிவர செயல்முறை கட்டுப்பாடு) வரைபடங்களின் மாதிரி

- சோதனை முறைகள் மற்றும் செயல்பாட்டு அளவீட்டு ஆவணங்கள்

இந்த ஆவணங்கள் நீங்கள் பல இடங்களில் அல்லது குழுக்களில் திட்டங்களை நிர்வகிக்கிறீர்கள் என்றாலும் கூட, கண்காணிப்புத்திறனை பராமரிக்கவும், தரத்தை உறுதிப்படுத்தவும், உங்கள் துவக்கத்தை பாதையில் வைத்திருக்கவும் உதவுகின்றன.

ஷாயோய் உலோக பாகங்கள் சப்ளையர் ஏன் சரியான தேர்வாகும்

நீங்கள் ஒரு CNC கூட்டாளரைத் தேர்ந்தெடுக்கும்போது, நீங்கள் ஒரு பகுதி விற்பனையாளரை விட அதிகமாக விரும்புகிறீர்கள், உங்களுக்கு ஒரு நாள் முதல் செயல்திறன், தரம் மற்றும் மன அமைதியை வழங்கும் ஒரு குழு தேவை. ஷாய் மெட்டல் பார்ட்ஸ் சப்ளையர் சீனாவில் ஒருங்கிணைந்த துல்லியமான ஆட்டோ உலோக பாகங்கள் தீர்வுகளை வழங்குபவராக உள்ளது, ஆடி, பிஎம்டபிள்யூ மற்றும் டெஸ்லா போன்ற உலகளாவிய பிராண்டுகளால் நம்பப்படுகிறது. அவர்களின் IATF 16949 சான்றிதழ், வலுவான தர அமைப்புகள் மற்றும் டிஜிட்டல் MES தளமானது ஒவ்வொரு திட்டமும் சீராக இயங்குவதை உறுதி செய்கிறது, உங்களுக்கு ஒரு முன்மாதிரி அல்லது முழு அளவிலான உற்பத்தி ரன் தேவைப்பட்டாலும்.

விரைவான டிஎஃப்எம் ஆதரவு மற்றும் மேம்பட்ட பல அச்சு எந்திரம் முதல் கடுமையான ஆவணங்கள் மற்றும் செயல்முறை கட்டுப்பாட்டு வரை ஷாயோயின் முனை முதல் முனை வரை வழங்கும் சலுகைகள், சிஎன்சி தொழில்நுட்பத்தைப் பயன்படுத்தி ஆட்டோமொபைல் பாகங்கள் உற்பத்தியில் செயல்திறன் மேம்பாடுகளை அடைய அவர்களின் நெகிழ்வான மாதிரி, ஒரு முறை சரிபார்ப்பிலிருந்து 5,000+ அலகுகளுக்கு சப்ளையர்களை மாற்றவோ அல்லது செயல்முறைகளை மறுதிறமைப்படுத்தவோ இல்லாமல் நீங்கள் அளவிட முடியும். நீங்கள் இன்னும் சிந்திக்கிறீர்கள் என்றால், ஒரு CNC இயந்திரம் ஆட்டோமொபைல் துறையில் என்ன செய்கிறது? பதில்ஃ இயந்திரக் கோட்டுகள் மற்றும் வீடுகள் முதல் சிக்கலான உட்புறப் பலகைகள் வரை அனைத்தும் வேகத்தோடும் துல்லியத்தோடும் வழங்கப்படுகின்றன.

உங்கள் அடுத்த ஏவுகணை ஆபத்து குறைக்க தயாரா? உங்கள் திட்டத்தை விரைவுபடுத்தவும் உங்கள் விநியோகச் சங்கிலியை எளிமைப்படுத்தவும் அவர்களின் ஒருங்கிணைந்த அணுகுமுறை எவ்வாறு உதவும் என்பதைப் பார்க்க ஷாயோயிலிருந்து ஒரு கடமை இல்லாத DFM மதிப்பாய்வையும் மேற்கோளையும் கோருங்கள். பகுதி வகைகள், திறன்கள் மற்றும் துவக்க ஆதரவு பற்றிய விவரங்களுக்கு, பார்க்கவும் cnc இயந்திரம் செய்யப்பட்ட வாகன பாகங்கள் .

தொகுப்பு நேரம், உற்பத்தி திறன் மற்றும் செலவு ஆகியவற்றை ஒத்திசைப்பது வெற்றிகரமான CNC ஆட்டோ திட்டத்தின் அடிப்படையாகும். சரியான கூட்டாளியுடன், ஒழுக்கமான ஏவுதல் திட்டத்துடன், நீங்கள் SOP காலக்கெடுவை பூர்த்தி செய்வீர்கள், ஆபத்தை குறைப்பீர்கள், மற்றும் ஒவ்வொரு முறையும் தரமான பாகங்களை வழங்க முடியும்.

இந்த நடவடிக்கை திட்டத்துடனும் சரியான பங்காளியுடனும், உங்கள் ஆட்டோமோட்டிவ் பார்வைக்கான CNC உற்பத்தியை லாபகரமான உண்மையாக மாற்ற நீங்கள் தயாராக இருக்கிறீர்கள் - திட்டமிட்டபடி மற்றும் தர விவரக்குறிப்புகளுக்கு ஏற்ப

ஆட்டோமோட்டிவ் உற்பத்திக்கான CNC பற்றிய அடிக்கடி கேட்கப்படும் கேள்விகள்

1. தொழில்துறையில் CNC என்றால் என்ன மற்றும் அது ஆட்டோமோட்டிவ் உற்பத்திக்கு ஏன் முக்கியம்?

CNC என்பதன் விரிவாக்கம் கணினி எண்ணியல் கட்டுப்பாடு (Computer Numerical Control) ஆகும். வாகனத் தொழிலில், CNC தொழில்நுட்பம் இலக்கமியல் (டிஜிட்டல்) வடிவமைப்புகளைத் துல்லியமான, மீண்டும் மீண்டும் உற்பத்தி செய்யக்கூடிய உலோக அல்லது பிளாஸ்டிக் பாகங்களாக மாற்றுகிறது. இது உயர் தொகுதிகளில் தரத்தை ஒரே மாதிரியாக பாதுகாப்பதற்கும், குறைந்த அளவு விலகலுடன் பாகங்களை உற்பத்தி செய்வதற்கும், தொழில்துறை தரநிலைகளை பூர்த்தி செய்வதற்கும், வடிவமைப்பு மாற்றங்களை விரைவில் செயல்படுத்த உதவுவதற்கும் மிகவும் முக்கியமானது.

2. வாகனத் தொழிலில் பொதுவாகப் பயன்படுத்தப்படும் CNC இயந்திரங்கள் எவை?

ஆட்டோமொபைல் தொழில் 3 அச்சு மற்றும் 5 அச்சு எந்திர மையங்கள், மில்-டிர்ன் இயந்திரங்கள், பாலேட் குளங்களுடன் கிடைமட்ட எந்திர மையங்கள் மற்றும் இரட்டை சுழல் திருப்பு மையங்கள் உள்ளிட்ட பலவிதமான சிஎன்சி இயந்திர வகைகளைப் பயன்படுத்துகிறது. ஒவ்வொருவரும் இயந்திரத் தொகுதிகள், அச்சுகள் அல்லது வீடுகள் போன்ற குறிப்பிட்ட வாகன பாகங்களின் சிக்கலான தன்மை, பொருள் மற்றும் உற்பத்தி அளவை அடிப்படையாகக் கொண்டு தேர்ந்தெடுக்கப்படுகின்றன.

3. CNC இயந்திரம் வாகனப் பாகங்களின் தரம் மற்றும் கண்காணிப்பை எவ்வாறு ஆதரிக்கிறது?

சிஎன்சி இயந்திரம் மூலப்பொருளிலிருந்து முடிக்கப்பட்ட தயாரிப்பு வரை ஒவ்வொரு பகுதியையும் டிஜிட்டல் முறையில் கண்காணிக்க உதவுகிறது. இது IATF 16949 மற்றும் ISO 9001 போன்ற தரங்களுக்கு இணங்குதல், கண்காணிப்பு, SPC மற்றும் தொடர்ச்சியான லாட் கண்காணிப்பு மூலம் வலுவான தரக் கட்டுப்பாட்டை ஆதரிக்கிறது.

4. ஆட்டோமொபைல் கூறுகளுக்கான சிஎன்சி உற்பத்தியைப் பயன்படுத்துவதன் முக்கிய நன்மைகள் என்ன?

முக்கிய நன்மைகள் உயர் துல்லியம், விரைவான முன்மாதிரி மற்றும் உற்பத்தி, வடிவமைப்பு மாற்றங்களுக்கு நெகிழ்வுத்தன்மை மற்றும் விரிவான கண்காணிப்பு ஆகியவை அடங்கும். சிஎன்சி உற்பத்தி ஆபத்தை குறைக்கிறது, பாதுகாப்பு-கூட்டப்பட்ட சகிப்புத்தன்மையை உறுதி செய்கிறது, மற்றும் செலவுகளைக் கட்டுப்படுத்தும் அதே நேரத்தில் ஒற்றை முன்மாதிரிகளிலிருந்து வெகுஜன உற்பத்திக்கு திறமையான அளவை ஆதரிக்கிறது.

5. ஆட்டோமொபைல் திட்டங்களுக்கு சரியான CNC சப்ளையரை நான் எவ்வாறு தேர்வு செய்யலாம்?

IATF 16949 சான்றிதழ் பெற்ற சப்ளையர்களைத் தேடுங்கள், ஆட்டோமொபைல் வெளியீடுகளில் நிரூபிக்கப்பட்ட அனுபவம், மேம்பட்ட ஆட்டோமேஷன், மற்றும் இறுதி முதல் இறுதி தர அமைப்புகள். ஷாயோய் மெட்டல் பாகங்கள் சப்ளையர் ஒரு வலுவான தேர்வாகும், இது வேகமான முன்மாதிரி தயாரிப்பு, அளவிடக்கூடிய உற்பத்தி மற்றும் வலுவான ஆவணங்களை ஆட்டோமொபைல் சிஎன்சி திட்டங்களுக்கு வழங்குகிறது.

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —