5 Tanda Penting Lengan Kawalan Keluli Tercetak Bengkok

RINGKASAN

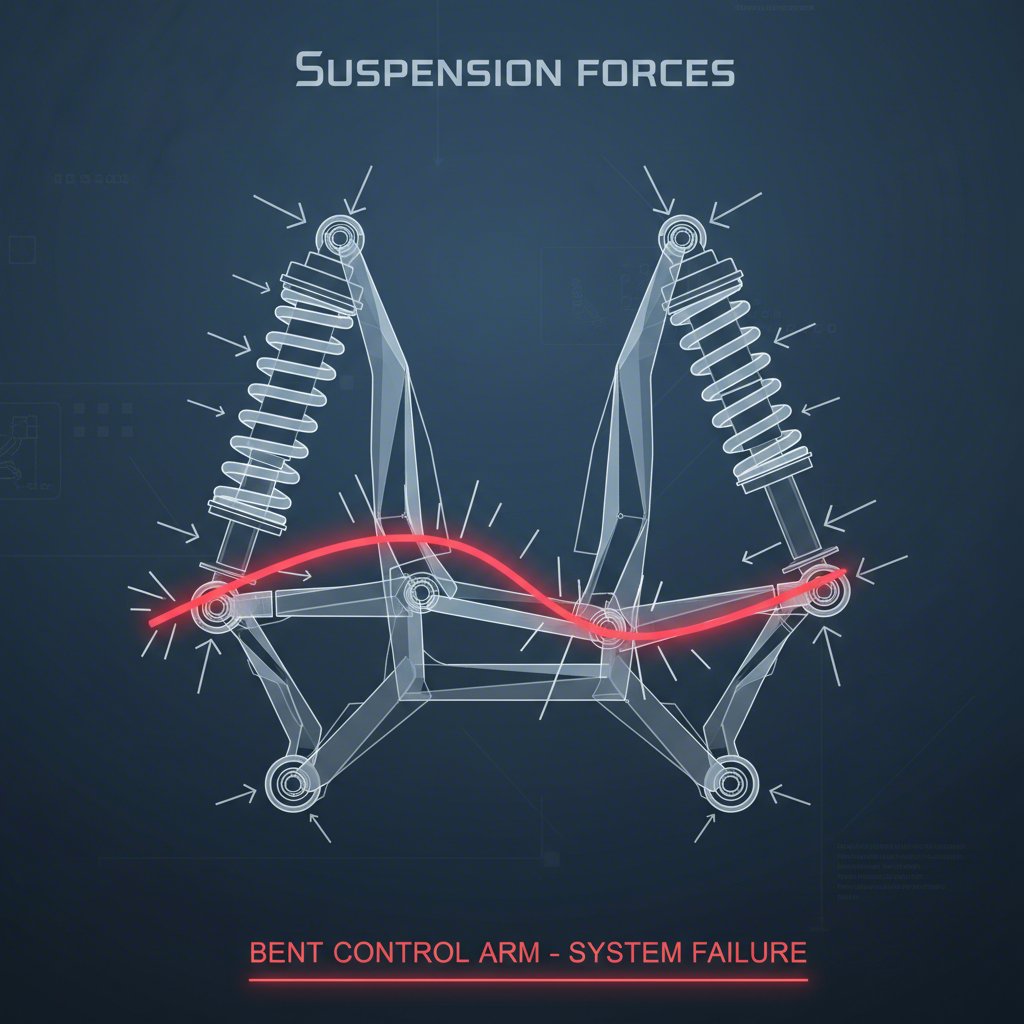

Lengan kawalan keluli berkanai yang bengkok atau rosak menunjukkan tanda-tanda amaran yang jelas dan tidak boleh diabaikan. Gejala paling biasa termasuk bunyi Gegaran atau Dentuman semasa memandu melalui bonggol, perasaan penghalaan tidak stabil atau merayau , getaran ketara melalui roda stereng, dan kehausan Tayar yang Tidak Sekata atau Pra-masa . Tanda-tanda ini menunjukkan masalah suspensi yang kritikal yang menggugat kawalan kenderaan dan keselamatan, serta memerlukan pemeriksaan dan pembaikan segera.

Amaran Bunyi & Sentuhan: Menafsirkan Bunyi dan Getaran

Petunjuk pertama masalah pada lengan kawalan keluli berkanai biasanya merupakan sesuatu yang anda dengar atau rasai. Suspensi yang sihat adalah senyap dan lancar, maka kemunculan bunyi atau getaran baharu secara tiba-tiba merupakan isyarat langsung bahawa komponen tersebut sedang gagal. Ini adalah amaran mekanikal yang menandakan bahawa penampan dan toleransi ketat yang direka dalam sistem telah terjejas. Mengabaikan amaran pendengaran dan sentuhan ini boleh menyebabkan kerosakan lebih teruk dan keadaan memandu yang tidak selamat.

Bunyi yang paling khas bagi bantalan lengan kawalan yang rosak ialah bunyi yang jelas "klik" atau "dug" apabila memandu melalui bonggol, perlahan atau lubang pada kelajuan rendah. Bunyi ini berlaku kerana bantalan getah, yang mengasingkan lengan logam daripada rangka kenderaan, telah terdegradasi dan mencipta ruang. Apabila suspensi bergerak, lengan logam berhentak pada rangka, menghasilkan bunyi klik. Sebaliknya, sendi bola yang haus di hujung lain lengan kawalan sering menghasilkan set bunyi yang berbeza, seperti gemeretak, pop, atau berderit, yang boleh lebih kerap berlaku di atas jalan yang kasar atau apabila memusingkan roda stereng pada kelajuan rendah.

Getaran yang dirasai melalui roda stereng adalah petanda penting lain. Injap lengan kawalan yang haus boleh menyebabkan getaran roda stereng yang kerap muncul dalam julat kelajuan tertentu, seperti 50-65 batu per jam, dan mungkin berkurang pada kelajuan lebih tinggi. Ini berlaku apabila kekenduran pada injap membenarkan osilasi yang mencapai resonans harmonik dengan roda yang berputar. Ini berbeza daripada ketidakseimbangan tayar biasa, yang biasanya semakin teruk dengan peningkatan kelajuan. Getaran hebat yang ketara, terutamanya semasa brek, boleh menjadi petunjuk langsung kepada kegagalan lengan kawalan.

Membedakan pelbagai bunyi di bahagian hadapan kenderaan boleh menjadi sukar, kerana beberapa komponen boleh menghasilkan bunyi yang serupa. Memahami perbezaan ini boleh membantu menentukan punca yang berkemungkinan besar. Pautan penstabil yang rosak, sebagai contoh, biasanya menghasilkan bunyi gencetan ringan yang berulang apabila melalui bonggol kecil, manakala injap lengan kawalan yang gagal menyebabkan bunyi 'klonk' yang lebih dalam dan padat.

| Gejala | Punca Berkemungkinan (Lengan Kawalan) | Punca Lain yang Mungkin (Pautan Penstabil) | Punca Potensi Lain (Hujung Rod Pengikat) |

|---|---|---|---|

| Bunyi Gempak Dalam Apabila Melalui Bonggol | Getah busing haus atau runtuh membenarkan sentuhan logam-ke-logam. | Kurang biasa; biasanya bunyi gemerincing yang lebih ringan. | Mungkin, tetapi biasanya dirasai lebih ketara pada roda stereng semasa pusingan. |

| Bunyi Gemerincing/Lompatan Semasa Memusing | Sendi bola yang haus di hujung lengan kawalan. | Tidak berkemungkinan besar untuk dikaitkan dengan pusingan. | Punca yang sangat biasa, kerana ia terlibat secara langsung dalam sistem stereng. |

| Goncangan pada Roda Stereng | Busi yang rosak menyebabkan getaran harmonik pada kelajuan tertentu. | Biasanya tidak menyebabkan getaran. | Boleh menyebabkan getaran, tetapi kurang biasa daripada masalah lengan kawalan. |

Pemeriksaan visual: Mengenal pasti lengan kawalan yang rosak

Walaupun bunyi dan perasaan adalah petunjuk penting, pemeriksaan visual boleh memberikan bukti pasti bahawa lengan kawalan rosak atau bengkok. Banyak titik kegagalan yang paling biasa, seperti busing getah yang merosot atau lengan yang bengkok akibat impak, mudah dilihat jika anda tahu apa yang harus dicari. Melakukan pemeriksaan yang selamat boleh mengesahkan kecurigaan anda dan membantu anda memahami sejauh mana masalah itu. Lengan kawalan keluli yang dicetak adalah kos efektif tetapi boleh terdedah kepada lenturan atau kakisan, menjadikan pemeriksaan visual sangat penting.

Integriti bahagian penting ini bermula dengan penciptaan mereka. Bagi pengeluar kereta, mencapai komponen yang tepat dan boleh dipercayai adalah penting. Syarikat seperti Shaoyi (Ningbo) Metal Technology Co., Ltd. mengkhususkan diri dalam pencetakan logam berkualiti tinggi yang diperlukan untuk menghasilkan bahagian penggantungan yang tahan lama, memastikan komponen memenuhi piawaian automotif IATF 16949 yang ketat dari prototaip hingga pengeluaran besar-besaran. Fokus pada kecemerlangan pembuatan adalah apa yang menyediakan asas untuk sistem penggantungan yang selamat dan boleh dipercayai.

Untuk menjalankan pemeriksaan, anda mesti menaikkan kenderaan dengan selamat. Berhenti di permukaan yang rata, tekan brek letak kereta, dan gunakan jack lantai untuk mengangkat sudut depan. Yang penting, anda mesti mengamankan kenderaan dengan pendirian jack yang diberi nama sebelum bekerja di bawahnya. Jangan pernah bergantung pada jack sahaja. Dengan lampu senter yang terang, anda boleh mula pemeriksaan anda. Lihatlah pertama pada busing getah di mana lengan disambungkan ke bingkai. Busi yang sihat adalah getah hitam padat; yang rosak akan mempunyai retakan yang jelas, kepingan yang terpotong, atau mungkin terbelah dari lengan logam mereka. Anda boleh menggunakan bar pry untuk memeriksa gerakan dengan lembutbushing yang baik akan kukuh, sementara yang gagal akan membolehkan permainan yang signifikan dan tidak menentu.

Seterusnya, periksa sendi bola. Sepatu pelindung getahnya harus utuh dan disegel. Jika kasut ini robek atau hilang, sendi telah tercemar dengan kotoran dan air dan gagal, walaupun ia belum menjadi bising lagi. Akhirnya, lihatlah lengan itu sendiri. Lihat sepanjang panjangnya untuk memeriksa sebarang lenturan yang jelas, kemunduran, atau tanda-tanda karat yang teruk, yang boleh menjejaskan integriti strukturnya. Tangan yang bengkok membuat pelanturan roda yang betul mustahil dan mesti diganti.

Prestasi & Keselamatan: Akibat lengan kawalan yang gagal

Lengan kawalan keluli yang dipukul gagal bukan hanya gangguan bising; ia adalah ancaman langsung kepada prestasi kenderaan anda dan, yang paling penting, keselamatan anda. Komponen ini adalah asas geometri penggantungan anda, dan apabila mereka gagal, mereka boleh menyebabkan masalah berbahaya, dari pemanduan yang buruk hingga kehilangan kawalan kenderaan yang dahsyat. Soalan "selama berapa lama anda boleh memandu dengan lengan kawalan yang tidak baik" bergantung sepenuhnya pada keparahan kegagalan, tetapi jawapannya harus selalu "sejauh mungkin".

Salah satu akibat yang paling penting adalah kesan pada penyelarasan roda. Control lengan bertanggungjawab untuk memegang roda pada betul kembar (kecondongan menegak) dan roda (kecondongan depan-belakang). Apabila bantalan atau sendi bola haus, ia membenarkan sudut-sudut ini berubah secara dinamik semasa memandu. Ini menyebabkan hala stereng menjadi tidak menentu, di mana anda perlu sentiasa membuat pembetulan kecil untuk mengekalkan kenderaan dalam garis lurus. Ia juga menyebabkan kehausan tayar yang cepat dan tidak sekata, sering merosakkan tepi dalam atau luar tayar dalam tempoh yang jauh lebih pendek daripada jangka hayat yang dijangkakan. Satu tayar yang direka untuk 50,000 batu boleh rosak dalam kurang daripada 10,000 batu, mewakili kos yang besar dan tidak perlu.

Risiko utama mengabaikan lengan kawalan yang rosak, terutamanya sendi bola yang haus, ialah pemisahan sepenuhnya. Sendi bola merupakan titik pivot penting yang menyambungkan perakuan roda anda ke lengan kawalan. Jika ia haus sehingga gagal, ia boleh tercabut dari soketnya. Ini menyebabkan kejatuhan sistem gantungan dan roda terlipat di bawah kenderaan, mengakibatkan kehilangan kawalan stereng secara tiba-tiba dan sepenuhnya. Ini merupakan salah satu kegagalan mekanikal paling berbahaya yang boleh berlaku. Oleh itu, sebarang gejala seperti getaran hebat, masalah stereng teruk, atau bunyi letupan kuat harus dianggap sebagai isyarat untuk segera berhenti memandu kenderaan tersebut dan membawanya untuk diperiksa oleh profesional.

Soalan Lazim

1. Cara mengetahui sama ada anda mempunyai lengan kawalan keluli tuang?

Cara yang mudah untuk membezakan ialah dengan menggunakan magnet dan tukul. Jika magnet melekat pada lengan tersebut, ia terbuat daripada keluli berganda atau besi tuang/keluli tuang. Lengan aluminium tidak akan bermagnet. Untuk membezakan keluli berganda dengan keluli tuang, perhatikan pembinaannya. Lengan keluli berganda biasanya diperbuat daripada kepingan logam lembaran yang dikimpal bersama dan mungkin kelihatan berongga atau berbentuk-C dari bahagian bawah. Lengan tuang pula merupakan satu kepingan padu dan akan mempunyai permukaan yang lebih kasar dan bertekstur akibat proses pengecoran. Mengetuknya dengan tukul juga akan menghasilkan bunyi yang berbeza; lengan berganda akan menghasilkan bunyi gema yang lebih nyaring, manakala lengan tuang padu akan menghasilkan bunyi gebukan yang tumpul.

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —