Өнімділік бөлшектері үшін қажетті 7075 Т6 алюминий қасиеттері

ҚЫСҚАША

7075 T6 алюминий — көптеген болат қорытпаларына ұқсас ерекше беріктік-салмақ қатынасымен танымал жоғары өнімді қорытпа. T6 шарты деп аталатын нақты жылулық өңдеу процесі арқылы қол жеткізілетін оның қасиеттері ауабағдарлау және моторспорт сияқты өнеркәсіптерде төзімділік пен минималды салмақ маңызды болып табылатын жоғары жүктемеге түсірілген құрылымдық компоненттер мен өнімділік бөлшектері үшін идеалды материал болып табылады.

7075 T6 алюминий деген не?

7075 алюминий — негізгі легирлеу элементі мырыш болып табылатын 7000 сериясының жылуға шыдамды құймасы. Бұл құрам оның ерекше материалдық сипаттамаларының негізін құрайды. Қалыпты, термиялық өңделмеген күйінде берік болса да, құйма тек «T6» дәрежесі арқылы өзінің толық қабілетіне жетеді. Бұл белгі екі кезеңді жылулық процесті білдіреді: алдымен алюминийді шамамен 460-480°C температураға дейін қыздырып, содан кейін тез суыту арқылы ерітіндіге түсіру үшін жылумен өңдейді. Кейін оны шамамен 24 сағат бойы 120°C шамасында төмен температурада жасанды жүздеуге (жетілдіруге) ұстайды.

Бұл дәл жылулық өңдеу тек қана соңғы кезең болып табылмайды; ол материалдың ішкі құрылымын негізінен өзгертетін түрлендіру процесі болып табылады. Кресцелеу процесі алюминийдің дән құрылымында ұсақ бөлінген бөлшектердің пайда болуын ынталандырады. Бұл микроскопиялық бөлшектер металдардағы деформацияның негізгі механизмі болып табылатын дислокация қозғалысына кедергі болып табылады. Нәтижесінде қаттылық, ағу шегі және соңғы созылу беріктігінің маңызды түрде артуына қол жеткізіледі, осылайша 7075 Т6 коммерциялық жолмен қолжетімді ең берік алюминий қорытпаларының біріне айналады.

Т6 шартының маңызы — оның болаттың үштен біріндей тығыздықтағы материалда болат сияқты беріктікті ашу қабілетінде. Бұл қасиеттердің бұл ерекше үйлесімі 7075 Т6 алюминий қасиеттері өнім бөлшектері үшін экстремалды кернеу жағдайында құрылымдық бүтіндікті немесе беріктікті құрғақтауға тырысатын инженерлер мен дизайнерлер үшін маңызды тақырып болып табылады.

Негізгі механикалық қасиеттер: беріктік, қаттылық және ұзақ мерзімділік

Инженерлер 7075 Т6 алюминийді өнімділік бөлшектері үшін көрсетуінің негізгі себебі — оның ерекше механикалық қасиеттер жиынтығы. Бұл сипаттамалар материалдың кернеу, жүктеме және қайталанатын циклдар әсерінде қалай әрекет ететінін анықтайды және кез-келген қатаң қолдану үшін маңызды болып табылады. Қорытпаның беріктігі жалғыз ғана сипаттама емес, сенімділікті және жоғары кернеулі ортада ұзақ пайдалануды қамтамасыз ететін бірнеше негізгі көрсеткіштердің жиынтығы.

Созылуға беріктік шегі (UTS) және Тұрақтылық күші ең көп аталатын қасиеттер болып табылады. Шектік беріктік (UTS) — материал сынбас бұрын шыдай алатын максималды кернеу, ал серпімді деформация шегі — материал тұрақты деформациялануды бастайтын нүкте. 7075 Т6 үшін бұл мәндер алюминий қорытпалары үшін өте жоғары болып келеді және жиі жеңіл болаттың көрсеткіштерін асып түседі. Бұл жоғары беріктік компоненттің экстремалды жүктемелер кезінде істен шығуын болдырмауға мүмкіндік береді, бұл әуежаю конструкциялары мен автомобиль жарыс компоненттері үшін маңызды фактор.

Таза беріктіктен тыс, Қаттылық материалдың бетіне қатты әсер етуге және сызылуға қарсы тұруын өлшейді, бұл тозуға қарсы тұрумен байланысты. 7075 T6-ның байқатарлық қаттылығы орамалар мен жұлдызшалар сияқты бөлшектер үшін қолайлы болып табылады. Сонымен қатар, оның Түйіршіктілік беріктігі қайталанатын жүктеу мен босату циклдарына істен шықпай төтеп бере алу қабілетін көрсетеді. Ұшу кезінде тұрақты тербеліс пен циклдік кернеуге ұшырайтын әдетте ұшақ қанаттары немесе көлік құралдарының серіппелері сияқты бөлшектер үшін бұл маңызды.

| Қасиет | Метрикалық мән | Империялық мән | Өнім бөлшектері үшін маңызы |

|---|---|---|---|

| Соңғы керілу беріктігі | 572 МПа | 83,000 фунт/кв. дюйм | Ең жоғары жүктемеге сынбай төтеп береді. |

| Керілу әлсіздену беріктігі | 503 МПа | 73,000 фунт/кв. дюйм | Тұрақты бүгілу немесе деформацияланудан сақтайды. |

| Қаттылығы (Бринелл) | 150 HB | 150 HB | Жақсы тозуға және үйкеліске төзімділік қасиеті бар. |

| Түйіршіктілік беріктігі | 159 MPa | 23,000 psi | Істен шығуға қарамастан, қайталанатын кернеу циклдеріне шыдайды. |

| Жылдамдық қабілеті | 331 MPa | 48,000 psi | Материалдың кесілуі немесе қиюы мүмкін күштерге қарсы тұрады. |

Мәліметтердің дерек көзі MatWeb-те ASM материалдарының деректер парағы . Мәндер типтік болып табылады және материалдың түрі мен қалыңдығына байланысты өзгеруі мүмкін.

Негізгі физикалық және жылулық қасиеттер

Механикалық беріктік жиі негізгі тартылыс болса да, 7075 Т6 алюминийдің физикалық және жылулық қасиеттері жоғары өнімді бөлшектерді жобалау үшін тең маңызды. Бұл сипаттамалар материалдың салмағын, температура өзгерістеріне жауабын және жылуды басқаруын анықтайды — динамикалық қолданыстағы барлық маңызды факторлар.

Ең маңызды физикалық қасиет — оның тығыздық . Шамамен 2,81 г/см³ болатын 7075 Т6 болатпен салыстырғанда (шамамен 7,85 г/см³) ерекше жеңіл. Бұл төменгі тығыздық оның өте жақсы беріктік-салмақ қатынасының кілті болып табылады және әуе қозғалысында отынның пайдалы әрекет коэффициентін жақсарту үшін және жарыс көліктерінде үдеуді мен басқарылуын арттыру үшін берік, бірақ жеңіл бөлшектерді жасауға мүмкіндік береді.

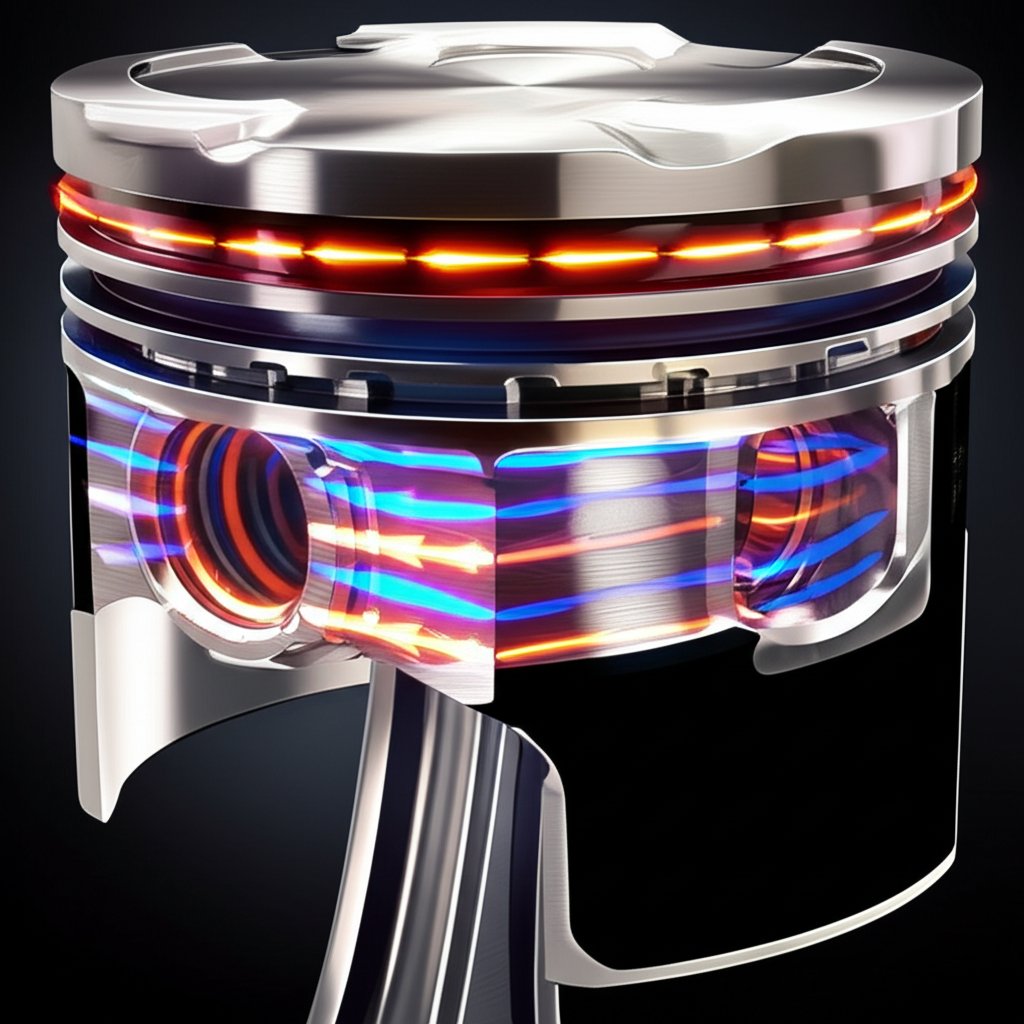

Жылулық қасиеттер тұрғысынан оның термік проводимдік 130 Вт/м-К жылуын тиімді шашыратуға мүмкіндік береді. Бұл жоғары температурада жұмыс істейтін, мысалы, жоғары өнімді двигатель компоненттері немесе тежеу жүйелері сияқты бөлшектер үшін пайдалы, себебі бұл асыра қызып кетуді және сонымен қатар материалдың бұзылуын болдырмауға көмектеседі. Оның балқу нүктесі 477°C (890°F) басталады, бұл болатқа қарағанда төмен болса да, тікелей экстремалды жану температурасына ұшырамайтын көптеген жоғары өнімді қолданыстар үшін жеткілікті.

7075 Т6 Алюминий мен болат және 6061 Алюминий

Дұрыс материалды таңдау — бұл компромистерді түсінумен байланысты. 7075 Т6 өте жоғары өнімділік көрсетсе де, оның шынымен ең жақсы көрсеткіш беретін және шектеулері бар жағдайларын анықтау үшін конструкциялық болат пен тағы бір кеңінен қолданылатын алюминий қорытпасы — 6061 Т6 — сияқты басқа ортақ материалдармен салыстыру маңызды.

Көптеген болат қорытпаларымен салыстырғанда, 7075 T6-ның негізгі артықшылығы - салмаққа шаққандағы беріктігі. Ол ауырлықтың тек үштен бір бөлігінде ұзынша беріктік көрсеткішін ұсынуы мүмкін, бұл әуежәне мотор спорттары үшін ойынды түбегейлі өзгертетін фактор. Дегенмен, болат әдетте қаттылық, жорамал төзімділік және ерігенде температураның намайысқа асып кетуі жағынан жоғарырақ болып келеді, сондықтан экстремалды жылу немесе үйкеліске төзімді қолданулар үшін ол жақсырақ таңдау болып табылады. Сонымен қатар, болат әдетте арзанырақ.

6061 T6 алюминиймен салыстырғанда, 7075 T6 әлдеқайда берік және қатты. Бұл оны механикалық кернеуге ұшырайтын бөлшектер үшін айқын жеңімге айналдырады. Алайда, 7075 T6 төменгі коррозияға төзімділікке ие, пісіру қиындау және қымбатырақ. 6061 T6 әдетте жақсы беріктігі, өте жақсы коррозияға төзімділігі және жақсы пішінделуі жеткілікті болатын жалпы мақсаттағы қолдануларда қолданылады және тиімді шешім ұсынады.

| Метрика | 7075 т6 алюминий | 6061 T6 Алюминий | Әдеттегі қорытпа болат |

|---|---|---|---|

| Күш-саппоры | Еңбекшіл | Жақсы | Орташа |

| Коррозияға тұрақтылық | Орташа | Керемет | Төмен (қаптамасыз) |

| Дәнекерлеу | Төмен (арнайы әдістер қажет) | Жақсы | Керемет |

| Баға | Жогары | Орташа | Төменнен орташаға дейін |

Жоғары өнімді бөлшектердің идеалды қолданылу аясы

Жоғары беріктік, төменгі тығыздық және жақсы қаттылықтың ерекше үйлесімі 7075 T6 алюминийді өнімділік шарты міндетті және әрбір грамм маңызды болып табылатын қолданыстарда таңдауға лайық материал етеді. Бұл материал инженерлік және материалдар ғылымының шектерін кеңейтетін бірнеше салада кеңінен қолданылады.

Әуе-кеңістік өнеркәсібінде 7075 T6 негізгі материал болып табылады. Оның беріктік-салмақ қатынасы отын тиімділігі мен пайдалы жүк көлеміне тікелей әсер ететін әуеқойылтқыштар, қанат жапырақтары және фюзеляждың рамалары сияқты механикалық жүктемеге төтеп бере алатын конструкциялық бөлшектерде оны кеңінен қолдануға мүмкіндік береді. Қорғаныс саласы да қозғалыс қабілеті мен өнімділік үшін төзімділік пен жеңіл салмақ маңызды болып табылатын әскери көлік құралдарының бөлшектері, ракета бөлшектері және басқа да конструкциялық қолданыстарда осы қорытпаны кеңінен пайдаланады.

Автокөлік әлемі, әсіресе мотор спорты 7075 Т6 құймаларын жоғары өнімділікті компоненттер: тістегіштер, валдар, шасси бөлшектері мен реттегіш клапан бөлшектері үшін пайдаланады. Дәл осындай дәлме-дәл инженерлік компоненттерді талап ететін автомобиль жобалары үшін сенімді серіктестен дайындалған алюминий профильдерін қарастыру тиімді болып табылады. Арнайы жеткізушілер жедел прототиптеуден бастап сертификатталған сапа жүйесінде толық көлемді өндіріске дейінгі біртұтас қызмет көрсетуі мүмкін, бұл бөлшектердің беріктігін, жеңілдігін және дәл сипаттамаларға сай болуын қамтамасыз етеді.

Басқа да салалардан тыс, 7075 Т6 жоғары сапалы спорт заттарында да, онда өнімділік маңызды рөл атқаратын жерде қолданылады. Мыналарға жатады:

- Велосипед бөлшектері: Жоғары сапалы рамалар, жұлдызшалар мен иінтіректер алдыңғы қуатты беруді жақсарту үшін массаны азайту және қаттылықты арттыру мақсатында құйманы пайдаланады.

- Тау шыңына шығу құралдары: Карабиндер мен басқа да қауіпсіздік құралдары максималды беріктік пен сенімділікке ие болу үшін және минималды салмақта 7075 Т6 құймасынан жасалады.

- Жарыс йо-йолары мен RC модельдері: Оның беріктігі және дәл сақталуы үшін өңдеуге болатындығы үшін пайдаланылады, бұл оған тұрақтылық пен өнімділік қамтамасыз етеді.

Өнімділік үшін Дұрыс Материалды Таңдау

7075 Т6 алюминий — күш, қаттылық және жеңілдіктің қуатты комбинациясын ұсынатын инженериялық тамаша материал, оның қасиеттерін аз ғана басқа материалдар ғана қамтамасыз ете алады. Оның қасиеттері оны әуежайлар, автомобильдер және жоғарғы санаттағы тұтынушы өнімдердегі өнімділігі маңызды бөлшектер үшін ауыстыруға келмейтін таңдауға айналдырады. Инженерлер осы күрделі қорытпаны механикалық, физикалық және жылулық сипаттамаларын түсіну арқылы әрі жеңіл, әрі берік болатын бөлшектерді жобалау үшін пайдалана алады.

Дегенмен, оны таңдау келісім-шарттарды мұқият қарастыруды талап етеді. Оның беріктігі болатқа ұқсас болса да, ол 6061 сияқты жалпы мақсаттағы құймалармен салыстырғанда қымбатқа түседі және пайдаланылуы мен коррозияға төзімсіздік сияқты жағдайларда өнімділігі төмен болады. Нәтижесінде, максималды өнімділік пен минималды салмақ негізгі мақсат болып табылатын қолданулар үшін 7075 Т6 алюминийдің жоғары қасиеттері оны айқын және қуатты таңдауға айналдырады.

Жиі қойылатын сұрақтар

7075 Т6 алюминийдің шекті беріктігі қандай?

7075 Т6 алюминийдің шекті созылу беріктігі әдетте шамамен 572 МПа немесе 83 000 фунт/кв. дюйм. Бұл мән оны коммерциялық түрде қолжетімді ең берік алюминий құймаларының біріне жатқызады және оны қатаң жүктемеге төзетін қолданулар үшін қолайлы етеді.

7075 Т6 алюминийді анодтауға бола ма?

Иә, 7075 T6 алюминийді анодтауға болады. Анодтау — оның табиғи коррозияға төзімділігін арттыратын, бетінің қаттылығы мен тозуға төзімділігін жақсартатын кең таралған беттік өңдеу тәсілі. Сонымен қатар, эстетикалық мақсаттар үшін әртүрлі түстерді пайдалануға мүмкіндік береді.

3. 7075 T6 алюминий жоғары температураға арналған қолданбалар үшін сәйкес келе ме?

7075 T6 құймасының құрамы оның механикалық қасиеттері жоғары температурада төмендей бастайтын қалыпты температурада жоғары беріктікке ие, әдетте 120-150°C (250-300°F) жоғары. Тұрақты жоғары температураны қажет ететін қолданбалар үшін титан немесе болат сияқты басқа құймалар немесе материалдар одан қолайлырақ болуы мүмкін.

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —