டை காஸ்டிங்கில் பொத்துக்கள் ஏற்படுவதற்கான முக்கிய காரணங்கள் விளக்கம்

சுருக்கமாக

டை காஸ்டிங்கில் புண்ணுகள் என்பது உலோகத்தின் புறப்பரப்பிற்கு அடியில் சிக்கிய வாயு விரிவடைவதால் ஏற்படும் உயர்ந்த குமிழிகளுடன் கூடிய புறப்பரப்பு குறைபாடாகும். இதன் முதன்மை காரணம் குழப்பமான உலோக ஓட்டம் மற்றும் போதுமான வென்டிங் இல்லாமை காரணமாக வாயு அல்லது காற்று சிக்கிக்கொள்வதாகும். மற்ற முக்கிய காரணிகளில் அதிகப்படியான உருகிய உலோகம் அல்லது கட்டு வெப்பநிலை, தவறான கட்டு சுருக்கு திரவங்களின் பயன்பாடு, அலுமினிய உலோகக்கலவைக்குள் உள்ள கலப்புப் பொருட்கள் அல்லது உடல் குறைபாடுகள் ஆகியவை அடங்கும்.

புண் உருவாக்கத்தில் வாயு மற்றும் காற்று சிக்கித் தவிப்பதன் பங்கு

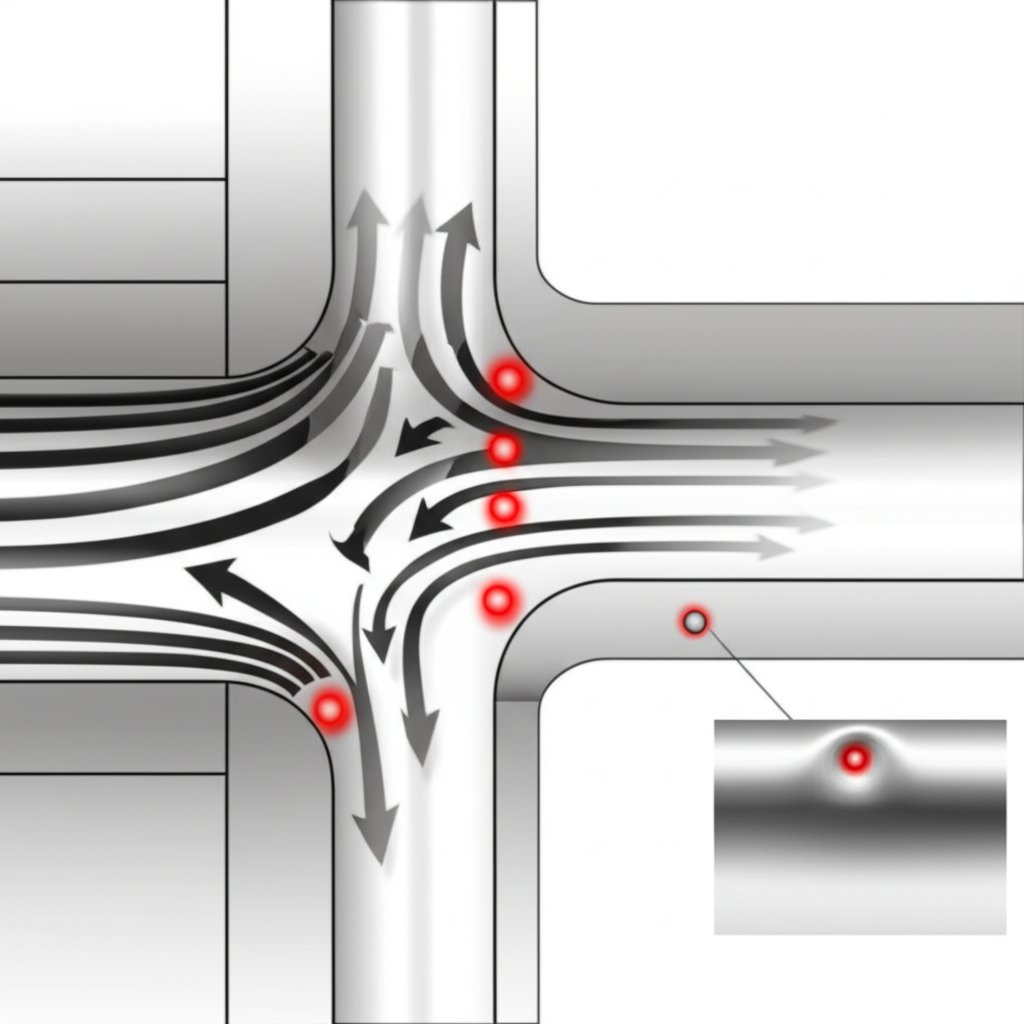

டை காஸ்டிங்கில் புண்ணுகள் உருவாவதற்கான மிக அடிப்படையான காரணம், உலோகம் செலுத்தப்படும் போது வார்ப்புக் குழியினுள் வாயு சிக்கிக்கொள்வதாகும். புண்கள் என்பது வாயு துளைத்தன்மையின் ஒரு குறிப்பிட்ட வடிவமாகும், இதில் சிக்கிய வாயு வார்ப்பின் பரப்பிற்கு அடியில் இருக்கும். உருகிய உலோகம் திடமடையும் போது, இந்த சிக்கிய வாயு மிக அதிக அழுத்தத்திற்கு உட்பட்டிருக்கும். பாகம் டையிலிருந்து வெளியேற்றப்படும் போது, வெளி ஆதரவு நீக்கப்படுகிறது, மேலும் இன்னும் மென்மையான உலோகத் தோல் விரிவடையும் வாயுவால் வெளிப்புறமாக தள்ளப்படலாம், இதனால் தனித்துவமான புண் உருவாகிறது.

இந்த வாயு பல ஆதாரங்களிலிருந்து வரலாம். மிகவும் பொதுவானது, ஷாட் செய்வதற்கு முன்பே வார்ப்புக் குழியிலும் ரன்னர் அமைப்பிலும் ஏற்கனவே இருக்கும் காற்று ஆகும். உருகிய உலோகம் மிக வேகமாக செலுத்தப்பட்டாலோ அல்லது ஓட்டப்பாதை சரியாக ஏற்பாடு செய்யப்படாவிட்டாலோ, இது சூழ்ச்சித்தனமான ஓட்டத்தை உருவாக்குகிறது. இந்த சூழ்ச்சித்தனமான, குழப்பமான ஓட்டம் தன்னைத்தானே மடித்துக்கொள்கிறது, உலோகம் திடமடைவதற்கு முன்பு தப்பிக்க முடியாத காற்றுப் பைகளைச் சிக்க வைக்கிறது. ஒரு தொழில்நுட்ப பகுப்பாய்வில் விரிவாக குறிப்பிட்டுள்ளபடி CEX Casting , மோசமான கேட் மற்றும் ரன்னர் வடிவமைப்பு அடிக்கடி காரணமாக இருக்கிறது, உலையில் உருகிய உலோகத்தை சீரான, அடுக்கு ஓட்டமாக நிரப்புவதில் தோல்வி.

போதுமான வென்டிங் இல்லாதது மற்றொரு முக்கிய காரணமாகும். உருகிய உலோகம் குழியை நிரப்பும்போது குழியில் உள்ள காற்று வெளியேற உதவும் வகையில் வடிவமைக்கப்பட்ட சிறிய வாயில்களே வென்டுகள் ஆகும். இந்த வென்டுகள் மூடப்பட்டிருந்தாலோ, மிகச் சிறியதாக இருந்தாலோ அல்லது தவறான இடத்தில் இருந்தாலோ, காற்று செல்வதற்கு எங்கும் இடமில்லை மற்றும் ஓட்டுதலில் சிக்கிக்கொள்கிறது. இதன் விளைவாக துளைகள் ஏற்படுகின்றன மற்றும் பரப்பிற்கு அருகில் இருந்தால், கொப்புளங்கள் ஏற்படுகின்றன. இதுபோன்ற குறைபாடுகளைத் தடுப்பதில் வென்டிங் அமைப்பை உகந்த நிலைக்கு மாற்றுவது ஒரு முக்கிய படியாகும்.

வாயு மற்றும் காற்று சிக்கித் திணறுவதைக் குறைப்பதற்காக, பல சிறந்த நடைமுறைகளைச் செயல்படுத்த வேண்டும்:

- கேட்டிங் மற்றும் ரன்னர் வடிவமைப்பை உகந்த நிலைக்கு மாற்றுதல்: டை குழியை சீரான, சீற்றமின்றி நிரப்புவதை ஊக்குவிக்கும் வகையில் வடிவமைக்க மோல்ட் ஃப்ளோ சிமுலேஷன் மென்பொருளைப் பயன்படுத்தவும்.

- போதுமான வென்டிங்கை உறுதி செய்தல்: காற்றை முழுமையாக வெளியேற்ற தூய்மையான, திறமையான வென்டுகள் மற்றும் ஓவர்ஃப்ளோ கேட்களை வடிவமைத்தல் மற்றும் பராமரித்தல்.

- இன்ஜெக்ஷன் வேகத்தைக் கட்டுப்படுத்துதல்: உயர் வேக நிரப்புதல் தொடங்குவதற்கு முன் குழியிலிருந்து காற்றை மெதுவாக வெளியேற்றும் வகையில், ஷாட் சுருக்கத்தை, குறிப்பாக ஆரம்ப மெது ஷாட் கட்டத்தை சரி செய்க.

- வெற்றிட உதவியைப் பயன்படுத்தவும்: முக்கியமான பாகங்களுக்கு, ஊசியிடுவதற்கு முன் குழியிலிருந்து காற்றை தீவிரமாக அகற்றும் வெற்றிட டை காஸ்டிங் செயல்முறையை செயல்படுத்துவது, பொருக்கு-வாயு குறைபாடுகளின் அபாயத்தை கிட்டத்தட்ட நீக்கும்.

செயல்முறை அளவுருக்கள்: வெப்பநிலை மற்றும் தேய்மான எண்ணெய்கள் புண்களை எவ்வாறு ஏற்படுத்துகின்றன

காற்று சிக்கிக்கொள்வதைத் தவிர, செயல்பாட்டு செயல்முறை அளவுருக்கள் புண்கள் உருவாகும் நிலைகளை உருவாக்குவதில் முக்கிய பங்கு வகிக்கின்றன. வெப்பநிலை கட்டுப்பாடு மற்றும் தேய்மான எண்ணெய் பயன்பாடு கையாள வேண்டிய மிக முக்கியமான இரண்டு துறைகளாகும். உருகிய உலோகம் அல்லது டை தானாக இருந்தாலும், மிகையான உயர் வெப்பநிலைகள் வாயு தொடர்பான பிரச்சினைகளை மேலும் மோசமாக்கும். ஒரு சுருக்க கண்ணோட்டத்தின் படி, சன்ரைஸ் மெட்டல் உயர் வெப்பநிலைகள் உருகிய உலோகக்கலவையின் உள்ளே ஆவி அழுத்தத்தை அதிகரிக்கும் மற்றும் டை தேய்மான எண்ணெய்கள் சிதைவதை ஏற்படுத்தி, சிக்கிக்கொள்ளும் வாயுவை வெளியிடும்.

இடைவெளி சுருக்குதலைத் தடுக்க, வார்ப்பை வார்ப்பனில் ஒட்டாமல் இருக்க சுருக்குதல் எண்ணெய்கள் அல்லது விடுவிப்பு முகவர்கள் அவசியம், ஆனால் அவற்றைத் தவறாகப் பயன்படுத்துவது வாயு துளைகள் மற்றும் கொப்புளங்களுக்கு முக்கிய காரணமாக உள்ளது. அதிக அளவு சுருக்குதல் எண்ணெய் பயன்படுத்தப்பட்டாலோ அல்லது சீரற்ற முறையில் பூசப்பட்டாலோ, அதிக திரவம் வார்ப்பனில் தேங்கி நிற்கலாம். சூடான உருகிய உலோகத்துடன் தொடர்பு கொண்டதும், இந்த அதிக சுருக்குதல் எண்ணெய் உடனடியாக ஆவியாகி, வெளியேற நேரமின்றி பெருமளவு வாயுவை உருவாக்குகிறது. த ஹில் & கிரிஃபித் கம்பெனி என்று அறிக்கையில் குறிப்பிடப்பட்டுள்ளபடி, பிளஞ்சர் சுருக்குதல் எண்ணெய் பெரும்பாலும் மிகப்பெரிய பங்களிப்பாளராக உள்ளது, குறிப்பாக அழுக்கான பிளஞ்சர் முனையை ஈடுகட்ட கூடுதல் சுருக்குதல் எண்ணெய் பயன்படுத்தப்படும்போது.

ஈரப்பதம் மற்றொரு முக்கிய காரணியாகும். வார்ப்பனில் ஏதேனும் மீதமுள்ள ஈரப்பதம், கசியும் நீர்க் குழாய்கள், தெளிக்கும் ஸ்ப்ரேயர்கள் அல்லது விடுவிப்பு முகவரிலிருந்தே வந்தாலும், செலுத்தும்போது ஆவியாக மாறும். இந்த ஆவி வேறு எந்த சிக்கிய வாயுவைப் போலவே நடந்து கொள்கிறது, கொப்புளங்களுக்கு வழிவகுக்கும் வார்ப்பின் தோலின் கீழ் அழுத்தத்தை உருவாக்குகிறது. எனவே, உலர்ந்த வார்ப்பன் சூழலைப் பராமரிப்பது மிகவும் முக்கியம்.

செயல்முறை அளவுருக்களால் ஏற்படும் கொப்புளங்களைத் தடுக்க, ஆபரேட்டர்கள் பின்வரும் சரிசெய்தல் நடவடிக்கைகளைப் பின்பற்ற வேண்டும்:

- கண்டிப்பான வெப்பநிலை கட்டுப்பாட்டை பராமரிக்கவும்: அதிக வெப்பம் மற்றும் அதிகப்படியான வாயு உருவாவதைத் தடுக்க, உருகிய உலோகக்கலவையும், செதிலும் குறிப்பிட்ட வெப்பநிலை வரம்புக்குள் இருப்பதை உறுதி செய்யவும்.

- சிறிதளவு மற்றும் சீராக சுருக்குதல் பொருளைப் பயன்படுத்தவும்: உயர் தரம் கொண்ட, குறைந்த எஞ்சிய விடுபடும் பொருளை குறைந்தபட்சமாகவும், சீராகவும் பூச தானியங்கி ஸ்பிரே அமைப்புகளைப் பயன்படுத்தவும்.

- ஆவியாதலுக்கான நேரத்தை அனுமதிக்கவும்: செதில் மூடுவதற்கு முன், சுருக்குதல் பொருளில் உள்ள நீர் அல்லது கரைப்பான் காரணிகள் முழுமையாக ஆவியாவதற்கு போதுமான இடைவெளி இருப்பதை உறுதி செய்யவும்.

- தொழில்நுட்ப பராமரிப்பை மேற்கொள்ளவும்: நீர் அல்லது ஐதராலிக் கசிவுகள் இருப்பதை தொடர்ந்து சரிபார்த்து, சரிசெய்து, ஸ்பிரே நோஸில்கள் சொட்டுவதில்லை என்பதை உறுதி செய்யவும்.

மூலக்காரணிகளாக பொருள் மற்றும் இயற்பியல் குறைபாடுகள்

இறுதி காரணிகள் ஊற்று பொருளின் ஒருமைப்பாட்டையும், உலோக ஓட்டத்தில் உள்ள இயற்பியல் தொடர்ச்சியின்மைகளையும் சார்ந்தவை. புண் போன்ற குமிழிகள் உலோகக்கலவையில் உள்ள கலந்த பொருட்களிலிருந்து தோன்றலாம். உதாரணமாக, குறைந்த கொதி நிலை கொண்ட தனிமங்கள், காலியம் அல்லது காட்மியம் போன்றவை, ஊற்றுதல் செயல்முறையின் போது அல்லது அதற்குப் பின் வெப்ப சிகிச்சையின் போது ஆவியாகலாம், இது உள் வாயு அழுத்தத்தை உருவாக்கும். இதேபோல், அலுமினிய உலோகக்கலவைகள் உருகும் போது ஹைட்ரஜனை உறிஞ்சிக்கொள்ளலாம், இது திடமாதலின் போது வெளியேற முயலும், இதன் விளைவாக துளைகளும், புண் போன்ற குமிழிகளும் ஏற்படும்.

நிரப்பும் செயல்முறையின் போது அறிமுகப்படுத்தப்பட்ட இயற்பியல் குறைபாடுகளும் மிகவும் தீங்கு விளைவிக்கக்கூடியவை. எஞ்சினியரிங் ஃபெயிலியர் அனாலிசிஸ் கேட்டிங் சிஸ்டமுக்கு அருகில் உள்ள பகுதிகளில் குறிப்பாக பெரிய பொதுக்களுக்கு முக்கிய காரணமாக இருப்பதாக குளிர்ந்த துகள்கள்—ஷாட் சீவ் சுவர்களில் இருந்து பிரிந்து வரும் அரை-இறுகிய உலோகத் துண்டுகள்—உள்ளன, என்பதை சுட்டிக்காட்டுகிறது. இந்த துகள்கள் காஸ்டிங்கின் நுண்ணமைப்பில் தொடர்ச்சியின்மையை உருவாக்குகின்றன. இந்த குழிகளில் உள்ள வாயு வெப்ப சிகிச்சையின் போது விரிவடைகிறது, மேற்பரப்பில் குறிப்பிடத்தக்க பொதுக்களை உருவாக்குகிறது. குளிர்ந்த துளிகள், குளிர்ந்த ஷாட்கள் மற்றும் ஆக்சைடு படங்கள் போன்ற மற்ற ஒத்த குறைபாடுகள் உலோகத்தின் ஒருங்கிணைப்பை சீர்குலைக்கின்றன மற்றும் பொதுப்படையான தொடக்க இடங்களாக செயல்படுகின்றன.

பொருள் சார்ந்த இந்தக் குறைபாடுகளைத் தடுப்பதற்கு, மூலப்பொருள் கையாளுதல் முதல் இறுதி உற்பத்தி வரையிலான முழுச் செயல்முறையின் கண்டமைப்பான கட்டுப்பாடு தேவைப்படுகிறது. தரக் கட்டுப்பாட்டில் உயர்ந்த பொறுப்புணர்வைக் காட்டும் ஒரு வழங்குநருடன் இணைந்து செயல்படுவது அவசியம். எடுத்துக்காட்டாக, உயர் செயல்திறன் கொண்ட வாகன பாகங்களைத் தயாரிப்பவர்கள் பெரும்பாலும் IATF16949 போன்ற சான்றளிக்கப்பட்ட செயல்முறைகள் மற்றும் உள்நிறுவன தரக் கட்டுப்பாடு ஆகியவற்றை நம்பியிருக்கிறார்கள்; இது தொடக்கத்தில் இருந்து இறுதி வரை பொருளின் ஒருமைப்பாட்டை உறுதி செய்கிறது, இது போன்ற குறைபாடுகளைத் தடுப்பதற்கு ஒரு முக்கியமான நடைமுறையாகும்.

இந்த வேறுபட்ட காரணங்களை நன்கு புரிந்துகொள்ள, கீழே உள்ள அட்டவணை வாயு துளைத்தன்மையால் ஏற்படும் கொப்புளங்களையும், இயற்பியல் அல்லது வேதியியல் குறைபாடுகளால் ஏற்படும் கொப்புளங்களையும் ஒப்பிடுகிறது:

| குறைபாட்டின் தோற்றம் | உருவாக்க முறை | சாதாரண தோற்றம் & இருப்பிடம் |

|---|---|---|

| வாயு துளைத்தன்மை | தூசி அல்லது ஆவியான தேய்மான எண்ணெய்/ஈரப்பதம் எஜெக்ஷன் சமயத்திலோ அல்லது வெப்ப சிகிச்சையின் போதோ மென்மையான உலோகத் தோலின் கீழ் விரிவடைகிறது. | பொதுவாக மென்மையான, வட்டமான அல்லது அரைக்கோள வடிவ காற்றுக்குழிகள் பரப்பில் காணப்படுகின்றன. எங்கும் தோன்றலாம், ஆனால் பெரும்பாலும் மோசமான வென்டிங் அல்லது சீரற்ற ஓட்டப் பாதைகளுடன் தொடர்புடையதாக இருக்கும். |

| பொருள்/இயற்பியல் குறைபாடுகள் | குளிர்ந்த துகள்கள், ஆக்சைடு படங்கள் அல்லது இடைத்தனி ஊடுருவல் பகுதிகள் போன்ற முன்னரே உள்ள காற்றுப் பைகளில் வாயு சேர்கிறது. வெப்பமடைதல் சிகிச்சையின் போது இந்த வாயு விரிவடைந்து, மேற்பரப்பை மேலே தள்ளுகிறது. | அளவில் பெரியதாகவும், ஒழுங்கற்ற வடிவமைப்புடனும் இருக்கலாம். கேட்டின் அருகே உள்ள பெரிய கட்டிகள் (குளிர்ந்த துகள்களால்) அல்லது குளிர்ந்த பகுதிகளில் சிறியவை (குளிர்ந்த துளிகளால்) போன்ற குறிப்பிட்ட இடங்களுடன் அடிக்கடி இணைக்கப்படுகிறது. |

தீர்வுகளில் மூலப்பொருட்களை முழுமையாக முன்கூட்டியே சூடேற்றி உலர்த்துதல், அதிக தூய்மை கொண்ட உலோகக்கலவைகளைப் பயன்படுத்துதல், மற்றும் இரும்பு செய்வதற்கு முன் கரைந்துள்ள ஹைட்ரஜனை நீக்க நைட்ரஜன் அல்லது ஆர்கானைப் பயன்படுத்தி பயனுள்ள வாயு நீக்கம் சிகிச்சைகளைச் செயல்படுத்துதல் ஆகியவை அடங்கும்.

டை காஸ்டிங் கட்டிகள் பற்றிய அடிக்கடி கேட்கப்படும் கேள்விகள்

1. டை காஸ்டிங்கில் கட்டிகளுக்கு முக்கிய காரணம் என்ன?

கட்டிகளுக்கான முதன்மை காரணம் சிக்கிய வாயு, பெரும்பாலும் வார்ப்புக் குழியிலிருந்து வரும் காற்று, இது சூடான உலோகத்தின் சீரற்ற ஓட்டத்தாலும், போதுமான வாயு வெளியேற்றமின்மையாலும் சிக்கிக்கொள்கிறது. இந்த வாயு, வார்ப்பு மேற்பரப்பிற்கு அடியில் இருக்கும் போது, மென்மையான உலோகத்தின் மேற்பரப்பை விரிவாக்கி, குமிழியை உருவாக்குகிறது.

2. வெப்ப சிகிச்சை ஒரு டை-காஸ்ட் பாகத்தில் கொப்புளங்கள் உருவாக காரணமாக இருக்குமா?

ஆம், வெப்ப சிகிச்சை என்பது கொப்புளங்கள் உருவாவதற்கு ஒரு பொதுவான தூண்டுதலாகும். ஒரு பாகம் அதன் காஸ்ட் நிலையில் முற்றிலும் சரியாக தோன்றலாம், ஆனால் பரப்பின் கீழே பிடிபட்ட வாயு அல்லது ஒரு இயற்பியல் தடை இருந்தால், வெப்ப சிகிச்சையின் அதிக வெப்பநிலை வாயுவை மிகவும் விரிவடையச் செய்து, பரப்பில் கொப்புளமாக குறைபாட்டை வெளிப்படுத்தும்.

3. கொப்புளத்தையும் பொதுவான துளைத்தன்மையையும் எவ்வாறு வேறுபடுத்துவது?

கொப்புளங்கள் என்பது பரப்பளவில் அல்லது பரப்பிற்கு அருகில் உள்ள குறைபாடுகள் ஆகும், காஸ்டிங்கின் தோலில் உயர்ந்த உப்பிய பகுதிகளாக தோன்றும். மாறாக, பொதுவான துளைத்தன்மை என்பது பாகத்தின் உள்ளே எங்கும், உள் ஆழத்தில் கூட இருக்கக்கூடிய காலியிடங்களைக் குறிக்கிறது. இரண்டுமே பிடிபட்ட வாயுவால் ஏற்பட்டாலும், பரப்பை மாற்றும் அளவிற்கு மேற்பரப்பை அண்டியிருக்கும் துளைகளே குறிப்பாக கொப்புளங்கள் எனப்படுகின்றன.

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —