Laser Cutting Metal Services Decoded: From Quote To Finished Part

Understanding Laser Cutting Technology for Metal Fabrication

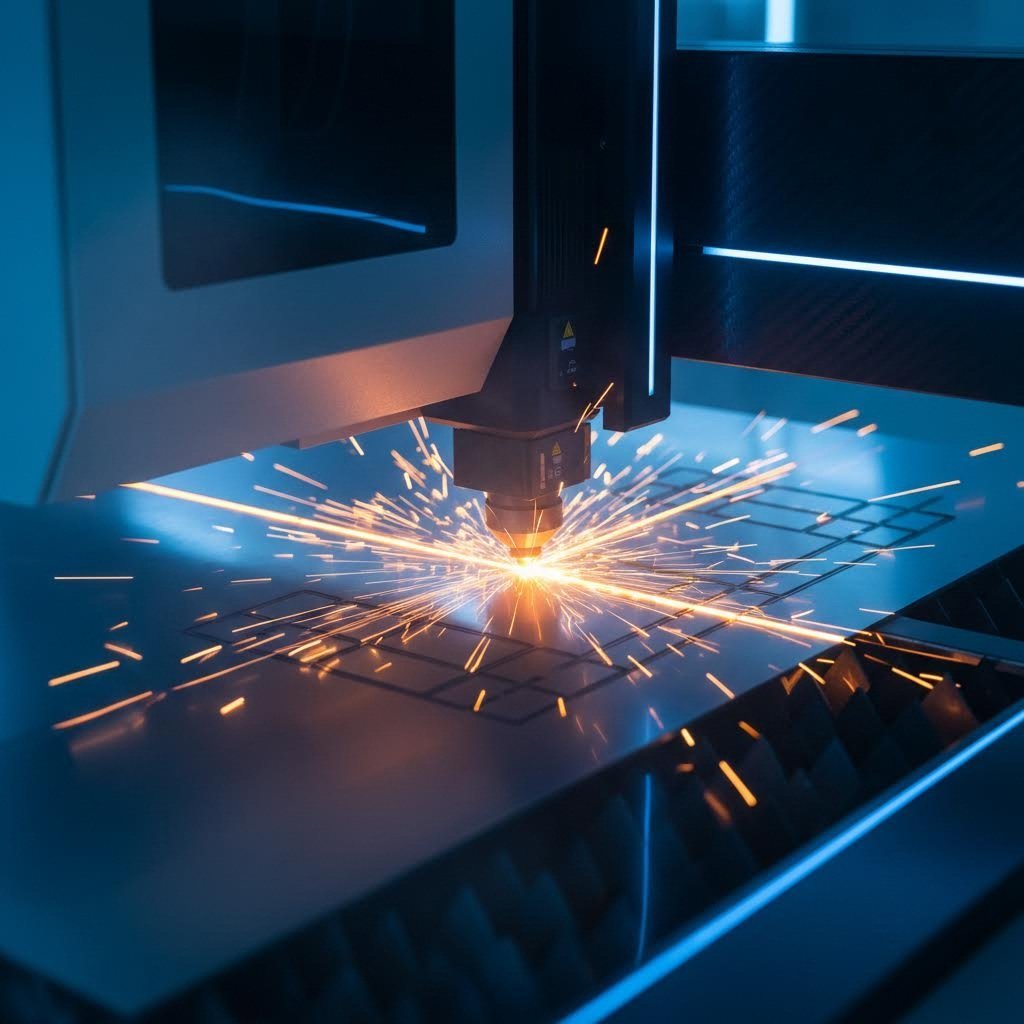

Ever wondered how manufacturers create those impossibly precise metal components with intricate patterns and razor-sharp edges? The answer lies in one of the most transformative technologies in modern fabrication: laser cutting metal. This process has revolutionized how industries approach metalwork, replacing slower mechanical methods with speed, accuracy, and remarkable versatility.

Laser cutting is a thermal-based process that uses a highly focused beam of light to melt, burn, or vaporize metal along a computer-programmed path, creating precise cuts with minimal material waste.

So, what is laser cutting exactly, and why has it become the go-to solution for everything from automotive parts to architectural metalwork? Let's break down the fundamentals so you can understand exactly what happens when you send your designs to a professional metal laser cutting service.

How Focused Light Transforms Raw Metal

Imagine concentrating sunlight through a magnifying glass, but amplifying that principle by orders of magnitude. That's essentially how cutting with a laser works. The process begins inside a device called a resonator, where a specific medium generates an intensely focused beam of coherent light.

Here's where it gets fascinating. When photons interact with electrons in the lasing medium, they trigger a chain reaction called stimulated emission. Each excited electron releases an identical photon, creating a cascade of perfectly synchronized light waves. These photons bounce between mirrors until they build enough intensity to pass through a semi-reflective surface as a powerful, concentrated beam.

Once the beam exits the resonator, it travels through a series of mirrors or fiber optic cables before passing through a focusing lens. This lens concentrates all that energy into an incredibly small diameter, sometimes as narrow as a fraction of a millimeter. The result? A localized point of extreme heat that can reach temperatures high enough to melt or vaporize virtually any metal.

The Science Behind Precision Metal Fabrication

You might be wondering how laser metal cutting achieves such remarkable accuracy. The secret lies in the computer-controlled process. Before any cutting begins, your design file gets converted into G-code, which is essentially a set of machine-readable instructions telling the laser head exactly where to move.

As the focused beam contacts the metal surface, one of three things happens depending on the material and technique used:

- Fusion cutting: A high-pressure jet of inert gas like nitrogen blows molten material away from the cut while shielding the edge from oxidation

- Flame cutting: Oxygen assists the process by creating an exothermic reaction that accelerates cutting speed

- Vaporization cutting: For thin or sensitive materials, the laser ablates material directly without gas assistance

This precision is why laser cutting metal services have become the industry standard for accuracy and repeatability. The CNC control enables quick adjustments, automated cutting paths, and the ability to produce identical parts consistently, whether you need one prototype or thousands of production pieces.

Throughout this guide, you'll discover how different laser technologies compare, which metals work best for various applications, and how to optimize your designs for cost-effective results. Whether you're sourcing parts for a manufacturing project or exploring options for custom metalwork, understanding these fundamentals will help you make informed decisions and communicate effectively with service providers.

CO2 vs Fiber vs Nd YAG Laser Technologies Explained

Now that you understand the basic physics behind laser cutting, here's the question that really matters: which laser type should handle your project? Not all lasers are created equal, and choosing the wrong technology can mean slower production times, higher costs, or subpar edge quality. Let's demystify the three primary laser for cutting machine options you'll encounter when sourcing metal fabrication services.

Fiber Lasers vs CO2 for Metal Applications

When you're evaluating a laser cutting machine for metal, you'll most commonly encounter two dominant technologies: CO2 and fiber lasers. Each excels in different scenarios, and understanding their strengths helps you match technology to your specific material needs.

CO2 lasers generate infrared light at a wavelength of 10.6 microns using a gas mixture containing carbon dioxide. These machines have been the workhorse of the industry since the 1970s and remain popular for their versatility. A CO2 laser cut metal machine handles thicker materials exceptionally well, particularly mild steel and stainless steel in heavier gauges. According to research from Laser Expertise Ltd, modern CO2 systems operating at 4-5 kW can cut mild steel up to 25mm thick and stainless steel up to 20mm.

What makes CO2 technology stand out? Its longer wavelength interacts effectively with organic materials, making these machines ideal when your shop also processes plastics, wood, or textiles. However, this same wavelength characteristic creates challenges with highly reflective metals like copper and aluminum, where the beam can bounce back and damage optical components.

Fiber lasers represent the newer generation of metal cutting laser machine technology. Operating at a much shorter 1.06-micron wavelength, fiber systems deliver exceptional performance on thin to medium-thickness metals. These machines convert electrical energy into laser light with remarkable efficiency, typically 30-50% compared to roughly 10-15% for CO2 systems.

When you're working with a sheet metal laser cutting machine processing materials under 6mm, fiber technology often delivers significantly faster cutting speeds. The shorter wavelength also means fiber lasers handle reflective metals like aluminum, brass, and copper with greater reliability. Many fiber laser cutting services report 2-3 times faster processing on thin stainless steel compared to equivalent CO2 systems.

Matching Laser Technology to Your Material Needs

Nd:YAG lasers occupy a specialized niche in the metal cutting landscape. These solid-state systems also operate at 1.06 microns, similar to fiber lasers, but use a crystalline medium rather than optical fiber. Their primary advantage? The ability to transport the beam through optical fibers to robotic arms or hard-to-reach positions on automotive production lines.

According to research documented by laser cutting specialists, Nd:YAG systems excel in three specific scenarios:

- Fine detailed work on thin materials where extremely small focused spots are essential

- Cutting highly reflective metals like silver alloys on a regular production basis

- Applications requiring flexible beam delivery through optical fibers to workpieces

However, Nd:YAG lasers cannot process most organic materials because plastics and wood products are transparent to their wavelength. This limitation means they're rarely found in general job shops but remain valuable for specialized manufacturing cells.

To help you quickly identify which laser cutting machine sheet metal technology fits your project requirements, here's a comprehensive comparison:

| Factor | CO2 Laser | Fiber Laser | Nd:YAG Laser |

|---|---|---|---|

| Ideal Material Types | Mild steel, stainless steel, plastics, wood, textiles | Thin metals, reflective metals (aluminum, copper, brass) | Reflective alloys, fine detail work, silver |

| Thickness Capability | Up to 25mm mild steel, 20mm stainless | Best under 20mm, excels at thin gauges | Typically thin sections only |

| Cutting Speed (Thin Metal) | Moderate | Fastest option | Moderate to slow |

| Energy Efficiency | 10-15% wall plug efficiency | 30-50% wall plug efficiency | 3-5% wall plug efficiency |

| Maintenance Requirements | Higher (mirrors, gas refills, turbines) | Lower (solid-state, minimal optics) | Moderate (lamp or diode replacement) |

| Typical Applications | General fabrication, thick plate, mixed-material shops | High-volume thin metal production, automotive parts | Robotic welding cells, specialized fine cutting |

So which technology should you specify when requesting quotes? For most metal fabrication projects, the choice comes down to material type and thickness. If you're cutting steel plate over 12mm, CO2 remains highly competitive. For high-volume production of thin stainless or aluminum components, fiber laser cutting services typically deliver the best combination of speed and edge quality. And when your application demands extremely fine features or involves highly reflective specialty alloys, Nd:YAG may be worth the premium.

Understanding these distinctions positions you to ask smarter questions when evaluating service providers and ensures your parts get processed on equipment optimized for your specific requirements. Next, we'll explore exactly which metals each technology handles best and the thickness limitations you need to consider for your designs.

Metal Compatibility and Thickness Limitations Guide

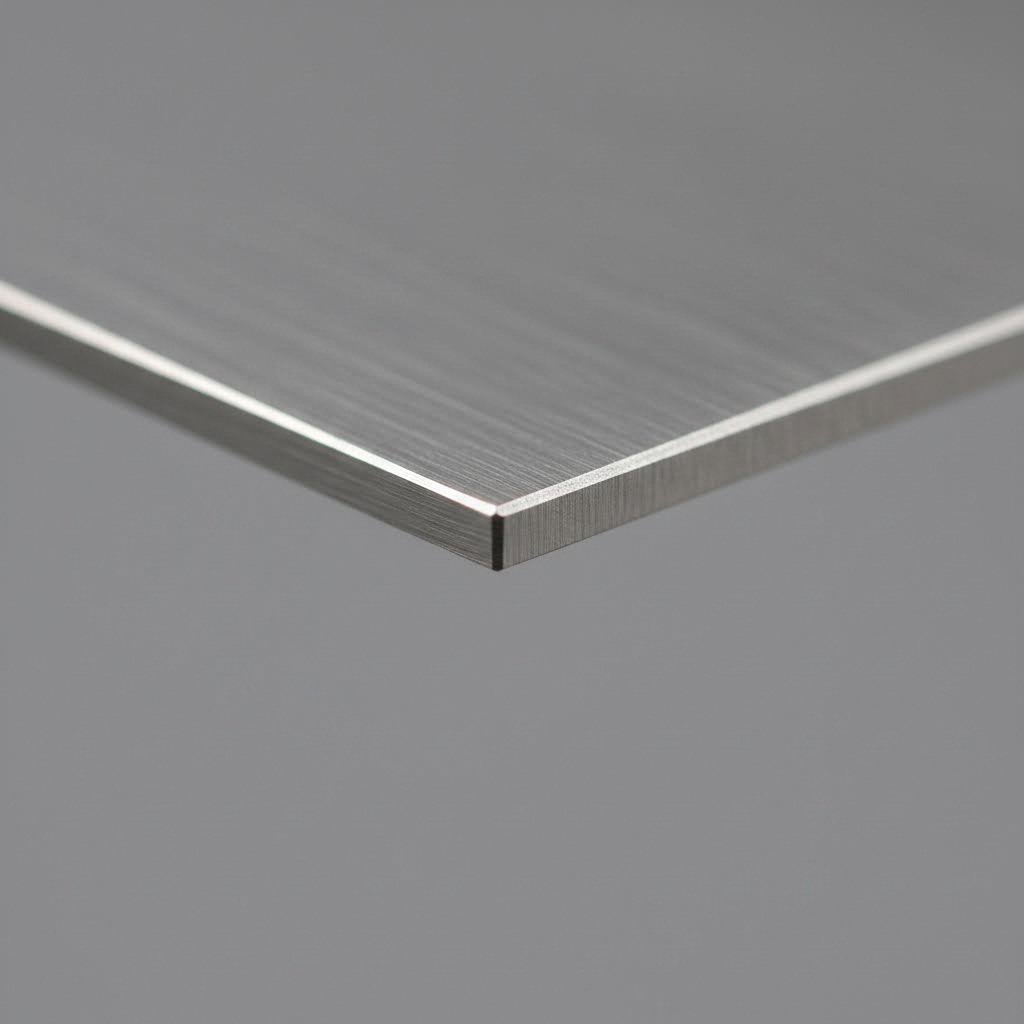

You've learned how different laser technologies work, but here's the practical question on every buyer's mind: can laser cutting handle the specific metal your project requires? The answer depends on material properties that directly affect how laser energy interacts with the workpiece. Understanding these dynamics helps you choose the right material upfront and avoid costly surprises during production.

Not all metals respond equally to laser cutting of metal sheets. Physical characteristics like reflectivity, thermal conductivity, and melting point determine whether a material cuts cleanly or presents challenges that require specialized expertise. Let's examine what makes each common metal unique and how professional services achieve excellent results across the spectrum.

Steel and Stainless Steel Cutting Parameters

Good news first: if you're working with steel, you've chosen one of the most laser-friendly materials available. Laser cutting steel is straightforward because carbon steel and mild steel absorb laser energy efficiently and have manageable thermal properties.

Mild steel laser cutting produces clean, oxide-free edges when processed with nitrogen assist gas, or faster cuts with oxygen assistance. According to industry thickness guidelines, thin steel sheets between 0.5mm and 3mm cut easily with 1000W to 2000W lasers, while medium plates from 4mm to 12mm require 2000W to 4000W systems. For thick steel plates ranging from 13mm to 20mm, high-power lasers between 4000W and 6000W deliver the necessary penetration.

Stainless steel laser cutting follows similar principles but demands attention to edge quality. Because stainless contains chromium that can oxidize at high temperatures, many applications specify nitrogen assist gas to maintain corrosion resistance at the cut edge. As noted by Universal Tool specialists, stainless steel produces clean, high-quality edges with fiber lasers even at higher thicknesses, making it an excellent choice for both practical and decorative applications.

When working with laser cutting ss (stainless steel), keep these parameters in mind:

- Thin stainless (0.5mm to 3mm) cuts precisely with 1000W to 2000W lasers

- Medium thicknesses (4mm to 8mm) require 2000W to 4000W systems for smooth cuts

- Thick stainless (9mm to 20mm) demands 4000W to 6000W lasers for proper penetration

- Nitrogen assist gas preserves the material's natural corrosion resistance

Working with Reflective Metals Like Aluminum and Copper

Here's where material selection gets more nuanced. Highly reflective metals present genuine challenges, but modern fiber laser technology has largely solved these problems. Understanding why these materials behave differently helps you set realistic expectations and communicate effectively with service providers.

Aluminum laser cutting requires careful parameter management for two reasons. First, aluminum's high reflectivity means it bounces back a significant portion of the laser beam's energy. Second, its excellent thermal conductivity rapidly dissipates heat away from the cutting zone. The result? You need more power to achieve the same cut compared to steel of equivalent thickness.

According to fiber laser cutting specialists, aluminum cuts exceptionally well with fiber laser machines despite being challenging on older CO2 systems. For laser cut aluminum projects, thin sheets between 0.5mm and 3mm work well with 1000W to 2000W lasers. Medium aluminium laser cutting at 4mm to 8mm thickness requires 2000W to 4000W systems, while thick plates from 9mm to 15mm demand 4000W or greater power levels to overcome the material's reflectivity.

Copper and brass push these challenges even further. Both metals exhibit extremely high reflectivity and thermal conductivity, making them the most demanding common materials for laser processing. However, fiber lasers operating at their shorter 1.06-micron wavelength handle copper alloys far more reliably than CO2 systems ever could.

For copper specifically, thickness charts indicate that 3000W to 5000W lasers are typically required even for relatively thin sections between 0.5mm and 6mm. Professional services compensate for copper's challenging properties by adjusting cutting speeds, increasing power density, and using specialized assist gas configurations.

Here's a comprehensive reference guide showing what to expect across common metals:

| Metal Type | Maximum Thickness Range | Recommended Laser Type | Special Considerations |

|---|---|---|---|

| Mild Steel | Up to 25mm | CO2 or Fiber | Easiest to cut; oxygen assist increases speed; nitrogen produces oxide-free edges |

| Stainless Steel | Up to 20mm | CO2 or Fiber | Use nitrogen assist to preserve corrosion resistance; excellent edge quality achievable |

| Aluminum | Up to 15mm | Fiber (strongly preferred) | High reflectivity and thermal conductivity require increased power; nitrogen assist recommended |

| Copper | Up to 6mm | Fiber only | Extremely reflective; requires high power (3000W+); slower cutting speeds necessary |

| Brass | Up to 8mm | Fiber (strongly preferred) | Similar challenges to copper; fiber wavelength handles reflectivity better than CO2 |

| Titanium | Up to 10mm | CO2 or Fiber | Highest strength-to-weight ratio; requires inert atmosphere to prevent oxidation; premium pricing |

Titanium deserves special mention because it combines excellent laser compatibility with demanding process requirements. This metal cuts more easily than it stamps or machines mechanically, making laser processing particularly attractive for aerospace and medical applications. However, titanium reacts aggressively with oxygen at elevated temperatures, so argon or nitrogen shielding is essential to prevent embrittlement at the cut edge.

What should you take away from these material considerations? First, steel and stainless steel remain the most forgiving choices for laser cutting projects. Second, aluminum and copper are absolutely viable with modern fiber laser technology, but expect adjusted pricing to reflect the additional power and slower speeds required. Finally, always discuss material specifics with your service provider before finalizing designs, as thickness limitations can vary based on the equipment they operate.

Now that you understand which materials work best with laser technology, you might wonder how laser cutting stacks up against alternative methods. When should you choose waterjet, plasma, or CNC machining instead? The next section provides an honest comparison to help you select the optimal process for your application.

Laser Cutting vs Waterjet Plasma and CNC Alternatives

Here's an honest truth that sales-focused content rarely acknowledges: laser cutting isn't always the best choice. Surprised? While laser technology excels in many applications, understanding when alternative metal cutting services outperform lasers can save you significant time, money, and frustration. Let's compare your options objectively so you can match the right technology to your specific project requirements.

Each cutting method brings distinct advantages to the table. The key lies in understanding where laser and CNC technologies complement each other versus where alternatives like waterjet or plasma deliver superior results. Think of it this way: a cnc laser cutter for metal might be perfect for your intricate bracket design, but that same technology could be the wrong choice for your thick structural steel project.

When Waterjet Outperforms Laser Cutting

Waterjet cutting uses high-pressure water mixed with abrasive particles to slice through virtually any material. According to industry testing from Wurth Machinery, the waterjet market is projected to reach over $2.39 billion by 2034, driven largely by applications where heat-sensitive cutting is essential.

When should you choose waterjet over laser? Consider these scenarios:

- Heat-sensitive materials: Waterjet produces zero heat-affected zone, meaning no warping, hardening, or metallurgical changes to your workpiece

- Extremely thick materials: Waterjet handles materials up to 12 inches thick where lasers cannot penetrate effectively

- Mixed-material cutting: A single waterjet system cuts stone, glass, composites, and metals without equipment changes

- Reflective specialty alloys: Brass, titanium, and Inconel cut reliably without the reflectivity concerns that challenge laser systems

- Food-grade applications: No thermal contamination makes waterjet ideal for food processing equipment

The tradeoffs? Waterjet cutting runs significantly slower than laser processing, particularly on thin materials. Operating costs are also higher due to abrasive consumption, and cleanup requires more attention because of the water and garnet mixture produced during cutting. Equipment investment is substantial too, with quality waterjet systems starting around $100,000 compared to $60,000 for smaller units.

Plasma vs Laser for Thick Steel Applications

If you're searching for plasma cutting near me for thick steel fabrication, you're asking the right question. Plasma cutting dominates when working with conductive metals over half an inch thick while keeping costs manageable.

According to comparative testing, plasma cutting 1-inch steel runs about 3-4 times faster than waterjet, with operating costs roughly half as much per linear foot. The equipment investment tells an even more compelling story: a complete plasma system costs around $90,000 compared to approximately $195,000 for a similar-sized waterjet setup.

Choose plasma cutting when your projects involve:

- Structural steel fabrication: Beams, plates, and heavy-gauge components cut quickly and economically

- Heavy equipment manufacturing: Construction and agricultural machinery components

- Shipbuilding applications: Large-scale thick plate processing where speed matters more than fine detail

- Budget-conscious thick metal work: When precision requirements allow for plasma's wider tolerances

However, plasma has clear limitations. Edge precision is far less accurate than laser cutting, making plasma unsuitable for intricate designs or tight-tolerance parts. Workers also require additional safety precautions due to electromagnetic radiation produced during cutting. If your design demands clean edges, small holes, or complex geometries, cnc laser cutting remains the superior choice.

For a complete picture of how laser cnc technology compares against all major alternatives, here's a comprehensive breakdown:

| Factor | Laser Cutting | Waterjet | Plasma | CNC Routing | EDM |

|---|---|---|---|---|---|

| Precision Tolerance | ±0.1mm to ±0.25mm | ±0.1mm to ±0.5mm | ±0.5mm to ±1.5mm | ±0.05mm to ±0.25mm | ±0.005mm to ±0.025mm |

| Edge Quality | Excellent, minimal finishing needed | Good, slight taper possible | Rougher, often requires secondary finishing | Good, depends on tooling | Mirror finish achievable |

| Heat-Affected Zone | Small but present | None | Large | None (mechanical) | Very small |

| Material Thickness Range | 0.5mm to 25mm (steel) | Up to 300mm+ | 3mm to 150mm+ | Limited by cutter depth | Up to 300mm |

| Cutting Speed | Very fast on thin materials | Slow to moderate | Fast on thick metals | Moderate | Very slow |

| Relative Cost | Moderate to high | High operating costs | Low equipment and operating costs | Moderate | High |

| Best Material Types | Thin to medium metals, some non-metals | Any material including stone, glass | Conductive metals only | Softer metals, plastics, wood | Conductive materials only |

CNC routing offers advantages when you're working with softer metals like aluminum or need to create 3D contours rather than simple 2D profiles. Mechanical cutting produces no heat-affected zone, similar to waterjet, and equipment costs can be lower for basic operations. According to Xometry's comparison, mechanical cutting remains competitive for cost and flexibility in applications where extreme precision isn't required.

EDM (Electrical Discharge Machining) occupies a specialized niche for ultra-precision work. When tolerances tighter than ±0.025mm are mandatory, or when you need to cut hardened tool steels that would destroy mechanical cutters, EDM becomes the only viable option. The tradeoff is dramatically slower processing speeds.

So when should you specifically avoid laser cutting?

- Thick plate over 25mm: Plasma or waterjet process faster and more economically

- Heat-sensitive applications: Medical implants or materials that cannot tolerate any thermal input require waterjet

- Non-conductive materials: Stone, glass, and many composites cut better with waterjet

- Ultra-precision requirements: When tolerances below ±0.1mm are mandatory, EDM may be necessary

- Budget-constrained thick steel: Plasma delivers acceptable quality at significantly lower cost

Many successful fabrication shops operate multiple technologies precisely because no single method handles every application optimally. Plasma and laser often pair well together, covering thin precision work through heavy structural fabrication. Adding waterjet capability extends versatility to virtually any material without heat concerns.

Understanding these tradeoffs positions you to request quotes from the right service providers and ensures your parts get processed using the optimal technology. With your cutting method selected, the next step involves optimizing your design files to minimize costs and maximize quality from whichever process you choose.

Design Optimization Guidelines for Laser Cut Parts

You've selected the right cutting technology and verified your material compatibility. Now comes the step that separates smooth production runs from costly delays: preparing your design files correctly. Proper design-for-manufacturability doesn't just prevent problems; it actively reduces your per-part costs while improving quality. Whether you're creating laser cut parts for a prototype or preparing thousands of production pieces, these guidelines will help you get it right the first time.

Think of your design file as a set of instructions for a precision laser cutting machine metal system. The clearer and more optimized those instructions, the faster and more accurately the machine can execute them. According to DFM specialists at Jiga, integrating design-for-manufacturing principles early in the design phase leads to precise cuts with minimal waste, reduced cutting time, and improved overall production throughput.

Minimum Feature Sizes and Hole Specifications

Here's a question that catches many first-time buyers off guard: how small can you actually go? The answer depends on your material thickness, and getting this wrong can mean incomplete cuts, excessive heat buildup, or parts that don't function as intended.

Minimum hole diameter is directly tied to material thickness. As a general rule for precision laser cutting, hole diameters should be at least equal to the material thickness. For example, a 2mm thick steel sheet should have holes no smaller than 2mm in diameter. Going smaller is technically possible but requires slower cutting speeds and may result in heat distortion around the hole perimeter.

When designing holes and internal features, follow these guidelines:

- Hole-to-edge distance: Maintain at least 1.5 times the material thickness between any hole and the part edge to prevent warping and ensure structural integrity

- Hole-to-hole spacing: Keep a minimum of one material thickness between adjacent holes to avoid heat accumulation that can distort thin bridges between features

- Slot width: Slots should be at least 1.5 times the kerf width to ensure complete material removal during cutting

- Sharp internal corners: True 90-degree internal corners are impossible because the laser beam has a finite diameter; design with small radii (typically 0.5mm minimum) at internal corners

According to Datum Alloys' precision cutting specifications, professional services can achieve tolerances of ±0.05mm on linear dimensions and ±0.15mm positional tolerance on features. These industry benchmarks help you understand what's realistically achievable when specifying your laser cut cnc machine work.

Kerf width compensation is another critical consideration many designers overlook. The kerf is the width of material removed by the laser beam itself, typically ranging from 0.1mm to 0.3mm depending on material type and thickness. When precise final dimensions matter, your design must account for this material loss. Most professional services apply kerf compensation automatically, but understanding the concept helps you communicate dimensional requirements clearly.

Optimizing Your Design for Cost-Effective Cutting

Want to reduce your quote by 20% or more? Smart design optimization often delivers exactly that kind of savings. The principles are straightforward once you understand what drives laser cutting costs: machine time, material consumption, and post-processing requirements.

Nesting optimization maximizes how many parts fit on each sheet of material. According to industry DFM guidelines, efficient nesting and shared cut lines contribute directly to cost savings by minimizing material waste and reducing total cutting time. When designing custom cut sheet metal parts, consider these nesting-friendly approaches:

- Common cut lines: Design adjacent parts to share edges where possible, reducing total cutting length

- Interlocking shapes: Create complementary geometries that nest together efficiently without wasted space

- Standard sheet sizes: Design part dimensions that divide evenly into common sheet sizes to minimize remnant material

- Orientation flexibility: Avoid features that restrict how parts can be rotated during nesting

Tab placement for part stability prevents small or lightweight components from shifting during cutting. These small bridges hold parts in place within the sheet skeleton until cutting completes. A laser cutter for sheet metal automatically manages tabs in most cases, but understanding the concept helps you anticipate where witness marks might appear on finished parts.

When preparing files for laser cutting steel sheet or other materials, these design simplifications reduce costs without compromising functionality:

- Simplify geometry: Use smooth, continuous lines instead of complex curves or excessive detail that increases cutting time

- Eliminate unnecessary features: Every hole, slot, and contour adds machine time; remove decorative elements that don't serve functional purposes

- Standardize thicknesses: According to Komacut's material guide, using standard material thicknesses is one of the easiest ways to optimize costs since laser cutters are calibrated for standard sizes

- Consider assembly: Incorporate tab-and-slot designs that facilitate self-locating assembly, reducing fixture requirements

File format preparation directly affects quote turnaround and production accuracy. Professional services typically accept DWG and DXF CAD file formats. According to preparation guidelines from Datum Alloys, your files should meet these specifications:

| Requirement | Specification | Why It Matters |

|---|---|---|

| File Format | DWG or DXF (2D only) | Machine-readable formats that translate directly to cutting paths |

| Scale | 1:1 (actual size) | Mismatched scales result in parts cutting too small or large |

| Line Continuity | Complete, unbroken paths | Broken or dashed lines cannot be interpreted by cutting software |

| Extraneous Elements | Remove title blocks, dimensions, notes | Only cut geometry should appear in the file |

| Components Per File | One part per file (preferred) | Simplifies quoting and reduces processing errors |

What about those lead-ins you might see mentioned in specifications? According to Datum's guidelines, a lead-in is a short entry path the laser uses to start cutting smoothly, leaving a tiny witness mark on the edge. Most professional services add these automatically unless you specify that a particular edge must remain unmarked.

Proper design optimization creates a virtuous cycle. Better nesting means less material waste. Simpler geometry means faster cutting. Appropriate feature sizing means fewer quality issues. Together, these factors reduce your costs while delivering higher-quality laser cut parts. With your design files optimized, understanding what quality factors affect your finished parts becomes the next critical knowledge area.

Quality Factors and Troubleshooting Common Cutting Issues

Your design files are optimized and your material is selected. Now here's the question that determines whether your laser cut metal parts actually perform as intended: what separates a quality cut from a subpar result? Understanding the factors that affect finished part quality helps you specify requirements clearly, evaluate samples effectively, and troubleshoot issues before they become expensive problems.

When you examine a laser cut stainless steel component or any steel laser cutting output, five key indicators reveal the true quality level: surface smoothness, burr formation, kerf consistency, cut perpendicularity, and heat-affected zone size. According to fiber laser quality specialists, these factors directly impact both the precision and functionality of your workpieces. Let's examine what causes common issues and how professional services prevent them.

Preventing Warping and Heat Distortion

Ever received parts that looked perfect in the CAD file but arrived slightly twisted or bowed? Warping is perhaps the most frustrating quality issue in cutting laser metal applications because it can render otherwise excellent parts unusable.

Distortion occurs when the intense heat generated by the laser beam causes localized expansion and contraction in the metal. According to Central Laser Services' engineering team, common causes include:

- Uneven heat distribution: When cutting paths concentrate heat in specific areas rather than distributing thermal load across the workpiece

- Insufficient material support: Parts that shift or flex during cutting develop internal stresses as they cool unevenly

- Improper cutting sequence: The order in which features are cut affects how stress accumulates in the remaining material

- Excessive laser power: More power than necessary creates larger heat-affected zones and increased thermal stress

How do professional laser cut sheet metal services prevent these issues? Thermal management is the key. Quality providers calibrate power, speed, and focus to balance cut quality with minimal heat input. Their setup teams ensure materials are securely supported throughout cutting to maintain dimensional integrity and flatness. Additionally, optimizing part placement and cutting sequence minimizes residual stresses while improving sheet utilization.

The heat-affected zone (HAZ) deserves special attention because it directly impacts material properties. This area surrounding each cut experiences microstructural changes due to thermal exposure. A large HAZ can reduce material strength or create brittleness. Factors influencing HAZ size include laser power level, cutting speed, material thickness, and assist gas selection. Fiber laser technology generally produces smaller heat-affected zones than older CO2 systems due to faster energy transfer and higher cutting speeds.

Different metals react uniquely to heat exposure. Aluminum's high thermal conductivity helps dissipate heat quickly but requires careful parameter management to prevent localized distortion. Stainless steel tolerates heat reasonably well but can experience slight discoloration near cut edges without proper gas shielding. Copper presents the greatest challenge because its extreme thermal conductivity makes controlling heat accumulation difficult.

Achieving Clean Edges Without Burrs

Run your finger along a laser-cut edge. Is it smooth, or do you feel rough, raised material catching on your skin? Those rough edges are burrs, and they're one of the most common quality issues in sheet metal laser cutter operations.

According to laser cutting quality control specialists, burrs occur when cutting speed is too slow or laser power is too high, causing molten material to resolidify along the cut edge rather than being cleanly ejected. Other contributing factors include insufficient assist gas pressure and misaligned beam focus.

When evaluating finished parts from any laser cutting metal services provider, check for these quality indicators:

- Surface smoothness: Examine the cut face for diagonal striations; smaller marks indicate better cutting quality

- Burr presence: Feel the bottom edge for raised material that indicates incomplete slag ejection

- Kerf consistency: Measure cut width at multiple points to verify uniform cutting throughout the part

- Perpendicularity: Check whether cut edges are truly vertical relative to the material surface, especially on thicker materials

- Discoloration: Look for heat-related color changes near edges that might indicate excessive thermal exposure

Burn marks and discoloration result from excessive heat around the cutting area. To prevent these issues, professional services adjust laser power settings, increase cutting speeds appropriately, and use assist gases like nitrogen or air that cool the cutting zone while blowing away debris. Choosing the correct laser type for specific materials also minimizes burn risk.

What separates quality laser cutting from subpar results? It comes down to proper equipment calibration, optimized cutting parameters matched to each specific material and thickness, and consistent process monitoring. According to quality control best practices, regular machine calibration ensures the laser beam remains properly aligned for precise cuts. Operators should monitor and adjust parameters based on material type and thickness to maintain consistency throughout production runs.

When specifying quality requirements to your service provider, be explicit about critical dimensions, surface finish expectations, and any edges that must remain burr-free without secondary processing. Understanding these quality factors positions you to evaluate samples effectively and ensures your finished parts meet functional requirements. With quality expectations defined, the next critical question becomes understanding what drives the costs you'll see in your quotes.

Understanding Laser Cutting Costs and Pricing Variables

You've designed your parts, selected the right material, and verified quality expectations. Now comes the question everyone wants answered but few sources address honestly: how much will this actually cost? Unlike commodity purchases with fixed price tags, laser cutting charges depend on multiple interconnected variables that can swing your quote dramatically in either direction. Understanding these factors helps you budget realistically and identify opportunities to reduce costs without sacrificing quality.

Here's the reality that surprises many first-time buyers: two seemingly similar projects can have vastly different pricing. A simple rectangular bracket might cost a fraction of what an intricate decorative panel runs, even when both use identical material. The difference lies in cutting time, material efficiency, and processing complexity. Let's break down exactly what drives your laser cutting quote so you can make informed decisions.

Variables That Drive Laser Cutting Quotes

When a service provider calculates your custom laser cutting price, they're evaluating several interconnected factors. According to industry pricing specialists at Komacut, the primary cost drivers include material type, thickness, design complexity, cutting time, labor costs, and finishing processes. Each element contributes to the overall expense by impacting efficiency and resource requirements.

Material type and thickness form the foundation of any quote. Different metals have unique properties that affect cutting speed, energy consumption, and equipment wear. For example, cutting stainless steel generally requires more energy and time compared to carbon steel, making it more expensive per linear foot. Thicker materials compound this effect because they require more power and slower cutting speeds to achieve clean penetration.

According to pricing research from Thinklaser, material cost calculation follows a straightforward formula: Material Price per Unit Area multiplied by Material Area Used. However, this baseline cost gets multiplied by processing factors that vary significantly based on what you're cutting.

Design complexity directly impacts machine time. Every cutout requires a pierce point where the laser initiates the cut. More pierce points and longer cutting paths increase energy consumption and processing duration. According to Komacut's analysis, intricate designs with numerous cutouts demand greater precision, adding to labor and equipment expenses. Simple geometries with minimal internal features always cost less than elaborate patterns with dozens of holes and curves.

Here's a breakdown of the key factors affecting your custom cut metal pricing:

- Material costs: Raw material price plus waste factor based on how efficiently your parts nest on standard sheet sizes

- Machine operating costs: Laser power consumption multiplied by operational hours, plus energy costs per hour

- Labor costs: Setup time plus operation time plus any post-processing time, multiplied by labor rate

- Design complexity fees: Additional charges for intricate patterns requiring specialized programming or slower cutting speeds

- Setup costs: One-time fees for machine configuration, particularly significant for small batch orders

- Secondary operations: Processes like deburring, bending, welding, or surface finishing add labor and equipment time

Quantity and batch size significantly affect per-piece pricing. Fixed setup costs get distributed across all parts in an order, so larger quantities reduce the per-unit expense. According to industry analysis, bulk ordering can significantly reduce per-unit cost by spreading fixed setup costs over more units. Additionally, larger orders often qualify for material discounts from suppliers, further lowering overall expenses.

Turnaround time requirements can dramatically affect pricing. Rush orders requiring expedited processing typically carry premium charges because they may require overtime labor, schedule disruption for other jobs, or priority material sourcing. Standard lead times almost always offer better value than emergency turnarounds.

Balancing Speed and Budget in Your Project

Want to reduce your laser cutting instant quote without compromising part quality? Smart buyers use several proven strategies to optimize costs while meeting project requirements.

According to design optimization research, efficient nesting maximizes material usage by arranging parts closely together on material sheets, minimizing waste. This reduces raw material requirements and decreases cutting time, leading to significant savings. Advanced nesting software helps optimize layouts, enhancing efficiency and reducing scrap.

Consider these cost-reduction strategies when preparing your custom metal cutting projects:

- Simplify geometries: Reduce the number of cutouts and eliminate unnecessary decorative features that don't serve functional purposes

- Use standard material thicknesses: Non-standard gauges require special ordering and often carry premium pricing

- Optimize for nesting: Design parts that fit together efficiently on standard sheet sizes to minimize waste

- Consolidate orders: Combine multiple part numbers into single orders to share setup costs

- Choose appropriate materials: Don't specify stainless steel when mild steel meets functional requirements

- Allow standard lead times: Avoid rush charges by planning ahead and building buffer into project schedules

- Consider prototype quantities carefully: Order enough prototypes to validate designs but avoid over-ordering before design finalization

Online quoting systems have transformed how buyers interact with laser cutting services. Modern platforms allow you to upload design files and receive automated estimates within minutes. To get accurate quotes quickly, prepare this information before starting:

- Complete design files in DXF or DWG format at 1:1 scale

- Material type and specific alloy designation

- Material thickness

- Quantity required

- Any secondary operations needed (bending, hardware insertion, finishing)

- Delivery timeline requirements

- Quality certifications required for your industry

According to industry recommendations, getting quotes from multiple providers helps you understand market rates and find the best value. Don't forget to account for setup fees, shipping costs, and any post-processing expenses like polishing, painting, or assembly when comparing total project costs.

What should you realistically expect? While specific prices vary by region, provider, and current material costs, the relationship between quantity and per-piece pricing follows predictable patterns. Setup costs that seem significant on a 10-piece order become negligible when distributed across 1,000 parts. Material efficiency improves as quantities increase because providers can optimize nesting across multiple sheets. Labor per piece decreases as operators gain familiarity with your specific job requirements.

Understanding these pricing dynamics positions you to have productive conversations with service providers and make informed tradeoffs between cost, quality, and timeline. With budget expectations established, the next step involves understanding how different industries apply laser cutting technology to their specific requirements and what that means for your projects.

Industry Applications from Automotive to Architectural Metalwork

You understand the technology, materials, and costs. But here's what truly separates successful projects from problematic ones: recognizing that different industries demand fundamentally different approaches to laser cutting metal services. A bracket for a residential signage project has almost nothing in common with a structural component destined for an automotive assembly line, even when both start as identical steel sheets.

Why does this matter for your project? Because industry-specific requirements dictate everything from tolerance specifications to certification documentation. Understanding these distinctions helps you communicate effectively with service providers and ensures your parts meet the standards your application demands. According to industry application research, laser cutting technology has transformed various industries with its precision and versatility, from creating detailed jewelry to manufacturing critical components in aerospace and automotive sectors.

Automotive and Aerospace Precision Requirements

In the automotive industry, industrial laser cutting stands as a pivotal tool for crafting intricate components and customizations. Every millimeter counts when you're producing parts for chassis, suspension systems, and structural assemblies. The margin for error? Essentially zero.

According to automotive fabrication specialists, laser cutting in this sector is significantly more efficient than traditional metal fabrication processes like die cutting or plasma cutting. The high power laser, typically a fiber laser cutter, provides precision essential in automotive applications where components must fit together perfectly across thousands of assembled vehicles.

Typical automotive laser fabrication projects include:

- Chassis components: Structural brackets, cross members, and reinforcement plates requiring precise fit-up for welded assemblies

- Suspension parts: Control arm brackets, spring mounts, and stabilizer bar components with tight tolerance requirements

- Body panels: Door reinforcements, pillar structures, and crash-resistant components where dimensional accuracy affects safety performance

- Engine compartment parts: Heat shields, mounting brackets, and accessory supports that must withstand thermal cycling and vibration

- Interior components: Seat frames, console brackets, and structural supports hidden beneath trim panels

What separates automotive-grade laser cutting fabrication from general fabrication work? Certification requirements. According to quality management specialists, the IATF 16949 certification meets all ISO 9001 requirements and then extends further to ensure compliance with lean manufacturing, defect prevention, variance deterrence, and waste reduction. This certification, backed by automotive trade associations, establishes the benchmark for sourcing suppliers and building reliable supply chains.

For manufacturers serving the automotive sector, IATF 16949 certification delivers tangible benefits including consistent quality through monitored and measured processes, reduced product variation through improved manufacturing processes, and defect prevention through tested and proven fabrication methods. Companies like Shaoyi (Ningbo) Metal Technology exemplify this approach, delivering IATF 16949-certified quality for chassis, suspension, and structural components with capabilities ranging from 5-day rapid prototyping to automated mass production.

Aerospace applications push precision laser cutting services to their absolute limits. According to aerospace manufacturing research, the need for lightweight, high-strength materials in this sector cannot be overstated. Precision is the hallmark of aerospace components, and laser cutting with its high precision and ability to handle specialized materials is perfectly suited for this demanding application.

The aerospace industry benefits from laser cutting's ability to produce components meeting strict tolerance levels. The process ensures structural integrity of materials is maintained, which is paramount in applications where failure is catastrophic. Typical aerospace projects involve titanium structural components, aluminum skin panels, and specialty alloy brackets where weight savings measured in grams can translate to significant fuel efficiency improvements over an aircraft's operational lifetime.

Architectural and Artistic Metal Applications

Shift your perspective from functional precision to visual impact, and you enter the world of architectural and artistic metalwork. Here, custom metal laser cutting enables creative possibilities that were simply impossible with traditional fabrication methods.

According to architectural application specialists, laser cutting technology has made a significant impact in the construction industry. Its use in fabricating steel frameworks and detailed architectural elements brings a new level of creativity and precision to the field. The technology's ability to cut through thick steel plates and produce precise cuts makes it invaluable for modern architecture.

Architectural laser cut metal sheets projects typically include:

- Decorative facades: Building cladding with intricate patterns that create dynamic shadow effects throughout the day

- Privacy screens: Perforated metal panels balancing visual privacy with light transmission and airflow

- Staircase components: Ornamental stringers, decorative risers, and custom railing panels

- Signage and wayfinding: Dimensional letters, illuminated channel signs, and directional systems

- Interior design elements: Room dividers, ceiling features, and custom furniture components

The requirements differ dramatically from automotive work. While dimensional accuracy remains important, the emphasis shifts toward edge quality, surface finish, and visual consistency across large decorative panels. Architectural projects often prioritize aesthetic perfection over the micrometer-level tolerances demanded by mechanical assemblies.

Electronics and enclosure manufacturing represents another major application area. According to electronics industry research, laser cutting technology plays a pivotal role in the miniaturization of electronic devices. The industry relies heavily on precision cutting capabilities where a fraction of a millimeter can make a significant difference.

Typical electronics enclosure projects include:

- Server chassis: Rack-mount enclosures with precise ventilation patterns and component mounting features

- Control panel housings: Industrial cabinets with cutouts for displays, switches, and cable management

- EMI shielding: Specialized enclosures blocking electromagnetic interference in sensitive equipment

- Consumer electronics cases: High-volume housings for networking equipment, power supplies, and audio components

Prototyping applications deserve special mention because they leverage laser cutting's greatest strength: the ability to go from digital design to physical part with zero tooling investment. According to R&D application research, laser cutting technology is invaluable for prototype development and experimental part fabrication. Its precision and versatility allow for creating components with intricate designs and tight tolerances essential in the development process.

For prototyping, laser cutting's ability to quickly and accurately produce parts plays a critical role in the iterative design process. Engineers can test fit, function, and aesthetics before committing to production tooling. Services offering rapid prototyping capabilities, such as providers with 5-day turnaround for first articles, enable design teams to validate concepts quickly and move to production with confidence.

Here's a summary of how requirements vary across major industries:

| Industry | Primary Requirements | Typical Tolerances | Key Certifications |

|---|---|---|---|

| Automotive | Dimensional accuracy, repeatability, traceability | ±0.1mm to ±0.25mm | IATF 16949, ISO 9001 |

| Aerospace | Material integrity, weight optimization, documentation | ±0.05mm to ±0.15mm | AS9100, NADCAP |

| Architecture | Visual quality, edge finish, pattern consistency | ±0.5mm typical | Project-specific |

| Electronics | Precision cutouts, clean edges, EMI considerations | ±0.1mm to ±0.2mm | ISO 9001, UL listings |

| Prototyping | Speed, design flexibility, iteration capability | Application-dependent | Varies by end use |

Understanding these industry-specific requirements positions you to select service providers whose capabilities align with your application demands. A shop specializing in architectural metalwork may lack the quality management systems required for automotive production, while an aerospace-certified facility might be unnecessarily expensive for decorative signage projects.

With this understanding of how different industries leverage laser cutting technology, the next critical step involves evaluating potential service providers against criteria that matter for your specific application and requirements.

Choosing the Right Metal Laser Cutting Service Provider

You've mastered the technology, understand material compatibility, and know what quality to expect. Now comes perhaps the most consequential decision in your entire project: selecting the right partner to actually produce your parts. A metal laser cutter is only as good as the team operating it, and the difference between an excellent provider and a mediocre one can mean the difference between project success and costly delays.

Here's what many buyers discover too late: the lowest quote rarely delivers the best value. When you're searching for laser cutting services near me or evaluating providers across the country, price represents just one factor in a much larger equation. According to fabrication specialists at Ametals, choosing the right partner to outsource work to can actually reduce your stress, cut your costs, and improve your efficiency. The key lies in knowing what to evaluate beyond the bottom line of a quote.

Certifications and Quality Standards to Verify

When precision matters, certifications provide your first filter for separating serious metal laser cutting services from shops that simply own a laser. But what do these certifications actually mean, and which ones matter for your specific application?

ISO 9001 certification establishes the baseline for quality management systems. According to industry evaluation guidelines, while certifications aren't a guarantee, ISO 9001 standards do give you reassurance that you're working with a shop with a solid quality management system in place. This certification indicates documented processes, regular audits, and systematic approaches to preventing defects rather than just catching them.

IATF 16949 certification goes significantly further for automotive applications. This standard encompasses all ISO 9001 requirements while adding automotive-specific demands for lean manufacturing, defect prevention, and supply chain traceability. If you're producing components for vehicles or transportation equipment, this certification should be non-negotiable.

When evaluating any cnc laser cutting services provider, ask these verification questions:

- What accuracy and tolerances can you achieve? Request specific numbers rather than vague assurances

- How often do you calibrate your equipment? Regular calibration ensures consistent precision over time

- What inspections do you perform on finished products? Understand their quality control checkpoints

- Can you provide material certifications and traceability? Critical for regulated industries

- What is your defect rate and how do you handle non-conforming parts? Their answer reveals process maturity

Beyond formal certifications, evaluate equipment capabilities directly. According to equipment evaluation recommendations, you want a shop that has up-to-date laser cutting machines and other machine shop tools since newer systems have automated material handling capabilities, minimal setup time, and high levels of precision. Ask specifically about how thick their laser can cut, how precisely, and which metals they can work with.

Here's a comprehensive evaluation framework for assessing potential providers:

| Evaluation Criteria | What to Look For | Red Flags |

|---|---|---|

| Equipment Capabilities | Modern fiber and CO2 systems, automated material handling, stated thickness and precision specifications | Vague answers about capabilities, outdated equipment, inability to specify tolerances |

| Material Expertise | Experience with your specific metals, understanding of material-specific challenges, proper assist gas capabilities | Limited material range, no experience with reflective metals if needed |

| Quality Certifications | ISO 9001 minimum, IATF 16949 for automotive, documented quality procedures | No certifications, unwillingness to share quality documentation |

| Secondary Services | Bending, welding, finishing, hardware insertion available in-house | Must outsource critical secondary operations, adding lead time and handoff risk |

| DFM Support | Design-for-manufacturability review included, proactive optimization suggestions | No design feedback, takes files exactly as submitted without review |

Evaluating Turnaround Time and Communication

How quickly can you get a quote? How fast can parts ship? These questions matter enormously when project schedules are tight. But equally important is how the provider communicates throughout the process.

According to customer service evaluation guidelines, pay attention to how well your potential laser cutting partner communicates with you. They should listen to your needs and, even more important, ask good questions. Clear communication is critical to getting a job done quickly and accurately.

When evaluating turnaround capabilities, look for these service features that indicate a responsive, customer-focused operation:

- Quote responsiveness: Top-tier providers offer rapid quote turnaround, with leaders in the industry delivering estimates within 12 hours of receiving complete design files

- Prototyping speed: The ability to produce first articles quickly validates designs before production commitment. Look for providers offering 5-day rapid prototyping capabilities

- Production scalability: Verify the shop can handle both small prototype runs and larger production quantities without sacrificing quality

- DFM support availability: Comprehensive design-for-manufacturability feedback helps optimize your parts before cutting begins, reducing iterations and costs

- Digital communication tools: According to industry recommendations, providers should make it easy for you to send drawings and update information easily through email or online portals

Prototyping capabilities deserve special emphasis. Before committing to production runs, smart buyers validate their designs with physical samples. This step catches fit issues, reveals unexpected manufacturing challenges, and confirms that the provider truly understands your requirements. A laser cutter near me with rapid prototyping capabilities lets you iterate quickly and move to production with confidence.

Consider providers like Shaoyi (Ningbo) Metal Technology that combine multiple service features buyers should prioritize: 5-day rapid prototyping for fast design validation, 12-hour quote turnaround for responsive project planning, and comprehensive DFM support to optimize manufacturability before production begins.

Flexibility matters too. According to service evaluation specialists, flexibility allows you to keep your work with one shop rather than having to send it out to different places. You want a shop that can do routine cutting but also one that can handle special orders. For tube laser cutting services or specialized applications, verify the provider has specific experience with your part geometry.

What questions should you ask potential providers during your evaluation?

- Can you show me examples of similar projects you've completed?

- What is your typical lead time for my quantity requirements?

- Do you offer expedited options if my schedule changes?

- How do you handle design changes after quoting?

- What happens if parts don't meet specifications?

- Can you provide references from customers in my industry?

- What secondary operations can you perform in-house?

According to reference verification recommendations, take time to verify skills with previous and current clients. References and reviews allow you to learn more about what it's like to work with the team as well as confirm their skill set. While online reviews provide a starting point, direct conversations with references reveal the complete picture.

A provider's portfolio reveals both breadth and depth of experience. Look for many different types of projects demonstrating versatility, plus multiple examples of specific skills relevant to your application. If your project requires intricate patterns, verify they have that capability rather than just general precision cutting experience.

The right laser cutting service near me becomes a true partner rather than just a vendor. They anticipate problems before they occur, suggest improvements you hadn't considered, and communicate proactively throughout production. Finding this kind of provider requires careful evaluation upfront, but the investment pays dividends across every project you entrust to them.

Frequently Asked Questions About Laser Cutting Metal Services

1. How much does metal laser cutting cost?

Laser cutting metal costs depend on several interconnected factors including material type and thickness, design complexity, quantity, and turnaround time. Steel cutting generally costs between $13-$20 per hour of machine time, but your total expense also includes material costs, setup fees, and any secondary operations like bending or finishing. Bulk orders significantly reduce per-unit costs by spreading fixed setup expenses across more parts. To get accurate pricing, prepare complete DXF or DWG design files and request quotes from multiple providers.

2. What metals can be laser cut effectively?

Laser cutting works exceptionally well on mild steel, stainless steel, and carbon steel, which are the most laser-friendly materials. Modern fiber lasers also handle reflective metals like aluminum (up to 15mm), copper (up to 6mm), and brass (up to 8mm) effectively, though these require higher power settings due to their reflectivity and thermal conductivity. Titanium cuts well but requires inert gas shielding to prevent oxidation. Each metal has specific thickness limitations based on laser power, with mild steel cutting up to 25mm on high-power systems.

3. What is the difference between fiber laser and CO2 laser cutting?

CO2 lasers operate at a 10.6-micron wavelength and excel at cutting thicker materials (up to 25mm mild steel) plus non-metals like plastics and wood. Fiber lasers use a shorter 1.06-micron wavelength, delivering 2-3 times faster cutting speeds on thin metals and superior performance on reflective materials like aluminum, copper, and brass. Fiber lasers also offer 30-50% energy efficiency compared to 10-15% for CO2 systems, with lower maintenance requirements due to their solid-state design.

4. How do I prepare design files for laser cutting services?

Submit design files in DWG or DXF format at 1:1 scale with complete, unbroken line paths. Remove all extraneous elements like title blocks, dimensions, and notes—only cut geometry should appear. Follow design-for-manufacturability guidelines: maintain minimum hole diameters equal to material thickness, keep hole-to-edge distances at 1.5x material thickness, and design internal corners with small radii (0.5mm minimum) since true 90-degree internal corners are impossible. Consider nesting efficiency by designing parts that fit together on standard sheet sizes.

5. When should I choose waterjet or plasma cutting instead of laser?

Choose waterjet cutting for heat-sensitive materials requiring zero heat-affected zone, extremely thick materials (up to 12 inches), or when cutting mixed materials like stone, glass, and composites. Plasma cutting outperforms laser for thick conductive metals over half an inch, offering 3-4 times faster speeds than waterjet with roughly half the operating costs. Laser cutting remains superior for thin to medium-thickness metals requiring tight tolerances (±0.1mm), intricate designs, and clean edges with minimal finishing.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —