Laserové rezanie kovu vysvetlené: Od surového plechu po hotový diel

Čo skutočne znamená laserové rezanie kovov pre modernú výrobu

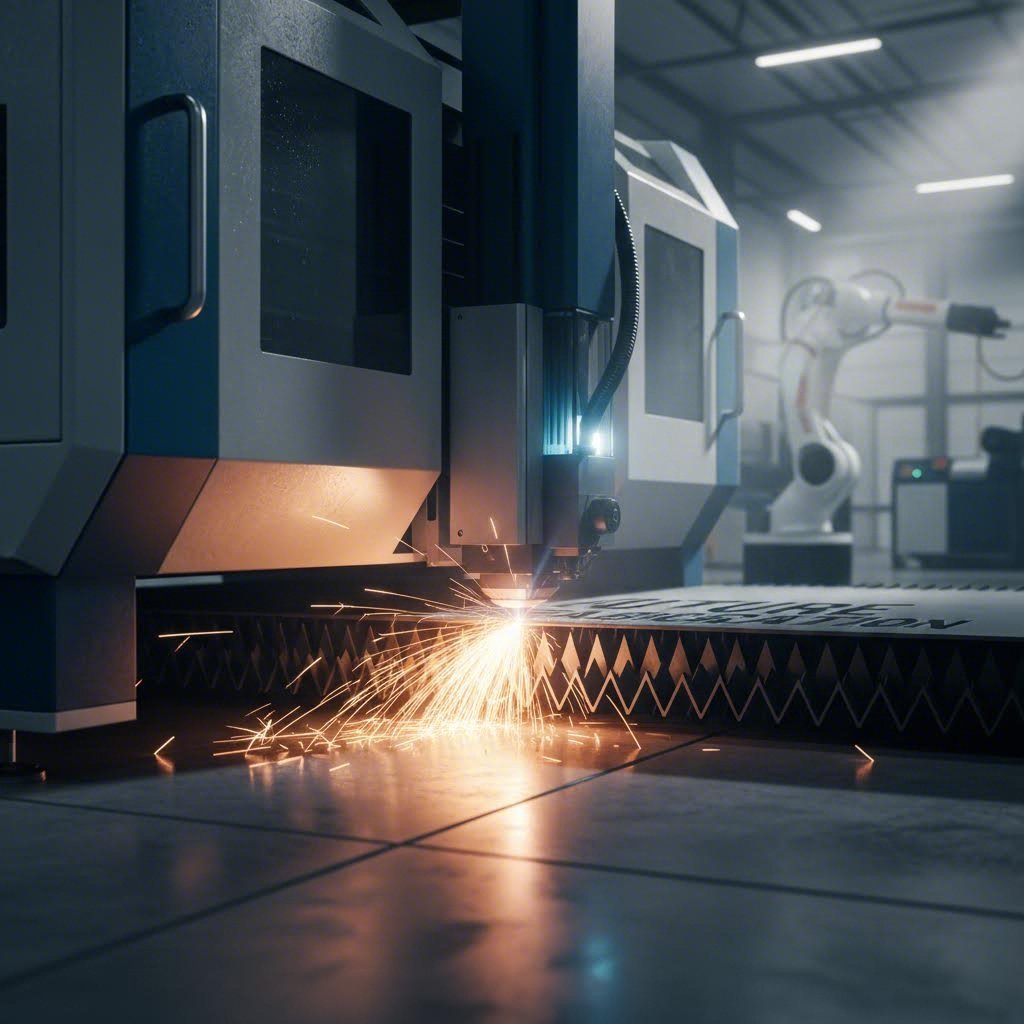

Môže laser rezať kov? Absolútne – a s úžasnou presnosťou, ktorú tradičné metódy jednoducho nedokážu dosiahnuť. Laserové rezanie kovov označuje proces používania vysoce koncentrovaného lúča svetla na prerezávanie plechov a dosiek, pri ktorom vznikajú nielen komplikované dekoratívne vzory, ale aj kritické priemyselné súčasti. Na rozdiel od mechanického rezania, ktoré sa opiera o fyzický kontakt a silu, laser, ktorý reže kov, pracuje prostredníctvom čistej tepelnej energie a dosahuje tak čistejšie hrany a tesnejšie tolerancie.

Dnes sa rezanie kovov laserom stalo zakladným kameňom modernej výroby . Priemyselné odvetvia od automobilového až po letecký priemysel touto technológiou každodenne využívajú, pretože ponúka niečo, čo mechanické metódy len ťažko dosahujú: konzistentnú, opakovateľnú presnosť pri rýchlostiach výroby.

Ako laserové lúče transformujú surové kovy na presné súčiastky

Predstavte si, že sústreďujete slnečné svetlo cez zväčšovacie sklo – teraz túto intenzitu vynásobte niekoľkými tisíckami. Vlastne presne to sa deje vo vnútri systému na rezanie kovov laserom. Laserový rezonátor generuje extrémne koncentrovaný lúč svetla, ktorý je následne smerovaný cez sériu zrkadiel a šošoviek do presného ohniska na povrchu kovu.

Keď tento sústredený lúč energie narazí na kov, odohráva sa niečo úžasné. Intenzívne teplo – dosahujúce teploty výrazne vyššie ako je teplota topenia kovu – spôsobí, že materiál buď okamžite roztaje, alebo sa odparí. Prúd asistenčného plynu, zvyčajne kyslíka alebo dusíka, odvádza roztavený materiál z miesta rezu, čím vzniká čistá a úzka rezaná plocha.

Tento proces prebieha tak rýchlo a presne, že možno dosiahnuť rezy s minimálnou tepelne ovplyvnenou zónou. To znamená menej deformácií, menej namáhania materiálu a súčiastok, ktoré vyžadujú len minimálne alebo žiadne dodatočné dokončovanie.

Veda za tepelným rezaním kovov

Tu sa fyzika stretáva s praktickosťou. Laserová svetelná energia sa v ohnisku premení na tepelnú energiu na základe jednoduchého princípu: keď fotóny narazia na povrch kovu, prenášajú svoju energiu atómom materiálu. Tento prenos energie spôsobuje rýchle zahrievanie a keďže lúč je tak presne zameraný, teplo sa koncentruje v extrémne malom priestore.

Výsledok? Môžete rezať komplexné tvary s toleranciami, ktoré by boli nemožné dosiahnuť pri tradičných metódach ako pichnutie, strihanie alebo pílenie.

Typické tolerancie laserového rezania kovov sa pohybujú od ±0,025 mm do ±0,1 mm v závislosti od hrúbky materiálu – úroveň presnosti, ktorá umožňuje dokonalé spojenie súčastí v náročných aplikáciách, ako sú letecký priemysel a lekársky prístrojstvo.

Táto úroveň presnosti vysvetľuje, prečo sa laserové rezanie vo veľkej miere rozšírilo v priemysle. Podľa odborné zdroje , technológia dokáže spracovať oceľ hrúbky až 1 palec (25,4 mm), nehrdzavejúcu oceľ hrúbky až 0,75 palca (19,05 mm) a hliník hrúbky až 0,5 palca (12,7 mm) – a to všetko pri zachovaní vynikajúcej kvality rezania.

Od svojich prvých priemyselných aplikácií pred desaťročiami sa laserové rezanie vyvinulo na kľúčový pilier výroby plechových súčiastok. Bez ohľadu na to, či vyrábate prototypové diely alebo bežíte vysokozdružnú výrobu, pochopenie tejto základnej technológie je vaším prvým krokom k využitiu jej plného potenciálu.

Vláknový laser vs CO2 laser vs Nd-YAG pre rezanie kovov

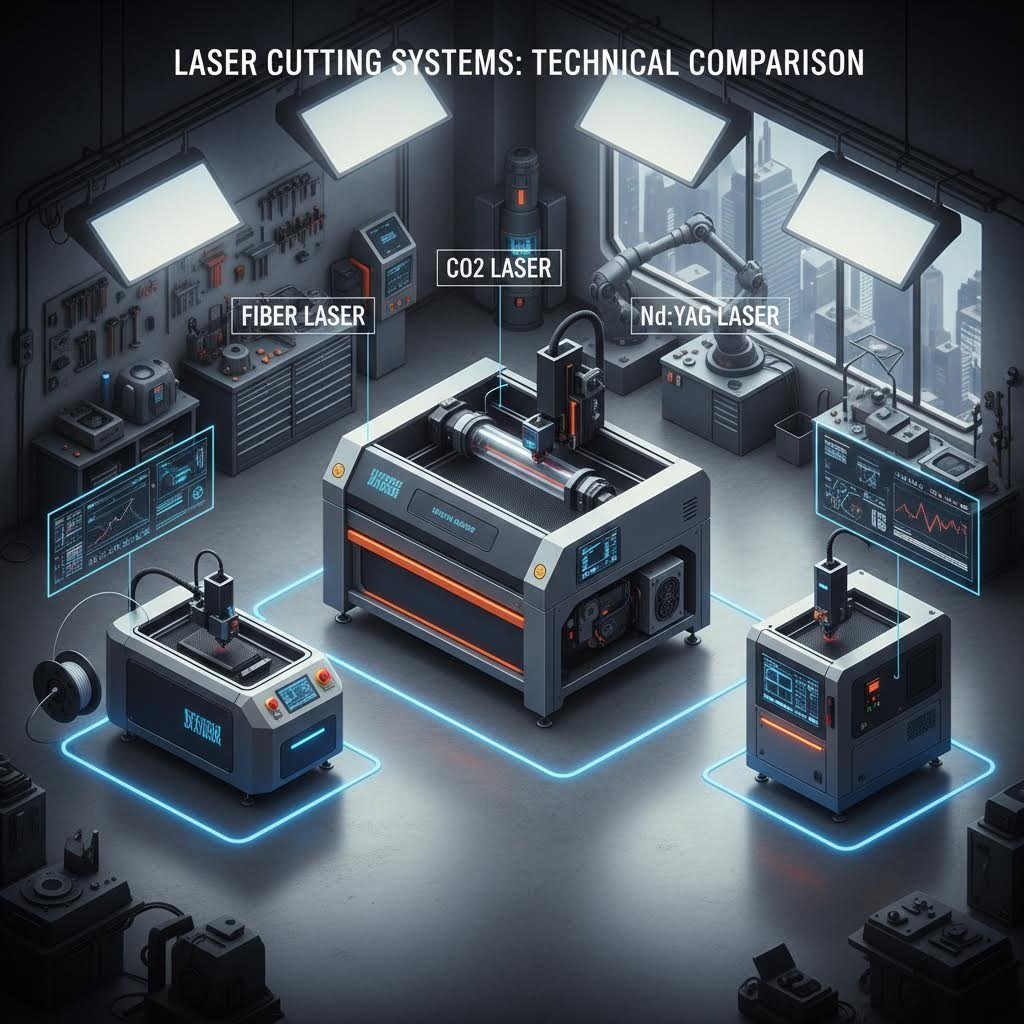

Teraz, keď rozumiete tomu, ako lasery premenia surový kov na presné súčiastky , vyvstáva dôležitá otázka: ktorú laserovú technológiu by ste mali skutočne použiť? Odpoveď závisí od vašich materiálov, výrobných cieľov a rozpočtu. Tri hlavné typy laserov dominujú v aplikáciách rezania kovov – vláknové lasery, CO2 lasery a Nd:YAG lasery – a každý z nich prináša výrazné výhody.

Pochopenie týchto rozdielov nie je len akademickou záležitosťou. Výber nesprávnej technológie môže znamenať pomalšie rýchlosti výroby, vyššie prevádzkové náklady alebo zlú kvalitu rezu na vašich konkrétnych materiáloch. Pozrime sa podrobne, čo tieto systémy od seba odlišuje.

| Parameter | Vláknový laser | CO2 laser | Nd:YAG Laser |

|---|---|---|---|

| Vlnová dĺžka | 1,06 mikrometra | 10,6 mikrometrov | 1,064 mikrometra |

| Najlepšie aplikácie na kovy | Oceľ, nehrdzavejúca oceľ, hliník, mosadz, meď | Tenké kovové plechy, zmiešané kovy/nekovové materiály | Šperky, elektronika, mikrofabrikácia |

| Možnosti hrúbky | Až 50 mm a viac (jednotky s vysokým výkonom) | Až do 25 mm | Obmedzené na tenké materiály |

| Energetická efektívnosť | Viac ako 90 % | 10-15% | Mierne |

| Prevádzkové náklady | ~4 USD za hodinu | ~20 USD za hodinu | Mierne až vysoké |

| Požiadavky na údržbu | 200–400 USD ročne (ochranné okienka) | 1 000–2 000 USD ročne (zrkadlá a šošovky) | Stredná (výmena žiarovky) |

Technológia vláknového lasera a jej výhody pri rezaní kovov

Vláknové laserové rezačky revolucionalizovali spracovanie kovov počas posledného desaťročia, a to z dobrého dôvodu. Pri prevádzke na vlnovej dĺžke približne 1,06 mikrometra dosahujú tieto systémy niečo úžasné: kovy ako nehrdzavejúca oceľ absorbujú 30 % až 50 % laserovej energie oproti len 2 % až 10 % absorpcie u CO2 laserov. To znamená, že viac rezného výkonu dosiahne váš materiál namiesto odrazu vo forme strátnej energie.

Čo sa to prekladá do praxe? CNC vláknový laserový rezací stroj dokáže rezať materiál až trikrát rýchlejšie ako tradičné metódy, pričom niektoré systémy dosahujú rýchlosť až 20 metrov za minútu pri tenkých kovových plechov. Táto výhoda v rýchlosti priamo ovplyvňuje vašu konečnú bilanciu – rýchlejšie rezanie znamená viac súčiastok za hodinu a rýchlejšie dokončenie projektov.

Príbeh efektivity je ešte lepší, keď sa pozrieme na prevádzkové náklady. Podľa analýza priemyslu , systémy na rezanie kovu s vláknovým laserom bežia približne za 4 doláre za hodinu, zatiaľ čo systémy CO2 stojia okolo 20 dolárov za hodinu. Počas jedného roka výroby sa tento rozdiel výrazne prejaví.

Moderné systémy na rezanie pomocou laserových vlákien sa tiež výborne vyrovnajú s reflexnými kovmi – materiálmi ako meď a mosadz, ktoré tradične spôsobovali problémy iným typom laserov. Kratšia vlnová dĺžka a vyššie koeficienty absorpcie robia z vláknového laserového rezača najlepšiu voľbu pre dielne pracujúce s rôznorodými typmi kovov.

Vstupné systémy s vláknovým laserom začínajú približne od 15 000 USD pre jednotky s výkonom 1-3 kW, priemyselné stroje s výkonom 12-30 kW sa pohybujú od 55 000 do 120 000 USD. Väčšina podnikov dosiahne plný návrat investície do 18–24 mesiacov prostredníctvom zvýšenej výrobnej kapacity a znížených prevádzkových nákladov.

Kedy má ešte stále význam používať CO2 lasery pri práci s kovmi

Napriek prevládajúcej úlohe vláknového lasera pri čistej rezaní kovov si rezný CO2 laser naďalej udržiava cenné postavenie v konkrétnych situáciách. Ak vaša dielňa spracúva nielen kovy, ale aj nekovy – napríklad akrylové nápisy spolu so oceľovými uhlíkmi – systém CO2 ponúka univerzálnosť, ktorú vláknové lasery nemôžu rovnať.

Vysokovýkonové aplikácie CO2 laserového rezania ocele (systémy 2 000 W až 5 000 W) zostávajú účinné pre tenšie materiály do 25 mm. Tieto systémy sú výrazne drahšie – v rozmedzí od 70 000 USD do viac ako 100 000 USD – no ponúkajú flexibilitu pre dielne spracúvajúce zmiešané materiály.

Hlavnou nevýhodou? Systémy CO2 vyžadujú vyššiu údržbu kvôli svojej konfigurácii optických zrkadiel. Ročné náklady na údržbu vo výške 1 000–2 000 USD za zrkadlá a objektívy navyše zvyšujú celkové náklady na prevádzku. Okrem toho nižšia energetická účinnosť (10–15 % oproti viac ako 90 % u vláknových laserov) znamená vyššie náklady na elektrinu počas prevádzky.

Pri špeciálnej výrobe kovov bol CO2 laserový rez oceľu do veľkej miery nahradený vláknovou technológiou. Avšak dielne s rôznorodými požiadavkami na materiál môžu stále využívať širšie možnosti CO2 technológie.

Laser Nd:YAG zaberá špecializované trhy – ultra vysoká presnosť pri práci s klenotníctvom, elektronikou a mikrovýrobou. Napriek podobnej vlnovej dĺžke ako u vláknových laserov sú tieto systémy obmedzené na tenšie materiály a konkrétne aplikácie, kde extrémna presnosť prevyšuje požiadavky na rýchlosť.

Pochopte, ktorá technológia zodpovedá vašim konkrétnym potrebám, je len prvým krokom. Ďalší kľúčový faktor? Presné vedomosti o tom, ako každý typ lasera pracuje s rôznymi kovmi a hrúbkami.

Vysvetlené typy kovov a možnosti hrúbok

Vybrali ste si svoju laserovú technológiu – ale dokáže skutočne spracovať konkrétny kov, ktorý máte vo svojej dielni? Tu sa stretáva materiálová veda s praktickou výrobou. Každý kov sa pod vplyvom laserovej energie správa inak a porozumenie týmto rozdielom oddeľuje čisté, výrobnopripravené rezy od nepoužiteľných výlomkov.

Či už pracujete s plech z nehrdzavejúcej ocele na kuchynské zariadenia alebo hliníkový plech na automobilové panely, poznanie rezacích vlastností vášho materiálu vám pomôže od začiatku nastaviť správne parametre. Pozrime sa podrobne, čo od vašej laserovej rezacej operácie vyžaduje každý bežný typ kovu.

| Typ kovu | Maximálna hrúbka (čisté rezy) | Odporúčaný typ laseru | Typická rýchlosť rezania | Kvalita hrany | Osobitné úvahy |

|---|---|---|---|---|---|

| Uhlíková oceľ | 22-25 mm | Vláknový laser (1-12 kW) | 7-42 m/min | Vynikajúce s asistenčným plynom bez oxidu | Korozívne vlastnosti vyžadujú viac výkonu; kyslíková asistencia umožňuje rýchlejšie rezy, ale so zoxidovanými okrajmi |

| Nehrdzavejúcu oceľ | 20-40mm | Vláknový laser (uprednostňovaný) | 8-85 m/min | Veľmi dobré; dusík vytvára jasné hrany | Vyšší výkon potrebný pri hrubších kalibroch; dusíková prídavná látka zabraňuje sfarbeniu |

| Hliník | 25-35 mm | Vláknový laser (nezbytný) | 4-85 m/min | Dobré pri správnych parametroch | Vysoká odrazivosť spôsobuje výzvy; vynikajúca tepelná vodivosť vyžaduje upravené nastavenia |

| Mosadz | 12-14mm | Vláknový laser | 4-85 m/min | Dobré; môže vyžadovať odstránenie hrotov | Odrazová povrchová látka; obsah zinku vytvára výpary vyžadujúce správne vetranie |

Hraničné hrúbky ocele a nehrdzavejúcej ocele

Oceľ zostáva pre laserové rezanie hlavným materiálom a to z dobrého dôvodu. Uhlíková oceľ efektívne absorbuje laserovú energiu, čo umožňuje čisté rezy cez značné hrúbky. S 12kW vláknový laserový systém môžete dosiahnuť čisté rezy cez uhlíkovú oceľ až 25 mm hrubé pri rýchlostiach dosahujúcich 35-42 metrov za minútu na tenších meradlách.

Dôležitým rozdielom je, že rýchlosť rezania uhlíkové ocele klesá s rastúcou hrúbkou materiálu. Systém s výkonom 500 W spracováva 1-6 mm uhlíkovú oceľ rýchlosťou 7-9 m/min, zatiaľ čo ten istý stroj s výkonom 12 kW udržiava rýchlosť výroby iba na materiáloch v optimálnom rozsahu. Tento vzťah medzi hrúbkou a rýchlosťou priamo ovplyvňuje vaše výrobné náklady na časť.

Nerezová oceľová plechová má mierne odlišné vlastnosti. Obsah chrómu v materiáli ovplyvňuje jeho reakciu na laserovú energiu, no moderné vláknové lasery s nerezovou oceľou výnimočne dobre pracujú. Maximálna hrúbka rezu dosahuje 40 mm na systémoch s vysokým výkonom, hoci väčšina výrobných prác sa zameriava na materiály pod 20 mm pre optimálnu kvalitu okraja a rýchlosť.

Pomocný plyn, ktorý si vyberiete, tu má významný vplyv. Dusík vytvára jasné, bezoxidové okraje na nehrdznutej ocele – ideálne pre potravinárské zariadenia, lekársku techniku a architektonické aplikácie, kde záleží na vzhľade. Kyslík reže rýchlejšie, ale zanecháva oxidovaný okraj, ktorý môže vyžadovať dodatočné dokončenie.

Výzvy a riešenia pri laserovom rezaní hliníka

Môžete rezať hliník laserom? Áno – ale vyžaduje to pochopenie toho, prečo sa tento materiál správa inak ako oceľ. Hlavnou výzvou je vysoká odrazivosť hliníka. Materiál prirodzene odráža významnú časť lúča späť smerom k reznej hlave, čím sa znižuje efektivita rezania a môže dôjsť k poškodeniu zariadenia, ak sa s týmto javom nezachádza správne.

Tu sa vláknové lasery ukazujú ako nevyhnutné pre rezanie hliníka laserom. Kratšia vlnová dĺžka vláknových laserov 1,06 mikrometra sa do hliníka pohlcuje efektívnejšie ako dlhšia vlnová dĺžka CO2 laserov. To znamená, že viac energie sa využije na rezanie a menej sa stratí odrazom.

Okrem odrazivosti predstavuje vynikajúca tepelná vodivosť hliníka ďalšiu prekážku. Teplo sa rýchlo šíri materiálom, čo sťažuje udržanie lokálneho roztavenia potrebného na presné rezy. Táto vlastnosť môže viesť k širším rezom a možným tepelne ovplyvneným zónam okolo okrajov rezov. Podľa odborníci z priemyslu , je kľúčové nájsť správnu rovnováhu medzi rýchlosťou rezu a výkonom – príliš pomalý rez spôsobuje nadmerný tepelný vstup; príliš rýchly rez zase bráni úplnému preniknutiu.

Tenká oxidová vrstva, ktorá sa prirodzene tvorí na povrchu hliníka, predstavuje ďalšiu premennú. Táto vrstva má vyšší bod topenia ako samotný hliník, čo môže spôsobiť nekonzistentnosť kvality rezu. Správna príprava povrchu a optimalizované parametre laseru pomáhajú túto prekážku prekonať.

Ak úspešne režete hliník laserom, môžete očakávať maximálne hrúbky okolo 25–35 mm pri systémoch s výkonom 12 kW, hoci väčšina výrobných aplikácií sa zameriava na tenšie plechy, kde sú rýchlosti rezu stále konkurencieschopné.

- Použite dusík ako pracovný plyn: Dusík vytvára bezoxidové rezy na hliníku, čím eliminuje potrebu sekundárneho čistenia hrán vo väčšine aplikácií.

- Experimentujte s polohou zaostrenia: Nastavenie ohniska mierne nad alebo pod povrch materiálu môže výrazne zlepšiť kvalitu rezu na odrazivých kovoch.

- Zabezpečte čistotu materiálu: Oleje, nečistoty alebo silné oxidačné vrstvy na hliníkových plechoch ovplyvňujú konzistenciu rezu. Čistené povrchy zabezpečujú predvídateľné výsledky.

- Optimalizujte pomer rýchlosti ku výkonu: Hliník vyžaduje opatrné nastavenie. Začnite s odporúčaniami výrobcu a následne jemne doladiť podľa konkrétnej zliatiny a hrúbky materiálu.

- Zaveste systém riadenia tepla: Pri väčších úlohách alebo hrubšom hliníku pomáhajú občasné prestávky na ochladenie pred zabránením prehriatiu, ktoré zhoršuje kvalitu rezov.

- Sledujte tvorbu strusky: Krehká štruktúra hliníka môže spôsobiť tvorbu hrotov na okrajoch. Ak počas výroby zaznamenáte pokles kvality, okamžite upravte parametre.

Mosadz dopĺňa bežne strihané kovy laserom, pričom maximálna hrúbka je obmedzená približne na 14 mm, aj na vysokovýkonných systémoch. Odrazové vlastnosti materiálu prinášajú rovnaké výzvy ako u hliníka, zároveň jeho obsah zinku spôsobuje tvorbu vôní, ktoré vyžadujú vhodné odsávacie systémy. Napriek tomu vláknové lasery efektívne spracovávajú mosadz na dekorácie, koncovky, hardvérové komponenty a dekoratívne aplikácie.

Pochopenie možností pre konkrétne materiály umožňuje realisticky stanoviť očakávania pre vaše projekty. Ale čo ak laserové rezanie vôbec nie je správnou voľbou? Niekedy metódy plazmového alebo vodného lúča prinášajú lepšie výsledky – pozrime sa, kedy každá technológia dáva najväčší zmysel.

Laserové rezanie vs. plazmové rezanie vs. rezanie vodným lúčom

Poznáte svoje materiály a ich hraničné hodnoty hrúbky – ale tu je otázka, ktorá chytá aj skúsených výrobcov: je laserové rezanie naozaj najlepšou metódou pre váš konkrétny projekt? Niekedy nie je. Plazmové a rezanie vodným lúčom riešia problémy, s ktorými má laserové rezanie kovov problémy, a znalosť toho, kedy použiť ktorú technológiu, vám môže ušetriť tisíce korún na výrobných nákladoch.

Pomyslite na tieto tri metódy ako na špecializované nástroje vo vašej dielni. Kladivo dokonale funguje na klince, ale zle na skrutky. Podobne laserové rezanie ocele vyniká v určitých situáciách, zatiaľ čo plazmové alebo vodné lúče sú v iných prípadoch lepšie. Pozrime sa presne, čo tieto technológie od seba odlišuje, aby ste mohli priradiť správny stroj na rezanie kovov ku každej úlohe.

| Parameter | Laserového rezania | Plazmové rezanie | Režanie vodným paprskom |

|---|---|---|---|

| Presnosť/tolerancia | ±0,025 mm až ±0,1 mm | ±0,5 mm až ±1,5 mm | ±0,1 mm až ±0,25 mm |

| Rozsah hrúbky materiálu | Až 25 mm (optimálne pod 20 mm) | 0,018" až 2"+ (optimálne 0,5"–1,5") | Takmer neobmedzené (bežne 6"+) |

| Teplom ovplyvnená zóna | Minimálne (0,1–0,5 mm) | Významné (1–3 mm+) | Žiadne – studený rezný proces |

| Kvalita hrany | Vynikajúce; často nevyžaduje dodatočné opracovanie | Dobré; pri presných pracovných operáciách môže vyžadovať brúsenie | Veľmi dobré; u hrubších materiálov možný mierne zužujúci sa rez |

| Prevádzkové náklady | Stredné ($4–20/hod. podľa typu) | Nízka (spotrebný materiál + elektrina) | Vysoká (významná spotreba abrazíva) |

| Rýchlosť rezania | Rýchla na tenkých materiáloch; výrazne spomaľuje nad 1" | Veľmi rýchla na hrubých kovoch (100+ ipm na ocele 0,5") | Pomalá (typická 5-20 ipm) |

| Najlepšie použitie | Tenké plechy, komplikované návrhy, presné diely | Stavebná oceľ, ťažká technika, hrubé kovy vo vysokej objemovej výrobe | Teplom citlivé materiály, zmiešané materiály, letecké komponenty |

Zóny ovplyvnené teplom a preč sú dôležité

Všimli ste si niekedy zmeny farby pozdĺž rezného okraja? To je práve prejav zóny ovplyvnenej teplom (HAZ) – a ide o viac než len estetiku. Keď metódy tepelného rezania zohrejú kov nad určitú teplotu, zmení sa molekulárna štruktúra materiálu. Táto zmenená zóna môže byť tvrdšia, krehkejšia alebo môže vykazovať vnútorné pnutia, ktoré ovplyvňujú výkon dielu.

Laserové rezanie ocele vytvára najmenšiu zónu tepelného ovplyvnenia (HAZ) medzi tepelnými metódami, typicky len 0,1–0,5 mm širokú. Táto úzka tepelná stopa vysvetľuje, prečo časti orezané laserom často nepotrebujú žiadnu sekundárnu úpravu povrchu a zachovávajú svoje pôvodné vlastnosti materiálu až po rezný okraj.

Plazmové rezanie generuje výrazne viac tepla, čím vznikajú HAZ široké 1–3 mm alebo viac, v závislosti od hrúbky materiálu a rýchlosti rezu. Pri konštrukčných aplikáciách, kde sa diely aj tak zvárajú dokopy, to zriedkavo hraje nejakú rolu. Avšak u presných komponentov alebo kalených materiálov môže táto zmenená zóna ohroziť celistvosť dielu.

Vodný prúd tento problém úplne eliminuje. Keďže používa vysokotlakovú vodu a abrazívne častice namiesto tepla, proces nevytvára žiadne tepelné deformácie. Podľa priemyselné testovanie , vodný lúč je zrejmou voľbou pri rezaní materiálov citlivých na teplo alebo keď nesmú diely prejsť žiadnou tepelnou zmenou – napríklad súčiastky pre letecký priemysel, predtvrdené oceľové nástroje alebo materiály so špeciálnou tepelnou úpravou.

Prečo je to dôležité pre váš projekt? Zvážte tvrdený polotovar ozubeného kolesa. Ak ho prerežete plazmou, pravdepodobne budete musieť celý diel po opracovaní znova ztvrdnúť. Ak ho prerežete vodným lúčom, pôvodná tepelná úprava zostane úplne nedotknutá.

Výber správnej metódy rezu pre váš projekt

Znie to zložito? Nemusí to byť. Vaše rozhodnutie sa skladá z odpovedí na niekoľko praktických otázok týkajúcich sa vašej konkrétnej situácie. Tu je návod, ako priradiť požiadavky vášho projektu k správnej technológii rezania kovov:

- Vyberte laserové rezanie, keď: Pracujete s tenkými až stredne hrubými plechmi (pod 20 mm), potrebujete tesné tolerancie pre diely, ktoré sa presne spojia, vyžadujete komplikované návrhy s malými otvormi alebo jemnými detailmi alebo uprednostňujete čisté okraje, ktoré vyžadujú minimálne dodatočné spracovanie. Laserové rezanie kovov dominuje v elektronike, lekárskych prístrojoch a výrobe presných komponentov.

- Vyberte plazmové rezanie, keď: Vaše materiály majú hrúbku viac ako 0,5 palca, rýchlosť je dôležitejšia ako extrémne jemná presnosť, spracovávate veľké objemy konštrukčnej ocele alebo platní, alebo rozpočtové obmedzenia robia z prevádzkových nákladov prioritu. Plazmové rezanie sa osvedčilo v lodeniciach, výrobe ťažkého vybavenia a konštrukčnej výrobe, kde má zmysel rezať 1 palec ocele rýchlosťou 100+ palcov za minútu.

- Zvoľte vodno-abrazívne rezanie, keď: Teplo nemôže za žiadnych okolností pôsobiť na váš materiál, režete nevodivé materiály, ktoré plazma nemôže spracovať, vaše diely vyžadujú nulové tepelné deformácie (letecký priemysel, predpneumené materiály) alebo potrebujete rezať zmiešané materiály vrátane skla, kameňa alebo kompozitov spolu s kovmi.

- Zvážte svoj objem výroby: Kovové dielne s vysokým objemom často profitujú z vyššej rýchlosti plazmy pri hrubých materiáloch. Presná práca s nižším objemom zvyčajne uprednostňuje presnosť a kvalitu okrajov laseru. Pomalšie rýchlosti vodného laku sú najvhodnejšie pre špecializované aplikácie, kde jeho jedinečné schopnosti odôvodňujú dlhšie cyklové časy.

- Vyhodnoťte celkové náklady – nie len cenu zariadenia: Podľa analýza výrobnej priemyselnosti , systémy plazmy začínajú približne na 90 000 USD oproti vodnému laku okolo 195 000 USD. Prevádzkové náklady sa však tiež výrazne líšia – spotreba abrazíva pri vodnom laku pridáva významné náklady na meter rezu, ktoré plazma a laser nevyžadujú.

- Zohľadnite zmes vašich materiálov: Dielne, ktoré hlavne režú oceľ od 0,018" do 2", zvyčajne zistia, že plazma ponúka najlepšiu celkovú hodnotu. Zariadenia spracúvajúce rôznorodé materiály vrátane nemetalov môžu profitovať z univerzálnej reznej schopnosti vodného laku. Operácie zamerané výlučne na tenké plechy často dosahujú najvyššiu produktivitu pomocou laserských systémov.

Mnoho úspešnych dielní na spracovanie kovov nakoniec využíva viacero technológií. Plazmové rezanie rýchlo a ekonomicky zvládne hrubé konštrukčné práce. Laser sa vyznačuje presnosťou pri rezaní plechov a zložitých tvarov. Vodný lúč pokrýva špecializované aplikácie, kde je rozhodujúce rezať bez tepla. Porozumenie tomu, kde každá metóda exceluje, vám pomôže urobiť informované rozhodnutia – či už si vyberáte zariadenie pre svoju vlastnú dielňu alebo správneho poskytovateľa služieb pre externé zákazky.

Keď raz odrežete súčiastky optimálnou metódou, proces spracovania pokračuje. Ohýbanie, dokončovacie operácie a montáž premieňajú ploché odrezané diely na kompletné komponenty pripravené na konečné použitie.

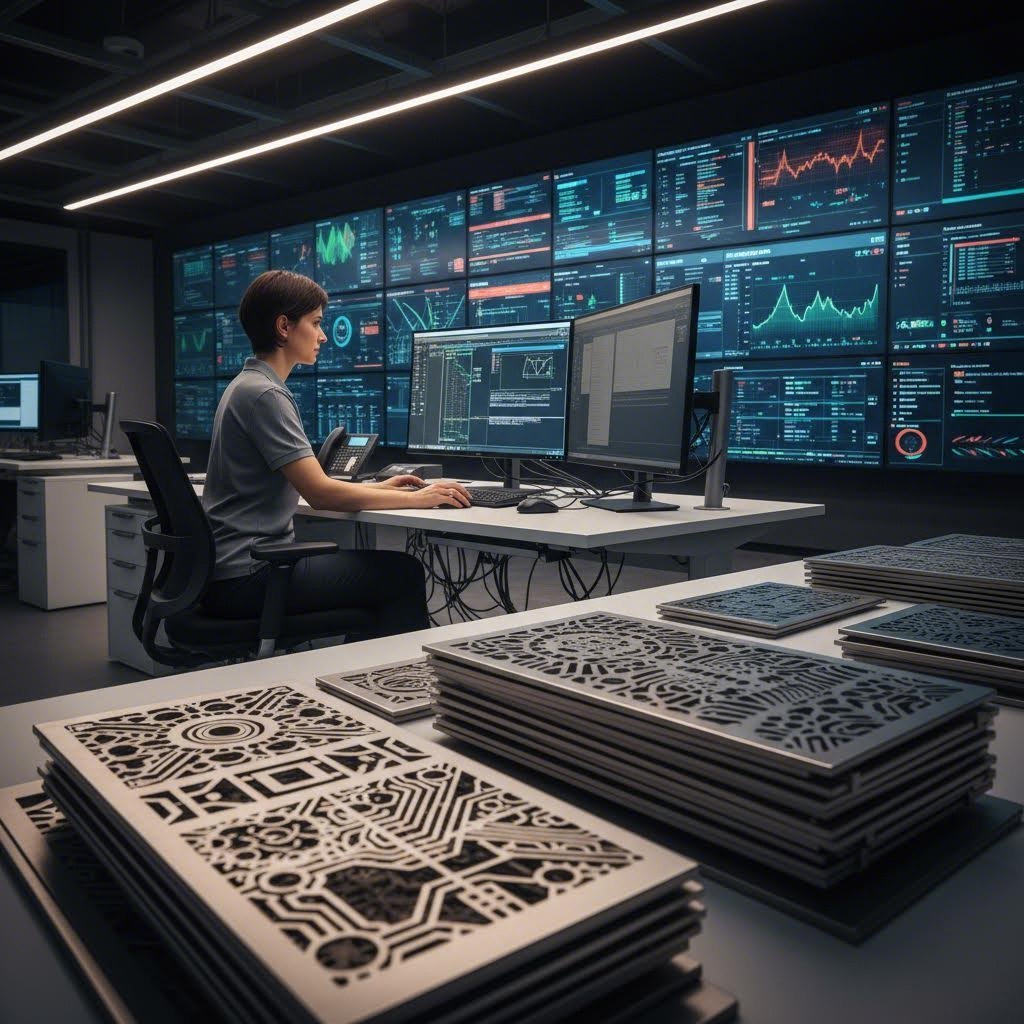

Kompletný pracovný postup pri spracovaní plechu

Vaše diely vyrezané laserom vyzerajú perfektne – čisté hrany, presné rozmery, presne podľa vášho CAD súboru. Ale tu je niečo, čo si mnohí prvýkrát nakupujúci zákazníci nevšimnú: rezanie je často len začiatok. Spracovanie plechov transformuje tieto ploché vyrezané diely na funkčné trojrozmerné komponenty prostredníctvom starostlivo koordinovanej postupnosti sekundárnych operácií.

Predstavte si laserové rezanie plechov ako základ domu. Nevyhnutný? Absolútne. Samostatne kompletný? Zriedkavo. Väčšina výrobných súčiastok vyžaduje ohýbanie na vytvorenie tvarov, úpravu povrchu na ochranu pred poškodením a niekedy aj vsadenie kovania na umožnenie montáže. Porozumenie tomuto komplexnému ekosystému spracovania kovov pomáha efektívnejšie plánovať projekty a lepšie komunikovať so svojimi výrobnými partnermi.

Od vyrezaných súčiastok po hotové zostavy

Čo sa deje po tom, ako sú vaše diely oddelené na rezacom stole? Cesta z plochého plechu ku hotovému dielu sleduje predvídateľnú postupnosť – hoci nie každý diel vyžaduje všetky kroky. Tu je typický výrobný tok, ktorý sledujú dielne zváracie kovu:

- Návrh a kontrola DFM: Inžinieri analyzujú vaše CAD súbory z hľadiska výrobnej spôsobilosti ešte pred tým, než bude materiál rezaný. To zahŕňa kontrolu polomerov ohybov, umiestnenia otvorov vo vzťahu k ohynom a rozostupov prvkov, ktoré ovplyvňujú následné operácie. Podľa priemyselných smerníc DFM môžu diely s hrúbkou pod 0,5 mm spôsobiť posunutie pri rezaní, zatiaľ čo materiály s hrúbkou nad 25 mm často vyžadujú alternatívne spracovateľské metódy.

- Výber a príprava materiálu: Výber vhodného kovu – ocele, hliníka, nehrdzavejúcej ocele, medi alebo mosadze – na základe požiadaviek vašej aplikácie, rozpočtových obmedzení a požadovaných vlastností. Každý materiál sa inak správa pri následných operáciách ohýbania a úpravy povrchu.

- Rezanie laserom: Operácia precízneho rezania, o ktorej už viete. Tieto konštrukčné rozhodnutia priamo ovplyvňujú každý nasledujúci krok – polohy otvorov musia zohľadňovať prídavky na ohyb a kvalita hrán ovplyvňuje priľnavosť povrchovej úpravy.

- Odstraňovanie hrotov a úprava hrán: Odstraňovanie strusy alebo ostrých hrán vzniknutých po rezaní. Hoci hrany vyrobené laserom zvyčajne vyžadujú minimálnu ďalšiu úpravu, hrubšie materiály alebo určité zliatiny môžu vyžadovať brousenie alebo kalenie pred manipuláciou.

- Ohýbanie a tvárnenie: Ohýbanie na CNC lísach premení ploché vyrezané diely na trojrozmerné tvary. Tento krok si vyžaduje starostlivé plánovanie – poradie ohýbania je dôležité, treba zohľadniť voľný priestor pre nástroje a rovnaké polomery ohybov skracujú výrobný čas a znížia náklady.

- Vkladanie komponentov: Inštalácia PEM matic, odstupových lišt, závitových kolíkov a iných spojovacích prvkov umožňujúcich montáž. Mnohé dielne používajú pri sériovej výrobe automatické zariadenia na ich vsádzanie.

- Zváranie a montáž: Zlúčenie viacerých komponentov do väčších zostáv, ak je to potrebné. Diely vyrezané laserom s ich presnými hranami zvyčajne vytvárajú čistejšie zvarové spoje ako alternatívy rezané plazmou.

- Povrchové dokončenie: Aplikácia ochranných alebo dekoratívnych povlakov – práškové náterové systémy patria k najobľúbenejším vďaka svojej odolnosti a ekologickej výhode. Možnosti dokončovania sa pohybujú od jednoduchých priehľadných náterov po komplexné viacvrstvové systémy.

- Kontrola kvality: Overenie rozmerov, vizuálna kontrola a akékoľvek špecifické testovanie pred dodaním súčastí. Dôkladná kontrola na úrovni surovín, počas výroby a vo finálnej fáze zabezpečuje konzistentnú kvalitu.

Druhotné operácie, ktoré dokončia váš projekt

Pozrime sa podrobnejšie na operácie, ktoré transformujú vyrezané polotovary na funkčné súčiastky. Každý krok pridáva hodnotu – a aj náklady – preto pochopenie, kedy ktorú operáciu potrebujete, vám pomôže presne špecifikovať svoje projekty.

Ohýbanie si zasluhuje osobitnú pozornosť, pretože práve tu vyniknú mnohé problémy s návrhom. Krajne orezaná časť nebude fungovať, ak nástroj na ohyb nemá prístup do rohov – potrebujete aspoň 90-stupňový voľný priestor od ohýbaných okrajov. Podľa osvedčených postupov pri výrobe používanie konzistentných polomerov ohybov a orientácií znižuje čas a náklady na nastavenie, pretože operátori nemusia opakovane preorientovať diely.

Poloha otvorov je tiež dôležitá. Otvory umiestnené príliš blízko čiar ohýbania hrozia roztrhnutím alebo deformáciou počas tvárnicového procesu, najmä u tenších materiálov. Dobré pravidlo: udržiavajte otvory vo vzdialenosti aspoň 2 až 3-násobku hrúbky materiálu od akéhokoľvek ohybu.

Služby prachového nátieru predstavujú jednu z najčastejšie požadovaných dokončovacích operácií pre laserom rezané kovové diely. Tento elektrostatický proces aplikuje suchý prášok, ktorý sa tepelne vytvrdzuje na trvalý a estetický povrch. Na rozdiel od kvapalných farieb prášková farba produkuje minimálne množstvo летúcich organických zlúčenín a vytvára hrubý, rovnomerný povlak odolný voči lúskaniu, škrabaniam a korózii.

Spojenie medzi rezaním a povlakom je dôležitejšie, ako by ste mohli očakávať. Kvalita hrany ovplyvňuje, ako dobre sa prášok prichytáva. Povrchové nečistoty spôsobené reznými olejmi alebo manipuláciou je potrebné odstrániť pred nanášaním povlaku. A akékoľvek závitové spoje alebo presné plochy sa zvyčajne kryjú, aby sa zachovala rozmerná presnosť.

Vloženie kovania často býva počas počiatočného návrhu opomínané, ale stáva sa kritickým počas montáže. Samozatrhávacie spojovacie prvky – matice, čapy, vzdialené závitové vložky – sa natrvalo inštalujú do plechu a vytvárajú pevné závity bez nutnosti zvárania alebo prístupu z rubovej strany. Plánovanie hardvéru už počas fázy rezania zabezpečuje správnu veľkosť a umiestnenie otvorov.

Prečo je toto všetko dôležité už v štádiu návrhu? Pretože rozhodnutia prijaté ešte pred rezaním sa prenášajú do každej nasledujúcej operácie. Otvor umiestnený o 0,5 mm mimo môže neovplyvniť rezanie, ale môže spôsobiť zlyhanie pri vkladaní komponentov. Ohybový polomer stanovený príliš tesný pre zvolenú hrúbku materiálu spôsobí praskliny počas tvárnenia. Ostré vnútorné rohy, ktoré vyzerajú v CAD softvéri v poriadku, môžu vyžadovať dodatočné obrábanie, čo strojnásobí náklady na jednotlivé súčiastky.

Preto skúsení výrobcovia zdôrazňujú význam návrhu zohľadňujúceho výrobnosť už od začiatku. Laserové rezanie kovových plechov sa deje v strede širšieho procesu – a porozumenie celému pracovnému postupu vám pomôže získať lepšie súčiastky rýchlejšie a hospodárnejšie. Ďalšou otázkou, ktorú si kladú väčšina kupujúcich: presne koľko to všetko bude stáť?

Faktory ovplyvňujúce náklady a pokyny k cenovej kalkulácii pre projekty laserového rezu kovov

Už ste si vymapovali svoj výrobný pracovný postup – teraz nastáva otázka, ktorú si položí každý, no máloktorý zdroj na ňu úprimne odpovedá: koľko v skutočnosti stojí laserové rezanie plechu? Na rozdiel od komoditných výrobkov s pevnou cenovkou sa cena laserového rezu plechu výrazne líši podľa faktorov, o ktorých väčšina nákupcov neuvažuje, kým neprídu cenové ponuky.

Tu je realita: dva zdalo by sa rovnaké diely môžu mať cenu odlišnú až o 300 % alebo viac, a to v závislosti od výberu materiálu, konštrukčných rozhodnutí a objemu výroby. Pochopenie toho, čo tieto náklady ovplyvňuje, vám umožní mať rozpočet pod kontrolou už predtým, ako si vôbec vyžiadate cenovú ponuku.

- Typ a trieda materiálu: Oceľ je lacnejšia na rezanie ako nehrdzavejúca oceľ, ktorá je lacnejšia ako hliník alebo meď. Okrem nákupnej ceny sa každý kov spracováva inak – odrazivosť hliníka vyžaduje väčšiu laserovú energiu, zatiaľ čo nehrdzavejúca oceľ často vyžaduje pomocný plyn dusík namiesto lacnejšieho kyslíka. Špeciálne zliatiny alebo certifikované materiály pre letecký priemysel pridávajú výrazné cenové prirážky.

- Hrúbka materiálu: Zdvojnásobenie hrúbky materiálu neznamená len zdvojnásobenie nákladov – môže ich zvýšiť až tri až päťkrát. Hrubší materiál vyžaduje pomalšie rezné rýchlosti, väčšiu laserovú energiu a vyššiu spotrebu plynu. Podľa analýza priemyslu tento vzťah medzi hrúbkou a časom spracovania priamo ovplyvňuje vaše náklady na výrobu jednej súčiastky.

- Zložitosť rezu a celková dĺžka rezu: Jednoduchý obdĺžnik so štyrmi rovnými hranami stojí oveľa menej ako komplikovaný dekoratívny vzor so stovkami kriviek a malých prvkov. Laserové rezanie plechov sa čiastočne účtuje podľa celkovej dĺžky rezu – každý palec, ktorý prejde laser, predlžuje čas. Tesné rohy, malé otvory a detailné geometrie prinútia stroj spomaliť, čím sa predlžuje výrobný čas.

- Množstvo a veľkosť dávky: Náklady na nastavenie sa rozpočítavajú na celú objednávku. Výroba 10 súčiastok môže stáť 15 USD za kus, zatiaľ čo objednanie 1 000 kusov môže znížiť cenu na 3 USD za kus. Efektivita rozmiestnenia na plechu sa tiež zvyšuje s objemom – viac súčiastok znamená lepšie využitie materiálu a menej odpadu na jednotku.

- Sekundárne operácie: Ohýbanie, vkladanie kovania, zváranie a dokončovacie práce pridávajú ďalšie nákladové úrovne. Nanášanie práškového náteru môže samostatne pridať 5–15 USD na štvorcový meter, v závislosti od zložitosti. Pri vyhodnocovaní ponúk sa uistite, že porovnávate celkové náklady na súčasti, nie len ceny rezania.

- Čas výroby: Potrebujete súčasti do 48 hodín namiesto dvoch týždňov? Poplatky za expedíciu zvyčajne pripočítavajú 25–50 % k bežným cenám. Plánovanie dopredu šetrí peniaze; núdzové objednávky sú zdražené.

Pochopenie modelov cenovania za palec a za súčasť

Poskytovatelia služieb používajú rôzne cenové štruktúry a ich pochopenie vám pomôže presne porovnávať cenové ponuky. Niektoré dielne účtujú za palec rezu – čo je priamy spôsob pre jednoduché súčasti, ale môže byť potenciálne drahší pre komplikované dizajny s rozsiahlymi reznými dráhami. Iné poskytujú cenu za súčasť, ktorá zahŕňa všetky faktory do jediného čísla, čo uľahčuje rozpočtovanie, ale sťažuje porovnávanie ponúk.

Cenová politika založená na projekte vyhodnotí váš celý úkon a poskytne pevnú celkovú cenu. Tento prístup dobre funguje pre komplexné zostavy vyžadujúce viacero operácií, ale vyžaduje jasne definovaný rozsah od začiatku. Podľa odborníkov v oblasti výroby sa pri akomkoľvek modeli, s ktorým sa stretnete, opýtajte upresňujúcich otázok o tom, čo je zahrnuté – poplatky za prípravu súborov, poplatky za manipuláciu s materiálom a minimálne požiadavky na objednávku môžu nečakane zvýšiť vašu konečnú faktúru.

Dávajte pozor na skryté náklady, ktoré sa v počiatočných cenových ponukách neobjavia. Poplatky za nastavenie komplikovaného nástroja, poplatky za konzultácie týkajúce sa dizajnu alebo konverziu súborov a minimálne požiadavky na množstvo všetko ovplyvňuje vaše skutočné výdavky. Keď je to možné, požiadajte o položkové cenové ponuky a neváhajte sa opýtať, čo sa stane, ak budú potrebné revízie.

Ako rozhodnutia o dizajne ovplyvnia vaše konečné náklady

Vaše rozhodnutia týkajúce sa CAD súborov priamo ovplyvňujú vašu faktúru. Tie elegantné tesné oblúky, ktoré vyžadujú výrazné spomalenie laseru? Zvyšujú čas spracovania. 47 malých dier, ktoré vyzerajú dokonale vo vašom návrhovom softvéri? Každá z nich vyžaduje prepichnutie, orezanie a posunutie laseru – výrazne tak navyšuje dĺžku rezu.

Inteligentné úpravy návrhu môžu výrazne znížiť náklady bez poškodenia funkčnosti:

- Mierne zväčšite polomer rohov: Zmena ostrých vnútorných rohov s uhlom 90 stupňov na polomer 2–3 mm umožňuje rýchlejšie rezanie s minimálnym rozdielom vo vizuálnej kvalite.

- Konsolidujte malé prvky: Niekoľko malých dieriek niekedy stojí viac ako menej väčších otvorov. Zvážte, či váš návrh naozaj vyžaduje každý malý prvok.

- Odstráňte nadbytočnú geometriu: Prekrývajúce sa čiary, nadmerné detaily v skrytých oblastiach a dekoratívne prvky v neviditeľných zónach zvyšujú náklady bez pridania hodnoty.

- Optimalizujte využitie materiálu: Súčiastky, ktoré sa efektívne umiestnia na štandardné formáty plechov, znižujú poplatky za odpad. Malé úpravy rozmerov môžu výrazne zlepšiť výnos.

- Štandardizujte polomery ohybov: Použitie rovnakých polomerov v celom návrhu skracuje čas na nastavenie ohýbania a počet výmen nástrojov počas výroby.

Zaujíma vás, koľko stojí laserový rezací stroj, ak uvažujete o presunutí kapacít do vlastného areálu? Vstupné vláknové lasery začínajú približne od 15 000 USD pre menšie jednotky, priemyselné stroje sa pohybujú od 55 000 do viac ako 100 000 USD v závislosti od výkonu a funkcií. Avšak nákupná cena predstavuje len časť príbehu. Podľa komplexná analýza nákladov , prevádzkové náklady vrátane elektrickej energie (približne 4 USD za hodinu pre vláknové lasery), spotreby asistenčných plynov, údržby (200–400 USD ročne za spotrebný materiál) a nárokov na priestor výrazne navyšujú celkové náklady vlastníctva.

Pre väčšinu podnikov sa rozhodnutie medzi vlastnou výrobou a odovzdaním do outsourcingu opiera o objem a konzistenciu. Vysoké objemy výroby s predvídateľnou poptávkou často ospravedlňujú investíciu do zariadení – plná návratnosť investície sa zvyčajne dosiahne do 18–24 mesiacov intenzívneho používania. Nižšie objemy, meniaca sa poptávka alebo rozmanité požiadavky na materiál zvyčajne uprednostňujú odovzdanie do outsourcingu u uznávaných výrobcov, ktorí už prehltli kapitálové náklady a vybudovali prevádzkové know-how.

Pri vyhodnocovaní cenových ponúk od poskytovateľov služieb sa nezameriavajte len na konečnú sumu. Zvážte ich skúsenosti s vašimi konkrétnymi materiálmi, ich procesy kontroly kvality a ich referencie z podobných projektov. Mierne vyššia ponuka od spoľahlivého partnera často prináša vyššiu hodnotu oproti najnižšej ponuke od dodávateľa, ktorý mešká s termínmi alebo produkuje nekonzistentnú kvalitu. Keď sú nákladové faktory jasné, ďalším kľúčovým aspektom, ktorý mnohí úplne prehliadajú, je prevádzková bezpečnosť – ako vo vlastných prevádzkach, tak pri hodnotení noriem poskytovateľov služieb.

Bezpečnostné zohľadnenia pri laserovom rezaní

Dôležité je pochopenie nákladov a možností – ale tu je to, čo väčšina zdrojov úplne vynecháva: bezpečnostné protokoly, ktoré chránia obsluhu a zariadenia počas laserového rezu. Či už prevádzkujete laser na kov vo vlastnom areáli alebo vyhodnocujete dodávateľov služieb, znalosť týchto požiadaviek vám pomôže zabezpečiť dodržiavanie predpisov a identifikovať dielne, ktoré kladia dôraz na ochranu pracovníkov.

Rezacie lasery generujú nebezpečenstvá, ktoré siahajú ďalej ako len zrejmé. Áno, samotný vysokej energie vyžarovaný lúč predstavuje riziká – ale rovnako si vyžadujú pozornosť potenciálne požiare, toxické výpary a elektrické nebezpečenstvá. Štandard ANSI Z136.1 poskytuje základ pre bezpečnostné programy pri práci s laserom v priemyselných, výskumných a výrobných prostrediach. Pozrime sa bližšie na to, ako v praxi vyzerá riadna bezpečnosť.

Nevyhnutné ochranné vybavenie pre prevádzku laserov

Osobná ochranná technika predstavuje posledný stupeň obrany, keď zlyhajú inžinierske opatrenia. Pri prevádzke laserových rezacích zariadení závisia konkrétne požiadavky na OOP od klasifikácie vášho zariadenia a spracovávaných materiálov.

Ochrana očí je najdôležitejšou úvahou. Priemyselné rezačky laserom – zvyčajne systémy triedy 3B alebo 4 – môžu spôsobiť vážne poškodenie očí vrátane trvalého slepoty pri priamom alebo odrazenom vystavení lúču. Podľa smerníc bezpečnosti univerzít je vysokoenergetický lúč vo väčšine systémov na rezanie kovov neviditeľný, čo robí správne ochranné okuliare nevyhnutnými, nie voliteľnými. Ochranné okuliare určené špecificky pre lasery musia byť prispôsobené vlnovej dĺžke vášho zariadenia – štandardné ochranné okuliare neposkytujú žiadnu ochranu proti laserovému žiareniu.

Okrem ochrany očí potrebujú operátori tepelne odolné rukavice na prevenciu popálenín pri manipulácii s nedávno rezanými materiálmi. Rezná medzera a okolité kovové povrchy si ihneď po rezaní zachovávajú významné množstvo tepla. Ochranný odiev, ktorý kryje odkryté pokožky, znižuje riziko popálenín od iskier a horúcich častíc, ktoré unikajú z rezného priestoru.

Väčšina uzatvorených systémov laserových rezacích zariadení obsahuje bezpečnostné zámky, ktoré vypnú lúč pri otvorení dvierok – tieto technické opatrenia však fungujú len vtedy, ak sú správne udržiavané. Nikdy nemodifikujte ani neobchádzajte výrobcove bezpečnostné prvky. Ak bezpečnostný zámok nefunguje, okamžite zastavte prevádzku, až kým nebudú opravy dokončené.

Požiadavky na vetranie a odsávanie vôní

Tu je nebezpečenstvo, ktoré mnohí podceňujú: výpary vznikajúce pri odparovaní kovu pomocou laseru. Rezné operácie produkujú suspendované častice, kovové páry a potenciálne toxické plyny, ktoré predstavujú vážne riziká pre dýchacie cesty. Definujte pojmom droz tuhnutý materiál vymršťovaný počas rezu – a uvedomte si, že podobné zvyšky sa počas procesu dostávajú aj do ovzdušia.

Správne odvádzanie vôd nie je voliteľnou výbavou – je nevyhnutné pre bezpečný prevádzku. Podľa stanovených bezpečnostných protokolov musia byť laserové rezačky vybavené odsávacími systémami a filtráciou, ktoré spĺňajú špecifikácie výrobcu. Prevádzka akejkoľvek laserovej rezačky s nefunkčným odsávacím systémom alebo zaneseným filtrom vytvára okamžité nebezpečenstvo pre zdravie a má spustiť okamžité prerušenie práce.

Rôzne kovy produkujú rôzne zloženia vôd. Materiály obsahujúce zinok, ako napríklad mosadz, vytvárajú obzvlášť nebezpečné výpary. Potiahnuté alebo natreté kovy môžu uvoľňovať toxické vedľajšie produkty, ktoré štandardná filtračná sústava nedokáže účinne zachytiť. Vždy skontrolujte, či sú vaše materiály kompatibilné s možnosťami vášho odvádzacieho systému pred rezaním.

- Pred každou operáciou: Skontrolujte, či sú všetky kryty na mieste a či správne fungujú bezpečnostné zámky. Skontrolujte prevádzku výfukového systému a stav filtra. Uistite sa, že je prístupný hasiaci prístroj – hasiace prístroje so zhasínacou látkou oxid uhličitý (trieda B) musia byť umiestnené v dosahu ruky.

- Počas rezu: Nikdy nenechávajte prevádzkované zariadenie bez dozoru. Udržiavajte priestor okolo laserového rezača voľný od horľavých materiálov. Neustále sledujte proces, aby ste včas zaregistrovali vznietenie materiálu.

- Po reze: Nechajte materiály vychladnúť pred manipuláciou – neodstraňujte diely z rezného lôžka, kým nie sú chladné na dotyk. Pred ďalšou prevádzkou vyčistite zariadenie od nečistôt a horľavých zvyškov.

- Zakázané úkony: Nikdy sa nepozerajte priamo do laserového lúča. Nikdy neprevádzkujte zariadenie so vypnutými bezpečnostnými funkciami. Nikdy neopravujte vysoce horľavé, výbušné alebo neznáme materiály bez predchádzajúceho overenia bezpečnostných postupov prostredníctvom bezpečnostných listov.

- Príprava na núdzové situácie: Dokončite školenie z hasenia požiarov pred použitím akéhokoľvek laserového rezača. Poznajte postupy pre núdzové vypnutie. Okamžite hláste všetky požiare, zranenia a takmer nehody – vrátane škôd na majetku bez zranení.

- Požiadavky na priestor: Zabezpečte primeranú úroveň vetrania pre konkrétne materiály a objem rezania. Umiestnite vhodné výstražné značky a štítky podľa požiadaviek ANSI Z136.1. Zavedenie kontrolovaného prístupu do priestorov s laserovými rezačmi.

Pri hodnotení externých výrobných partnerov tieto rovnaké bezpečnostné normy poukazujú na kvalitu prevádzky. Dielne so správnymi odvádzacími systémami, udržiavaným zariadením a vyškolenými operátormi zvyčajne poskytujú konzistentnejšie výsledky ako prevádzky, ktoré šetria na bezpečnostnej infraštruktúre. Kvalita vašich dielov často priamo koreluje s ochotou dodávateľa dodržiavať profesionálne štandardy vo všetkých operáciách – vrátane ochrany pracovníkov.

Keďže základné bezpečnostné požiadavky sú splnené, ostáva posledné rozhodnutie: investovať do vlastného vybavenia alebo spolupracovať s odbornými výrobcami, ktorí tieto kapacity už majú?

Voľba medzi vlastným vybavením a profesionálnymi službami

Už ste vyhodnotili technológie rezania, porozumeli možnostiam materiálov, vypočítali náklady a prebrali bezpečnostné požiadavky. Teraz prichádza praktické rozhodnutie, ktoré určí váš skutočný ďalší postup: či investovať do vlastného laserového rezacieho zariadenia, používať online rezačské služby alebo spolupracovať s odbornými kovodielňami v blízkosti mňa? Každá možnosť slúži iným potrebám – a nesprávna voľba vás môže stáť tisíce eur stratených investícií alebo nepostačujúcimi výsledkami.

Správna odpoveď úplne závisí od vašej konkrétnej situácie. Objem požiadaviek, nároky na presnosť, rozpočtové obmedzenia a dlhodobé výrobné ciele všetky ovplyvňujú toto rozhodnutie. Porovnajme vaše možnosti podľa kritérií, ktoré skutočne rozhodujú o úspechu výroby.

| Parameter | Profesionálni výrobní partneri | Online rezačské služby | Stolný/malý laserový rezací stroj pre kov |

|---|---|---|---|

| Počiatočná investícia | Žiadne – platba za projekt | Žiadne – platba za projekt | 3 000–15 000+ USD pre jednotky schopné spracovať kov |

| Náklady na diel (10 dielov) | Vyššia distribúcia nastavenia, ale profesionálna kvalita | Stredné; vrátane dopravy | Iba náklady na materiál po odkúpení zariadenia |

| Náklady na diel (1 000 dielov) | Najnižšie ceny podľa objemu a výhody automatizácie | Stredná úroveň; niektoré zľavy podľa objemu | Nepraktické pre tento objem |

| Schopnosti | Celá škála hrúbok, sekundárne operácie, montáž | Iba rezanie; obmedzené sekundárne operácie | Iba tenké materiály (zvyčajne pod 3 mm) |

| Čas odovzdania | Možnosť rýchleho prototypovania; plánovanie výroby | bežne 3–10 pracovných dní | Okamžité pri malých úlohách |

| Konštancia kvality | Certifikované procesy; kontrolné protokoly | Závislé od poskytovateľa | Závislé od prevádzkovateľa; obmedzená kontrola |

Kedy dávajú zmysel stolné laserové rezačky

Pokušenie vlastniť si stolný laserový gravírovač alebo malú kovovú laserovú rezačku je nezapierateľné – okamžitý prístup, žiadne poplatky za diely po počiatočnej investícii a úplná kontrola nad výrobným plánom. Realita však často odporuje marketingovým materiálom. Pochopenie, kedy samostatné zariadenie skutočne prináša hodnotu, vám pomôže vyhnúť sa drahým sklamaniam.

Stolná laserová rezačka alebo stolný laserový gravírovač funguje vynikajúco pre špecifické aplikácie: gravovanie tenkého kovu, práca na šperkárskych predmetoch, testovanie prototypov pred zadávaním výrobných objednávok a vzdelávacie účely. Nadšenci vyrábajúci vlastné nápisy, umelci pracujúci s tenkými dekoratívnymi kovmi, a tvorcovia vyrábajúci jednorazové kusy často tieto stroje považujú za skutočne užitočné.

Avšak platia významné obmedzenia. Väčšina kovových laserových rezačiek určených na domáce použitie má maximálnu hrúbku materiálu 2–3 mm, čo je oveľa menej ako priemyselné požiadavky. Existujú stolné laserové rezačky a gravírovacie zariadenia schopné rezať hrubšie kovy, ale náklady rýchlo stúpajú do výšky 10 000–15 000 USD pre zariadenia, ktoré napriek tomu nedosahujú profesionálne možnosti.

Zvážte tieto praktické obmedzenia pred zakúpením stolnej laserovej rezačky:

- Obmedzenia výkonu: Stolné jednotky zvyčajne dosahujú maximálne 20–60 W – to je neprimerané na rezanie ocele alebo nehrdzavejúcej ocele, okrem povrchovej značky. Skutočný rez kovov vyžaduje technológiu vláknového lasera, ktorá si vyžaduje vysoké ceny, aj keď ide o menšie formáty.

- Bezpečnostná infraštruktúra: Profesionálne odvádzanie dymov, vhodné uzatvorenia a primerané vetranie pridajú tisíce k vašim nákladom na inštaláciu navyše k samotnému stroju.

- Údržbová záťaž: Stanete sa zodpovednými za celú kalibráciu, opravy a výmenu spotrebného materiálu. Výroba sa zastaví, keď riešite problémy namiesto výroby.

- Učebná krivka: Dosiahnutie konzistentných výsledkov produkčnej kvality si vyžaduje mesiace cvičenia. Prvých sto dielov pravdepodobne bude zahŕňať vysokú mieru odpadu.

Ak sa vaše potreby sústreďujú na tenké materiály, nízke objemy a osvojenie si technológie, malý laserový rezací stroj na kov môže byť vhodnou voľbou. Pre výrobu sériových dielov profesionálne partnerstvá zvyčajne prinášajú lepšie výsledky za nižšie celkové náklady.

Spolupráca s profesionálnymi výrobцami kovových dielov

Profesionálni výrobní partneri ponúkajú schopnosti, ktoré žiadne stolné zariadenie nemôže ponúknuť – nie len v reznej sile, ale aj v celej ekosystéme okolo výroby. Podľa odborníkov vo svojom odvetví má výber správneho výrobného partnera oveľa väčší vplyv na náklady, výkon, kvalitu a dlhodobú spoľahlivosť než samotná rezacia technológia.

Čo oddeľuje vynikajúcich výrobcov od tých primeraných? Päť kľúčových faktorov spoľahlivo predpovedá úspech partnerstva:

- Skúsenosti a odborné znalosti: Počet rokov v podnikaní sa prejavuje hlbším odborným poznaním materiálov a schopnosťou predvídať problémy. Skúsení výrobcovia rozumejú správaniu sa ocele, hliníka, nehrdzavejúcej ocele a špeciálnych zliatin počas rezania, tvárnenia a zvárania – poznatky, ktoré zabraňujú nákladným chybám.

- Vlastné kapacity: Komplexné zariadenia, ktoré ponúkajú laserové rezanie, CNC obrábanie, presné ohýbanie, zváranie a dokončovacie práce pod jednou strechou, zabezpečujú vyšší stupeň kontroly kvality a rýchlejšiu realizáciu v porovnaní so spoločnosťami, ktoré sú oddelene zmluvne viazané na dodatočné operácie.

- Inžinierska podpora a DFM: Najlepší partneri spolupracujú už od začiatku a skôr, ako sa začne rezať, kontrolujú vaše návrhy z hľadiska výrobnej vhodnosti. Toto sprievodné poradenstvo vylepšuje návrhy pre nákladovo efektívnu výrobu bez obeti požadovaného výkonu.

- Certifikáty kvality: Certifikácia ISO preukazuje záväzok voči zdokumentovaným systémom a opakovateľným výsledkom. Pre automobilové aplikácie certifikácia IATF 16949 indikuje prísne štandardy kvality, ktoré vyžadujú výrobcovia originálnych zariadení (OEM).

- Komunikácia a škálovateľnosť: Transparentné časové plány, pravidelné aktualizácie projektov a schopnosť škálovať od prototypov až po výrobné série bez straty kvality definujú spoľahlivých partnerov.

Pre automobilové a presné aplikácie sú tieto faktory ešte dôležitejšie. Spoločnosti ako Shaoyi (Ningbo) Metal Technology ilustrujú, ako v praxi vyzerá profesionálna výrobná kapacita – certifikácia IATF 16949 zabezpečujúca automobilovú kvalitu, 5-dňové rýchle prototypovanie pre rýchlosť vývoja a ponuky za 12 hodín, ktoré udržiavajú projekty v pohybe. Ich špecializácia na podvozky, tlmiace systémy a konštrukčné komponenty demonštruje odborné znalosti špecifické pre priemysel, ktoré bežní výrobcovia nemôžu ponúknuť.

Pri hodnotení akéhokoľvek výrobného partnera požiadajte o konkrétne informácie: Aké certifikácie majú? Môžu poskytnúť referencie z podobných projektov? Aký je ich protokol kontroly? Ponúkajú kontrolu navrhovania pre výrobu (DFM) pred spustením výroby? Tieto otázky odhaľujú prevádzkovú kvalitu oveľa lepšie než prehliadky zariadení alebo zoznamy zariadení.

Skutočná hodnota profesionálnych partnerstiev siaha ďalej ako len schopnosť rezať. Skúsení výrobcovia predchádzajú problémom s návrhom, než sa stanú nákladnými výrobnými problémami, zabezpečujú konzistentnú kvalitu tisícov dielov a preberajú kapitálové investície a prevádzkovú zložitosť, ktoré by inak zaťažili vašu organizáciu.

Online služby rezania zaberajú strednú pozíciu – sú užitočné pre jednoduché diely, kde potrebujete profesionálne vybavenie, ale minimálne poradenstvo. Fungujú dobre pre priame geometrie bez sekundárnych operácií. Avšak postrádajú inžiniersku podporu a integrované schopnosti, ktoré komplexné projekty vyžadujú.

Vaša optimálna voľba nakoniec závisí od toho, ako najlepšie spájate vaše konkrétne potreby s príslušnou úrovňou schopností. Začiatočníci a tvorcovia profitujú z prístupnosti stolných zariadení. Jednoduché diely zo štandardných materiálov vyhovujú online službám. Výrobné komponenty vyžadujúce presnosť, sekundárne operácie a certifikovanú kvalitu si vyžadujú profesionálnych výrobných partnerov, ktorí investovali do infraštruktúry, odbornosti a systémov kvality potrebných na dosiahnutie konzistentných výsledkov. Po výbere spôsobu výroby je posledným krokom pochopenie toho, kam sa laserom rezaný kov v skutočnosti používa – aplikácie pokrývajúce priemyselné odvetvia a rôzne prípady použitia, ktoré dokazujú mimoriadnu všestrannosť tejto technológie.

Praktické aplikácie a vaše ďalšie kroky

Absorbovali ste základy technológie, vyhodnotili svoje možnosti výroby a pochopili, ako vyzerá kvalita. Teraz si predstavte, kam všade toto vedomie skutočne aplikujete – pretože laserom rezaný kov sa prakticky vyskytuje všade okolo nás, od automobilu, ktorým jazdíte, až po budovu, v ktorej pracujete.

Univerzálnosť laserového rezania vysvetľuje jeho rýchle prijímanie vo viacerých odvetviach. Z jedného kovového plechu sa môže stať presná automobilová konzola, dekoratívny stenový panel alebo kritická súčasť lekárskych prístrojov – všetko závisí od toho, kto ju navrhuje. Pozrime sa na konkrétne aplikácie, kde táto technológia prináša mimoriadnu hodnotu, usporiadané podľa odvetví, ktoré na ňu najviac spoliehajú.

Automobilové a dopravné aplikácie

Automobilový priemysel patrí medzi najväčších spotrebiteľov súčiastok z laserom rezaného kovu – a to z dobrého dôvodu. Moderné vozidlá obsahujú stovky presne opracovaných komponentov, pri ktorých úzke tolerancie priamo ovplyvňujú bezpečnosť, výkon a efektivitu montáže.

- Podvozok a konštrukčné komponenty: Nosníky rámu, priečne nosníky a zosilňovacie konzoly vyžadujú stálu presnosť pri výrobe tisícov kusov. Podľa odborníkov na automobilovú výrobu je schopnosť laserového rezania udržiavať presnosť v zlomkoch milimetra nevyhnutná pre komponenty, kde každý rozmer ovplyvňuje bezpečnosť vozidla.

- Súčasti systému podvozku: Ramená riadenia, montážne konzoly a časti spojovacieho mechanizmu profitujú z minimálnej tepelne ovplyvnenej zóny pri laserovom rezaní. Vlastnosti materiálu zostávajú zachované až po okraj rezu – čo je kritické pre diely vystavené opakovaným zaťažovacím cyklom.

- Karosériové panely a lišty: Vonkajšie a vnútorné kovové panely vyžadujú nielen presnosť, ale aj estetickú kvalitu okrajov. Laserovo rezané diely často nepotrebujú dodatočné dokončovanie, čo skracuje výrobný čas a znížuje náklady.

- Špeciálne plechové držiaky tvárnené podľa objednávky: Špecializované montážne riešenia pre snímače, elektroniku a príslušenstvo sa pri vývoji prototypov a pri malých až stredných sériách spoliehajú na laserové rezanie, kým sa pre veľké série neprejde na tvárnenie.

Pre automobilové aplikácie zabezpečuje spolupráca s výrobcami certifikovanými podľa IATF 16949 systémy kvality, ktoré vyžadujú výrobcovia originálnych zariadení. Spoločnosti ako Shaoyi (Ningbo) Metal Technology sa špecializujú na podvozky, tlmiace systémy a konštrukčné komponenty – kombinujú rýchle prototypovanie do 5 dní s komplexnou podporou DFM, ktorá odhaľuje problémy s výrobnosťou ešte predtým, než sa stanú výrobnými problémami.

Architektonické a dekoratívne kovové projekty

Prejdite sa každou súčasnou budovou a stretnete sa s aplikáciami laserovo rezaných kovových panelov, ktoré premieňajú funkčné materiály na umelecké výpovede. Presnosť tejto technológie umožňuje dizajny, ktoré by boli pri použití tradičných rezacích metód nemožné alebo finančne neprijateľné.

- Dekoratívne stenové systémy: Podľa odborníci na architektonické kovy , laserom rezané dekoratívne kovové panely tvoria výrazné architektonické prvky, ktoré upútajú pozornosť. Geometrické vzory, motívy inšpirované prírodou a abstraktné návrhy sa stávajú možnými vďaka presnému rezaniu, ktoré odstraňuje obmedzenia ručnej výroby.

- Stropné systémy: Laserom rezané oceľové panely a komponenty z hliníkových plechov vytvárajú vizuálne pôsobivé nadstropné inštalácie, ktoré zároveň riešia požiadavky na akustickú reguláciu v komerčných priestoroch.

- Systémy slnečnej ochrany a tieňovania: Perforované kovové mriežky filtrovajú svetlo a zároveň vytvárajú dynamické tieňové vzory. Presnosť laserového rezania umožňuje optimalizáciu denného osvetlenia pri súčasnom riadení oslnenia a tepelného zaťaženia.

- Výroba kovových tabúľ na mieru: Od firemných logotypov až po navigačné systémy – laserové rezanie vyrába nálepky s čistými okrajmi a jemnými detailmi, ktoré zvyšujú postavenie značky.

- Zábradlia a rebríky: Dekoratívne kovové panely integrované do zábradlí kombinujú bezpečnostnú funkciu s estetickou personalizáciou.

Stavebný priemysel čoraz viac špecifikuje laserovo rezané komponenty pre ich kombináciu konštrukčnej integrity a flexibility konštrukcie. Či už vytvoríte stenu z laserovo rezaného kovového panelu alebo vyrábate konštrukčné oceľové rámy, technológia sa prispôsobuje funkčným aj dekoratívnym požiadavkám.

Priemyselné a špecializované aplikácie

Okrem automobilového a architektonického využitia slúži laserové rezanie aj v špecializovaných odvetviach, kde sa presnosť a spoľahlivosť nepresadzujú:

- Výroba zdravotníckych pomôcok: Chirurgické nástroje, komponenty implantátov a obaly diagnostických zariadení vyžadujú mimoriadnu presnosť a materiály, ktoré udržiavajú biokompatibilitu. Podľa výskumu priemyselných aplikácií, presnosť zabezpečuje, že nástroje a implantáty spĺňajú najvyššie normy bezpečnosti a účinnosti.

- Letecké komponenty: Ľahké, vysoko pevné časti pre lietadlá vyžadujú prísne tolerančné úrovne. Minimálne tepelne ovplyvnené zóny zachovávajú konštrukčnú integritu materiálu, čo je v leteckom priestore mimoriadne dôležité.

- Elektronické koše: Presné skrine pre citlivé zariadenia využívajú schopnosť laserového rezu vyrábať presné vzory montážnych otvorov a vetiacich otvorov bez hrubíc, ktoré by mohli poškodiť komponenty.

- Výrobné zariadenia na spracovanie potravín: Komponenty z nehrdznúcej ocele určené na kontakt s potravinami vyžadujú čisté rezy a povrchy, ktoré spĺňajú hygienické normy. Laserový rez tieto požiadavky splňuje.

- Energetický sektor: Komponenty pre veterné turbíny, systémy uchytenia solárnych panelov a energetickú infraštruktúru sa opierajú o schopnosť laserového rezu spracovávať rôzne hrúbky materiálu s konzistentnou kvalitou.

Vaše ďalšie kroky vpred

Či už ste nadšenec do DIY projektov, ktorý skúma možnosti stolných zariadení, alebo odborník z oblasti nákupu hodnotiaci výrobných partnerov, váš ďalší postup závisí od toho, ako prispôsobíte svoje konkrétne požiadavky najvhodnejšiemu prístupu.

Pre nadšencov a hobbymilovníkov: Začnite s tenkými materiálmi a jednoduchými dizajnami, aby ste si postupne vytvorili zručnosti. Pred prvým rezaním investujte do vhodného bezpečnostného vybavenia. Zvážte služby online rezania pre materiály alebo hrúbky, ktoré presahujú možnosti vášho zariadenia. Pripojte sa k komunitám výrobcov, kde skúsení operátori zdieľajú nastavenia parametrov a pomáhajú pri odstraňovaní problémov.

Pre inžinierov a dizajnérov: Používajte princípy DFM už od najskorších fáz návrhu. Poradte sa so spoločníkmi vo výrobe pred definitívnym stanovením špecifikácií – ich príspevok zabráni nákladným revíziám. Vyžiadajte si vzorky materiálov, aby ste overili, či úprava povrchu a kvalita okrajov spĺňajú vaše požiadavky. Budujte vzťahy s výrobcami, ktorí rozumejú špecifickým požiadavkám vášho odvetvia.

Pre odborníkov v oblasti nákupu a výroby: Vyhodnoťte potenciálnych partnerov na základe certifikácií, kapacít a komunikácie – nie len podľa cien. Požiadajte o referencie z podobných projektov. Potvrďte, že protokoly kontroly kvality zodpovedajú vašim požiadavkám. Pre automobilové aplikácie overte certifikáciu IATF 16949 a posúďte schopnosti rýchleho prototypovania, ktoré udržia vývojové časové plány na sľúbenej úrovni.

Technológia sa ďalej vyvíja. Vláknové lasery vyššejho výkonu ešte viac posúvajú hranice hrúbky rezaných materiálov. Automatizácia zníži náklady na jednotlivé diely pri veľkosériovej výrobe. Pokročilý softvér pre pokročilé rozmiestňovanie optimalizuje využitie materiálu. Aktuálny prehľad týchto vývojových trendov vám pomôže plne využiť potenciál laserového rezania – bez ohľadu na to, či režete prvý kus hliníkového plechu alebo zvyšujete výrobu na tisíce presných komponentov mesačne.

Vaša cesta s laserovo rezaným kovom začína jedným rozhodnutím: čo vytvoríte ako prvé?

Často kladené otázky o laserovo rezanom kove

1. Aké sú náklady na laserové rezanie kovov?

Náklady na laserové rezanie kovov sa líšia v závislosti od druhu materiálu, hrúbky, zložitosti rezu a množstva. Prevádzkové náklady sú približne 4 €/hod pre vláknové lasery oproti 20 €/hod pre CO2 systémy. Cena za diel závisí od celkovej dĺžky rezu, sekundárnych operácií, ako je ohýbanie alebo práškové nástrekovanie, a požiadaviek na dodaciu lehotu. Objednávky vo väčšom objeme výrazne znížia náklady na jednotku prostredníctvom efektívnejšieho rozdelenia prípravy a úsporného rozmiestnenia na plechy. Odborní partneri, ako sú výrobcovia certifikovaní podľa štandardu IATF 16949, ponúkajú konkurencieschopné ceny s možnosťou poskytnutia cenovej ponuky do 12 hodín pre presné rozpočtovanie projektu.

2. Ktoré materiály nie je možné rezať na laserovej rezačke?

Laserové rezačky nemôžu bezpečne spracovávať PVC, polycarbonát, Lexan ani polystyrén kvôli uvoľňovaniu toxických vôní alebo požiarnemu nebezpečenstvu. Pri kovoch predstavujú vysoce odrazivé materiály ako čistá meď výzvu pre CO2 lasery, no vláknové lasery ich efektívne zvládajú. Povrchovo upravené alebo natreté kovy môžu uvoľňovať škodlivé vedľajšie produkty, ktoré vyžadujú špecializované filtračné systémy. Pred rezaním vždy overte kompatibilitu materiálu pomocou bezpečnostných listov a zaistite, aby systémy vetrania zodpovedali konkrétnym požiadavkám na spracovávaný materiál.

3. Dokáže 40-wattový laser rezať kovy?

Laser s výkonom 40 W CO2 nemá dostatočný výkon na rezanie kovov, okrem povrchovej značky alebo gravírovania tenkých fólií. Skutočné rezanie kovov vyžaduje technológiu vláknového lasera s vyšším výkonom. Vstupné systémy vláknových laserov schopné rezať oceľ a hliník začínajú približne od 1–3 kW. Stolné jednotky pod 60 W sú vhodné na gravírovanie tenkých materiálov a prácu v mierke šperkov, avšak nedokážu vykonať rez dostačujúcej kvality pri doskách zo železa, nehrdzavejúcej ocele alebo hliníka s hrúbkou vyššou ako 1–2 mm.

4. Akú hrúbku kovu dokážu laserové rezačky rezať?

Moderné vláknové lasery režú uhlíkovú oceľ do 25 mm, nehrdzavejúcu oceľ do 40 mm a hliník do 35 mm v závislosti od výkonu. Systém s výkonom 12 kW zvládne väčšinu výrobných požiadaviek, pričom jednotky s vyšším výkonom tieto limity ďalej rozširujú. Optimálna kvalita a rýchlosť rezania sa dosahujú pri tenších materiáloch – zdvojnásobenie hrúbky rezania nenasleduje úmerne náklady, ale môže ich zvýšiť 3 až 5-krát kvôli nižšej rýchlosti a vyššej spotrebe plynu. Väčšina výrobných úloh sa zameriava na materiály pod 20 mm pre najlepšiu efektívnosť.

5. Aký je rozdiel medzi vláknovým laserom a CO2 laserom pri rezaní kovov?

Vláknové lasery pracujú na vlnovej dĺžke 1,06 mikrónu s absorpciou kovov 30–50 % oproti CO2 laserom s 10,6 mikrónmi a len 2–10 % absorpcie. To znamená, že vláknové lasery režú až 3-krát rýchlejšie, stojí ich prevádzka približne 4 $/hodinu oproti 20 $/hodinu u CO2, a efektívnejšie spracovávajú odrazné kovy ako hliník a meď. Vláknové systémy vyžadujú menšiu údržbu (200–400 $ ročne) voči CO2, kde sú náklady na údržbu zrkadiel a šošoviek 1 000–2 000 $. CO2 si zachováva hodnotu pre prácu so zmiešanými kovmi a nekovmi, no vláknové lasery dominujú pri špecializovanej kovospracovateľskej výrobe.

Malé dávky, vysoké štandardy. Naša služba rýchlejho prototypovania urobí overenie rýchlejšie a jednoduchšie —

Malé dávky, vysoké štandardy. Naša služba rýchlejho prototypovania urobí overenie rýchlejšie a jednoduchšie —