Lengan Kawalan Keluli Berkanai: Penambahbaikan Prestasi atau Kelemahan OEM?

RINGKASAN

Lengan kawalan keluli ditekap merupakan piawaian yang ringan dan berkesan dari segi kos untuk kebanyakan kenderaan pengeluaran, tetapi mempunyai batasan untuk kereta prestasi. Kekurangan utama mereka ialah kecenderungan untuk melentur di bawah keadaan tekanan tinggi, yang boleh menjejaskan pengendalian dan pemindahan kuasa. Untuk aplikasi prestasi yang serius, peningkatan kepada alternatif yang lebih tegar seperti lengan keluli tiub atau lengan diperkukuh biasanya diperlukan untuk meningkatkan kestabilan, meningkatkan pergerakan roda, dan memastikan geometri suspensi yang konsisten.

Memahami Lengan Kawalan Keluli Berganda

Lengan kawalan, sering dipanggil lengan-A, adalah komponen gantungan yang penting yang menyambungkan kerangka kenderaan ke hab roda. Fungsinya adalah untuk membenarkan roda bergerak ke atas dan ke bawah mengikut permukaan jalan sambil mengekalkan kestabilan dan kawalan. Lengan kawalan keluli bergas dihasilkan dengan menekan helaian keluli berkekuatan tinggi ke dalam bentuk tertentu menggunakan acuan kuat. Proses ini sangat cekap dan membolehkan pengeluaran besar-besaran, menjadikannya pilihan biasa bagi pengeluar peralatan asal (OEM).

Proses pengeluaran melibatkan pelbagai peringkat termasuk memotong keluli mentah dengan laser, diikuti oleh penempaan berterusan berbilang stesen dan cetakan hidraulik untuk mencapai geometri kompleks akhir. Bagi pengilang automotif, pencapaian had ketepatan yang ketat adalah penting untuk kesesuaian dan prestasi. Pembekal pakar dalam industri bahagian penempaan automotif, seperti Shaoyi (Ningbo) Metal Technology Co., Ltd. , menyediakan kejuruteraan persisan dan proses bersijil IATF 16949 yang diperlukan untuk menghasilkan komponen-komponen ini secara boleh dipercayai dalam skala besar. Selepas pembentukan, lengan-lengan tersebut melalui rawatan permukaan seperti salutan elektroforetik untuk menahan kakisan, satu kelemahan yang diketahui bagi komponen keluli dalam persekitaran yang mencabar.

Lengan kawalan keluli tampa memiliki satu set ciri yang jelas yang menentukan peranan mereka dalam sistem gantungan kenderaan. Sifat-sifat mereka menjadikannya sesuai untuk pelbagai aplikasi, terutamanya dalam kenderaan harian dan pemulihan kereta klasik di mana keaslian dan keberkesanan kos adalah keutamaan.

- Berat ringan: Berbanding komponen besi tuang atau keluli tuang yang lebih lama, lengan keluli tampa mengurangkan berat komponen, menyumbang kepada kecekapan bahan api yang lebih baik.

- Kos-Efektif: Proses penampaan jauh lebih murah untuk pengeluaran skala besar berbanding pengecoran atau tempaan, yang membantu mengekalkan kos pengeluaran kenderaan rendah.

- Magnetik: Cara mudah untuk mengenal pasti lengan kawalan keluli adalah dengan menggunakan magnet. Tidak seperti aluminium, magnet akan melekat dengan kuat pada keluli cetak atau besi tuang, membantu mekanik dan peminat membezakan antara bahan-bahan tersebut.

- Piawaian OEM: Disebabkan keseimbangan kos, berat, dan kekuatan yang mencukupi untuk keadaan pemanduan biasa, mereka telah menjadi pilihan utama selama beberapa dekad dalam berjuta-juta kereta dan trak pengeluaran.

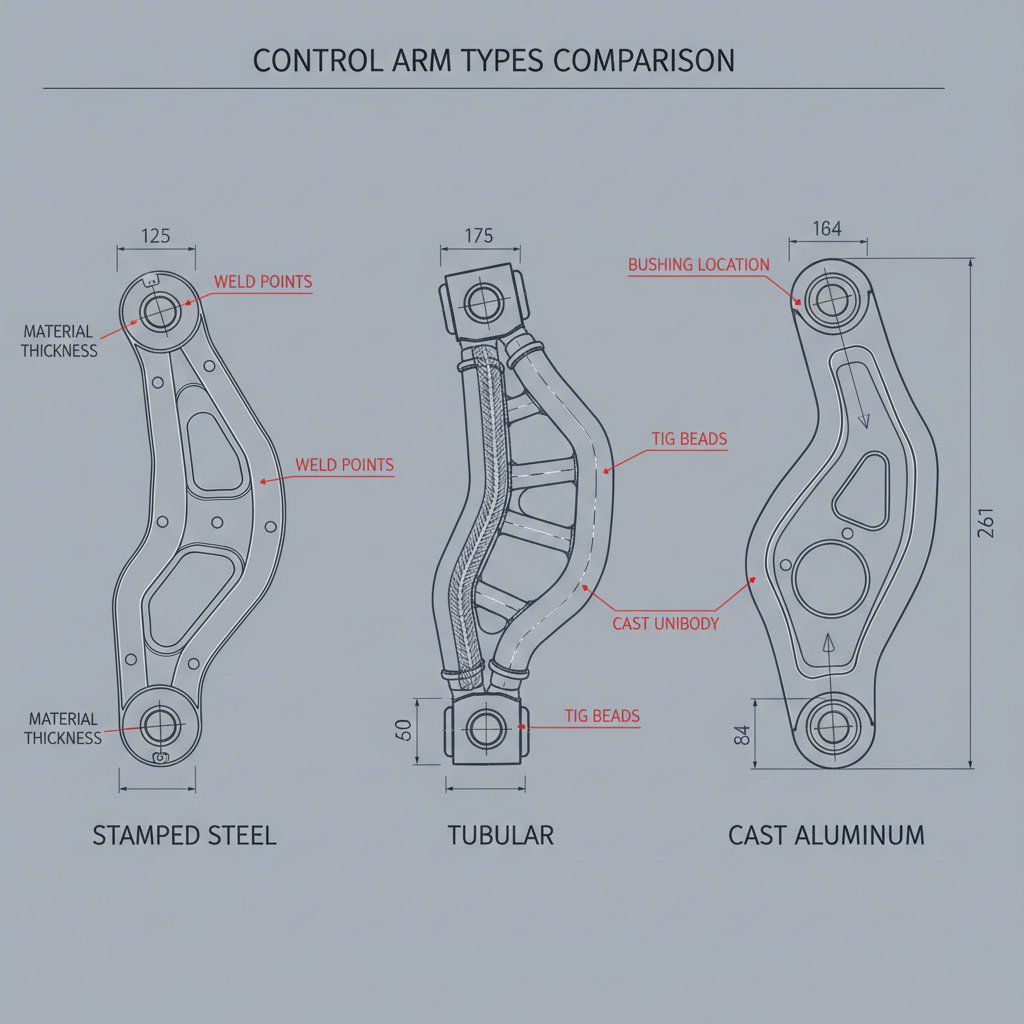

Keluli Cetak lawan Alternatif Utama untuk Penggunaan Prestasi

Apabila meningkatkan kereta prestasi, pemilihan bahan lengan kawalan menjadi keputusan penting yang melibatkan kompromi antara kekakuan, berat, dan kos. Walaupun keluli cetak adalah piawaian kilang, beberapa alternatif menawarkan kelebihan tersendiri untuk senario pemanduan yang mencabar seperti perlumbaan, pemanduan luar jalan, atau pemanduan jalan agresif. Memahami perbezaan ini adalah penting untuk membuat keputusan yang bijak yang selaras dengan matlamat prestasi dan bajet anda.

Lengan kawalan keluli tiub adalah peningkatan prestasi yang popular. Seperti yang diterangkan oleh pembekal seperti Classic Performance Products , mereka direkabentuk daripada paip keluli kimpalan yang kuat (contohnya, D.O.M. - Drawn Over Mandrel) untuk menjadi jauh lebih tegar berbanding rakan sepadan yang ditekan. Kekakuan ini menghalang lengan daripada melentur di bawah pusingan tajam atau pecutan kuat, memastikan tapak sentuhan tayar kekal stabil dan boleh diramal. Mereka kerap direkabentuk untuk mengoptimumkan geometri gantungan bagi pengendalian yang lebih baik, menawarkan perjalanan roda yang lebih panjang dan geseran minima, menjadikannya sesuai untuk pemasangan pro-touring dan lumba.

Lengan besi tuang dan aluminium tuang mewakili pilihan lain yang biasa. Besi tuang sangat kuat dan tahan lama, menjadikannya pilihan kerap untuk trak dan SUV berprestasi tinggi di mana ia mampu menahan persekitaran yang keras tanpa sebarang masalah. Namun, beratnya yang besar merupakan kelemahan utama untuk kereta prestasi di mana jisim tak tersangga adalah perkara yang perlu dipertimbangkan. Aluminium tuang menawarkan kompromi yang menarik, memberikan kekuatan yang sebanding dengan besi tuang tetapi dengan berat yang jauh lebih ringan. Seperti yang dinyatakan dalam panduan daripada sumber-sumber seperti GMT Rubber , aluminium juga sangat tahan terhadap kakisan, walaupun ia lebih mudah retak akibat hentaman tajam berbanding sifat mulur keluli.

Untuk memperjelas proses pengambilan keputusan, berikut adalah perbandingan bahan-bahan ini berdasarkan ciri utama:

| Atribut | Keluli Berganda | Keluli tiub | Besi tuang | Aluminium tuang |

|---|---|---|---|---|

| Proses Pengilangan | Dicetak dari logam lembaran | Dikimpal dari tiub keluli | Dituang ke dalam acuan | Dituang ke dalam acuan |

| Berat | Sederhana | Sederhana | Sangat Berat | Cahaya |

| Kekakuan/Kelenturan | Cenderung lentur di bawah beban | Kekakuan Sangat Tinggi | Sangat Kekal | Kekakuan Sangat Tinggi |

| Kos | Rendah | Tinggi | Sederhana | Tinggi |

| Kes Guna Terbaik | OEM, Pemanduan Harian, Penyahpulihan Bajet | Perlumbaan, Pro-Touring, Prestasi Serius | Lori Kuat, Off-Road | Kereta Prestasi Moden, Binaan Premium |

Impak Prestasi Dalam Dunia Sebenar

Menaik taraf lengan kawalan pasti memberi perbezaan nyata terhadap prestasi kenderaan. Manfaat utama datang daripada peningkatan kekukuhan. Lengan kawalan keluli tempa asal diketahui mengalami lenturan dan ubah bentuk di bawah tekanan pecutan, brek, dan pusingan yang kuat. Lenturan ini menyerap tenaga yang sepatutnya dipindahkan kepada tayar dan boleh menyebabkan perubahan geometri suspensi yang tidak diingini, mengakibatkan pengendalian yang kurang tepat, lompatan roda, dan rasa terputus hubungan dengan jalan raya.

Lengan kawalan prestasi, sama ada keluli tiub fabrikasi atau rekabentuk diperkukuh, dibina untuk menghapuskan lenturan ini. Dengan mengekalkan sambungan tegar antara rangka dan roda, mereka memastikan tetapan penjajaran seperti camber dan caster kekal konsisten di bawah beban. Ini memberi kesan langsung kepada tindak balas stereng yang lebih tajam, peningkatan kestabilan semasa pusingan, dan pemindahan kuasa yang lebih berkesan ke atas permukaan jalan. Sesetengah peminat malah memilih untuk mengubah suai lengan keluli tampa sedia ada dengan mengotakkannya—mengimpal plat tambahan untuk mencipta struktur tertutup sepenuhnya yang lebih tegar—sebagai cara menjimatkan kos untuk memperoleh sebahagian daripada manfaat ini.

Namun, lengan kawalan itu sendiri hanyalah sebahagian daripada persamaan. Bushing, yang merupakan titik pivot yang menyambungkan lengan ke rangka, memainkan peranan sama penting. Bushing getah kilang direka untuk keselesaan serta menyerap bunyi dan getaran, tetapi ia juga membenarkan pesongan yang ketara. Menaik taraf kepada bahan yang lebih keras seperti poliuretana atau galas sfera padu secara mendalam mengurangkan pergerakan tidak diingini ini, seterusnya meningkatkan ketepatan sistem gantungan. Lengan paip berkualiti tinggi yang dipadankan dengan bushing prestasi akan mencipta sistem yang memberikan pemacu maklum balas dan kawalan maksimum.

Pertimbangkan untuk menaik taraf jika anda mengalami mana-mana yang berikut:

- Lompatan roda yang jelas semasa pecutan kuat.

- Stereng kabur atau tidak dapat diramal semasa pusingan agresif.

- Kehausan atau kerosakan yang kelihatan pada lengan kawalan atau bushing sedia ada.

- Anda meningkatkan kuasa enjin secara ketara atau memasang tayar yang lebih melekap, yang akan memberi tekanan lebih besar kepada komponen asal.

Soalan Lazim

1. Adakah lengan kawalan prestasi memberi perbezaan?

Ya, ia membuat perbezaan yang ketara. Lengan kawalan prestasi pasaran sekunder meningkatkan prestasi pemanduan dengan menambahkan kekakuan, yang mengurangkan lenturan dan mengekalkan geometri gantungan yang betul semasa memandu secara agresif. Ini membawa kepada pengendalian yang lebih baik, kestabilan yang lebih tinggi, dan pemindahan kuasa yang lebih cekap dari enjin ke tayar.

2. Apakah logam terbaik untuk lengan kawalan?

Tiada satu logam sahaja yang dianggap "terbaik"; pilihan terbaik bergantung pada kegunaannya. Untuk kegunaan berat dan ketahanan maksimum, keluli sering dipilih kerana kekuatannya. Untuk perlumbaan prestasi tinggi di mana pengurangan berat adalah kritikal, keluli tiub atau aluminium tuang merupakan pilihan yang lebih unggul. Keluli cetak adalah pilihan terbaik untuk pemandu harian kerana kosnya yang rendah dan prestasinya yang mencukupi untuk keadaan jalan biasa.

3. Adakah lengan kawalan keluli bergam bermagnet?

Ya, lengan kawalan keluli cetak adalah magnetik. Cara mudah untuk membezakannya daripada lengan aluminium adalah dengan menggunakan magnet. Jika magnet melekat, lengan kawalan tersebut diperbuat daripada keluli cetak atau besi tuang. Jika ia tidak melekat, maka bahan tersebut adalah aluminium.

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —