Menguasai Toleransi untuk Ekstrusi Khusus: Panduan Praktikal

Menguasai Toleransi untuk Ekstrusi Khusus: Panduan Praktikal

RINGKASAN

Menentukan had ketelusan untuk pengeluaran suai memberi maksud menetapkan penyimpangan yang diterima daripada dimensi nominal reka bentuk bagi memastikan kecocokan, fungsi, dan prestasi yang betul. Proses kritikal ini melibatkan keseimbangan antara ketepatan dan kos pembuatan. Pertimbangan utama termasuk bahan (aluminium berbanding plastik), kerumitan profil, ketebalan dinding, dan merujuk kepada piawaian industri, seperti yang dikeluarkan oleh The Aluminum Association.

Memahami Asas-asas Had Ketelusan Pengeluaran

Dalam sebarang proses pembuatan, mustahil untuk mencapai dimensi yang sempurna setiap kali. Had ketelusan pengeluaran menentukan julat variasi yang diterima bagi dimensi spesifikasi sesuatu komponen. Seperti yang ditakrifkan oleh pakar dalam pengeluaran plastik, mereka merupakan parameter penting yang menentukan penyimpangan yang dibenarkan daripada rekabentuk nominal. Variasi ini biasanya dinyatakan sebagai nilai tambah-atau-tolak (contohnya, ±0.01 inci) dan merupakan asas kepada kawalan kualiti dan kefungsian komponen.

Kepentingan mentakrifkan had toleransi dengan betul tidak dapat ditekankan terlalu banyak. Ia secara langsung memberi kesan kepada tiga bidang kritikal: kesesuaian, fungsi, dan kos. Bagi komponen yang perlu dipasang dengan bahagian lain, had toleransi memastikan kesesuaian yang tepat tanpa gangguan atau kekenduran. Dari segi fungsi, ia menjamin bahagian tersebut akan berfungsi seperti yang dirancang di bawah tekanan operasi. Yang paling penting, toleransi memberi kesan besar terhadap kos; menuntut toleransi yang terlalu ketat secara tidak perlu boleh meningkatkan kos perkakasan dengan ketara, memperlahankan kadar pengeluaran, dan menyebabkan kadar penolakan yang lebih tinggi. Sebaliknya, toleransi yang dirancang dengan baik menjadikan proses pembuatan lebih cepat dan lebih berkesan dari segi kos.

Toleransi secara umum dikategorikan kepada dua jenis: piawai dan presisi. Toleransi piawai adalah had yang diterima oleh industri dan diterbitkan oleh organisasi seperti Persatuan Aluminium . Ini berfungsi sebagai asas ekonomi untuk kebanyakan aplikasi umum dan memastikan tahap konsistensi merentasi pengeluar yang berbeza. Toleransi ketepatan, atau tersuai, adalah had yang lebih ketat yang diperlukan untuk komponen dengan keperluan pemasangan rumit atau aplikasi prestasi tinggi. Walaupun menawarkan ketepatan yang lebih tinggi, ia memerlukan peralatan dan kawalan proses yang lebih maju, yang meningkatkan kos keseluruhan.

Faktor Utama Yang Mempengaruhi Toleransi Penyemperitan

Toleransi yang boleh dicapai untuk penyemperitan tersuai bukanlah secara sewenang-wenang; ia dipengaruhi oleh gabungan faktor fizikal dan mekanikal. Pemahaman yang menyeluruh tentang pemboleh ubah ini semasa fasa rekabentuk adalah penting untuk mencipta produk yang boleh dikilangkan dan berkesan dari segi kos.

Jenis dan Sifat Bahan

Bahan yang diekstrusi adalah penentu utama kawalan had ralat. Bahan yang berbeza berkelakuan berbeza di bawah haba dan tekanan proses ekstrusi. Sebagai contoh, aloi aluminium yang lebih lembut seperti 6063 secara amnya lebih mudah diekstrusi dan boleh mengekalkan had ralat yang lebih ketat berbanding aloi yang lebih keras dan berkekuatan tinggi seperti 6061. Begitu juga, dalam plastik, bahan dengan kadar pengembangan dan pengecutan haba yang tinggi boleh menunjukkan variasi dimensi yang lebih besar semasa penyejukan, menjadikan pemeliharaan had ralat yang ketat lebih mencabar.

Kerumitan profil

Geometri profil yang diekstrusi memainkan peranan utama. Bentuk yang mudah, padat, dan simetri adalah yang paling mudah dikawal. Apabila kerumitan meningkat, semakin sukar untuk mengekalkan had ralat yang ketat. Ciri-ciri yang mencabar termasuk:

- Bahagian berongga: Ini memerlukan acuan yang lebih rumit dan kawalan aliran bahan yang teliti untuk memastikan ketebalan dinding yang konsisten.

- Ciri tak simetri: Reka bentuk yang tidak seimbang boleh menyebabkan aliran bahan yang tidak sekata dan ubah bentuk semasa penyejukan.

- Saluran dalam dan sempit: Ciri-ciri ini boleh sukar diisi secara konsisten oleh bahan.

- Sudut tajam: Sudut tajam yang sempurna sukar dicapai; menentukan jejari kecil biasanya lebih praktikal dan mudah dikeluarkan.

Ketebalan Dinding dan Keseragaman

Pengekalan ketebalan dinding yang konsisten sepanjang profil adalah penting. Perbezaan ketebalan yang besar boleh menyebabkan bahagian profil menyejuk pada kadar yang berbeza. Penyejukan yang tidak sekata ini merupakan punca utama tekanan dalaman, yang boleh menyebabkan lenturan, piuhan, atau kebengkokan pada komponen akhir. Semasa peringkat rekabentuk, usaha untuk mencapai dinding yang seragam seboleh mungkin merupakan prinsip utama Rekabentuk untuk Kebolehkeluaran (DFM).

Rekabentuk Acuan dan Kualiti

Acuan ekstrusi adalah alat yang membentuk bahan, dan kualitinya adalah perkara utama. Acuan yang direkabentuk dengan baik, diperbuat daripada keluli perkakas berkualiti tinggi oleh pembuat acuan yang berpengalaman, boleh mengimbangi isu aliran bahan yang berpotensi dan meramalkan bagaimana profil tersebut mungkin berubah bentuk semasa penyejukan. Ketepatan acuan secara langsung menentukan kejituan dimensi dan kekonsistenan bahagian-bahagian ekstrusi. Melabur dalam perkakas berkualiti tinggi adalah asas untuk mencapai had toleransi yang ketat dan boleh diulang.

Panduan Praktikal untuk Menentukan Toleransi pada Rekabentuk Anda

Menterjemahkan pengetahuan teori kepada spesifikasi yang praktikal dan jelas adalah langkah terakhir untuk memastikan ekstrusi tersuai anda memenuhi keperluannya. Mengikuti proses berstruktur membantu menyampaikan keperluan anda dengan jelas kepada pengilang dan mengelakkan kesilapan yang mahal.

- Kenal pasti Dimensi yang Kritikal terhadap Fungsi. Tidak semua dimensi pada suatu bahagian adalah sama penting. Analisis rekabentuk anda untuk menentukan ciri-ciri yang kritikal bagi kesesuaian, pemasangan, atau prestasi. Tandakan ciri-ciri ini dengan jelas pada lukisan teknikal anda. Fokus ini membolehkan pengilang mengenakan kawalan yang lebih ketat di mana perlu sambil menggunakan had terima piawaian yang lebih ekonomikal di tempat lain.

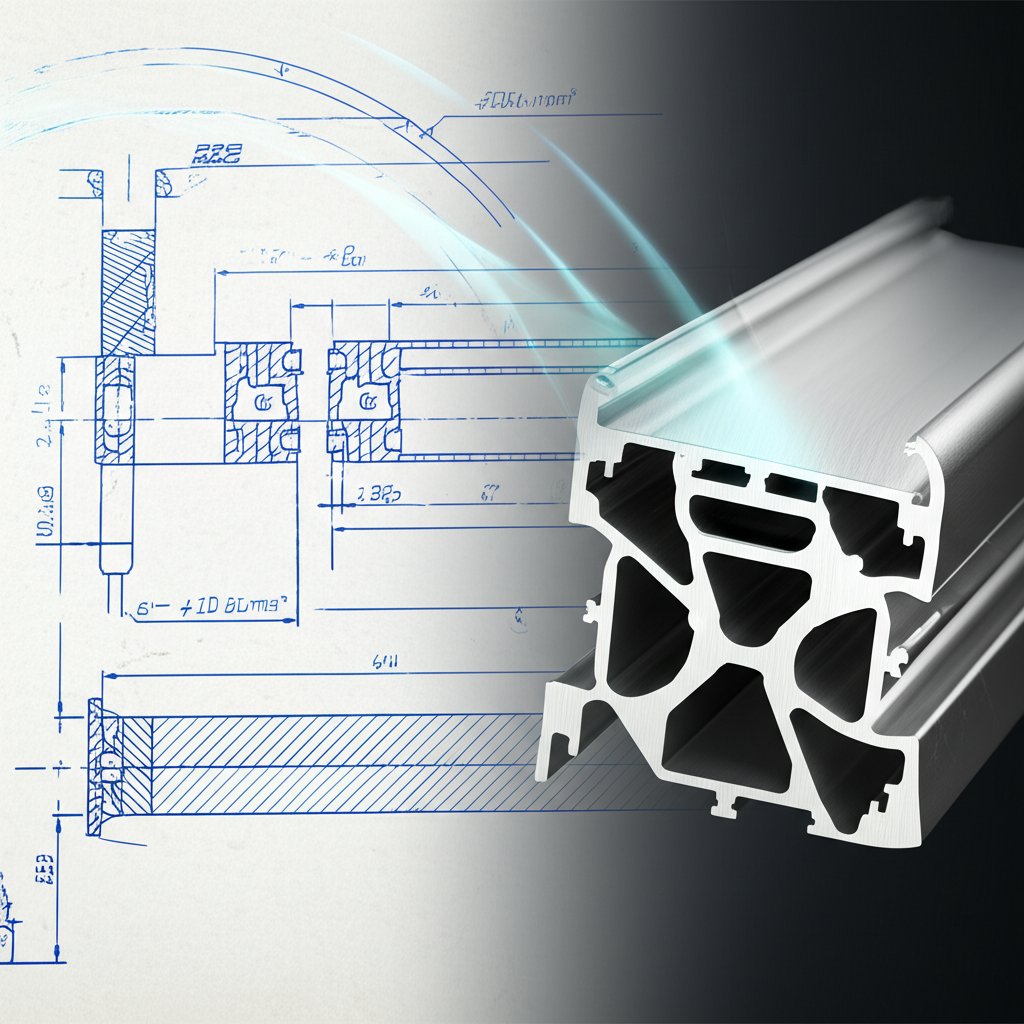

- Rujuk Jadual Piawaian Industri. Sebelum menetapkan nilai tersuai, sentiasa bermula dengan piawaian industri. Untuk aluminium, sumber utama ialah Piawaian Aluminium dan Data terbitan dari The Aluminum Association, yang dirujuk oleh Majlis Pengeluar Profil Aluminium . Jadual-jadual ini memberikan had terima yang telah ditetapkan untuk dimensi, kelurusan, kilatan, dan ciri geometri lain berdasarkan saiz dan bentuk profil.

- Lakukan Analisis Kos-Manfaat. Bagi setiap dimensi penting, nilaikan sama ada had terima piawai adalah mencukupi. Jika had terima yang lebih ketat diperlukan, fahamilah bahawa ini kemungkinan akan meningkatkan kos. Matlamatnya adalah untuk menentukan had terima yang paling longgar (terluas) yang masih membolehkan komponen berfungsi dengan betul, satu amalan yang mengelakkan perbelanjaan pembuatan yang tidak perlu.

- Dokumen Had Terima dengan Jelas pada Lukisan. Gunakan notasi piawaian untuk menentukan had terima pada lukisan kejuruteraan anda. Walaupun notasi tambah/tolak (±) ringkas adalah biasa digunakan, bagi hubungan geometri yang lebih kompleks, pertimbangkan penggunaan Penentuan Dimensi dan Had Terima Geometrik (GD&T). GD&T adalah suatu bahasa simbolik yang menyediakan cara yang lebih tepat untuk mentakrifkan variasi yang dibenarkan dalam bentuk, orientasi, dan lokasi ciri-ciri sesuatu komponen.

- Bekerjasama dengan Pengeluar Anda. Libatkan rakan kongsi pengeluaran ekstrusi anda lebih awal dalam proses rekabentuk. Seorang pengeluar ekstrusi yang berpengalaman boleh memberikan maklum balas yang sangat berharga mengenai kemampuan pengeluaran rekabentuk anda dan membantu anda menentukan had toleransi yang realistik dan berkesan dari segi kos. Bagi projek automotif yang memerlukan komponen direkabentuk secara tepat, pertimbangkan rakan kongsi terpercaya seperti Shaoyi Metal Technology , yang menawarkan perkhidmatan satu hentian yang komprehensif dari prototaip pantas hingga pengeluaran skala penuh di bawah sistem kualiti bersijil ketat IATF 16949. Kerjasama awal mengelakkan rekabentuk semula yang mahal dan kelewatan pengeluaran.

Navigasi Piawaian Industri untuk Aluminium dan Plastik

Piawaian industri menyediakan bahasa sepunya antara pereka dan pengeluar, memastikan konsistensi dan kualiti. Walau bagaimanapun, ekosistem piawaian berbeza secara ketara antara aluminium dan plastik.

Piawaian Ekstrusi Aluminium

Industri aluminium dikawal dengan baik dengan satu set standard yang komprehensif, yang terutamanya dikendalikan oleh The Aluminium Association. Standard ini, terperinci dalam dokumen seperti yang tersedia dari MK Metal , meliputi pelbagai sifat geometri dan dimensi. Berkomunikasi dengan pembekal anda dari segi toleransi standard ini adalah kunci untuk proses yang cekap. Beberapa jenis yang paling biasa ialah:

| Jenis Toleransi | Penerangan |

|---|---|

| Perenggan Tanduk | Mengendalikan penyimpangan yang dibenarkan untuk dimensi profil, seperti ketinggian, lebar, dan ketebalan dinding. |

| Kejujuran | Mengukur penyimpangan maksimum yang dibenarkan dari garis lurus yang sempurna di sepanjang panjang ekstrusi. |

| Pusing | Menentukan putaran yang dibenarkan profil di sepanjang paksi longitudinal, sering diukur dalam darjah setiap kaki. |

| Rata | Ia digunakan untuk permukaan rata dan mengukur penyimpangan mereka dari bidang sempurna. |

| Ketegalan | Mengendalikan variasi yang boleh diterima dalam sudut antara dua permukaan, memastikan sudut 90° berada dalam julat yang ditentukan (contohnya, 90° ±1°). |

Toleransi Pengekstrusi Plastik

Tidak seperti aluminium, industri pengeluaran plastik tidak mempunyai satu set piawaian rongga yang diterima secara universal. Rongga untuk plastik sangat bergantung kepada bahan tertentu, kerumitan profil, dan keupayaan dalaman pengilang. Plastik yang berbeza mempunyai sifat unik, seperti kadar pengembangan haba dan susutan, yang sangat mempengaruhi kestabilan dimensi. Oleh itu, adalah penting untuk bekerjasama rapat dengan pengilang pengeluaran plastik anda bagi menentukan rongga yang boleh dicapai untuk aplikasi dan pilihan bahan tertentu anda. Perwakilan awal dan percubaan ujian sering diperlukan untuk mengesahkan rongga sebelum melaksanakan pengeluaran skala penuh.

Soalan Lazim

1. Bagaimanakah anda menentukan rongga?

Toleransi ditentukan dalam lukisan kejuruteraan dan teknikal. Ini biasanya dilakukan menggunakan simbol tambah-tolak (±) di sebelah dimensi (contohnya, 1.500" ±0.010"). Untuk keperluan yang lebih kompleks berkaitan bentuk atau kedudukan fitur, simbol Geometric Dimensioning and Tolerancing (GD&T) digunakan mengikut piawaian seperti ASME Y14.5.

2. Apakah toleransi bagi ekstrusi bahan?

Tiada satu saiz toleransi untuk ekstrusi bahan, kerana ia berbeza-beza secara meluas. Faktor-faktor termasuk bahan (aluminium, PVC, ABS), saiz dan kerumitan profil, serta kualiti perkakasan. Bagi aluminium, toleransi dimensi piawai mungkin berkisar antara ±0.008" untuk ciri-ciri kecil hingga melebihi ±0.100" untuk profil yang sangat besar. Toleransi ekstrusi plastik biasanya lebih longgar disebabkan oleh pengembangan haba. Sentiasa rujuk piawaian industri atau pengeluar anda untuk julat tertentu.

3. Bagaimana mentakrifkan had toleransi?

Had toleransi ditentukan berdasarkan keperluan fungsian komponen tersebut. Proses ini melibatkan pengenalpastian dimensi yang kritikal terhadap kesesuaian dan fungsi komponen, menjalankan analisis kos-manfaat untuk mengelakkan toleransi yang terlalu ketat, serta memahami keupayaan proses pembuatan. Had tersebut haruslah selonggar mungkin sambil tetap memastikan komponen berfungsi seperti yang dirancang.

4. Bagaimanakah saya memilih toleransi yang sesuai?

Pemilihan toleransi yang sesuai melibatkan proses berperingkat. Pertama, kenal pasti ciri-ciri utama rekabentuk anda. Kedua, rujuk jadual toleransi piawaian industri sebagai asas. Ketiga, tentukan sama ada sebarang ciri memerlukan toleransi tersuai yang lebih ketat atas sebab prestasi. Akhirnya, dan yang paling penting, bekerjasama dengan pengilang ekstrusi pilihan anda untuk mengesahkan bahawa toleransi yang dinyatakan adalah boleh dicapai dan berkesan dari segi kos bagi proses mereka.

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —

Jumlah kecil, piawai tinggi. Perkhidmatan prototaip pantas kami membuat pengesahan lebih cepat dan mudah —