Автомобиль өнеркәсібіндегі прогрессивті матрицалардың негізгі артықшылықтары

ҚЫСҚАША

Прогрессивті матрицалық штамптау автомобиль өнеркәсібі үшін өте пайдалы өндірістік процестің бір түрі болып табылады, негізінен жоғары көлемді өндіру кезінде қатты қажетті шығындарды үнемдеуге мүмкіндік береді. Бұл металл формалау әдісі ерекше дәлдік пен тұрақтылықпен күрделі бөлшектердің үлкен мөлшерін тез арада жасауға мүмкіндік береді. Автомобиль қолданбаларында прогрессивті матрицалардың негізгі артықшылықтары — салыстырмалы түрде жоғары өндіріс жылдамдығы, бөлшек пен бөлшектің қайталануының жоғары деңгейі және материалдардың аз қалдығы, осылайша заманауи көлік құралдарын өндірудің негізгі тірегіне айналады.

Негізгі экономикалық артықшылық: Жоғары көлемді өндірудің тиімділігі

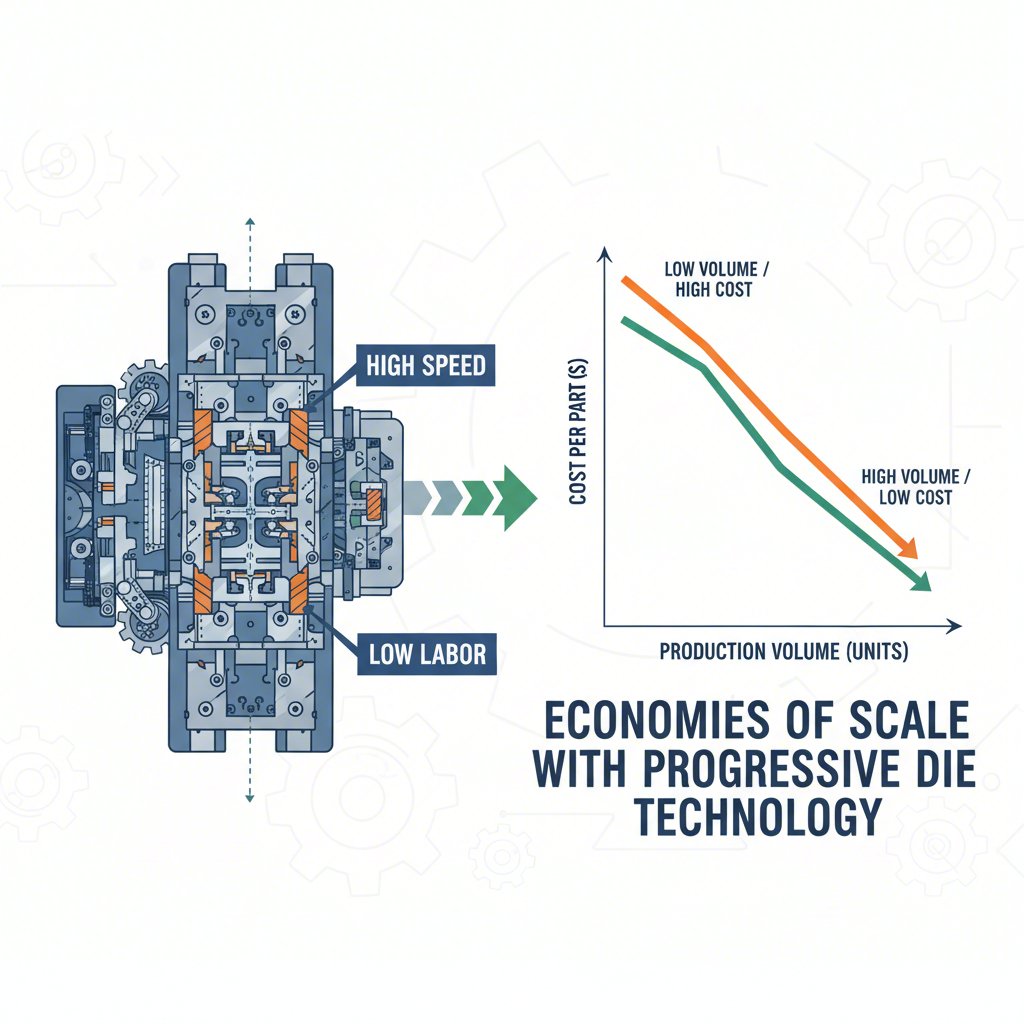

Автокөлік саласында прогрессивті матрицалық штамптауды қолданудың негізгі себебі оның бизнес табысына тигізетін әсері. Орташа немесе жоғары көлемдегі өндіріс үшін бұл процесс басқа өндірістік әдістерге қарағанда бөлшектің бір данасына келетін құнын айтарлықтай төмендетеді. Бұл экономикалық тиімділік кездейсоқ емес, өндірісті жеңілдетіп және шығындарды азайтатын бірнеше факторлардың үйлесімді әрекетінің нәтижесі болып табылады. Құрал-жабдықтарға алғашқы салым (бөлшектің күрделілігіне байланысты $10 000-нан аз немесе $100 000-нан аса болуы мүмкін) массалық өндіріс кезінде қол жеткізілетін үлкен үнемдеу есебінен тез арада өтеледі.

Бұл шығындарды үнемдеудің негізгі көздері процестің тән сипатына негізделген. Бір панельдің үздіксіз тізбекте кесу, иілу және тесу сияқты бірнеше операцияларды орындауы арқасында қолмен қатысу қажеттілігі мен бірнеше машиналарды орнату қажеттілігі едәуір азаяды. Бұл автоматтандыру еңбек шығындарын төмендетеді және операциялар арасындағы тоқтап тұру уақытын азайтады. Сонымен қатар, бұл процесс материалды тиімді пайдалану үшін құрылған. Инженерлер бөлшектерді мүмкіндігінше тығыз орналастыру үшін жолақтың орналасуын ұқыпты түрде жобалайды, бұл шикізат ретінде пайда болатын қалдық металдың мөлшерін едәуір азайтады.

Тасымалдау матрицасын пісірумен салыстырғанда, прогрессивті матрицамен пісіру кішігірім бөлшектердің үлкен мөлшерде шығарылуы үшін жиі қолайлы болып табылады. Тасымалдау матрицалары жеке бөлшектерді өңдеу арқылы икемділік ұсынса да, прогрессивті пісірудегі металл орамның үздіксіз берілуі жоғары жылдамдықтарға және аз қолданысқа қол жеткізуге мүмкіндік береді, бұл массалық өндірісте оның құнын төмендетуге тікелей ықпал етеді. Миллиондаған бірдей бөлшектер жылына қажет болатын автомобиль өнеркәсібінде көптеген компоненттер үшін оны таңдауға себепші болады.

Напақалы өндіріс жылдамдығы мен әсер етушілігі

Автокөлік жасау саласындағы жылдам дамып келе жатқан әлемде жылдамдық – бұл маңызды бәсекелестік артықшылық. Прогрессивті матрицалық тегістеу осы салада үстемдік етеді, кейбір станоктар минутына жүздеген, тіпті мыңдаған бөлшектер шығаруға қабілетті. Бұл сондай-ақ қатты жылдамдыққа қол жеткізілгені, өйткені шикізат — металл орамасы — матрицаның әртүрлі бекеттері арқылы үздіксіз және автономды беріледі. Престің әрбір жүрісінде дайын бөлшек алынып, сыртқа шығарылады, осылайша үздіксіз және өте тиімді өндіріс ағымы қамтамасыз етіледі.

Бұл үздіксіз жұмыс бір ғана құралдың ішінде орналасқан мүмкіндігінше тиімді жинау жолына ұқсас. Басқа станоктарға бөлшекті ауыстыру кезінде туындайтын үзілістер болмайды, бұл басқа процестерде жиі кездесетін тежеу себебі. Нәтижесінде әлдеқайда қысқа дайындау уақыты пайда болады, бұл автомобиль жасаушы компаниялар мен олардың жеткізушілеріне өте қатаң өндірістік кестелерге сай келуге және нарықтың сұранысына жедел реакция беруге мүмкіндік береді. Бұл деңгейдегі тиімділік автомобиль өнеркәсібінде доминантты орын алып отырған дәл уақытында жеткізу үшін қажетті жеткізу тізбегінің ритмін сақтау үшін маңызды.

Өте үлкен немесе күрделі бөлшектер үшін икемділік беретін тандемді матрицалық штамптау сияқты басқа әдістермен салыстырғанда, прогрессивті матрицалар жоғары көлемді бөлшектер үшін ең жақсы жылдамдықты қамтамасыз етеді. Бұл операциялық артықшылық тек өндірісті ғана емес, сонымен қатар жалпы өнімділікті де арттырады, бір ғана өндірістік желіден максималды шығару көлемін алуға мүмкіндік береді.

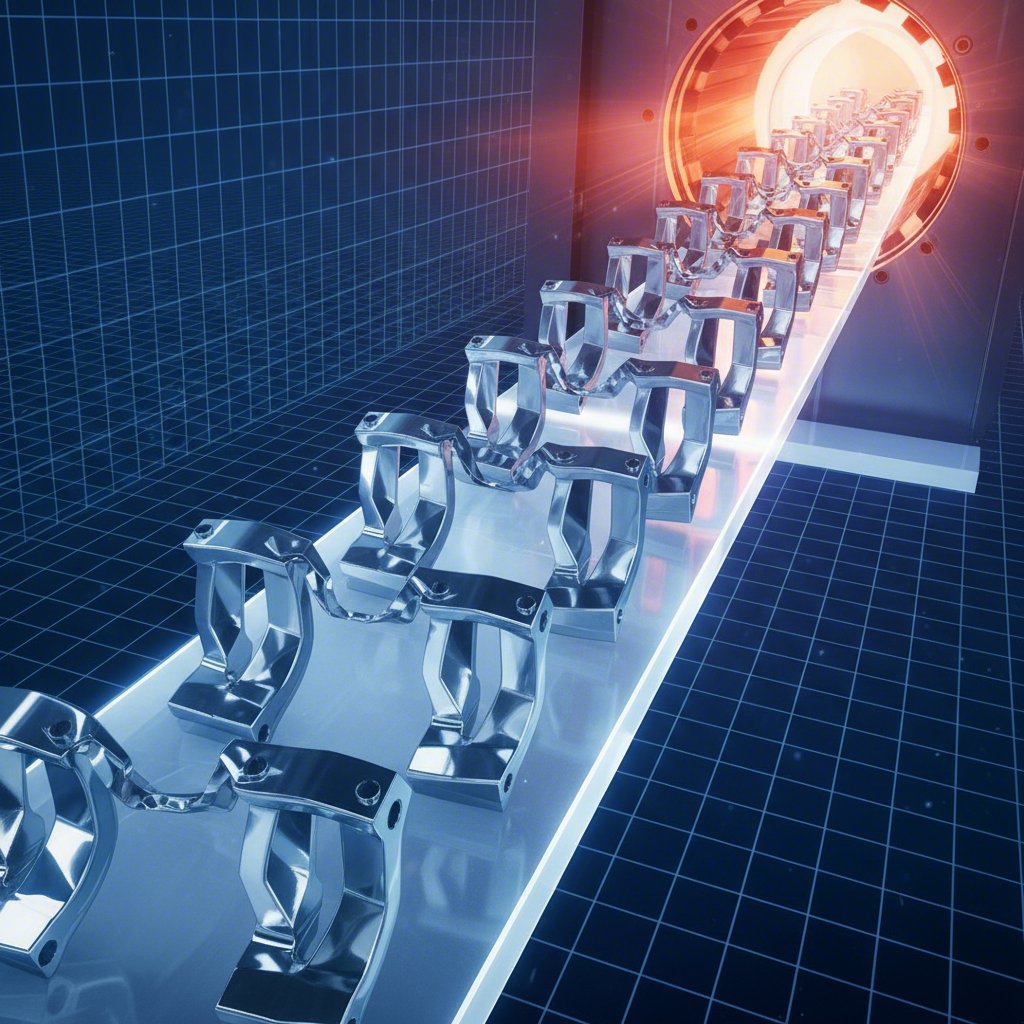

Нәзік дәлдік және бөлшек пен бөлшектің бір-біріне сәйкестігі

Автокөлік өнеркәсібі аздаған ауытқулар да көліктің қауіпсіздігі мен жұмыс істеуіне әсер етуі мүмкін болғандықтан, өте нақты допусстар мен сапаның тұрақтылығын талап етеді. Прогрессивті матрицалық штамптау миллиондаған бөлшектер бойынша өте жоғары тұрақтылық пен дәлдік қамтамасыз етуімен танымал. Бұл жоғары қайталану қабілеті барлық пішіндеу және кесу станцияларының бір ғана мықты матрица жиынына бекітілуі арқасында мүмкін болады. Металл жолақ әрбір станция арқылы дәл бағытталады, бөлшек бөлек машиналар арасында жылжытылған кезде пайда болуы мүмкін айнымалылықты жояды.

Бұл тән туындайтын дәлдік әрбір шығарылған бөлшектің соңғысымен шамалап бірдей болуын қамтамасыз етеді. Автокөлік қолданбалары үшін бұл жинау кезінде бөлшектердің мүмкіндігінше дәл келуі, қайта жөндеуді азайту, жарамсыз бөлшектерден пайда болатын қалдықтарды минимизациялау және соңғы өнімнің қатаң сапа стандарттарына сай болуы дегенді білдіреді. Күрделі геометриялық пішіндерді жалғыз процесте шығару қабілеті оның құндылығын одан әрі арттырады, осылайша әрі жеңіл, әрі берік күрделі бөлшектерді жасауға мүмкіндік береді.

Осындай сенімділіктің деңгейінен-ақ көшбасшы өндірушілер маңызды компоненттер үшін осы процеске сүйенеді. Мысалы, Shaoyi (Ningbo) Metal Technology Co., Ltd. автокөлік саласындағы қажетті өзгерістерге ие матрицаларды мамандандырып, OEM және Tier 1 жеткізушілерге қызмет көрсету үшін прогрессивті тегістеудің дәлдігін пайдаланады. IATF 16949 сияқты стандарттарға деген олардың басымдылығы бұл өндірістік әдіс мүмкіндік беретін сапаны бақылаудың маңыздылығын көрсетеді. Бұл тұрақтылық мыналар сияқты кең спектрлі автокөлік бөлшектері үшін маңызды:

- Электр қосылыстары мен контактілер

- Қолақшалар мен орнату фурнитурасы

- Сенсор корпусы мен қорғаныш экрандары

- Тежегіш және отын жүйелерінің компоненттері

- Конструкциялық күшейтілулер

Жоғары дәрежедегі конструкциялық икемділік пен материалды оптимизациялау

Прогрессивті матрицалық штамптау инженерлерге маңызды дәрежеде конструкциялық еркіндік береді және бір уақытта материалдың тиімділігін арттырады. Бұл процесс иіру, соғу, созу және тесу сияқты бірнеше металл өңдеу операцияларын бір үздіксіз циклға біріктіреді. Бұл басқаша жағдайда өндірістің бірнеше жеке кезеңдерін талап ететін күрделі, көптеген құрылымдық элементтері бар бөлшектерді жасауға мүмкіндік береді, ал бұл өз кезегінде құнын да, өндіріс уақытын да арттырады. Бұл мүмкіндік конструкторларға өнімділік пен салмақты азайтуға бағытталған оптимизацияланған инновациялық компоненттерді әзірлеуге мүмкіндік береді.

Негізгі артықшылық - шикізаттың өте тиімді пайдаланылуы болып табылады. Өндіріс металдың орамасынан басталады және бұл жолақтағы бөлшектердің орналасуы қалдықтарды минималдандыру үшін мұқият жоспарланады. Материалды матрица арқылы жеткізу үшін тасымалдаушы жолақ қажет, ал соңында бұл жолақ қалдыққа айналады, бірақ бөлшектерді тығыз орналастыру мүмкіндігі жеке заготовкалардан штамптеуге қарағанда материалдың жалпы шығынын азайтады. Материалды оптимизациялауға назар аудару тек қана шығындарды төмендетіп қоймайды, сонымен қатар тұрақты өндірістік практиканы қолдайды.

Бірақ ескерілуі керек компромистер де бар. Бұл үдеріс терең созылған бөлшектер немесе материалдың әртүрлі бұрыштарынан ағуын талап ететін элементтер үшін сәл қолайсыз, ал бұл тасымалдау матрицасымен штамптеудің күшті жағы болып табылады. Осыған қарамастан, автомобиль компоненттерінің кең спектрі үшін дизайнның көптүрлілігі мен материал үнемдеудің үйлесімі өнімділік, шығын және тұрақтылық арасында теңдестіруді қамтамасыз ететін идеал шешімге айналады.

Жиі қойылатын сұрақтар

1. Прогрессивті матрицаның негізгі артықшылықтары қандай?

Прогрессивті матрицаның негізгі артықшылықтары - жоғары көлемді өндірісте оның жылдамдығы, тиімділігі және экономикалық тиімділігі. Материал бір ғана құралдағы әртүрлі станциялар арқылы автономды түрде жылжығандықтан, ол қосымша престер арасында қолмен немесе роботтық тасымалдауды қажет ететін әдістерге қарағанда бөлшектерді әлдеқайда тез дайындай алады. Бұл еңбек шығындарын төмендетеді, қайталану қабілетін арттырады және бір бөлшекке шаққандағы құнды азайтады.

2. Прогрессивті матрицамен штамптеудің кемшіліктері қандай?

Негізгі кемшіліктерге күрделі және жасауы қымбат болғандықтан, алғашқы құрал-жабдықтарға жоғары шығындар жатады. Құрал жасалғаннан кейін конструкцияны өзгертуге де осы үдеріс аз икемді. Сонымен қатар, бөлшек соңғы станцияға дейін тасымалдаушы жолаққа бекіп тұратындықтан, бөлшекке толық қол жеткізу талап етілетін кейбір амалдар қосымша процестерсіз мүмкін болмайды.

3. Прогрессивті матрица қанша тұрады?

Прогрессивті матрицаның құны бөлшектің өлшемі мен күрделілігіне байланысты әлдеқайда өзгереді. Кіші, қарапайым бөлшектер үшін құрал-жабдықтардың құны 10 000 доллардан төмен болуы мүмкін, алайда үлкен және күрделі конструкциялар үшін ол оңай 50 000 немесе тіпті 100 000 доллардан аса алады. Жоғары өндіріс көлемінде бір бөлшекке шаққандағы төмен құн арқылы бастапқы жоғары шығындар тез өтеледі.

4. Жеке матрица мен прогрессивті матрица арасындағы айырмашылық неде?

Жеке матрица престің бір жүрісіне бір ғана операция жасайды, мысалы, дөңгелектеп кесу немесе иілу. Басқа жағынан, прогрессивті матрица бір құралдың ішіндегі әртүрлі станцияларда бір уақытта бірнеше операцияларды орындайды. Металл жолақ матрица арқылы берілетін сайын әрбір станцияда біртіндеп пішінделеді, сондықтан престің әрбір жүрісінде толық бөлшек алуға мүмкіндік береді, бұл күрделі бөлшектер мен үлкен өндіріс көлемдері үшін әлдеқайда тиімді.

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —