Laserjanje kovin razumljeno: Od vlaknaste tehnologije do tovarniškega poda

Razumevanje laserjskega rezanja kovin in zakaj je pomembno

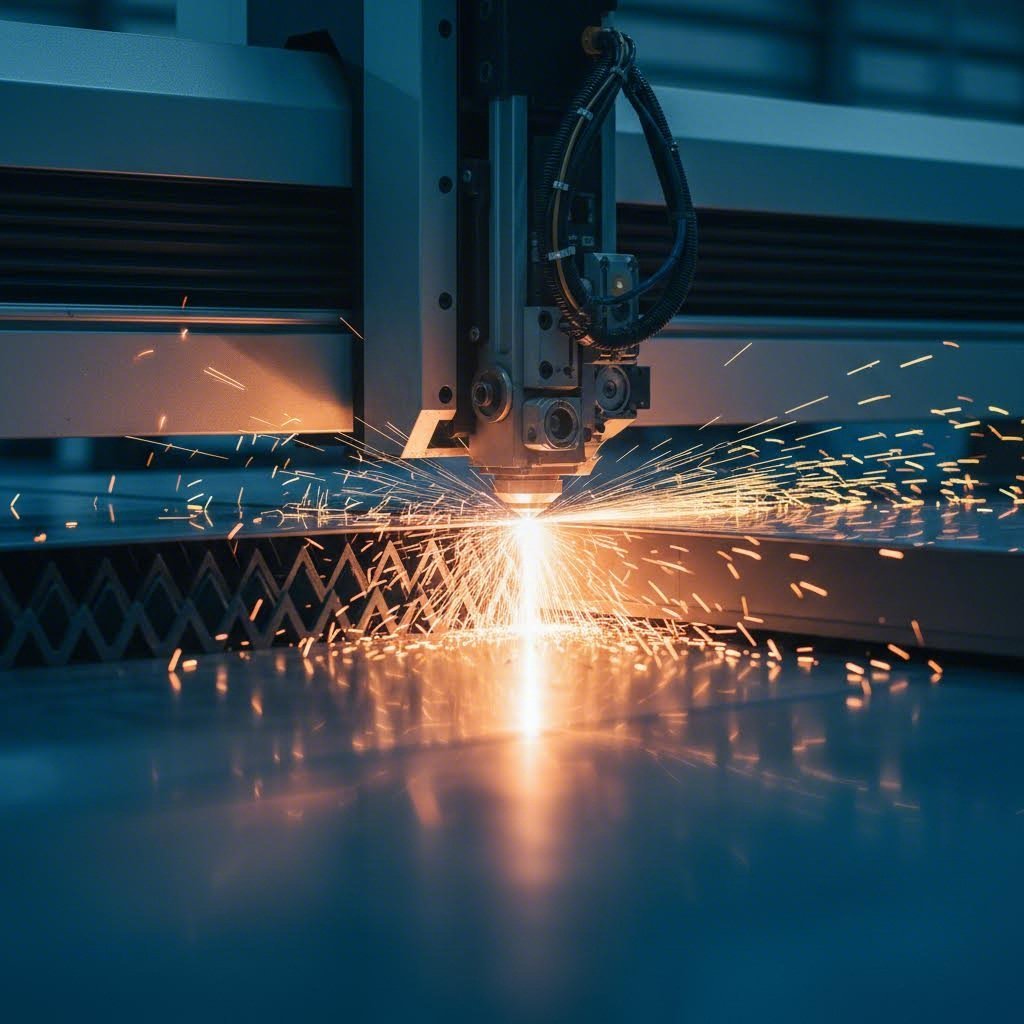

Zamislite si žarek svetlobe tako močan, da prereže jeklo kot vroče nož skozi maslo. Prav to vsakodnevno omogoča laserjsko rezanje kovin v proizvodnih obratih po vsem svetu. Ta napredna tehnika izdelave uporablja visokomočni laserski žarek za taljenje, izgorevanje ali izparevanje materiala v natančno programirani poti in ustvarja reze z izjemno natančnostjo, ki jih tradicionalne metode preprosto ne morejo doseči.

Od takrat, ko je prvi stroj za laserjsko rezanje izstopil iz laboratorijev Bell Labs v zgodnjih 60. letih 20. stoletja, se je ta tehnologija razvila v nepogrešljivo orodje sodobne proizvodnje. Danes se na področjih, ki segajo od avtomobilske in letalske industrije do elektronike in proizvodnje medicinskih naprav, zanašajo na postopek laserjskega rezanja za izdelavo sestavnih delov z dopusti, ki razširjajo meje tega, kar je mogoče.

Kako usmerjena svetloba pretvori surovo kovino

Tukaj postane znanost fascinantna. Laser, ki reže kovine, ustvari izjemno koncentriran žarek svetlobe, ki lahko doseže temperature nad 20.000 stopinj Celzija. Ko ta intenzivna energija zadene površino kovine, povzroči lokalno segrevanje tako hitro, da material takoj zavre ali stopi.

Čarovnija poteka prek niza zrcal in leč, ki žarek lasera usmerijo v izredno majhno točko. Ta usmerjena energija, skupaj s Računalniškim numeričnim nadzorom (CNC) , omogoča glavi lasera premikanje z izjemno natančnostjo in točnostjo. Rezultat? Čisti in natančni rezi tudi za najbolj zapletene oblike – ne glede na to, ali iščete informacije o laserskem rezanju kovin ali raziskujete možnosti lazerskega rezanja za vaš naslednji projekt.

Fizika, ki stoji za natančnim rezanjem

Zakaj lasersko rezanje kovin prekaša tradicionalne metode? Odgovor leži v več ključnih znanstvenih principih, ki delujejo skupaj:

- Učinkovitost absorpcije: Različni kovinski materiali absorbirajo določene valovne dolžine svetlobe, kar omogoča proizvajalcem, da prilegajo vrste laserjev materialom za optimalno rezkanje

- Termalna prevodnost: Kovine hitro prevajajo toploto stran od režnega območja, zaradi česar ostane okoliški material neprizadet in nastanejo čisti, natančni robovi

- Delovanje brez stika: V nasprotju s strojnim rezkanjem laserji ne prihajajo v fizični stik s kosom, kar odpravlja obrabo orodja in ohranja stalno natančnost

Laserjsko rezkanje predstavlja srečanje znanosti, umetnosti in domišljije – razširja meje tega, kar je mogoče v proizvodnji in oblikovanju, hkrati pa ponuja nepremagovljivo natančnost, učinkovitost in prilagodljivost

V tem priročniku boste odkrili ključne razlike med vlaknastimi, CO2 in Nd:YAG laserskimi tehnologijami. Spoznali boste, za katera kovina je najprimernejši vsak sistem, razumeli boste zmogljivosti glede debeline ter pridobili vpogled v varnostne protokole in tehnike odpravljanja težav. Ne da bi ocenjevali lasersko rezkanje za svoje proizvodne potrebe ali preprosto radovedni, kako ta tehnologija oblikuje sodobno proizvodnjo, bo ta celovit pregled poskrbel za znanje, ki vam omogoča sprejemanje informiranih odločitev.

Razlaga tehnologij Fiberski, CO2 in Nd:YAG laser

Ko izbirate orodja za lasersko rezkanje kovin za svoje delovanje, izvor lasera, ki ga izberete, osnovno določa vse – od kakovosti reza do obratovalnih stroškov. Trenutno prevladujejo tri različne tehnologije v obdelavi kovin: vlaknasti laserji, CO2 laserji in Nd:YAG laserji. Vsaka ponuja edinstvene prednosti, razumevanje njihovih razlik pa vam pomaga pravilno izbrati ustrezno tehnologijo za vaše specifične aplikacije.

Ključna razlika med temi vrstami laserskih rezalnikov je v njihovi valovni dolžini. Fiberski laserji delujejo pri približno 1,06 mikrometru, CO2 laserji oddajajo svetlobo pri 10,6 mikrometru, Nd:YAG laserji pa imajo enako valovno dolžino 1,06 mikrometra kot fiberski sistemi. Zakaj je to pomembno? Ker različni kovinski materiali absorbirajo te valovne dolžine pri zelo različnih hitrostih, kar neposredno vpliva na učinkovitost in kakovost rezanja.

Fiberski laserji in njihova prevladujoča vloga pri obdelavi tankih kovin

Rezanje kovin s fiberskim laserjem je v zadnjih dveh desetletjih preobrazilo industrijo. Ti sistemi uporabljajo stekleno vlakno, dopirano s surovinami redkih zemelj, kot aktivno sredstvo, ki generira in prenaša laserski žarek preko integriranega fleksibilnega optičnega vlakna. Rezultat? Zelo kompakten, učinkovit in zanesljiv rezalni sistem.

Kaj naredi fiberski laser za rezanje kovin tako privlačnega? Upoštevajte te prednosti:

- Nadpovprečna učinkovitost izkoriščanja energije: Vlaknasti laserji porabljajo približno tretjino moči primerljivih CO2 sistemov, kar znatno zmanjša stroške električne energije

- Podaljšana življenjska doba: Pričakujte približno 100.000 ur obratovanja – okoli desetkrat več kot pri CO2 laserskih ceveh

- Minimalno vzdrževanje: Brez zrcal, ki jih je treba poravnati, brez plina za polnjenje in brez porabnih bliskavk, ki jih je treba zamenjati

- Izjemna kakovost žarka: Konstrukcija valovoda odpravi izkrivljanje optične poti zaradi toplotnih težav

- Kompaktna konstrukcija: Manjša velikost pri enaki moči izhodnega signala v primerjavi s trdotalnimi ali plinskimi alternativami

Pri obdelavi refleksivnih kovin, kot so baker, mesing in aluminij, se vlaknasti laserji resnično izkazujejo. Njihova krajša valovna dolžina omogoča boljše stopnje absorpcije pri teh zahtevnih materialih ter hitrejše hitrosti rezkanja tankih do srednje debelih pločevin. Za obrti za intenzivno izdelavo kovinskih konstrukcij, osredotočene na jeklo in aluminij, vlaknasta tehnologija ponuja nepremagljivo produktivnost.

Ko CO2 laserji prekašajo vlaknasto tehnologijo

Ne zanemarite CO2 laserskega rezkanja kovin še zdaj. Čeprav je vlaknasta tehnologija pridobila pomemben delež trga, CO2 sistemi ohranjajo pomembne prednosti pri določenih aplikacijah. Ti plinski laserji uporabljajo mešanico ogljikovega dioksida, dušika in helija za ustvarjanje žarka daljše valovne dolžine.

Rezanje jekla z CO2 laserjem ostaja najbolj primeren izbor pri delu z debelejšimi materiali – navadno nad 20 mm. Daljša valovna dolžina ustvari širši rež, ki dejansko pomaga pri odstranjevanju ostruškov pri globokih rezih in omogoča čistejše robove na debelih ploščah. Poleg tega se CO2 laserji izjemajo pri rezkanju nemetalnih materialov, kot so les, akrilno steklo in tekstil, kar ponuja univerzalnost, s katero sistemov na osnovi vlaken ni mogoče tekmovati.

Višji obratovalni stroški pa povedo le del zgodbe. CO2 sistemi zahtevajo redno poravnavo zrcal, polnjenje resonatorja z novim plinom ter pogostejšo zamenjavo porabnih delov. Poraba energije je znatno višja, kar vpliva tako na račune za komunalne storitve kot tudi na okoljski otis.

Razumevanje uporab Nd:YAG laserjev

Nd:YAG (neodimom dopirani itrij-aluminijev granat) laserji predstavljajo starejšo tehnologijo trdnega stanja, ki še naprej služi specializiranim področjem. Te sisteme uporabljajo kristalno palico kot delovno sredstvo, ki se črpa z bliskavkami ali laserskimi diodami za ustvarjanje rezalne moči.

Kje še vedno imajo smisel Nd:YAG laserji? Njihove močne strani izstopajo pri točnostnih aplikacijah, ki zahtevajo izjemno natančnost:

- Proizvodnja medicinskih naprav z zahtevami po mikro-rezanju

- Komponente za letalstvo, ki zahtevajo ekstremno natančnost

- Obdelava keramike in določenih plastičnih mas skupaj s kovinami

- Aplikacije, ki zahtevajo delovanje v impulzih za previdno nadzorovanje toplote

Pomanjkljivosti vključujejo višje zahteve glede vzdrževanja, nižjo učinkovitost pretvorbe svetlobe v električno energijo ter težave s toplotnim napetostnim stanjem, ki omejuje povprečno moč. Zamenjava bliskavk povečuje stalne obratovalne stroške, zapletena konstrukcija pa zahteva več tehničnega znanja za vzdrževanje.

Celovita primerjava tehnologij

Pri ocenjevanju teh treh tehnologij za vaše potrebe po rezanju kovin ta primerjalna tabela poudarja ključne razlike:

| Kategorija | Vlaken laser | Co2 laser | Nd:YAG Laser |

|---|---|---|---|

| Valovna dolžina | 1,06 μm | 10,6 μm | 1,06 μm |

| Najboljše uporabe kovin | Jeklo, aluminij, baker, mesing | Debel jeklo, nerjaveče jeklo | Natančne kovine, keramika, nekateri plastični materiali |

| Optimalno območje debeline | 0,5 mm - 20 mm | 6 mm - 25 mm+ | 0,1 mm - 10 mm |

| Poraba energije | Nizka (približno 1/3 CO2) | Visoko | Srednja do visoka |

| Zahteve glede vzdrževanja | Minimalna – praktično brez vzdrževanja | Redna – zrcala, plin, porabni materiali | Pogosto - žarnice s svetlobnimi bliski, poravnava |

| Pričakovana življenjska doba | ~100.000 ur | ~10.000 - 20.000 ur | ~10.000 - 15.000 ur |

| Začetni vlagatelj | Višja začetna cena | Umeren | Nižja do zmerna |

| Hitrost rezanja (tanki kovinski material) | Najhitrejša | Umeren | Počasnejše |

Pravilna izbira je odvisna od vaših specifičnih proizvodnih zahtev. Delavnice z visoko obsežnostjo obdelave jekla in aluminija običajno ugotovijo, da optični vlaknasti laserji omogočajo najboljši donos investicij zaradi nižjih obratovalnih stroškov in hitrejšega obdelovalnega procesa. Dejavnosti, ki obdelujejo debelejše materiale ali potrebujejo večnamensko uporabo tudi za nekovinske materiale, lahko raje izberejo CO2 tehnologijo. Specializirana natančnostna dela – zlasti v medicinski in letalski industriji – včasih upravičijo uporabo Nd:YAG sistemov, čeprav zahtevajo več vzdrževanja.

Ko je izbira vrste laserske tehnologije pojasnjena, naslednja pomembna točka vključuje razumevanje, kakšne debeline materiala lahko posamezna moč laserja obdela pri različnih vrstah kovin.

Zmogljivosti debeline kovin in združljivost materialov

Ste se kdaj vprašali, zakaj se sosedov laser z močjo 3 kW težko spopada s materiali, ki jih vaš sistem z močjo 12 kW prereže brez napora? Razmerje med močjo lasera in rezalno zmogljivostjo ni zgolj linearno – temelji vsako uspešno obratovanje laserskega rezanja pločevine. Razumevanje omejitev debeline pred izbiro opreme prihrani številne ure razočaranja in prepreči dragocene napake.

Kdaj ocenjevanje laserskega rezanja kovinskih pločevin , dva dejavnika prevladujeta pogovor: moč lasera, merjena v kilovatih (kW), ter lastnosti materiala. Različni kovini na edinstven način reagirata na lasersko energijo glede na njuno svetlobno odbojnost, toplotno prevodnost in talilne temperature. Poglejmo si natančno, kaj lahko pričakujete od posameznih ravni moči pri najpogostejših industrijskih kovinah.

Največje globine rezanja po vrsti kovine

Laserjevanje jekla ostaja osnovna uporaba za večino tovarn za obdelavo kovin, in s pravim razlogom. Rezanje ogljikovega jekla in mehkega jekla imajo koristi od izjemnih stopinj absorpcije pri valovnih dolžinah fiber laserjev, kar omogoča učinkovito obdelavo v širokem območju debelin. Skromni 3 kW fiber laser lahko učinkovito reže mehko jeklo do približno 16 mm, medtem ko povečanje moči na 6 kW razširi dosežljivost do okoli 20 mm z izboljšano kakovostjo roba.

Zgodba se dramatično spremeni pri zrcalnih kovinah. Ko laserjevsko režete pločevino, material zlahka absorbira energijo žarka. Toda baker in mesing predstavljata povsem drugačno izzivnost. Njuna visoka svetlobna odbojnost odbija pomembno količino laserske energije nazaj proti viru, kar zahteva bistveno več moči za rezanje tanjših materialov. Sistem z močjo 6 kW morda učinkovito reže 12 mm ogljikovega jekla, a se mu bo težko posrečilo pri rezanju 6 mm bakra.

Tako se različne kovine primerjajo glede zmogljivosti rezanja pri pogostih močeh laserjev:

| Vrsta kovina | Priporočeni laser | 3 kW Največja debelina | največja debelina 6 kW | največja debelina 12 kW |

|---|---|---|---|---|

| Mehen ocel | Fiber | 16 mm | 20mm | 30mm |

| Nepokvarjeno jeklo | Fiber | 10mm | 16 mm | 25mm |

| Aluminij | Fiber | 8mm | 12mm | 20mm |

| Med | Vlakno (visoka moč) | 4mm | 6mm | 10mm |

| Iz železa | Vlakno (visoka moč) | 5mm | 8mm | 12mm |

Opazite, kako za enake debeline nerjaveča jekla in aluminij potrebujeta več moči kot ogljikovo jeklo? To izhaja iz njihovih toplotnih lastnosti. Zaradi nižje toplotne prevodnosti nerjaveče jeklo ustvarja večje cone toplotnega vpliva, medtem ko aluminij zaradi visoke toplotne prevodnosti hitro odvaja toploto iz režnega območja, kar zahteva več vhodne energije za ohranjanje temperatur rezanja.

Prilagoditev moči laserja debelini materiala

Izbira ustreznega nivoja moči zajema več kot le usklajevanje največjih zmogljivosti glede na debelino. Pri tem morate upoštevati hitrost rezanja, kakovost roba in zahteve glede proizvodnega obsega. Spodaj je praktični okvir za izbiro moči laserja pri rezkanju kovinskih pločevin:

- Vstopna raven (500 W–1,5 kW): Idealno za tanke pločevine do 3 mm. Popolno za prototipiranje, prometne znake in lahke izdelovalne naloge

- Srednji razred (3 kW–6 kW): Opravlja večino industrijskih aplikacij. Primerno za proizvodna okolja, ki obdelujejo materiale do 20 mm

- Visoka moč (10 kW-40 kW): Zasnovan za delo z debelimi ploščami in hitro proizvodnjo na tanjših materialih

Razmerje med močjo in hitrostjo razkrije pomembne vidike proizvodnje. Podvojitev moči lasera ne pomeni preprostega podvojitve hitrosti rezanja – pridobitki se bistveno razlikujejo glede na material in debelino. Pri aplikacijah laserskega rezanja jeklenih plošč 6-kW laser nareže 6 mm mehko jeklo s hitrostjo 4.000 mm na minuto, medtem ko 12-kW sistem doseže približno 6.500 mm na minuto na istem materialu. Ta 50-odstotna povečanje hitrosti se neposredno prenese na zmogljivost proizvodnje.

Pri obdelavi refleksivnih kovin, kot sta baker in mesing, omogočajo vlaknasti laserji z močjo vsaj 3 kW učinkovitost, potrebno za dosledne rezultate. Krajša valovna dolžina vlaknaste tehnologije dosegel boljše stopnje absorpcije pri teh zahtevnih materialih v primerjavi s CO2 alternativami. Za proizvodne okolja, ki obdelujejo mešane vrste kovin, izbira lasera z rezervno močjo nad vašimi največjimi zahtevami glede debeline zagotavlja prilagodljivost za prihodnje projekte, hkrati pa ohranja optimalne hitrosti rezanja pri trenutni kombinaciji materialov.

Razumevanje zmogljivosti glede debeline in odnosov moči pripravi teren za naslednjo ključno odločitev: izbiro med laserskim rezanjem in alternativnimi metodami, kot so plazma, vodni curek ali EDM, za vaše specifične aplikacije.

Lasersko rezanje proti plazmi, vodnemu curku in EDM metodam

Torej ste ugotovili pravo lasersko tehnologijo in razumete zmogljivosti glede debeline – a je rezkanje z laserjem dejansko najboljša izbira za vašo uporabo? Rezkanje z laserjem ponuja izjemno natančnost, vendar pa vsaka od metod plazemskega, vodnega curka in EDM-ja prinese svoje prednosti, ki jih v določenih primerih naredijo bolj primernimi.

Resnica je, da nobena samodejna tehnologija rezkanja ne zmaguje pri vsaki priložnosti. Vrsta materiala, zahteve po debelini, tolerance in količina proizvodnje vplivajo na to, katera metoda zagotavlja optimalne rezultate. Poglejmo si podrobno, kako se te štiri tehnologije med seboj primerjajo glede dejavnikov, ki so najpomembnejši za vaš poslovni uspeh.

Primerjava natančnosti med tehnologijami rezkanja

Ko je pomembna natančnost, razlike med metodami rezkanja postanejo popolnoma jasne. Rezanje kovin z laserskim žarkom dosega tolerance ±0,002 do ±0,005 palca – izjemno natančnost, ki zadovoljuje zahtevne aplikacije v letalski in medicinski industriji. Usmerjeni žarek ustvari ozek rez, ponavadi 0,1 mm do 0,3 mm, kar omogoča zapletene geometrije, ki jih druge toplotne metode ne morejo izdelati.

Rezanje z vodnim curkom se po natančnosti približuje laserju z tolerancami okoli ±0,003 do ±0,005 palca, kot kaže Primerjalna analiza podjetja Flow Waterjet . Hladni postopek rezanja proizvaja satensko gladke robove, ki skoraj ne potrebujejo dodatne obdelave. Kjer pa vodni curk res izstopa, je univerzalnost materialov – obvlada skoraj vsak material debeline do 24 palcev za grube reze, vključno s toplotno občutljivimi kompoziti in kaljenim steklom, ki bi pri toplotnih postopkih počilo.

Plazemsko rezkanje žrtvuje natančnost v korist hitrosti in sposobnosti rezanja debelih materialov. Pri dopustih med ±0,01 in ±0,03 palca plazma deluje najbolje, kadar točne dimenzije niso tako pomembne kot zmogljivost proizvodnje. Večje območje toplotnega vpliva in nastanek šlama pogosto zahteva dodatno obdelavo za doseganje čistih robov – kompromis, ki ga mnogi izdelovalci sprejmejo, kadar je potrebno hitro rezati debele pločevine.

Žični EDM zavzema edinstveno nišo visoke natančnosti. Ta postopek električnega izpusta dosega najtesnejše dopuste med vsemi štirimi metodami – pogosto pod ±0,001 palca – brez mehanskih sil ali pomembnih območij toplotnega vpliva. Kaj je cena? Deluje le na električno prevodnih materialih in ima znatno počasnejše hitrosti.

Celovita primerjava metod rezkanja

Ta podrobna primerjava poudarja ključne razlike, ki jih morate oceniti:

| Faktor | Laserjeva rezovanja | Plazmensko rezanje | Vodnjakovsko rezanje | Žična EDM |

|---|---|---|---|---|

| Natančnost/dopustna odstopanja | ±0,002" - ±0,005" | ±0,01" - ±0,03" | ±0,003" - ±0,005" | ±0,0001" - ±0,001" |

| Kakovost roba | Gladko, minimalni žleb | Grubo, prisoten šlam/droz | Satensko gladko, ni potrebna dodatna obdelava | Zrcalno podoben izgled |

| Toplotno vplivna cona | Majhno (lokalizirano) | Veliko (pomembno) | Brez (hladni postopek) | Minimalno do nič |

| Debelina materiala | Do 1" - 1,5" (kovine) | Do 1,5" učinkovito | Do 12" - 24" | Do 16" (samo prevodno) |

| Hitrost rezanja | Hitro (tanko- do srednje debelo) | Zelo hitro (do 200 ipm) | Počasi (~20 ipm) | Zelo počasi (20–300 mm²/min) |

| Cene eksploatacije | Srednje (nižje pri vlaknu) | Najnižji začetni in obratovalni stroški | Višji (abraziv, vzdrževanje) | Višji (žica, elektrika) |

| Vsestranskost materialov | Kovine, nekateri nekovinski materiali | Samo prevodne kovine | Skoraj vsak material | Samo prevodni materiali |

Izbiro pravilne metode za vašo aplikacijo

Zveni zapleteno? Jasneje postane, ko uskladite prednosti tehnologije s specifičnimi zahtevami posamezne uporabe. Vsaka rezalna metoda odlično opravlja v različnih primerih – tukaj je, kje vsaka daje največjo vrednost:

Idealne uporabe laserskega rezanja:

- Natančni kovinski deli tankih do srednje debelih pločevin (pod 1 palec)

- Proizvodnja visokih količin, ki zahteva kratke cikle

- Zapletene geometrije in podrobni vzorci

- Sestavni deli avtomobilske in elektronske industrije z majhnimi dopustnimi odstopanji

- Uporabe, kjer je minimalna nadaljnja obdelava bistvena

Idealne uporabe plazemskega rezanja:

- Izdelava debele jeklene pločevine (izven zmogljivosti lasera)

- Izdelava konstrukcijskega jekla in težke opreme

- Aplikacije, ki dajejo prednost hitrosti pred natančnostjo

- Dejavnosti z omejenim proračunom za rezanje prevodnih kovin

- Poljski pogoji in prenosne režeče potrebe

Idealne aplikacije za rezanje z vodnim curkom:

- Toplotno občutljivi materiali (kompoziti, plastične mase, guma)

- Zelo debeli materiali do 30 cm ali več

- Aplikacije v živilski in medicinski industriji, kjer se izogibamo onesnaženju

- Obdelava kamna, stekla in keramike

- Projekti, ki zahtevajo ničelno toplotno deformacijo

Idealne aplikacije za rezkanje z navadnim EDM:

- Utrjeni kovinski materiali in eksotične zlitine

- Izdelava natančnostnih kalibrov in orodij

- Mikrodeli, ki zahtevajo izjemno natančnost

- Kompleksne geometrije, ki jih ni mogoče izdelati z drugimi metodami

- Uporabe, ki zahtevajo rob z učinkom zrcala

Odločitev se pogosto zreducira na enostavno vprašanje: kaj je najpomembnejše za vaš določen projekt? Če z laserjem rezate tanke pločevine iz aluminija v visokih količinah, zmaga laserska tehnologija. Če obdelujete 2-palčne pločevine iz jekla? Bolj smiselna je plazma ali vodni curek. Potrebujete natančnost na ravni mikronov v utrjenem orodnem jeklu? Odgovor je EDM.

Številna uspešna obrtništva ohranjajo več različnih tehnologij rezanja in posamezne naloge usmerjajo v optimalni proces glede na material, debelino in zahteve po kakovosti. Ta prilagodljivost poveča učinkovitost in hkrati zagotavlja, da vsak del prejme najbolj ekonomsko učinkovito obdelavo.

Ko je izbira rezalne tehnologije pojasnjena, naslednja pomembna težava vključuje uvedbo ustrezni protokolov za varnost in skladnost z regulativami – področje, kjer lasersko rezanje predstavlja edinstvene izzive, ki zahtevajo pozorno obravnavo.

Protokoli za varnost in zahteve glede skladnosti z regulativi

Tu je realnost: ta močan laserski stroj za rezanje kovin v vaši napravi lahko v milisekundah povzroči hud poškodbe, če se ne upoštevajo ustrezni protokoli. Za razliko od tradicionalnega mehanskega rezanja, laserski sistemi predstavljajo edinstvene nevarnosti, ki segajo od nevidnega sevanja žarka do strupenih kovinskih dimov in nevarnosti požara. Razumevanje in uvedba celovitih varnostnih ukrepov ni le stvar skladnosti z regulativami – gre za zaščito vašega osebja in vašega obratovanja.

Ali že upravljate z laserskim rezalnikom za kovine v proizvodnem okolju ali pa vodite delavnico za obdelavo, mora biti varnost vpeta v vsak vidik vašega poslovanja. Dobra novica? Sistematičen pristop k laserski varnosti, ki temelji na uveljavljenih standardih in praktičnih protokolih, znatno zmanjša tveganje, hkrati pa ohranja produktivnost.

Krmarjenje po klasifikacijah laserske varnosti

Preden uporabljate katerega koli laserski rezalnik za kovine, morate razumeti klasifikacijski sistem, ki določa varnostne zahteve. Glede na Smernice za certifikacijo laserske varnosti so laserji razdeljeni v štiri glavne razrede nevarnosti glede na njihovo sposobnost povzročanja poškodb oči ali kože:

- Razred 1: Vgrajeno varno pri normalnem obratovanju. Večina zaprtih industrijskih laserskih rezalnikov spada v to kategorijo, ker njihova konstrukcija popolnoma onemogoča dostop do nevarnega žarka med normalnim uporabljanjem

- Razred 2: Omejeno na vidne valovne dolžine (400–700 nm) in se zanaša na naravni refleks trepetanja oči za zaščito. Redko uporabno pri sistemih za rezkanje kovin

- Razred 3R/3B: Lahko povzroči takojšnjo poškodbo oči zaradi neposrednih ali zrcalnih odsevov. Sistemi razreda 3B lahko predstavljajo tudi nevarnost za kožo

- Klasa 4: Najbolj nevarna kategorija – predstavlja resne tveganja za oči in kožo ob neposredni ali razpršeni izpostavljenosti, poleg tega veliko tveganje za požar

Tu je nekaj, kar si mnogi obratovalci niso zavedajo: večina industrijskih laserskih strojev za rezkanje kovin je uvrščenih v razred 1 le zato, ker vsebujejo popolnoma zaprte lasere razreda 3B ali razreda 4. Med vzdrževanjem, servisiranjem ali kadar so varnostni blokiri zaobideni, postane ta vgrajeni laser visoke moči neposredno dostopen – in nevaren.

Za vsako operacijo z uporabo sistemov razreda 3B ali razreda 4 standard ANSI Z136.1 zahteva imenovanje Odgovornega za varnost laserja (LSO), ki ima pooblastilo za uveljavljanje varnostnih protokolov. Ta pooblaščeni strokovnjak nadzoruje ocene nevarnosti, programe usposabljanja, izbiro OZI ter zagotavlja skladnost z zahtevami standarda ANSI in OSHA.

Osnovna zaščitna oprema in zahteve za delovni prostor

Zaščita vašega ekipe pred nevarnostmi pri rezkanju z laserjem zahteva večplastni pristop, ki združuje tehnične ukrepe, administrativne postopke in osebno zaščitno opremo. Glede na Smernice za varno uporabo laserjev na univerzi Carnegie Mellon , je tu obvezna varnostna oprema, ki jo potrebuje vsaka operacija rezkanja z laserjem:

- Varnostna očala, namensko za laserje: Morajo biti prilagojena specifični valovni dolžini in moči vašega lasera – generična varnostna očala ne ponujajo nobene zaščite

- Odporna rokavica za visoke temperature: Nujna pri rokovanju vročih obdelovancev ali površin

- Rokavice, odporne proti obrabi: Zahtevano pri odstranjevanju materialov z ostrimi ali nazobčanimi robovi

- Ugašalniki s CO2 ali suho prahom: Morajo biti hitro dostopni, jeklenke pa ne smejo presegati 5 lbs (2,3 kg) za hitro reakcijo

- Poseben izpuh ali sistemi za čiščenje zraka: Zahtevani za zajemanje zrakom prenašanih onesnaževal, ki jih ustvarja laser, vključno s težkimi kovinami, benzenom, formaldehidom in drugimi nevarnimi emisijami

Prezračevanju je treba nameniti posebno pozornost. Ko laserski žarek zadene kovino, nastanejo nevarne delce, vključno s hlapi težkih kovin, ki predstavljajo resno tveganje za dihalni sistem. V vašem delovnem prostoru mora biti zagotovljenih vsaj 15 zamenjav zraka na uro, prezračevalni sistemi pa morajo biti vklopljeni že pred začetkom rezanja.

Korak po korak varnostni postopki pred zagonom

Uvedba doslednih protokolov pred zagonom preprečuje nesreče in zagotavlja skladnost z regulativami. Sledite temu zaporedju pred vsako sejo rezanja:

- Izvedite preverjanje pred vročim delom, da potrdite, da je laserski rezalnik v zadovoljivem obratovalnem stanju in dobro vzdrževan

- Prepričajte se, da so površine neposredno ob rezilu proste gorljivih snovi ali da so gorljive snovi ustrezno zaščitene

- Preglejte tla in površine okoli in znotraj laserskega rezalnika glede čistosti – prah in odpadki povzročajo požarne nevarnosti

- Preverite, ali so nadzorne naprave za prezračevanje vklopljene in delujejo pravilno

- Preverite, ali je funkcija pomožnega zraka delujoča

- Prepričajte se, da so ugasnilni aparati s CO2 na voljo in v dobrem stanju

- Samodejno nastavite fokus laserja pred začetkom rezanja

- Poskrbite, da boste med obratovanjem ostali pri napravi – nikoli ne puščajte delujočega lasera brez nadzora

Varnostne težave pri pomožnih plinih

Pomožni plini, kot so kisik, dušik in stisnjen zrak, dodajajo dodatne nevarnosti, za katere so potrebni posebni postopki ravnanja. Kisik močno pospeši gorenje in tako poveča požarno nevarnost med rezanjem. Dušik, čeprav inerten, lahko izpodrine kisik v zaprtih prostorih ter povzroči nevarnost zadušitve. Sistemi stisnjenega zraka predstavljajo nevarnosti, povezane s tlakom, če jih ni primerno vzdrževano.

Vedno preverite priklop plina pred zagonom, zagotovite ustrezno prezračevanje pri uporabi inertnih plinov in sledite navodilom proizvajalca za nastavitve tlaka. Jeklenke s plinom shranjujte varno, stran od virov toplote, in nikoli ne poskušajte popravljati sistemov z visokim tlakom brez ustrezne usposobljenosti.

Ko pride do požarov – v okoljih laserskega rezkanja se majhni požari občasno zgodijo – takoj uporabite izklop v sili, med umikanjem imite izhod za hrbtom ter uporabite CO2 gašenje, pri čemer ciljate na osnovo plamena in gibljete sem in tja. Pri požarjih, večjih od tipičnega gospodinjskega koša za smeti, se nemudoma umaknite in sprožite požarno alarmno napravo.

Ustvarjanje kulture varnosti okoli vaše naprave za lasersko rezkanje kovin ščiti tako vašo ekipo kot vašo naložbo. Ko so uveljavljene ustrezne postopke, se fokus premakne s upravljanja tveganj na optimizacijo kakovosti reza – kar nas privede do diagnosticiranja in odpravljanja pogostih napak pri rezkanju.

Odpravljanje pogostih napak pri laserskem rezanju in težav s kakovostjo

Varnostni protokoli so v redu in laser deluje – a kaj, če rezi niso pravi? Tudi izkušeni operaterji naletijo na frustrirajoče napake, ki ogrozijo kakovost del in povzročijo izgubo dragocenega materiala. Pri laserskem rezanju kovin je razlika med brezhibnim robom in zavrnjenim delom pogosto odvisna od tega, kako hitro prepoznamo vzrok napake in jo odpravimo.

Dobra novica? Večina napak pri laserskem rezanju se pojavi po predvidljivih vzorcih in ima prepoznavne vzroke. Ne da bi šlo za odstranjevanje drobovja, grobe robove ali upognjene dele – sistematična diagnoza vodi do zanesljivih rešitev. Razvozlajmo najpogostejše težave s kakovostjo in ponovno pripeljimo vaš postopek laserskega rezanja kovin na pravo pot.

Diagnosticiranje pogostih težav z kakovostjo roba

Ko kovino rezate z laserjem, kakovost roba pove celotno zgodbo. Napake, vidne vzdolž reznega roba, neposredno kažejo na napačne parametre ali težave s opremo. Tukaj je, kaj morate išči, in kaj vsaka napaka razkrije o vašem postopku:

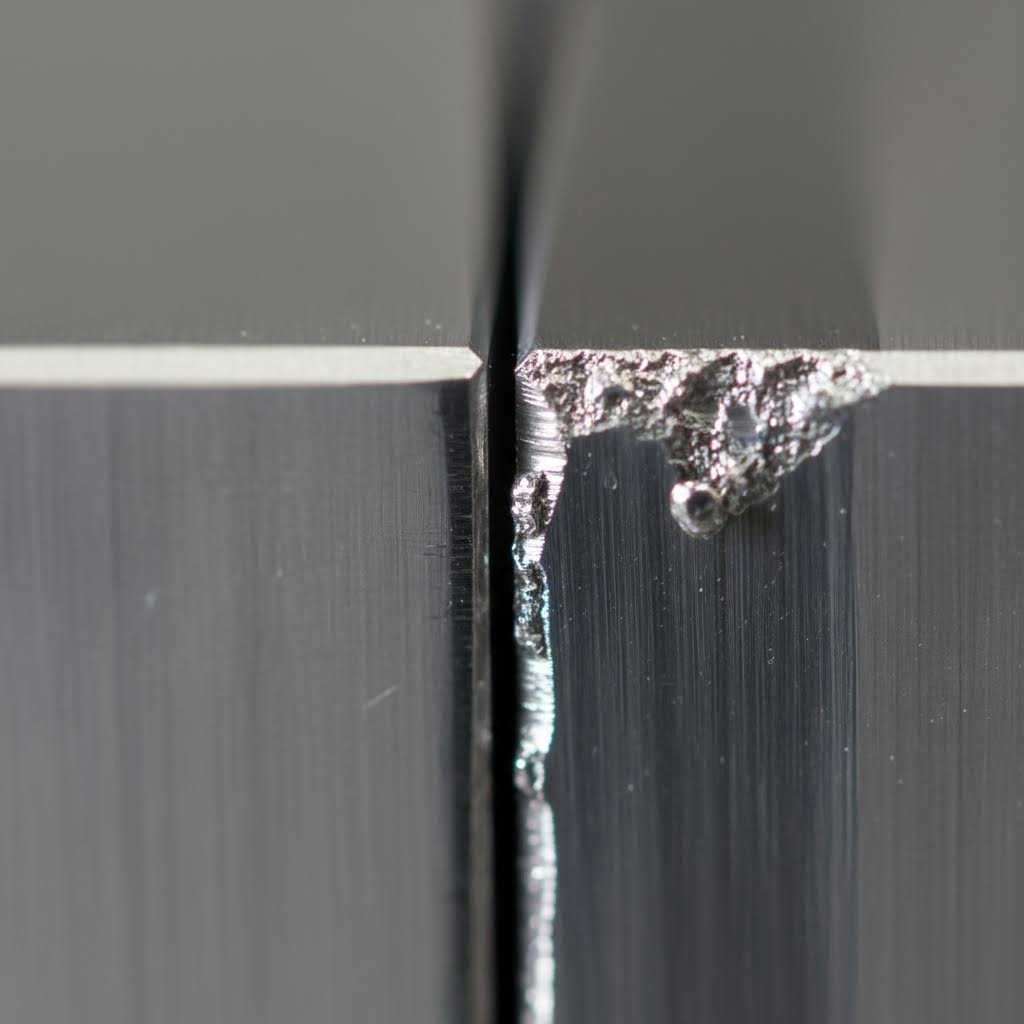

Oblikovanje drosove in šlak se pojavlja kot raztaljen material, ki se strdi na spodnji površini dela. Ta trdovratni ostanki zahtevajo dodatno obdelavo za odstranitev, kar poveča čas in stroške za vsak del. Krivec? Ponavadi hitrost rezanja, ki je previsoka ali prenizka za nastavitve moči, ali nedostaten tlak pomožnega plina, ki ne izpiha raztaljenega materiala iz reza.

Prekomerno nastajanje žlebov ustvarja grube, izbočene robove, ki poslabšajo tako videz kot funkcionalnost. Glede na Analizo kontrole kakovosti Halden CN , žlebkari nastanejo ponavadi, kadar je hitrost rezanja prenizka ali moč lasera previsoka. Ta neravnovesje povzroči prekomerno segrevanje in preprečuje čisto ločitev materiala.

Grubi ali strijasti robovi prikaže vidne črte, ki tečejo navpično vzdolž reza. Te striacije kažejo na neenakomerno dostavo energije—pogosto posledica napačnega položaja fokusa, nestabilnega toka plina ali laserskega žarka, ki je izgubil optimalno kakovost zaradi onesnaženih optičnih elementov.

Nepopolni rezi pustijo material delno pritrjenega ali zahtevajo večkratno rezkanje. To frustrirajočo napako povzroča premajhna moč za debelino materiala, prevelika hitrost rezkanja ali fokus, ki je postavljen preveč stran od optimalne točke.

Prevelike cone toplotnega vpliva (HAZ) se pojavijo kot sprememba barve ali metalurške spremembe, ki segajo zunaj roba reza. Obsežne cone HAZ kažejo na prevelik toplotni vhod—običajno posledica počasne hitrosti rezkanja ali previsokih nastavitev moči, ki omogočajo prevajanje toplote v okolišnji material.

Ukrivljanje in popačenje vpliva na skupno geometrijo dela, zlasti pri tankih materialih ali velikih ploščah. Toplotni napetosti iz postopka rezkanja povzročijo upogibanje ali zasukanje materiala, kar pogosto nepopravljivo poškoduje obdelovanec.

Popoln referenčni priročnik za odpravljanje napak

Uporabite to podrobno razpredelnico, da hitro prepoznate in odpravite pogoste napake pri laserju rezkanju pločevine:

| Vrsta napake | Verjetni vzroki | Popravni ukrepi |

|---|---|---|

| Oblikovanje drose/šlak | Hitrost rezanja prehitra ali premajhna; nezadostni tlak asistentnega plina; napačna razdalja šobe do površine | Optimirajte hitrost rezanja glede na debelino materiala; povečajte tlak plina (običajno 10–15 barov za dušik); zmanjšajte razdaljo do manj kot 1 mm; preverite šobo za poškodbe |

| Prekomerno nastajanje žlebov | Hitrost prepočasna; moč previsoka; napačna fokusna točka; onesnažena površina materiala | Povečajte hitrost rezanja; zmanjšajte lasersko moč; preverite, če je fokus v središču materiala; očistite material pred rezanjem |

| Hrapovi/nivojni robovi | Napačna fokusna lega; umazana optika; nestabilen tok plina; obrabljena šoba | Ponovno umerite višino fokusa; očistite leče in zaščitna stekla; stabilizirajte oskrbo z plinom; zamenjajte obrabljene šobe |

| Nepopolni rezi | Nezadostna moč; prevelika hitrost; fokus previsok ali prenizek; šibek laserski vir | Povečajte moč ali zmanjšajte hitrost; prilagodite fokus na središče materiala; preverite izhod laserskega vira |

| Prevelika cona toplotnega vpliva (HAZ) | Hitrost prepočasna; moč prevelika; nezadostno hladjenje z plinom | Povečajte hitrost rezanja; zmanjšajte moč; preklopite na dušik kot pomožni plin za reaktivne materiale |

| Zvijanje/deformacija | Prevelik toplotni vnos; nepravilno zaporedje rezanja; neustrezno vpenjanje | Optimirajte ravnovesje med hitrostjo in močjo; programirajte izmenične poti reza za enakomeren razpored toplote; uporabite ustrezno opremo za vpenjanje |

| Opekline | Moč prevelika; hitrost prepočasna; napačna vrsta pomožnega plina | Zmanjšajte moč; povečajte hitrost; uporabite dušik namesto kisika za čistejše reze |

Prilagoditve parametrov za optimalne rezultate

Razumevanje medsebojnega vpliva rezalnih parametrov spremeni odpravljanje težav iz ugibanja v sistematično reševanje problemov. Štirje glavni parametri nadzorujejo kakovost reza – in njihova pravilna nastavitev naredi vso razliko pri delovanju laserskega stroja za rezanje kovin.

Hitrost rezanja določa, kako dolgo laser ostaja na določeni točki. Glede na Vodnik Accurl za optimizacijo parametrov , prevelika hitrost povzroči nepopolne reze, prepočasna pa opekline in prevelike cone toplotnega vpliva. Pri tankem nerjavnem jeklu se tipične hitrosti gibljejo med 3.000 in 6.000 mm/min, odvisno od moči.

Nastavitve moči morajo ustrezati debelini in vrsti materiala. Splošno pravilo: začnite z najmanjšo močjo, potrebno za prediranje, nato pa jo dodatno prilagajajte glede na kakovost roba. Upoštevajte, da 1 kW vlaknasti laser učinkovito reže do 5 mm nerjavnega jekla, medtem ko 3 kW razširita zmogljivost do približno 12 mm.

Fokusna pozicija močno vpliva na koncentracijo žarka na površini materiala. Za optimalno rezkanje mora biti žarišče poravnano s središčem debeline materiala. Tanjši materiali imajo koristi od krajših goriščnih razdalj, medtem ko debelejši materiali zahtevajo daljše goriščne razdalje za ohranjanje kakovosti reza skozi celotno globino.

Pomožni plinski tlak opravlja več funkcij: iztiskanje taljenega materiala, zaščita območja reza in hlajenje robov. Višji tlaki (12–20 bar) delujejo bolje pri debelejših materialih in rezkanju z dušikom, medtem ko nižji tlaki (0,5–5 bar) ustrezajo rezkanju mehkega jekla z dodatkom kisika.

Prepoznavanje trenutka, ko je treba menjati porabne dele

Tudi če so nastavitve parametrov popolne, obrabljeni porabni deli poslabšajo kakovost reza. Bodite pozorni na te opozorilne znake:

- Staranje šobe: Vidna poškodba, asimetrični vzorci pretoka plina ali nakopičenje drosov okoli odprtine kažejo, da je čas za zamenjavo

- Zamazan objektiv: Zmanjšana moč rezanja, neustaljeno fokusiranje ali vidne pike na površini objektiva zahtevajo takojšnje čiščenje ali zamenjavo

- Zaščitna okna: Oblak in ožig na zaščitnih steklih vplivata na prenos žarka – pregledujte vsak dan

Pri natančnostnih aplikacijah pričakujte tolerance med ±0,05 mm do ±0,25 mm, odvisno od materiala in zmogljivosti stroja. Če vaši deli kljub optimizaciji parametrov sistematično izstopajo iz specifikacije, je obraba porabnega materiala pogosto skrit vzrok.

Obvladovanje diagnostike napak omogoča učinkovito delovanje vaše dejavnosti – razumevanje dejanskih stroškov, ki so skriti za laserskim rezanjem, pa vam pomaga sprejeti bolj pametne odločitve glede investicij v opremo in proizvodno strategijo.

Analiza stroškov in upoštevanje donosa pri laserskem rezanju

Ali ste že kdaj pogledali račun svojega dobavitelja za lasersko rezkanje in se vprašali, ali v bistvu plačujete za opremo nekoga drugega? Niste sami. Ali že preučujete nakup laserskega rezalnika za kovine ali pa premislekate o izbiri izdelave izven podjetja, razumevanje dejanske strukture stroškov za operacijami laserskega rezkanja omogoča pametnejše finančne odločitve. Številke vas bodo morda presenetile – in zagotovo vplivajo na to, ali je za vašo dejavnost smiselno pridobiti lastne zmogljivosti rezkanja.

Gospodarstvo laserskega rezkanja sega daleč prek cene samih naprav za lasersko rezkanje kovin. Od porabe električne energije do stroškov pomožnih plinov, zamenjave porabnega materiala in porabe dela – vsak sestavni del prispeva k strošku posamezne komponente. Poglejmo si natančno, kaj gonilo te stroške in kako izračunati smiselno donosnost investicije za vašo specifično situacijo.

Razčlenitev sestavin obratovalnih stroškov

Pri ocenjevanju naložbe v stroj za lasersko rezkanje lima predstavlja kapitalski odhodek le začetno točko. Glede na Podrobno analizo stroškov podjetja SendCutSend , industrijski vlaknasti laserji stanejo od 250.000 $ za manjše sisteme z nižjo močjo (1–3 kW) do več kot 2 milijona $ za visokomočne sisteme, ki lahko z avtomatiziranimi funkcijami režejo jeklo debelo en palec.

A kaj se zgodi po tem, ko podpišete naročilo? Nadaljnji obratovalni stroški določajo, ali se bo ta naložba izplačala:

Stroški električne energije predstavljajo pomembno prednost sodobnih vlaknastih tehnologij. Sistem z močjo 3 kW porabi za električno energijo približno 1,50–2,50 $ na uro – kar je znatno manj kot pri starejših sistemih CO2. Po podatkih razdelitve stroškov podjetja Arcus CNC skupni stroški obratovanja stroja (elektrika, plin, delovna sila) znašajo povprečno okoli 30 $/uro za standardne vlaknaste sisteme.

Poraba pomožnega plina se zelo razlikuje glede na pristop k rezkanju. Rezanje z dušikom za čiste, oksidno proste robove na nerjavnem jeklu stane od 2 do 15 dolarjev na uro, odvisno od debeline in pretoka. Rezanje s pomočjo kisika za ogljično jeklo je cenejše, vendar ustvarja oksidne plasti, ki zahtevajo dodatno obdelavo. Stisnjen zrak ponuja najbolj ekonomično možnost za primerna uporabna področja.

Zamenjava porabnih delov doda približno 1 dolar na uro obratovalnim stroškom. To vključuje šobe, zaščitne leče in glave za rezkanje, ki se s časom obrabijo. Vzdrževanje industrijskih laserjev za kovanje kovin zahteva redne preglede – zgodnje odkrivanje obrabljenih komponent prepreči dragocene težave s kakovostjo in nepričakovane izpade.

Zahteve glede dela so odvisni predvsem od stopnje avtomatizacije in proizvodnega obsega. En sam operater lahko upravlja manjše CO2 sisteme, medtem ko visoko zmogljivi vlaknasti laserji, ki delujejo 24/7, idealno zahtevajo ekipi po 2–3 delavce na turnus – operater, manipulator materiala in manipulator delov – za ohranjanje optimalne zmogljivosti.

Dejavniki, ki vplivajo na stroške na kos

Razumevanje dejavnikov, ki vplivajo na vaše stroške na kos, pomaga optimizirati odločitve glede cen in proizvodnje. Naslednje spremenljivke povečujejo ali zmanjšujejo stroške laserskega rezkanja:

Dejavniki, ki povečujejo stroške:

- Debelejši materiali, ki zahtevajo počasnejše hitrosti rezkanja in več moči

- Refleksivni kovini (bakar, mesing), ki zahtevata višjo raven moči

- Kompleksne geometrije z mnogimi spremembami smeri in točkami prebadanja

- Tehnične tolerance, ki zahtevajo počasnejše hitrosti in natančno nastavitev parametrov

- Majhne serije, ki ne omogočajo učinkovitega amortiziranja pripravljalnega časa

- Premium pomožni plini, kot je dušik visoke čistote za rob brez oksidov

Dejavniki, ki zmanjšujejo stroške:

- Proizvodnja velikih količin, ki razdeli fiksne stroške na več delov

- Učinkovito postavljanje delov za maksimalno izkoriščanje pločevine (zmanjšanje odpadkov materiala za 10–50 %)

- Standardna mehka jekla z odličnimi lastnostmi dušenja udarcev

- Nabava materialov v večjih količinah s popusti zaradi količine

- Avtomatizirano nalaganje/razlaganje zmanjša potrebo po ročnem delu

- delovanje 24/7 za maksimalno izkoriščenost opreme

Razmislek o investicijah glede na različne obsege proizvodnje

Kdaj se investicija v rezanje v lastni režiji res splača? Računica je ugodnejša, kot si mnogi proizvajalci predstavljajo. Upoštevajte ta primer iz vsakodnevne prakse Analize 'izdelaj ali kupi' podjetja Arcus CNC :

Proizvajalec, ki obdeluje 2.000 jeklenih plošč mesečno po 6 dolarjev na kos pri zunanjem dobavitelju, letno porabi 144.000 dolarjev. Če to opravilo prenese v lastno režijo z laserskim sistemom za 50.000 dolarjev, se letni stroški zmanjšajo na približno 54.000 dolarjev – kar pomeni letni prihranek 89.880 dolarjev. Obdobje povračila vlaganja? Le 6,7 meseca.

Vendar velikost obsega značilno vpliva. Če porabite manj kot 1500–2000 USD mesečno za izvajanje laserskega rezkanja pri tretji osebi, se čas povračila investicije znatno podaljša. Optimalna točka za naložbo v opremo se navadno začne, ko stroški izvajanja pri tretji osebi presegajo 20.000 USD letno – v tem primeru dejansko plačujete za stroj, ki ga ne lastite.

Pri ocenjevanju cene CNC laserskega rezalnika glede na stroške izvajanja pri tretji osebi upoštevajte naslednje dejavnike odločanja:

- Zahteve po prostoru: Standardni zaprti stroji velikosti 5x10 ft potrebujejo približno 25x15 čevljev, vključno s prostorom za vzdrževanje

- Shranjevanje materialov: Velike plošče (4x10' ali 5x12') zahtevajo vilice, dvigala in pomembno talno površino

- Dovoljenja in skladnost: Dovoljenja EPA, OSHA in požarnega inšpektorja dodatno zapleteta notranje delovanje

- Možnosti financiranja: Najem opreme pogosto omogoči nižje mesečne obroke kot prejšnje račune za izvajanje pri tretji osebi

Odločitev za lasersko rezalno napravo za pločevino končno uravnava nadzor in zapletenost. Lastne zmogljivosti omogočajo hitrejši odziv, popoln nadzor kakovosti in zaščito lastnih dizajnov. Outsourcing odpravi kapitalska tveganja, težave z vzdrževanjem in upravljanje s kadri – hkrati pa omogoča dostop do opreme višje kakovosti, kot bi si jo lahko privoščili sami.

Številna uspešna podjetja uporabljajo hibridni pristop: nakup srednje razrednih sistemov za 90 % vsakodnevnih opravil, medtem ko izvajajo specializirane naloge prek outsourcinga, ki zahtevajo ultra-visoko moč ali eksotične materiale. Ta strategija zagotovi varčevanje pri redni proizvodnji, ne da bi se preveč vlagali v opremo za občasne potrebe.

Ko so stroškovne strukture pojasnjene, razumevanje tega, kako lasersko rezanje ustvarja dodano vrednost v določenih panogah, razkrije, kje ta tehnologija omogoča največje konkurenčne prednosti.

Uporaba v panogah od avtomobilske do letalske

Kje se lasersko rezanje kovin resnično izkazuje? Stopite na katero koli sodobno proizvodno linijo avtomobilov ali obrat za proizvodnjo letalskih naprav, in odgovor boste videli povsod. Od strukturnih okvirskih komponent do zapletenih letalskih spojnikov omogoča tehnologija laserskega rezanja kovin kompleksne geometrije in tesne tolerance, ki gonijo inovacije v najzahtevnejših panogah. Razumevanje teh uporab razkriva, zakaj se je lasersko rezanje postalo temelj natančne proizvodnje.

Univerzalnost opreme za lasersko rezanje kovin sega daleč prek preprostega obdelovanja pločevine. Ko preučimo, kako vodilni proizvajalci izkoriščajo to tehnologijo, se pojavi jasen vzorec: panoge, ki zahtevajo dosledno kakovost, kompleksne oblike in merljivo proizvodnjo, se zanašajo na lasersko rezanje kot osnovni postopek izdelave.

Proizvodnja avtomobilskih komponent v velikem obsegu

Zamislite si izziv proizvodnje milijonov identičnih komponent, ki se morajo popolnoma ujemati – vsakokrat. To je realnost, s katero se soočajo proizvajalci avtomobilov, in rezanje kovinskih delov z laserjem zagotavlja ravno tako doslednost, kot jo ta industrija zahteva. Glede na Analizo industrije OMTech so stroji za rezanje s fibernim laserjem revolucionirali izdelavo vozil ter omogočili natančnost in učinkovitost, s katerima tradicionalne metode preprosto ne morejo tekmovati.

Vsako vozilo se začne z nizom kovinskih pločevin, ki jih je treba oblikovati v karoserijske plošče, okvirje in strukturne komponente. Oprema za lasersko rezanje pločevine zagotavlja popolno ujemanje teh delov in hkrati ohranja strukturno celovitost skozi milijone ciklov proizvodnje. Uporabe segajo skoraj po vseh sistemih vozila:

- Karoserijske plošče in okvirji: Natančno izrezani okrepitevni elementi, nosilci in prirobnice za pritrditev, ki določajo strukturo vozila

- Sestavi podvozja: Prečni nosilci, nosilci za obešenje in ohišja baterij za klasična in električna vozila

- Notranje komponente: Elementi armaturne plošče, okrasni deli in zapletene podrobnosti, ki zahtevajo doslednost pri serijski proizvodnji

- Del motorja in pogonskega sistema: Sestavni deli, izdelani v točno določenih specifikacijah za optimalno učinkovitost in dolgo življenjsko dobo

- Ohišja elektronskih sistemov: Majhni sestavni deli za varnostne sisteme, informacijsko-razbavalne sisteme in vedno bolj zapleteno elektroniko vozil

- Posebni in dodatni deli: Dekorativni elementi in komponente za izboljšanje zmogljivosti za personalizacijo

Zahtevni standardi kakovosti v avtomobilski industriji – še posebej standardi certifikacije IATF 16949 – naredijo natančno proizvodnjo bistveno. Tu integrirani pristopi k proizvodnji ponujajo pomembne prednosti. Podjetja kot so Shaoyi (Ningbo) Metal Technology pokazati, kako kombinacija laserskega rezanja s pomožnimi postopki, kot je kovanje kovin, ustvarja brezšivne rešitve za avtomobilske dobavne verige. Operacije, certificirane po IATF 16949, hitro izdelavo prototipov v petih dneh in celovita podpora pri DFM-ju so primer integriranega pristopa, ki ga vedno bolj zahtevajo dobavitelji prve ravni v avtomobilski industriji.

Proizvodni roki v avtomobilski industriji so znani po tem, da so zelo tesni. Stroj za CNC lasersko rezanje za obdelavo jekla bistveno skrajša čas do trženja v primerjavi s tradicionalnimi metodami, hkrati pa ohranja doslednost, potrebno pri stotine tisoč vozilih. Še posebej pri proizvodnji električnih vozil tehnologija vlaknastega lasera izdeluje komponente, ki ohranjajo trdnost, hkrati pa dosegajo zmanjšanje mase, kar je ključno za učinkovitost baterij.

Aerospace Applications Demanding Zero Defects

Ko je odvisno življenje od brezhibnega delovanja vsakega sestavnega dela, proizvajalci v letalski industriji ne sprejmejo nič manj kot popolnosti. Laserjska obdelava pločevine s sekanjem s sekanjem zadosti tem zahtevnim standardom tako, da zagotavlja robove brez grudic, natančne položaje lukenj in dimenzijsko točnost, ki ustreza strogi sledljivosti in certifikacijskim zahtevam industrije.

Uporaba laserjskega rezanja kovinskih delov v letalski industriji presega meje možnega:

- Aluminijasti strukturni elementi: Okvirji trupa in rebra kril z natančnimi vzorci lukenj za namestitev zakovic

- Delov iz titanove zlitine: Obdelani s kontrolirano kakovostjo robov, da se prepreči nastanek razpok pod cikličnim obremenjevanjem

- Ohišča senzorjev: Minutno izdelani sestavni deli za sisteme avtonomnega letenja, ki zahtevajo ekstremno natančnost

- Prototipi motoričnih komponent: Hitra iteracija brez investicij v orodja med razvojnimi fazami

- Notranjna oprema: Lahke plošče in strukturne podpore, optimizirane za aplikacije, kjer je pomemben manjši teža

Zahteva za nič defektov sega dlje od dimenzijske natančnosti. Glede na THACO Industries morajo proizvajalci v letalski industriji ohranjati certifikat AS9100 ter razumeti zahteve glede sledljivosti materialov, ki urejajo vsak korak proizvodnje. To sektorju lastno znanje ločuje kvalificirane dobavitelje od tistih, ki imajo le lasersko opremo.

Natančna proizvodnja v različnih panogah

Poleg avtomobilske in letalske industrije lasersko rezanje omogoča izjemno dodano vrednost povsod, kjer je pomembna natančnost. Proizvajalci elektronike uporabljajo ohišja, izrezana s laserjem, s točnimi režami za prezračevanje in izrezi za komponente. Arhitekturni izdelovalci ustvarjajo parametrične vzorce na fasadnih ploščah, ki uravnavajo toploto sončnega sevanja in hkrati ustvarjajo dinamične vizualne učinke. Proizvajalci industrijske opreme izdelujejo zobnike, nosilce in ohišja, ki izpolnjujejo stroge obratovalne in kakovostne zahteve.

Skupna nit? Vsaka uporaba izkorišča osnovne prednosti laserskega rezanja: tesne tolerance (±0,05 mm, dosegljive z modernimi sistemi), odlično kakovost robov, ki zahtevajo minimalno sekundarno obdelavo, ter prilagodljivost za obravnavanje prototipnih serij in serijsko proizvodnjo brez izgube natančnosti.

Za proizvajalce, ki ocenjujejo možnosti izdelave, vprašanje ni, ali se lasersko rezanje uporablja v njihovi panogi – gre za to, kako najučinkoviteje dostopati do teh zmogljivosti. Ne da bi investirali v lastno opremo ali sodelovali s specializiranimi proizvajalci, naslednji korak pomeni uskladitev izbire tehnologije s specifičnimi zahtevami proizvodnje in poslovnimi cilji.

Izbira prave rešitve za lasersko rezanje za vaše potrebe

Preučili ste tehnologijo, razumeli stroške in videli uporabe – zdaj je na vrsti odločitev, ki oblikuje vašo proizvodno prihodnost. Izbira pravega laserskega rezalnika za jeklo in druge kovine ni univerzalna rešitev. Vaša proizvodna količina, zahteve glede materiala, natančnost in omejitve proračuna vplivajo na to, ali je najbolj strateško smiselno kupiti opremo, jo najemati ali sodelovati s specializiranimi proizvajalci.

Naprej vodil pot je poštena ocena vaših trenutnih potreb in realistične napovedi rasti. Naložba v laserski rezalnik za kovine, ki popolnoma ustrezajo visokokolutni proizvodnji, bi lahko oslabila delovanje prototipsko usmerjene dejavnosti zaradi previsokih stroškov. Poglejmo si postopek ocenjevanja, ki vodi do samozavestnih in donosnih odločitev.

Prilagoditev tehnologije vaši proizvodni količini

Proizvodna količina temeljito določa vaš optimalni pristop. Ekonomski pogoji za delovanje laserskega rezalnega stroja za pločevino, ki obratuje 24/7, so popolnoma drugačni kot pri delavnici, ki obdeluje občasne naročila. Tako vpliva količina na vašo odločitev:

Nizka količina (manj kot 20.000 USD letnih stroškov rezanja): Outsourcing skoraj vedno zmaguje. Kapitalske naložbe, stroški vzdrževanja in obratovalna zapletenost preprosto ne morejo biti upravičeni. Sodelujte z uveljavljenimi izdelovalci, ki opremo in strokovnjake že imajo.

Srednja količina (20.000–75.000 USD letno): Tu postane odločitev zanimiva. Če se vaše delo osredotoča na določene vrste materialov in debeline, lahko osnovni sistemi vlaknastih laserjev (1–3 kW) ponudijo privlačne obdobja povračila. Vendar je treba pozorno razmisliti o skritih stroških, kot so usposabljanje, vzdrževanje in alokacija prostora.

Visoka količina (več kot 75.000 USD letno): Oprema za rezkanje lima z lastnim laserskim rezalnikom ponuja običajno zelo dober donos investicij. V tem merilu dejansko plačujete za stroje, ki jih ne lastite, prek tretjiških provizij. Sistemi srednjega do visokega močnostnega razreda (6 kW in več) se sami upravičijo prek operativnih prihrankov in nadzora nad proizvodnjo.

Upoštevajte, da napovedi volumna morajo vključevati pričakovani rast. Nakup sistema, ki komaj zadostuje trenutnim potrebam, ne pusti prostora za razvoj – medtem ko prevelik vlaganji v zmogljivost, ki je morda nikoli ne boste uporabili, vezeta kapital, ki bi lahko spodbudil rast na drugih področjih.

Ključna vprašanja pred vlaganjem v lasersko rezkanje

Preden se odločite za nakup ali sodelovanje pri nakupu laserskega rezalnika za jeklo, izvedite ta sistematični postopek ocenjevanja:

- Natančno določite svoje zahteve glede materiala. Naštejte vsako vrsto kovine in debelino, ki jo boste obdelovali. Stroj, ki lepo reže mehko jeklo debelo 6 mm, se lahko sooča s težavami pri aluminiju debelim 3 mm ali nerjavljivem jeklu debelim 4 mm. Prilagodite zmogljivosti opreme dejanski mešanici materialov – ne zgolj najpogostejšim aplikacijam.

- Določite zahtevane tolerance. Ali izdelujete dekorativne komponente, kjer je odstopanje ±0,5 mm povsem primerno, ali natančne dele, ki zahtevajo odstopanje ±0,05 mm? Ožje tolerance ponavadi zahtevajo naprednejšo opremo, veščega osebja in stroge sisteme kontrole kakovosti.

- Izračunajte dejansko razpoložljivost prostora. Laser, ki reže kovino, potrebuje več prostora, kot bi nakazala samo njegova površina. Vključite območja za predelovanje materiala, skladiščenje končanih delov, dostop za vzdrževanje in prezračevalno opremo. Večina naprav velikosti 5x10 čevljev potrebuje 400–500 kvadratnih čevljev namenskega prostora.

- Ocenite svoje tehnične sposobnosti na pošten način. Ali imate zaposlene, ki znajo upravljati, odpravljati težave in vzdrževati lasersko opremo? Usposabljanje stane 2.000–5.000 USD na operaterja, učna krivulja pa vpliva na produktivnost več mesecev.

- Ocenite potrebo po prilagodljivosti dobavnega veriga. Ali se lahko zavezete k določenim materialom in debelinam, ali vaša dela zahtevajo obdelavo vseh materialov, ki jih stranke zahtevajo? Velika raznolikost spodbuja sodelovanje z zunanjimi partnerji, ki imajo raznolike zmogljivosti.

- Projicirajte svojo petletno pot. Kje bodo vaše proizvodne potrebe leta 2030? Oprema, ki jo kupujete danes, bi morala podpirati vašo rast, ne le trenutne zahteve.

Ko sodelovanje premaga nakup

Včasih je najpametnejša naložba tista, da sploh ne naložite v opremo. Strategični proizvodni partnerstvi omogočata pridobitev zmogljivosti brez kapitalskega tveganja – še posebej pomembno, kadar so pomembne certifikacije kakovosti.

Razmislite o avtomobilski panogi, kjer predstavlja certifikat IATF 16949 osnovni pogoj za uvrstitev dobavitelja. Doseganje in vzdrževanje tega certifikata zahteva znatne naložbe v sisteme kakovosti, dokumentacijo in procese stalnega izboljševanja. Za proizvajalce, ki vstopajo v avtomobilske dobavne verige ali razširjajo ponudbo točnih kovinskih komponent, sodelovanje z že certificiranimi obrati pospeši dostop do trga in odpravi breme certifikacije.

Shaoyi (Ningbo) Metal Technology to prikazuje model strategske partnerstva. Njihove dejavnosti, certificirane po standardu IATF 16949, skupaj s hitrim obratom ponudbe v 12 urah in celovito podporo pri oblikovanju za proizvodnjo (DFM), omogočajo proizvajalcem avtomobilov dostop do izdelave natančnih kovinskih komponent brez investicije v opremo. Ko vaša jedrnska usposobljenost leži drugje—morda pri sestavljanju, načrtovanju ali integraciji končnega izdelka—je izkoriščanje specializiranih proizvodnih partnerjev za natančne rezalne in žigosne operacije pogosto bolj učinkovito in s nižjimi skupnimi stroški.

Odločitev za izvedbo iz outsourcinga zlasti ugoduje naslednjim scenarijem:

- Prototipi in nizka serija, kjer so stroški nastavitve odločilni za gospodarnost na kos

- Specializirani materiali, ki zahtevajo konfiguracijo opreme, ki bi jo redko uporabljali

- Zahteve za certifikacijo kakovosti, ki presegajo vaše trenutne zmogljivosti

- Potrebe po hitrem prototipiranju, ki zahtevajo hitrejši obrat kot ga dovoljujejo krivulje učenja v lastni proizvodnji

- Preobremenitev zmogljivosti med piki povpraševanja brez trajne investicije v opremo

Prihodnost tehnologije laserskega rezkanja

V prihodnje bodo nekateri novi trendi preoblikovali zmogljivosti in ekonomiko laserskega rezkanja. Glede na Analizo trendov The Sol Machine za leto 2025 , se pričakuje, da bo trg tehnologije laserjev do leta 2032 dosegel 37,26 milijarde USD, kar bo poganjalo stalno inovacijo učinkovitosti in zmogljivosti.

Integracija avtomatizacije predstavlja najpomembnejšo spremembo v bližnjem času. Moderni sistemi vse pogosteje vključujejo AI-poganjeno optimizacijo parametrov, spremljanje kakovosti v realnem času ter avtomatizirano rokovanje z materiali, kar zmanjšuje potrebo po delovni sili in izboljšuje doslednost. Za operacije z visoko proizvodnjo te funkcije spremenijo ekonomiko lastnega rezkanja tako, da maksimalizirajo izkoriščenost opreme.

Razmišljanje o trajnostnosti prav tako ponovno oblikuje odločitve glede opreme. Energetska učinkovitost tehnologije vlaknastih laserjev – ki porabi približno tretjino energije v primerjavi s podobnimi sistemi CO2 – ustrezajo tako ciljem zmanjšanja stroškov kot tudi okoljske odgovornosti. Ko se stroški energije povečujejo in se zahteve za poročanje o emisijah ogljikovega dioksida širijo, postaja ta prednost učinkovitosti vedno bolj privlačna.

Prav tako dobivajo na popularnosti hibridni proizvodni pristopi. Večfunkcijski sistemi, ki združujejo lasersko rezkanje s 3D tiskanjem ali drugimi procesi, zmanjšujejo prostorske potrebe po opremi in hkrati razširjujejo zmogljivosti. Za podjetja majhne in srednje velikosti ponujajo ti vsestranski stroji več procesnih zmogljivosti brez sorazmernega naloženega kapitala.

Katero koli pot izberete – nakup laserskega rezalnega stroja za kovine za lastno proizvodnjo, najem opreme za ohranitev kapitala ali sodelovanje s specializiranimi proizvajalci – se mora odločitev uskladiti z vašo osnovno poslovno strategijo. Tehnologija napreduje, stroški padajo in zmogljivosti se širijo. Postavite svojo dejavnost tako, da boste lahko izkoriščali te trende, namesto da bi jim jih gonili, in postane laserjko rezanje konkurenčna prednost, ne pa breme v obliki kapitalskih vlaganj.

Pogosta vprašanja o laserskem rezanju kovin

1. Koliko stane lasersko rezanje kovin?

Laserjevanje kovin običajno stane 13–20 dolarjev na uro za obdelavo jekla. Stroški na kos so odvisni od vrste materiala, debeline, zapletenosti in količine. Dejavniki, kot so izbira pomožnega plina (dušik ali kisik), hitrost rezkanja in zahtevi glede tolerance, znatno vplivajo na ceno. Pri seriji velike količine se fiksni stroški porazdelijo na večje število kosov, kar zmanjša strošek na enoto. Pri izvedenih delih pričakujte ponudbe, ki temeljijo na rezu v palcih na minuto – projekt, ki zahteva 15.000 palcev rezanja s hitrostjo 70 palcev na minuto, predstavlja približno 3,5 ure dejanskega časa rezanja.

katera kovina je najbolj primerna za laserjevanje?

Nerjavno jeklo je najpogosteje izbirano zaradi odlične absorpcije, odpornosti proti koroziji ter čistega reza z minimalnim nastankom žlebencev. Nizkoogljično in ogljično jeklo prav tako odlično obdelujeta, še posebej z vlaknastimi laserji. Aluminij se učinkovito reže, vendar zahteva višjo moč zaradi toplotne prevodnosti. Zrcalni kovini, kot sta baker in mesing, predstavljata izziv in zahtevata močne vlaknaste lasere (3 kW ali več) za dosledne rezultate. Izbira materiala mora biti usklajena z vrsto lasera – vlaknasti laseri odlično obdelujejo tanke do srednje debeline kovine, medtem ko CO2 laseri učinkovito obdelujejo debelejše materiale.

3. Katera je razlika med vlaknastim in CO2 laserskim rezanjem kovin?

Fiberski laserji delujejo na valovni dolžini 1,06 mikrometrov in dosegajo odlično absorpcijo v refleksivnih kovinah, kot sta baker in aluminij, pri tem pa porabijo približno tretjino moči CO2 sistemov. Ponujajo življenjsko dobo 100.000 ur z minimalnim vzdrževanjem. CO2 laserji uporabljajo valovno dolžino 10,6 mikrometrov in se izkazujejo pri rezanju debelejčega jekla (20 mm in več) ter nemetalnih materialov. Vendar pa sistemi CO2 zahtevajo redno poravnavo zrcal, dopolnjevanje plina in porabljajo več energije. Pri obdelavi tankih do srednje debelih kovinskih pločevin omogoča tehnologija vlaken boljši donos naložbe; pri delu z debelimi pločevinami ali mešanimi materiali pa ostaja CO2 konkurenčen.

4. Kako debelo kovino lahko prereže laserski rezalnik?

Moč rezkanja z laserjem je odvisna od moči lasera in vrste kovine. Optični laser z močjo 3 kW prereže mehko jeklo do 16 mm, nerjaveče jeklo do 10 mm in aluminij do 8 mm. Pri naprednejših sistemih z močjo 6 kW so meje dvignjene na 20 mm pri mehkem jeklu, 16 mm pri nerjavečem jeklu in 12 mm pri aluminiju. Sistemi z visoko močjo 12 kW obdelajo do 30 mm mehkega jekla in 25 mm nerjavečega jekla. Za zrcalne kovine, kot sta baker in mesing, je potrebna znatno višja moč – pri 3 kW lahko pričakujete največ 4 mm, pri 12 kW pa do 10 mm. Navedeni obsegi predpostavljajo optimalne parametre in kakovostno dovajanje pomožnega plina.

5. Ali naj kupim laserski rezalnik ali izvedem rezkanje kovin prek izvajalca?

Odločitev je odvisna od letnih stroškov rezanja in obsega proizvodnje. Če letno za izdelavo rezov na zunanji strani porabite manj kot 20.000 dolarjev, je sodelovanje z uveljavljenimi izdelovalci navadno finančno bolj smiselno. Pri letnih stroških med 20.000 in 75.000 dolarji lahko osnovni sistemi s kovinskimi vlakni prinesete privlačen donos investicij. Pri letnih stroških nad 75.000 dolarjev pogosto zagotavlja oprema v lasti primerno donosnost – v bistvu plačujete za stroje, ki jih ne lastite. Upoštevajte zahteve po prostoru (minimalno 400–500 kvadratnih čevljev), stroške usposabljanja (2.000–5.000 dolarjev na operaterja) in potrebo po certifikaciji. Za avtomobilske aplikacije, ki zahtevajo certifikacijo IATF 16949, sodelovanje s certificiranimi proizvajalci, kot je Shaoyi, zagotavlja jamstvo kakovosti brez kapitalske naložbe.

Majhne serije, visoki standardi. Naša storitev hitrega prototipiranja omogoča hitrejšo in enostavnejšo validacijo —

Majhne serije, visoki standardi. Naša storitev hitrega prototipiranja omogoča hitrejšo in enostavnejšo validacijo —