Memahami Aliran Butir dalam Penempaan untuk Kekuatan yang Lebih Unggul

Memahami Aliran Butir dalam Penempaan untuk Kekuatan yang Lebih Unggul

RINGKASAN

Aliran butir bahan adalah penyelarasan berarah terhadap struktur hablur dalaman logam, yang dicapai melalui proses penempaan. Penyelarasan terkawal ini memaksa butir-butir tersebut mengikut kontur komponen, meningkatkan sifat mekanikalnya secara ketara. Hasilnya adalah komponen dengan kekuatan, ketahanan dan rintangan terhadap kelesuan serta hentaman yang lebih baik berbanding komponen yang dibuat melalui pengecoran atau pemesinan.

Apakah Itu Aliran Butir Bahan?

Untuk memahami aliran butir, seseorang mesti terlebih dahulu memahami struktur asas logam. Pada peringkat mikroskopik, semua logam terdiri daripada hablur individu yang dikenali sebagai butir. Dalam bahan mentah, seperti ingot tuang atau bar stok piawai, butir-butir ini biasanya berserabut dan tidak seragam dari segi orientasinya. Bayangkan seperti timbunan pasir—setiap butir tidak mempunyai arah kolektif. Titik-titik di mana butir-butir rawak yang berlainan ini bertemu dikenali sebagai sempadan butir.

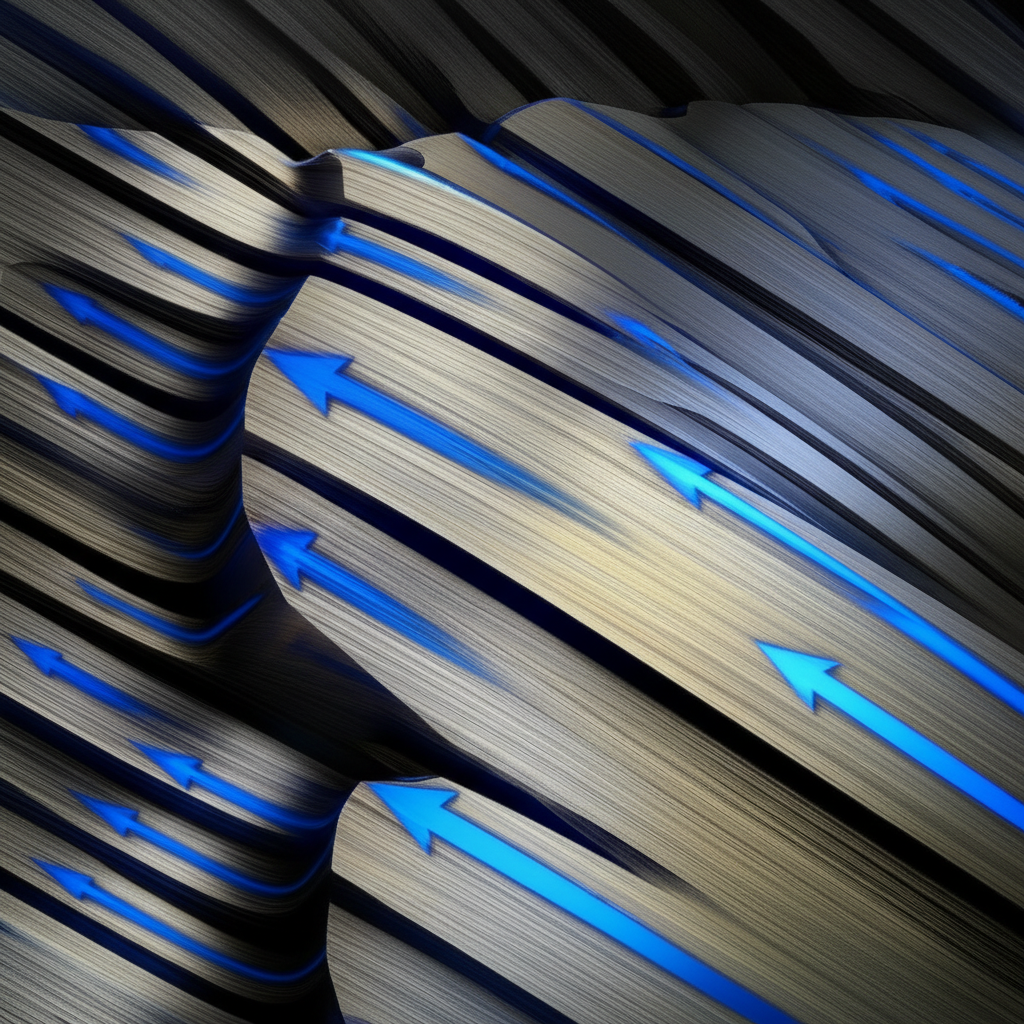

Aliran bijirin merujuk kepada orientasi berarah yang diambil oleh bijirin-bijirin ini apabila logam dikenakan perubahan plastik, seperti semasa proses tempa. Satu analogi yang baik ialah bijirin pada sekeping kayu. Papan kayu adalah paling kuat sepanjang arah bijirinnya dan lebih mudah pecah apabila daya dikenakan bertentangan dengannya. Begitu juga, komponen logam yang ditempa adalah paling kuat dalam arah aliran bijirinnya. Seperti yang diterangkan oleh pakar-pakar di Trenton Forging , penyelarasan berarah ini bukanlah kebetulan; ia adalah hasil yang disengajakan dan sangat menguntungkan daripada proses penempaan yang secara asasnya mengubah prestasi bahan di bawah tekanan.

Dalam komponen tempa, butiran-butiran diregangkan dan dipaksa selari dengan bentuk komponen tersebut. Ini mencipta struktur dalaman yang berterusan dan tidak terganggu. Berbeza dengan logam mentah yang mempunyai orientasi butiran rawak, komponen tempa mempunyai struktur yang dioptimumkan untuk kekuatan, mengarahkan daya dalaman sepanjang laluan berterusan ini berbanding sempadan butiran yang lebih lemah dan berorientasi secara rawak.

Proses Penempaan: Bagaimana Aliran Butiran Dicapai

Penciptaan aliran butiran yang optimum adalah hasil langsung proses penempaan, di mana logam dipanaskan hingga keadaan plastik (tidak dilebur) dan dibentuk menggunakan daya mampatan yang sangat besar. Proses ini melibatkan acuan yang direka dengan teliti untuk menekan atau memalu billet logam menjadi bentuk yang diingini. Apabila logam dipaksa bergerak dan mengikut rongga acuan, butiran dalaman logam tersebut turut terdeformasi, diregangkan, dan diselaraskan semula.

Arah aliran butiran ditentukan oleh rekabentuk acuan dan prosedur kerja panas. Seperti yang dinyatakan oleh Milwaukee Forge , ini membolehkan struktur bijirin 'mengalir' mengelilingi sudut dan mengikuti kontur komponen. Daripada dipotong, struktur bijirin diarahkan, memastikan penyusunan yang berterusan sepanjang komponen tersebut, terutamanya pada titik tekanan kritikal seperti sudut dan lekuk. Perubahan bentuk yang terkawal ini memadatkan logam, menutup mana-mana ruang dalaman yang mungkin wujud dalam bahan tuangan, serta memperhalus struktur bijirin kepada bentuk yang lebih kuat dan lebih mulur.

Proses ini penting untuk menghasilkan komponen prestasi tinggi. Bagi syarikat dalam sektor yang menuntut, pemanfaatan proses ini adalah perkara utama. Sebagai contoh, firma khusus dalam industri automotif menggunakan teknik penempaan lanjutan untuk menghasilkan komponen yang mampu menahan tekanan ekstrem. Salah satu penyedia tersebut, Shaoyi Metal Technology , mengkhususkan diri dalam penempaan panas yang bersijil IATF16949 untuk komponen automotif, menggunakan prinsip-prinsip ini bagi memastikan kebolehpercayaan dan prestasi maksimum dalam semua komponen, daripada prototaip keluaran kecil hingga komponen pengeluaran besar-besaran.

Pada akhirnya, proses penempaan bukan sahaja membentuk logam dari luar; malahan ia mengubahsuai struktur dalaman logam tersebut secara asas. Transformasi metalurgi inilah yang memberikan kekuatan dan ketahanan ciri khas kepada komponen ditempa, menjadikannya sangat penting untuk aplikasi yang kritikal terhadap keselamatan.

Kelebihan Mekanikal: Mengapa Aliran Butir Penting untuk Kekuatan Komponen

Sebab utama aliran butir sangat dihargai dalam pembuatan ialah peningkatan ketara yang dibawanya kepada sifat mekanikal sesuatu komponen. Dengan menyelaraskan struktur butir mengikut arah tegasan utama yang akan dialami komponen semasa digunakan, penempaan menghasilkan komponen yang jauh lebih unggul berbanding komponen dengan struktur butir rawak atau terputus. Peningkatan ini bukan kecil; malahan ia meningkatkan kebolehpercayaan dan jangka hayat komponen secara asas.

Manfaat utama aliran butir yang dioptimumkan termasuk:

- Kekuatan Regangan dan Impak yang Meningkat: Dengan pengaturan butiran sejajar, komponen ini dapat menahan daya regangan dan hentakan yang jauh lebih tinggi tanpa retak. Aliran berterusan ini mengagihkan tekanan merentasi keseluruhan panjang struktur butiran, mengelakkan kepekatan pada titik-titik lemah. Cornell Forge menekankan satu kajian yang menunjukkan komponen tempa boleh menunjukkan kekuatan regangan 26% lebih tinggi berbanding komponen tuangan.

- Rintangan Lesu yang Dipertingkatkan: Kegagalan lesu kerap bermula dengan retakan mikroskopik yang merebak melalui bahan di bawah beban kitaran. Pada komponen tempa, aliran butiran yang berterusan menentang perambatan retakan ini, memandangkan tiada sempadan butiran yang tiba-tiba bertindak sebagai laluan mudah untuk kegagalan. Ini menghasilkan jangka hayat perkhidmatan yang jauh lebih panjang dalam persekitaran bergetar tinggi atau tekanan tinggi.

- Kekenyalan dan Kekuatan yang Dipertingkatkan: Kekenyalan adalah keupayaan bahan untuk mengalami perubahan bentuk tanpa patah, manakala ketahanan adalah keupayaannya menyerap tenaga. Struktur biji yang diperhalus dan berarah pada komponen tempa meningkatkan kedua-dua sifat ini, menjadikan komponen lebih kenyal dan kurang berkemungkinan gagal secara rapuh apabila beban berlebihan.

Sifat-sifat ini bukan sekadar kelebihan teori; ia penting untuk aplikasi di mana kegagalan tidak boleh diterima, seperti dalam peralatan pendaratan aerospace, komponen stereng automotif, dan sambungan tekanan tinggi dalam industri minyak dan gas.

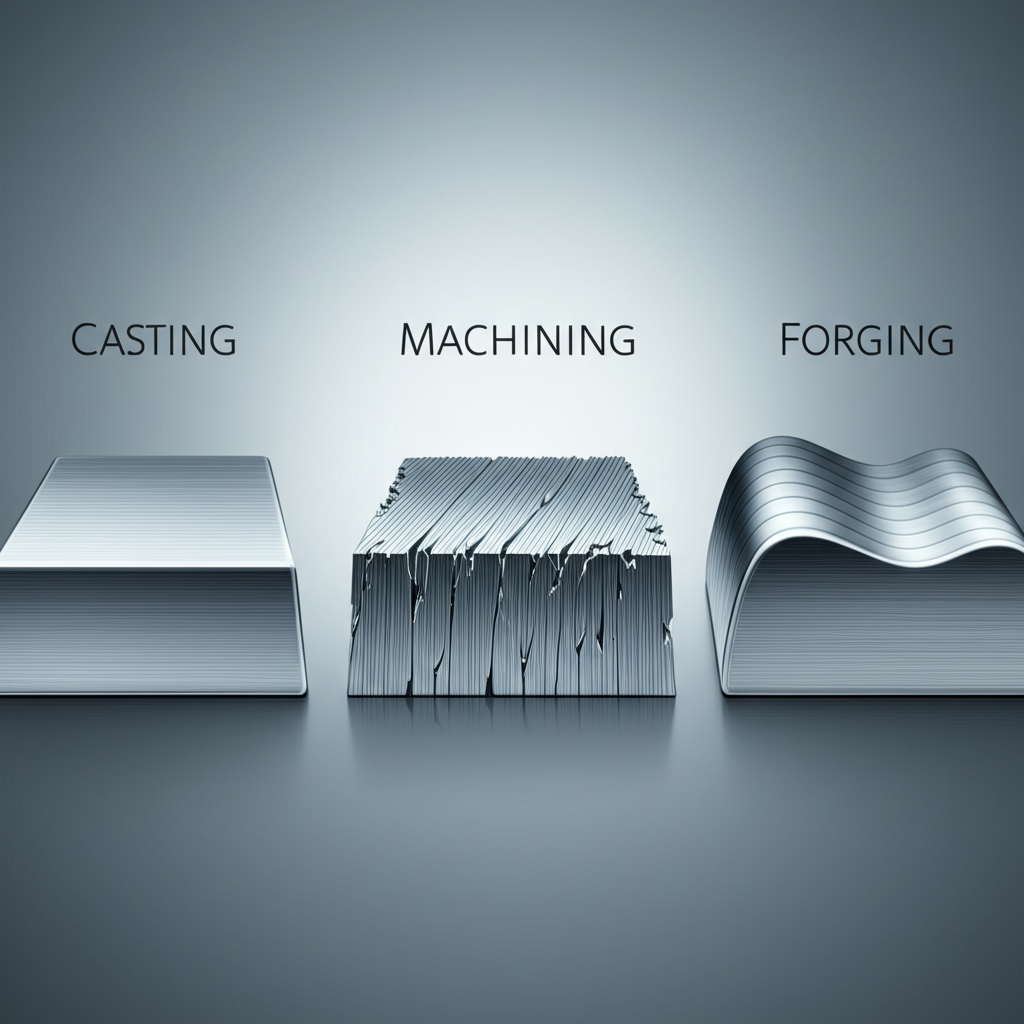

Aliran Biji dalam Penempaan berbanding Kaedah Pengeluaran Lain

Keunggulan penempaan menjadi jelas apabila dibandingkan struktur biji produknya dengan produk yang dihasilkan melalui pengecoran dan pemesinan. Setiap kaedah menghasilkan struktur dalaman yang secara asasnya berbeza, yang secara langsung memberi kesan kepada prestasi.

Penempaan berbanding Pengecoran: Pengecoran melibatkan menuang logam cair ke dalam acuan dan membiarkannya membeku. Proses ini menghasilkan struktur butiran rawak yang tidak berarah (equiaksed). Apabila logam menyejuk, ketidaksempurnaan seperti keropos (ruang halus) dan susutan boleh berlaku, mencipta titik lemah semula jadi. Bahagian tuangan tidak mempunyai aliran butiran berterusan seperti tempaan, bermakna rintangan terhadap hentaman dan kelesuan adalah jauh lebih rendah.

Tempaan berbanding Pemesinan: Pemesinan bermula dengan bar pepejal bahan asas yang sudah mempunyai aliran butiran unidireksional dari proses penggulungannya yang awal. Walau bagaimanapun, proses pemesinan melibatkan pemotongan bahan untuk mencapai bentuk akhir. Tindakan pemotongan ini memutuskan garis aliran butiran. Di mana sahaja aliran butiran dipotong, hujung butiran yang terdedah terbentuk, yang bertindak sebagai pengumpul tegasan dan titik potensi retak kelesuan bermula. Bahagian dimesin mungkin mempunyai bentuk yang diingini, tetapi kekuatan dalaman telah dikurangkan.

| Kaedah pengeluaran | Struktur Butir | Kekuatan & Ketahanan | Daya Tahan Lelah |

|---|---|---|---|

| Penempaan | Aliran berarah, berterusan mengikut bentuk komponen. Halus dan padat. | Tinggi | Tinggi |

| PENGCASTINGAN | Orientasi rawak, tidak berarah. Berpotensi untuk kereongan. | Terendah | Rendah |

| Pemesinan | Aliran searah terputus, mendedahkan hujung bijirin. | Baik, tetapi dikurangkan pada permukaan yang terpotong. | Lebih rendah disebabkan oleh bijirin yang terputus. |

Memeriksa dan Mengesahkan Aliran Biji

Memandangkan aliran biji yang betul adalah penting untuk prestasi komponen tempa, pengilang menggunakan kaedah kawalan kualiti untuk mengesahkannya. Proses pemeriksaan ini memastikan bahawa proses penempaan telah menghasilkan struktur dalaman yang dikehendaki dan bahawa komponen tersebut memenuhi spesifikasi kejuruteraannya. Pengesahan aliran biji merupakan kaedah pengujian merosakkan, maka ia biasanya dilakukan ke atas sampel komponen daripada kelompok pengeluaran.

Kaedah yang paling biasa untuk memvisualisasikan aliran butir melibatkan beberapa langkah utama. Pertama, satu sampel dikeluarkan daripada tempaan, biasanya di kawasan kritikal di mana tekanan dijangka paling tinggi. Permukaan yang dipotong kemudian digerus dan digilap dengan teliti sehingga mencapai permukaan seperti cermin. Penyediaan ini adalah penting untuk memastikan struktur dapat dilihat dengan jelas pada langkah seterusnya.

Selepas penggilapan, permukaan dirawat dengan bahan pendamai. Seperti yang diterangkan oleh pakar tempaan di Runchi Forging , ini merupakan larutan asid yang disapu ke atas permukaan yang telah digilap untuk menjadikan aliran butir kelihatan. Pemeriksa kemudian memeriksa permukaan yang didamai bagi mengesan garisan aliran yang berterusan dan tidak terganggu, yang mengikut kontur komponen tersebut. Mereka juga memeriksa sebarang kecacatan seperti kelupasan, lipatan, atau aliran balik, yang boleh menunjukkan masalah dalam proses penempaan dan menyebabkan titik lemah pada komponen akhir.

Kelebihan Penempaan: Ringkasan Kesan Aliran Butir

Memahami aliran butir bahan adalah kunci untuk menghargai mengapa penempaan kekal sebagai proses pengeluaran yang tidak dapat digantikan bagi komponen-komponen kritikal. Ia bukan sekadar kaedah membentuk logam, tetapi merupakan proses canggih yang memurnikan dan mengarahkan struktur dalaman logam bagi mencapai kekuatan dan kebolehpercayaan maksimum. Dengan menyelaraskan butiran logam mengikut kontur sesuatu komponen, penempaan menghasilkan bahagian-bahagian yang secara semula jadi lebih kuat dan lebih tahan terhadap kelesuan berbanding rakan sepadannya yang dicor atau dimesin.

Daripada perubahan bentuk awal dorong yang dipanaskan hingga pengesahan akhir struktur dalaman, setiap langkah direka untuk memanfaatkan kuasa aliran butir. Ini menghasilkan komponen yang memberikan keselamatan lebih tinggi, jangka hayat perkhidmatan yang lebih panjang, dan prestasi unggul dalam keadaan ekstrem, menjadikan penempaan pilihan terpercaya bagi industri di mana kegagalan bukan satu pilihan.

Soalan Lazim

1. Apakah arah aliran butir dalam penempaan?

Dalam penempaan, aliran bijirin sengaja diarahkan untuk mengikuti bentuk dan kontur bahagian tersebut. Semasa proses ini, daya mampatan daripada acuan menyebabkan bijirin dalaman logam berubah bentuk dan memanjang, menyelaraskan diri dalam arah pergerakan logam. Bagi penempaan yang direka dengan baik, ini bermakna aliran bijirin adalah berterusan dan tidak terputus, terutamanya di sekitar sudut dan bahagian yang akan menanggung tekanan paling tinggi.

2. Bagaimana cara memeriksa aliran bijirin dalam penempaan?

Aliran bijirin biasanya diperiksa melalui proses ujian merosakkan. Sampel dipotong daripada bahagian yang ditempa, dan permukaan potongan digerus, dipoles, kemudian dicelup dengan larutan asid. Asid bertindak balas dengan logam untuk mendedahkan corak struktur bijirin, menjadikan garis-garis aliran kelihatan. Pemeriksa kemudian memeriksa corak ini di bawah pembesaran untuk memastikan ia berterusan dan mengikut kontur bahagian seperti yang dirancang, tanpa sebarang kecacatan.

3. Apakah maksud aliran bijirin dalam kes komponen yang ditempa atau diguling?

Dalam komponen yang ditempa dan digulingkan, aliran bijirin merujuk kepada orientasi berarah bijirin hablur logam yang disebabkan oleh ubah bentuk plastik. Dalam penggulingan, bijirin dipanjangkan sepanjang bar atau kepingan. Dalam penempaan, penyelarasan berarah ini diperhalus lagi untuk mengikuti geometri khusus komponen tiga dimensi. Orientasi yang terkawal ini merupakan kelebihan utama, kerana ia meningkatkan sifat mekanikal seperti rintangan lesu dan kekuatan hentaman dalam arah yang penting kepada fungsi komponen tersebut.

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —