Die And Stamping Secrets: Why 80% Of Defects Are Preventable

Understanding Die and Stamping in Manufacturing

When you hear manufacturers talk about producing millions of identical metal parts with remarkable precision, they're almost certainly referring to die and stamping processes. But what is metal stamping, and why does it remain the backbone of high-volume production worldwide?

Die and stamping is a cold-forming manufacturing process where specialized tooling (dies) works with stamping presses to transform flat sheet metal into precise, predetermined shapes through operations like cutting, bending, and forming.

This stamping definition captures the essence of a process that powers industries from automotive to aerospace. Understanding how dies and stamping work together is your first step toward preventing the defects that plague 80% of poorly managed operations.

The Die-Stamping Relationship Explained

Think of dies as the custom-designed molds that determine what your finished part looks like. So, what is a die in manufacturing? It's a specialized tool engineered to cut, shape, or form metal with extreme accuracy. The stamping press provides the force, while the die provides the precision.

This tool and die definition helps clarify an important distinction: stamping refers to the overall process, while dies are the critical tooling components that make it possible. When flat sheet metal feeds into a stamping press, the die transforms it through pressure and precisely engineered contact surfaces. The result? Consistent, repeatable parts produced at speeds that alternative methods simply cannot match.

Why Dies Matter in Modern Manufacturing

You might wonder why this decades-old technology remains essential when newer manufacturing methods exist. The answer lies in efficiency and economics. According to Schaumburg Specialties, the increasing global demand for mass-produced complex parts makes metal stamping a cost-efficient solution across countless applications.

What is a stamping operation capable of producing? The list includes automotive components, aerospace parts, medical devices, electronic housings, and everyday appliances. This versatility explains why understanding what is dies in manufacturing matters for anyone involved in procurement or production decisions.

In this article, you'll discover the secrets behind preventing common stamping defects, learn how to select the right die types for your applications, and gain practical insights into material selection, quality control, and maintenance best practices. Whether you're new to this manufacturing method or looking to optimize existing operations, these insights will help you achieve better results.

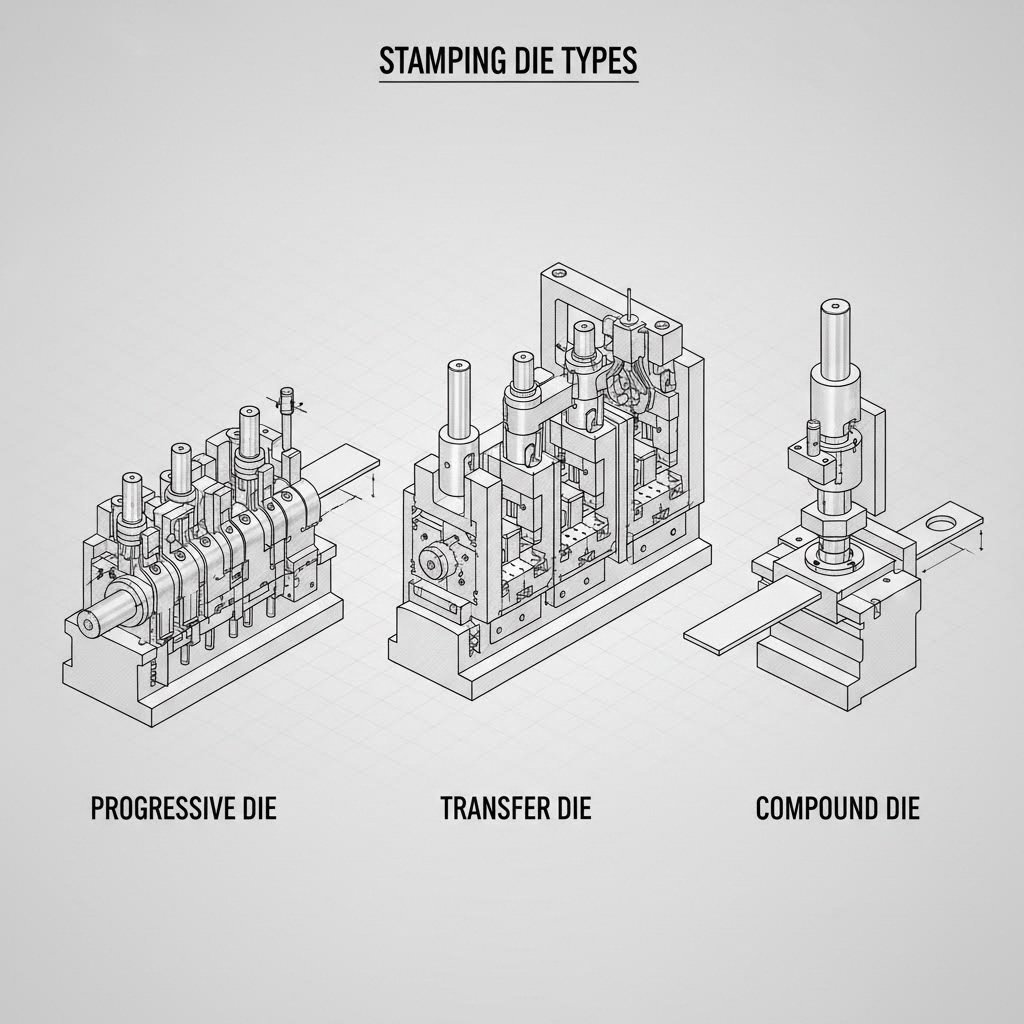

Types of Stamping Dies and When to Use Each

Choosing the right stamping die isn't just a technical decision—it's the foundation for preventing defects before they start. With three main die types dominating the industry, understanding their strengths and limitations helps you match your production requirements to the optimal tooling solution. Let's break down progressive stamping, transfer dies, and compound dies so you can make informed decisions.

Progressive Dies for High-Speed Production

Imagine an assembly line where multiple operations happen simultaneously as metal advances through different stations—that's the progressive stamping process in action. These sophisticated dies perform sequential operations like cutting, punching, and bending as the metal strip moves from station to station with each press stroke.

Why do manufacturers love progressive dies? According to JV Manufacturing, they're the workhorses of high-volume production lines, particularly for intricate parts requiring numerous forming steps. The progressive die stamping process excels when you need:

- Consistent production of complex parts with multiple features

- High-speed output for large volume requirements

- Reduced handling between operations

- Lower per-unit costs at scale

However, progressive dies come with significant upfront investment. They require advanced press systems and skilled operators to ensure seamless functionality. For manufacturers producing automotive components, electronics enclosures, or intricate mechanical parts in high volumes, this investment typically pays off through dramatically reduced per-part costs.

Material thickness matters here. Progressive dies work best with thinner gauge materials, typically ranging from 0.005" to 0.250". Thicker materials create excessive stress on the die stations and can compromise precision across the sequential operations.

Transfer Dies vs Compound Dies

When progressive dies don't fit your application, transfer stamping and compound dies offer powerful alternatives—each serving distinct manufacturing needs.

Transfer dies move individual parts mechanically from one stamping station to the next, like a skilled craftsman passing work between specialized workstations. This method shines when producing larger, more complex parts that require multiple sequential operations. As noted by Worthy Hardware, transfer die stamping allows more flexibility in part handling and orientation, making it suitable for intricate designs and shapes.

Transfer dies handle thicker materials more effectively than progressive dies, accommodating gauges from 0.020" up to 0.500" or more depending on the specific design. This makes them ideal for structural components and heavy-gauge applications.

Compound dies, on the other hand, perform multiple operations simultaneously in a single stroke. Think of cutting and punching happening at the exact same moment. They're commonly used for tasks requiring high-speed accuracy, such as producing parts for electronics or medical equipment. While slower than progressive dies, compound dies deliver exceptional precision for simpler, flat parts.

Compound dies typically work with material thicknesses from 0.010" to 0.375", depending on the material hardness and the complexity of simultaneous operations.

| Characteristic | Progressive Dies | Transfer Dies | Compound Dies |

|---|---|---|---|

| Part Complexity | High - multiple features, intricate designs | Very High - large complex geometries | Low to Medium - flat parts, basic shapes |

| Production Speed | Fastest - continuous strip feeding | Moderate - individual part transfer | Moderate - single stroke operations |

| Material Thickness Range | 0.005" - 0.250" | 0.020" - 0.500"+ | 0.010" - 0.375" |

| Setup Costs | High - complex tooling required | High - sophisticated transfer mechanisms | Moderate - simpler die construction |

| Ideal Applications | Automotive components, electronics, high-volume runs | Large structural parts, aerospace components, custom manufacturing | Electronics, medical devices, precision flat parts |

| Best Volume Range | 100,000+ parts annually | 10,000 - 500,000 parts annually | 5,000 - 100,000 parts annually |

So how do you decide which die type fits your project? Consider these key decision factors:

- Production volume: High-volume runs favor progressive dies; shorter runs may benefit from compound or transfer dies

- Part size: Larger parts typically require transfer dies; smaller intricate parts suit progressive stamping

- Material gauge: Thicker materials push you toward transfer dies; thinner gauges work well with progressive dies

- Geometric complexity: Multi-dimensional parts needing distinct operations at each stage call for transfer dies

- Budget constraints: Compound dies offer lower initial investment for simpler applications

Understanding these types of stamping dies positions you to prevent defects at the source—by selecting tooling that matches your exact manufacturing requirements. With the right die choice made, the next critical factor is selecting the appropriate stamping operations for your parts.

Essential Stamping Operations and Their Applications

Now that you've selected the right die type, understanding the specific operations your tooling will perform becomes critical for defect prevention. Every stamped part results from one or more fundamental operations—and knowing when each technique applies helps you anticipate quality challenges before they occur.

The metal stamping process relies on two primary categories of operations: cutting and forming. Cutting operations separate or remove material, while forming operations reshape it without cutting through. Let's explore how each technique works and when you'll need them.

Cutting Operations in Metal Stamping

Cutting operations use sharp-edged tools within the press and die setup to shear metal along precise contours. Think of these as the operations that define your part's outline and create openings. According to Fictiv's manufacturing guide, these operations work by applying immense pressure to shear or separate material cleanly.

- Blanking: This operation cuts the entire outer perimeter of a part from the sheet metal in one stroke. The separated piece becomes your workpiece, while the remaining sheet becomes scrap. Blanking creates the foundational shape for components like automotive brackets, appliance panels, and electronic chassis.

- Punching: Similar to blanking, but here the cut-out material is the scrap, leaving a hole in the workpiece. When you see mounting holes, ventilation slots, or cable pass-throughs in stamped parts, punching created them. The die punch applies concentrated force through a cutting die to remove material precisely.

- Piercing: Often confused with punching, piercing creates smaller holes or slots where the material isn't completely separated from the parent metal. This technique proves essential for creating locating features or partial cuts that guide subsequent forming operations.

- Fineblanking: A specialized high-precision shearing technique using tight punch-to-die clearances. This method produces smooth, fracture-free edges across the entire material thickness—eliminating secondary finishing operations for critical components in automotive safety systems and medical devices.

When selecting cutting operations, consider your edge quality requirements. Standard blanking and punching produce adequate edges for most applications, but components requiring smooth, burr-free edges may need fineblanking or post-processing.

Forming Operations That Shape Your Parts

Once cutting establishes your part's outline, forming operations create three-dimensional geometry without removing material. These metal stamping techniques apply pressure to deform sheet metal into desired shapes, adding depth, contours, and functional features.

- Bending: Deforms material along a straight line to create angled features like flanges, tabs, and brackets. Engineers must account for springback—the material's tendency to partially return to its original shape. Your die design compensates by over-bending slightly.

- Drawing: Creates seamless, cup-shaped, or hollow parts by pulling material into a die cavity. Punch drawing transforms flat blanks into three-dimensional containers, housings, and enclosures. Deep parts often require multiple draw stages to prevent tearing or wrinkling.

- Embossing: Raises or depresses portions of the sheet to create localized features, logos, or structural ribs. This operation adds stiffness to panels and creates aesthetic details without additional components.

- Coining: A precision forming operation that uses extreme pressure to flow metal into fine die details. The coining process produces exceptionally tight tolerances and smooth surfaces—ideal for electrical contacts, decorative hardware, and precision mechanical components.

- Flanging: Bends the edge of a part at an angle, often to create lips for assembly, strengthen edges, or prepare surfaces for welding. HVAC ductwork and automotive panels frequently require flanged edges.

The stamping process in most progressive die sequences combines multiple operations in carefully planned succession. A typical automotive bracket might begin with blanking, proceed through piercing for mounting holes, move to forming stations for bends, and finish with a coining operation for critical contact surfaces.

How do you select the right operations for your part geometry? Consider these practical guidelines:

- Parts with simple outlines and holes: Blanking and punching in compound or single-stroke dies

- Parts requiring bends without depth: Bending operations in progressive or transfer dies

- Cup-shaped or hollow components: Drawing operations, often with multiple stages

- Parts needing ultra-precise features: Coining or fineblanking for critical dimensions

- Complex multi-feature parts: Progressive die sequences combining cutting and forming stations

Understanding how these operations interact within your manufacturing stamping process directly impacts defect rates. Each operation creates specific stresses and material flow patterns—and selecting incompatible sequences leads to the quality problems we'll address later. First, though, you need to understand how material selection influences which operations will succeed.

Material Selection for Die Stamping Success

You've chosen the right die type and mapped out your stamping operations—but none of that matters if you're working with the wrong material. Selecting the appropriate sheet metal stamping material is where many preventable defects originate, yet it's often treated as an afterthought.

Here's the reality: your material choice affects everything downstream. According to PANS CNC, material selection is critical not only for meeting end-use requirements but also for controlling the stamping process itself. Variables like sheet thickness, bending stress, and stamping force are all influenced by material type. Get this wrong, and you'll fight quality issues throughout production.

Matching Materials to Manufacturing Requirements

When evaluating materials for sheet metal stamping dies, you need to balance multiple factors simultaneously. Think of it as solving an equation where formability, strength, cost, and environmental resistance must all reach acceptable values.

Steel dominates metal stamping and forming applications for good reason. Low carbon steel grades like 1008, 1010, and 1018 offer excellent formability combined with good tensile strength and cost efficiency. As noted by industry experts, these grades contain approximately 0.05% to 0.3% carbon, which improves strength while maintaining the ductility needed for complex forming operations. Steel stamping dies handle everything from automotive brackets to appliance panels.

Stainless steel grades—including 301, 302, 316, and 400 series—provide superior corrosion resistance for demanding environments. However, the 300 series austenitic steels exhibit higher work-hardening rates, requiring adjustments to your die design and press parameters.

Aluminum brings a completely different profile to stamped sheet metal applications. According to Metal Craft Spinning & Stamping, aluminum is more elastic and ductile, allowing it to be bent, extruded, or stretched without cracking. The aluminum stamping process doesn't require complex setups—even a simple progressive die press can produce complex parts. Common alloys include 1100 (excellent ductility for deep draws), 5052 (balanced strength and stampability), and 6061 (heat-treatable for structural applications).

Copper and copper alloys excel in electrical applications due to their conductivity and corrosion resistance. Pure copper grades like C101 and C110 work well for power busbars and low-loss conductors. Brass alloys (C26000, C27000) offer excellent ductility for complex bends and tight radii, while phosphor bronze provides superior fatigue resistance.

Specialty alloys serve extreme applications. Titanium grades deliver outstanding strength-to-weight ratios for aerospace and marine environments, though they require tool steel or carbide dies with higher forming pressures. Inconel superalloys maintain stability under extreme temperatures but demand specialized tooling and often hot forming techniques.

Thickness and Formability Considerations

Material thickness directly impacts your sheet metal die design and process parameters. Thicker materials require greater tonnage, different clearances, and modified forming sequences. Here's how to think through these decisions:

| Material | Typical Thickness Range | Formability Rating | Relative Cost | Best Applications |

|---|---|---|---|---|

| Low Carbon Steel | 0.010" - 0.500" | Excellent | Low | Automotive brackets, appliance panels, general fabrication |

| Stainless Steel (300 series) | 0.010" - 0.250" | Good (work hardens) | Medium-High | Food processing, medical devices, marine components |

| Aluminum (1100, 3003) | 0.008" - 0.250" | Excellent | Medium | Deep-drawn parts, electronics enclosures, heat sinks |

| Aluminum (5052, 6061) | 0.020" - 0.190" | Good | Medium | Structural components, automotive panels |

| Copper (C110) | 0.005" - 0.125" | Excellent | High | Electrical busbars, conductors, RF shielding |

| Brass (C26000) | 0.005" - 0.125" | Excellent | Medium-High | Decorative hardware, electrical terminals, fittings |

| Titanium (Grade 2) | 0.016" - 0.125" | Poor-Fair | Very High | Aerospace brackets, medical implants, marine hardware |

Your end-use environment plays a decisive role in material selection. According to Kenmode Precision Metal Stamping, choosing an unsuitable material can directly compromise function and performance while increasing the risk of material cracking during forming.

Consider these environmental factors when selecting materials:

- Moisture exposure: Aluminum's natural oxide film provides inherent rust protection; steel requires coatings or plating

- Temperature extremes: Aluminum increases strength in cold environments; titanium and Inconel handle high-temperature applications

- Electrical requirements: Copper and brass deliver superior conductivity; aluminum offers a lighter, more economical alternative

- Weight constraints: Aluminum weighs roughly one-third of steel at equivalent volumes—critical for automotive and aerospace applications

Your material choice also affects die wear patterns and maintenance schedules. Harder materials like stainless steel and titanium accelerate tool wear, requiring more frequent sharpening and potentially carbide or coated tooling. Softer materials like aluminum and copper are gentler on dies but may require different lubricants to prevent galling.

Understanding these material-process interactions positions you to prevent defects at their source. Now let's examine how proper die design translates your material and operation choices into precision results.

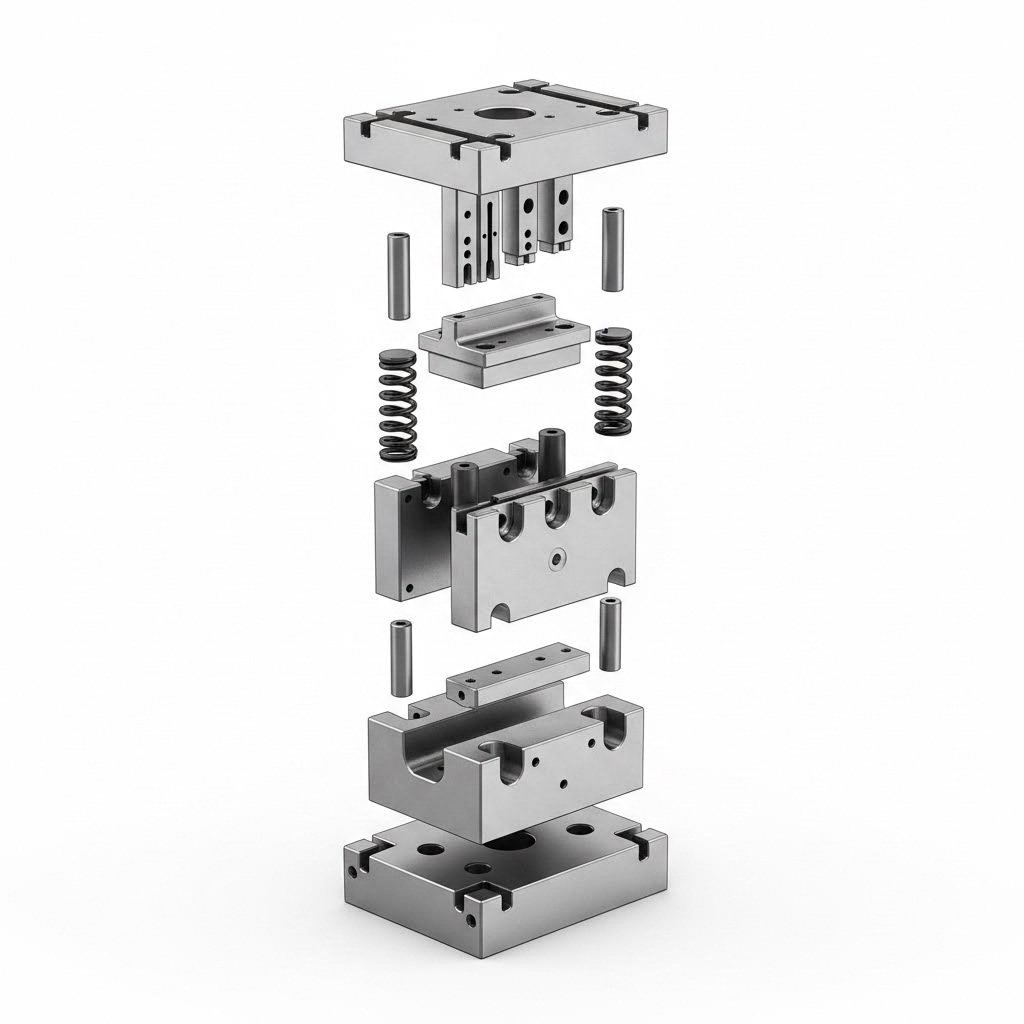

Die Design Fundamentals and Component Functions

You've selected your materials and mapped out your operations—but the real secret to preventing defects lies in how your die tool is designed and constructed. Every component within your stamping die design serves a specific purpose, and understanding these functions helps you recognize potential quality issues before they reach the production floor.

Think of a precision stamping die as a finely tuned machine where each part must work in harmony. When one component fails or wears prematurely, the entire system suffers. According to industry experts, understanding the function of each component is crucial in the design and production of stamping dies. Let's break down what makes these tools tick.

Critical Die Components and Their Functions

Every metal stamping die design relies on core components working together with precision tolerances. When you examine a pressing die closely, you'll find these essential elements:

Die Set (Die Shoe Assembly): This is the backbone of your entire stamping die components system. The die set consists of upper and lower die shoes that provide a rigid mounting platform for all other components. Without a properly designed die set, even the best punch and die components will produce inconsistent results. The die set absorbs and distributes the massive forces generated during each press stroke.

Punch and Die Block: These are your primary working components—the parts that actually cut, form, or shape your material. The punch is the male component that descends with force, while the die block acts as the female counterpart. As noted by manufacturing specialists, the clearance between punch and die is critical, determining both cut quality and overall die performance. Improper clearance is one of the leading causes of burrs and premature tool wear.

Stripper Plate: Ever wonder how parts release cleanly from the punch after forming? That's the stripper's job. This spring-loaded component holds material firmly against the die press during the cutting or forming stroke, then releases the finished part as the punch retracts. According to stamping experts, strippers prevent parts from sticking to the punch or die, ensuring clean ejection without damage.

Guide Pins and Bushings: Precision alignment is non-negotiable in stamping operations. Guide pins are cylindrical rods that ensure the upper and lower die shoes remain perfectly parallel throughout operation. Bushings provide smooth, controlled movement for components within the die. Together, they maintain the accuracy that prevents misalignment defects.

Die Springs: These coil springs provide the return force needed to reset moving components after each stroke. Proper spring selection affects everything from stripper function to pilot pin retraction. Springs must be calibrated precisely—too weak, and components won't return properly; too strong, and you'll create excessive stress and premature wear.

Design Principles for Precision Results

Understanding bypass notches sheet metal forming purpose reveals one of the lesser-known design principles that separates good dies from great ones. Bypass notches are strategically placed relief cuts that allow material to flow smoothly during forming operations. They prevent material binding, reduce forming forces, and eliminate wrinkles in complex geometries. When engineers skip this design element, they often discover quality problems only after production begins.

What design considerations should guide your stamping die development? Focus on these critical factors:

- Clearance optimization: Punch-to-die clearance typically ranges from 5% to 10% of material thickness for cutting operations—adjust based on material hardness and desired edge quality

- Material flow planning: Design forming stations to guide material progressively, avoiding sudden deformations that cause cracking or tearing

- Springback compensation: Over-bend forming features slightly to account for material's elastic recovery, especially in high-strength steels and stainless alloys

- Pilot positioning: Locate pilots to control strip progression accurately, preventing misregistration between stations in progressive dies

- Lubrication channels: Incorporate pathways for lubricant distribution to high-friction areas, extending die life and improving surface finish

- Accessibility for maintenance: Design die components for easy removal and replacement, reducing downtime during sharpening and repairs

Modern CAE simulation has transformed how engineers approach metal stamping die design. According to research published in ScienceDirect, CAE simulation technology helps practitioners generate, verify, validate and optimize design solutions. In current manufacturing, product development is shifting from traditional trial-and-error to proof-of-concept based on CAE-enabled simulation.

What does this mean practically? Engineers can now simulate material flow, predict defect locations, and optimize die geometry before cutting any steel. The research demonstrates that by comparing simulation results across multiple design iterations, optimal layouts can be identified—reducing costly physical prototypes and accelerating time to production.

As noted by Approved Sheet Metal, forming software can analyze part shapes to ensure the right die configuration is selected. This capability is particularly valuable for complex geometries where traditional experience-based design might miss critical issues.

Consider tolerance stack-up in your die design process. Each bend and forming station introduces variation, and these variations accumulate across multiple operations. Designing with realistic tolerances—tighter only where functionally critical—prevents manufacturing challenges while controlling costs. Using common bend radii that align with available tooling further reduces setup time and tooling expenses.

For manufacturers seeking high first-pass approval rates on demanding automotive applications, partnering with die makers who leverage advanced CAE simulation capabilities delivers measurable advantages. IATF 16949 certified manufacturers combine simulation-driven design with precision fabrication to achieve defect-free results—turning design decisions into consistent production quality.

Your die design choices directly determine downstream outcomes. Proper component selection, thoughtful material flow planning, and simulation-validated geometry create the foundation for the 80% of defects that are truly preventable. With solid design fundamentals in place, you're ready to address what happens when problems do occur—and how to catch them before they reach your customers.

Troubleshooting Defects and Quality Control Methods

Here's the uncomfortable truth about the manufacturing stamping process: most quality problems are self-inflicted. When you understand what causes defects in die stamping operations, you gain the power to prevent them. The good news? Industry data suggests that roughly 80% of stamped parts defects trace back to identifiable, correctable root causes.

Whether you're troubleshooting burrs on freshly stamped parts or investigating dimensional drift during a production run, this section gives you the diagnostic framework and prevention strategies that separate high-yield operations from those constantly fighting quality fires.

Identifying Common Stamping Defects

Every defect tells a story about what went wrong during production. According to DGMF Mold Clamps, die stamping molds in use are prone to different amounts of wear on each side position of the punch core, with some parts showing larger scratches and wearing faster—particularly pronounced on thin and narrow rectangular dies. Understanding these patterns helps you intervene before minor issues become major quality failures.

Let's examine the most common defects you'll encounter with stamped parts:

Burring: Those raised, rough edges along cut lines that can cut fingers and scratch mating surfaces. Burrs form when punch-to-die clearance is incorrect or when cutting edges become dull. Excessive burrs indicate it's time to inspect your tooling.

Cracking: Material fractures during forming operations, typically appearing at bend lines or draw radii. Cracking signals that you're exceeding the material's formability limits—either through excessive deformation, insufficient bend radii, or work-hardened material that's lost its ductility.

Wrinkling: Wavy, buckled surfaces that appear during drawing operations when compressive stresses exceed material stability. You'll often see wrinkling in flanged areas or deep-drawn parts where material flow isn't properly controlled.

Springback: The elastic recovery that causes bent parts to partially unbend after forming. Every material exhibits some springback, but high-strength steels and stainless alloys are particularly problematic. Uncorrected springback leads to out-of-tolerance parts and assembly issues.

Dimensional Inaccuracies: Parts that fall outside specified tolerances despite appearing visually acceptable. According to Metal Infinity, dimensional tolerance for stamped parts often hovers around ±0.05mm—equivalent to the thickness of two sheets of A4 paper. Without an inspection mechanism, this tiny discrepancy could lead to assembly issues, misaligned screws, or equipment seizure.

| Defect Type | Primary Causes | Corrective Actions | Prevention Strategy |

|---|---|---|---|

| Burring | Dull cutting edges; incorrect punch-to-die clearance; worn guide pins | Sharpen or replace tooling; adjust clearance to 5-10% of material thickness; replace worn guides | Scheduled sharpening intervals; clearance verification at setup; regular alignment checks |

| Cracking | Insufficient bend radius; excessive forming strain; material work hardening | Increase bend radii; add forming stages; anneal material between operations | Design validation using CAE simulation; material formability testing; proper sequencing |

| Wrinkling | Inadequate blank holder pressure; improper material flow; excessive clearance in draw dies | Increase blank holder force; add draw beads; reduce die clearance | Optimized blank holder design; simulation-validated draw parameters |

| Springback | Material elastic recovery; insufficient over-bend compensation; inconsistent material properties | Increase over-bend angle; add coining or restrike operations; adjust forming pressure | Material-specific compensation factors; simulation-based die design |

| Dimensional Inaccuracies | Die wear; thermal expansion; material variation; pilot misregistration | Measure and adjust die components; verify pilot positioning; tighten material specifications | Statistical process control; regular die inspection; incoming material verification |

| Surface Scratches | Debris in die; inadequate lubrication; rough die surfaces | Clean die thoroughly; increase lubricant application; polish contact surfaces | Regular die cleaning schedule; lubricant monitoring; protective coatings on dies |

Prevention Strategies for Quality Parts

Preventing defects starts long before parts reach final inspection. As Metal Infinity emphasizes, quality inspection isn't merely about picking out defective products—it's a vital basis for collecting data, identifying problems, and improving the manufacturing process.

Effective quality control for precision die & stamping operations follows a multi-stage approach:

Incoming Material Inspection: Your first line of defense. Verify that sheet thickness complies with specifications—according to industry standards, allowed deviations might be ±0.05mm for standard applications or ±0.03mm for high-precision requirements. Check for scratches, oxidation, and deformation before material enters production.

First Article Inspection: Before each production run, produce a sample part and inspect dimensions, appearance, and functionality. Only after confirmation should mass production begin. This single practice catches setup errors before they become batch-wide problems.

In-Process Patrol Inspection: Regular sampling during production—for example, checking five pieces every 30 minutes—ensures process stability. According to quality experts, patrol inspection catches issues like gradual dimensional drift caused by die wear before they affect large quantities.

Key Inspection Methods for Stamped Parts:

- Vernier calipers and thickness gauges for dimensional verification (precision to ±0.01mm)

- 2.5D measuring machines for precise hole positions and complex geometries

- Microscopes for detecting cracks, burrs, and surface defects invisible to naked eyes

- Feeler gauges for checking flatness and warp conditions

- Specialized fixtures for functional testing of bends, latches, and assembly fit

Die Wear Patterns and Their Impact on Quality

Understanding how dies wear helps you predict when quality will degrade. According to Keneng Hardware, die wear occurs as a result of repeated contact between the die surface and the metal being stamped, with several factors contributing to eventual failure.

Common wear patterns to monitor include:

- Adhesive wear: Material transfer between die and workpiece, creating galling and rough surfaces

- Abrasive wear: Gradual erosion of cutting edges, leading to increased burr formation

- Fatigue wear: Micro-cracking from repeated stress cycles, eventually causing chipping or fracture

- Uneven wear: Misalignment causing one side of the punch to wear faster than the other

As noted by troubleshooting experts, uneven die wear often stems from poor turret alignment, insufficient die precision, or improper clearance selection. Prevention requires regular alignment checks, timely guide bushing replacement, and full-guide die designs for precision applications.

Proper Die Maintenance Prevents Quality Issues

Your dies are precision instruments that require consistent care. The relationship between maintenance and quality is direct—neglected tooling produces defective parts. Implement these practices:

- Establish sharpening intervals based on material type and production volume

- Inspect cutting edges under magnification after each production run

- Verify punch-to-die clearances periodically using feeler gauges or measurement instruments

- Clean dies thoroughly between runs to remove debris and built-up material

- Document wear observations to establish predictive maintenance baselines

An example illustrates the stakes: one manufacturer producing automotive TFT-LCD brackets discovered during patrol inspection that dimensions were gradually increasing. Investigation confirmed wear on the die's guide posts. Without in-process quality control, the entire batch of 20,000 parts might have been scrapped. Because inspection caught it in time, only 200 pieces were lost—minimizing losses dramatically.

Quality control in the metal stamping manufacturing process isn't a cost center—it's your insurance policy against far greater losses. By combining systematic inspection, understanding of wear patterns, and proactive maintenance, you transform quality from a reactive firefight into a competitive advantage. With defect prevention mastered, the next step is understanding how proper maintenance schedules maximize your die investment over time.

Die Maintenance and Longevity Best Practices

You've invested thousands—sometimes tens of thousands—of dollars in your stamping dies. But here's what many manufacturers overlook: that investment starts depreciating the moment your dies enter production without a proper maintenance strategy. According to Phoenix Group experts, a poorly defined die shop management system can dramatically decrease press line productivity and increase costs.

The connection between metal stamping dies maintenance and part quality isn't just theoretical. Poor die maintenance causes quality defects during production, drives up sorting costs, increases the likelihood of shipping defective parts, and risks expensive forced containments. Let's explore how systematic maintenance transforms your stamping tooling from a liability into a long-term asset.

Preventive Maintenance Schedules

Think of preventive maintenance as your insurance policy against unplanned downtime. Rather than waiting for dies to fail catastrophically, you're addressing potential issues during controlled intervals. According to JV Manufacturing, preventative maintenance schedules enable workers to address minor issues during planned downtimes rather than during production—ensuring continuous workflow.

How often should you maintain your tooling dies? That depends on several factors working together:

- Production volume: High-volume runs demand more frequent inspection cycles—consider checking dies every 50,000 to 100,000 hits for demanding applications

- Material hardness: Stamping stainless steel or high-strength alloys accelerates wear compared to mild steel or aluminum, requiring shorter maintenance intervals

- Part complexity: Progressive dies with multiple stations need more attention than simple blanking dies

- Historical data: Track wear patterns over time to establish predictive baselines specific to each die

Your maintenance checklist should cover these essential activities:

- Visual inspection: Check cutting edges, forming surfaces, and guide components for visible wear, cracks, or damage

- Dimensional verification: Measure punch-to-die clearances using feeler gauges; verify they remain within 5-10% of material thickness for cutting operations

- Sharpening assessment: Examine cutting edges under magnification—dull edges produce burrs and require immediate attention

- Spring testing: Verify die springs maintain proper force; weakened springs cause stripping failures and part damage

- Alignment check: Confirm guide pins and bushings maintain precise alignment without excessive play

- Lubrication verification: Ensure all moving components receive adequate lubrication to prevent galling and premature wear

- Documentation: Record all observations on die maintenance cards for future reference and trend analysis

According to Manor Tool, once inspection finishes, you should fill out the die maintenance card with all work performed, tag the tool inspected, and order any replacement parts needed. This documentation becomes invaluable for predicting future maintenance needs.

Maximizing Die Lifespan

Proper lubrication is just as critical as sharpening for extending metal stamping tooling life. As industry experts note, lubrication reduces friction between surfaces, preventing excessive heat generation that could lead to material fatigue and failure. It also protects against corrosion and infiltration of harmful elements.

Match your lubricant type to your application:

- Oil lubrication: Best for high-speed operations and hydraulic systems

- Grease: Ideal for bearings, joints, and applications where liquid lubricants are impractical

- Dry lubricants: Use where oil contamination is a concern, such as electrical component manufacturing

Storage considerations also affect die longevity. When dies aren't in production:

- Apply rust preventive coating to all exposed steel surfaces

- Store in climate-controlled environments when possible to prevent moisture damage

- Support dies properly to prevent warping or distortion

- Keep dies covered to prevent dust and debris accumulation

When should you refurbish versus replace stamping dies? Consider these decision factors:

- Refurbish when: Wear is limited to cutting edges and forming surfaces; core die structure remains sound; dimensional accuracy can be restored through grinding and shimming; repair costs are less than 40-50% of replacement cost

- Replace when: Structural components show fatigue cracking; multiple stations require simultaneous major repairs; die design is outdated and causing recurring quality issues; cumulative repair costs approach replacement value

According to Phoenix Group, data from previous work orders can be utilized to improve preventative maintenance plans and scheduling across part families. By tracking repair frequency and types of failures, you'll develop predictive capabilities that prevent problems before they disrupt production.

The bottom line? Consistent maintenance of your die manufacturing investment pays dividends through reduced scrap, fewer emergency repairs, and predictable production quality. With your maintenance strategy established, you're ready to evaluate when stamping remains your best manufacturing choice—and when alternatives might serve you better.

Die Stamping vs Alternative Manufacturing Methods

You've mastered die selection, materials, operations, and maintenance—but here's a question that trips up even experienced procurement professionals: when should you use metal stamping versus other manufacturing methods? Choosing the wrong process can mean overpaying by 40% or more, waiting weeks longer than necessary, or settling for inferior part quality.

The reality is that stamping isn't always the answer. Understanding where die cutting and stamping excel—and where alternatives outperform them—helps you make decisions that optimize cost, quality, and timeline simultaneously.

When Stamping Outperforms Alternatives

Die stamping dominates high-volume production for good reason. According to Hotean's manufacturing analysis, stamping's per-unit processing cost advantage becomes significant once you cross certain volume thresholds—typically around 3,000 to 10,000 units depending on part complexity.

What makes metal stamping unbeatable at scale? Several factors compound in your favor:

- Speed: Stamping presses produce 600 to 2,400 parts per hour, dwarfing alternative methods

- Consistency: Die-formed parts maintain tight tolerances across millions of cycles

- Material efficiency: Progressive dies minimize scrap through optimized nesting

- Labor costs: Automated feeding and ejection reduce per-part labor content dramatically

Consider this comparison: a stamping operation running at 600 strokes per hour can produce enough parts in one hour to satisfy a month's production for many applications. That throughput simply cannot be matched by cutting-based processes.

However, stamping requires significant upfront investment. According to MIT research on automotive stamping costs, tooling expenses for stamped assemblies represent substantial capital costs that must be amortized across production volumes. This is where understanding break-even points becomes critical.

Choosing the Right Manufacturing Method

So how do you decide between stamping, laser cutting, CNC machining, waterjet cutting, or additive manufacturing? Each method serves distinct needs across the volume, complexity, and material spectrum.

Laser Cutting: If you're wondering how to cut steel sheet for prototype quantities or small batches, laser cutting delivers compelling advantages. According to manufacturing cost analysis, laser cutting delivers 40% cost reduction versus stamping for batches under 3,000 units by eliminating $15,000+ tooling costs. The technology achieves ±0.1mm precision compared to stamping's typical ±0.3mm tolerance—and production can begin within 24 hours of receiving digital files.

CNC Machining: When your parts require three-dimensional features, tight tolerances, or hard materials, CNC machining fills gaps that stamping cannot address. It excels for prototypes, low volumes, and parts requiring features on multiple faces. However, per-part costs remain high regardless of volume.

Waterjet Cutting: This cold-cutting process handles virtually any material without heat-affected zones—ideal for heat-sensitive alloys or composites. Waterjet works well for medium-thickness materials where thermal distortion is unacceptable, but slower cutting speeds limit throughput.

Additive Manufacturing: Metal 3D printing enables geometries impossible with any subtractive or forming process. According to Protolabs' manufacturing guide, direct metal laser sintering (DMLS) builds parts layer by layer, achieving tolerances to +/- 0.003 in. with features smaller than a period. However, production speed and cost limit this technology to prototypes, low volumes, and highly complex parts.

An industrial die cutting machine or die cutter for metal applications bridges some gaps—offering faster setup than traditional stamping dies while handling medium volumes more economically than laser cutting. Machine die cutting works particularly well for softer materials and simpler geometries.

| Characteristic | Die Stamping | Laser Cutting | CNC Machining | Waterjet | Additive (DMLS) |

|---|---|---|---|---|---|

| Ideal Volume Range | 10,000+ units | 1 - 3,000 units | 1 - 500 units | 1 - 1,000 units | 1 - 100 units |

| Part Complexity | High (2D with forming) | Medium (2D profiles) | Very High (3D features) | Medium (2D profiles) | Extreme (organic shapes) |

| Material Options | Sheet metals to 0.5" | Metals to 1"; plastics | Nearly all metals/plastics | Any material to 6" | Select metals/alloys |

| Unit Cost at 100 pcs | Very High (tooling burden) | Low-Medium | High | Medium | Very High |

| Unit Cost at 10,000 pcs | Very Low | Medium | High | Medium-High | Impractical |

| Typical Tolerance | ±0.1 - 0.3mm | ±0.1mm | ±0.025mm | ±0.1 - 0.2mm | ±0.08mm |

| Lead Time (First Parts) | 4-8 weeks (tooling) | 24-48 hours | 1-5 days | 1-3 days | 3-7 days |

| Setup/Tooling Cost | $10,000 - $50,000+ | None (digital) | Minimal (fixturing) | None (digital) | None (digital) |

Understanding Break-Even Points

The critical question isn't which method is "best"—it's where the cost curves cross. According to manufacturing cost studies, stamping typically becomes cost-effective when:

- Simple parts: Break-even around 3,000-5,000 units

- Moderate complexity: Break-even around 5,000-10,000 units

- Complex progressive die parts: Break-even around 10,000-25,000 units

These thresholds shift based on tooling costs, material type, and part size. A detailed cost analysis from manufacturing experts shows laser cutting averages $8.50 per unit versus stamping's $14.20 for small batches—but those numbers invert dramatically at high volumes where stamping's tooling investment amortizes across many parts.

When evaluating your options, consider this decision framework:

- Choose stamping when: Production volumes exceed 10,000 units; part geometry suits forming operations; material thickness is under 6mm; you have predictable long-term demand; per-part cost is the primary driver

- Choose laser cutting when: Volumes stay under 3,000 units; you need rapid prototyping capability; designs change frequently; precision requirements are tight (±0.1mm); timeline is urgent

- Choose CNC machining when: Parts require 3D features; tolerances must be extremely tight; material is difficult to form; quantities are very low

- Choose waterjet when: Heat distortion is unacceptable; materials are exotic or composite; moderate precision is sufficient

- Choose additive when: Geometry is impossible to form or machine; weight optimization requires internal lattices; quantities are minimal

The manufacturing landscape continues shifting toward smaller batch sizes and faster iteration cycles. For many applications, a hybrid approach works best—laser cutting for prototypes and initial production, transitioning to stamping once volumes justify tooling investment. Understanding these trade-offs positions you to optimize both cost and timeline across your product's lifecycle.

With manufacturing method selection clarified, the final piece of the puzzle is understanding how these processes apply to one of the most demanding industries: automotive manufacturing, where quality standards and volume requirements push die and stamping capabilities to their limits.

Automotive Die and Stamping Applications

The automotive industry represents the ultimate proving ground for die and stamping excellence. When you're producing metal stamped parts destined for vehicles traveling at highway speeds, carrying passengers, and operating in extreme conditions—quality isn't optional. It's life-critical. This is why automotive stamping dies face the most demanding specifications in the manufacturing world.

Consider the scale: according to LMC Industries, the average car is made up of around 30,000 components. A significant portion of those parts—from structural brackets to visible body panels—rely on stamping manufacturing processes. Understanding how this industry applies die and stamping principles reveals best practices applicable across all sectors.

Meeting Automotive Quality Standards

If you've ever wondered why automotive metal parts stamping commands such rigorous attention to detail, IATF 16949 certification tells the story. This internationally recognized standard goes far beyond basic quality management—it establishes the framework for preventing defects before they occur.

According to OGS Industries, while ISO 9001 centers on customer satisfaction, IATF 16949 goes further to ensure compliance with lean manufacturing, defects prevention, variance deterrence, waste reduction, and company-specific requirements. For stamping metal parts destined for vehicles, this means:

- Consistent quality: Manufacturing processes are monitored and measured to maximize productivity and deliver consistent outcomes across millions of parts

- Reduced product variation: Reviewed and improved manufacturing processes ensure metal components consistently meet the needs of high-performance vehicles, regardless of application

- Defect prevention: Processes for metal fabrication, production, and related services are tested and proven to meet product safety requirements, diminish inefficiencies, and minimize defects

- Reliable supply chain: This certification sets the benchmark for sourcing suppliers, establishing stronger, more reliable partnerships

- Reduced waste: Streamlined manufacturing processes and improved management systems provide infrastructure to minimize waste and meet environmental initiatives

OEM specification requirements add another layer of complexity. Each automaker maintains proprietary standards for material properties, dimensional tolerances, surface finish, and functional performance. Your automotive stamping die must produce parts meeting both industry-wide IATF 16949 requirements and specific OEM criteria—simultaneously and consistently.

What types of components rely on automotive components progressive stamping? The list spans virtually every vehicle system:

- Body panels: Doors, hoods, fenders, and roof sections requiring precise fit and Class A surface finish

- Structural components: Floor pans, cross members, and reinforcements providing crash protection and chassis rigidity

- Brackets and mounts: Engine mounts, suspension brackets, and accessory supports demanding tight tolerances and fatigue resistance

- Chassis components: Control arms, frame rails, and subframe assemblies requiring high strength and dimensional stability

- Interior stampings: Seat frames, instrument panel supports, and trim brackets balancing weight reduction with durability

- Fuel system parts: Tanks, filler necks, and brackets requiring leak-tight construction and corrosion resistance

From Prototyping to Production Volume

Automotive projects don't jump straight from concept to million-unit production. The journey from initial design to full-scale stamping manufacturing involves multiple validation stages—each presenting opportunities to prevent the defects that plague 80% of poorly managed programs.

According to Neway Precision, engineers use advanced CAD software to model parts and simulate the stamping process, helping identify potential issues before production begins. This simulation-first approach has transformed automotive die development from trial-and-error into predictable engineering.

The rapid prototyping phase establishes design feasibility. Modern manufacturers can deliver initial prototype parts within days—not weeks—using soft tooling or alternative processes. This speed enables design teams to validate form, fit, and function before committing to production tooling investments.

The tooling development phase translates validated designs into production-ready automotive stamping dies. Here's where engineering partnerships prove their value. According to industry experts, collaboration and clear communication between automotive manufacturers and stamping providers are essential for overcoming obstacles and keeping projects on track.

Common challenges during this phase include:

- Managing complex part geometries requiring multi-stage forming

- Balancing material strength requirements against formability limits

- Achieving surface finish standards while maintaining cycle time targets

- Coordinating tooling timelines with vehicle launch schedules

The production validation phase proves that stamping dies perform consistently at production speeds and volumes. According to manufacturing research, tolerance and precision in automotive stamping often achieve ±0.01mm for critical dimensions—a level of accuracy that demands rigorous process control.

This is where advanced CAE simulation capabilities deliver measurable advantages. As Neway Precision explains, the tooling development process can achieve efficiency levels producing over 150 parts per hour while maintaining ±0.01mm tolerances—achieved through advanced tool design, optimized material selection, and precise control of stamping parameters.

Full-scale production demands sustained performance across hundreds of thousands or millions of cycles. The automotive stamping die must maintain dimensional accuracy, surface quality, and cycle time consistency throughout its service life. This is where preventive maintenance programs and quality monitoring systems prove their worth.

For manufacturers seeking to accelerate automotive production timelines while achieving defect-free results, partnering with IATF 16949 certified suppliers backed by advanced CAE simulation capabilities offers a proven path. From rapid prototyping in as little as 5 days to high-volume manufacturing with a 93% first-pass approval rate, engineering partnerships that combine simulation-driven design with precision fabrication deliver the quality standards automotive OEMs demand.

The automotive industry's uncompromising standards have driven continuous improvement in die and stamping technology. The lessons learned here—rigorous process control, simulation-validated design, preventive maintenance, and engineering collaboration—apply across every industry where stamped parts must perform reliably. By adopting these automotive-grade practices, any manufacturer can join the ranks of operations where 80% of defects truly are preventable.

Frequently Asked Questions About Die and Stamping

1. What is the difference between die cut and stamping?

Die cutting and metal stamping are distinct processes with different applications. Die cutting typically refers to shearing or punching operations that separate material using sharp-edged tools, producing flat profiles or shapes. Metal stamping encompasses a broader range of cold-forming operations including cutting, bending, drawing, and coining that transform flat sheet metal into three-dimensional parts. While die cutting focuses on 2D profile creation, stamping combines multiple operations to produce complex formed components. Stamping uses progressive, transfer, or compound dies working with presses that apply immense pressure to shape metal precisely.

2. What is the difference between die casting and stamping?

Die casting and metal stamping differ fundamentally in process and application. Die casting involves heating metal past its melting point and injecting molten material into molds to create complex 3D parts—ideal for intricate geometries but requiring expensive, long-lasting molds. Metal stamping is a cold-forming process using sheet metal blanks or coils, shaped through pressure without heating. Stamping excels at high-volume production of sheet metal components with faster cycle times and lower per-part costs at scale. Die casting suits complex cast geometries while stamping produces formed sheet metal parts like brackets, panels, and enclosures.

3. What are the main types of stamping dies and when should each be used?

Three main die types serve different manufacturing needs. Progressive dies perform sequential operations as metal advances through stations, ideal for high-volume production exceeding 100,000 parts annually with material thickness from 0.005 to 0.250 inches. Transfer dies mechanically move individual parts between stations, handling larger complex parts and thicker materials up to 0.500 inches—suited for 10,000 to 500,000 annual volumes. Compound dies perform multiple operations simultaneously in one stroke, best for simpler flat parts requiring high precision in volumes of 5,000 to 100,000 units. Selection depends on part complexity, production volume, material gauge, and budget constraints.

4. How do you prevent common defects in die stamping operations?

Preventing stamping defects requires a systematic approach across design, materials, and process control. Address burring by maintaining proper punch-to-die clearance at 5-10% of material thickness and scheduling regular sharpening intervals. Prevent cracking through adequate bend radii and CAE simulation validation. Control wrinkling with optimized blank holder pressure and draw beads. Compensate for springback by over-bending based on material-specific factors. Implement first article inspection before production runs, conduct patrol inspections every 30 minutes during production, and maintain dies according to volume-based schedules. IATF 16949 certified manufacturers achieve 93% first-pass approval rates through these practices.

5. When does die stamping become more cost-effective than laser cutting?

Die stamping becomes cost-effective at different volume thresholds depending on part complexity. For simple parts, break-even occurs around 3,000-5,000 units; moderate complexity parts break even at 5,000-10,000 units; complex progressive die parts require 10,000-25,000 units to justify tooling investment. Below these thresholds, laser cutting delivers 40% cost savings by eliminating $15,000+ tooling costs with 24-hour turnaround. However, stamping produces 600-2,400 parts per hour versus laser cutting's slower speeds, dramatically reducing per-part costs at high volumes. Consider a hybrid approach—laser cutting for prototypes transitioning to stamping once volumes justify tooling investment.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —