Lengan Kawalan Keluli Berganda dan Penerangan Berat Tak Disokong

RINGKASAN

Lengan kawalan keluli bergalur adalah komponen kilang yang biasa dan berkesan dari segi kos, tetapi beratnya yang besar meningkatkan berat tak tersangga kenderaan. Jisim berlebihan ini boleh menjejaskan pengendalian, menyebabkan sistem gantungan kurang responsif terhadap ketidakteraturan jalan. Alternatif yang lebih ringan, seperti lengan kawalan aluminium, tiub, atau tempa, mengurangkan berat tak tersangga, membawa kepada peningkatan ketara dari segi kualiti pemanduan, cengkaman, dan prestasi kenderaan secara keseluruhan.

Memahami Berat Tak Tersangga: Mengapa Ia Penting untuk Prestasi

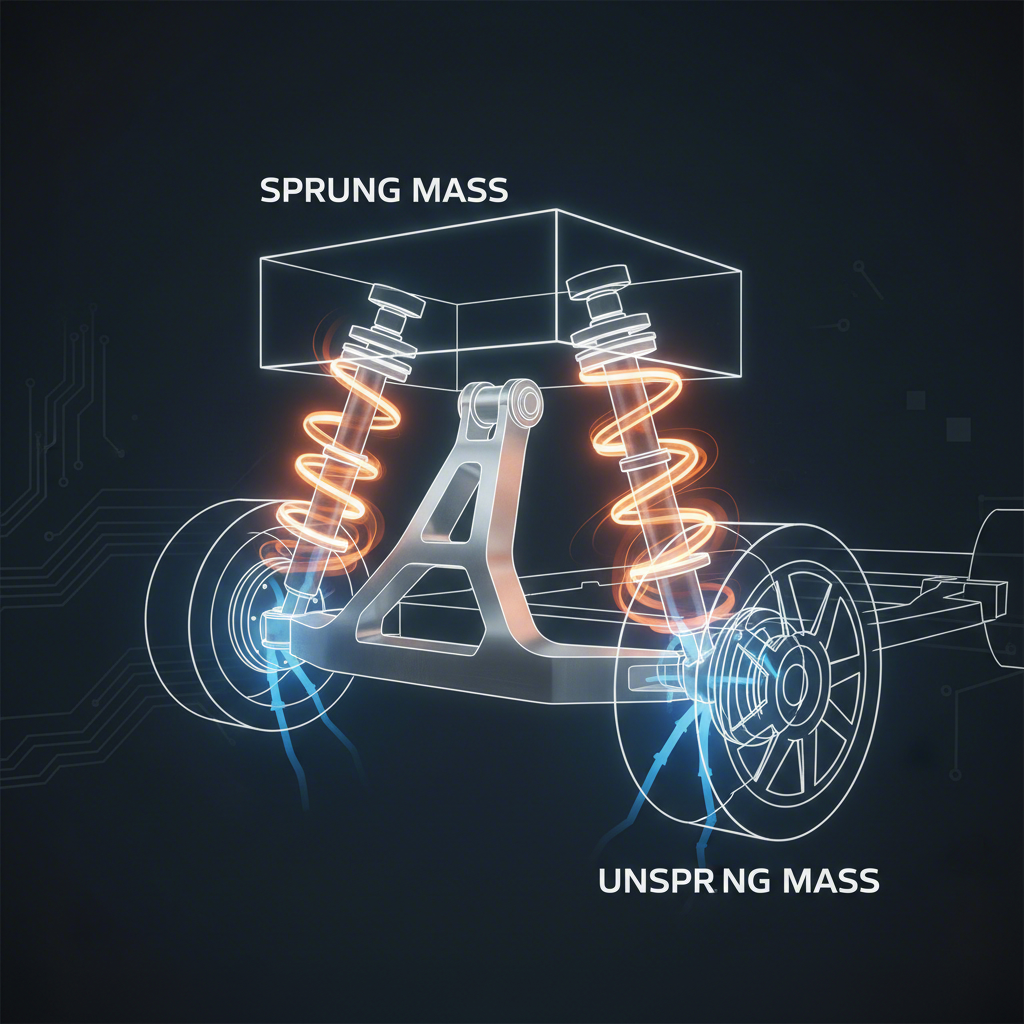

Dalam sebarang perbincangan mengenai suspensi dan pengendalian kenderaan, istilah 'berat tak tersangga' (atau 'jisim tak tersangga') adalah kritikal. Ia merujuk kepada jumlah berat semua komponen yang tidak disokong oleh spring kenderaan. Memahami konsep ini adalah penting untuk memahami mengapa bahan lengan kawalan begitu penting. Cara mudah untuk memikirkannya ialah sekiranya anda mengangkat sasis kereta, semua yang kekal di atas jalan merupakan sebahagian daripada berat tak tersangga. Jisim ini mesti bergerak naik dan turun dengan setiap hentaman dan lekuk di jalan raya.

Prinsip utamanya adalah mudah: semakin ringan komponen yang tidak disokong, semakin baik prestasi sistem gantungan. Komponen yang lebih berat mempunyai inersia yang lebih tinggi, menjadikannya sukar untuk menukar arah dengan cepat. Apabila roda yang berat dan assembli gantungan menghentam bonggol, ia memerlukan lebih banyak tenaga bagi spring dan penyerap kejut untuk mengawal pergerakan ke atasnya dan kemudian menolaknya kembali ke bawah bagi mengekalkan sentuhan dengan jalan. Ini boleh menyebabkan pemanduan yang lebih kasar dan pengurangan cengkaman, kerana tayar mungkin secara sementara melompat di atas permukaan jalan. Menurut pakar gantungan di QA1 , pengurangan jisim komponen yang tidak disokong adalah kritikal kerana ia membolehkan sistem gantungan bertindak balas dengan lebih pantas terhadap ketidaksempurnaan jalan, meningkatkan kedua-dua pengendalian dan kualiti pemanduan.

Sebaliknya, berat tak terjuntai yang lebih rendah membolehkan assemberi roda mengikut kontur jalan dengan lebih rapat. Sistem gantungan boleh bertindak balas lebih pantas, mengekalkan tayar ditekan dengan kuat pada permukaan jalan. Ini memberi kesan langsung kepada cengkaman yang lebih baik, stereng yang lebih responsif, serta peningkatan dalam brek dan pecutan. Kesan ini begitu ketara sehingga peningkatan yang berfokus pada prestasi kerap kali menekankan pengurangan jenis berat tertentu ini. Komponen tak terjuntai yang biasa termasuk:

- Roda dan tire

- Rotor brek, kaliper, dan pad

- Paksu roda dan berang

- Spindel atau buku stereng

- Separuh daripada berat lengan kawalan, spring, dan penyerap kejut

Lengan Kawalan Keluli Tercetak: Kelebihan dan Kekurangan

Lengan kawalan keluli berkanai adalah piawaian bagi kebanyakan kenderaan pengeluaran, dari sedan keluarga hingga trak ringan. Ia dikeluarkan dengan mengikanai kepingan keluli kepada bentuk yang diingini dan kemudian dikimpal bersama. Proses ini sangat cekap dan berkesan secara kos, menjadikannya pilihan ideal untuk pembuat kereta yang menghasilkan kenderaan dalam skala besar. Bagi perniagaan dalam sektor automotif, mencapai ketepatan dalam proses ini adalah perkara utama. Sebagai contoh, pengilang khusus seperti Shaoyi (Ningbo) Metal Technology Co., Ltd. memberi tumpuan kepada penghantaran komponen peninju auto berkualiti tinggi yang bersijil IATF 16949, memastikan bahawa walaupun komponen asas ini memenuhi piawaian ketat dari segi kebolehpercayaan dan ketepatan pemasangan, daripada perintis hingga pengeluaran besar-besaran.

Kelebihan utama keluli berganda adalah keseimbangan kekuatan yang mencukupi dan kos pengeluaran yang rendah. Bagi pemandu biasa di bawah keadaan jalan raya normal, lengan kawalan ini berfungsi dengan boleh dipercayai sepanjang hayat kenderaan. Keluli juga tahan lama dan mampu menahan hentaman besar, kerap membengkok berbanding pecah, yang boleh menjadi mod kegagalan yang boleh diramal dalam kemalangan. Namun, kekurangan terbesar mereka secara langsung berkaitan dengan prestasi: beratnya. Keluli bersifat padat, dan kaedah pembinaan ini menghasilkan komponen yang berat yang menyumbang ketara kepada jisim tak tersangga kenderaan.

Berat tambahan inilah yang menjadi sebab utama peminat prestasi kerap ingin menggantikannya. Seperti yang dibincangkan, jisim tak tersangga yang lebih tinggi boleh menyebabkan sistem gantungan yang kurang responsif. Kekurangan lain yang ketara adalah kerentanan keluli terhadap kakisan. Seperti yang diterangkan dalam panduan oleh PartsAvatar Canada , kecuali dilapisi dengan betul, lengan kawalan keluli boleh berkarat dari semasa ke semasa, terutamanya di kawasan dengan musim sejuk yang teruk di mana garam jalan adalah biasa. Kakisan ini boleh melemahkan komponen dan akhirnya menyebabkan kegagalan.

| Kelebihan | Keburukan |

|---|---|

| Kos pengeluaran rendah | Berat, meningkatkan berat tak disangga |

| Kekuatan mencukupi untuk pemanduan harian | Mudah terjejas oleh karat dan kakisan |

| Tersedia secara meluas sebagai komponen OEM | Kurang tegar berbanding rekabentuk tempa atau tiub |

| Tahan Lama dan Rintang Hentaman | Boleh menjejaskan pengendalian dan kualiti pemanduan |

Alternatif: Lengan Kawalan Aluminium, Tempa, dan Tiub

Bagi pemandu yang ingin meningkatkan prestasi kenderaan mereka dengan mengurangkan berat tak bersentuh, beberapa alternatif kepada lengan kawalan keluli pencetakan adalah tersedia. Setiap satu menawarkan keseimbangan unik dari segi berat, kekuatan, kos, dan ciri prestasi, sesuai untuk pelbagai aplikasi daripada pemanduan harian hingga perlumbaan kompetitif.

Dijalankan ujian dengan严谨 untuk memastikan anda membeli produk berkualiti yang memenuhi piawai prestasi dan keselamatan yang tinggi, memberikan anda ketenangan minda. adalah peningkatan yang popular, dihargai kerana pengurangan berat yang ketara. Sebagai Metrix Premium Parts antara keistimewaan, aluminium jauh lebih ringan daripada keluli, yang secara langsung mengurangkan berat tak tersangga dan meningkatkan sambutan sistem gantungan. Bahan ini juga secara semula jadi tahan kakisan. Kompromi utama biasanya dari segi kos dan, dalam beberapa kes, ketahanan. Walaupun kuat, aluminium mungkin lebih cenderung retak atau patah di bawah hentaman ekstrem berbanding keluli yang cenderung lentur.

Lengan kawalan tempa mewakili peningkatan dari segi kekuatan. Proses tempa melibatkan pembentukan logam di bawah tekanan yang sangat tinggi, yang menyelaraskan struktur bijirin dalaman bahan tersebut. Ini menghasilkan komponen yang sangat kuat dan rintang terhadap kelesuan, kerap kali lebih kuat daripada komponen keluli cetakan dan aluminium tuangan. Ia menawarkan gabungan kekuatan dan berat yang berpatutan, walaupun biasanya lebih mahal berbanding pilihan keluli cetakan.

Lengan kawalan tubular adalah penyelesaian berprestasi tinggi yang kerap digunakan dalam lumba-lumba dan pemulihan kereta klasik. Dibina daripada tiub keluli berkekuatan tinggi, ia menawarkan nisbah kekuatan terhadap berat yang sangat baik. Ia jauh lebih ringan dan lebih tegar berbanding rakan sepadan keluli cetakannya, memberikan geometri gantungan yang tepat dan mengurangkan berat tak tersangkut dengan ketara. Reka bentuknya membolehkan sudut yang dioptimumkan untuk camber dan caster, seterusnya meningkatkan dinamik pengendalian.

| Jenis Lengan Kawalan | Kelebihan utama | Kekurangan Utama | Kes Penggunaan Biasa | Kos Relatif |

|---|---|---|---|---|

| Keluli Berganda | Kos rendah | Berat Tinggi / Karat | OEM / Pemandu Harian | Rendah |

| Aluminium | Ringan / Rintangan Kakisan | Kos Lebih Tinggi / Boleh Retak | Kenderaan Prestasi & Mewah | Sederhana |

| Ditempa (Keluli/Alum.) | Kekuatan Unggul | Kos tinggi | Berat Tahan Lama / Prestasi | Tinggi |

| Keluli tiub | Nisbah Kekuatan Tinggi ke Berat | Kos Tertinggi / Fokus Lumba | Lumba / Pro-Touring | Tinggi |

Soalan Lazim

1. Apakah perbezaan antara lengan kawalan berjenis stamped dan forged?

Perbezaan utama terletak pada proses pembuatan dan kekuatan yang dihasilkan. Lengan kawalan tampa dibuat dengan menekan dan mengimpal kepingan keluli, yang berkos rendah tetapi menghasilkan komponen yang lebih berat dan kurang tegar. Lengan kawalan tempa dihasilkan dengan memampatkan logam yang dipanaskan ke dalam acuan, yang menyelaraskan struktur bijirin dalaman, menghasilkan komponen yang jauh lebih kuat, padat, dan tahan lasak tanpa berat berlebihan seperti sesetengah reka bentuk tampa.

2. Adakah lengan kawalan keluli tampar bermagnet?

Ya, memang betul. Keluli adalah logam ferus, yang bermaksud ia mengandungi besi dan bersifat magnetik. Cara mudah untuk menentukan sama ada lengan kawalan diperbuat daripada keluli atau aluminium ialah dengan menggunakan magnet. Jika magnet melekat dengan kuat pada lengan kawalan tersebut, maka ia diperbuat daripada besi tuang atau keluli tampa. Jika ia tidak melekat, kemungkinan besar lengan itu diperbuat daripada aluminium.

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —