Het Concurrentievoordeel: Geëxtrudeerde Aluminium Frames voor Voertuigen

TL;DR

Geëxtrudeerde aluminium frames zijn essentiële componenten voor speciale voertuigen en bieden een krachtige combinatie van gewichtsreductie, hoge sterkte en uitzonderlijke ontwerpvrijheid. Fabrikanten geven de voorkeur aan deze op maat ontworpen profielen voor voertuigen zoals campers, hulp- en nooddienstvoertuigen en commerciële vrachtwagens, omdat ze de brandstofefficiëntie en duurzaamheid verbeteren zonder afbreuk te doen aan de structurele integriteit. Het extrusieproces maakt complexe, afgestemde vormen mogelijk die voldoen aan nauwkeurige automobiele specificaties.

Het strategische voordeel: waarom aluminiumprofielen domineren in speciale voertuigen

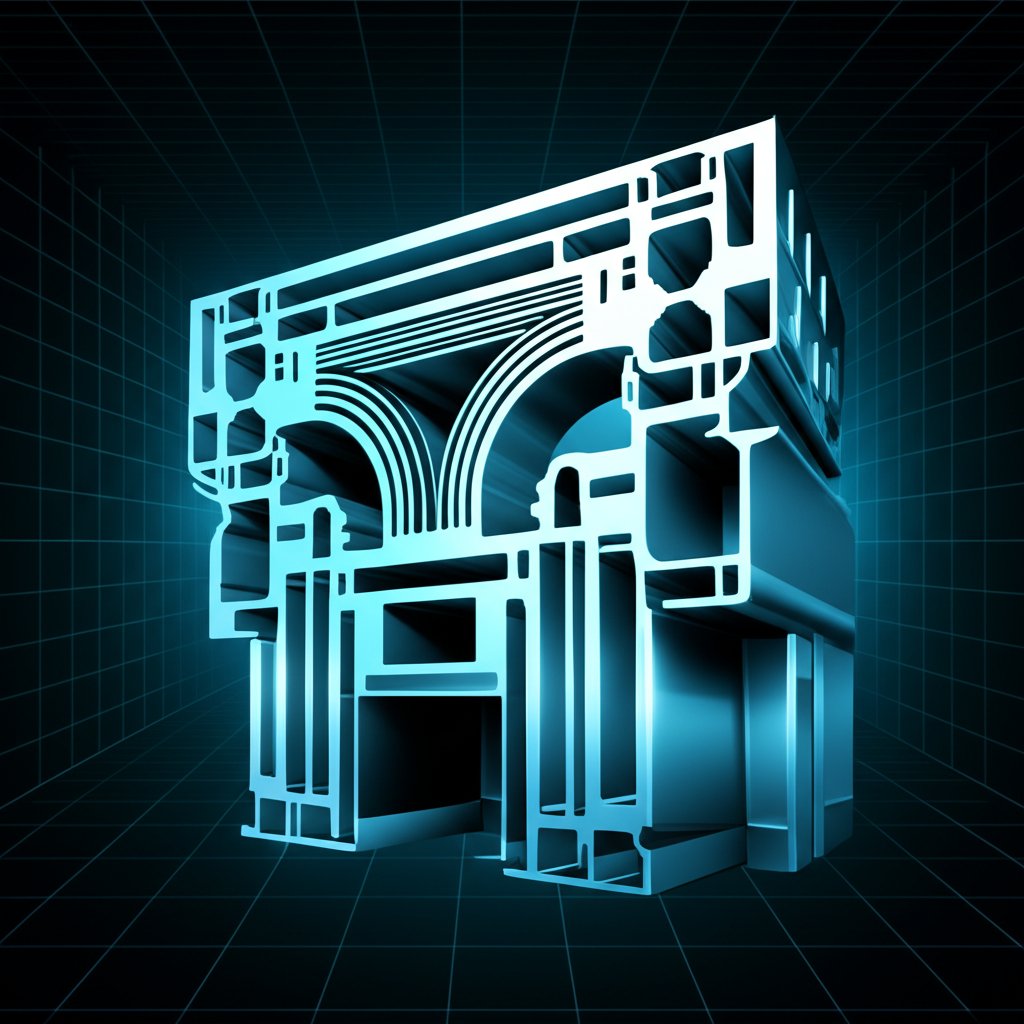

Het proces van aluminium-uitdrijving omvat het verhitten van een cilindrisch stuk aluminiumlegering en het door een gevormpte mal persen, vergelijkbaar met tandpasta uit een tube knijpen. Deze methode creëert continue profielen met een constante doorsnede, die vervolgens op maat kunnen worden gesneden. Voor de productie van speciale voertuigen is dit proces transformatief, omdat het de creatie van ingewikkelde, geoptimaliseerde en zeer reproduceerbare onderdelen mogelijk maakt die superieur zijn aan die welke worden gemaakt met traditionele vormmethoden of lassen. Deze mogelijkheid vormt de basis voor modern voertuigontwerp en -prestaties.

Een van de belangrijkste voordelen van het gebruik van aluminium is de bijdrage aan verlichting — de strategie om het gewicht van een voertuig te verminderen om de prestaties te verbeteren. Zoals reeds opgemerkt door leveranciers zoals Gabrian International , dit is al jaren een belangrijke trend in de auto-industrie. Lichtere voertuigen verbruiken minder brandstof, stoten minder uit en kunnen vaak zwaardere ladingen vervoeren, wat een cruciale factor is voor commerciële vrachtwagens en campers. Door zwaardere materialen zoals staal te vervangen, helpen geëxtrudeerde aluminium frames fabrikanten om strenge efficiencyregelgeving en de consumenteneisen voor beter brandstofverbruik te halen.

Ondanks dat ze lichtgewicht zijn, bieden aluminiumlegeringen die worden gebruikt in profielen een opmerkelijke sterkte-gewichtsverhouding. Legeringen uit de 6000- en 7000-serie worden in het bijzonder gewaardeerd vanwege hun hoge sterkte, waardoor ze geschikt zijn voor veiligheidskritische en structurele toepassingen. Dit zorgt ervoor dat voertuigen duurzaam en veilig blijven, en bestand zijn tegen de belastingen van de weg. Bovendien vormt aluminium van nature een beschermende oxide laag op het oppervlak, die roest voorkomt. Deze inherente corrosieweerstand kan worden verbeterd met afwerkingsprocessen zoals anodiseren, wat een lange levensduur garandeert en onderhoudskosten verlaagt, een belangrijk voordeel voor voertuigen die voortdurend aan weersinvloeden zijn blootgesteld.

Misschien is het meest overtuigende voordeel voor ontwerpers van speciale voertuigen de enorme ontwerpvrijheid die het extrusieproces biedt. In tegenstelling tot standaardmaterialen die uitgebreid moeten worden gesneden, gebogen en gelast, kan aluminium worden geëxtrudeerd in complexe, op maat gemaakte profielen die zijn afgestemd op specifieke functies. Dit stelt ingenieurs in staat om kenmerken zoals montagegleuven, scharnieren en afwerking direct in één onderdeel te integreren, waardoor de assemblage wordt vereenvoudigd en het totale aantal onderdelen wordt verminderd. Bedrijven zoals Eagle Aluminum specialiseren zich in deze kleine, ingewikkelde en zeer fijngewerkte op maat gemaakte afwerkingen die essentieel zijn voor toepassingen variërend van camperbouw tot custom auto's.

Belangrijke toepassingen: Van campers tot op maat gemaakte automobiele oplossingen

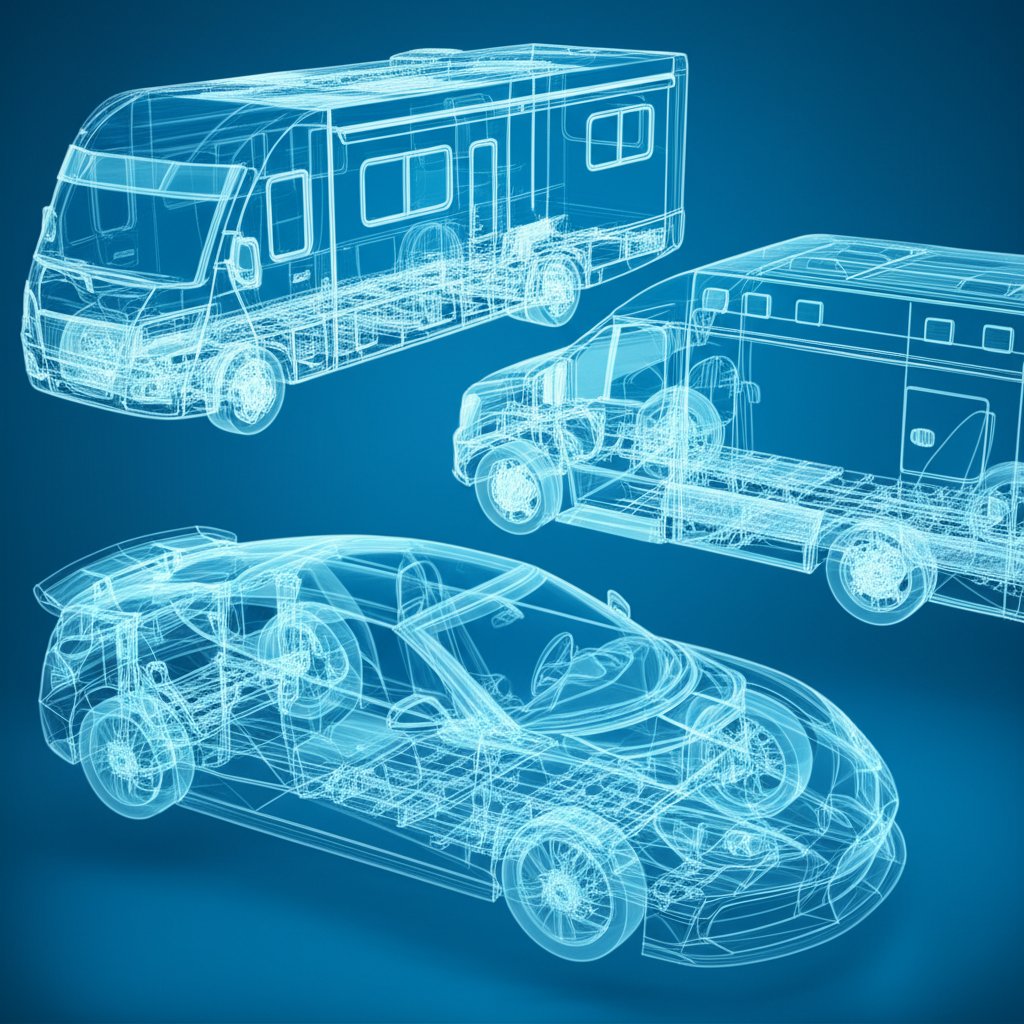

Geëxtrudeerde aluminium frames zijn geen standaardoplossing; hun veelzijdigheid komt tot uiting in de toepassing in een breed scala aan speciale voertuigen. Elke categorie maakt gebruik van de unieke eigenschappen van aluminium om specifieke eisen op het gebied van prestaties, duurzaamheid en design te vervullen, wat de aanpasbaarheid van het materiaal aantoont.

Recreatievoertuigen (RV's) en aanhangwagens

In de wereld van recreatievoertuigen telt elke kilo mee. Geëxtrudeerd aluminium is het ideale materiaal voor structurele frames, deur- en raamkozijnen, luifelonderdelen en decoratieve lijsten, omdat het zowel lichtgewicht als duurzaam is. Leveranciers zoals Tri-State Aluminum bieden een breed assortiment componenten zoals gootlijsten, dakranden en beschermingsprofielen. Het gebruik van aluminium houdt het totale gewicht van het voertuig laag, wat de sleepbaarheid en brandstofefficiëntie verbetert, terwijl het voldoende sterkte biedt om jarenlang reizen en blootstelling aan weersinvloeden te weerstaan.

Nood- en bedrijfsvoertuigen

Noodvoertuigen zoals ambulances en brandweerwagens, evenals commerciële bestelwagens en bedrijfswagens, vereisen een robuuste en betrouwbare constructie. Geëxtrudeerd aluminium wordt gebruikt voor kasten, bevestigingen voor apparatuur, de frameconstructie en leggersystemen. De hoge sterkte zorgt ervoor dat het voertuig zware uitrusting kan dragen, terwijl de corrosieweerstand essentieel is voor een lange levensduur, met name bij blootstelling aan slecht weer en wegzout. De mogelijkheid om op maat gemaakte profielen te maken, zorgt voor zeer geordende en efficiënte inrichtingen die zijn afgestemd op de specifieke behoeften van eerstehulpverleners of vakmensen.

Op maat gemaakte en hoogwaardige automobielen

In de wereld van op maat gemaakte auto's, van hoogwaardige racesimulatoren tot exclusieve autoprojecten, bieden aluminiumprofielen het ultieme niveau van flexibiliteit en prestaties. Modulaire framesystemen, zoals aangeboden door 80/20 Inc. , stellen bouwers in staat om op maat gemaakte chassis, montageframes en werkstations te maken die sterk, lichtgewichtig en eenvoudig configureerbaar zijn. Deze T-sleufprofielen stellen ontwerpers in staat componenten moeiteloos toe te voegen en te verplaatsen, waardoor ze ideaal zijn voor prototyping en het creëren van unieke voertuigstructuren zonder behoefte aan lassen of complexe fabricage.

Het proces van personalisatie: van profielontwerp tot afwerking

Het maken van op maat geëxtrudeerde aluminium frames is een samenwerkingsproces tussen klant en fabrikant. Het begrijpen van de belangrijkste fasen zorgt ervoor dat het eindproduct exact voldoet aan de specificaties voor prestaties en esthetiek. De reis van concept naar afgewerkt onderdeel omvat verschillende cruciale stappen.

- Consultatie & Ontwerp Het proces begint met een uitgebreid overleg om de vereisten van het project te bepalen. Ingenieurs en ontwerpers werken samen met de leverancier om de vorm, afmetingen en functionele kenmerken van het profiel definitief vast te stellen. In dit stadium worden CAD-tekeningen gemaakt en wordt een geschikt aluminiumlegering geselecteerd (bijvoorbeeld 6061 voor sterkte of 6063 voor een betere oppervlakteafwerking), afgestemd op de eisen van de toepassing.

- Prototypemaken: Voordat wordt overgegaan tot volledige productie, wordt vaak een prototype matrijs gemaakt om een kleine serie van het specifieke profiel te produceren. Dit maakt testen en valideren mogelijk, zodat wordt gewaarborgd dat het onderdeel goed past en functioneert zoals bedoeld. Eventuele noodzakelijke aanpassingen in het ontwerp kunnen in dit stadium worden doorgevoerd, wat later tijd en middelen bespaart in de productiecyclus.

- Extrusie & Bewerking: Zodra het ontwerp is goedgekeurd, wordt de definitieve matrijs vervaardigd en worden de aluminium billets geëxtrudeerd tot het op maat gemaakte profiel. Na extrusie kunnen de profielen verschillende bewerkingsprocessen ondergaan. Deze secundaire bewerkingen kunnen precisiekappen op maat, boren van gaten, CNC-bewerking voor complexe kenmerken of buigen om gebogen onderdelen te creëren, omvatten.

- Afwerking & Montage: De laatste stap is het aanbrengen van een oppervlakteafwerking om het uiterlijk en de corrosieweerstand te verbeteren. Veelvoorkomende opties zijn anodiseren (waardoor een harde, duurzame oxide laag wordt gevormd), poedercoaten voor een breed scala aan kleuren, of mechanische afwerkingen zoals borstelen. Na afwerking kunnen componenten worden gemonteerd tot grotere frames of als losse onderdelen worden verzonden.

Hoe de juiste partner voor aluminiumprofielen te kiezen

Het kiezen van de juiste leverancier is net zo belangrijk als het ontwerp van het onderdeel zelf. Een sterke partner levert niet alleen hoogwaardige onderdelen, maar biedt ook technische ondersteuning en betrouwbare service die uw productieproces kunnen stroomlijnen. Houd bij het beoordelen van potentiële leveranciers een holistische aanpak aan, waarbij u hun technische capaciteiten, kwaliteitssystemen en algehele toegevoegde waarde evalueert.

Eerst beoordelen ze hun productiecapaciteiten en ervaring. Een geschikte partner moet een uitgebreid scala aan diensten bieden, van ontwerpondersteuning en prototyping tot diverse fabricage- en afwerkingsmogelijkheden. Zoek een leverancier met een bewezen staat van dienst in de automobielindustrie en de mogelijkheid om zowel kleine, geavanceerde lijsten als grotere structurele onderdelen te verwerken. Voor automobielprojecten die precisie-engineered componenten vereisen, overweeg dan een partner met end-to-end diensten. Sommige bedrijven bieden bijvoorbeeld een uitgebreide one-stop service, van snel prototypen tot volledige seriesproductie, allemaal beheerd binnen een strikt, gecertificeerd kwaliteitssysteem volgens IATF 16949. Deze geïntegreerde aanpak, zoals gezien bij specialisten als Shaoyi Metal Technology , kan uw productieproces stroomlijnen en consistentie van begin tot eind waarborgen.

Kwaliteitscontrole en sectorcertificeringen zijn niet verhandelbaar. Zorg ervoor dat de leverancier voldoet aan erkende kwaliteitsnormen, zoals ISO 9001, en documentatie kan verstrekken over materiaalspoorbaarheid en dimensionele nauwkeurigheid. Vraag naar hun kwaliteitsborgingsprocessen, van het inspecteren van grondstoffen tot de verificatie van het eindproduct. Deze zorgvuldigheid garandeert dat de onderdelen die u ontvangt telkens voldoen aan uw prestatie- en veiligheidsvereisten.

Beoordeel ten slotte hun klantenservice en logistiek. Een goede partner communiceert duidelijk, biedt transparante prijzen en realistische levertijden. Informeer naar hun voorraadprogramma's voor op maat gemaakte profielen, omdat dit uw voorraadkosten aanzienlijk kan verlagen en productievertragingen kan voorkomen. Een leverancier die bereid is als echte partner samen te werken, met advies over ontwerp en flexibele oplossingen, zal een onmisbare troef zijn voor uw bedrijf.

De toekomst van speciale voertuigen bouwen

De toepassing van geperste aluminium frames is meer dan een materiaalkeuze; het is een strategische beslissing die innovatie stimuleert in de special voertuigindustrie. Door fabrikanten in staat te stellen lichtere, sterkere en duurzamere voertuigen te bouwen, dragen aluminiumprofielen rechtstreeks bij aan verbeterde brandstofefficiëntie, grotere laadvermogen en een langere levensduur. De ongeëvenaarde ontwerpvrijheid maakt continue optimalisatie mogelijk, of het nu gaat om het fijne afwerkingsprofiel van een camper of de robuuste constructie van een ambulance.

Naarmate de technologie evolueert en de eisen aan prestaties en duurzaamheid toenemen, zal de rol van geavanceerde materialen zoals aluminium alleen maar groter worden. De mogelijkheid om aangepaste, speciaal ontworpen onderdelen te produceren via extrusie is cruciaal voor de ontwikkeling van de volgende generatie special voertuigen. Het kiezen van het juiste materiaal en de juiste productiepartner stelt ontwerpers en ingenieurs in staat om grenzen te verleggen en veiligere, efficiëntere en beter presterende voertuigen te bouwen voor de weg van de toekomst.

Veelgestelde Vragen

1. Welke auto's hebben een aluminium frame?

Hoewel volledige aluminium frames meestal worden aangetroffen in hoogwaardige en luxe voertuigen om gewicht te besparen en het rijgedrag te verbeteren, gebruiken veel moderne auto's uitgebreid aluminium onderdelen. Voorbeelden van auto's die bekendstaan om hun aanzienlijk gebruik van aluminium in de chassis- of carrosseriestructuur zijn de Acura NSX, Audi A8, Jaguar XJ en Tesla Model S.

2. Gaat geëxtrudeerd aluminium roesten?

Nee, geëxtrudeerd aluminium roest niet. Roest is een vorm van ijzeroxide, dat alleen ijzerhoudende metalen zoals staal beïnvloedt. Aluminium is zeer bestand tegen corrosie omdat het op natuurlijke wijze een dunne, harde laag aluminiumoxide op het oppervlak vormt die het metaal beschermt tegen de omgeving. Deze bescherming kan verder worden versterkt door afwerkingsprocessen zoals anodiseren.

Kleine series, hoge eisen. Onze snelprototyperingservice maakt validatie sneller en eenvoudiger —

Kleine series, hoge eisen. Onze snelprototyperingservice maakt validatie sneller en eenvoudiger —