Mengapa Penempaan Adalah Penting untuk Ketahanan Komponen

Mengapa Penempaan Adalah Penting untuk Ketahanan Komponen

RINGKASAN

Meningkatkan ketahanan komponen dengan penempaan melibatkan pembentukan logam menggunakan daya mampatan yang kuat. Proses ini memperhalus struktur bijirin dalaman logam, menyelaraskannya untuk kekuatan yang optimum, dan menghapuskan kecacatan mikroskopik. Hasilnya adalah komponen dengan kekuatan tegangan, ketahanan hentaman, dan rintangan lesu yang jauh lebih tinggi, menjadikannya lebih tahan lama dan boleh dipercayai di bawah tekanan berbanding komponen yang dibuat melalui kaedah seperti pengecoran atau pemesinan.

Sains Penempaan: Bagaimana Daya Mampatan Mencipta Kekuatan yang Lebih Unggul

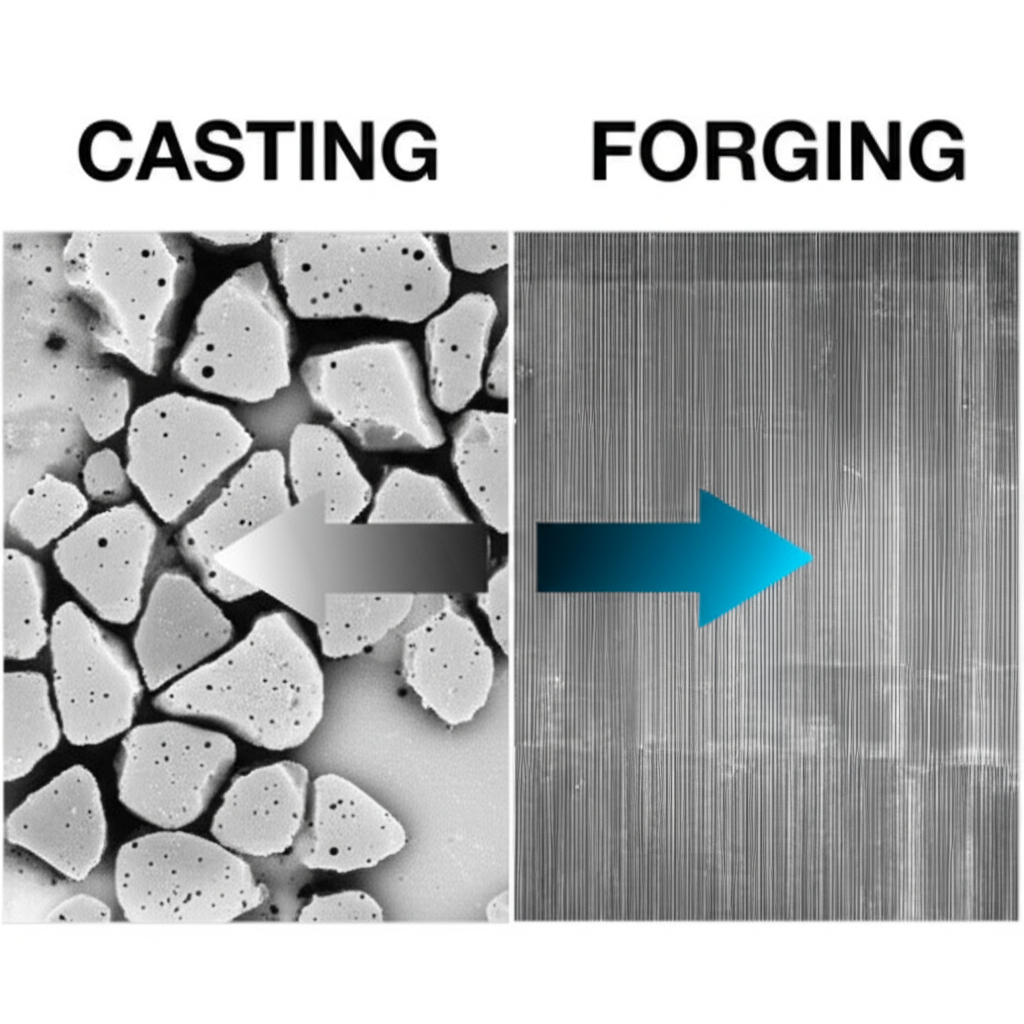

Pada asasnya, penempaan adalah proses pembuatan yang membentuk logam melalui daya mampatan setempat, yang diberikan dengan cara dipalu atau ditekan. Berbeza dengan kaedah lain yang melebur dan menuang logam (pengecoran) atau memotongnya (pemesinan), penempaan mengubah logam secara fizikal dalam keadaan pepejal. Perubahan plastik inilah yang menjadi kunci kepada keupayaannya meningkatkan sifat mekanikal komponen secara ketara. Kelebihan sebenar penempaan terletak pada apa yang berlaku pada peringkat mikroskopik: penyusutan dan penyelarian struktur butiran logam.

Setiap keping logam terdiri daripada butir-butir hablur. Dalam keadaan mentah atau tuangan, butiran ini biasanya rawak dan tidak seragam, yang boleh mencipta titik-titik lemah. Tekanan yang sangat besar yang dikenakan semasa proses penempaan memaksa butiran ini membentuk semula hablurnya dan menjadi lebih kecil serta lebih seragam. Menurut sains bahan, butiran yang lebih halus membawa kepada peningkatan kekuatan dan ketangguhan kerana terdapat lebih banyak sempadan butir untuk menghalang pergerakan dislokasi—cacat dalam kekisi hablur yang menyebabkan kegagalan bahan. Seperti yang diterangkan oleh pakar pengeluaran di Queen City Forging , pembetulan butiran ini merupakan penyumbang utama kepada kekuatan unggul komponen tempaan.

Selain itu, proses penempaan mengarahkan aliran biji-biji halus ini secara bijak mengikut kontur komponen akhir. Ini dikenali sebagai kekuatan mengikut arah atau aliran biji. Bayangkan biji-biji ini seperti gentian dalam sekeping kayu; papan adalah jauh lebih kuat sepanjang arah biji berbanding melawan arah tersebut. Begitu juga, penempaan menyelaraskan aliran biji sepanjang garis tekanan yang dijangka, menjadikan komponen tersebut sangat tahan terhadap kelesuan dan hentaman dalam arah kritikal. Proses ini juga secara fizikal menutup dan menyegel ruang dalaman, kebolehporosan, dan kerosakan lain yang boleh menjejaskan integriti komponen, menghasilkan struktur bahan yang lebih padat dan seragam.

Manfaat Ketahanan Utama Komponen Ditempa

Transformasi metalurgi yang berlaku semasa penempaan diterjemahkan secara langsung kepada kelebihan prestasi yang nyata, menjadikan komponen ditempa sebagai pilihan utama untuk aplikasi yang mengalami tekanan tinggi dan kritikal dari segi keselamatan. Kelebihan-kelebihan ini menyumbang kepada jangka hayat perkhidmatan yang lebih panjang, kebolehpercayaan yang lebih tinggi, dan peningkatan prestasi keseluruhan.

Kekuatan Regangan dan Impak yang Dipertingkat

Penempaan menghasilkan komponen dengan kekuatan regangan yang luar biasa—keupayaan untuk menahan tarikan yang boleh menyebabkannya terlerai. Struktur bijirin yang halus dan berterusan ini bebas daripada kecacatan dalaman seperti keporosan yang sering dijumpai pada komponen tuangan. Integriti struktur sebegini bermakna komponen ditempa mampu menahan beban dan tekanan yang lebih tinggi sebelum mengalami ubah bentuk atau kegagalan. Ini adalah kritikal bagi komponen seperti aci engkol dan batang penyambung dalam industri automotif, yang mesti menahan daya yang berterusan dan melampau. Seperti yang dinyatakan dalam pelbagai analisis industri, proses ini menghasilkan bahan yang lebih kuat dan lebih boleh diramal.

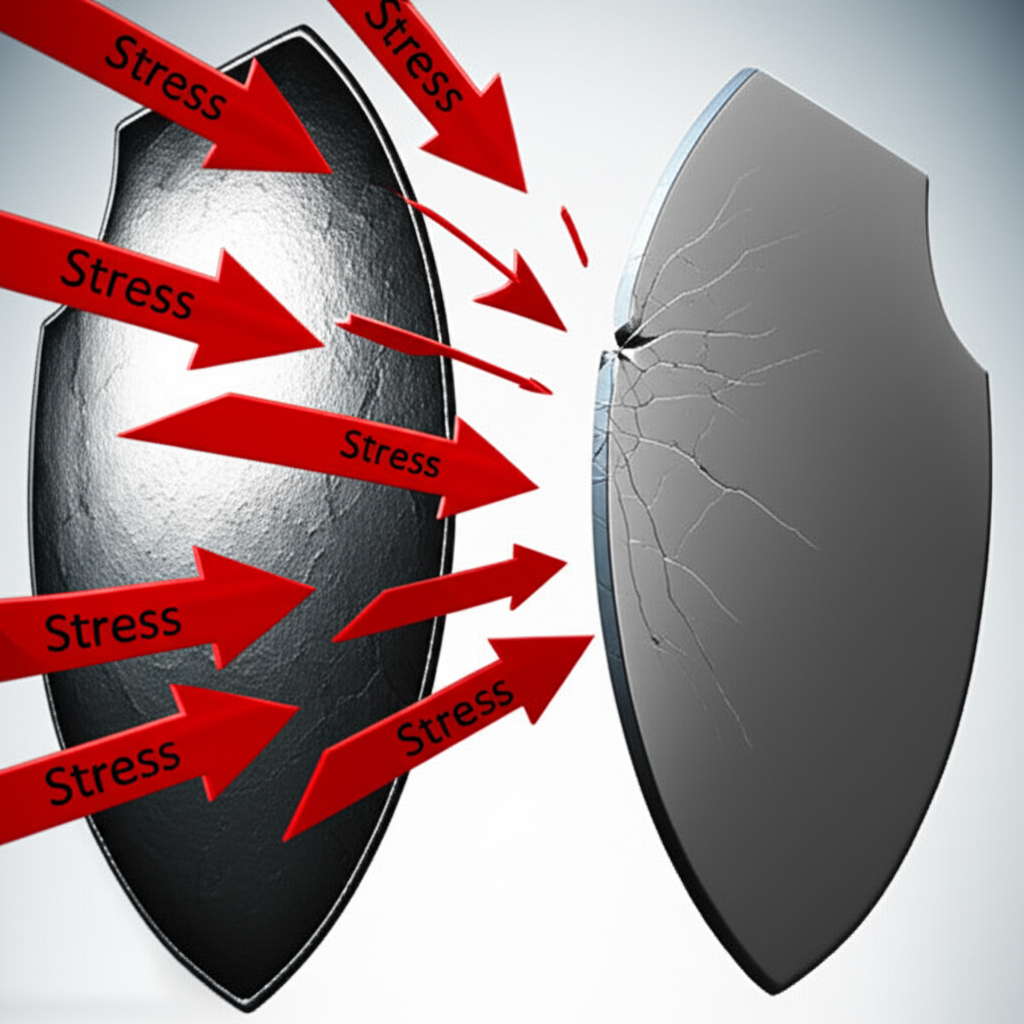

Rintangan Lesu yang Unggul

Ramai komponen gagal bukan disebabkan oleh beban berlebih tunggal, tetapi akibat pengumpulan tekanan selama berjuta-juta kitaran, suatu fenomena yang dikenali sebagai keletihan logam. Penempaan memberikan pertahanan yang kuat terhadap perkara ini. Aliran butir yang sejajar dan permukaan bebas daripada kecacatan menghalang pembentukan dan perkembangan retakan mikroskopik yang menyebabkan kegagalan akibat keletihan. Oleh sebab itu, komponen aeroangkasa yang kritikal, seperti gear pendaratan dan bilah turbin, dihasilkan melalui penempaan; komponen-komponen ini memerlukan kebolehpercayaan tertinggi sepanjang jangka hayat operasi yang panjang di bawah beban kitaran.

Ketahanan Kesan dan Haus yang Dipertingkatkan

Ketahanan adalah keupayaan bahan menyerap tenaga dan mengalami ubah bentuk tanpa pecah, yang merupakan ciri penting bagi komponen yang mengalami hentakan atau kejutan secara tiba-tiba. Struktur logam tempa yang padat dan seragam memberikan rintangan hentaman yang unggul. Selain itu, pengerasan kerja yang boleh berlaku semasa proses penempaan tertentu meningkatkan kekerasan permukaan, menghasilkan rintangan haus yang lebih baik. Ini menjadikan komponen tempa sesuai untuk gear, galas, dan komponen lain dalam jentera berat di mana geseran dan kehausan merupakan cabaran berterusan.

Penempaan berbanding Pengecoran: Perbandingan Kritikal untuk Jangka Hayat Komponen

Apabila memilih proses pembuatan untuk komponen logam, pilihannya sering kali terletak pada penempaan atau pengecoran. Walaupun pengecoran—menuang logam lebur ke dalam acuan—boleh menjadi efisien untuk bentuk kompleks, ia menghasilkan struktur dalaman yang berbeza secara asasnya dan mempengaruhi ketahanan. Bagi aplikasi yang mengutamakan kekuatan dan jangka hayat panjang, penempaan mempunyai kelebihan yang jelas.

Perbezaan utama terletak pada struktur bijirin. Bahagian tuangan mempunyai struktur bijirin rawak dan tidak berarah yang terbentuk semasa logam menyejuk dan membeku. Proses ini boleh memerangkap gelembung gas, mencipta kebolehtelapan, dan mengakibatkan produk akhir yang kurang padat dan lebih lemah. Sebaliknya, penempaan menghasilkan aliran bijirin yang halus, sejajar, dan padat tanpa kecacatan sedemikian. Kekukuhan struktur ini menjadikan bahagian tempaan jauh lebih kuat dan boleh dipercayai.

| Harta | Penempaan | PENGCASTINGAN |

|---|---|---|

| Struktur Butir | Aliran bijirin yang halus, sejajar, dan berterusan. | Rawak, tidak berarah, dan berpotensi bolihtelap. |

| Kekuatan | Kekuatan tegangan dan kelesuan yang tinggi disebabkan oleh struktur yang padat. | Kekuatan lebih rendah; mudah terjejas oleh kecacatan dalaman. |

| Ketahanan | Rintangan yang sangat baik terhadap hentaman, kelesuan, dan haus. | Lebih rapuh dan mudah gagal di bawah tekanan tinggi. |

| Kebolehtuan | Tinggi, dengan sifat bahan yang konsisten. | Berubah-ubah; prestasi boleh terjejas oleh kecacatan tersembunyi. |

Walaupun pengecoran mungkin menawarkan kos awal yang lebih rendah untuk reka bentuk kompleks tertentu, prestasi unggul dan jangka hayat yang lebih panjang bagi komponen tempa sering kali menghasilkan jumlah kos pemilikan yang lebih rendah. Ketahanan yang ditingkatkan bermakna kurang penggantian, masa hentian yang kurang, dan keselamatan yang lebih baik, menjadikan penempaan pilihan yang lebih berkesan dari segi kos untuk aplikasi kritikal dalam jangka panjang.

Proses Penempaan Biasa dan Aplikasinya

Istilah "penempaan" merangkumi beberapa teknik berbeza, yang setiap satunya sesuai untuk saiz, bentuk, dan isi pengeluaran komponen yang berbeza. Memahami proses-proses ini membantu dalam memilih kaedah yang paling optimum untuk memaksimumkan ketahanan bagi aplikasi tertentu.

Penempaan Die Terbuka: Proses ini melibatkan pembentukan bahan kerja antara dua acuan rata atau acuan mudah yang tidak sepenuhnya menutup logam tersebut. Bahan ditempa atau ditekan, dan bahagian tersebut dimanipulasi di antara hentaman untuk mencapai bentuk yang diingini. Penempaan acuan terbuka sangat fleksibel dan sesuai untuk komponen besar seperti aci dan gelang industri atau untuk pengeluaran khusus dalam kuantiti kecil.

Penempaan Die Tertutup: Juga dikenali sebagai penempaan acuan kesan, kaedah ini menggunakan dua acuan yang mengandungi kesan tepat bagi komponen akhir. Sekeping logam yang dipanaskan diletakkan di dalam acuan bawah, dan acuan atas ditekan ke bawah, menyebabkan logam mengalir dan memenuhi rongga acuan. Proses ini sangat sesuai untuk pengeluaran besar komponen kompleks yang berkualiti tinggi dengan had toleransi ketat, seperti yang digunakan dalam industri automotif dan aerospace. Untuk komponen automotif yang kukuh dan boleh dipercayai, perkhidmatan khusus adalah perkara utama. Sebagai contoh, sesetengah syarikat memberi tumpuan kepada penempaan panas berkualiti tinggi dan bersijil untuk industri automotif, mengendalikan segala-galanya daripada prototaip hingga pengeluaran besar. Bagi mereka yang berminat, Shaoyi Metal Technology menawarkan penyelesaian penempaan lanjutan dengan pengeluaran acuan dalam rumah untuk memastikan ketepatan dan kecekapan.

Penempaan Cincin Gulung Tanpa Sambungan: Proses khas ini digunakan untuk menghasilkan cincin yang kuat dan tanpa sambungan. Ia bermula dengan preform berbentuk donat yang dipanaskan dan kemudian diputar sambil dikenakan tekanan, menyebabkan cincin mengembang kepada diameter dan ketebalan dinding yang diingini. Kaedah ini menghasilkan aliran bijirin yang berterusan, menjadikannya sesuai untuk galas prestasi tinggi, gear, dan flens yang digunakan dalam persekitaran mencabar.

Soalan Lazim

1. Apakah yang dilakukan oleh penempaan untuk memperbaiki logam?

Penempaan memperbaiki logam dengan merapatkan struktur bijirinnya pada peringkat mikroskopik. Proses ini menggunakan daya mampatan untuk mengurangkan saiz bijirin, melaraskan aliran bijirin mengikut bentuk komponen, dan menghapuskan kecacatan dalaman seperti keropos. Ini menghasilkan bahan yang lebih padat, lebih kuat, dan lebih tahan lama dengan rintangan yang ditingkatkan terhadap kelesuan dan hentaman.

2. Adakah penempaan membuatkan logam lebih kuat?

Ya, penempaan secara ketara mengukuhkan logam. Proses membentuk logam di bawah tekanan tinggi memperbaiki struktur butirannya dan menjadikannya lebih padat, menghasilkan kekuatan tegangan yang lebih baik berbanding produk tuangan atau mesinan. Aliran butiran yang sejajar juga memberikan kekuatan mengikut arah, menjadikan komponen tersebut sangat kukuh pada kawasan yang mengalami tekanan tinggi.

3. Bagaimanakah penempaan meningkatkan sifat mekanikal?

Penempaan meningkatkan sifat mekanikal melalui perubahan plastik yang terkawal. Ini memperhalus struktur butiran, yang menambahkan kekuatan, ketahanan, dan keanjalan. Ia juga mencipta aliran butiran yang berterusan mengikut kontur komponen, secara drastik meningkatkan rintangan kakisan dan keupayaan menahan beban kitaran tanpa kegagalan.

4. Apakah 4 jenis penempaan?

Walaupun terdapat pelbagai variasi, empat jenis penempaan yang biasa ialah penempaan acuan lekuk (atau penempaan acuan tertutup), penempaan acuan terbuka, penempaan sejuk, dan penempaan cincin gulung tanpa kelim. Setiap kaedah sesuai untuk aplikasi yang berbeza, saiz komponen, dan jumlah pengeluaran, daripada bahagian tersuai yang besar hingga komponen presisi berjumlah tinggi.

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —