Laser Cut Metal Service Decoded: From Design File To Finished Part

What Makes Laser Cut Metal Service Essential for Modern Manufacturing

Imagine transforming a flat sheet of steel into a precision component with tolerances tighter than a human hair—all without physical contact between tool and material. That's exactly what a laser cut metal service delivers. At its core, this technology uses focused beams of high-energy light to cut, engrave, or shape metal sheets and components with exceptional accuracy. Whether you're sourcing parts for aerospace applications or prototyping a new product design, understanding how this process works gives you a significant advantage when evaluating your manufacturing options.

From Light Beam to Precision Part

So how does a beam of light cut through solid metal? The process begins when a powerful laser source generates a concentrated beam that's directed through specialized lenses and mirrors. This focused energy heats the metal to its melting or vaporization point along a precisely controlled path. Computer numerical control (CNC) systems guide the laser cutter with remarkable accuracy, following digital design files to create complex shapes that would be difficult or impossible with traditional cutting methods.

The result? Clean, accurate cuts with minimal material waste. Unlike mechanical cutting that physically contacts and wears against the workpiece, laser metal cutting is a non-contact process. This means less mechanical stress on your parts and no tool wear to compromise precision over time.

The Science Behind Metal Laser Cutting

Metal laser cutting relies on three primary laser types, each with distinct characteristics:

- CO2 lasers use electrically stimulated carbon dioxide gas to generate infrared light, working well for thinner metals and non-metallic materials

- Fiber lasers employ fiber optic cables doped with rare-earth elements like ytterbium, delivering superior performance for cutting steel, aluminum, copper, and brass

- Nd:YAG lasers utilize neodymium-doped crystals for specialized applications requiring micro-machining precision

The wavelength differences between these laser types determine how effectively they interact with various metals. Fiber lasers, for instance, produce wavelengths that metals absorb more efficiently, which is why they've become the dominant choice for metal fabrication operations requiring speed and precision.

Laser cutting technology delivers unmatched precision, efficiency, and adaptability—making it essential for manufacturers seeking to remain competitive while meeting stringent industry standards.

Why Laser Cutting Dominates Modern Manufacturing

From automotive chassis components to aerospace structural parts, a metal laser cutter has become indispensable across virtually every manufacturing sector. Why? The advantages are compelling:

- Exceptional precision: Tolerances as tight as ±0.03mm are achievable, reducing or eliminating secondary machining requirements

- Speed and productivity: Rapid cutting cycles dramatically increase throughput compared to traditional methods

- Material efficiency: Narrow kerf widths minimize scrap, optimizing material usage and reducing costs

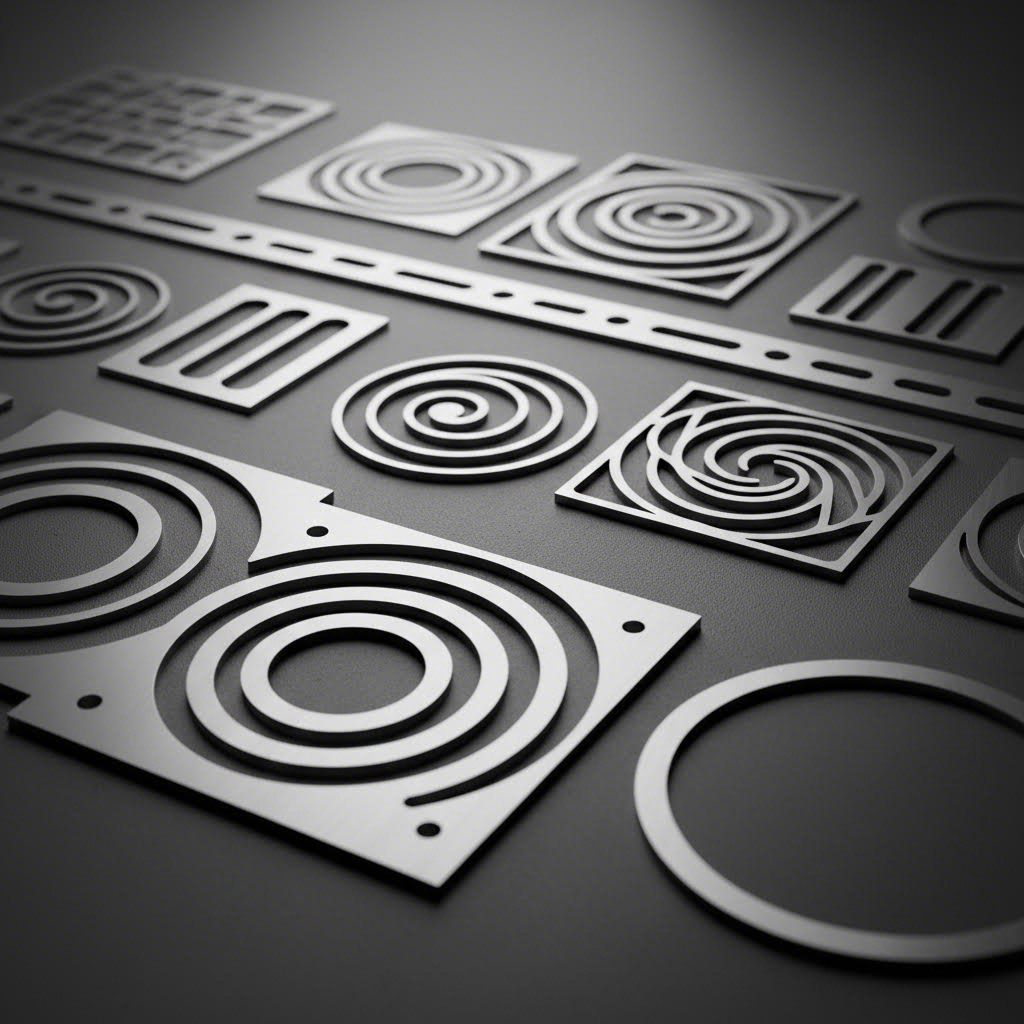

- Design flexibility: Complex geometries and intricate patterns are produced without custom tooling

- Consistent quality: CNC automation ensures identical results across production runs of any size

Whether you're an engineer specifying parts, a procurement specialist comparing vendors, or a project manager planning production timelines, this guide will walk you through everything you need to know about laser cut metal services—from the technology fundamentals covered here to material selection, design guidelines, tolerance specifications, and provider evaluation criteria in the sections ahead.

Understanding Laser Cutting Technology Types and Their Capabilities

When you're evaluating a laser cutting machine for metal projects, the type of laser technology behind the equipment directly impacts your results. Not all lasers are created equal—each type excels in specific applications while presenting limitations in others. Understanding these differences helps you select the right service provider and set realistic expectations for your project outcomes.

Fiber Lasers and Their Dominance in Metal Cutting

Why have fiber lasers become the go-to choice for metal cutting laser machine operations? The answer lies in their efficiency and versatility. Fiber lasers generate light through fiber optic cables doped with rare-earth elements like ytterbium. This solid-state design produces wavelengths around 1.06 micrometers—a frequency that metals absorb far more efficiently than the longer wavelengths from CO2 systems.

The practical benefits are substantial. According to industry data from DP Laser, fiber laser cutting machines deliver exceptional precision while handling metal sheets of varying thicknesses with minimal waste. Power ranges extend from entry-level systems around 1.5KW for delicate electrical components to industrial units exceeding 100KW for heavy structural work.

What makes fiber lasers particularly attractive for CNC laser cutting operations is their low maintenance requirements. Unlike CO2 systems that need regular mirror alignment and gas refills, fiber lasers have fewer moving parts and consumables. This translates to reduced downtime and lower long-term operating costs—a critical consideration when selecting your sheet metal laser cutting machine provider.

CO2 vs Fiber Technology Breakdown

CO2 lasers have served the metal fabrication industry for decades, and they still offer advantages in specific applications. These systems use electrically stimulated carbon dioxide gas to generate infrared light at wavelengths around 10.6 micrometers. While this wavelength is excellent for cutting non-metals like wood, acrylic, and leather, metals reflect much of this energy rather than absorbing it.

That said, CO2 laser cut metal machines remain viable for certain operations. They typically offer power ranges from 40W to 150W in commercial settings, providing a balance between cutting capability and operating costs. For thinner metals and shops that also process non-metallic materials, a CO2 system can serve dual purposes.

Crystal lasers—specifically Nd:YAG (neodymium-doped yttrium aluminum garnet) systems—represent a third option. According to technical specifications from 4Lasers, these crystals emit at 1064nm wavelength with excellent thermal conductivity and optical quality. They're particularly suited for precision applications requiring micro-machining capabilities, including medical device manufacturing and fine jewelry work.

Matching Laser Type to Your Metal Application

Selecting the right laser sheet metal cutter depends on your specific requirements. Consider this comparison when evaluating service providers:

| Factor | Fiber Laser | CO2 Laser | Crystal (Nd:YAG) Laser |

|---|---|---|---|

| Metal Compatibility | Excellent for steel, aluminum, brass, copper | Limited; works best with thin metals | Specialized for precision metal work |

| Thickness Capacity | Up to 30mm+ depending on power | Typically under 6mm for metals | Best for thin materials under 3mm |

| Cutting Speed | Fastest for metals | Moderate; slower on reflective metals | Slower; suited for detailed work |

| Edge Quality | Clean, minimal heat-affected zone | Good on thin materials | Excellent for micro-precision |

| Operating Costs | Lowest long-term costs | Mid-range; gas and maintenance costs | Higher; crystal replacement required |

| Best Applications | General metal fabrication, high-volume production | Mixed material shops, thinner metals | Medical, jewelry, micro-machining |

For most metal laser cutting machine for home workshops or small fabrication operations, entry-level fiber systems offer the best balance of capability and value. Industrial operations benefit from higher-powered fiber systems that handle everything from thin aluminum sheets to thick steel plates without switching equipment.

When requesting quotes from service providers, ask about their equipment specifications. A shop running modern fiber laser technology will typically deliver faster turnaround times and better edge quality on metal projects than one relying on older CO2 laser cut metal machine systems. This equipment knowledge helps you evaluate whether a provider's capabilities align with your project requirements—a topic we'll explore further when discussing material compatibility in the next section.

Material Compatibility Guide for Laser Cut Metal Projects

You've selected the right laser technology—but have you considered how your material choice affects cutting performance? Not all metals behave the same way under a laser beam. Some cut cleanly at impressive thicknesses, while others demand careful parameter adjustments to achieve acceptable results. Understanding these differences before submitting your design files saves time, reduces costs, and prevents frustrating quality issues.

Whether you're working with a stainless steel sheet for food-grade equipment or aluminum sheet metal for lightweight enclosures, each material brings unique characteristics that influence cutting speed, edge quality, and maximum achievable thickness. Let's break down what you need to know for the most common metals.

Steel and Stainless Steel Cutting Parameters

Carbon steel remains the easiest metal to cut with laser technology—and for good reason. According to GWEIKE's technical documentation, oxygen-assisted cutting creates an exothermic reaction that actually helps the laser do its work. The oxygen reacts with the heated steel, generating additional heat that improves cutting efficiency. This is why carbon steel plate can be cut significantly thicker than other metals at equivalent power levels.

For practical reference, a 6kW fiber laser handles carbon steel up to approximately 20mm with production-quality results. Push to 12kW systems, and you're looking at reliable cuts through 25mm or thicker material. The key phrase here is "production-quality"—maximum thickness specifications you'll see in marketing materials represent what's technically possible, not what delivers consistent, saleable parts.

Stainless steel sheet metal presents a different challenge. Unlike carbon steel, stainless typically requires nitrogen assist gas to achieve bright, oxide-free edges. As Universal Tool explains, stainless steel produces clean, high-quality edges even at higher thicknesses—but you'll sacrifice some cutting capacity compared to carbon steel at the same power level.

Why the difference? Nitrogen doesn't contribute energy to the cutting process like oxygen does with carbon steel. The laser must do virtually all the work alone. For applications requiring 316 stainless steel or other corrosion-resistant grades, expect maximum thickness capabilities roughly 30-40% lower than carbon steel specifications.

Aluminum and Reflective Metal Challenges

Here's where material selection gets interesting. Aluminum confuses many first-time buyers because its behavior under a laser seems counterintuitive. Despite being softer than steel, aluminum sheet is actually harder to cut at equivalent thicknesses. Two physical properties create this challenge:

- High reflectivity: Aluminum reflects significant laser energy rather than absorbing it, reducing cutting efficiency

- Excellent thermal conductivity: Heat dissipates rapidly through the material instead of concentrating at the cut zone

In practical terms, aluminum "throws energy away" rather than staying hot enough to cut cleanly. Even with high-power fiber lasers that handle reflectivity better than older CO2 systems, maximum aluminum thickness typically falls 40-50% below carbon steel capabilities.

Galvanized sheet metal adds another consideration. The zinc coating vaporizes differently than the base steel, potentially affecting edge quality and creating additional fumes that require proper ventilation. Most service providers handle galvanized materials routinely, but it's worth confirming their experience with your specific coating type.

Copper and brass present similar reflectivity challenges amplified by their excellent thermal conductivity. According to industry benchmarks, these materials typically max out around 5-8mm even with high-power equipment. For thicker copper applications, many fabricators recommend alternative cutting methods rather than pushing laser technology beyond its sweet spot.

Specialty Metals and Thickness Limitations

Titanium occupies a unique position in laser cutting. As Universal Tool notes, titanium offers the highest strength-to-weight ratio among commonly cut metals—and also the highest price tag. The good news? Titanium cuts more easily with lasers than it stamps or machines mechanically, making laser cutting an attractive option for aerospace and medical applications.

Before diving into material selection, understanding thickness specifications helps you communicate effectively with service providers. The gauge size chart system can seem confusing at first—it's not linear, and lower numbers actually indicate thicker material. According to Xometry's technical reference, gauge numbers were historically developed by measuring sheet metal thickness in relation to weight per square foot.

For example, 10-gauge metal measures approximately 3.4mm (0.1345 inches)—ideal for heavy-duty structural components. Meanwhile, 26-gauge material is just 0.45mm thick, suited for decorative panels or light enclosures. Most sheet metals range from 0.5mm to 6mm; anything thicker is typically classified as plate rather than sheet.

| Material Type | Maximum Thickness (Production Quality) | Typical Tolerance | Edge Quality | Key Considerations |

|---|---|---|---|---|

| Carbon Steel | 25-30mm (with 12kW+ fiber) | ±0.1mm to ±0.25mm | Good; slight oxidation with O2 assist | Easiest to cut; oxygen assist improves efficiency |

| Stainless Steel | 15-20mm (with 12kW+ fiber) | ±0.1mm to ±0.2mm | Excellent; bright edges with N2 assist | Nitrogen required for oxide-free finish |

| Aluminum | 12-15mm (with high power) | ±0.1mm to ±0.3mm | Good; may show slight burring | Reflective; requires careful heat management |

| Brass | 6-8mm | ±0.1mm to ±0.2mm | Good with proper parameters | High reflectivity; slower cutting speeds |

| Copper | 5-8mm | ±0.15mm to ±0.25mm | Acceptable; challenging at thickness | Most challenging reflective metal |

| Titanium | 8-12mm | ±0.1mm to ±0.2mm | Excellent | Requires inert atmosphere; premium pricing |

When selecting materials for your project, consider these practical guidelines:

- Prioritize application requirements: Corrosion resistance, weight constraints, and mechanical properties should drive material selection before cutting considerations

- Stay within production-quality ranges: Maximum thickness specs represent technical limits, not optimal operating conditions

- Factor in finishing needs: Some materials require post-processing that adds cost and lead time

- Communicate clearly with providers: Specify both material grade and thickness using consistent units (mm or gauge)

Understanding material behavior under laser cutting sets realistic expectations and helps you collaborate effectively with service providers. But even the perfect material choice won't compensate for design issues—which brings us to the critical design guidelines that ensure your parts come out right the first time.

Design Guidelines That Ensure Successful Laser Cut Parts

You've selected the ideal material and understand the laser technology that will process it—but here's a reality check. Even experienced engineers sometimes submit designs that look perfect on screen yet create headaches in production. The difference between laser cut parts that arrive ready to use and those requiring rework often comes down to design decisions made before the file ever leaves your computer.

Proper design-for-manufacturing (DFM) principles reduce costs, improve part quality, and accelerate turnaround times. Let's walk through the essential guidelines that separate smooth projects from frustrating delays.

File Formats and Design Software Requirements

Before diving into geometry rules, you'll need to understand what file formats actually work for laser cutting of metal sheets. According to Xometry's laser cutting guidelines, vector-based file formats are essential. Why? Vector files define edges through mathematical expressions rather than pixels. When you zoom into a bitmap image, you'll see individual pixels degrade the image quality. Vector files maintain their precise edges regardless of scaling.

The most commonly accepted formats include:

- DXF (Drawing Exchange Format): The industry standard for 2D laser cutting; compatible with virtually all CAM software

- DWG: AutoCAD's native format; widely supported but may require conversion

- AI (Adobe Illustrator): Vector format often used for decorative or signage work

- SVG (Scalable Vector Graphics): Open-source vector format; useful for simpler designs

Does your CAD program draw curves with flat segments instead of true arcs? This matters more than you might expect. As Baillie Fabricators explains, longer segment lines can translate to curved features resembling a series of short flat sides rather than smooth contours. Imagine ordering a circle but receiving something closer to a hexagon—that's an extreme example, but the principle holds. Before submitting your design for custom laser cutting, verify that curved lines use true arcs rather than approximated segments.

One more critical check: connect all the dots. Unconnected lines or open contours may result in poorly cut parts or require additional drafting time from the service provider—often at your expense.

Critical Design Rules for Clean Cuts

Here's where laser cut sheet metal projects succeed or fail. Following these fundamental rules ensures your parts cut cleanly and meet dimensional requirements:

- Minimum hole diameters: Hole diameters must be at least equal to your material's thickness. Cutting a 3/16" (4.8mm) stainless steel sheet? Your minimum hole diameter is also 3/16". Smaller holes may produce poor edge quality or dimensional inaccuracy.

- Edge-to-hole distance: Avoid designing holes too close to material edges. Allow a distance of at least the material thickness between any hole and the edge. Aluminum often requires 2x that distance or more due to its thermal properties.

- Kerf compensation: The kerf—the width of material removed during cutting—typically ranges from 0.1mm to 1.0mm depending on material type, laser power, and cutting speed. Your design should account for this material loss, either by offsetting the cut path in CAD or allowing the laser cutting software to compensate automatically.

- Corner radius requirements: Sharp internal corners are physically impossible with laser cutting. The beam has a measurable diameter, so all internal corners will have a radius equal to at least half the kerf width. Design internal corners with intentional radii rather than expecting perfect 90-degree angles.

- Tab and slot tolerances: For interlocking designs, plan for 0.1-0.2mm clearance between tabs and slots. This accommodates kerf variation and ensures parts assemble without forcing.

- Feature spacing: For thick materials or those with low melting points, closely spaced cutting paths may cause localized melting or warping between cuts. Test your design if spacing between features approaches the material thickness.

When designing laser cut aluminum parts specifically, remember that reflective metals demand even more careful attention to hole placement and feature spacing. The thermal conductivity that makes aluminum challenging to cut also means heat dissipates differently around small features.

Avoiding Costly Design Mistakes

Sounds complex? These common errors trip up even experienced designers. Avoiding them saves both time and money:

Mistake #1: Ignoring material sheet sizes. Standard metal sheets measure 4'x8' or 4'x10' with lengthwise grain. While two 4'x4' parts seem like they should fit perfectly on a 4'x8' sheet, laser cutters require a border of up to 0.5" around every part. Designing parts that maximize sheet utilization—accounting for this border—significantly reduces material costs.

Mistake #2: Overlooking grain direction. For brushed stainless steel or other directional finishes, failing to specify which side faces "up" and the desired grain orientation leads to parts that don't match your aesthetic requirements. Add clear callouts to your drawings indicating the front face and grain direction.

Mistake #3: Designing beyond thickness limits. Just because a laser can technically cut 3/8" material doesn't mean it's the most cost-effective approach. According to industry guidelines, standard multi-process fabrication shops typically cut most materials up to 3/8" (9.5mm) efficiently. Thicker materials may require specialty equipment or alternative cutting methods, increasing costs and lead times.

Mistake #4: Specifying non-standard thicknesses. As KomaCut notes, laser cutters are calibrated for standard material sizes. Requesting a custom 3.2mm sheet instead of standard 3mm can require minimum order quantities of dozens or hundreds of sheets, add weeks to delivery, and carry significant price premiums.

Connect with your service provider during the design phase—not after. They'll help you determine correct measurements for tapped holes, optimal material selection, and the ideal manufacturing processes for your specific part.

When should you request DFM support? If your design includes any of these elements, professional review before quoting saves headaches later:

- Features approaching minimum size thresholds

- Complex interlocking assemblies

- Tight tolerance requirements on critical dimensions

- Unusual materials or thickness specifications

- High-volume production where small optimizations compound into significant savings

Most reputable service providers offer DFM feedback as part of their quoting process. Take advantage of it—their fabrication expertise often identifies improvements that reduce costs while improving part quality. Speaking of quality, understanding tolerance specifications ensures you get exactly the precision your application demands without over-engineering your requirements.

Tolerance and Precision Specifications Explained

You've designed your part perfectly and selected the ideal material—but how do you ensure the finished component matches your specifications? Understanding tolerance requirements separates projects that assemble flawlessly from those requiring costly rework. Yet here's the catch: over-specifying tolerances can inflate your costs by 50-200% without adding functional benefit. Let's demystify what precision laser cutting actually delivers and when tighter specifications genuinely matter.

Standard vs Precision Tolerance Specifications

What tolerances can you realistically expect from sheet metal laser cutting operations? According to A-Laser's technical documentation, achievable precision varies significantly by laser type:

- CO2 lasers: Typically achieve tolerances ranging from ±0.002 to ±0.005 inches (±0.05mm to ±0.13mm)

- Fiber lasers: Deliver tighter tolerances from ±0.001 to ±0.003 inches (±0.025mm to ±0.076mm)

- UV lasers: Reach astonishingly tight tolerances as low as ±0.0001 inches (±0.0025mm) for micro-machining applications

For most precision laser cutting services, standard tolerances fall in the ±0.1mm range for typical sheet metal work. This level of precision satisfies the majority of industrial applications—from enclosures and brackets to structural components. Precision laser cutting operations can push tighter when your application demands it, but the equipment, setup time, and inspection requirements escalate accordingly.

When you laser cut stainless steel or other metals, the material itself influences achievable precision. Stainless laser cutting typically holds tighter tolerances than aluminum due to stainless steel's superior thermal stability during cutting. Highly reflective metals like copper and brass present greater challenges, often requiring wider tolerance allowances.

Reading and Specifying Dimensional Requirements

Understanding specification sheets requires knowing what factors actually drive tolerance capability. According to ADHMT's technical analysis, four primary elements determine whether your parts meet dimensional requirements:

- Machine calibration: High-end laser systems with linear motor drives achieve positioning precision of ±0.001mm, while rack-and-pinion systems typically manage ±0.1mm

- Material properties: Thermal conductivity, reflectivity, and thickness all influence how consistently the laser cuts along programmed paths

- Thermal expansion: Temperature variations during machining cause aluminum to expand 23 micrometers per meter per degree Celsius—making environmental control critical for tight tolerances

- Operator expertise: Experienced operators fine-tune power, speed, and focus position to optimize results for each material and thickness combination

The relationship between material thickness and tolerance capability follows a predictable pattern. Thinner materials hold tighter tolerances more easily, while thicker plates present greater challenges due to heat accumulation and potential taper.

| Material Type | Thickness Range | Standard Tolerance | Precision Tolerance (Available) | Key Factors |

|---|---|---|---|---|

| Carbon Steel | Under 6mm | ±0.1mm | ±0.05mm | Easiest to control; stable cutting |

| Carbon Steel | 6-15mm | ±0.15mm | ±0.1mm | Increased heat-affected zone |

| Carbon Steel | Over 15mm | ±0.25mm | ±0.15mm | Taper becomes more pronounced |

| Stainless Steel | Under 6mm | ±0.1mm | ±0.05mm | Excellent dimensional stability |

| Stainless Steel | 6-12mm | ±0.15mm | ±0.08mm | Nitrogen assist maintains precision |

| Aluminum | Under 4mm | ±0.1mm | ±0.05mm | Thermal expansion requires control |

| Aluminum | 4-10mm | ±0.2mm | ±0.1mm | Reflectivity affects consistency |

| Brass/Copper | Under 5mm | ±0.15mm | ±0.1mm | Most challenging; slowest cutting |

When Tight Tolerances Actually Matter

Here's the question many engineers overlook: does your application genuinely require precision tolerances? According to manufacturing experts at Okdor, most CNC parts need tight tolerances only on functional features—typically ±0.01mm for bearing fits, mating surfaces, and seal grooves. Non-critical dimensions perform identically at ±0.05mm or wider.

Reserve tight tolerances for features that genuinely demand them:

- Bearing press fits and sliding clearances

- O-ring grooves and sealing surfaces

- Threaded holes for critical fasteners

- Mating surfaces between assembled components

External edges, mounting flanges, and decorative features rarely benefit from precision specifications. Applying ISO 2768-m tolerances to non-critical dimensions keeps costs reasonable while ensuring functional performance.

Tight tolerances (±0.01mm) increase costs 50-200% due to specialized tooling, slower feeds, multiple setups, and CMM inspection requirements. Standard tolerances use conventional tools and basic measuring equipment, reducing time and cost significantly.

Inspection requirements also escalate with tighter specifications. Parts with ±0.1mm tolerances are verified quickly using calipers and micrometers. Push to ±0.01mm, and coordinate measuring machines (CMM) become necessary—adding both equipment costs and inspection time. For precision laser cutting services handling critical aerospace or medical components, this investment makes sense. For general fabrication work, it's often unnecessary overhead.

The smartest approach? Specify selectively. Call out tight tolerances only on dimensions that affect fit, function, or assembly. Let everything else follow standard manufacturing tolerances. This strategy optimizes both cost and quality—ensuring precision where it counts while avoiding unnecessary expenses. Understanding when laser cutting is the right choice—and when alternative methods might serve you better—helps complete this decision-making picture.

Laser Cutting vs Alternative Metal Cutting Methods

Here's the honest truth that many fabrication guides skip: laser cutting isn't always the best choice for every project. While a cutting laser excels at precision work on thin to medium-thickness metals, alternative methods sometimes deliver superior results at lower costs. Understanding when to choose—and when to avoid—laser cutting empowers you to make decisions that optimize both quality and budget.

Let's break down how laser cutting stacks up against waterjet, plasma, CNC punching, and EDM across the factors that actually matter for your project outcomes.

Laser vs Waterjet for Thick Materials

When your project involves materials thicker than 25mm or heat-sensitive alloys, waterjet cutting deserves serious consideration. According to Flow Waterjet's technical comparison, waterjet systems handle materials up to 24 inches thick for rough cuts—far exceeding laser capabilities.

The critical difference? Temperature. Laser cutting generates significant heat at the cut zone, creating a heat-affected zone (HAZ) that can alter material properties near the edge. Waterjet cutting is a cold-cutting process that leaves a satin-smooth edge without thermal stress or hardening. For aerospace components, hardened tool steels, or materials that cannot tolerate any metallurgical changes, waterjet often becomes the only viable option.

However, waterjet has trade-offs:

- Speed: Waterjet cuts 3-4 times slower than plasma on thick metals

- Operating costs: Abrasive consumption adds significant ongoing expense

- Precision on thin materials: Laser cutting achieves tighter tolerances on sheet metal

- Cleanup requirements: Water and abrasive mixture creates more mess than dry cutting methods

Choose waterjet when heat damage must be avoided, when cutting composites or stone alongside metals, or when material thickness exceeds laser capabilities. Stick with laser cutting for thin-to-medium sheet metal where speed and precision matter most.

When Plasma Cutting Makes More Sense

Searching for "plasma cutting near me" for your project? Plasma technology offers compelling advantages for specific applications—particularly thick conductive metals where precision requirements are moderate.

According to Wurth Machinery's testing data, plasma cutting dominates when working with steel plate over 1/2 inch thick. The combination of speed and cost efficiency makes plasma the go-to choice for structural steel fabrication, heavy equipment manufacturing, and shipbuilding applications.

The cost advantage is substantial. A complete plasma system costs approximately $90,000 compared to $195,000 for a similar-sized waterjet system—and operating costs per foot of cut are roughly half. For metal fabrication shops focused primarily on steel and aluminum at thickness, plasma often delivers the best return on investment.

But plasma has clear limitations:

- Precision: Laser cutting is far more accurate for intricate details and small features

- Edge quality: Plasma leaves slag or dross requiring secondary finishing

- Heat-affected zone: Similar to laser cutting, plasma creates thermal stress at cut edges

- Material restriction: Only works on conductive metals—no plastics, wood, or composites

- Safety considerations: Plasma produces harmful electromagnetic radiation and requires additional protective equipment

A machine cutter metal shops often deploy? Plasma. When your project involves simple shapes, thick borders, and doesn't demand pristine edge finishes, plasma cutting delivers excellent value.

Choosing Between Laser and CNC Punching

CNC punching uses hardened steel tools to mechanically punch shapes from sheet metal—a fundamentally different approach than thermal cutting methods. For high-volume production of simple shapes with standard features like louvers, embosses, and formed tabs, punching often outperforms laser cutting on both speed and cost.

The decision hinges on your specific requirements:

- Volume: Punching excels at high-volume runs where tooling costs amortize across thousands of parts

- Geometry: Complex curves and intricate patterns favor laser; repetitive standard shapes favor punching

- Secondary operations: Punching can form features (like tabs and louvers) simultaneously with cutting

- Material thickness: Both methods handle similar thickness ranges for sheet metal

Many modern fabrication shops combine technologies. Laser cutting handles prototypes and complex geometries, while CNC punching tackles high-volume production of standardized parts. Some machines even integrate both capabilities, automatically selecting the optimal method for each feature.

For a die cut machine comparison, consider that tooling costs make punching expensive for small runs or custom shapes. Laser cutting requires no part-specific tooling, making it ideal for prototypes, short runs, and designs that change frequently.

Comprehensive Method Comparison

This comparison table summarizes how each metal cutter technology performs across critical evaluation factors:

| Factor | Laser Cutting | Waterjet | Plasma | CNC Punching | EDM |

|---|---|---|---|---|---|

| Material Thickness Range | Up to 25-30mm (steel) | Up to 600mm (rough cuts) | Up to 150mm+ | Up to 8mm typical | Up to 300mm |

| Precision Capability | ±0.05mm to ±0.1mm | ±0.1mm to ±0.25mm | ±0.5mm to ±1.5mm | ±0.1mm to ±0.25mm | ±0.005mm to ±0.025mm |

| Edge Quality | Excellent; minimal finishing | Good; satin-smooth finish | Moderate; requires deburring | Good; slight rollover | Excellent; mirror finish possible |

| Heat-Affected Zone | Small but present | None (cold cutting) | Significant | None (mechanical) | Minimal |

| Cutting Speed | Fast on thin materials | Slow | Fast on thick materials | Very fast for standard shapes | Very slow |

| Equipment Cost | Medium to high | High | Low to medium | Medium | High |

| Operating Cost | Low (fiber lasers) | High (abrasives) | Low | Low (after tooling) | Medium |

| Material Versatility | Metals primarily | Almost any material | Conductive metals only | Sheet metals | Conductive materials only |

| Best Applications | Precision sheet metal, prototypes | Thick materials, composites, heat-sensitive | Structural steel, heavy fabrication | High-volume production | Hardened steels, complex geometries |

EDM deserves mention for specialized applications. According to industry comparisons, Electrical Discharge Machining delivers exceptional precision for roughing out large parts requiring specific edge finishes or cutting advanced geometries in hardened materials. However, it's typically the slowest method and only works with conductive materials.

There's no single "best" cutting technology—each has its place. Plasma excels with thick conductive metals at lower costs. Laser delivers precision for thin materials and complex designs. Waterjet provides versatility across materials without heat effects.

The smartest fabricators don't limit themselves to one technology. Understanding laser cutting and its alternatives helps you match each project to the optimal method—sometimes choosing laser for precision features while specifying plasma or waterjet for thick sections of the same assembly. This flexibility ensures you get the best combination of quality, speed, and cost for every component. Once you've determined laser cutting is right for your project, selecting the appropriate finishing options completes your part specification.

Post-Processing and Finishing Options for Laser Cut Metal

Your laser cut parts arrive with clean edges and precise dimensions—but are they ready to use? In many cases, the cutting process is just the beginning. Post-processing transforms raw cut metal into components that resist corrosion, match aesthetic requirements, and perform reliably in their final applications. Understanding your finishing options helps you specify exactly what your project needs without overpaying for unnecessary treatments.

According to SendCutSend's finishing guide, metal finishes can improve multiple properties simultaneously—from abrasion resistance and surface hardness to corrosion protection and electrical conductivity. The right finish adds that final touch that completes your project while ensuring long-term performance.

Powder Coating and Paint Finishing Options

When you need durable color and corrosion protection, powder coat finishes deliver exceptional results. Unlike liquid paint applied wet, powder coating uses electrostatically charged dry powder that adheres to metal surfaces before curing in an oven. The result? A finish that lasts up to 10 times longer than traditional paint while eliminating volatile organic compounds (VOCs) from the application process.

Powder coating services work best on metals that hold an electrostatic charge—making aluminum, steel, and stainless steel ideal candidates. The cured finish provides both corrosion and abrasion resistance, protecting your parts in demanding environments.

- Matte finishes: Reduce glare and fingerprint visibility; ideal for industrial equipment and enclosures

- Gloss finishes: Deliver visual impact and easier cleaning; popular for consumer products and signage

- Wrinkle textures: Hide surface imperfections while adding grip; common for tool handles and equipment housings

One consideration: tabs and micro-joints from the cutting process may remain visible through powder coating, especially on thicker materials. If seamless appearance matters, discuss tab removal with your provider before finishing.

Anodizing for Aluminum Components

Working with anodized aluminum offers advantages no other finish quite matches. Anodizing creates a protective oxide layer by immersing aluminum in a charged acid bath—typically sulfuric acid. This electrochemical process thickens the metal's natural oxide coating, producing a finish that's integral to the material rather than simply applied on top.

The benefits extend beyond appearance:

- Exceptional durability: The hardened oxide layer resists scratching better than paint or powder coat

- Corrosion resistance: Ideal for outdoor applications and harsh environments

- Heat and electrical resistance: Useful for electronic enclosures and thermal management

- Color versatility: Dyes penetrate the porous oxide layer for vibrant, fade-resistant colors

Anodizing does add lead time—typically 7-10 additional production days. However, for parts exposed to outdoor elements or requiring premium aesthetics, the investment pays dividends in longevity and appearance.

Edge Finishing and Deburring Processes

Laser cutting produces remarkably clean edges compared to mechanical cutting methods, but some applications demand even smoother results. Deburring removes the slight raised edges (burrs) and minor imperfections left from the manufacturing process. Two primary methods address these needs:

- Linear deburring: A brushing process that smooths one side of larger parts, preparing surfaces for painting or further finishing. Parts still may show minor scratches on the bottom face.

- Tumbling: Vibratory-abrasive finishing for smaller parts, using harmonically tuned ceramic media to achieve consistent edge smoothing across all surfaces

Bending operations often follow cutting, transforming flat laser cut blanks into three-dimensional components. Proper deburring before bending prevents edge cracks and ensures clean fold lines—particularly important for visible parts or those requiring tight bend radii.

Plating offers another finishing avenue, depositing metal coatings onto substrates for enhanced properties. Zinc plating improves corrosion resistance on steel components, while nickel plating adds conductivity and wear resistance to copper and steel parts.

Quality Control and Certification Standards

How do you know your finished parts meet specifications? Quality certifications provide assurance that manufacturing processes are monitored, measured, and continuously improved. Two certifications matter most for metal fabrication:

- ISO 9001:2015: The foundational quality management standard emphasizing customer satisfaction, process consistency, and continuous improvement

- IATF 16949: Built on ISO 9001 requirements, this automotive-specific certification adds lean manufacturing, defect prevention, and variance reduction requirements

According to OGS Industries' certification overview, IATF 16949 ensures consistent quality, reduced product variation, reliable supply chains, and minimized waste. For automotive applications—or any project demanding stringent quality assurance—working with certified providers reduces risk and ensures parts meet tough specifications.

Finishing Impact on Lead Times and Costs

Every finishing operation adds time and expense to your project. Plan accordingly:

| Finishing Option | Typical Added Lead Time | Cost Factor | Best Applications |

|---|---|---|---|

| Deburring | 0-1 days | Low (often free) | General edge smoothing, paint prep |

| Tumbling | 1-2 days | Low to moderate | Small parts, consistent finish |

| Powder Coat | 3-5 days | Moderate | Corrosion protection, color |

| Anodizing | 7-10 days | Moderate to high | Aluminum, premium aesthetics |

| Plating | 5-7 days | Moderate | Conductivity, wear resistance |

Selecting the right finish comes down to balancing performance requirements, visual expectations, timeline constraints, and budget. Many service providers offer multiple options in-house, streamlining your supply chain while ensuring quality consistency from cutting through finishing. Understanding your application requirements—and communicating them clearly—sets the stage for choosing a service provider who can deliver complete solutions.

Industry Applications and Project Planning Considerations

Now that you understand finishing options and quality standards, where does laser cutting technology actually make its mark? From the vehicle you drive to the signage outside your office, precision laser cutting touches nearly every industry sector. Understanding these applications helps you identify opportunities for your own projects while learning from established best practices across different manufacturing environments.

According to Great Lakes Engineering's industry analysis, precision laser cutting has become indispensable across multiple sectors due to its unmatched accuracy, efficiency, and versatility. The technology's ability to handle complex contours and thin materials without damaging the workpiece makes it suitable for everything from aerospace components to decorative architectural elements.

Automotive and Transportation Applications

The automotive industry relies heavily on precision laser cutting to produce high-quality components efficiently. When you're sourcing parts for vehicles, speed and accuracy directly impact both cost and safety. Manufacturers use this technology to create:

- Chassis and structural components: Frame brackets, cross-members, and reinforcement plates requiring tight tolerances

- Body panels and trim: Door panels, fender components, and decorative trim pieces

- Engine components: Heat shields, gaskets, and precision fittings

- Suspension parts: Control arm brackets, spring perches, and mounting hardware

- Interior elements: Dashboard brackets, seat frames, and console components

The automotive sector's demand for precision extends beyond individual parts. Sheet metal fabrication operations serving this industry must maintain IATF 16949 certification—the quality standard that ensures consistent, defect-free production across high-volume runs. Manufacturers like Shaoyi (Ningbo) Metal Technology combine laser cutting with metal stamping capabilities to deliver complete chassis and suspension component solutions, offering 5-day rapid prototyping alongside automated mass production to meet demanding automotive supply chain requirements.

Steel fabrication for transportation extends beyond passenger vehicles. Commercial trucks, rail cars, agricultural equipment, and marine vessels all incorporate laser cut components. The technology's high speed and accuracy allow for rapid production of parts meeting tight tolerances—critical when vehicle safety depends on precise fits and consistent quality.

Architectural and Decorative Metalwork

Ever walked past a building facade with intricate metal screening or admired custom metal signs on a storefront? Precision laser cutting makes these designs possible. According to HeatSign's decorative applications overview, the technology has revolutionized metal decor by enabling intricate patterns impossible with traditional cutting methods.

Architectural applications span both functional and aesthetic purposes:

- Building facades: Decorative screening, sun shades, and privacy panels

- Interior design: Wall art, room dividers, and ceiling elements

- Signage: Custom metal signs for businesses, wayfinding systems, and commemorative plaques

- Furniture: Table bases, decorative panels, and custom hardware

- Outdoor installations: Garden sculptures, landscape lighting fixtures, and gate designs

If you're searching for fabrication shops near me to handle decorative metalwork, look for providers experienced with materials that deliver visual impact. Stainless steel and aluminum dominate architectural applications due to their corrosion resistance and finishing versatility. Copper and brass add warmth for premium installations, while weathering steel (Corten) creates dramatic oxidized finishes for outdoor art.

The ability to translate digital designs directly into cut metal opens creative possibilities that traditional methods couldn't match. Designers input complex patterns—floral motifs, geometric tessellations, or custom typography—and receive parts with clean edges and smooth curves that previously required extensive hand finishing.

Industrial Equipment and Machinery Components

Behind every manufacturing operation sits equipment built from precision components. Metal fabricators near me and across global supply chains produce critical parts that keep industrial machinery running reliably:

- Enclosures and housings: Electrical cabinets, control boxes, and protective covers

- Precision brackets: Motor mounts, sensor brackets, and support structures

- Machine guards: Safety enclosures with ventilation patterns and access panels

- Conveyor components: Guide rails, mounting plates, and adjustment brackets

- HVAC parts: Ductwork transitions, damper blades, and mounting flanges

Steel fabricators serving industrial markets often handle projects ranging from single prototypes to production runs of thousands. The electronics industry particularly benefits from laser cutting's precision, using the technology to cut circuit boards, semiconductor materials, and connectors from metals like copper and brass.

According to industry research, the energy sector relies on precision laser cutting for power-generating equipment and renewable energy systems—cutting parts for turbines, heat exchangers, and containers that must withstand high temperatures and corrosive environments.

Lead Time Factors and Project Planning

Understanding what drives delivery timelines helps you plan projects effectively. Several factors influence how quickly your laser cut parts move from design file to finished component:

- Design complexity: Intricate patterns with tight tolerances require slower cutting speeds and more careful setup

- Material availability: Standard materials ship faster than specialty alloys requiring special orders

- Secondary operations: Bending, finishing, and assembly add processing time

- Queue position: Production schedules at busy metal fabrication near me facilities affect turnaround

- Quality requirements: IATF 16949 or aerospace certifications add inspection steps

According to Fortune Laser's pricing analysis, the single most important factor driving both cost and lead time isn't material area—it's machine time required for your specific design. Complex geometries with many tight curves force the machine to slow down, extending both cutting time and delivery schedules.

How Volume Requirements Affect Pricing and Turnaround

Order quantity dramatically impacts your per-part costs. Here's why: every job carries fixed costs for setup, programming, and material handling that get distributed across however many parts you order.

| Order Volume | Typical Per-Part Impact | Lead Time Consideration |

|---|---|---|

| Prototype (1-5 parts) | Highest per-part cost; setup costs not amortized | Often fastest; minimal queue impact |

| Low Volume (6-50 parts) | Moderate reduction; some economies begin | Standard production scheduling |

| Medium Volume (51-500 parts) | Significant savings; efficient nesting reduces waste | May require dedicated machine time |

| High Volume (500+ parts) | Best pricing; discounts up to 70% reported | Longer lead times; production planning required |

Nesting efficiency also affects pricing. Skilled programmers arrange parts on material sheets to minimize waste—better nesting directly reduces your material costs. When requesting quotes, ask how the provider handles part arrangement and whether they optimize layouts for your specific order quantities.

For automotive projects requiring rapid response, look for providers offering expedited services. Some manufacturers deliver 5-day rapid prototyping with 12-hour quote turnaround—benchmarks that indicate serious investment in customer responsiveness. Shaoyi's comprehensive DFM support exemplifies the value-added services that distinguish premium providers from basic cutting operations.

Economies of scale work in your favor: the fixed setup costs spread across all parts in an order, so the cost per part decreases significantly as quantity increases.

Planning ahead pays dividends. Consolidating multiple part designs into single orders, specifying materials the provider stocks, and allowing flexible delivery windows often unlocks better pricing and faster service. Understanding these dynamics prepares you to evaluate service providers effectively—matching their capabilities to your specific application requirements.

Selecting the Right Laser Cut Metal Service Provider

You've mastered the technology, materials, and design principles—but finding the right partner to execute your project? That's where many engineers and procurement specialists stumble. Not all metal laser cutting services deliver equal results, and the wrong choice can mean missed deadlines, quality issues, and budget overruns. Whether you're searching for laser cutting near me or evaluating global suppliers, knowing what separates exceptional providers from mediocre ones protects your project outcomes.

According to California Steel Services' industry guidance, choosing the right laser cutting service significantly impacts project success. From equipment quality to communication responsiveness, multiple factors determine whether you'll receive parts that meet specifications—or face frustrating rework cycles.

Evaluating Equipment and Capabilities

The machinery behind your parts matters more than you might expect. When evaluating laser cutting services near me or remote providers, start with their equipment specifications:

- Laser technology type: Fiber lasers dominate modern metal cutting for speed, precision, and operating efficiency. Ask specifically what systems providers operate—TRUMPF represents the premium tier, with machines known for exceptional precision and reliability

- Power capacity: Higher wattage systems handle thicker materials and cut faster. A shop with 6-12kW fiber lasers offers more capability than one limited to 2-3kW equipment

- Table size and capacity: Larger cutting beds accommodate bigger parts and enable efficient nesting for high-volume orders

- Material inventory: Providers stocking common materials (steel, stainless, aluminum in standard thicknesses) deliver faster than those requiring special orders for every job

- Secondary operations: Does the provider offer bending, finishing, and assembly? Consolidating operations simplifies your supply chain and ensures quality consistency

According to industry equipment reviews, premium manufacturers like TRUMPF, Mazak, and Bystronic consistently deliver superior cutting precision and reliability. When a CNC laser cutting services provider invests in top-tier equipment, they're signaling commitment to quality outcomes.

Don't overlook production capacity. A laser cutter service near me might offer excellent quality but lack bandwidth for your volume requirements. Ask about current lead times, machine utilization rates, and whether they run multiple shifts. Providers operating 24/7 with automated material handling systems typically deliver faster turnaround on larger orders.

Certifications and Quality Assurance Indicators

Certifications tell you whether a provider's quality systems meet established standards. For cnc laser cutting services serving demanding industries, these credentials matter:

- ISO 9001:2015: The foundational quality management certification ensuring documented processes, customer focus, and continuous improvement

- IATF 16949: Essential for automotive supply chain work—this certification adds lean manufacturing requirements, defect prevention protocols, and rigorous variance reduction

- AS9100: The aerospace equivalent, demanding even stricter controls for flight-critical components

- NADCAP: Special process accreditation for heat treating, welding, and other controlled operations

Beyond certifications, evaluate quality control practices directly. According to industry best practices, reputable providers follow strict quality control measures and readily share samples of previous work. Ask to see sample parts, request tolerance capability studies, and inquire about inspection equipment—CMM machines, optical comparators, and calibrated measuring instruments indicate serious quality investment.

Customer reviews and industry reputation provide additional insight. A well-established company with strong references will likely deliver better overall experiences. Don't hesitate to request testimonials from clients with similar project requirements to yours.

Getting Accurate Quotes and Comparing Services

Ready to request a laser cutting quote? How you approach this process affects both accuracy and your ability to compare providers fairly. Modern metal laser cutting services often feature online quoting systems that generate instant estimates from uploaded design files. While convenient, these automated quotes work best for straightforward parts—complex projects benefit from direct communication.

When requesting quotes, provide complete information:

- Design files: Vector formats (DXF, DWG) with clearly defined cut paths

- Material specification: Exact grade, thickness, and any surface finish requirements

- Quantity: Both immediate needs and anticipated annual volumes if applicable

- Tolerances: Specify critical dimensions separately from general requirements

- Secondary operations: Bending, finishing, hardware insertion, or assembly needs

- Delivery requirements: Target dates and shipping preferences

Interpreting quotes requires attention to what's included—and what isn't. Material costs, cutting time, secondary operations, and finishing each contribute to total pricing. Some providers bundle services; others itemize everything. Ask clarifying questions to ensure you're comparing equivalent scope when evaluating multiple quotes.

A company that values customer service will be more likely to deliver a positive experience and high-quality results. Look for providers that are responsive, attentive, and keep you informed throughout the entire process.

Response time itself signals provider quality. When evaluating laser cutting service near me options, note how quickly potential suppliers respond to inquiries. Leading manufacturers benchmark themselves on rapid turnaround—some offering 12-hour quote responses as standard practice. Shaoyi's 5-day rapid prototyping capability and comprehensive DFM support exemplify the value-added services buyers should seek when project timelines matter.

The Value of DFM Support for Complex Projects

Design for Manufacturing (DFM) support separates basic cutting services from true manufacturing partners. According to industry guidance, design assistance can be invaluable if you need help refining your project's design or have limited experience with laser cutting.

What does effective DFM support include?

- Design review: Identifying features that may cause cutting problems before production begins

- Material recommendations: Suggesting alternatives that improve manufacturability or reduce cost

- Tolerance optimization: Helping specify precision where it matters while relaxing non-critical dimensions

- Cost reduction suggestions: Recommending design modifications that simplify manufacturing

- Assembly considerations: Ensuring parts work together when multiple components must fit precisely

For automotive and aerospace projects especially, DFM support prevents costly iterations. Providers like Shaoyi that combine laser cutting with metal stamping expertise understand how design choices cascade through entire manufacturing processes—offering insights that pure cutting shops simply can't provide.

Key Evaluation Checklist

Before committing to any laser cutting services near me or remote provider, verify these essentials:

| Evaluation Factor | What to Look For | Red Flags |

|---|---|---|

| Equipment Quality | Modern fiber lasers (TRUMPF, Mazak, Bystronic); adequate power for your materials | Outdated CO2-only systems; vague equipment descriptions |

| Material Inventory | Common materials stocked; quick access to specialty grades | Every material requires special order |

| Secondary Operations | Bending, finishing, assembly in-house | Must outsource everything; fragmented supply chain |

| Certifications | ISO 9001 minimum; IATF 16949 for automotive | No quality certifications; can't provide documentation |

| Communication | Responsive quotes; clear project updates; accessible contacts | Slow responses; unclear pricing; difficult to reach |

| DFM Support | Proactive design feedback; manufacturing expertise | "Send file and we'll cut it" mentality only |

Geographic considerations also influence your decision. A laser cutting near me provider may offer advantages in shipping costs, turnaround time, and face-to-face communication when needed. However, specialized capabilities or competitive pricing from more distant suppliers can outweigh proximity benefits for larger projects.

The right laser cut metal service provider becomes a manufacturing partner rather than just a vendor. By evaluating equipment, certifications, communication quality, and value-added services like DFM support, you'll identify providers capable of delivering your projects successfully—from initial design file through finished parts ready for assembly.

Frequently Asked Questions About Laser Cut Metal Service

1. What is the cost of metal laser cutting?

Metal laser cutting costs depend on several factors including machine time, material type, thickness, and design complexity. Hourly rates typically range from $60-$150, with cutting speeds varying from 1-20 m/min based on material and laser power. Simple designs on thin materials cost less, while intricate patterns on thick plates require more machine time and expense. Volume discounts can reduce per-part costs significantly—high-volume orders of 500+ parts may see savings up to 70% compared to prototype quantities.

2. Is laser cutting metal expensive?

Laser cutting metal offers competitive pricing compared to alternative methods, especially for precision work on thin to medium-thickness materials. While initial quotes may seem higher than plasma cutting, laser cutting often eliminates secondary finishing operations, reducing total project costs. Fiber laser technology has lowered operating expenses significantly, with minimal consumables and maintenance requirements. For complex geometries and tight tolerances, laser cutting frequently proves more cost-effective than mechanical alternatives requiring custom tooling.

3. How much is laser cutting service?

Laser cutting service pricing varies based on machine time, which directly correlates with design complexity and material thickness. Many providers charge $50-$150 per hour of machine time. Online quoting platforms offer instant estimates for standard parts, while complex projects benefit from direct consultation. Factors affecting price include material costs, secondary operations like bending or finishing, and order quantity. Requesting quotes from multiple providers with complete specifications ensures accurate cost comparisons.

4. What materials can be laser cut?

Laser cutting handles a wide range of metals including carbon steel (up to 30mm), stainless steel (up to 20mm), aluminum (up to 15mm), brass, copper, and titanium. Carbon steel cuts most efficiently due to oxygen-assisted reactions, while reflective metals like aluminum and copper require higher-powered fiber lasers. Material selection should prioritize application requirements—corrosion resistance, weight constraints, and mechanical properties—with cutting considerations secondary. Providers stock common materials for faster turnaround.

5. How do I choose a laser cutting service provider?

Evaluate providers based on equipment quality (modern fiber lasers from TRUMPF, Mazak, or Bystronic), certifications (ISO 9001, IATF 16949 for automotive), material inventory, and secondary operation capabilities. Response time indicates service quality—leading manufacturers offer 12-hour quote turnaround and 5-day rapid prototyping. Request sample parts, verify quality control processes, and assess DFM support availability. Providers offering comprehensive services from cutting through finishing streamline your supply chain and ensure consistent quality.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —