Custom Aluminum Cutting: Match Your Alloy, Thickness, And Method

Understanding Custom Aluminum Cutting Fundamentals

Whether you're engineering aerospace components, building architectural features, or tackling a weekend DIY project, chances are you'll encounter aluminum. But here's the thing—off-the-shelf aluminum rarely fits your exact specifications. That's where custom aluminum cutting comes into play, transforming raw material into precisely shaped components tailored to your unique requirements.

Custom aluminum cutting refers to precision fabrication services that shape aluminum sheets, plates, and extrusions to exact specifications using various cutting technologies. Unlike grabbing pre-cut stock from a hardware store, this process allows you to define the dimensions, tolerances, and edge quality your project demands. Think of it as the difference between buying a ready-made suit and having one tailored specifically to your measurements.

This guide serves as your comprehensive learning resource for understanding how to cut aluminum effectively. You'll discover the critical relationships between alloy selection, material thickness, and cutting method choices. By the end, you'll have the knowledge to make informed decisions—whether you're working with a local metal fab shop or submitting files to an online cutting service.

What Makes Aluminum Cutting Custom

The "custom" in custom aluminum cutting encompasses several key elements that differentiate it from standard fabrication:

- Precise dimensional control: You specify exact measurements down to thousandths of an inch, rather than accepting standard sizes

- Shape flexibility: Complex geometries, intricate patterns, and unique profiles become possible through advanced cutting technologies

- Material selection: You choose the specific alloy grade that matches your application's strength, corrosion resistance, and workability requirements

- Tolerance specification: Critical applications demand tight tolerances that mass-produced parts simply cannot guarantee

According to industry experts, custom aluminum fabrication has emerged as a pillar of many industries in the contemporary era of innovation and design. The process involves cutting, shaping, welding, and assembling aluminum into products that serve both functional and aesthetic purposes.

Why Precision Matters in Aluminum Fabrication

Aluminum presents a fascinating paradox for fabricators. Its properties make it incredibly popular—yet those same characteristics create unique cutting challenges.

Aluminum is light, stable with tensile strengths nearly rivaling steel, naturally corrosion-resistant, and an excellent thermal conductor. These properties facilitate machining and enable high cutting speeds, but they also mean that improper cutting techniques can quickly lead to material distortion, built-up edges, and compromised dimensional accuracy.

When you're working with aluminum sheet metal, precision isn't just about hitting the right dimensions. The material's high thermal conductivity means heat dissipates quickly during cutting—a benefit for preventing warping, but a factor that demands proper technique. Meanwhile, aluminum's tendency to form adhesive chips can affect edge quality if cutting parameters aren't optimized for the specific alloy.

For aluminium fabrication projects ranging from automotive components to custom signage, understanding these material behaviors helps you select the right cutting method and communicate effectively with your fabrication partner. Whether you need to cut aluminum for a prototype enclosure or produce hundreds of identical brackets, the fundamentals remain the same: match your alloy, thickness, and cutting method to achieve optimal results.

Throughout this guide, you'll learn to navigate five primary cutting methods, understand how different alloys behave under various cutting conditions, and prepare specifications that prevent costly mistakes. Consider this your roadmap to successful custom aluminum cutting projects.

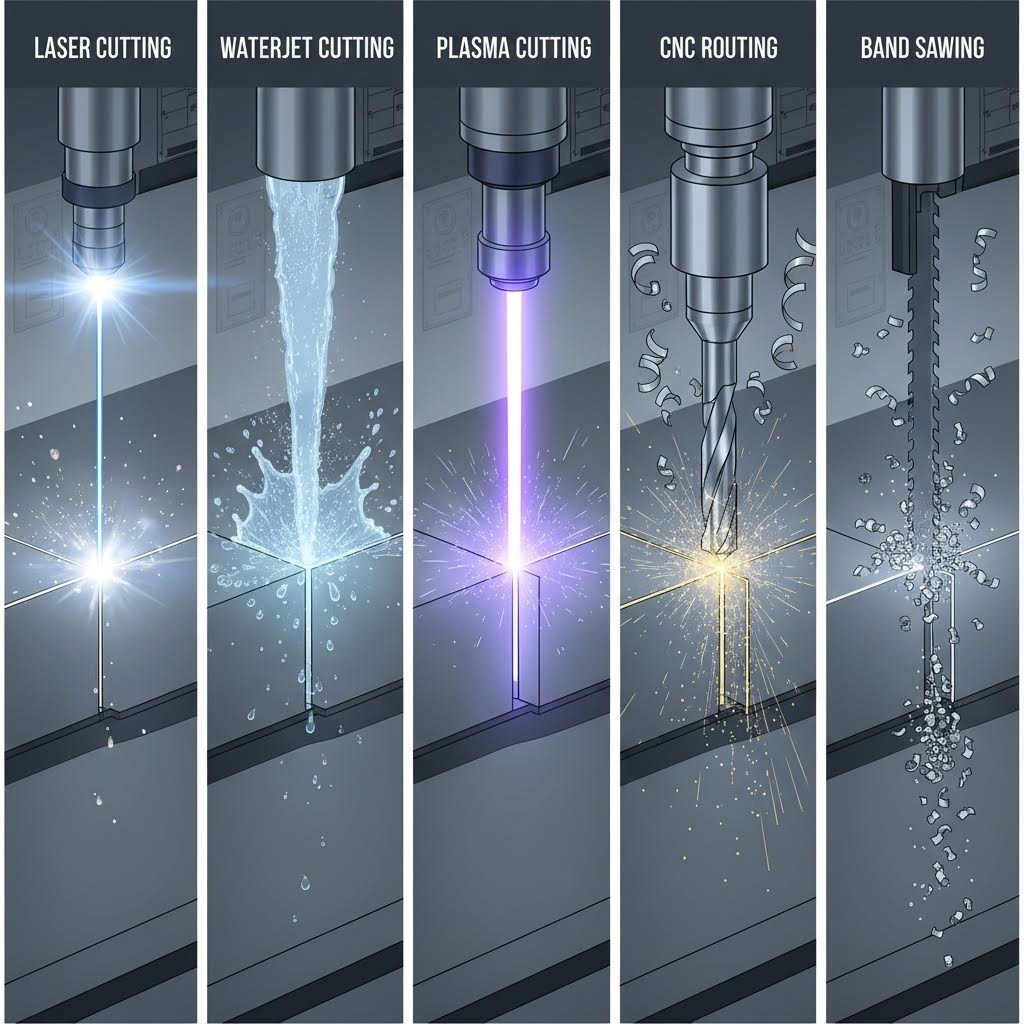

Five Cutting Methods Compared for Aluminum

Now that you understand what makes aluminum cutting custom, let's explore the technologies that make it possible. Each cutting method interacts differently with aluminum's unique properties—and choosing the wrong one can mean the difference between pristine edges and a frustrating redo. Here's your comprehensive breakdown of the five primary methods used to cut aluminum in professional fabrication settings.

Laser Cutting for Aluminum Precision

Imagine focusing sunlight through a magnifying glass, then multiplying that intensity thousands of times. That's essentially how a laser cutter works. This technology employs a highly focused beam of light—typically from a CO2 or fiber laser—to melt, vaporize, or burn away material along a programmed path.

For aluminum specifically, fiber lasers have become the preferred choice. They handle aluminum's reflectivity better than older CO2 systems and deliver exceptional results on thin to medium-thickness material. According to industry sources, laser cutting is exceptionally well-suited for aluminum sheets generally up to 20mm (approximately 0.75 inches), though maximum thickness depends on laser power and the specific alloy being processed.

What makes laser cutting stand out for precision work? The technology produces an extremely narrow kerf—the width of material removed during cutting—which minimizes waste and allows for intricate designs. Edge quality is typically smooth and clean, often requiring no secondary finishing. However, aluminum's high thermal conductivity means the heat-affected zone, while small, still requires consideration for applications where material properties are critical.

- Best thickness range: Up to 0.5 inches (optimal under 0.25 inches)

- Typical tolerance: ±0.005 inches

- Edge quality: Excellent, smooth with minimal burring

- Heat-affected zone: Small but present—may affect temper in heat-treated alloys

Waterjet vs Plasma for Thick Aluminum Plates

When your aluminum plate thickness increases, two cutting methods compete for dominance: waterjet and plasma. Each takes a fundamentally different approach to separating metal, and understanding these differences helps you make smarter decisions for your projects.

Waterjet cutting uses a high-pressure stream of water—often mixed with abrasive particles like garnet—to erode material along the cutting path. Operating at pressures up to 90,000 PSI, this cold-cutting process eliminates heat-affected zones entirely. Your aluminum retains its original material properties from edge to edge.

This method cuts metal without thermal distortion, making it ideal when you're working with heat-treated alloys like 7075-T6 where maintaining temper is essential. Waterjet also handles virtually any thickness of aluminum plate, though cutting speed decreases significantly as material gets thicker.

Plasma cutting takes the opposite approach. It uses an accelerated jet of ionized gas—reaching temperatures up to 45,000°F—to melt through electrically conductive materials. Modern CNC plasma systems combine this cutting power with computer-controlled precision.

Where plasma shines is speed and cost-effectiveness on medium to thick aluminum. A plasma system can cut 0.5-inch aluminum significantly faster than waterjet, making it attractive for production environments. However, the intense heat creates a more pronounced heat-affected zone, and edge quality typically requires more post-processing than waterjet cuts.

CNC Routing and Saw Cutting

Not every aluminum cutting application requires thermal or abrasive processes. Mechanical cutting methods—CNC routing and saw cutting—remain valuable tools in the fabricator's arsenal.

CNC routing uses rotating cutting tools guided by computer numerical control to remove material. Think of it as a die cut machine approach for aluminum, where the router bit physically carves away material rather than melting or eroding it. This method excels at creating complex 3D shapes and works well across various aluminum thicknesses.

The advantages? No heat-affected zone, excellent dimensional accuracy, and the ability to create pockets, slots, and chamfers that other cutting methods cannot. The tradeoff is speed—routing typically runs slower than laser or plasma cutting for simple 2D profiles.

Saw cutting utilizes toothed blades (circular, band, or reciprocating) to mechanically cut through aluminum. It's the most straightforward and cost-effective method for straight cuts and simple shapes. While it won't win awards for intricate designs, saw cutting handles everything from thin sheets to thick plates reliably.

Comprehensive Method Comparison

Choosing the right metal cutter for your aluminum project requires weighing multiple factors simultaneously. This table synthesizes the practical differences you need to know:

| Method | Best Thickness Range | Edge Quality | Tolerance | Speed | Best Applications |

|---|---|---|---|---|---|

| Laser Cutting | Up to 0.5" (optimal under 0.25") | Excellent—smooth, minimal burr | ±0.005" | Very fast on thin material | Intricate designs, precision parts, electronics enclosures |

| Waterjet Cutting | Any thickness (commonly up to 6") | Good—slight texture, no heat marks | ±0.005" to ±0.010" | Slow to moderate | Thick plates, heat-sensitive alloys, aerospace components |

| Plasma Cutting | 0.125" to 2" | Moderate—may require deburring | ±0.015" to ±0.030" | Very fast | Structural components, HVAC, high-volume production |

| CNC Routing | Up to 2" (varies by machine) | Good—clean mechanical cut | ±0.005" | Moderate | Complex 3D shapes, pockets, signage |

| Saw Cutting | Any thickness | Fair—may need finishing | ±0.030" to ±0.060" | Moderate to fast | Straight cuts, rough cutting, bar stock |

Heat-Affected Zones and Material Integrity

Here's something many fabricators overlook: thermal cutting methods don't just remove material—they temporarily change the aluminum around the cut. This heat-affected zone (HAZ) can alter mechanical properties, affect corrosion resistance, and compromise dimensional stability in precision applications.

Laser cutting produces the smallest HAZ among thermal methods, thanks to its concentrated energy and rapid cutting speed. According to metalworking specialists, the concentrated energy of the laser means the heat-affected zone is very small, causing minimal thermal distortion—which is crucial for maintaining aluminum's mechanical and structural properties.

Plasma cutting, by contrast, generates a larger HAZ due to its extremely high temperatures. For structural applications where edge hardness isn't critical, this rarely matters. But for precision components or heat-treated alloys, the difference becomes significant.

Waterjet and mechanical cutting (routing, sawing) eliminate thermal concerns entirely. When your aluminum plate specification demands zero heat impact—think aerospace applications or components requiring subsequent anodizing—these cold-cutting processes preserve complete material integrity.

Understanding these distinctions positions you to select the optimal cutting method based on your specific requirements. But cutting technology is only part of the equation—the alloy you're cutting matters just as much, which is exactly what we'll explore next.

Aluminum Alloys and Their Cutting Characteristics

You've selected your cutting method—but here's a question that trips up even experienced fabricators: which aluminum alloy should you actually cut? Unlike choosing between brass vs bronze where the distinctions are obvious, aluminum alloys can seem interchangeable at first glance. They're not. The alloy you select directly impacts edge quality, cutting speed, and whether your finished part performs as expected.

Think of aluminum alloys like coffee blends. Pure aluminum is too soft for most applications—just as pure, unroasted beans wouldn't satisfy your morning routine. Manufacturers add elements like magnesium, silicon, zinc, and copper to create alloys with specific performance characteristics. Understanding these differences transforms you from someone ordering "aluminum" to someone specifying exactly what their project requires.

Choosing Between 6061 and 5052 Aluminum

These two alloys dominate custom aluminum cutting orders—and for good reason. Both offer excellent versatility, but they excel in different situations. Knowing when to choose each saves money and prevents performance issues down the line.

5052-H32 Aluminum earns its reputation as the workhorse alloy. The addition of magnesium and chromium to pure aluminum delivers superior corrosion resistance while maintaining excellent formability. That H32 temper designation? It means the material has been strain-hardened and stabilized, making it ductile enough for cold working—including bending—without cracking.

- Tensile strength: Approximately 33,000 PSI—sufficient for most non-structural applications

- Corrosion resistance: Outstanding, particularly in marine and outdoor environments

- Weldability: Excellent—produces strong, reliable welds

- Formability: Superior—bends easily without cracking

- Best applications: Marine components, fuel tanks, outdoor signage, architectural panels, and any project requiring post-cut bending

According to SendCutSend's material experts, 5052 H32 is easily one of their most popular materials, offering a great balance of durability and affordability for fabrication projects.

6061-T6 Aluminum steps up when strength becomes critical. This alloy includes magnesium and silicon, and that T6 designation indicates heat treatment and artificial aging—processes that significantly increase both tensile strength and fatigue resistance.

- Tensile strength: Approximately 45,000 PSI—32% stronger than 5052

- Yield strength: 276 MPa, making it suitable for structural components

- Machinability: Excellent—allows high-speed operations with superior surface finish

- Weldability: Good, though welding reduces strength in the heat-affected zone

- Best applications: Structural frames, automotive components, machinery parts, and precision enclosures where strength matters more than formability

Here's the critical distinction for cutting decisions: 6061 machines beautifully but doesn't bend as predictably as 5052. If your project requires sharp bends after cutting, 5052 is typically the safer choice. Need maximum strength without bending? 6061 delivers.

When High-Strength 7075 Makes Sense

Sometimes aluminum sheets need to compete with steel. That's where 7075-T6 enters the picture. Significant additions of zinc, magnesium, and copper push this alloy's strength into territory that approaches titanium—while maintaining aluminum's weight advantage.

- Tensile strength: Approximately 83,000 PSI—nearly double that of 6061

- Yield strength: 503 MPa, the highest among common aluminum alloys

- Fatigue resistance: Exceptional—critical for components experiencing repeated stress cycles

- Corrosion resistance: Lower than 5052 or 6061—may require protective coatings

- Weldability: Poor—generally not recommended for welded assemblies

- Best applications: Aerospace components, high-performance sporting equipment, bicycle frames, and any application demanding maximum strength-to-weight ratio

The tradeoff? 7075 costs more per pound and presents cutting challenges. Its hardness increases tool wear, and the heat treatment that provides its strength makes it nearly impossible to bend without cracking. As machining specialists note, 7075 requires specific parameter settings due to its lower machinability compared to 6061.

Understanding 3003-H14 for General Applications

Not every project demands high-strength alloys. 3003-H14 offers the most affordable option for applications where moderate strength suffices. This alloy contains manganese as its primary addition, providing approximately 20% more strength than pure aluminum while maintaining excellent workability.

- Cost: Most economical aluminum alloy option

- Formability: Outstanding—ideal for deep drawing and spinning

- Corrosion resistance: Very good for general atmospheric exposure

- Best applications: Chemical equipment, cooking utensils, decorative trim, and HVAC components

How Alloy Selection Affects Your Cutting Results

Here's where material science meets practical fabrication. The alloy you choose directly influences what happens during cutting—and what you'll need to do afterward.

Edge quality considerations: Softer alloys like 3003 and 5052 tend to produce slightly more burring during laser cutting compared to heat-treated 6061. However, all common aluminum alloys achieve clean cuts with properly configured equipment. For anodized aluminum applications, edge smoothness becomes particularly important since the anodizing process highlights surface imperfections.

Cutting speed impacts: Harder alloys require slower cutting speeds to maintain edge quality. A laser cutting a 0.125-inch 5052 sheet might run 20% faster than the same setup cutting 7075. This speed difference translates directly to cost on production runs.

Post-processing requirements: Consider what happens after cutting. If aluminum welding is part of your assembly process, 5052 and 6061 accommodate this easily—while 7075 essentially eliminates welding as an option. Planning to anodize? All four alloys accept anodizing well, though 6061 typically produces the most consistent cosmetic finish.

This framework—matching alloy properties to your project's mechanical, fabrication, and finishing requirements—positions you to specify materials confidently. But alloy selection is only half the equation. The thickness of your aluminum sheets plays an equally critical role in determining which cutting method will deliver optimal results.

Matching Thickness to the Right Cutting Method

You've chosen your alloy—now comes the question that determines whether your cutting project succeeds or struggles: how thick is your material? Sounds simple, right? Yet thickness selection creates more confusion than almost any other specification in custom aluminum cutting. Understanding the relationship between material thickness and cutting method transforms guesswork into confident decision-making.

Here's the reality: a cutting method that delivers flawless results on thin aluminum sheet might produce unacceptable edge quality on thick plate. The physics change as thickness increases—heat dissipation patterns shift, kerf characteristics evolve, and achievable tolerances narrow or widen depending on the process. Let's break down exactly what works for each thickness category.

Understanding Gauge Sizes and Thickness Specifications

Before diving into method selection, you need to speak the language of thickness. Aluminum sheet thickness gets specified two ways: decimal inches (or millimeters) and gauge numbers. Confusingly, gauge sizes work counterintuitively—higher gauge numbers indicate thinner material.

According to the Brown & Sharpe gauge system (also known as American Wire Gauge), an 18 gauge aluminum sheet measures approximately 0.040 inches thick, while 14 gauge steel thickness comes in at roughly 0.075 inches. Here's the critical point many fabricators miss: aluminum and steel use different gauge systems. A 14 gauge designation translates to very different thicknesses between these metals.

For precision work, always specify thickness in decimal inches rather than relying on gauge numbers. This eliminates confusion and ensures your fabrication partner cuts material matching your exact requirements. When referencing a sheet metal gauge chart, verify it's specifically for aluminum—using a steel gauge size chart for aluminum orders creates costly mistakes.

Thin Aluminum Sheet Cutting Options

Thin gauge sheets—material under 0.125 inches (approximately 11 gauge steel thickness equivalent)—offer the most cutting method flexibility. At these thicknesses, thermal processes work efficiently, mechanical methods remain practical, and precision tolerances become readily achievable.

What makes thin aluminum particularly cooperative? Heat generated during cutting dissipates quickly through the material's high thermal conductivity without causing significant distortion. The reduced material mass also means less resistance to the cutting force, whether that's a laser beam, water stream, or rotating bit.

- Laser cutting: The optimal choice for thin aluminum sheet applications. Fiber lasers slice through material under 0.125 inches at high speeds with exceptional edge quality. Expect tolerances of ±0.005 inches consistently. Best for intricate designs, tight nested patterns, and production runs where speed matters.

- Waterjet cutting: Works well but often represents overkill for thin material. The process delivers cold-cutting benefits but runs slower than laser. Consider waterjet when working with pre-anodized or heat-sensitive specialized alloys.

- CNC routing: Excellent for projects combining 2D cutting with 3D features like pockets or chamfers. Produces clean mechanical cuts without heat-affected zones. Speed falls between laser and waterjet.

- Shearing: Most economical for straight cuts on thin sheets. Limited to simple geometries but delivers fast results at low cost.

For thin material, your primary decision factors become edge finish requirements, design complexity, and production volume—not method capability. Almost any professional cutting technology handles thin aluminum effectively.

Medium Thickness: The Versatile Range

Material between 0.125 and 0.5 inches represents the sweet spot where multiple cutting methods compete effectively. Your decision here depends heavily on edge quality requirements, tolerance specifications, and budget constraints.

At medium thicknesses, cutting dynamics shift noticeably. Kerf width—the material removed during cutting—becomes more significant in your material yield calculations. Edge taper, where the cut angle deviates slightly from perpendicular, starts appearing in thermal processes. And tolerances become method-dependent rather than universally achievable.

- Laser cutting: Remains highly effective up to approximately 0.375 inches for most aluminum alloys. Beyond this, edge quality degrades and cutting speed drops significantly. High-powered fiber lasers (6kW+) extend this range but at increased operating cost.

- Waterjet cutting: Becomes increasingly competitive as thickness grows. No heat-affected zone concerns, consistent edge quality regardless of thickness, and tolerances typically holding ±0.005 to ±0.010 inches. The cold-cutting process preserves alloy temper completely—critical for heat-treated materials like 6061-T6 or 7075-T6.

- Plasma cutting: Enters practical range above 0.125 inches. Delivers excellent cutting speed at lower cost per inch than laser or waterjet. Tradeoff: wider kerf, larger heat-affected zone, and tolerances typically ±0.015 to ±0.030 inches. Requires post-cut deburring.

- CNC routing: Continues performing well throughout this range. Tool selection becomes more critical—larger diameter endmills handle thicker material more efficiently. Excellent choice when combining cutting with machining operations.

Cutting Thick Aluminum Plate Successfully

Once your aluminum plate exceeds 0.5 inches, the playing field narrows dramatically. Thick plate cutting demands methods capable of handling substantial material mass while maintaining reasonable edge quality and dimensional accuracy.

According to fabrication experts, laser cutting falls short when tackling thick aluminum because the metal's high thermal conductivity quickly drains away the laser's concentrated heat, while its reflective surface can deflect energy back toward the cutting head. For material thicker than roughly 0.75 inches, waterjet almost always delivers better results.

- Waterjet cutting: The clear winner for thick aluminum plate. Handles material up to 6 inches or more without thermal distortion. Edge quality remains consistent regardless of thickness, though cutting speed decreases proportionally. For aerospace-grade 7075 plate, waterjet preserves the heat treatment that provides the alloy's exceptional strength.

- Plasma cutting: Viable for structural applications where edge finish requirements are less stringent. Cuts faster than waterjet at significant cost savings. Expect larger heat-affected zones and plan for secondary finishing operations.

- Band saw cutting: Most economical for simple straight cuts through thick plate. Produces rougher edges requiring machining but handles virtually any thickness your shop can physically manage.

How Thickness Affects Tolerances and Edge Quality

Thickness doesn't just determine which methods work—it directly influences the precision you can achieve. Understanding these relationships prevents over-specifying tolerances that drive up costs or under-specifying tolerances that cause assembly failures.

Kerf width increases with thickness. A laser cutting 0.040-inch aluminum might produce a 0.010-inch kerf, while the same laser cutting 0.375-inch material generates a kerf approaching 0.025 inches. This matters for nested parts and material yield calculations.

Edge taper becomes more pronounced. Thermal cutting methods produce slightly angled edges on thick material—the top of the cut may be wider than the bottom. For critical fit applications, specify which surface requires dimensional accuracy.

Tolerances tighten at a cost. Achieving ±0.005 inches on 0.063-inch aluminum costs less than achieving the same tolerance on 0.500-inch plate. When your application permits, specifying ±0.010 inches on thicker material often reduces project cost significantly without functional compromise.

With thickness-to-method matching now clear, you're ready to translate your project requirements into specifications your fabrication partner can execute. That process—preparing files and communicating specifications accurately—is where many custom cutting projects succeed or stumble.

How to Prepare Files and Specifications

You've selected your alloy, determined your thickness, and chosen the optimal cutting method. Now comes the step that separates smooth projects from frustrating delays: translating your design into files and specifications your fabrication partner can actually execute. Sounds straightforward? It should be—but this stage trips up even experienced engineers more often than you'd expect.

Here's the truth: your CNC machine is only as good as the file you give it. According to JLCCNC's engineering team, incomplete CAD data, wrong formats, or overly complex geometry leads to delays, misinterpretation, or rejected quotes. Understanding what fabricators need—and why they need it—transforms file preparation from a guessing game into a reliable process.

Preparing Your Design Files for Cutting

Think of file preparation like packing for international travel. You need the right documents in the right format, or you're not getting through customs. Custom cut sheet metal services accept specific file types, and submitting the wrong format creates unnecessary back-and-forth before your project even begins.

Accepted file formats for sheet metal fabrication:

- STEP (.stp, .step): The universal standard for 3D CAD data exchange. STEP files preserve solid geometry accurately across different software platforms—making them the preferred format for most fabricators.

- DXF (.dxf): Ideal for 2D cutting profiles. This AutoCAD format works well for laser, waterjet, and plasma cutting where you're defining a flat cutting path.

- DWG (.dwg): Native AutoCAD format that many services accept, though DXF often provides better compatibility.

- AI (.ai): Adobe Illustrator files work for simpler 2D designs, particularly signage and decorative work. Ensure all text is converted to outlines before submission.

- IGES (.igs): Another universal 3D format, though STEP generally offers better feature preservation.

What should you avoid? Mesh-based formats like STL or OBJ work for 3D printing but not for precision cutting. These formats break smooth curves into tiny triangles, losing the mathematical precision that CNC meaning—computer numerical control—requires for accurate toolpath generation.

Your File Preparation Checklist

Before submitting your custom cut aluminum sheet order, work through this sequence to catch common issues:

- Verify your units: Confirm whether your CAD file uses inches or millimeters. Mixed units create dimensional disasters.

- Convert text to geometry: Any text in your design must be converted to outlines, paths, or exploded geometry. Fabrication equipment can't interpret font files—only cutting paths.

- Check for open contours: Every cutting path must form a closed loop. Open or broken lines won't generate valid toolpaths.

- Remove duplicate lines: Overlapping geometry causes the cutting head to trace the same path twice, wasting time and potentially damaging edge quality.

- Eliminate unnecessary layers: Keep only the geometry you want cut. Construction lines, dimensions, and reference geometry should be deleted or moved to non-cutting layers.

- Verify minimum feature sizes: Check that holes, slots, and internal features meet your chosen cutting method's minimums. For laser cutting, design guidelines typically specify minimum hole diameters relative to material thickness.

- Print at 100% scale: If you've converted from a raster image or received files from another source, printing at actual size helps confirm dimensions match your intent.

Specification Details That Prevent Costly Mistakes

Your file defines what gets cut. Your specifications define how it gets cut—and what quality standards apply. Missing or ambiguous specifications force fabricators to make assumptions, and their assumptions may not match your expectations.

Tolerances that make sense: Specifying ±0.001 inches on a decorative panel wastes money. Specifying ±0.030 inches on a precision bracket causes assembly failures. Match your tolerance callouts to functional requirements. For reference, standard laser cutting achieves ±0.005 inches readily, while plasma cutting typically delivers ±0.015 to ±0.030 inches.

Edge finish requirements: Do you need edges smooth enough for bare-hand handling, or will the part receive secondary finishing? Specify "deburr required" if edge smoothness matters, and indicate the critical edges if only certain sides need attention.

Corner radii considerations: Inside corners can't be perfectly sharp—every cutting method leaves some radius. Laser cutting typically produces the smallest corner radii (as small as the beam width), while routing radii depend on tool diameter. Design your mating parts accordingly, or specify corner relief cuts where sharp internal corners are required.

Common Specification Errors and How to Avoid Them

Design for manufacturability isn't just a buzzword—it's the difference between parts that work and expensive scrap. According to CNC machining specialists, considering manufacturability early in the design phase reduces production costs and shortens lead times.

Mistake #1: Specifying impossibly tight tolerances. Requesting ±0.002 inches on a waterjet-cut part drives up cost through slower cutting and multiple quality checks—when ±0.010 inches would function identically.

Mistake #2: Ignoring minimum feature rules. Designing internal cutouts smaller than the cutting method can achieve means those features either won't be cut or will require method changes that affect your quote.

Mistake #3: Forgetting about kerf. The cutting process removes material. If you need a precise hole diameter, your design file should account for kerf width—or explicitly note that the dimension is a finished size requirement.

Mistake #4: Omitting material callouts. "Aluminum" isn't a specification. "6061-T6 aluminum, 0.125 inches thick" tells your fabricator exactly what to source and how it will behave during cutting.

Mistake #5: Leaving retained cutouts floating. Internal pieces that aren't connected to the main part will fall away during cutting. If you need these retained, add bridging tabs or submit them as separate designs.

For projects involving text milling or engraved features, ensure your ship drawing clearly distinguishes between through-cuts and surface operations. Engraving depth, font size minimums, and line spacing all require explicit specification to achieve readable results.

With properly prepared files and clear specifications in hand, you're positioned to submit orders confidently. But understanding the theory of file preparation is one thing—knowing how your cut parts will actually be used helps you make smarter design decisions from the start.

Common Applications and Project Considerations

You've mastered the theory—alloy selection, thickness matching, cutting methods, and file preparation. But here's where knowledge transforms into action: understanding how real-world projects apply these concepts. Whether you're engineering custom aluminum products for aerospace or crafting a weekend project in your garage, the same fundamental decisions apply. What changes is how you weight each factor.

Think of this section as your translation guide. Every application has its own priorities—some demand maximum strength, others prioritize corrosion resistance, and many focus primarily on cost-effectiveness. By examining specific use cases across industries and project types, you'll develop the intuition to make smart decisions for your own metal fabrication needs.

Industrial Applications for Precision Aluminum Parts

Professional manufacturing environments demand precision aluminum parts that perform reliably under stress, meet strict quality standards, and integrate seamlessly into larger assemblies. According to Washington Metal Fabricators, businesses across multiple sectors benefit from custom aluminum fabrication—from HVAC systems to agricultural equipment and beyond.

Automotive Components

The automotive industry relies heavily on custom aluminum cutting for lightweight components that improve fuel efficiency without sacrificing structural integrity. When you need an aluminum block for milling into engine brackets or suspension components, 6061-T6 typically delivers the optimal balance of strength and machinability.

- Brackets and mounting plates: Laser cutting delivers the precision tolerances required for bolt-hole alignment. Specify 6061-T6 for structural applications.

- Body panels and structural reinforcements: Waterjet cutting preserves heat treatment in 7075-T6 components where maximum strength matters.

- Heat shields and covers: 5052-H32 offers excellent formability for parts requiring post-cut bending.

Aerospace and Defense

When failure isn't an option, aerospace manufacturers specify the tightest tolerances and most rigorous quality standards. According to Protolabs, aerospace companies request metal prototypes in the development of airborne drones, microsatellites, planetary rovers, complex rocket engines, and countless other innovations pushing engineering boundaries.

- Structural frames: Waterjet cutting on 7075-T6 plate—no heat-affected zone means full strength retention.

- Instrument enclosures: Laser-cut 6061-T6 with tight tolerances for precision fit.

- Prototype components: CNC routing enables rapid iteration on complex 3D geometries.

Architectural and Construction

From building facades to decorative interior elements, architectural applications often prioritize aesthetics alongside durability. Custom metal shapes for architectural panels typically use 5052 for its superior corrosion resistance and excellent anodizing characteristics.

- Facade panels: Laser cutting creates intricate patterns in 5052-H32; waterjet handles thicker decorative plates.

- Railings and structural trim: 6061-T6 extrusions cut to length with saw cutting, profile details added via laser.

- Signage and wayfinding: Laser-cut 5052 or 3003 accepts paint and powder coating beautifully.

Electronics and Enclosures

Electronic enclosures protect sensitive components while managing heat dissipation—aluminum's thermal conductivity makes it ideal. Industries requiring electrical systems need robust enclosures that provide safety, accessibility, and durability across various environments.

- Chassis and housings: Laser cutting on 5052-H32 for parts requiring formed edges; 6061-T6 for machined features.

- Heat sinks: CNC routing creates complex fin patterns that maximize surface area.

- RF shielding: Precision laser cutting ensures tight seams that block electromagnetic interference.

Hobbyist Projects and Small-Batch Production

You don't need an aerospace budget to benefit from custom aluminum cutting. DIY makers, small manufacturers, and prototyping operations access the same technologies at accessible price points. According to Make It From Metal, even hobbyist CNC routers can produce impressive results on aluminum when operators understand the material's characteristics.

Custom Signage and Art

Custom metal signs represent one of the most popular hobbyist applications for aluminum cutting. The material's durability, weather resistance, and visual appeal make it perfect for everything from business signage to decorative home accents.

- Address plaques and house numbers: Laser-cut 3003 or 5052—affordable and accepts paint well.

- Decorative wall art: Intricate designs shine with laser cutting's fine detail capability.

- Business signage: 5052-H32 resists outdoor weathering; specify anodizing for enhanced durability.

Prototyping and Product Development

Engineers and inventors use custom aluminum cutting to validate designs before committing to production tooling. As Protolabs notes, you can test machined aluminum parts with an anodized finish and know those parts will function properly even when scaled to production quantities.

- Functional prototypes: Match your production alloy and cutting method to ensure test results translate accurately.

- Fit-check models: Less critical tolerances allow faster, more economical cutting methods.

- Small production runs: Laser or waterjet cutting eliminates tooling costs for quantities under 100 pieces.

Maker and DIY Projects

From drone frames to custom motorcycle parts, makers leverage online cutting services to access professional-quality fabrication without owning expensive equipment.

- Drone and RC vehicle components: Laser-cut 6061-T6 offers excellent strength-to-weight ratio.

- Workshop jigs and fixtures: 6061 or 5052 cut via laser or waterjet—choose based on complexity.

- Custom brackets and mounts: Simple geometries work well with plasma cutting at lower cost.

Matching Applications to Methods: Quick Reference

When you're deciding how to approach your specific project, consider this framework that connects application requirements to optimal cutting choices:

| Application Type | Recommended Alloy | Best Cutting Method | Key Considerations |

|---|---|---|---|

| Structural components | 6061-T6 or 7075-T6 | Waterjet (thick) / Laser (thin) | Preserve heat treatment; maintain tight tolerances |

| Formed parts (bending required) | 5052-H32 | Laser or waterjet | Formability matters more than maximum strength |

| Outdoor/marine exposure | 5052-H32 | Laser or waterjet | Superior corrosion resistance essential |

| Cost-sensitive decorative | 3003-H14 | Laser | Economical material; accepts finishing well |

| High-volume production | Application-dependent | Laser (thin) / Plasma (thick) | Speed and cost per piece drive method selection |

| Prototype iteration | Match production intent | Laser or CNC routing | Fast turnaround; design flexibility |

Understanding these application-to-method pairings helps you communicate effectively with fabrication partners and avoid costly mismatches. But even perfect cutting leaves you with raw edges—what happens next depends on your edge quality requirements and finishing plans.

Edge Quality and Finishing Options

Ever picked up a freshly cut piece of aluminum and felt that sharp, jagged edge catching your finger? You're not alone. According to industry fabrication experts, the cutting job isn't finished until the edges are safe and smooth—and understanding what to expect from each cutting method helps you plan for post-processing before your parts even arrive.

Here's the reality: every cutting technology leaves its own signature on aluminum edges. Some methods produce nearly finished surfaces ready for assembly, while others require significant cleanup before your parts are usable. Knowing these differences upfront prevents surprises and helps you budget time and cost accurately.

Edge Quality by Cutting Method

What exactly happens at the cut edge depends entirely on how the material was separated. Thermal processes behave differently than mechanical ones, and even within categories, significant variations exist.

Burr formation represents the most common edge quality concern. Those tiny, sharp fragments clinging to cut edges aren't just unsightly—they create safety hazards and can interfere with assembly fit. Different cutting methods produce dramatically different burr levels:

- Laser cutting: Produces minimal burring on thin aluminum. The concentrated heat creates a slight recast layer at the edge, but properly optimized settings yield edges smooth enough for many applications without secondary processing.

- Waterjet cutting: Leaves a characteristic textured surface from abrasive particle impact. Minimal thermal effects mean no oxide discoloration, but expect slight surface roughness that may require smoothing for aesthetic applications.

- Plasma cutting: Generates the most significant burring among thermal methods. The intense heat creates dross (resolidified metal) on the bottom edge that requires grinding or deburring before use.

- CNC routing: Mechanical cutting produces predictable burr patterns—typically small burrs on the exit side of the cut. Sharp tooling and proper speeds minimize this effect.

- Saw cutting: Creates consistent but noticeable burrs that require filing or sanding. Edge roughness depends heavily on blade tooth count and cutting speed.

Oxide layer considerations matter particularly for aluminum. The material naturally forms a thin aluminum oxide layer within seconds of exposure to air. Thermal cutting methods can disrupt this layer and create thicker oxide deposits at cut edges—potentially affecting subsequent finishing processes like welding or anodizing.

Edge Characteristics Comparison

| Method | Typical Edge Finish | Burr Level | Recommended Post-Processing |

|---|---|---|---|

| Laser Cutting | Smooth with slight recast layer | Minimal to none | Light deburring if needed; ready for finishing |

| Waterjet Cutting | Matte texture, slight striations | Low | Sanding for cosmetic applications |

| Plasma Cutting | Rough with dross deposits | Moderate to heavy | Grinding, deburring required |

| CNC Routing | Clean mechanical cut | Low to moderate | Light deburring on exit edges |

| Saw Cutting | Visible tool marks | Moderate | Filing, sanding for finished appearance |

Finishing Options for Cut Aluminum

Once your parts arrive, several finishing pathways transform raw-cut edges into professional, safe, and durable surfaces. Your choice depends on the application's functional requirements and aesthetic expectations.

Deburring: The essential first step for almost any cut aluminum part. Options range from simple hand tools—files, deburring blades, and sandpaper—to automated tumbling processes for production quantities. As fabrication guides note, start with a metal file or deburring tool and work along all cut edges, then progress to finer grits for smoother results.

Anodizing: This electrochemical process creates a durable, corrosion-resistant oxide layer that can be dyed virtually any color. Anodizing works exceptionally well on 6061 aluminum, producing consistent cosmetic finishes. For powder coating services or paint adhesion, anodizing provides an excellent base layer.

Powder coat: Applies a thick, durable finish that resists chipping, scratching, and fading. Unlike liquid paint, powder coating electrostatically bonds to aluminum surfaces before heat-curing. Clean, deburred edges are essential—the coating follows surface contours and can highlight rather than hide edge imperfections.

Polishing: For applications demanding visual impact, polished aluminum sheet delivers mirror-like brilliance. Progressive sanding from 220 through 400, 600, and finally 1000+ grit creates the foundation, followed by buffing compounds for the final shine.

Cutting Pre-Finished Materials

What happens when you're cutting anodized aluminum sheets or other pre-finished material? The rules change significantly.

Anodized surfaces present unique challenges. The hard oxide layer—while excellent for durability—can chip or crack at cut edges, leaving an exposed aluminum core vulnerable to corrosion. Laser cutting typically produces cleaner results on anodized aluminum sheet metal than plasma, but expect visible contrast between the anodized surface and the raw cut edge.

For projects using pre-anodized or pre-painted material, plan for edge touch-up or accept that cut edges will show bare aluminum. Some fabricators offer edge-sealing services, while others recommend designing parts so cut edges face away from visible surfaces.

Understanding these edge quality realities and finishing options positions you to specify requirements accurately—and budget appropriately for the complete fabrication process. With finishing considerations addressed, you're ready to evaluate potential cutting service providers who can execute your project to these standards.

Choosing the Right Cutting Service Provider

You've mastered alloy selection, matched your thickness to the right cutting method, prepared flawless design files, and understand exactly what edge quality to expect. Now comes the decision that determines whether all that preparation pays off: selecting the right fabrication partner. Whether you're searching for "metal fabrication near me" or evaluating online cutting services like Oshcut or Send Cut Send, the evaluation criteria remain remarkably consistent.

Here's the reality: not all fabricators are created equal. According to industry specialists, laser cutting involves high-precision work that requires specialized equipment, experienced operators, and efficient processes. Ensuring your chosen provider can deliver the exact specifications you need—whether for prototyping, custom components, or large-scale production—saves time and money while avoiding costly mistakes.

Think of this selection process like hiring a contractor for home renovation. Credentials matter, but so does communication style, responsiveness, and whether their capabilities actually match your project requirements. Let's break down exactly what to evaluate.

Evaluating Cutting Service Capabilities

Before requesting quotes, you need to understand whether a potential partner can actually execute your project. Some fabrication shops near me might excel at steel fabrication but lack experience with aluminum's unique characteristics. Others might handle thin sheets beautifully but struggle with thick plate. Asking the right questions upfront prevents wasted time and disappointing results.

Material and thickness range: Confirm the provider works with your specific aluminum alloy in your required thickness. According to fabrication experts, not all cutting services are equipped to handle a wide range of materials—high-power fiber lasers can cut thicker and more reflective materials than traditional CO₂ lasers, though suitability depends on many factors.

Precision capabilities: Clarify their cutting accuracy and ability to produce clean edges without burrs. High-quality services often offer tight tolerances for intricate designs. If your project demands ±0.005 inches, verify they can deliver consistently—not just occasionally.

Design support: Look for providers offering design for manufacturability (DFM) guidance. The best partners review your files before cutting, flagging potential issues like features too small for your chosen method or tolerance specifications that drive unnecessary cost. Comprehensive DFM support transforms potential problems into solutions before metal ever gets cut.

Key Questions to Ask Potential Providers

- What cutting technologies do you operate, and which do you recommend for my specific alloy and thickness? Their answer reveals both capability and expertise.

- What tolerances can you consistently achieve on aluminum parts similar to mine? Ask for specifics, not generalities.

- Do you offer prototyping services with fast turnaround? According to industry sources, prototyping allows you to validate a design before committing to full-scale production—invaluable for fine-tuning specifications.

- How do you optimize material usage to reduce waste? Providers with advanced CAD/CAM software can position multiple designs on a single sheet to minimize waste and maximize yield.

- What is your typical turnaround time, and do you offer expedited options? Fast-track services may be essential for time-sensitive projects.

- What file formats do you accept, and can you assist with design modifications? Standard formats include DXF and DWG—some providers also work with PDFs or hand-drawn sketches.

- Do you offer additional services like deburring, finishing, or assembly? A one-stop shop saves logistics coordination.

- What experience do you have with projects similar to mine? Familiarity with your industry's standards helps anticipate needs.

Quality Certifications That Matter

Certifications aren't just wall decorations—they represent verified commitments to consistent quality processes. For critical applications, particularly in automotive or aerospace sectors, specific certifications become non-negotiable requirements.

IATF 16949: This automotive-specific quality management standard goes beyond basic ISO 9001, adding requirements for defect prevention, reduction of variation, and continuous improvement throughout the supply chain. For automotive aluminum components—chassis parts, brackets, structural reinforcements—working with an IATF 16949-certified partner ensures your parts meet industry-standard quality expectations.

For example, Shaoyi (Ningbo) Metal Technology demonstrates what quality-focused automotive manufacturers should offer: IATF 16949-certified production for chassis and structural components, combined with 5-day rapid prototyping capabilities and 12-hour quote turnaround. This combination of certification, speed, and comprehensive DFM support illustrates the benchmarks to evaluate against when selecting metal fabricators near me for automotive applications.

ISO 9001: The foundational quality management certification. While less rigorous than IATF 16949, ISO 9001 indicates documented quality processes and commitment to continuous improvement.

AS9100: Essential for aerospace applications. This standard builds on ISO 9001 with additional requirements specific to aviation, space, and defense industries.

Turnaround Time and Communication

Speed matters—but predictable speed matters more. According to manufacturing specialists, long lead times can disrupt production schedules, delay deliveries, and inflate costs, leading to unhappy customers and strained relationships.

Quote responsiveness: How quickly does a potential partner respond to quote requests? This initial interaction often predicts future communication quality. Providers offering 12-hour quote turnaround demonstrate both capability and customer focus.

Production lead times: Understand standard production timelines and whether rush orders are available. Some providers ship within a day or two for urgent jobs, while others require weeks. Match their capabilities to your project timeline.

Prototype vs. production timing: Rapid prototyping services—some offering 5-day turnaround—allow design validation before committing to full production runs. This capability proves invaluable for engineering teams iterating on designs.

Material Sourcing and Flexibility

Where does your fabricator source aluminum? This question affects both quality consistency and lead times.

Inventory vs. special order: Providers maintaining common alloys in stock (6061-T6, 5052-H32) can begin cutting immediately. Specialty alloys like 7075-T6 may require sourcing time that extends your project timeline.

Order size flexibility: Whether you need one-off prototypes or high-volume production, a reliable service should accommodate your order size. According to industry experts, this flexibility ensures you can scale orders as needed without switching providers—maintaining quality consistency across prototype and production phases.

Material certification: For critical applications, request mill certifications verifying alloy composition and temper. Reputable steel fabricators and aluminum specialists provide this documentation routinely.

Making Your Selection

With evaluation complete, weigh your findings against project priorities. A hobbyist project might prioritize cost and convenience, making online services attractive. Automotive production runs demand certified quality processes and consistent tolerances—narrowing the field to qualified metal fabricators near you or specialized manufacturers.

Consider starting relationships with smaller orders. A test project reveals communication style, actual (not promised) quality levels, and whether the partnership works before you commit to critical production runs. The extra time invested upfront prevents costly surprises when stakes are highest.

With your fabrication partner selected, you're positioned to execute your custom aluminum cutting project successfully. Let's consolidate everything into an actionable decision framework you can apply immediately.

Making Your Custom Cutting Decision

You've journeyed through alloy characteristics, thickness considerations, cutting technologies, file preparation, and provider evaluation. Now it's time to transform that knowledge into action. Whether you're wondering about the best way to cut aluminum sheet for a prototype bracket or planning production runs of precision components, you have the framework to make confident decisions.

Here's the key insight: successful custom aluminum projects aren't about finding one "perfect" answer. They're about matching your specific requirements—strength, formability, edge quality, tolerance, and budget—to the right combination of alloy, thickness, and cutting method. That matching process becomes intuitive once you understand how these variables interact.

Your Custom Aluminum Cutting Decision Checklist

Before submitting your next order, work through this sequence to ensure nothing falls through the cracks:

- Define your application requirements first. Will the part experience stress? Need bending? Face outdoor exposure? Your answers determine alloy selection—6061-T6 for strength, 5052-H32 for formability and corrosion resistance, 7075-T6 for maximum strength-to-weight ratio.

- Specify thickness in decimal inches. Avoid gauge number confusion by using precise measurements. Verify your aluminum sheet thickness matches your design intent.

- Match cutting method to thickness and tolerance needs. Thin material under 0.125 inches pairs beautifully with laser cutting. Thick plates above 0.5 inches typically demand waterjet. Medium thicknesses offer the most flexibility—let tolerance requirements guide your choice.

- Prepare clean, properly formatted design files. Convert text to outlines, close all contours, remove duplicate geometry, and specify units clearly. Submit STEP or DXF files for best compatibility.

- Communicate specifications explicitly. Don't assume your fabricator knows your tolerance requirements, edge finish expectations, or which surfaces are critical. Write it down.

- Plan for post-processing. Factor deburring, anodizing, or powder coating into your timeline and budget before cutting begins.

- Verify provider capabilities match your needs. Request material certifications, confirm tolerance capabilities, and evaluate turnaround times before committing.

Moving Forward With Your Project

Understanding how to cut aluminum sheet metal effectively comes down to respecting the material's unique properties while leveraging the right technology for your specific situation. The fabrication partner you choose matters—but so does the clarity of your communication with them.

According to custom fabrication specialists, one of the most important tools in successful projects is communication. Everything from the smallest to the largest, most complex project begins with clear objectives and thorough planning during the initial process.

Start small if you're new to custom aluminum cutting. A prototype order tests your file preparation process, validates your specifications, and reveals how well you and your fabrication partner communicate—all before high-stakes production runs. That learning investment pays dividends on every subsequent project.

You now possess the knowledge to navigate alloy selection confidently, match thickness to appropriate cutting methods, prepare professional-quality design files, and evaluate fabrication partners effectively. Whether you're working with local metal fabricators or submitting orders to online cutting services, you're equipped to make informed decisions that deliver the results your projects demand.

The best way to cut aluminum isn't a single method—it's the method that matches your unique combination of requirements. Armed with this guide, you're ready to find that match.

Frequently Asked Questions About Custom Aluminum Cutting

1. What is the best method for cutting custom aluminum?

The optimal cutting method depends on your aluminum thickness and precision requirements. Laser cutting excels for thin material under 0.25 inches, delivering tolerances of ±0.005 inches with excellent edge quality. Waterjet cutting works best for thick plates over 0.5 inches or heat-sensitive alloys like 7075-T6, as it eliminates heat-affected zones entirely. Plasma cutting offers fast, cost-effective results for structural components where edge finish is less critical. For projects requiring automotive-grade precision, IATF 16949-certified manufacturers like Shaoyi Metal Technology provide comprehensive DFM support to recommend the ideal method for your specific application.

2. How much does custom aluminum cutting cost?

Custom aluminum cutting costs vary based on material thickness, alloy grade, cutting method, tolerance requirements, and quantity. Thin sheets cut via laser typically cost less per piece due to faster processing speeds. Thick plate waterjet cutting runs higher due to slower operation and abrasive consumption. Specialty alloys like 7075-T6 cost more than common 6061 or 5052. Most services offer instant online quoting—providers with 12-hour quote turnaround help you compare options quickly. Ordering prototypes before production runs validates specifications without committing to large quantities.

3. What file formats are accepted for custom metal cutting?

Professional cutting services accept STEP (.stp, .step) files as the universal standard for 3D CAD data exchange. DXF files work well for 2D cutting profiles on laser, waterjet, and plasma equipment. DWG (AutoCAD native format) and AI (Adobe Illustrator) files are commonly accepted for simpler designs. Before submitting, convert all text to outlines, close open contours, remove duplicate geometry, and verify your dimensional units. Clean file preparation prevents delays and ensures accurate toolpath generation for precision results.

4. What aluminum alloy is best for custom fabrication projects?

The best aluminum alloy depends on your application requirements. 6061-T6 offers excellent machinability and strength (45,000 PSI tensile) for structural components and precision parts. 5052-H32 provides superior corrosion resistance and formability, making it ideal for marine applications or parts requiring post-cut bending. 7075-T6 delivers maximum strength-to-weight ratio for aerospace and high-performance applications but costs more and cannot be welded. 3003-H14 offers the most economical option for general-purpose decorative applications where moderate strength suffices.

5. How do I find reliable custom metal cutting services near me?

Evaluate potential fabricators by confirming their cutting technology capabilities, tolerance specifications, and experience with aluminum specifically. Request material certifications and verify quality management credentials—IATF 16949 certification is essential for automotive applications, while AS9100 matters for aerospace. Assess quote responsiveness and turnaround times; providers offering rapid prototyping (5-day turnaround) and fast quotes demonstrate customer focus. Start with a small test order to evaluate communication quality and actual results before committing to production quantities.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —