Die Stamping Costs Exposed: Budget Smarter Before Your Next Project

What Is Die Stamping and Why It Matters in Manufacturing

When you're planning a manufacturing project that requires precision metal parts, understanding what is stamping becomes essential before you commit any budget. Die stamping is a cold forming process that transforms flat sheet metal into finished components using specialized tooling called dies. Unlike die cutting in print applications—which simply cuts paper or cardboard—this metalworking technique shapes, bends, and forms metals into complex three-dimensional parts at remarkable speeds.

Die stamping is a metal forming process where sheet metal is shaped, cut, or formed by pressing it between specialized tooling (dies) mounted in presses, producing precision components for automotive, aerospace, electronics, and consumer goods industries.

From Raw Sheet to Precision Part

Imagine a flat strip of steel entering a press and emerging seconds later as a perfectly formed automotive bracket. That's the power of this process in action. The fundamental mechanics are straightforward: a punch descends into a die cavity, applying controlled force that plastically deforms the metal workpiece. This force alters the blank's structure and geometry, allowing manufacturers to bend, cut, or sculpt it into virtually any configuration—from palm-sized electronic connectors to components spanning 20 square feet.

So, what is a stamping in practical terms? It's any metal part produced through this pressing operation. According to IQS Directory, the process includes diverse methods such as blanking, punching, piercing, and coining. Each technique serves a specific purpose, whether you're creating holes, cutting complete shapes, or adding fine surface details. The precision in die design is crucial—every punch must achieve consistent, high-quality results across thousands or even millions of production cycles.

The Die Stamping Difference

Understanding what is dies in manufacturing helps clarify why this process dominates high-volume production. Dies are specialized tools crafted to create specific designs, ranging from simple everyday items to intricate components in electronics. They function as both cutting instruments and forming stencils, capable of executing multiple operations in a single stroke.

The versatility of metal stamping makes it indispensable across industries. Automotive manufacturers rely on it for body panels and structural components. Aerospace companies use it to produce lightweight, high-precision parts for aircraft structures. Electronics manufacturers depend on stamping for connectors, terminals, and heat sinks. Even your household appliances contain dozens of stamped metal parts you never see.

What makes a stamping die particularly valuable is its repeatability. Once tooling is developed, manufacturers can produce identical parts with tight tolerances at speeds exceeding 1,000 units per hour. This combination of precision, speed, and cost efficiency explains why understanding die stamping economics is crucial before launching your next project.

Essential Stamping Operations from Blanking to Coining

Now that you understand the fundamentals, let's explore the specific operations that transform raw sheet metal into finished parts. Every die stamping project relies on a combination of cutting and forming techniques—and knowing the difference directly impacts your tooling costs and part quality. Think of cutting operations as removing material, while forming operations reshape it without cutting anything away.

Cutting Operations Explained

Cutting operations use a die punch to separate material from the sheet. The distinction between these methods lies in what becomes your finished product and what becomes scrap.

Blanking cuts complete shapes from the sheet metal workpiece. The punched-out piece is your product, while the remaining skeleton becomes scrap. This is your go-to operation when you need flat starting shapes for further processing—think automotive brackets, electrical contacts, or appliance panels. According to Master Products, blanking is extremely similar to punching, except the punched parts become the finished product.

Punching creates precisely located holes within your workpiece using a die press and cutting die. Here's the key difference: the punched-out slugs are scrap, and your sheet with the holes is the product. You'll use punching for positioning holes, ventilation patterns, or connection points in enclosures and housings.

Piercing functions nearly identically to punching—both create holes—but the terminology often depends on industry context. The scrap removed is called a slug, and precise punch and die clearances determine hole quality. When you need dozens of identical holes in electrical junction boxes or mounting plates, piercing delivers consistent results at production speeds.

Forming Operations That Shape Metal

Forming operations reshape your workpiece without removing material. These techniques require careful consideration of material properties and springback behavior.

Bending applies extreme force through a press tool to fold metal at specific angles. According to Fictiv, engineers must account for springback—the material's tendency to partially return to its original shape—by designing the die to over-bend the part. This is essential for producing V-shaped or U-shaped components like brackets, channels, and enclosure frames.

Drawing creates hollow, cup-shaped, or recessed features by forcing sheet metal into a die cavity. The punch pushes material down into the die, stretching and forming it around the cavity walls. Deep drawing—used for seamless containers, automotive fuel tanks, and cookware—requires multiple draw stages to prevent tearing or wrinkling.

Embossing stamps a single side of the workpiece to create raised or indented patterns without cutting through. Common embossed features include numbers, lettering, logos, or decorative designs on appliance panels and signage.

Coining takes embossing further by compressing metal on both sides simultaneously. The coining process applies tremendous pressure to create extremely fine details with superior dimensional accuracy. This example of stamping is how currency coins, commemorative medallions, and precision hardware components with logos receive their intricate surface features.

| Operation | Purpose | Typical Applications | Material Thickness Range |

|---|---|---|---|

| Blanking | Cut complete shapes from sheet | Brackets, electrical contacts, flat components | 0.005" - 0.25" |

| Punching | Create holes in workpiece | Ventilation holes, mounting points, connection holes | 0.005" - 0.25" |

| Piercing | Create precision holes (slug is scrap) | Positioning holes, electrical knockouts | 0.005" - 0.20" |

| Bending | Fold metal at specific angles | Brackets, channels, enclosure frames | 0.010" - 0.25" |

| Drawing | Create hollow or cup-shaped parts | Containers, fuel tanks, cookware, enclosures | 0.010" - 0.20" |

| Embossing | Create raised or indented patterns | Logos, lettering, decorative panels | 0.010" - 0.125" |

| Coining | Compress metal for fine surface detail | Coins, medallions, precision hardware | 0.005" - 0.10" |

Understanding these operations helps you communicate effectively with your stamping supplier. Most production parts combine multiple techniques—a bracket might require blanking to cut the outline, punching for mounting holes, and bending to form its final shape. The more operations your part requires, the more complex your die cutting tooling becomes, directly affecting your project budget. With these fundamentals in place, you're ready to explore how different die configurations—progressive, transfer, and compound—handle these operations at production scale.

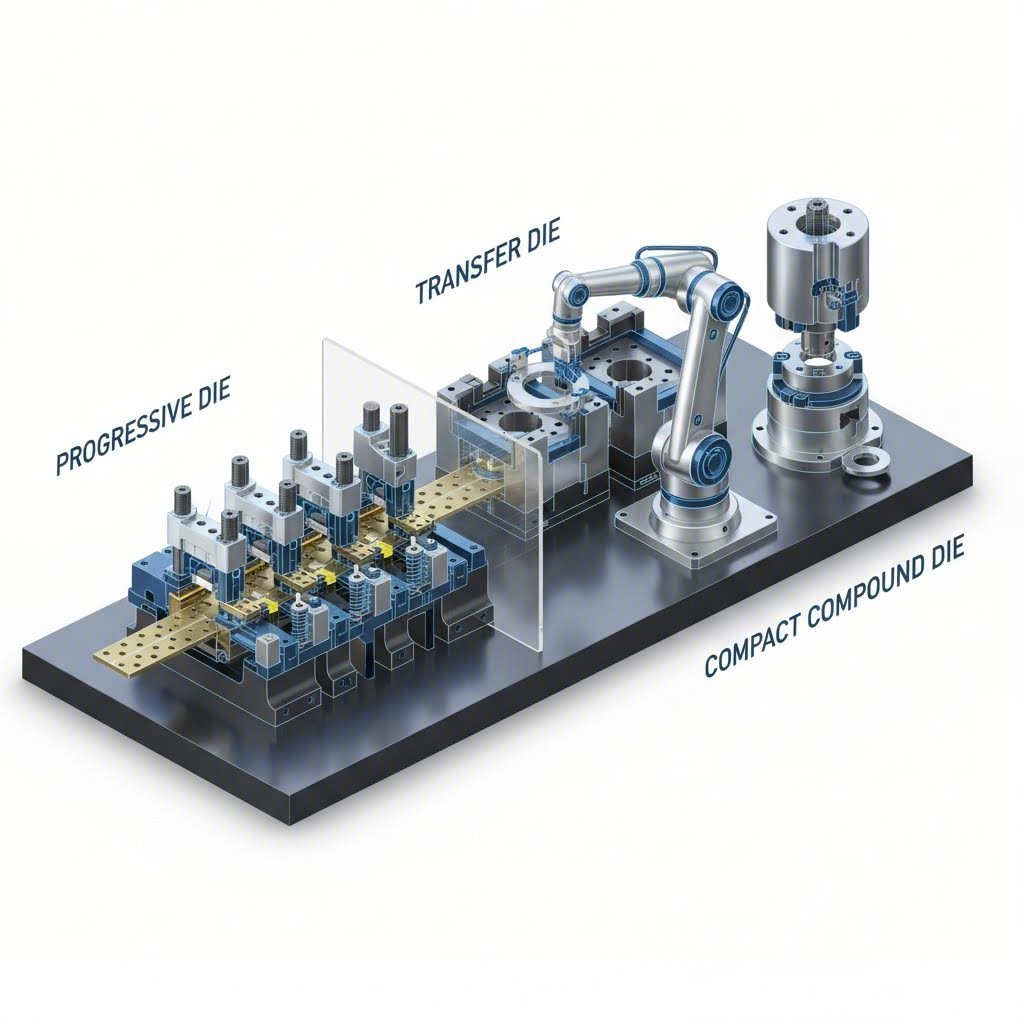

Progressive vs Transfer vs Compound Die Stamping

You've learned the individual operations—blanking, punching, bending, drawing. But here's where budget planning gets interesting: how these operations are configured within your die dramatically affects your tooling investment and per-part costs. Choosing between progressive, transfer, and compound die stamping isn't just a technical decision—it's a financial one that can make or break your project economics.

Think of it this way: all three methods use the same fundamental operations, but they organize them differently based on your part's complexity, size, and production volume. Let's break down each approach so you can match the right die configuration to your specific requirements.

Progressive Dies for High-Volume Efficiency

Progressive stamping is the workhorse of high-volume manufacturing. In the progressive die stamping process, a continuous metal strip feeds through a single die containing multiple stations arranged in sequence. Each station performs a specific operation—punching, bending, forming, or cutting—as the strip advances with each press stroke. The workpiece remains attached to the carrier strip from start to finish, only separating as a completed part in the final station.

Imagine producing automotive components progressive stamping style: a coil of steel enters one end, and finished brackets, clips, or connectors emerge from the other at rates exceeding 1,000 parts per hour. This continuous flow eliminates handling between operations, dramatically reducing labor costs and cycle times.

According to Larson Tool, progressive dies demand higher upfront design and tooling costs due to their complex nature and precision engineering requirements. However, the cost per part decreases significantly with large production runs, making this approach highly cost-effective for long-term projects.

- High efficiency: Multiple operations occur simultaneously across stations, maximizing throughput

- Reduced waste: Optimized strip layouts minimize scrap material

- Lower labor costs: Automated feeding eliminates manual part handling between operations

- Tight tolerances: Parts remain registered to the strip throughout processing, ensuring consistency

- Complex geometries: Sequential stations can achieve intricate shapes impossible in single operations

Best applications: Small to medium-sized parts (palm-sized components are ideal), high production volumes exceeding 10,000 units, and parts requiring multiple forming and cutting operations. Progressive dies excel at producing electrical connectors, brackets, clips, and terminal components.

Transfer Dies for Complex Geometries

What happens when your part is too large for progressive stamping, or requires deep drawing that can't happen while attached to a carrier strip? That's where transfer die stamping enters the picture.

Transfer stamping separates the workpiece from the metal strip at the beginning of the process. Mechanical fingers, robots, or other automated transfer mechanisms then move each individual part between separate die stations. This independence allows for operations impossible in progressive setups—deep draws, extensive forming, and work on all surfaces of the part.

According to Keats Manufacturing, the multiple-step process of transfer die stamping allows for designs with high levels of intricacy, including threading, ribs, and knurls. Because the metal strip's removal occurs at the beginning, transfer dies are ideal for deep drawn parts and applications requiring extensive manipulation of the workpiece.

- Handles large parts: Components spanning several square feet can move between dedicated stations

- Deep drawing capability: Parts can be drawn without carrier strip constraints

- 360-degree access: Operations can occur on all surfaces since parts aren't attached to strips

- Reduced secondary operations: Threading, knurling, and specialized features integrate into the stamping process

- Versatile production volumes: Cost-effective for medium to high runs where complexity justifies tooling investment

Best applications: Large structural components, deep drawn housings and enclosures, parts requiring features on multiple surfaces, and components up to 20 square feet. Transfer dies shine in aerospace structural parts, automotive body panels, and heavy machinery components.

Compound Dies for Precision Cuts

Sometimes simplicity wins. Compound die stamping performs multiple cutting operations—blanking, punching, piercing—in a single press stroke. Rather than moving through sequential stations, the entire operation happens at once within one die set.

According to Keats Manufacturing, compound die stamping is ideal for producing flat parts like washers and wheel blanks in medium or high volumes. The simultaneous operation creates flatter parts than progressive methods because equal forces act on the workpiece from both sides.

Here's the trade-off: compound dies handle cutting operations beautifully but aren't designed for forming. If your part needs bending, drawing, or shaping, you'll need progressive or transfer methods—or secondary operations after compound stamping.

- Lower tooling costs: Simpler die construction reduces upfront investment compared to progressive dies

- Superior flatness: Simultaneous cutting from both sides produces flatter parts

- High repeatability: Single-stroke operation ensures consistent results

- Fast production: Simple flat parts exit quickly with minimal cycle time

- Reduced maintenance: Simpler structure means fewer components requiring upkeep

Best applications: Flat parts without forming requirements—washers, gaskets, blanks for further processing, electrical laminations, and simple mounting plates. Compound dies deliver excellent value for medium to high volumes of geometrically simple components.

Making Your Selection: A Decision Framework

Choosing between these three approaches comes down to evaluating your project against three criteria: part complexity, production volume, and budget constraints.

Choose progressive stamping when: You need high volumes (typically 10,000+ parts), your part is small to medium-sized, and it requires multiple operations including forming. The higher tooling investment pays off through dramatically lower per-piece costs at scale.

Choose transfer dies when: Your parts are large, require deep drawing, or need operations on multiple surfaces. Transfer dies justify their higher tooling and setup costs through capability—they handle work progressive dies simply cannot.

Choose compound dies when: You're producing flat parts with cutting operations only, want lower upfront tooling costs, or need parts with superior flatness. Compound dies offer the best value for simpler geometries at moderate to high volumes.

Understanding these distinctions positions you to have informed conversations with potential suppliers about material selection—the next critical factor that shapes both die design requirements and your project's bottom line.

Material Selection Criteria for Die Stamping Projects

You've selected your die configuration—progressive, transfer, or compound. Now comes a decision that directly impacts both your tooling costs and part performance: which material should you stamp? The wrong choice doesn't just affect your finished product; it can complicate sheet metal dies design, increase press tonnage requirements, and introduce quality problems that cascade through your entire production run.

Metal stamping and forming success starts with matching material properties to your application demands. Let's walk through the key criteria that should guide your selection, then examine how each common material stacks up.

Matching Materials to Performance Requirements

Before comparing specific metals, consider what your application actually requires. According to PANS CNC, selecting the appropriate stamping material is critical not only for meeting end-use requirements but also for controlling the stamping process itself. Variables such as sheet thickness, bending stress, and stamping force are all influenced by material type.

Ask yourself these questions:

- What environmental conditions will the part face? Corrosive atmospheres, high temperatures, or outdoor exposure demand specific material properties.

- What mechanical loads must the part withstand? Tensile strength and fatigue resistance vary dramatically between materials.

- How complex is your part geometry? Intricate bends and deep draws require materials with excellent formability.

- What's your budget tolerance? Material costs can range from $0.50 per pound for carbon steel to over $15 per pound for titanium.

Material thickness directly affects your die design and press requirements. Thicker materials need greater press tonnage, more robust tooling, and often larger clearances between punch and die. A 0.060" stainless steel blank requires significantly more force to form than a 0.030" aluminum sheet of the same size—sometimes doubling or tripling the tonnage needed.

Steel, Aluminum, and Beyond

Let's examine the most common sheet metal stamping materials and where each excels.

Low Carbon Steel offers the best value for general-purpose applications. According to PANS CNC, low carbon steel contains approximately 0.05% to 0.3% carbon, providing good weldability, ductility, and tensile strength at low cost. Common grades like 1008, 1010, and 1018 stamp easily but require protective coatings in corrosive environments.

Stainless Steel delivers superior corrosion resistance and an attractive finish. The 300 series austenitic grades (301, 302, 316) offer excellent ductility but exhibit higher work-hardening rates—meaning they become harder and more brittle as you stamp them. According to Ulbrich, austenitic stainless steel can transform during deformation, inducing a brittle martensitic phase that increases cracking risk. This requires careful die design and potentially intermediate annealing for complex parts.

Aluminum shines where weight matters. The aluminum stamping process produces parts 65% lighter than steel equivalents, with excellent corrosion resistance and thermal conductivity. However, aluminum presents a significant challenge: springback. According to The Fabricator, high-strength aluminum alloys have upended decades of springback best practices, requiring tension-compression testing and sophisticated simulation to predict material behavior accurately. Your sheet metal dies must compensate by over-bending the material, anticipating how much it will spring back after forming.

Copper and Brass excel in electrical and decorative applications. Copper's high conductivity makes it essential for power components, while brass offers an attractive appearance plus excellent formability for complex bends. Both materials work-harden during stamping, so consider alloy selection carefully for multi-stage operations.

| Material | Formability | Strength | Corrosion Resistance | Relative Cost | Typical Applications |

|---|---|---|---|---|---|

| Low Carbon Steel | Excellent | Moderate | Poor (needs coating) | $ | Brackets, enclosures, automotive panels |

| Stainless Steel (300 series) | Good | High | Excellent | $$$ | Food equipment, medical devices, appliances |

| Stainless Steel (400 series) | Good | High | Good | $$ | Automotive trim, industrial hardware |

| Aluminum (5052, 6061) | Very Good | Moderate | Very Good | $$ | Aerospace components, electronics housings |

| Copper (C110) | Excellent | Low-Moderate | Good | $$$ | Electrical contacts, busbars, terminals |

| Brass (C26000) | Excellent | Moderate | Good | $$ | Decorative hardware, electrical connectors |

Grain direction matters more than many engineers realize. When stamped sheet metal is rolled at the mill, the crystalline structure aligns in the rolling direction. Bending parallel to this grain direction requires more force and can cause cracking, while bending perpendicular produces smoother results. Specify grain direction requirements on your drawings when part geometry demands critical bends—especially for stainless steel and high-strength alloys.

When sourcing materials, verify that your supplier provides certified mill test reports documenting mechanical properties, chemistry, and grain size. Consistent material from coil to coil prevents the quality variations that plague production runs. According to Ulbrich, partnering with a precision reroll mill with metallurgical expertise can be tremendously helpful for stampers in performing root cause analysis when problems arise.

With your material selected, the next critical step involves understanding how die design and engineering transform your material choice into production-ready tooling—where precision tolerances and component selection determine whether your parts meet specification.

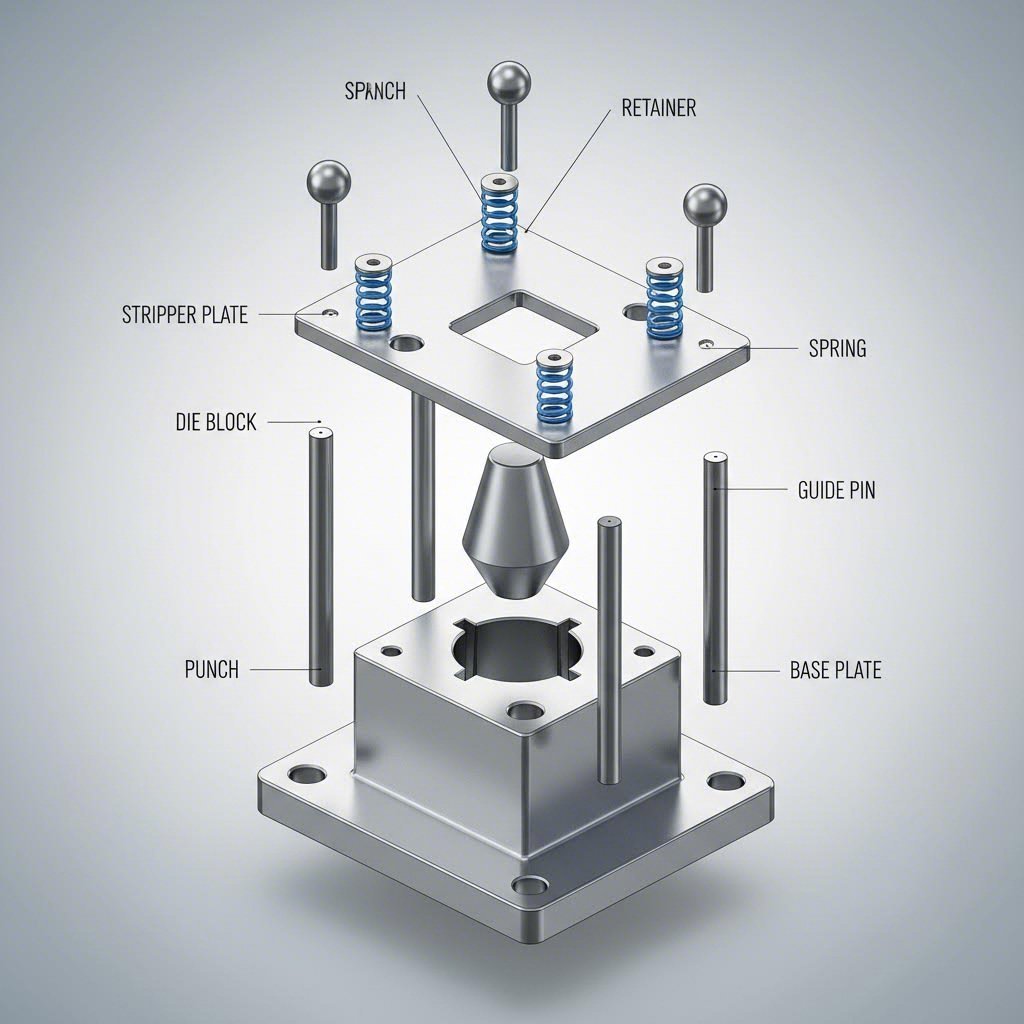

Die Design Engineering and Component Fundamentals

You've chosen your material and die configuration. Now comes the engineering phase that separates successful projects from costly failures: designing the actual tooling dies that will produce your parts. This is where precision meets practicality—where every clearance, component, and tolerance decision directly affects whether your production run meets specification or generates scrap.

Sounds complex? It is. But understanding the fundamentals helps you evaluate supplier capabilities, ask better questions, and recognize when engineering shortcuts might compromise your project. Let's break down how modern die design transforms your part concept into production-ready tooling.

Engineering Precision Into Every Die

A die for press operations is far more than a simple punch and cavity. According to U-Need Precision Manufacturing, a successful stamping die is the product of a structured, multi-stage design process where each step builds upon the last, moving from high-level concept to minutely detailed, validated engineering plans.

Every stamping die tool contains these critical components working together:

- Punch: The male component that descends into the die cavity, performing cutting or forming operations. Punches must withstand tremendous compressive forces—a 1/2" diameter punch perforating 0.062" mild steel requires approximately 2.5 tons of pressure behind it.

- Die Block: The female component containing the cavity or opening that receives the punch. The die block's hardened surfaces define the final part geometry and must maintain precise dimensions across millions of cycles.

- Stripper Plate: Holds the sheet metal flat against the die surface and strips material from the punch after each stroke. Without proper stripping action, parts stick to punches and cause jams.

- Guide Pins and Bushings: Precision alignment components that ensure the punch enters the die cavity at exactly the same position every stroke. Even 0.001" misalignment can cause uneven wear and dimensional problems.

- Springs: Provide controlled pressure for stripping, blank holding, and die cushion functions. Spring selection affects forming quality, part ejection, and overall die performance.

The interaction of these press and die components is what manufacturing engineers call a mechanical ballet—each element timed to fractions of a second by the press cycle. When you work with a die tool, understanding this interplay helps you appreciate why precision manufacturing matters.

Tolerance Considerations and Die Clearances

Here's a critical concept that directly affects your part quality: die clearance. This is the gap between the punch and die opening, typically specified as a percentage of material thickness per side.

According to Larson Tool's design guide, cutting clearances between punch and die are closely defined—normally around 8% to 10% of material thickness per side. This clearance creates a predictable edge condition: the punch initially compresses material, producing a rolled top edge. As cutting begins, it shears the material for about 1/4 to 1/3 of the thickness, leaving a burnished wall. Finally, the material yields and breaks away, leaving a slight burr on the bottom edge.

Why does this matter for your budget? Because tolerance requirements drive die complexity:

- Size tolerances of ±0.002" are achievable in most blanking and piercing applications

- Hole-to-hole location typically holds within ±0.002" when pierced in the same operation

- Features requiring tighter tolerances may need secondary shaving or sizing operations

- Formed features introduce additional variables—angular tolerances of ±1 degree are standard for bends

Bypass notches in sheet metal stamping dies deserve special mention. These are relief cuts positioned at critical locations to prevent material from binding during progressive operations. When a strip advances through multiple stations, bypass notches allow previously formed features to clear the die surfaces without interference. Without proper notch placement, formed sections can jam against subsequent stations, causing die damage and production stoppages.

From CAD to Production-Ready Tooling

Modern stamping die design relies heavily on digital tools that compress development timelines and reduce costly trial-and-error. Here's how the typical design-to-production workflow unfolds:

- Part Print Analysis: Engineers evaluate your part geometry for stampability—identifying potential problems with bend radii, draw depths, or feature spacing before any design work begins.

- Strip Layout Development: For progressive dies, this critical step arranges all cutting and forming operations in optimal sequence. According to U-Need, strip layout is an iterative process that minimizes material waste while maximizing production speed.

- 3D CAD Modeling: Using software like SolidWorks or CATIA, engineers create detailed models of every die component—punches, die blocks, strippers, and guide systems—all sized and toleranced for manufacturing.

- CAE Simulation: This is where modern technology dramatically reduces risk. Using platforms like AutoForm or DYNAFORM, engineers simulate the entire stamping process digitally before cutting any tool steel.

- CAM Programming: Validated designs are translated into machining instructions for CNC equipment, wire EDM, and grinding operations.

- Prototype Validation: First-article parts undergo dimensional inspection and functional testing before production approval.

The CAE simulation stage deserves special attention because it's where potential defects are identified before they become expensive problems. According to U-Need, simulation software allows designers to model the material's behavior under forming conditions—predicting where the sheet will stretch thin, buckle, wrinkle, or crack. This virtual validation process enables rapid iteration; adjusting a digital model is far cheaper and faster than re-machining hardened tool steel.

Simulation capabilities include:

- Predicting springback behavior and compensating die geometry accordingly

- Identifying areas prone to thinning, wrinkling, or splitting

- Optimizing blank shape and position for material efficiency

- Validating draw bead placement and blank holder pressure settings

- Confirming that final part dimensions fall within specification

This digital thread—from initial concept through validated CAM programs—creates what engineers call a design-to-production chain. When tooling dies are manufactured from thoroughly simulated designs, first-article approval rates climb dramatically and tryout time shrinks from weeks to days.

Understanding these engineering fundamentals positions you to evaluate potential suppliers effectively. Ask about their simulation capabilities, design validation processes, and first-pass success rates. A partner with robust engineering practices delivers tooling that runs right the first time—saving you the budget overruns that plague projects where dies require multiple correction cycles. With design principles established, the next critical consideration is maintaining part quality throughout production and keeping your dies performing at peak efficiency.

Quality Control and Die Maintenance Best Practices

Your die design is flawless. Your material selection is perfect. But here's a reality check: even the best stamping dies degrade over time, and quality problems will eventually surface in your production run. The difference between profitable operations and costly scrap rates comes down to one thing—how quickly you identify defects and how systematically you maintain your tooling.

Think of your stamping dies as high-performance athletes. They need regular conditioning, proper nutrition (lubrication), and immediate attention when injuries occur. Neglect these fundamentals, and even the most sophisticated steel stamping dies will underperform. Let's build your troubleshooting playbook and maintenance strategy.

Identifying Common Defects Before They Multiply

Every defective part that exits your press is sending you a message. According to Jeelix, stamped parts are far from mere scrap—they are the most faithful war correspondents of your mold's condition. Learning to interpret these signals separates reactive firefighting from proactive quality management.

The five most common defects in die stamping operations each point to specific root causes. When you spot one of these issues, don't just fix the symptom—trace it back to the source and address the underlying problem.

| Defect | Symptoms | Common Causes | Corrective Actions |

|---|---|---|---|

| Burrs | Raised edges, sharp protrusions on cut surfaces | Excessive punch-die clearance, worn cutting edges, dull tooling | Sharpen or replace punch/die, reduce clearance, verify alignment |

| Wrinkles | Wavy surfaces, material bunching in flange areas | Insufficient blank holder force, excessive material flow, improper draw bead design | Increase blank holder pressure, add or modify draw beads, adjust lubrication |

| Cracks/Tears | Splits in material, fractures at bend radii or draw walls | Excessive blank holder force, insufficient die radii, poor lubrication, material defects | Reduce blank holder pressure, increase die/punch radii, improve lubrication, verify material specifications |

| Springback | Parts out of angular specification after forming | Material elastic recovery, insufficient overbend compensation, improper coining pressure | Increase overbend angle, add coining at bend areas, use post-stretching techniques |

| Dimensional Variation | Parts outside tolerance limits, inconsistent measurements | Die wear, thermal expansion, press deflection, material thickness variation | Recalibrate dies, verify material consistency, adjust press settings, implement SPC monitoring |

According to Jeelix, the relationship between blank holder force, die radii, and lubrication forms a critical triangle governing all deep drawing operations. Too much restraint causes tearing; too little causes wrinkling. Your sheet metal die must balance these competing forces precisely.

Root Cause Analysis for Stamping Problems

When defects appear, resist the temptation to adjust press parameters randomly. Instead, follow a systematic diagnostic approach that examines both the stamped parts and the dies themselves.

In-Process Inspection Techniques

Continuous monitoring catches problems before they multiply into costly scrap runs. According to Acro Metal, in-process inspection involves regular checks for part dimensions, surface finish, and overall quality. Automated systems, sensors, and cameras may assess part conformity and identify deviations from established standards in real-time.

Effective inspection methods include:

- First-piece inspection: Verify dimensional accuracy before committing to production runs

- Periodic sampling: Check parts at regular intervals throughout the run

- Visual surface inspection: Identify scratches, galling marks, or surface imperfections

- Go/no-go gauging: Quick verification of critical dimensions using fixed gauges

- CMM measurement: Coordinate measuring machines provide comprehensive dimensional data for complex parts

Statistical Process Control (SPC)

According to Acro Metal, SPC is a method used to monitor and control the consistency of the stamping process. Through the collection and analysis of data at various stages, manufacturers can identify trends, variations, or anomalies in the production process. Control charts tracking critical dimensions reveal when your process drifts toward specification limits—allowing intervention before defective parts are produced.

Die Inspection and Wear Assessment

According to Die-Made, tool and die inspection includes regular examination for wear, damage, or any deviations from design specifications. Proper maintenance and timely replacement of worn-out dies are crucial to ensuring consistent part quality.

When examining your metal stamping dies, distinguish between wear types:

- Abrasive wear: Visible grooves and scratches from hard particles or material sliding

- Adhesive wear (galling): Material transfer between die surfaces and workpiece, creating torn or rough surfaces

- Fatigue cracking: Beach-mark patterns indicating progressive crack growth from repeated stress cycles

- Plastic deformation: Collapsed or mushroomed edges from pressures exceeding material yield strength

Extending Die Life Through Preventive Maintenance

Here's a harsh truth that impacts your budget directly: according to Jeelix, 80% of on-site galling, scratching, and abnormal wear issues are directly linked to improper lubrication. Elevating lubrication from an overlooked auxiliary task to a fully-fledged engineering discipline is one of the most immediate ways to extend your types of stamping dies' service life.

Lubrication Best Practices

The higher the forming pressure and the more intense the material flow, the higher the viscosity and extreme pressure (EP) additive content your lubricant should have. EP additives create a chemical reaction film on the metal surface, preventing direct metal-to-metal contact under high pressure.

Critical lubrication considerations include:

- Match lubricant viscosity to forming severity—deep draws require heavier lubricants than simple blanking

- Apply lubricant uniformly across the blank surface

- Verify compatibility between lubricant and post-stamping processes (welding, painting, plating)

- Monitor lubricant condition and replace contaminated supplies

Sharpening Schedules and Maintenance Intervals

According to Die-Made, establishing a regular maintenance schedule for stamping dies is vital for ensuring longevity and optimal performance. The frequency depends on usage level, material being stamped, and production requirements.

Develop maintenance schedules based on:

- Stroke counts: Track total press cycles and schedule inspection at defined intervals

- Part quality indicators: Burr height measurements signal when sharpening is needed

- Material hardness: Stamping abrasive materials like stainless steel accelerates wear

- Visual inspection: Check cutting edges for chipping, wear lines, or buildup

A well-maintained sheet metal stamping dies set should deliver hundreds of thousands—even millions—of quality parts. Neglected dies fail prematurely, requiring expensive replacement or repair that disrupts production schedules.

Refurbish or Replace: Making the Right Call

When your dies show wear, you face a critical decision: invest in refurbishment or purchase new tooling? The answer depends on three factors according to Jeelix:

- Wear severity: Surface wear and minor edge damage can be repaired through grinding, welding, and recoating. Structural cracks or extensive plastic deformation often mean replacement.

- Remaining production requirements: If you need only 50,000 more parts, refurbishment may be cost-effective. If millions remain, new tooling ensures consistent quality.

- Technology advances: Sometimes replacing dies allows incorporating improved designs, better materials, or surface treatments that weren't available when original tooling was built.

Surface treatments like PVD coatings or nitriding applied during refurbishment can dramatically extend die life. According to Jeelix, PVD coatings with hardness values of HV 2000-3000—three to four times that of hardened steel—provide excellent resistance for materials prone to galling like stainless steel or high-strength alloys.

Document every maintenance action, repair, and inspection result. This maintenance log becomes invaluable for predicting future needs, identifying recurring problems, and building data-driven replacement schedules. With robust quality control and maintenance practices in place, you're positioned to understand the complete cost picture of your die stamping project—from initial tooling investment through long-term production economics.

Cost Analysis and Budgeting for Die Stamping Projects

You've mastered the technical fundamentals—die configurations, material selection, quality control. Now let's talk money. Understanding the true cost structure of die stamping is what separates projects that deliver ROI from those that drain budgets unexpectedly. The challenge? Most manufacturers quote tooling and per-part prices without explaining how these numbers connect to your total project economics.

Here's the reality: die stamping involves significant upfront investment that pays dividends only when production volumes justify the tooling expense. Get this calculation wrong, and you'll either overspend on tooling you don't need or underestimate costs that surface mid-production. Let's build a framework you can actually use.

Understanding Die Stamping Economics

Die manufacturing costs break into two distinct categories: tooling investment (fixed costs) and production costs (variable costs). According to Manor Tool, metal stamping pricing includes the tooling and die investment, material requirements, part complexity, quality control and documentation, estimated annual usage (EAU), and shipping costs. Together, these elements determine the total cost per part for your components.

Your upfront tooling investment covers:

- Die design engineering: CAD/CAM development, simulation validation, and prototype testing

- Tool steel and materials: High-grade tool steels for punches, die blocks, and wear components

- CNC machining and EDM: Precision manufacturing of die components

- Assembly and tryout: Die fitting, adjustment, and first-article validation

- Heat treatment and coatings: Hardening processes that extend die life

Your per-part production costs include:

- Raw material: Sheet metal consumed for each part plus scrap

- Press time: Machine operating costs per stroke or hour

- Labor: Operator time for setup, monitoring, and quality checks

- Secondary operations: Deburring, plating, heat treating, or assembly

- Quality documentation: Inspection, certification, and traceability requirements

The critical insight here? According to Manor Tool, metal stamping isn't ideal for prototypes or low-volume runs. The upfront investment in stamping tooling often exceeds the cost of traditional machining for small batches. However, once production reaches around 10,000+ parts per month, the tooling cost becomes far more economical.

The Volume Break-Even Calculation

When does die stamping make financial sense? The answer lies in a simple break-even formula that every project manager should understand.

According to The Supplier, the break-even quantity (Q*) can be calculated as: Q* ≈ Tooling Cost / (Alternative Process Unit Cost − Stamping Unit Cost). If your forecast quantity exceeds Q*, move to stamping.

Imagine you're comparing a $25,000 progressive die against laser cutting. Laser cutting costs $2.50 per part with no tooling investment. Stamping costs $0.35 per part after tooling. Your break-even calculation:

Q* = $25,000 / ($2.50 − $0.35) = 11,628 parts

If you need 15,000 parts, stamping saves you money. If you need only 5,000, stick with laser cutting. This math explains why stamping manufacturing dominates high-volume production while alternative processes handle prototypes and short runs.

Several factors push your break-even point lower, making die stamping more attractive:

- High annual volumes: Spreading tooling costs across more parts reduces per-piece investment

- Multi-year programs: Automotive and appliance parts often run for 5-7 years, amortizing tooling extensively

- In-die operations: Progressive dies that pierce, tap, and form eliminate secondary process costs

- Optimized strip layouts: Better material utilization reduces raw material expense per part

- Repeat orders: Existing tooling requires only setup costs for subsequent runs

Calculating Your Project Investment

Let's get practical. How do you estimate costs before requesting formal quotes? While exact pricing varies by supplier and complexity, understanding the cost drivers helps you budget realistically.

Tooling Complexity Factors

According to Manor Tool, some components can be formed in a single die strike, while more complex parts require progressive die stamping, which uses multiple stations to create detailed features efficiently. Die complexity scales with your part requirements:

- Simple compound dies: $5,000–$15,000 for basic flat blanking operations

- Moderate progressive dies: $15,000–$50,000 for parts requiring 4-8 stations

- Complex progressive dies: $50,000–$150,000+ for intricate multi-station tooling

- Transfer die systems: $75,000–$300,000+ for large, deep-drawn components

According to Manor Tool, when it comes to metal stamping tooling, quality matters. Dies manufactured overseas often use lower-grade steel that wears faster and produces inconsistent parts. Manor Tool guarantees their dies for 1,000,000+ strikes before maintenance is required—a critical consideration when evaluating true tool and die manufacturing costs.

Material Cost Considerations

Your material selection directly impacts long-term costs. According to Manor Tool, over-designing—by selecting a grade or strip thickness that exceeds your performance needs—can significantly increase cost without improving results. Use finite element analysis (FEA) to test component performance virtually before committing to material specifications.

Design Impact on Costs

According to Manor Tool, every unnecessary design element adds cost. Key DFM principles that reduce expenses include:

- Eliminate thin sections that accelerate die wear

- Use parallel edges allowing multiple parts to run simultaneously

- Define tolerances carefully—avoid arbitrary tight specifications

- Maintain proper edge spacing for holes and features

- Request only necessary QC documentation

ROI: Die Stamping vs Alternative Processes

How does stamping compare financially to laser cutting, waterjet, or CNC machining? According to The Supplier, the decision framework centers on volume and design stability.

Choose laser cutting when:

- Quantities are under your break-even threshold

- Design changes are still occurring

- Mixed SKUs prevent dedicated tooling justification

- Lead time is critical (parts in hours, not weeks)

Choose die stamping when:

- Annual volumes exceed break-even quantities

- Design is frozen and validated

- Multi-year production programs are planned

- In-die forming operations eliminate secondary costs

- Per-part costs must minimize for competitive pricing

According to The Supplier, a hybrid path often makes sense: start with laser cutting to validate assembly, GD&T, and finish requirements. Freeze the design, then cut progressive or compound dies when annual quantities clear the break-even threshold.

Lead Time Realities

Budget planning must account for the calendar, not just dollars. According to Jeelix, building a progressive die system requires a structured, multi-stage process from feasibility analysis through die tryout and production ramp-up.

Typical timeline expectations:

- Die design and engineering: 2-4 weeks for moderate complexity

- Tooling fabrication: 6-12 weeks depending on die complexity

- Die tryout and validation: 1-2 weeks for first-article approval

- Production qualification: 1-2 weeks for capability studies

Total lead time from order to production parts typically ranges from 10-18 weeks for new tooling. Planning for this timeline prevents schedule surprises that force expediting costs or production delays.

With your cost framework established, you're ready to compare die stamping directly against alternative manufacturing processes—understanding exactly when each approach delivers the best value for your specific project requirements.

When to Choose Die Stamping Over Alternative Processes

You've crunched the numbers and understand die stamping economics. But here's where theory meets reality: how do you actually decide whether stamping is right for your project—or whether laser cutting, waterjet, CNC punching, or hydroforming would serve you better? The answer isn't always obvious, and choosing wrong can mean either overspending on unnecessary tooling or missing the cost savings that high-volume stamping delivers.

Let's build a decision framework you can apply immediately. Each manufacturing stamping process has sweet spots where it outperforms alternatives—and understanding these boundaries prevents expensive mistakes.

Making the Right Manufacturing Choice

The metal stamping process excels in specific scenarios that alternative methods simply cannot match economically. According to Hansen Industries, each process has its strengths and limitations in terms of cost, edge quality, and accuracy. The key is matching your project requirements to the right technology.

Ask yourself these five questions before committing to any process:

- What's your production volume? The sheet metal stamping process becomes cost-effective when run sizes exceed 1,000 parts or repeat frequently.

- Is your design finalized? Stamping tooling locks in geometry—changes after die fabrication are expensive.

- How complex is your part? Multiple operations like forming, piercing, and bending favor progressive stamping.

- What material are you using? Copper parts are too reflective for CO2 lasers, making waterjet or stamping better choices.

- What edge quality do you need? Different processes produce different edge conditions.

According to Hansen Industries, metal stamping can reduce part cost by an order of magnitude compared to cutting processes and becomes cost-effective when run sizes are 1,000 or more or repeat often. That's a 10x potential savings—but only when your project profile matches the stamping process strengths.

Die Stamping vs Alternative Processes

Understanding how the stamping metal process compares to alternatives helps you make informed decisions. According to Worthy Hardware, the best process depends entirely on your project's complexity, quantity, and cost targets.

| Process | Volume Suitability | Part Complexity | Material Options | Precision | Cost Structure |

|---|---|---|---|---|---|

| Die Stamping | High (10,000+) | Moderate to High | Most metals | ±0.002" | High tooling, low per-part |

| Laser Cutting | Low to Medium | 2D profiles only | Most metals (not reflective) | ±0.005" | No tooling, moderate per-part |

| Waterjet | Low to Medium | 2D profiles only | Any material | ±0.005" | No tooling, higher per-part |

| CNC Punching | Low to High | Holes and standard shapes | Sheet metals | ±0.003" | Low tooling, moderate per-part |

| Hydroforming | Medium to High | Very High (deep/complex) | Ductile metals | ±0.005" | High tooling, moderate per-part |

When Laser Cutting Wins

According to Hansen Industries, in thin gauge materials that have curves or long cut lines, laser cutting is often the fastest. A flying optics laser minimizes scratches on the material and can eliminate microjoints. Choose laser cutting for prototypes, design validation, and runs under your break-even threshold.

When CNC Punching Makes Sense

If your part has many holes—as electronic chassis tend to have—CNC punching offers speed advantages. According to Hansen Industries, CNC punching excels because of punching speed, roundness of holes, and the ability to form features and tap holes in the same operation.

When Waterjet Delivers Superior Results

According to Hansen Industries, as soon as material approaches half an inch in thickness, waterjet produces superior edge quality. You can also stack materials and the cold processing allows welding and powder coating without problems—unlike laser cutting with oxygen assist gas, which can cause scaling that creates problems in downstream processes.

When Hydroforming Outperforms Stamping

According to Worthy Hardware, hydroforming uses one rigid die and high-pressure fluid on the other side. This fluid pressure allows the metal to flow more evenly into complex shapes without tearing or excessive thinning. For deep-drawn parts with asymmetrical geometries or uniform wall thickness requirements, hydroforming may justify its higher costs.

Hybrid Approaches: Combining Processes Strategically

Here's what experienced manufacturers know: you don't always have to choose just one process. The stamping manufacturing process often works best when combined with secondary operations or used alongside cutting technologies.

Consider these hybrid strategies:

- Laser prototyping, then stamping: Validate your design with laser-cut parts before investing in tooling. This confirms fit, function, and finish requirements.

- Stamping plus laser trimming: Stamp the primary geometry, then use laser cutting for complex peripheral features that would complicate die design.

- Progressive stamping with robotic welding: Stamp sub-components, then assemble them automatically for complex assemblies.

- Compound blanking with hydroforming: Blank flat shapes efficiently, then hydroform deep or complex features.

According to Worthy Hardware, nearly every sheet metal part goes through at least one, and often all three, fundamental stages: cutting, forming, and joining. Your optimized manufacturing strategy may leverage different technologies at each stage.

Your Decision Criteria Checklist

Before your next project, run through this practical checklist:

- Volume exceeds 10,000 annually? Stamping likely delivers lowest total cost.

- Design frozen and validated? Safe to invest in dedicated tooling.

- Part requires forming operations? Stamping handles bending, drawing, and coining in-die.

- Tight tolerances needed? Stamping achieves ±0.002" consistently.

- Multi-year production program? Tooling investment amortizes favorably.

- Using reflective materials like copper? Stamping or waterjet—not CO2 laser.

- Need rapid design iteration? Start with laser or waterjet until design stabilizes.

The stamping process shines when volume, complexity, and design stability align. When they don't, alternative methods—or hybrid approaches—may serve you better. With this comparative framework in hand, you're positioned to explore how modern automation and technology are pushing the boundaries of what die stamping can achieve.

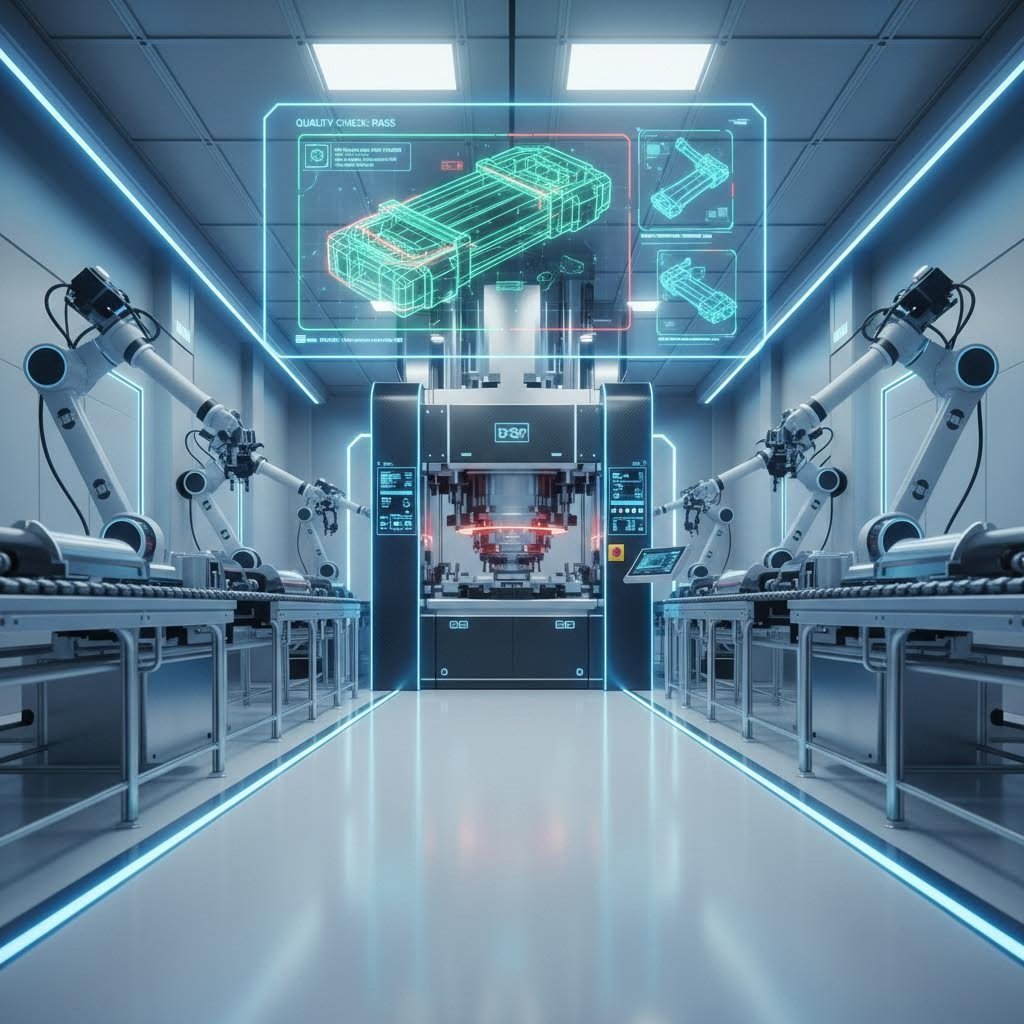

Modern Die Stamping Technologies and Automation

You've built a solid foundation—understanding die configurations, material selection, cost analysis, and process comparisons. But here's what separates manufacturers who merely survive from those who thrive: embracing the technological revolution transforming every die stamping machine on the production floor. The equipment running today looks nothing like the presses of even a decade ago, and understanding these advances directly impacts your project's quality, speed, and bottom line.

Imagine a die-stamping machine that adjusts its forming speed mid-stroke based on real-time material feedback. Picture quality inspection happening automatically between press cycles, catching defects before they multiply. This isn't science fiction—it's happening right now in advanced stamping operations worldwide. Let's explore how these technologies can work for your next project.

Technology Driving Stamping Innovation

The most significant advancement reshaping die stamping operations is the servo-driven press. Unlike traditional mechanical presses with fixed motion profiles, servo presses use programmable motors that provide complete control over ram movement throughout the entire stroke.

According to Shuntec Press, servo presses can be programmed for various speeds and positions, making them highly adaptable to different forming processes. This flexibility leads to improved part quality, reduced wear on tools, and lower energy consumption.

Why does this matter for your automotive stamping die projects or complex forming operations? Consider what programmable motion enables:

- Variable approach speeds: Fast approach reduces cycle time, while slow forming prevents material defects

- Controlled dwell time: Holding pressure at bottom dead center improves coining and embossing quality

- Reduced impact forces: Gentle contact with the workpiece extends die life and reduces noise

- Springback compensation: Programmed over-forming addresses material recovery in real-time

- Energy regeneration: Servo motors consume power only when moving, with some systems recovering energy during deceleration

According to Shuntec Press, the smooth, controlled motion of servo presses minimizes shock and stress on tooling. This leads to lower maintenance costs and fewer tool replacements over time—a direct budget benefit that compounds across high-volume production runs.

For complex progressive stamping process applications, servo technology enables operations that were previously impossible. Deep draws that once required multiple hits can now happen in a single controlled stroke. High-strength aluminum alloys that frustrated traditional presses now form predictably thanks to precisely programmed motion profiles.

In-Die Sensing and Real-Time Monitoring

What if your die could tell you when something was going wrong—before defective parts ever left the press? That's exactly what modern in-die sensing delivers.

According to the Penn State Digital Foundry's case study with JV Manufacturing, legacy die control systems offered little to no visibility into real-time process performance or the root causes of downtime. Without integrated monitoring or diagnostics, quality-impacting events went undetected until after the fact.

Modern die stamping machine installations incorporate sensors that monitor:

- Tonnage signatures: Force sensors detect variations indicating material changes, die wear, or misfeed conditions

- Part presence: Proximity sensors confirm proper strip advancement and part ejection

- Die temperature: Thermal monitoring identifies friction-generated heat that signals lubrication problems

- Vibration patterns: Accelerometers detect abnormal die behavior before catastrophic failure

- Strip position: Encoders verify accurate feeding and pilot engagement

The JV Manufacturing modernization project, developed with the Penn State Digital Foundry, created a next-generation stamping die controller integrating programmable logic controllers (PLCs), real-time dashboards, recipe management, alarm features, and sensors. The result? A scalable, smart-manufacturing-ready control architecture that enables faster response to production issues and reduces unplanned downtime.

Automation and Smart Manufacturing Integration

Beyond the press itself, automation is transforming how parts move through stamping operations. Industrial die cutting machine cells now integrate robotic handling systems that load blanks, transfer parts between operations, and stack finished components—all without human intervention.

The emerging technologies reshaping die stamping efficiency and quality include:

- Robotic part handling: Six-axis robots transfer parts between presses or load/unload coil-fed systems

- Vision-guided inspection: Camera systems verify part quality, dimensional accuracy, and surface condition between press strokes

- AI-driven process optimization: Machine learning algorithms analyze production data to recommend parameter adjustments

- Predictive maintenance: Analytics platforms forecast die wear and schedule maintenance before failures occur

- Digital twin simulation: Virtual models of dies and presses enable offline optimization and operator training

- Cloud-connected monitoring: Remote dashboards provide real-time visibility into production across multiple facilities

According to Shuntec Press, advanced servo presses are now being equipped with AI-driven control algorithms that can automatically adjust motion profiles based on material feedback or process variables. This level of adaptability improves forming accuracy and reduces human error, making operations more efficient and consistent.

Industry 4.0 integration connects these individual technologies into cohesive smart manufacturing systems. When your machine die cutting operation links press controls, quality inspection, and material handling into a unified data ecosystem, you gain insights impossible with isolated equipment. Production managers can identify trends, predict problems, and optimize performance based on actual operational data rather than assumptions.

CAE Simulation: Defect Prevention Before First Article

Perhaps no technology has transformed automotive stamping dies development more than computer-aided engineering (CAE) simulation. Before cutting a single piece of tool steel, engineers can now virtually form parts millions of times, identifying exactly where material will thin, wrinkle, or crack.

Advanced manufacturers leverage CAE simulation to achieve defect-free results by:

- Predicting springback behavior and compensating die geometry before fabrication

- Optimizing blank size and shape for material efficiency

- Validating draw bead placement and blank holder pressure settings

- Identifying potential splitting or wrinkling before physical tryout

- Reducing die correction cycles from weeks to days

This simulation-first approach dramatically accelerates time-to-production. When die designs are validated virtually, first-article approval rates climb into the 90%+ range, eliminating the expensive trial-and-error cycles that traditionally plagued complex tooling development.

For projects demanding automotive-grade quality, IATF 16949 certification ensures suppliers maintain the rigorous quality management systems required by major OEMs. This certification covers everything from design validation through production control, providing confidence that your stamping partner can deliver consistent results.

Leading suppliers like Shaoyi combine these advanced capabilities—CAE simulation, certified quality systems, and modern manufacturing technology—to deliver rapid prototyping in as little as 5 days with 93% first-pass approval rates. Their comprehensive automotive stamping die solutions demonstrate how integrated engineering and fabrication capabilities translate these technological advances into real-world project success.

The Future of Die Stamping Technology

Where is this technological evolution heading? According to Shuntec Press, miniaturization and modularization of servo systems is allowing manufacturers to customize machines for specific applications or floor space constraints. Compact servo presses are increasingly used in cleanroom environments and specialized industries such as medical and microelectronics.

The convergence of sustainability pressures and technological capability is also reshaping equipment decisions. Servo presses consume significantly less energy than flywheel-driven systems, aligning with corporate sustainability goals while reducing operating costs. As manufacturers face increasing pressure to reduce carbon footprints, energy-efficient stamping technology becomes both an environmental and financial imperative.

For your next project, these technological advances translate into tangible benefits: faster development timelines, higher first-pass approval rates, better part quality, and more predictable production costs. The question isn't whether to embrace these technologies—it's finding the right partner who has already invested in them. With this understanding of modern capabilities, you're ready to map out the complete project planning process from initial concept through production launch.

Planning Your Die Stamping Project for Success

You've absorbed the technical fundamentals, crunched the cost numbers, and evaluated alternative processes. Now comes the moment of truth: actually executing your die stamping project from concept through production launch. This is where theory meets reality—and where careful planning separates successful projects from budget-busting disasters.

Think of project planning as building a bridge. Every phase connects to the next, and skipping steps creates gaps that surface later as delays, cost overruns, or quality problems. Whether you're launching your first die stamp program or optimizing an established production line, this roadmap helps you navigate each milestone with confidence.

Your Roadmap from Concept to Production

What is metal stamping success really built on? Systematic planning that anticipates challenges before they derail your timeline. According to 6sigma.us, the difference between success and failure often hinges on decisions made long before a product reaches the assembly line. Design for Manufacturing principles integrated early prevent costly corrections later.

Follow this project planning checklist to guide your die stamped components from initial concept through full production:

- Define Project Requirements Clearly: Document your part's function, assembly environment, and critical-to-function features before engaging suppliers. According to KY Hardware, go beyond a simple part drawing—specify material type, thickness, temper, and precise dimensional tolerances. Unclear requirements lead to misquoted projects and frustrated suppliers.

- Conduct Design for Manufacturability (DFM) Review: Before finalizing your design, have experienced stamping engineers evaluate it for producibility. According to 6sigma.us, DFM is the practice of designing products with manufacturing in mind—anticipating and addressing potential production challenges before they arise. This review identifies features that complicate tooling, increase costs, or create quality risks.

- Establish Volume Forecasts and Timeline Requirements: Determine your Estimated Annual Usage (EAU) and typical order quantities. According to KY Hardware, this information is crucial for the supplier to decide on the most efficient tooling approach and calculate accurate pricing. Also define your prototyping needs and production launch timeline.

- Evaluate and Select Qualified Suppliers: Create a weighted scorecard covering equipment capabilities, quality certifications, engineering support, material expertise, and capacity. According to KY Hardware, the lowest price per part is rarely the best value—true value comes from a supplier who acts as a strategic partner.

- Request and Compare Quotations: Provide identical specifications to all potential suppliers for apples-to-apples comparison. Ensure quotes itemize tooling costs, per-part pricing, secondary operations, and quality documentation requirements separately.

- Approve Die Design and Engineering: Review 3D CAD models, strip layouts, and simulation results before tooling fabrication begins. This is your last opportunity to influence geometry before hardened steel gets cut.

- Validate Prototypes: Inspect first-article metal stamped parts against all dimensional and functional requirements. According to 6sigma.us, thorough validation and testing ensures the product meets all design for manufacturability criteria and performs as intended.

- Complete Production Part Approval Process (PPAP): For automotive and industrial applications, formal production qualification demonstrates process capability meets specification requirements consistently.

- Ramp to Full Production: Begin with controlled initial runs, monitoring quality metrics closely before scaling to full-volume production of your stamped parts.

Communication Between Design Engineering and Die Makers

Here's where many projects stumble: the handoff between your design team and the die maker. According to 6sigma.us, successful DFM implementation requires collaboration across various departments—this cross-functional approach is essential for design for manufacturing and assembly.

Effective communication requires:

- Complete documentation: Provide 3D models, 2D drawings with GD&T, material specifications, and finish requirements in compatible file formats

- Critical feature identification: Highlight dimensions and tolerances that affect function versus those that are cosmetic or less critical

- Application context: Explain how the part functions in assembly—this helps die makers optimize tooling for what actually matters

- Change management protocol: Establish clear procedures for handling design modifications after tooling begins

- Regular design reviews: Schedule milestone check-ins during die development to catch issues early

According to KY Hardware, the best stamping suppliers are true partners who provide engineering expertise, not just manufacturing capacity. Their early involvement can lead to significant cost savings and a more robust part design. Ask potential suppliers: "Can you walk me through a recent example where your engineering team suggested a design change that reduced costs or improved manufacturability?"

Timeline Expectations: From Order to Production

Realistic scheduling prevents the panic that leads to expediting costs and quality shortcuts. What timeline should you plan for your die stamps project?

| Phase | Typical Duration | Key Deliverables |

|---|---|---|

| DFM Review & Quotation | 1-2 weeks | Manufacturability feedback, formal quotation, timeline commitment |

| Die Design Engineering | 2-4 weeks | 3D CAD models, strip layouts, simulation validation |

| Tooling Fabrication | 6-10 weeks | Completed die assembly, ready for tryout |

| Die Tryout & First Article | 1-2 weeks | Sample parts for dimensional and functional approval |

| Production Qualification | 1-2 weeks | Capability studies, PPAP documentation if required |

| Total: Concept to Production | 11-20 weeks | Production-ready precision die & stamping capability |

These timelines assume moderate die complexity. Simple compound dies may complete faster; complex progressive dies with many stations may extend longer. Working with experienced partners who have invested in advanced CAE simulation and efficient fabrication processes can compress these schedules significantly.

Partnering for Die Stamping Success

Your supplier selection ultimately determines whether your project timeline holds and your budget remains intact. According to KY Hardware, selecting the right stamping supplier is a critical decision that directly impacts your product quality, production timeline, and bottom line.

Key supplier evaluation criteria include:

- Equipment capabilities: Does their press tonnage range and bed size accommodate your part requirements?

- Quality certifications: ISO 9001 is baseline; IATF 16949 demonstrates automotive-grade quality systems

- Engineering depth: Do they offer DFM review, CAE simulation, and prototype validation in-house?

- Material expertise: Have they successfully stamped your specified material before?

- Industry experience: Do they understand your sector's specific requirements and approval processes?

- Capacity and flexibility: Can they scale with your volume growth and accommodate schedule changes?

Working with partners who combine engineering expertise with modern manufacturing capabilities accelerates your production timeline while reducing risk. Shaoyi's engineering team exemplifies this comprehensive approach, delivering cost-effective, high-quality tooling tailored to OEM standards. Their rapid prototyping capability—producing sample parts in as little as 5 days with 93% first-pass approval rates—demonstrates how integrated design and fabrication expertise translates directly into compressed project schedules.

For projects requiring precision and reliability, explore their automotive stamping die solutions to see how comprehensive mold design and fabrication capabilities support everything from initial concept through high-volume manufacturing.

The journey from concept to production demands careful planning, clear communication, and the right partnerships. By following this roadmap and selecting suppliers who function as true engineering partners, your next die stamping project can deliver the precision, quality, and cost efficiency that justify the investment. Your budget will thank you—and so will your production schedule.

Frequently Asked Questions About Die Stamping

1. What is the difference between die cut and stamping?

Die cutting and metal stamping are fundamentally different processes. Die cutting typically refers to cutting flat materials like paper, cardboard, or thin plastics using sharp blades or rules. Metal stamping, however, is a cold forming process that shapes sheet metal using specialized dies mounted in presses. Stamping can perform multiple operations—cutting, bending, drawing, and forming—in a single press stroke, transforming flat metal into three-dimensional precision components for automotive, aerospace, and electronics industries.

2. What is a die stamper?

A die stamper refers to both the equipment and the skilled professional operating metal stamping machinery. The die-stamping machine uses specialized tooling (dies) mounted in hydraulic or mechanical presses to cut and form sheet metal into precise shapes. In traditional printing, a die stamper is a craftsman who engraves images into steel blocks. In manufacturing, modern die stampers operate servo-driven presses with programmable motion profiles, in-die sensing, and real-time monitoring systems to produce millions of consistent parts.

3. What is the difference between die casting and stamping?

Die casting and stamping differ significantly in material form, process temperature, and application. Die casting melts metal and injects it into molds under high pressure to create complex three-dimensional parts—ideal for intricate geometries but with higher tooling costs. Metal stamping uses sheet metal blanks or coils at room temperature, pressing them through dies to cut and form parts. Stamping offers lower per-part costs at high volumes and excels at producing brackets, enclosures, and components requiring tight tolerances.

4. How much does die stamping tooling cost?

Die stamping tooling costs vary significantly based on complexity. Simple compound dies for basic blanking operations range from $5,000-$15,000. Moderate progressive dies with 4-8 stations cost $15,000-$50,000. Complex progressive dies requiring intricate multi-station tooling can reach $50,000-$150,000 or more. Transfer die systems for large, deep-drawn components may cost $75,000-$300,000+. Quality tooling from reputable manufacturers guarantees 1,000,000+ strikes before maintenance, making the investment worthwhile for high-volume production.

5. When does die stamping become more cost-effective than laser cutting?

Die stamping typically becomes cost-effective when production volumes exceed 10,000 parts annually. The break-even calculation divides your tooling investment by the difference between alternative process costs and stamping per-part costs. For example, a $25,000 progressive die producing parts at $0.35 each versus laser cutting at $2.50 per part breaks even at approximately 11,628 parts. Beyond this threshold, stamping delivers significant savings that compound over multi-year production programs, potentially reducing costs by 10x compared to cutting processes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —