Metal Die Stamps Decoded: From Raw Steel To Perfect Impressions

What Metal Die Stamps Are and How They Work

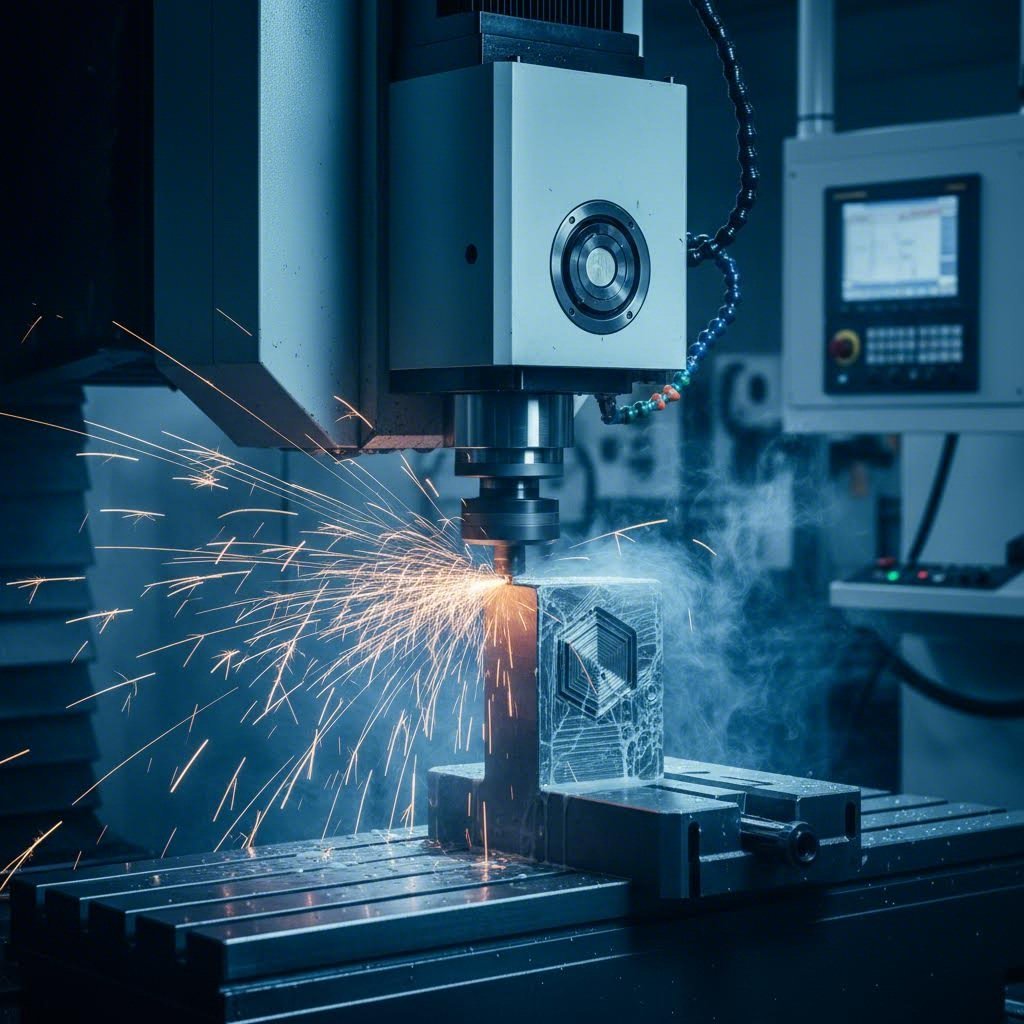

Ever wondered how manufacturers permanently mark serial numbers on engine parts, or how jewelers imprint their signature logos onto precious metals? The answer lies in metal die stamps—precision tools that create lasting impressions through direct physical force. Unlike temporary marking methods, these tools physically displace material to produce marks that withstand extreme conditions, from industrial wear to environmental exposure.

A metal stamp is essentially a hardened steel or carbide tool with a raised or recessed design on its working face. When force is applied—whether by hammer, arbor press, or hydraulic machine—the stamp die transfers its pattern into the workpiece, creating a permanent impression. This simple yet effective principle has remained fundamentally unchanged for centuries, though modern manufacturing has dramatically improved precision and durability.

The Mechanics Behind Permanent Metal Marking

Understanding how metal stamping works starts with material science. The stamp must always be harder than the workpiece. Tool steel stamps typically achieve 58-62 HRC (Rockwell hardness), while carbide options reach even higher ratings. When the harder stamp contacts softer material under pressure, it displaces metal rather than cutting it—this cold-forming process creates impressions that become integral to the workpiece itself.

There's an important distinction between two main categories. Custom-shaped stamp dies feature unique designs—logos, symbols, or specialized marks created for specific applications. Letter and number stamps, by contrast, come as standardized character sets for creating text-based identifications. Both types rely on the same mechanical principle, but their applications differ significantly.

From Industrial Floors to Artisan Workshops

Why does permanent marking matter so much? In regulated industries like aerospace and defense, traceability is essential for safety, compliance, and quality control. As noted by industry experts, every component—from fasteners to structural elements—must carry identification throughout its entire life cycle, with markings durable enough to resist harsh environments while remaining legible for inspections.

Metal stamps serve three primary application categories:

- Industrial part identification: Serial numbers, date codes, and specification marks that enable traceability and quality verification on manufactured components

- Artisan crafting: Jewelry makers, leather workers, and metalsmiths use these tools to add personalized touches, maker's marks, and decorative elements

- Brand marking: Company logos and certification symbols that establish authenticity and meet regulatory requirements

When a component is die stamped properly, the resulting mark becomes inseparable from the material itself. Unlike labels that peel, paints that fade, or inks that wear away, a physical impression remains readable even after years of service—making these tools indispensable across countless industries.

Types of Metal Die Stamps and Their Best Applications

Now that you understand how metal die stamps work, the next question becomes: which type should you choose? With options ranging from simple handheld tools to sophisticated press-mounted stamper dies, selecting the right stamp can feel overwhelming. The key lies in matching your tool to your specific production volume, workpiece material, and precision requirements.

Think of it this way—using a precision carbide stamp for occasional hobby projects is overkill, while relying on basic steel stamping dies for high-volume aerospace marking will lead to premature wear and inconsistent results. Let's break down each category so you can make informed decisions.

Handheld vs Plate Stamps for Different Production Volumes

Handheld stamps represent the most accessible entry point into metal marking. These tools—struck with a hammer or mallet—offer portability and flexibility that machine-mounted options simply cannot match. According to Durable Technologies, steel hand stamps are made from special grade tool steel to resist spalling and mushrooming, making them surprisingly durable for manual applications.

When should you reach for handheld stamps? Consider these scenarios:

- Field work where power sources are unavailable

- Low-volume production runs (under 100 pieces daily)

- Repair facilities requiring on-site marking

- Artisan workshops producing custom pieces

- Situations requiring marking on curved, concave, or irregular surfaces

Plate stamps (also called holder stamps or press stamps), by contrast, mount into arbor presses, hydraulic systems, or pneumatic equipment. They deliver consistent depth and alignment across thousands of impressions—something impossible to achieve by hand. For production environments marking 500+ parts daily, plate stamps eliminate the fatigue and variation that come with manual striking.

A quality number stamp set in plate configuration can produce tens of thousands of impressions before requiring replacement, whereas the same characters in handheld form might show wear after several thousand strikes due to slight angle variations during impact.

When Carbide Outperforms Tool Steel

Material selection dramatically affects stamp performance. Standard tool steel stamps work excellently for marking aluminum, brass, copper, and mild steel. But what happens when you need to mark hardened steel, stainless alloys, or titanium? That's where carbide enters the picture.

Carbide stamps achieve hardness ratings exceeding 70 HRC—significantly harder than the 58-62 HRC range typical of tool steel. This extreme hardness translates directly into longevity when marking tough materials. However, carbide's brittleness means these stamps require proper support and controlled force application; they're not suitable for hammer strikes.

Low stress stamps deserve special attention for anyone working with heat-treated or hardened materials. Traditional sharp-face stamps concentrate force at character edges, potentially causing micro-cracking in stressed components. Low stress designs—available in both full character and dot configurations—distribute force more evenly, making them essential for aerospace applications, pressure vessels, and any situation where material integrity cannot be compromised.

| Stamp Type | Material Hardness (HRC) | Typical Applications | Force Requirements | Expected Lifespan | Cost Level |

|---|---|---|---|---|---|

| Standard Handheld (Tool Steel) | 58-62 | General marking, soft metals, low volume | Manual hammer strike | 5,000-15,000 impressions | $ |

| Hevi-Bevl Handheld | 60-62 | Hard metals, high-volume hand marking | Heavy hammer strike | 15,000-30,000 impressions | $$ |

| Low Stress (Full Character) | 58-62 | Aerospace, pressure vessels, hardened parts | Controlled press or careful strike | 10,000-25,000 impressions | $$ |

| Low Stress (Dot Character) | 58-62 | Underground piping, stress-critical components | Light to moderate | 20,000-40,000 impressions | $$ |

| Plate/Holder Stamps | 58-62 | Production lines, consistent high-volume marking | Press-controlled (hydraulic/pneumatic) | 50,000-100,000+ impressions | $$$ |

| Carbide Stamps | 70+ | Hardened steel, stainless, titanium marking | Press-controlled only | 100,000-500,000+ impressions | $$$$ |

Specialized Stamps for Unique Requirements

Beyond these main categories, several specialized options address specific marking challenges. Border stamps feature characters contained within circles, squares, or triangles—commonly used for welder identification where marks must be instantly recognizable. Reverse character stamps create mirror-image impressions, essential when marking molds or forging dies that will produce the final readable mark on cast or forged parts.

Looking for a complete metal stamping kit? Consider your actual needs first. A basic alphabet stamps and number stamps combination covers most text-based marking. Add logo dies only when branding requirements demand them. For shops handling diverse projects, investing in both letter stamps for text and custom dies for repeated logo applications provides maximum flexibility.

How long will your stamps actually last? The answer depends on three factors: stamp material, workpiece hardness, and striking technique. A properly maintained tool steel stamp marking aluminum can exceed 50,000 impressions, while the same stamp marking stainless steel might show significant wear after 5,000 strikes. Carbide stamps marking hardened materials can achieve lifespans measured in hundreds of thousands of impressions—justifying their higher initial cost for high-volume applications.

With stamp types clarified, the next critical decision involves matching your stamp material to your workpiece—a pairing that directly determines impression quality and tool longevity.

Material Selection for Stamps and Workpieces

Selecting the right stamp material isn't just about durability—it directly determines whether your impressions come out crisp and readable or shallow and distorted. The fundamental rule? Your stamp must always be significantly harder than the material you're marking. Get this pairing wrong, and you'll face premature stamp wear, inconsistent mark depth, and costly rework.

But hardness alone doesn't tell the complete story. You also need to consider toughness (resistance to chipping under impact), wear resistance, and how the stamp material behaves under repeated thermal cycling. Let's decode the science behind successful material matching.

Matching Stamp Hardness to Your Workpiece

Hardness in the stamping world is measured using the Rockwell scale—specifically the HRC (Rockwell C) scale for tool steels and HRA (Rockwell A) scale for carbides. Think of these numbers as a direct indicator of which material will "win" when stamp meets workpiece. A higher number means greater resistance to indentation and wear.

Here's what the numbers mean practically:

- HRC 58-62: Standard range for quality tool steel stamps—suitable for marking most common metals

- HRC 62-65: Premium tool steel range for harder workpieces like stainless steel

- HRA 89-93: Carbide territory (roughly equivalent to HRC 70+)—reserved for the toughest marking applications

According to Metric Stamping, carbide with a 6 percent cobalt grade achieving 92 HRA is considerably harder than heat-treated traditional tool steel at 62 HRC. This hardness advantage translates directly into extended service life when marking abrasive or hardened materials.

When choosing a stainless steel stamp for marking stainless workpieces, you'll need stamps at the higher end of the hardness spectrum. Austenitic stainless steels (304/316) work-harden during marking, meaning they actually become harder as you stamp them—demanding stamps that can handle this increasing resistance.

Steel Types That Define Stamp Quality

Not all tool steels perform equally. Three grades dominate professional metal for stamping applications, each offering distinct advantages:

S7 Tool Steel excels in shock resistance. As noted by Prime Fab Works, S7's toughness makes it ideal for handheld impact applications where the stamp absorbs repeated hammer strikes. If you're building a steel stamp kit for manual marking across various materials, S7 handles the abuse without chipping.

D2 Tool Steel offers superior wear resistance thanks to its high chromium carbide content. This makes D2 the preferred choice for press-mounted dies marking abrasive stainless steel and coated sheet metal. Production environments running thousands of impressions daily benefit from D2's extended service life.

A2 Tool Steel represents the versatile middle ground—good toughness combined with reasonable wear resistance. For general-purpose marking across mixed production, A2 delivers balanced performance without the specialized characteristics (and costs) of S7 or D2.

Carbide stamps enter the picture when steel stamps simply can't keep up. For marking hardened steel, titanium, or running extremely high volumes on any material, tungsten carbide's exceptional hardness and compressive strength justify the investment. However, carbide's brittleness requires controlled press applications—never strike carbide stamps with a hammer.

| Stamp Material | Aluminum (Soft) | Brass/Copper | Mild Steel | Stainless Steel | Hardened Steel |

|---|---|---|---|---|---|

| S7 Tool Steel (HRC 58-60) | Excellent | Excellent | Good | Fair | Not Recommended |

| A2 Tool Steel (HRC 58-62) | Excellent | Excellent | Excellent | Good | Fair |

| D2 Tool Steel (HRC 60-62) | Excellent | Excellent | Excellent | Excellent | Good |

| Tungsten Carbide (HRA 89-93) | Excellent | Excellent | Excellent | Excellent | Excellent |

Dimensional Tolerances and Marking Depth

Impression clarity depends on more than just material hardness. Dimensional tolerances—the precision of character height, width, and spacing—determine whether your stamped metal carries readable, professional marks or blurry approximations.

Quality steel stamps maintain tolerances within ±0.001" to ±0.003" on character dimensions. Tighter tolerances cost more but deliver consistently legible impressions across production runs. For applications requiring optical character recognition (OCR) or automated inspection, invest in stamps with documented dimensional specifications.

Marking depth requirements vary by application:

- Light identification (0.003"-0.005"): Suitable for parts that won't see heavy wear or finishing operations

- Standard industrial (0.005"-0.010"): Adequate for most manufacturing traceability needs

- Heavy-duty/post-finishing (0.010"-0.020"): Required when parts undergo painting, powder coating, or abrasive environments

A useful guideline from industry practice targets mark depth at 10-20% of character height on ductile metals. So a 3mm character should produce impressions between 0.3mm and 0.6mm deep for optimal readability and longevity.

Surface finish also affects your stamp selection. Anodized aluminum requires deeper impressions for contrast visibility, while painted steel benefits from post-mark paint fill techniques. Always validate stamp performance on your actual production material and finish—not just bare test coupons.

With material compatibility understood, you're ready to explore how these precision tools support quality standards and regulatory compliance in demanding industrial environments.

Quality Standards and Industrial Compliance

When a single misread character on a stamped part can trigger a product recall or compromise safety, quality isn't just a marketing claim—it's a measurable requirement. For manufacturers in automotive, aerospace, and medical industries, the stamps they use must meet rigorous standards that ensure every impression remains legible throughout the component's entire service life.

But what separates professional-grade metal stamping dies from hobby-level tools? The answer lies in certifications, documented processes, and the systematic quality controls that govern how stamps are manufactured and verified. Understanding these standards helps you select tooling that won't let you down when compliance auditors come calling.

What ISO Certification Means for Stamp Quality

ISO 9001:2015 is one of the most widely recognized quality standards globally, but its real value extends far beyond a certificate on the wall. According to Jennison Corporation, ISO 9001 requires companies to build quality into their processes through documented workflows, risk identification, measurable goals, and regular reviews to ensure continuous improvement.

In practical terms for metal stamping die manufacturing, ISO certification translates to:

- Consistency: Every stamp follows established procedures, so outcomes don't depend on which operator runs the equipment or which shift produces your order

- Traceability: If a problem surfaces, ISO processes make it possible to trace the root cause and fix it systematically rather than just patching symptoms

- Corrective action: When issues occur, they're analyzed and corrected to prevent repetition—not simply accepted as normal variation

What does this mean for you as a buyer? Stamps from ISO-certified manufacturers exhibit less variability between batches. The characters on your replacement stamp sets will match those from orders placed years earlier. Heat treatment processes that determine hardness are controlled and documented, not left to operator judgment.

Beyond ISO 9001, specialized certifications address industry-specific demands. IATF 16949 covers automotive quality requirements, while AS9100 governs aerospace applications. For defense-related projects, ITAR registration ensures sensitive technical data and manufacturing processes comply with federal regulations. These layered certifications reflect increasing levels of process discipline—each adding documentation, controls, and verification steps that directly benefit end users.

Traceability Requirements in Regulated Industries

Imagine an aircraft component fails during inspection. Investigators need to know exactly which batch of material, which manufacturing process revision, and which quality checks that specific part passed through. This backward traceability—knowing everything that went into a product—is fundamental to regulated manufacturing.

The marks your stamps create become permanent records that enable this traceability. As outlined in AS9100 requirements, aerospace quality management demands suitable identification that maintains configuration throughout the product's entire life cycle. This includes knowing exactly which serial numbers of each part are included in an assembly at any given time, with traceability extending right down to raw materials.

Quality stamps support this regulatory framework by producing marks with specific, verifiable characteristics:

- Depth consistency: Impressions must meet specified depth tolerances (typically ±0.002") to ensure readability after finishing operations like painting or plating

- Character clarity: Sharp, well-defined edges that remain legible under optical inspection systems and human visual verification

- Durability under environmental stress: Marks that withstand thermal cycling, chemical exposure, and mechanical wear without degrading beyond readable limits

- Audit traceability: Documentation linking the marking tool to calibration records, material certificates, and manufacturing specifications

According to Laser Marking Technologies, ISO 9001:2015 Clause 8.5.2 specifically outlines the need for clear product identification and documented traceability, requiring manufacturers to assign unique identifiers to parts or batches and maintain accessible records from raw material to final delivery.

Compliance Demands Across Critical Industries

Different sectors impose distinct marking requirements that directly influence which types of stamps qualify for the job:

Automotive manufacturing demands marks that survive decades of exposure to road salt, temperature extremes, and mechanical vibration. Components carrying VIN-related data or safety-critical identifications must remain readable throughout the vehicle's service life. IATF 16949 certification demonstrates a supplier's capability to meet these stringent requirements.

Aerospace applications require compliance with MIL-STD-130 and AS9132, which mandate permanent, legible identifiers on all traceable parts. These standards define minimum contrast ratios, size requirements for data matrix codes, and durability specifications that parts must meet through surface treatments and harsh operating conditions.

Medical device manufacturing operates under FDA 21 CFR Part 801.20 and EU MDR 2017/745, requiring unique device identifiers (UDI) that withstand repeated sterilization cycles. Surgical instruments may undergo hundreds of autoclave cycles—marks must remain scannable and readable throughout this demanding service.

The common thread? Each industry requires documented evidence that marking tools consistently produce compliant impressions. This documentation—material certificates, hardness test reports, dimensional inspection records—distinguishes professional metal stamping dies from tools lacking verified specifications.

How Quality Stamps Enable Regulatory Success

Sounds complex? The practical takeaway is straightforward: quality stamps from certified manufacturers come with documentation that supports your compliance needs. When auditors ask how you verified your marking tools meet specifications, you can point to traceable records rather than vague assurances.

This documentation typically includes material composition certificates, heat treatment verification, hardness testing results, and dimensional inspection reports. For custom dies, add design approval records and first-article inspection data. Together, these records demonstrate that your marking process operates within controlled parameters—exactly what regulatory frameworks require.

The investment in certified tooling pays dividends beyond audit readiness. Consistent stamp quality means fewer rejected parts due to illegible marks, reduced rework from shallow impressions, and confidence that your traceability system actually works when someone needs to trace a component back through your production history.

With quality standards and compliance requirements understood, you're prepared to explore how these principles apply across different marking applications—from industrial part identification to artisan craftsmanship.

Application-Specific Stamping Requirements

Here's a question worth considering: what exactly do you want to accomplish with your metal die stamps? The answer shapes everything—from which stamp type you select to how much force you'll need and whether manual striking or press-based methods make more sense for your situation.

Too often, buyers focus on stamp specifications before clarifying their actual application requirements. Let's flip that approach. By starting with your end goal, you'll make smarter decisions about tooling, technique, and investment levels that match your real-world needs.

Industrial Part Marking for Traceability

Manufacturing environments demand marks that survive decades of service while remaining instantly readable. Whether you're identifying automotive components, aerospace fasteners, or medical device housings, industrial marking carries specific requirements that hobby-grade tools simply cannot meet.

Industrial applications typically require:

- Serial number and date code marking: Deep impressions (0.010"-0.020") that remain legible after painting, powder coating, or plating operations

- Specification compliance marks: Character heights and styles conforming to MIL-STD-130, AS9132, or customer-specific requirements

- Welder and operator identification: Border stamps or unique symbols that trace work back to qualified personnel

- Material grade verification: Marks indicating alloy type, heat treatment status, or batch identification

Force requirements in industrial settings scale dramatically with character size and workpiece hardness. According to Durable Technologies, the striking force required increases exponentially when marking multiple characters simultaneously. What works for a single character becomes far more challenging when you're stamping complete part numbers or multi-line text in one operation.

For production volumes exceeding 100 parts daily, pneumatic impact presses deliver consistent pressure every time—eliminating the human variability that plagues hand stamping operations. The operator positions the part, activates the press, and achieves uniform results regardless of experience level or shift fatigue. When marking harder materials like stainless steel, these systems prove especially valuable by delivering necessary force without operator strain.

Artisan Applications from Jewelry to Leather

The artisan market presents entirely different challenges. Here, precision matters less than creative expression, and force requirements drop significantly when working with softer materials. Metal letter stamps designed for jewelry blanks require far gentler handling than their industrial counterparts.

Jewelry and metalsmithing applications include:

- Personalized jewelry tags: Names, dates, and meaningful phrases on pendants, charms, and bracelet blanks

- Maker's marks: Artist signatures and studio logos establishing authenticity

- Decorative borders and patterns: Design stamps adding visual interest to finished pieces

- Metal content hallmarks: Sterling silver, gold karat, or metal purity indicators

When you stamp letters into metal blanks for jewelry, the technique differs substantially from industrial marking. As noted by Beaducation, different metals require varying amounts of striking force—aluminum generally doesn't need as hard a hit as brass might. Practice helps you develop feel for how much force each alloy demands.

Leather stamp and leather stamping tools occupy their own category entirely. Vegetable-tanned leather accepts impressions beautifully when properly moistened, requiring moderate pressure through a mallet strike or arbor press. The material's natural give means impressions deepen with sustained pressure rather than sharp impact—a significant technique difference from metal marking.

Woodworking applications favor heated branding dies over cold stamping. The burning action creates contrast and permanence that cold impressions cannot achieve in porous wood fibers. However, letters stamps designed for soft metals can create acceptable marks in dense hardwoods when combined with sufficient force.

Selecting Between Manual and Press-Based Methods

Your production volume and precision requirements determine whether handheld or press-mounted stamps make sense. Consider these thresholds:

| Application Type | Daily Volume | Recommended Method | Key Considerations |

|---|---|---|---|

| Hobby/Craft jewelry | 1-20 pieces | Handheld with mallet | Flexibility, low cost, creative control |

| Custom jewelry production | 20-100 pieces | Handheld or light arbor press | Balance of speed and flexibility |

| Small manufacturing | 50-200 parts | Arbor press or pneumatic | Consistency becomes important |

| Production manufacturing | 200+ parts | Pneumatic or hydraulic press | Speed, safety, and repeatability critical |

| High-volume industrial | 500+ parts | Automated press systems | Integration with production line required |

Safety considerations often influence this decision. Durable Technologies notes that hand stamping inherently places operators' hands in the striking zone. Even with proper safety equipment like stamp holders and hand shields, some risk remains. Pneumatic presses with two-hand safety controls remove the operator entirely from the impact zone—an important factor as volumes increase.

The crossover point varies by application complexity. Simple single-character marks might remain efficient with hand methods up to 200 daily parts. Complex multi-line marking or logo stamping pushes the balance toward pneumatic systems even at lower volumes, where the difficulty of achieving consistent hand-struck results makes mechanical assistance worthwhile.

Impression depth requirements also influence your method choice. Artisan applications typically need shallow marks (0.003"-0.005") that add visual interest without weakening thin metal blanks. Industrial traceability demands deeper impressions that survive finishing operations—force levels that cause operator fatigue when delivered manually hundreds of times per shift.

Whatever application drives your interest in metal letter stamp technology, matching your method to your actual requirements prevents both under-investment (leading to quality problems) and over-investment (tying up capital in unnecessary capability). Start with what you need to accomplish, then work backward to the right tools.

Understanding your application requirements prepares you for the next consideration: how custom metal die stamps are actually manufactured, and what separates quality tooling from commodity products.

How Custom Metal Die Stamps Are Manufactured

Ever wondered what happens between submitting your logo file and receiving a precision custom metal stamp that produces flawless impressions? The manufacturing journey involves far more complexity than most buyers realize—and understanding this process helps you evaluate suppliers, set realistic timelines, and recognize quality when you see it.

Unlike off-the-shelf letter sets, custom metal stamps require specialized engineering at every stage. Each decision—from material grade selection to heat treatment parameters—directly affects how your stamp performs over thousands of impressions. Let's walk through the complete manufacturing sequence that transforms raw steel into precision stamping tool and die components.

From Design File to Finished Die

The journey from concept to finished custom metal stamp die follows a systematic sequence where quality controls at each stage determine final performance. Skip or rush any step, and you'll pay the price in premature wear, inconsistent impressions, or outright stamp failure.

- Design and engineering review: Your artwork or CAD file undergoes analysis for stampability. Engineers evaluate character spacing, line thickness, and detail resolution to ensure the design will transfer cleanly under impact. Overly fine details that won't survive the stamping process get flagged for modification.

- Material selection: Based on your workpiece material, production volume, and force application method, engineers specify the appropriate tool steel grade or carbide composition. This decision locks in hardness, toughness, and wear resistance characteristics.

- CNC machining or EDM processing: Computer-controlled machining removes material to create the stamp's basic geometry. For intricate logos or fine details, Electrical Discharge Machining (EDM) cuts features that conventional cutting tools cannot achieve—burning away material with controlled electrical sparks to produce sharp internal corners and complex contours.

- Heat treatment: The machined stamp undergoes precisely controlled heating and cooling cycles to achieve target hardness. This critical step transforms relatively soft machinable steel into hardened tooling capable of withstanding thousands of impacts. Temperature accuracy, soak times, and quenching methods must match the specific steel grade.

- Finishing and polishing: Post-heat-treatment grinding and polishing refine surfaces and sharpen character edges. The quality of this finishing directly affects impression clarity—rough stamp faces transfer their imperfections to every mark they create.

- Quality verification: Final inspection confirms dimensional accuracy, hardness values, and surface finish meet specifications. Professional manufacturers document these measurements, providing traceability records that support your quality management system.

According to Green Oak Tool, the stamping die fabrication process begins with computer software plotting out every step from start to finish. This digital foundation—combined with CNC machining, EDM, prototyping, and traditional tool and die building expertise—assures the geometry and specifications of your product before physical production begins.

Engineering Factors That Affect Stamp Performance

What separates a die stamp that lasts 500,000 impressions from one that fails after 5,000? The answer lies in engineering decisions made before manufacturing even starts—and in the simulation tools that predict real-world performance.

Modern custom metal stamping dies benefit from Computer-Aided Engineering (CAE) simulation that identifies potential problems before cutting any steel. As noted by DFE-Tech, early simulation and process optimization help identify and address issues such as cracks, wrinkles, or uneven thickness before production begins. This predictive capability reduces production risks while optimizing geometry and process parameters.

Key engineering factors that influence stamp quality include:

- Character geometry optimization: Draft angles, corner radii, and relief depths engineered to release cleanly from workpiece material without sticking or distortion

- Stress distribution analysis: Identifying high-stress concentration points that could lead to premature cracking or chipping under repeated impact

- Material flow modeling: Predicting how workpiece metal will displace during stamping to ensure complete, consistent impressions

- Thermal behavior prediction: Understanding how heat treatment will affect final dimensions and compensating in the machining stage

These engineering capabilities explain why certification credentials matter. Manufacturers holding IATF 16949 certification—the automotive industry's quality management standard—demonstrate systematic engineering processes that reduce defects. For example, Shaoyi's precision stamping die solutions combine IATF 16949 certification with advanced CAE simulation, achieving a 93% first-pass approval rate that reflects robust engineering discipline.

Rapid Prototyping vs. Production Tooling

Timeline expectations vary dramatically depending on whether you need prototype tooling for validation or production-grade metal stamping die sets for long-term manufacturing.

Rapid prototyping prioritizes speed over maximum durability. Simplified heat treatment cycles, reduced finishing steps, and faster machining strategies can deliver functional stamps in as little as 5 days—allowing you to validate designs, test marking parameters, and confirm workpiece compatibility before committing to production tooling. These prototype stamps may handle thousands of impressions but aren't optimized for extended service life.

Production tooling invests additional time in material preparation, precision machining, optimal heat treatment, and thorough finishing. Expect 2-4 weeks for custom metal stamping dies intended for high-volume production. This investment pays dividends through extended service life, consistent impression quality across production runs, and reduced per-part tooling costs when amortized over hundreds of thousands of impressions.

The choice between approaches depends on your project phase:

| Consideration | Rapid Prototype | Production Tooling |

|---|---|---|

| Typical lead time | 5-10 days | 2-4 weeks |

| Expected lifespan | 5,000-20,000 impressions | 100,000-500,000+ impressions |

| Best application | Design validation, sampling | Production manufacturing |

| Material grade | Standard tool steel | Premium tool steel or carbide |

| Documentation level | Basic inspection | Full quality records |

| Cost per impression | Higher (shorter lifespan) | Lower (amortized over volume) |

Manufacturers offering both capabilities—like Shaoyi with their rapid prototyping in as few as 5 days alongside high-volume production—provide flexibility to validate designs quickly, then transition to optimized production tooling once specifications are confirmed.

What Quality Manufacturing Actually Looks Like

How do you distinguish quality custom die manufacturing from commodity production? Look for these indicators:

- Engineering consultation: Quality manufacturers review your design for stampability before quoting, identifying potential issues rather than simply producing whatever file you submit

- Material certification: Documentation tracing tool steel to specific heat numbers with verified chemical composition and mechanical properties

- Process controls: Documented heat treatment parameters, calibrated inspection equipment, and systematic quality checkpoints throughout production

- First-article inspection: Verification that initial production stamps meet all specifications before releasing the complete order

- Performance guarantees: Confidence in their process demonstrated through warranty terms and responsiveness to quality concerns

The difference between a 93% first-pass approval rate and industry-average rejection rates represents significant cost and schedule implications for your projects. When evaluating suppliers for custom metal stamps, ask about their engineering capabilities, certification credentials, and quality metrics—these indicators reveal far more than quoted prices alone.

With manufacturing fundamentals understood, you're prepared to explore the operational techniques that maximize stamp performance and longevity in your specific applications.

Operating Techniques and Stamp Maintenance

You've selected the right stamp type, matched materials correctly, and invested in quality tooling—but none of that matters if your technique undermines the results. Whether you're new to letter stamping or an experienced operator seeking to optimize your process, mastering the fundamentals of force application and maintenance directly determines impression quality and stamp lifespan.

Think of your stamp and die as precision instruments that demand respect. Proper technique delivers crisp, consistent marks every time. Poor habits accelerate wear, produce illegible impressions, and transform your tooling investment into scrap metal far sooner than necessary.

Achieving Consistent Impression Depth

Inconsistent depth ranks among the most common stamping frustrations. One character sits deep and readable while the next barely scratches the surface. What causes this variation—and how do you eliminate it?

For handheld letter stamp and number stamp applications, technique matters more than raw force. According to DeVore Engraving, uniform depth is essential to ensure clarity without weakening the component—and skilled use of hand stamps produces high-quality impressions when proper technique is applied.

Master these fundamentals for consistent hand stamping:

- Secure your workpiece: Any movement during impact causes shallow or double impressions. Use a steel bench block, vise, or dedicated fixture that prevents shifting

- Position perpendicular: Hold your stamp perfectly vertical to the work surface. Even slight angles create uneven character depth and distorted marks

- Strike once with commitment: A single confident hammer blow outperforms multiple tentative taps. Hesitant striking produces layered impressions that blur character edges

- Match force to material: Aluminum requires lighter strikes than brass; mild steel demands more force than either. Practice on scrap material to calibrate your technique

Press-based stamping set operations eliminate most technique variables but introduce setup considerations. Proper die alignment, consistent stroke depth settings, and appropriate pressure adjustment ensure repeatable results across production runs. As noted by Die-Made, machine-controlled stamping ensures consistency, and regular press calibration combined with tight tool build standards maintains that consistency even over long production runs.

When shallow impressions persist despite proper technique, investigate these root causes:

- Workpiece hardness exceeds stamp capability—consider upgrading to carbide

- Insufficient press tonnage for character size and material combination

- Worn stamp face no longer transfers full character depth

- Workpiece surface contamination preventing clean material displacement

Extending Stamp Service Life

Quality stamps represent significant investments—protecting that investment through proper care maximizes your return. The difference between stamps lasting 10,000 impressions versus 100,000 often comes down to maintenance discipline rather than material quality.

Implement these maintenance best practices:

- Clean after each use: Remove metal debris, lubricant residue, and contaminants with appropriate solvents and brushes. Accumulated debris transfers to subsequent impressions and accelerates wear

- Inspect stamp faces regularly: Examine character edges for chipping, rounding, or buildup. Catching early wear prevents quality problems from reaching your production parts

- Apply protective coating for storage: Light oil prevents corrosion on tool steel stamps during extended storage. Wipe clean before use to avoid contaminating workpieces

- Store in controlled environments: Humidity accelerates rust formation; temperature swings cause dimensional changes. Climate-controlled storage with protective cases or racks extends service life

- Maintain striking tools: Mushroomed hammer faces and worn press components transfer damage to your stamps. Replace or dress striking surfaces before they compromise your precision tooling

According to Die-Made's maintenance guidance, using appropriate lubricants helps minimize friction between moving parts, reducing wear and tear. Regularly lubricated dies operate smoothly, resulting in decreased risk of breakdowns during stamping operations.

Troubleshooting Common Stamping Problems

Even with proper technique and maintenance, problems occasionally arise. Knowing how to diagnose and correct issues quickly minimizes production disruption and prevents unnecessary stamp replacement.

Shallow impressions typically indicate insufficient force, workpiece hardness exceeding stamp capability, or worn stamp faces. Verify your force settings, confirm material compatibility, and inspect stamp condition before assuming replacement is needed.

Uneven marks suggest alignment problems—either the stamp isn't perpendicular to the work surface, the workpiece isn't properly secured, or press alignment has drifted. As Die-Matic notes, press misalignment and die inconsistencies cause parts to fall outside dimensional tolerances, and regular press calibration combined with tool repeatability controls maintains consistent results.

Character distortion often results from excessive force, stamp overheating during rapid production, or striking a worn alphabet stamp set at improper angles. Reduce force incrementally, allow cooling between intensive marking sessions, and verify perpendicular positioning.

Burrs or rough edges on impressions indicate dull tooling or improper clearances. Die-Matic recommends maintaining proper tool clearances and using wear-resistant coatings on dies to extend tool life and reduce defect rates.

When to Replace vs. Recondition

Not every worn stamp requires replacement. Minor edge wear, surface contamination, and light corrosion often respond to reconditioning—cleaning, light polishing, or professional sharpening that restores performance at a fraction of replacement cost.

However, certain damage demands replacement:

- Chipped or broken character elements that cannot be restored

- Significant face wear reducing character depth beyond acceptable limits

- Cracking in the stamp body indicating fatigue failure

- Deformation from improper use or excessive force application

Establish inspection intervals based on your production volume. High-volume operations might inspect weekly; lower-volume users might check monthly. Document stamp condition over time to identify wear patterns and predict replacement timing before quality problems reach your production parts.

With operational techniques and maintenance fundamentals mastered, you're equipped to evaluate stamp suppliers based on what actually matters for your specific applications and requirements.

Selecting the Right Stamp Supplier for Your Needs

You've mastered stamp types, understood material compatibility, and learned proper operating techniques—but where do you actually purchase metal die stamps that meet your standards? The supplier you choose influences everything from initial quality to long-term support, and the lowest price rarely delivers the best value.

Navigating the market can feel overwhelming. Catalog suppliers offer convenience for standard items. Custom manufacturers build precisely what you need. Specialty providers focus on specific industries or applications. Understanding what each type offers—and what questions to ask—helps you find the right partner for your specific requirements.

Evaluating Stamp Suppliers Beyond Price

Price per stamp tells you almost nothing about total cost of ownership. A cheaper stamp that wears out in 5,000 impressions costs far more than a premium tool lasting 50,000. According to KY Hardware's supplier selection guide, the lowest price per part is rarely the best value—true value comes from a supplier who acts as a strategic partner.

Evaluate potential suppliers across these critical dimensions:

- Material quality and documentation: Can they provide material certificates tracing tool steel to specific heat numbers? Quality metal stamping tooling comes with verifiable specifications, not vague assurances

- Customization capabilities: Do they offer engineering consultation, or simply manufacture whatever file you submit? Suppliers who review designs for stampability catch problems before they become expensive mistakes

- Turnaround time: What's realistic for your timeline—and do they offer expedited options when projects demand speed?

- Technical support: Will engineers help troubleshoot application problems, or does the relationship end at shipping?

- Certification credentials: ISO 9001:2015 demonstrates basic quality discipline; IATF 16949 indicates automotive-grade process control

As noted by Standard Die, the best customization services include assisting with design, choosing materials, identifying finishes, and providing engineering expertise throughout the process—not just manufacturing capacity.

Custom vs. Stock Stamp Considerations

When does a standard letter and number stamp set make sense, and when should you invest in custom metal stamping dies? The decision hinges on your specific application requirements and production context.

Stock stamps work well when:

- Your marking needs involve standard alphanumeric characters

- Volume doesn't justify custom tooling investment

- Immediate availability matters more than perfect optimization

- Applications like an aluminum stamping kit for occasional shop use or alphabet letter stamps for craft projects

Custom dies become worthwhile when:

- Logos, symbols, or proprietary marks require unique designs

- High volumes justify amortizing tooling costs across production

- Specific tolerances or material requirements exceed standard offerings

- You need a personalised metal stamp that competitors cannot replicate

Standard Die emphasizes that custom metal stamping provides unmatched benefits including compatibility with your specific components, reliability through engineering involvement, accuracy of creation to your tolerances, and proprietary ownership of your designs.

| Supplier Type | Best For | Typical Lead Time | Customization Level | Key Considerations |

|---|---|---|---|---|

| Certified Custom Manufacturers (e.g., Shaoyi) | Automotive, aerospace, high-volume production | 5 days (prototype) to 2-4 weeks (production) | Full custom with CAE simulation | IATF 16949 certification, 93% first-pass approval, OEM standards compliance |

| Catalog Suppliers | Standard letter/number sets, immediate needs | Same day to 1 week | Limited to stock options | Convenience and availability; verify material specifications |

| General Custom Manufacturers | Custom logos, moderate volumes | 1-3 weeks | Custom designs without advanced simulation | Request material certificates and quality documentation |

| Specialty Providers | Industry-specific applications (jewelry, leather) | Varies by complexity | Application-optimized designs | Deep expertise in specific materials and techniques |

Questions to Ask Before Ordering

Don't assume—verify. The right questions reveal supplier capabilities and prevent costly mismatches between your requirements and their actual offerings.

About materials and tolerances:

- What tool steel grades do you use, and can you provide material certificates?

- What dimensional tolerances do your stamps maintain on character height and spacing?

- Do you offer carbide options for hardened workpiece applications?

About quality and process:

- What certifications does your facility hold (ISO 9001, IATF 16949, AS9100)?

- What is your typical first-pass approval rate for custom tooling?

- Do you provide inspection documentation with completed orders?

About support and guarantees:

- What warranty terms cover material or manufacturing defects?

- Do you offer engineering consultation for design optimization?

- What's your process for addressing quality concerns after delivery?

KY Hardware recommends creating a weighted scorecard assigning importance to each criterion—Quality Systems, Engineering Support, Price, Lead Time—then scoring each supplier objectively. This approach removes personal bias and identifies the supplier that best aligns with your most critical needs.

Making the Final Decision

The supplier relationship extends far beyond your first order. Consider long-term factors: Can they scale with your growth? Will replacement stamps match originals ordered years later? Do they invest in capabilities that benefit your future projects?

For automotive or high-volume applications, suppliers demonstrating advanced capabilities—like Shaoyi's combination of IATF 16949 certification, CAE simulation for defect prevention, and rapid prototyping within 5 days—set benchmarks for what professional-grade manufacturing looks like. Their 93% first-pass approval rate reflects engineering discipline that translates directly into fewer rejected parts and faster project timelines.

Whatever your application, prioritize suppliers who function as partners rather than transaction processors. The right supplier helps you solve problems, optimize designs, and achieve marking results that support your quality objectives—not just ship stamps that may or may not meet your actual needs.

Frequently Asked Questions About Metal Die Stamps

1. How much does a metal stamping die cost?

Metal stamping die costs range from $500 to $15,000 depending on complexity, material requirements, and production volume. Simple handheld letter stamps start around $10-50 each, while custom logo dies with carbide construction for high-volume applications reach the upper range. For automotive or aerospace applications requiring IATF 16949 certified tooling with CAE simulation—like those from Shaoyi—the investment reflects engineering expertise that delivers 93% first-pass approval rates and significantly lower per-part costs when amortized over production runs.

2. What is a die in metal stamping?

A die in metal stamping is a specialized hardened tool that creates permanent impressions through applied force. Unlike cutting tools, stamping dies physically displace material to form raised or recessed marks. Dies range from simple handheld character stamps struck with hammers to precision press-mounted tools used in automated production. The die must always be harder than the workpiece—typically 58-62 HRC for tool steel or 70+ HRC for carbide—to transfer its pattern without wearing prematurely.

3. What are the four types of metal stamping?

The four main metal stamping processes are progressive die stamping (continuous strip feeding through multiple stations), transfer die stamping (parts moved between separate die stations), deep draw stamping (forming cup-shaped components), and micro/miniature stamping (precision small-scale work). For marking applications specifically, stamp types include handheld stamps for portability, plate stamps for press mounting, carbide stamps for hardened materials, and low stress stamps for heat-treated components where preventing micro-cracking is critical.

4. What is the difference between die casting and metal stamping?

Die casting and metal stamping use fundamentally different processes. Die casting melts metal and forces it into molds under pressure, creating complex three-dimensional shapes from molten material. Metal stamping works cold—pressing hardened tools against sheet metal or solid surfaces to create permanent impressions without melting. Stamping dies mark identification data, logos, and traceability codes, while casting dies produce entire component shapes. Each serves distinct manufacturing purposes.

5. How long do metal die stamps last before replacement?

Stamp lifespan varies dramatically based on material pairing and application method. Standard tool steel stamps marking aluminum achieve 50,000+ impressions, while the same stamps on stainless steel may show wear after 5,000 strikes. Carbide stamps marking hardened materials can exceed 500,000 impressions. Key longevity factors include proper striking technique, regular cleaning, appropriate force application, and matching stamp hardness to workpiece material. Press-mounted stamps typically outlast handheld versions due to consistent force delivery.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —