Ай сайын өткізілетін сапа бойынша оқытулар арқылы автомобиль өндірісін нығайту

ҚОСУЛЫ 27 маусым , біздің компания тұрақты ай сайынғы автомобиль сапасы бойынша оқыту бұл туралы біздің техникалық директорымыз Ху мырза мәлімдеді. Бұл бастама біздің ұзақ мерзімді сапаның үздіктігі өндіріс және сату бөлімдері бойынша. Негізгі тұжырымдамаларды және нақты кемшіліктерді басқару әдістерін нығайту арқылы біздің мақсатымыз - әрбір қызметкерге сенімді, жоғары өнімділікті жеткізуге ықпал ету автокөлік компоненттері біздің әлемдік клиенттерге.

Неліктен ай сайынғы сапалы оқыту маңызды

Бұл жерде автомобил құрылғы саласы бұл сапа тек соңғы тексеру ғана емес, ол өндірістің әрбір кезеңінде ойлау, процесс және жауапкершілік. Сюй мырзаның атап өткеніндей, сапа - іШКІ ТІРКЕМЕ тек тексерілген жоқ. Әсіресе күрделі металл бөлшектерін өндіруде кемшіліктерді тек желі соңында тексеру арқылы анықтау мүмкін емес. Шын сапа өнімнің талаптарына, ерекше ерекшеліктеріне және тұтынушылардың құрастыру нормаларына терең түсінік беруден басталады.

Негізгі оқыту мазмұнының шолуы

1. Өнім басқару негіздерін түсіну

Оқытудың бірінші бөлігінде өнім сапасын басқару негізі түсіндірілді. Негізгі қорытындылар мыналар болды:

- Сапа тексерілуге дейін болады – ол жобалау, дамыту және өндіруді бастайды.

- Барлық қызметкерлер бөлшектің қабылдануын бағаламас бұрын тұтынушының техникалық стандарттарын, негізгі өнім сипаттамаларын және соңғы пайдалану талаптарын түсінуі тиіс.

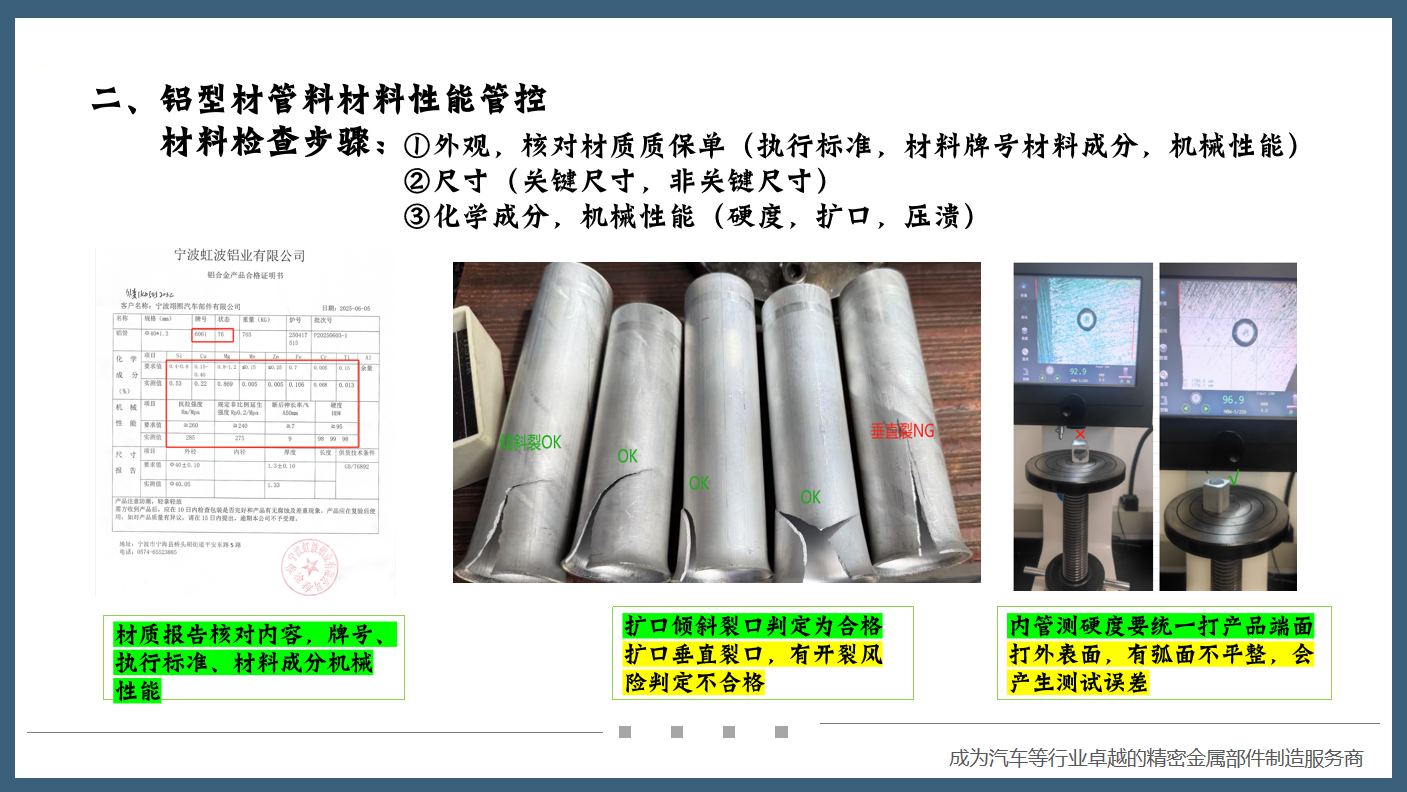

2. Алюминий құбырлардың материалдарын тексеру нұсқаулықтары

Біздің мына алюминий қорытпаларынан жасалған құбырлармен жұмыс жасауымызды ескере отырып ішінде автомобилдерге арналған қолданбалар , материалдық өнімділікті бақылау маңызды орын алады. Қызметкерлерге материалдарды тексеру бойынша дұрыс әріптерді үйретті:

- Көрнетістік тексеру : Бет сапасын тексеріңіз және бет зақымдануын тексеріңіз.

- Құжаттарды тексеру : Құйманың маркасын, химиялық құрамын және механикалық қасиеттерін қоса алғанда, материалдық сертификаттарды растаңыз.

- Өлшемдік тексеру : Маңызды және маңызды емес өлшемдерді өлшеңіз.

- Қашықтық тәсілдері бойынша бағалау : Түтік ұштарында біркелкілікті тексеруге назар аударыңыз, қателіктерді азайту үшін қисық беттерден құтылыңыз.

3. Кең таралған алюминий түтік кемшіліктері мен түбірлік себептері

Біліктілікті арттыру кезінде көп назар аударылды ақауларды болдырмауға септігін тигізеді : Сәйкессіз бөлшектердің көрнекі мысалдарын қоса алғанда, нақты әлемге

- Ішкі бетінің сызықтары : Тазалау немесе лак жабу кезінде жеткіліксіз ұзақ уақыт пайдалану салдарынан туындауы мүмкін.

- Бетінің шарбы немесе көпіршігі : Алюминий құймаларындағы қоспалар немесе газдар, немесе экструзия цилиндрлерінің лас болуы салдарынан пайда болады.

- Концентрлілік немесе қабырға қалыңдығы ауытқуы : Балқытылған материал ағынының тепе-теңдігінің болмауы немесе қалып деформациясы салдарынан туындайды.

Бұл практикалық мысалдар біздің жеткізілімнен кейінгі өндіріс немесе тұтынушыларға әсер етпей тұрып ақауларды ерте анықтауға және толтыру жөндеуін жүргізуге көмектеседі.

4. Гальваникалық өңдеу бетіндегі ақаулар мен шешімдері

Қосымша құнды бетін өңдеу процесінің бір бөлігі ретінде біз сонымен қатар қамтыдық электролиттік өңдеу кемшіліктері , сондай-ақ:

- Түс өзгеруі : Жарықтандырғыштың біркелкі емес қолданылуы немесе pH деңгейінің тұрақсыздығынан.

- Сары дақтар : Қышқыл жуудың нашар болуы немесе судың жоғары pH мәнінен.

- Қаптау коррозиясы немесе қара дақтар : Пластиналау кезінде қышқыл қалдықтары немесе резеңке ілгектердің зақымдануынан.

- Ішкі қаптаудың толық еместігі : Төменгі жерге қосу немесе токтың жеткіліксіздігінен.

Бұл сценарийлер арқылы қызметкерлер қалай жұмыс істейтінін көріп, түсінік алады металл бөлшектер бетін өңдеу өнімнің эстетикалық көрінісіне, коррозияға тұрақтылығына және жалпы тұтынушылардың қанағаттылығына әсер етеді

5. Проблемаларды шешу мәдениеті: «Төрт еркін шығару» ережесі

Жауапкершілікті бекіту үшін Сюй ағайымыздың «Төрт еркін шығару» ережесін сапа мәселесін шешуде енгізді:

- Түбір себеп анықталмайынша еркін шығару болмайды

- Жауапты тұлға табылмайынша еркін шығару болмайды

- Тиімді түзету шаралары қолданылмайынша еркін шығару болмайды

- Жауапты қызметкер қайта дайындалмайынша еркін шығару болмайды

Бұл әлпеттілік біз тек өрт сөндіріп қана тұрмайтынымызды, сонымен қатар болашақтағы оқиғаларды болдырмауға кепілдік береді.

Қорытынды: Үздіксіз жетілдіруге сенім беру

Shaoyi Metal Technology компаниясында біз сенеміз автокөлік сапасы бойынша оқыту бір реттік оқиға емес - бұл әдет. Біз айына бір рет оқытамыз, ақауларды ғылыми тұрғыда талдаймыз және әрбір топ мүшесін есепке алуға міндеттіміз. Түтік жасауды бастағанда, гальваникалық желілерді басқару немесе глобалды OEM-мен келісім шарт жабу кезінде де сіз біздің сапа брендімізді тасымыз.

Инвестиция жасау арқылы техникалық біліктілікті арттыру мен бөлімшелер арасындағы ынтымақтастықты , біздің автокөлік өндірісіндегі үздік сапаға байланысты ұмтылысымыздың ұйымның барлық қабаттарын қамтуын қамтамасыз етеміз. Осындай әдіспен біз әлем бойынша тапсырыс берушілердің күтімінен асып түсетін жоғары сапалы, дәл өңделген металдық компоненттерді тұрақты түрде жеткіземіз.

Бұл сабаққа қатысқан барлық ұжым мүшелеріне рахмет. Бірге өсіп жалғастырайық.

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —