Stamping Die Machine Secrets: What Manufacturers Won't Tell You

What Is a Stamping Die Machine and How Does It Work

Ever wondered how the intricate metal components in your car, smartphone, or kitchen appliances are made with such precision? The answer lies in a powerful piece of equipment that transforms flat sheet metal into complex shapes in mere seconds.

A stamping die machine is a specialized metal stamping machine that uses controlled force and custom-designed tooling (dies) to cut, bend, or form sheet metal into precision components through a cold-forming process.

Unlike general-purpose metal press equipment, these machines rely on the die—the specialized tooling that determines exactly what shape and features the finished part will have. Think of it this way: the press provides the power, but the die provides the blueprint. Without a precisely engineered die, even the most powerful stamping press would produce nothing more than flattened metal.

The Core Mechanism Behind Metal Transformation

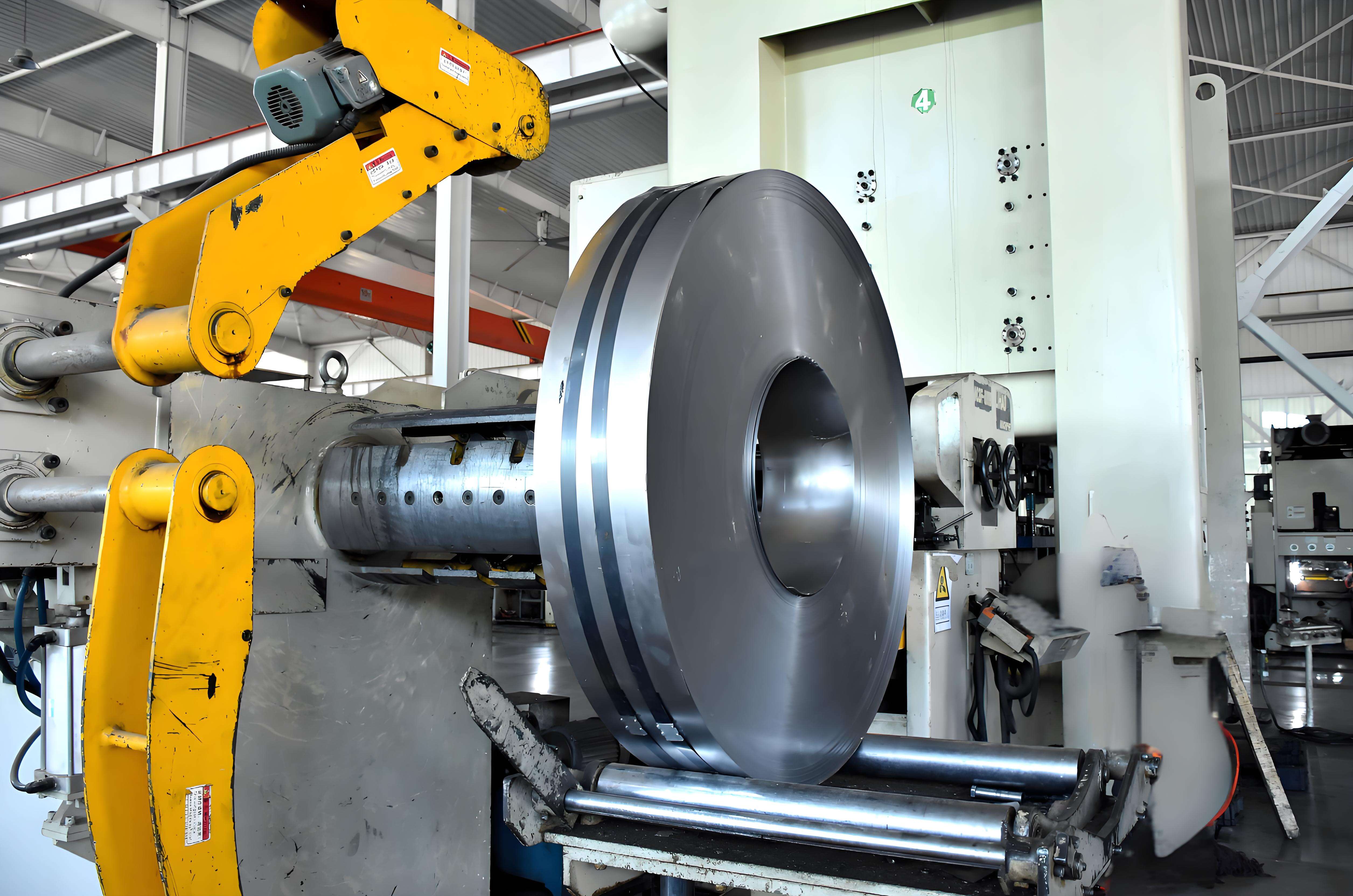

So, what is stamping at its core? The process begins when flat sheet metal feeds into the machine, either manually or through an automated coil system. The press mechanism then drives downward with tremendous force, pushing the upper portion of the die (called the punch) into the lower die cavity.

During this controlled impact, several things can happen simultaneously:

- The metal is cut to a specific outline (blanking)

- Holes are created (piercing or punching)

- The material is bent or formed into three-dimensional shapes

- Surface details are embossed or coined into the piece

The entire cycle—from feeding the material to ejecting the finished part—often takes less than a second. This speed, combined with remarkable repeatability, makes stamping one of the most efficient methods for producing high volumes of identical metal components.

Why Dies Make the Difference in Precision Manufacturing

Here's what separates a stamping die machine from ordinary press equipment: the die itself is a precision instrument, often engineered to tolerances measured in thousandths of an inch. Every curve, angle, and feature of your final part is determined by how the die is designed and manufactured.

When components are stamped and pressed through properly designed tooling, they emerge with consistent dimensions, clean edges, and exact specifications—part after part, shift after shift. This consistency is why industries with zero tolerance for error rely heavily on these machines.

Consider the scope of applications:

- Automotive: Body panels, brackets, engine components, and structural parts

- Aerospace: Lightweight structural elements and precision housings

- Electronics: Connectors, shielding, and heat sinks

- Appliances: Enclosures, internal frames, and decorative trim

According to industry sources, metal stamping serves countless industries worldwide, from medical machinery to telecommunications equipment. The process handles everything from simple flat washers to extremely intricate three-dimensional components that would be impossible to produce economically through other methods.

Understanding this fundamental relationship between the stamping press and its dies is your first step toward making informed decisions about metal forming equipment. In the sections ahead, you'll discover exactly what components make these machines work, which types suit different applications, and what manufacturers often leave out of their sales pitches.

Essential Components of Modern Stamping Die Machines

Now that you understand how these machines transform sheet metal into precision parts, let's pull back the curtain on what's actually inside. Most manufacturers gloss over the mechanical details, but understanding each component helps you evaluate equipment quality, troubleshoot problems faster, and make smarter purchasing decisions.

Every stamping machine—whether it's a compact benchtop unit or a thousand-ton production workhorse—contains the same core systems working in precise coordination. Here's what you need to know about each one.

Inside the Press Frame and Drive System

The frame is the backbone of any metal stamping press, and it must withstand tremendous dynamic forces without deflecting. Two frame designs dominate the industry:

- C-frame (gap frame): Provides easy access to three sides of the work area and takes up less floor space, but can experience angular deflection under heavy loads

- Straight-side frame: Features vertical columns that eliminate angular misalignment, delivering superior die life and part accuracy for demanding applications

The drive mechanism powers the press slide—the moving component that delivers forming force to your tooling. According to industry technical resources, mechanical drives use an electric motor spinning a flywheel, with a clutch engaging to transmit energy through a crankshaft to the ram. Hydraulic systems use fluid pressure for more controlled force application, while electro mechanical stamping systems with servo motors offer programmable motion profiles for complex forming operations.

The ram (also called the slide) is the workhorse that actually applies tonnage to your die. It moves vertically with each stroke, carrying the upper die half down into the workpiece. Ram parallelism and consistent stroke length directly affect part quality—even slight variations can cause dimensional problems or premature die wear.

Feed Systems That Keep Production Moving

Your stamping machinery is only as productive as its ability to move material into position quickly and accurately. Modern metal stamping equipment uses several feed system types:

- Coil feeds: Unroll strip material from large coils for continuous high-volume production

- Servo feeds: Use precision motors for exact positioning, enabling higher speeds and reduced scrap

- Air feeds: Pneumatically powered systems suitable for lighter-duty applications

- Gripper feeds: Mechanically advance material a set distance, release, and return for the next cycle

High-volume operations often use integrated 3-in-1 systems that combine decoiling, straightening, and feeding into a single synchronized unit. This eliminates alignment issues between separate machines and dramatically reduces changeover time.

The control system ties everything together. Modern stamping machines rely on PLCs (Programmable Logic Controllers) that coordinate feed timing, ram position, and safety interlocks. Sensors monitor critical parameters throughout each cycle, while safety systems—including light curtains, physical guards, and emergency stops—protect operators from the tremendous forces involved.

| Component | Function | Impact on Production Quality |

|---|---|---|

| Frame | Structural support for all press components | Rigidity prevents deflection; affects dimensional accuracy and die life |

| Ram (Slide) | Delivers vertical force to upper die | Parallelism and stroke consistency determine part uniformity |

| Bolster Plate | Supports lower die half; absorbs working forces | Flatness and rigidity ensure proper die alignment |

| Die Set | Punch and die combination that shapes material | Precision engineering determines final part geometry and tolerances |

| Drive System | Powers ram movement (mechanical, hydraulic, or servo) | Affects speed capability, force control, and energy efficiency |

| Feed System | Positions material for each stamping cycle | Accuracy prevents misfeeds; speed determines production rate |

| PLC Controls | Coordinates timing and monitors press operation | Enables consistent cycles and real-time quality monitoring |

| Safety Interlocks | Prevents operation when guards are open or hazards exist | Protects operators; required for regulatory compliance |

During a complete stamping cycle, these components work in precise sequence: the feed system advances material into position, the PLC verifies all safety conditions are met, the drive engages to move the ram downward, the die set performs its forming operation, and the ram retracts while the feed prepares the next section of material. This entire sequence often completes in under a second on high-speed equipment.

Understanding how these systems interact helps you identify weak points in your production line and ask the right questions when evaluating new equipment. With the mechanical foundation covered, let's explore the different types of stamping machines available and which applications each one handles best.

Types of Stamping Die Machines and Their Applications

Choosing between stamping presses isn't just about picking the biggest or fastest machine available. Each type of stamping die machine brings distinct advantages—and limitations—that directly impact your production efficiency, part quality, and bottom line. The secret manufacturers rarely share? The "best" machine doesn't exist. Only the best machine for your specific application does.

Let's break down the four major categories of metal stamping presses so you can match the right equipment to your production requirements.

Mechanical vs Hydraulic Press Performance Characteristics

Mechanical presses dominate high-volume production environments for good reason. These machines use an electric motor spinning a flywheel to store kinetic energy, which a clutch releases through a crankshaft to drive the ram downward. The result? Exceptionally fast cycle times and consistent stroke characteristics that make them ideal for repetitive operations.

What makes mechanical presses stand out:

- Speed: Capable of 20-1,500+ strokes per minute depending on size and configuration

- Consistency: Fixed stroke length ensures identical forming conditions every cycle

- Efficiency: Flywheel energy storage means high production rates with moderate energy consumption

- Durability: Simpler mechanical systems often mean longer service life and easier maintenance

However, mechanical presses have limitations. According to industry experts, they offer less control at the bottom of the stroke compared to hydraulic systems. This makes them less suitable for deep drawing operations or applications requiring variable force profiles.

A hydraulic stamping press takes a completely different approach. Instead of stored kinetic energy, these machines use pressurized fluid to generate forming force. The hydraulic cylinder provides full tonnage throughout the entire stroke—not just at the bottom dead center like mechanical systems.

Where hydraulic presses excel:

- Force flexibility: Adjustable pressure allows fine-tuning for different materials and operations

- Deep drawing capability: Controlled force throughout the stroke prevents tearing during complex forming

- Heavy materials: Preferred for high-tensile materials requiring sustained pressure

- Versatility: One machine can handle a wider range of applications with simple adjustments

The trade-off? Hydraulic systems run slower than their mechanical counterparts. If you're stamping thousands of simple parts per hour, a high speed stamping press with mechanical drive will outperform hydraulic equipment every time. But for complex stamped metal parts requiring precise force control, hydraulic wins.

When Servo Technology Delivers Superior Results

Servo presses represent the newest evolution in metalforming presses. These machines replace traditional flywheels and clutches with advanced servo motors that provide unprecedented control over ram motion, speed, and force throughout every millisecond of the forming cycle.

Imagine programming your press to move slowly during initial material contact, accelerate through the forming portion of the stroke, pause briefly for material flow, then retract at maximum speed. That's the power of servo technology—complete motion customization for each unique application.

Key servo press benefits include:

- Programmable motion profiles: Tailor ram speed and dwell time to optimize each operation

- Energy efficiency: Motors only consume power during active work, reducing operating costs by 30-50% compared to continuously running flywheel systems

- Reduced noise: Controlled deceleration eliminates the impact shock common in mechanical presses

- Quick setup changes: Store multiple programs for instant switching between different parts

The higher upfront investment in servo technology pays dividends for operations running multiple part numbers, requiring tight tolerances, or working with difficult-to-form materials. Medical device manufacturers and electronics producers particularly favor servo systems for their precision capabilities.

Transfer presses add another dimension: multi-station capability. These specialized machines move workpieces through a series of die stations, performing different operations at each stop. A single transfer press might blank, pierce, form, and trim a part in one automated sequence—eliminating manual handling between operations and dramatically boosting productivity for complex components.

Matching Press Type to Die Requirements

Understanding types of stamping dies helps clarify which press technology fits your needs:

- Progressive dies require presses with exceptional ram parallelism and consistent stroke since the strip material moves through multiple stations without leaving the die

- Transfer dies need machines with integrated part-handling automation and precise station-to-station timing

- Line dies (single-operation) can run on simpler equipment since each press performs just one forming step

| Press Type | Tonnage Range | Stroke Speed (SPM) | Energy Consumption | Best Applications | Material Thickness |

|---|---|---|---|---|---|

| Mechanical | 10-6,000+ tons | 20-1,500+ | Moderate (flywheel storage) | High-volume blanking, piercing, shallow forming | 0.005"-0.250" typical |

| Hydraulic | 10-10,000+ tons | 5-50 | Higher (continuous pumping) | Deep drawing, heavy materials, variable force needs | 0.020"-1.0"+ possible |

| Servo | 10-4,000+ tons | 10-300 (programmable) | Low (on-demand power) | Precision parts, difficult materials, frequent changeovers | 0.005"-0.375" typical |

| Transfer | 200-3,000+ tons | 10-80 | Moderate to high | Complex multi-operation parts, large stampings | 0.030"-0.500" typical |

When evaluating metal stamping presses for your operation, consider not just current needs but future flexibility. A servo press might cost more initially, but its adaptability could eliminate the need for multiple dedicated machines. Conversely, if you're running millions of identical simple parts, the proven reliability of mechanical presses may deliver better long-term value.

Now that you understand the equipment options available, how do you actually calculate which machine specifications match your specific part requirements? That's exactly what we'll cover next.

How to Choose the Right Stamping Die Machine

Here's what manufacturers rarely tell you upfront: selecting the wrong stamping machine for metal applications costs far more than the price difference between models. Undersized equipment struggles and fails prematurely. Oversized machines waste energy and floor space while delivering no additional value. The sweet spot? A methodical evaluation process that matches machine capabilities to your actual production requirements.

Whether you're investing in your first steel stamping press or expanding an existing operation, these selection criteria will help you avoid expensive mistakes.

Calculating the Right Tonnage for Your Parts

Tonnage is the starting point for every stamping machine purchase—and it's where most buyers make their first mistake. Simply adding up the force needed for your primary forming operation isn't enough.

According to industry experts at The Fabricator, accurate tonnage calculations must account for every load-producing element in your die:

- Primary operations: blanking, piercing, drawing, forming, bending, and coining

- Secondary forces: spring stripper pressures, strip lifter pins, nitrogen pressure pads

- Ancillary loads: driven cams, skeleton scrap cutting, pilot hole punching

The calculation formula requires knowing your material's shear strength (for cutting operations) or ultimate tensile strength (for drawing operations), material thickness, and the total cutting perimeter or forming area. Once you've recorded loads at each station, add them together for total required tonnage.

But here's what many manufacturers won't emphasize: tonnage alone doesn't guarantee success. You must also calculate energy requirements. Insufficient energy—even with adequate tonnage—causes press jams at bottom dead center. This common oversight results in costly downtime and potential equipment damage.

A practical rule of thumb? Size your metal stamping machines at 70-80% of rated capacity for your heaviest jobs. This provides a safety margin for material variation while avoiding the inefficiency of grossly oversized equipment.

Matching Machine Capability to Material Specifications

Your material selection directly constrains your machine options. A pressure stamp operation on thin aluminum requires completely different equipment than forming high-strength automotive steel.

Critical material considerations include:

- Material thickness range: Each press has minimum and maximum thickness capabilities based on tonnage, daylight opening, and shut height

- Material width: Must fit within the bed width with adequate margin for feeding and guidance

- Material properties: High-strength steels require more tonnage per inch than mild steel; aluminum needs different clearances than steel

- Coil weight capacity: For continuous operations, your decoiler must handle full production coils

According to equipment selection guides, for punching or forming 1/8-inch mild steel, you need a minimum of 30-50 tons depending on the surface area being worked. Always calculate exact force requirements using shear strength formulas rather than relying on general estimates.

A steel stamp machine rated for heavy-gauge materials often lacks the precision controls needed for thin foil work. Conversely, a metal stamp machine optimized for electronics components won't survive long forming thick brackets. Match the machine to your material reality—not your hopes for future versatility.

Evaluating Bed Size, Stroke, and Speed Requirements

Beyond tonnage, these mechanical specifications determine whether a machine actually fits your production needs:

- Bed size (bolster area): Must accommodate your largest die with room for clamping. The press tonnage rating assumes loads distributed over two-thirds of the bed area—exceeding this concentration risks deflection problems

- Shut height: The distance between bolster and ram at bottom dead center must exceed your die's closed height

- Stroke length: Must allow adequate clearance for part ejection and material feeding

- Strokes per minute: Match production volume requirements without exceeding safe feed system speeds

High-volume automotive work might demand 400+ strokes per minute, while heavy forming operations may run at 15-20 SPM. Your target production rate, multiplied by shifts per day and days per year, determines whether high-speed capability justifies its premium cost.

Production Volume and Die Investment Decisions

Here's the question that separates smart buyers from struggling operations: when does progressive die investment make sense versus simpler compound or single-operation tooling?

Progressive dies cost significantly more than compound dies—often 3-5 times as much for complex parts. But they dramatically reduce per-piece cost at high volumes by completing multiple operations in a single press stroke. The breakeven analysis depends on:

- Annual volume: Progressive dies typically justify investment above 100,000-500,000 pieces annually

- Part complexity: More operations favor progressive tooling

- Labor costs: Progressive dies eliminate handling between operations

- Quality requirements: Single-setup production reduces dimensional variation

Lower volumes might favor compound dies (performing multiple operations in one stroke but on individual blanks) or even secondary operations on simpler equipment. Don't let tooling salespeople push progressive solutions for applications where simpler approaches deliver better economics.

Critical Evaluation Criteria in Order of Importance

When comparing metal stamping machines, prioritize these factors:

- Tonnage capacity: Must exceed calculated requirements with appropriate safety margin

- Bed size and shut height: Must accommodate current and anticipated die sizes

- Stroke speed range: Must match production volume targets

- Automation compatibility: Feed systems, part extraction, and control integration

- Floor space requirements: Including coil handling, scrap removal, and operator access

- Energy efficiency: Servo systems reduce operating costs 30-50% versus conventional drives

- Maintenance accessibility: Easy access reduces downtime and service costs

- Safety systems: Light curtains, guards, and interlocks meeting ANSI B11.1 standards

- Dealer support: Parts availability and service response time in your region

Remember: the cheapest stamping machine is never the one with the lowest purchase price—it's the one delivering the lowest cost per quality part over its operational lifetime. With your machine selection criteria established, understanding the specific stamping operations these machines perform helps you match equipment capabilities to your production requirements.

Stamping Operations and Machine Requirements

You've selected the right tonnage, matched your material specifications, and identified the ideal press type. But here's what truly determines production success: understanding exactly what happens during each stamping operation—and which machine characteristics make those operations possible.

Every die press performs one or more fundamental operations. Some cut material. Others shape it. Many do both simultaneously. Knowing how each operation works helps you specify equipment that delivers consistent results rather than constant headaches.

From Blanking to Coining in a Single Stroke

Let's walk through the core operations your stamping die machine can perform, along with the specific equipment requirements for each:

Blanking separates a complete part from the surrounding sheet material. The punch pushes through the workpiece while the die provides the cutting edge below. What makes this operation demanding? The entire cutting perimeter engages simultaneously, requiring sufficient tonnage to shear through the material cleanly. Machines with rigid frames and minimal deflection produce parts with consistent edge quality and dimensional accuracy.

Piercing creates holes within the part—essentially blanking in reverse, where the slug becomes scrap and the surrounding material becomes your product. Press stamping for piercing operations demands precise punch-to-die alignment. Even slight misalignment accelerates tool wear and produces burrs that require secondary finishing.

Forming bends and shapes material without removing any of it. This includes:

- Simple bends along straight lines

- Complex curves and contours

- Flanges and hems

- Stiffening ribs and beads

Forming operations require machines with controlled force application throughout the stroke. Springback—the material's tendency to partially return toward its original shape—means your equipment must deliver enough force to overcome elastic recovery. Hydraulic and servo presses often excel here because of their adjustable pressure profiles.

Drawing creates depth by pulling flat material into a die cavity, forming cups, boxes, shells, and other three-dimensional shapes. This operation stresses stamping metal in multiple directions simultaneously, making it one of the most demanding processes. Machines performing deep drawing need:

- Consistent force throughout the entire stroke (not just at bottom dead center)

- Precisely controlled blank holder pressure to prevent wrinkling

- Appropriate stroke speed—too fast causes material tearing

Coining applies extreme compression to flow material into precise die cavities, creating fine details and tight tolerances. Currency production is the classic example, but industrial applications include electrical contacts and precision bearing surfaces. Coining requires significantly higher tonnage than other operations—often 3-5 times the force needed for blanking the same material. Your press stamp equipment must deliver this force without frame deflection that would compromise dimensional accuracy.

Embossing creates raised or recessed surface features without cutting through the material. Logos, text, and decorative patterns are common applications. While embossing requires less tonnage than coining, it demands excellent die alignment and consistent ram parallelism to produce uniform impressions across the entire part surface.

Progressive Die Operations and Machine Precision Requirements

Here's where stamping and pressing efficiency reaches its peak: progressive dies combine multiple operations into a single tool, performing them in sequence as strip material advances through the die.

According to industry resources, progressive die stamping is a high-volume, high-performance process that performs multiple operations in a single press cycle. Each station in the die handles a specific task, and the finished part emerges at the final station—often at rates exceeding 100 parts per minute.

A typical progressive die for press follows this operational sequence:

- Pilot holes: Precision holes punched first to locate the strip accurately at each subsequent station

- Piercing: Interior holes and features created while material is flat

- Notching: Material removed from strip edges to allow forming without interference

- Forming: Bends and shapes created progressively, often over multiple stations

- Blanking: Final separation of the completed part from the carrier strip

What machine characteristics do progressive dies demand? The requirements are stringent:

- Precise ram parallelism: The ram must remain perfectly parallel to the bolster throughout the stroke. Any angular deviation causes uneven cutting and accelerated die wear

- Consistent stroke length: Variation in bottom dead center position produces dimensional inconsistencies in formed features

- Accurate feeding: Strip must advance exactly the same distance every cycle—feed accuracy within ±0.001" is common for precision work

- Robust frame rigidity: With multiple operations loading the die simultaneously, frame deflection must remain minimal under peak forces

The die for press relationship in progressive tooling is particularly critical. Even high-quality machines cannot compensate for poorly designed dies, and even the best dies will underperform in machines lacking the precision these operations demand.

Understanding these operational requirements helps you ask better questions when evaluating equipment—and recognize when a machine's specifications truly match your production needs. Of course, even the best equipment requires proper care to maintain peak performance, which brings us to maintenance practices that prevent costly downtime.

Maintenance and Operational Best Practices

Here's what separates profitable stamping operations from those constantly fighting equipment failures: a disciplined maintenance program that prevents problems before they shut down production. Yet this is exactly what most equipment manufacturers barely mention—they're focused on selling machines, not keeping them running for decades.

Whether you're operating a stamper machine in a high-volume automotive plant or running shorter production batches, these maintenance protocols protect your investment and keep parts flowing. Let's break down what every stamping press operator should know.

Daily and Weekly Maintenance Routines That Prevent Downtime

Consistent daily attention catches small issues before they become expensive repairs. According to industry maintenance guides, before each shift the brake shaft points should be filled with lubricant, and clutch parts require daily oil pressure lubrication. Clean the machine before stopping each shift—a simple habit that pays dividends.

Why does cleanliness matter so much? A clean press allows operators and maintenance personnel to detect problems as soon as they occur. When your sheet metal stamping equipment is free of debris and oil residue, identifying the location of leaks, breaks, or unusual wear becomes significantly easier.

Daily maintenance checklist:

- Check and replenish lubrication at all specified points

- Inspect safety devices—light curtains, guards, and emergency stops

- Verify air pressure readings are within normal operating range

- Listen for unusual sounds during startup and operation

- Check for visible oil or air leaks around seals and fittings

- Remove accumulated scrap and debris from die area and bolster

- Drain water from pneumatic system reservoirs

Weekly maintenance tasks:

- Inspect die stamp components for wear, chipping, or damage

- Check fasteners and tighten any that have loosened

- Verify feed system alignment and timing accuracy

- Examine belt condition for cracks, fraying, or glazing

- Test clutch engagement and brake response times

- Review lubrication system filters and reservoirs

Pneumatic systems deserve special attention because they control your brakes and balancing systems. As equipment experts note, improper air pressure affects brake performance and balance system function—these systems control stopping time, and failures put both operators and equipment at risk.

Monthly and Annual Maintenance Requirements

Beyond daily and weekly routines, your metal stamper machine requires deeper periodic inspection:

Monthly tasks:

- Verify press alignment and ram parallelism using precision measuring equipment

- Inspect crankshaft bearings for excessive wear or play

- Check electrical circuits, motor condition, and solenoid operation

- Examine clutch friction plates and brake linings for wear

- Review lubricating device function and oil quality

- Measure slide gib clearances and adjust if necessary

Annual overhaul items:

- Complete press accuracy verification and recalibration

- Inspect crankshaft guide surfaces for wear patterns

- Examine body table coupling bolts and preload settings

- Replace lubricants and filter screens throughout the system

- Check flywheel balance and bearing condition

- Verify closing block and closing ring condition

A precisely balanced press performs better, so annual inspections should include balance verification. Replace lubricant screens at the same time you change oil—many operators neglect screen changes when operating circulating oil systems, leading to contamination issues that accelerate wear.

Die Maintenance for Extended Tool Life

Your dies represent a significant investment, and proper maintenance dramatically extends their productive lifespan:

- Sharpening intervals: Monitor burr height on stamped parts—when burrs exceed acceptable limits, dies need resharpening. Typical intervals range from 50,000 to 500,000 hits depending on material and die steel quality

- Clearance adjustments: As dies wear, punch-to-die clearance increases. Regular measurement ensures clearances remain within specification

- Spring replacement: Stripper springs lose tension over time. Replace before they fail to properly strip parts from punches

- Component inspection: Check pilots, bushings, and guide pins for wear that affects alignment accuracy

Implementing SMED for Faster Die Changeovers

Want to know a methodology that transformed manufacturing but rarely gets explained? SMED—Single-Minute Exchange of Die—was developed by Shigeo Shingo at Toyota in the 1960s and 1970s to reduce costly inventories and improve efficiency. According to lean manufacturing resources, large stamping dies that commonly took hours to change now swap out in under 10 minutes using these techniques.

The core concept? Distinguish between work performed while the press is stopped (Internal Setup) and preparatory work done while the press is still running (External Setup). Before SMED, almost all changeover work happened with the machine down.

SMED implementation follows four stages:

- Document current state: Record every step of your existing changeover process

- Separate internal and external setup: Identify which tasks truly require the machine to be stopped

- Convert internal to external: Move as many tasks as possible to occur while production continues

- Streamline remaining operations: Optimize both internal and external tasks for maximum speed

Practical techniques that slash changeover time include:

- Staged tooling: Have the next die ready on a dedicated cart beside the press

- Parallel operations: Multiple team members work simultaneously rather than sequentially

- Standardized die heights: Common shut height settings eliminate adjustment time

- Quick-release clamps: Replace bolts requiring multiple turns with cam-action or hydraulic clamping

- Roller tables or die carts: Move heavy dies faster than forklifts or cranes allow

- Pre-set tooling: Adjust and verify dies before bringing them to the press

The benefits extend far beyond saved minutes. Reduced changeover time enables smaller production batches, lower inventory costs, faster response to customer demands, and increased machine utilization. Operations that once avoided changeovers by building excess inventory can now run just-in-time production.

Operator Training and Safety Protocols

Even the best-maintained equipment becomes dangerous without properly trained operators. Safety must be integrated into every aspect of stamping operations:

- Develop targeted safety operating procedures based on specific press types and processing requirements

- Provide thorough job training before allowing independent operation

- Ensure operators understand and follow manufacturer safety instructions

- During maintenance, verify locking and lockout procedures are performed correctly

- Position the slide at bottom dead center before performing brake maintenance

- Never bypass or disable safety interlocks—they exist for critical reasons

Regular refresher training reinforces safe habits and introduces operators to updated procedures. Document all training and maintain records demonstrating compliance with OSHA and ANSI B11.1 requirements.

With proper maintenance protocols established and operators trained, you'll minimize unplanned downtime. But when problems do occur—and they inevitably will—knowing how to diagnose and resolve them quickly separates efficient operations from those constantly struggling with quality issues.

Troubleshooting Common Stamping Die Machine Problems

Even with disciplined maintenance, problems happen. Parts come off the press with burrs. Dimensions drift out of specification. Surface defects appear without warning. When production grinds to a halt, the pressure to fix things fast can lead to guesswork—and guesswork often makes problems worse.

Here's what experienced troubleshooters know: every defect tells a story. The key is reading that story correctly. By understanding the stamping definition of each defect type and tracing symptoms back to their root causes, you can resolve issues systematically rather than throwing adjustments at random.

Diagnosing the Source of Part Defects

When stamped metal parts fail inspection, the problem originates from one of four sources: the machine, the die, the material, or the process parameters. Jumping straight to die adjustments when the real culprit is material variation wastes time and can create new problems.

Start your diagnosis by asking these questions:

- When did the problem start? Sudden onset suggests a specific event—tool breakage, material lot change, or setup error. Gradual degradation points to wear-related issues.

- Is the defect consistent or intermittent? Consistent problems usually indicate die or machine issues. Intermittent defects often trace back to material variation or feed system irregularities.

- Does the defect appear in the same location on every part? Location-specific problems suggest localized die wear or damage. Random positioning points toward material or process variables.

- Did anything change recently? New material supplier, operator, die sharpening, or machine maintenance can all introduce variations.

According to industry troubleshooting resources, a die-stamping machine in use is prone to different amounts of wear on each side position of the punch core. Some parts experience larger scratches and wear faster—this situation is particularly pronounced on thin and narrow rectangular dies.

Let's examine the most common defects and their diagnostic pathways:

Burr formation appears as sharp raised edges or rolls of excess material along cut edges. The primary cause? Clearance between punch and die. As precision stamping experts explain, preventing burrs requires precision grinding of punches and dies for proper clearance control. Worn cutting edges also produce burrs—when tooling dulls, it tears rather than shears the material cleanly.

Part distortion shows as warped, twisted, or dimensionally inconsistent stamped steel components. Causes include uneven pressure distribution across the part, non-parallel upper and lower dies, temperature variations during forming, and material springback that wasn't adequately compensated. According to industry sources, managing springback requires over-bending and applying appropriate bend compensation during die design.

Inconsistent dimensions frustrate quality control when parts measure correctly one hour and fail specification the next. Feed accuracy problems—the strip advancing slightly more or less than intended—create variation in feature locations. Die wear gradually increases clearances and changes formed dimensions. Press setting drift, particularly in stroke depth, affects formed feature height and drawn depths.

Surface defects including scratches, galling, and staining degrade part appearance and can affect function. Lubrication issues rank among the most common causes—insufficient lubricant allows metal-to-metal contact that transfers material between die and part. Die damage from foreign objects or material slugs creates repeating marks on every subsequent part.

Problem-Cause-Solution Quick Reference

When you need answers fast, this matrix provides a starting point for diagnosis:

| Problem | Common Causes | Solutions |

|---|---|---|

| Excessive burrs | Worn punch/die edges; incorrect clearance; dull tooling | Resharpen cutting edges; adjust or regrind for proper clearance; replace worn components |

| Part distortion/warping | Uneven blank holder pressure; non-parallel dies; material springback | Adjust pressure pads; verify press parallelism; modify die for springback compensation |

| Dimensional variation | Feed inaccuracy; die wear; inconsistent stroke depth; material thickness variation | Calibrate feed system; inspect and refurbish dies; check press settings; verify incoming material |

| Surface scratches/galling | Insufficient lubrication; die surface damage; material buildup on tooling | Increase lubrication or change lubricant type; polish die surfaces; clean and coat tooling |

| Cracking/tearing | Excessive tonnage; worn tooling corners; improper material properties; insufficient lubrication | Reduce force; resharpen radii; verify material specification; improve lubrication |

| Uneven wear across die | Misaligned turret; poor die/guide precision; improper clearance; worn guide bushings | Realign mounting; replace guide components; verify clearances; use full-guide dies |

| Slug pulling | Insufficient die clearance; vacuum effect; worn punch | Increase clearance; add slug ejection features; replace worn punches |

| Mislocated features | Worn pilots; loose components; feed system errors; progressive die station misalignment | Replace pilots and bushings; tighten fasteners; calibrate feeds; realign die stations |

When to Repair vs Replace Stamping Dies

Every precision stamp eventually wears beyond economical repair. But replacing dies prematurely wastes tooling investment, while running worn dies too long produces scrap and risks catastrophic failure. Here's how to make the right call:

Repair makes sense when:

- Wear is localized to replaceable components—punches, pilots, bushings, springs

- Cutting edges can be resharpened without exceeding allowable grind limits

- Dimensional accuracy remains within specification after adjustment

- Total repair cost stays below 40-50% of replacement cost

- Die construction allows proper refurbishment without compromising structural integrity

Replacement becomes necessary when:

- Core die components—die blocks, punch holders, die shoes—show significant wear or damage

- Cumulative grinding has consumed available sharpening allowance

- Part geometry or tolerances have changed, requiring die modification beyond practical limits

- Repair frequency has increased to the point where downtime costs exceed replacement investment

- Die technology has advanced enough that new tooling offers significant productivity gains

According to troubleshooting experts, maintaining alignment is critical to die longevity. Regularly using alignment mandrels to check and adjust machine turret and mounting base alignment extends die life significantly. Timely replacement of guide bushings and selection of convex and concave molds with suitable clearance also prevents premature wear.

Track your die history: number of hits, sharpening cycles, repair costs, and quality trends. This data reveals when dies are approaching end-of-life and helps justify replacement investments before quality problems escalate.

Understanding how to diagnose and resolve these common issues keeps your operation running efficiently. But troubleshooting is only part of the equation—knowing the true costs of stamping operations and how to optimize your return on investment separates profitable operations from those constantly struggling with margins.

Cost Considerations and ROI for Stamping Operations

Here's what stamping press manufacturers rarely discuss during the sales process: the purchase price represents only a fraction of your true investment. The machine sitting on your floor accumulates costs every day—some obvious, others hidden until they appear on your financial statements months later.

Understanding total cost of ownership separates operations that thrive from those constantly surprised by budget overruns. Whether you're evaluating a metal stamping press machine for a new production line or analyzing an existing operation's profitability, this framework reveals where your money actually goes.

Calculating True Cost Per Stamped Part

Every stamped component carries a cost burden far beyond raw material. According to automotive stamping cost analysis, the core estimation formula is: Total Cost = Fixed Costs (Design + Tooling + Setup) + (Variable Cost/Unit × Volume). Simple enough—but accurately calculating each element requires detailed analysis.

Your total cost of ownership breaks down into distinct categories:

- Initial machine investment: Purchase price, installation, training, and facility modifications for your stamping press machine

- Die tooling costs: Custom dies range dramatically—from approximately $5,000 for simple blanking dies to over $100,000 for complex progressive dies with multiple forming stations

- Operational expenses: Energy consumption, preventive maintenance, unplanned repairs, and labor costs per shift

- Consumables: Lubricants, replacement punches, springs, and wear components that require regular replenishment

- Quality control: Inspection equipment, measurement systems, and the engineering hours required for validation

- Scrap and rework: Material waste and labor costs when parts fail specification

For an industrial stamping machine running production, material costs often account for 60-70% of the variable piece price. But here's what catches many operations off guard: machine hourly rates vary dramatically based on press tonnage and energy consumption. A 600-ton press commands a significantly higher hourly rate than a 100-ton unit due to energy and amortization factors.

The efficiency calculation matters too. As industry sources note, efficiency is never 100%—factor in coil changes, maintenance intervals, and unplanned downtime when calculating true machine costs. Most operations achieve 80-85% Overall Equipment Effectiveness (OEE), meaning your actual cost per part runs higher than theoretical calculations suggest.

How Production Volume Affects Per-Part Economics

Unlike processes where costs remain relatively flat per unit, stamping follows an asymptotic curve where cost per part drops precipitously as volume increases. Understanding this relationship determines whether your investment makes financial sense.

Consider the math on tooling amortization. If a progressive die costs $80,000 but produces 500,000 parts over five years, the tooling add-on is just $0.16 per part. Conversely, for a run of only 5,000 parts, that same die adds $16.00 per part—likely making the project economically unviable for stamping.

When does progressive die investment justify itself versus simpler alternatives? The volume threshold typically falls between 10,000 to 20,000 parts annually, where the efficiency of progressive tooling offsets its substantial initial price tag. For automotive projects exceeding 10,000 units annually, investing in complex progressive dies typically yields the lowest total cost of ownership by drastically reducing cycle times and labor.

Stamping press manufacturers often emphasize speed capabilities without explaining this economic reality. A high-speed industrial metal stamping machine running at 400 strokes per minute delivers incredible per-part efficiency—but only if your volume justifies the tooling investment required to achieve those rates.

How Die Quality Impacts Long-Term Production Economics

The largest barrier to entry is tooling, and die quality directly determines your long-term cost structure. A precision-engineered die machined from hardened tool steel withstands millions of impact cycles, while cheaper alternatives require frequent maintenance and earlier replacement.

Factors affecting die longevity and replacement cycles include:

- Tool steel quality: High-grade hardened steel (like carbide or D2) enables million-strike guarantees versus shorter lifespans from lesser materials

- Engineering precision: Proper clearances and optimized geometry reduce wear rates and extend sharpening intervals

- Maintenance discipline: Regular inspection and timely resharpening prevent cascading damage

- Material compatibility: Dies designed for your specific material properties last longer than generic solutions

Budget for die maintenance—typically 2-5% of tooling cost annually—for sharpening punches and replacing worn sections. This ongoing investment protects your initial tooling expenditure and maintains part quality.

Reducing Costs Through Simulation and Precision Engineering

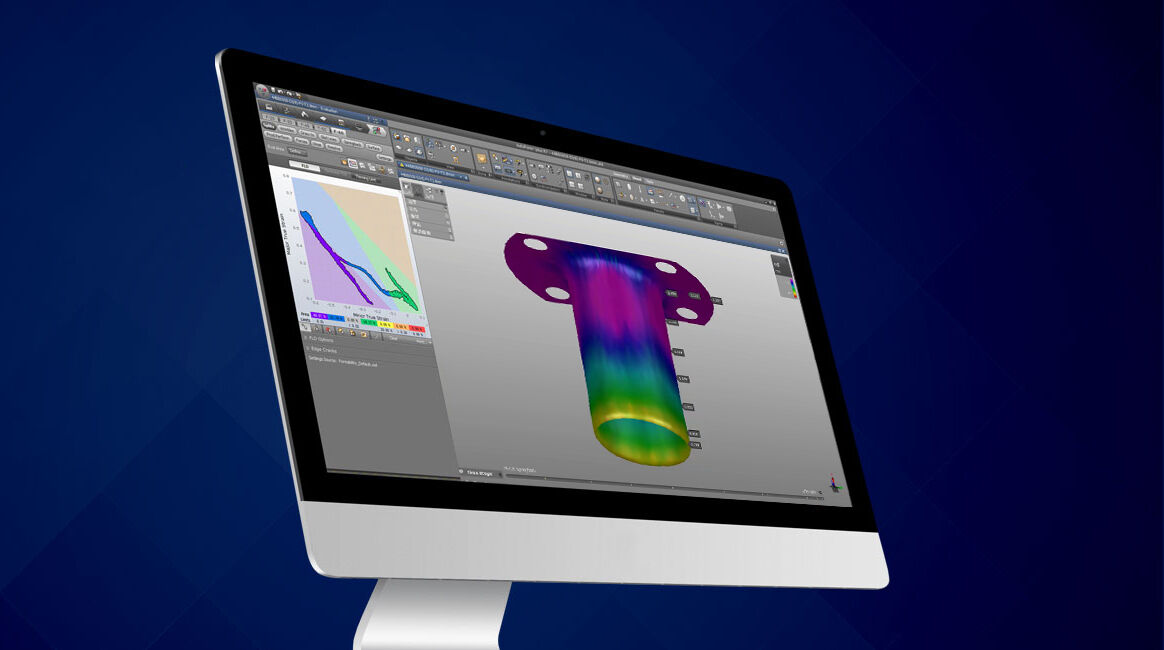

Here's where modern technology delivers measurable ROI: CAE (Computer-Aided Engineering) simulation eliminates costly trial-and-error during die development. Simulation technology optimizes blank shapes before a physical tool is ever cut, saving percentage points that translate to significant savings on high-volume runs.

The traditional die development process involved building physical prototypes, running trials, identifying problems, modifying tooling, and repeating—sometimes through multiple expensive iterations. Each cycle consumed material, machine time, and engineering hours while delaying production start.

Advanced simulation capabilities change this equation dramatically by predicting material behavior, identifying potential defects, and optimizing die geometry before cutting steel. The result? Faster time-to-production and fewer costly surprises during tryout.

This is where selecting the right die supplier becomes a strategic decision rather than simply a purchasing transaction. Shaoyi's IATF 16949-certified stamping die solutions demonstrate this value through their 93% first-pass approval rate—meaning dies work correctly without expensive rework cycles. Their CAE simulation capabilities minimize tooling iterations, while rapid prototyping in as little as 5 days accelerates time-to-production for sheet metal stamping machine applications.

Hidden Cost Factors That Impact Your Bottom Line

Beyond the obvious line items, several factors significantly impact stamping economics:

Quality control and certifications: Automotive components require rigorous validation, often involving PPAP (Production Part Approval Process) documentation. This isn't free—it requires inspection fixtures, CMM time, and engineering hours. Choosing stamping press machines and die suppliers without proper certifications can lead to costly quality failures.

Logistics and supply chain: While overseas tooling might appear 30% cheaper upfront, consider total landed cost. Shipping heavy steel dies, potential port delays, and the inability to quickly troubleshoot engineering changes can negate initial savings. Proximity to your die supplier matters when problems require rapid resolution.

Engineering support: The lowest piece price is often illusory. Dies that require constant adjustment consume engineering time that doesn't appear on the tooling invoice. Partnering with manufacturers who bridge the gap from prototyping to mass production reduces risk and hidden costs.

Design for manufacturability: Every feature on a part requires a corresponding station in the die. Smart DFM guidelines—like using symmetrical designs and eliminating extraneous shapes—reduce production time and tooling costs before they're incurred.

Cost Factor Summary

- Fixed costs: Machine purchase, die tooling investment, engineering design hours, initial tryout and calibration

- Variable costs: Raw material (coil stock), machine hourly rates, direct labor, lubricants and consumables

- Quality costs: Inspection equipment, PPAP documentation, scrap and rework when parts fail specification

- Maintenance costs: Preventive maintenance programs, die sharpening, component replacement, unplanned repairs

- Hidden costs: Engineering support time, supply chain delays, certification requirements, floor space allocation

Accurate cost estimation requires a strategic view of the entire product lifecycle—from amortization of tooling investments to micro-optimization of cycle times and scrap rates. The lowest quoted price rarely delivers the lowest total cost of ownership.

With a clear understanding of stamping economics, the final piece of the puzzle becomes clear: maximizing your return on investment requires more than just buying the right equipment—it demands the right partnerships and operational strategies.

Maximizing Your Stamping Die Machine Investment

You've explored the inner workings of stamping equipment, compared press types, calculated tonnage requirements, and learned how to troubleshoot common problems. Now comes the question that determines whether your investment delivers decades of profitable production or years of frustration: how do you tie everything together into a cohesive strategy that maximizes return?

The manufacturers selling stamp press equipment won't tell you this, but machine selection is only half the equation. What is a stamping press without properly engineered tooling? Just an expensive piece of metal sitting on your floor. The real secret to stamping success lies in understanding how every decision—from press type to die supplier to maintenance protocols—interconnects to determine your long-term results.

Building a Complete Stamping Production Strategy

Think of your stamping operation as a system where each element either supports or undermines the others. A steel stamping machine running at peak performance still produces scrap if the dies aren't properly engineered. Perfectly designed tooling fails prematurely in a machine that lacks adequate tonnage or precision. Maintenance neglect eventually degrades even the best equipment.

Your complete production strategy must address these interconnected elements:

- Machine-application alignment: Match press type (mechanical, hydraulic, servo, or transfer) to your specific forming requirements. High-speed progressive work demands different capabilities than deep drawing operations

- Tonnage and capability verification: Calculate true force requirements including all secondary loads—not just primary forming operations. Size equipment at 70-80% of rated capacity for your heaviest applications

- Material-equipment compatibility: Ensure your press specifications accommodate your material thickness range, width requirements, and coil weight capacity

- Maintenance infrastructure: Establish preventive maintenance schedules before production begins. Daily lubrication, weekly inspections, and annual overhauls protect your investment

- Operator training programs: Invest in comprehensive training that covers safe operation, basic troubleshooting, and quality verification procedures

- Die supplier partnership: Select tooling partners based on engineering capability and quality track record—not just quoted price

According to industry experts, selecting the right stamping manufacturer is about more than meeting specifications—it's about building a partnership that ensures reliability, precision, and long-term value. This principle applies equally to your equipment vendors and die suppliers.

When evaluating a stamping press for sale, look beyond the purchase price. Consider parts availability, service response time in your region, and the vendor's reputation for supporting equipment through its entire operational life. A machine pressed into service without adequate support infrastructure becomes a liability rather than an asset.

Partnering with the Right Die Engineering Team

Here's the reality that separates struggling operations from industry leaders: even the most sophisticated press cannot compensate for poorly designed tooling. Die quality determines part quality, production efficiency, and long-term operational costs.

The best stamping die machine in the world delivers mediocre results with mediocre dies. But a well-engineered die running in a properly matched press produces consistent, high-quality parts shift after shift, year after year.

What should you look for in a die engineering partner? The characteristics that matter most include:

- Early-stage collaboration: Partners who engage during product design can identify opportunities to reduce scrap, streamline tooling, and improve part performance before tooling is built

- Simulation capabilities: CAE analysis that predicts material behavior and identifies potential defects before cutting steel saves costly trial-and-error cycles

- Quality certifications: IATF 16949 certification signals consistent quality controls, documented traceability, and continuous improvement practices essential for automotive applications

- Prototyping speed: The ability to deliver functional prototypes quickly accelerates your time-to-market and reduces development risk

- Production scalability: Partners who support both prototype quantities and high-volume manufacturing provide continuity through your entire product lifecycle

For automotive stamping applications where tolerances are tight and quality expectations are uncompromising, Shaoyi's comprehensive mold design and fabrication capabilities demonstrate what a true engineering partnership looks like. Their IATF 16949-certified processes, backed by advanced CAE simulation, deliver a 93% first-pass approval rate—meaning tooling works correctly without expensive rework cycles. With rapid prototyping available in as little as 5 days and engineering teams experienced with OEM standards, they bridge the gap from concept to high-volume production.

The questions you ask potential die suppliers reveal their true capabilities. According to precision stamping experts, a capable stamping manufacturer should be more than a supplier—they should act as an engineering partner. Early-stage collaboration through Design for Manufacturability can identify opportunities to reduce scrap, streamline tooling, and improve product performance before production begins.

Key Takeaways for Long-Term Success

As you move forward with stamping equipment decisions, remember these principles:

- Total cost matters more than purchase price: The lowest equipment quote rarely delivers the lowest cost per quality part over operational lifetime

- Die quality drives results: Invest in precision-engineered tooling from partners with proven engineering capabilities

- Maintenance prevents costly surprises: Disciplined preventive maintenance programs protect your investment and maintain part quality

- Partnerships outperform transactions: Suppliers who provide engineering support, rapid response, and continuous improvement create more value than commodity vendors

- Knowledge reduces risk: Understanding your equipment, processes, and cost drivers enables better decisions at every level

The stamping industry rewards those who approach equipment selection strategically rather than reactively. By matching machine capabilities to application requirements, establishing robust maintenance protocols, and partnering with quality-focused die suppliers, you position your operation for years of productive, profitable manufacturing.

Whether you're specifying your first stamping die machine or optimizing an existing production line, the secrets shared throughout this guide give you the knowledge manufacturers often withhold. Use it to ask better questions, make informed decisions, and build stamping operations that deliver consistent results—part after part, year after year.

Frequently Asked Questions About Stamping Die Machines

1. How much does a metal stamping die cost?

Metal stamping die costs range from $500 for simple blanking dies to over $100,000 for complex progressive dies with multiple forming stations. The price depends on part complexity, material requirements, and production volume. High-volume automotive projects benefit from progressive die investments when annual volumes exceed 100,000 units, as the per-part tooling cost drops significantly. Working with IATF 16949-certified suppliers like Shaoyi, who achieve 93% first-pass approval rates, reduces costly rework cycles and delivers better long-term value.

2. How does a stamping die work?

A stamping die works through cold forming, where a press mechanism drives the upper die portion (punch) into the lower die cavity with tremendous force. During this controlled impact, the die cuts, bends, or shapes sheet metal into precision components. Progressive dies advance strip material through multiple stations, performing different operations at each stop—blanking, piercing, forming, and coining—often completing parts in under one second. The die's precision engineering determines the final part geometry, tolerances, and quality.

3. Which machine is used for stamping?

Stamping presses are the primary machines used for metal stamping operations. Four main types exist: mechanical presses (flywheel-driven for high-speed production), hydraulic presses (variable force for deep drawing), servo presses (programmable motion profiles for precision work), and transfer presses (multi-station capability for complex parts). Machine selection depends on tonnage requirements, stroke speed needs, material specifications, and production volume. Matching the right press type to your application ensures optimal part quality and production efficiency.

4. What is the difference between die cut and stamping?

While both processes shape metal, die cutting typically refers to simple cutting operations that separate material along defined outlines. Metal stamping encompasses a broader range of operations including blanking, piercing, forming, drawing, coining, and embossing—often combining multiple operations in a single die. Stamping uses sheet metal fed from coils or blanks through cold forming, while die casting uses molten metal poured into molds. Stamping excels at high-volume production of consistent precision parts across automotive, aerospace, and electronics industries.

5. How do I calculate the right tonnage for my stamping machine?

Calculate stamping tonnage by accounting for all load-producing elements: primary operations (blanking, piercing, forming), secondary forces (spring strippers, nitrogen pads), and ancillary loads (cams, scrap cutting). Use material shear strength for cutting operations and tensile strength for drawing. Add loads from all die stations for total required tonnage. Size your press at 70-80% of rated capacity for your heaviest applications to provide a safety margin. Also verify energy requirements—insufficient energy causes press jams even with adequate tonnage.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —