Die Forming Metal Exposed: 9 Essential Points Engineers Miss

What Is Die Forming Metal and Why It Matters

Ever wondered how manufacturers produce thousands of identical metal parts with near-perfect precision? The answer lies in die forming metal—a manufacturing process where sheet metal is shaped using specialized tooling called dies under controlled pressure. This technique creates precise, repeatable components that would be impossible to produce efficiently by hand.

So, what is a die in manufacturing? Simply put, a die is a specialized tool designed to cut, shape, or form material into a specific geometry. Unlike general-purpose tools, a die is used to produce the same part repeatedly with consistent accuracy across millions of production cycles. Think of it as a highly engineered mold that transforms flat metal sheets into complex three-dimensional components.

What is die making, then? It's the intricate process of designing and fabricating these precision tools—a discipline that combines materials science, engineering expertise, and manufacturing know-how to create tooling capable of withstanding extreme pressures while maintaining micron-level accuracy.

The Core Mechanics of Die Forming

Here's what sets this process apart from other metalworking methods: die forming relies on matched tooling sets that work together to stamp, bend, or draw material into desired shapes. Unlike machining, which removes material, or welding, which joins pieces together, this approach reshapes metal through controlled deformation.

The fundamental principle involves two key components:

- The punch: Performs stretching, bending, or blanking operations

- The die block: Securely clamps the workpiece and provides complementary forming action

When pressure is applied—typically through hydraulic or mechanical presses—the metal flows into the cavity created between these matched components. The result? Parts with precise dimensions, consistent wall thickness, and excellent surface quality.

Why Dies Matter in Modern Manufacturing

Dies in manufacturing serve as what industry experts call the "genetic code of product quality." An exceptional die tool can deliver micron-level accuracy over millions of cycles, eliminating defects like warpage, dimensional drift, and surface imperfections. This consistency directly impacts structural integrity, fatigue life, and functional reliability of finished components.

The applications span virtually every industry you can imagine:

- Automotive: Body panels, structural components, brackets

- Aerospace: Precision aircraft components requiring tight tolerances

- Consumer goods: Appliance housings, electronics enclosures

- Medical devices: Surgical instruments, implant components

What is dies in manufacturing worth to these industries? Consider this: investing in high-precision dies essentially means investing in quality stability and brand reputation. A well-engineered die transforms from a simple production tool into a strategic asset that determines competitive advantage in demanding markets.

Throughout this article, you'll discover the nine critical aspects of metal forming that even experienced engineers often overlook—from material selection and process optimization to emerging technologies reshaping the industry.

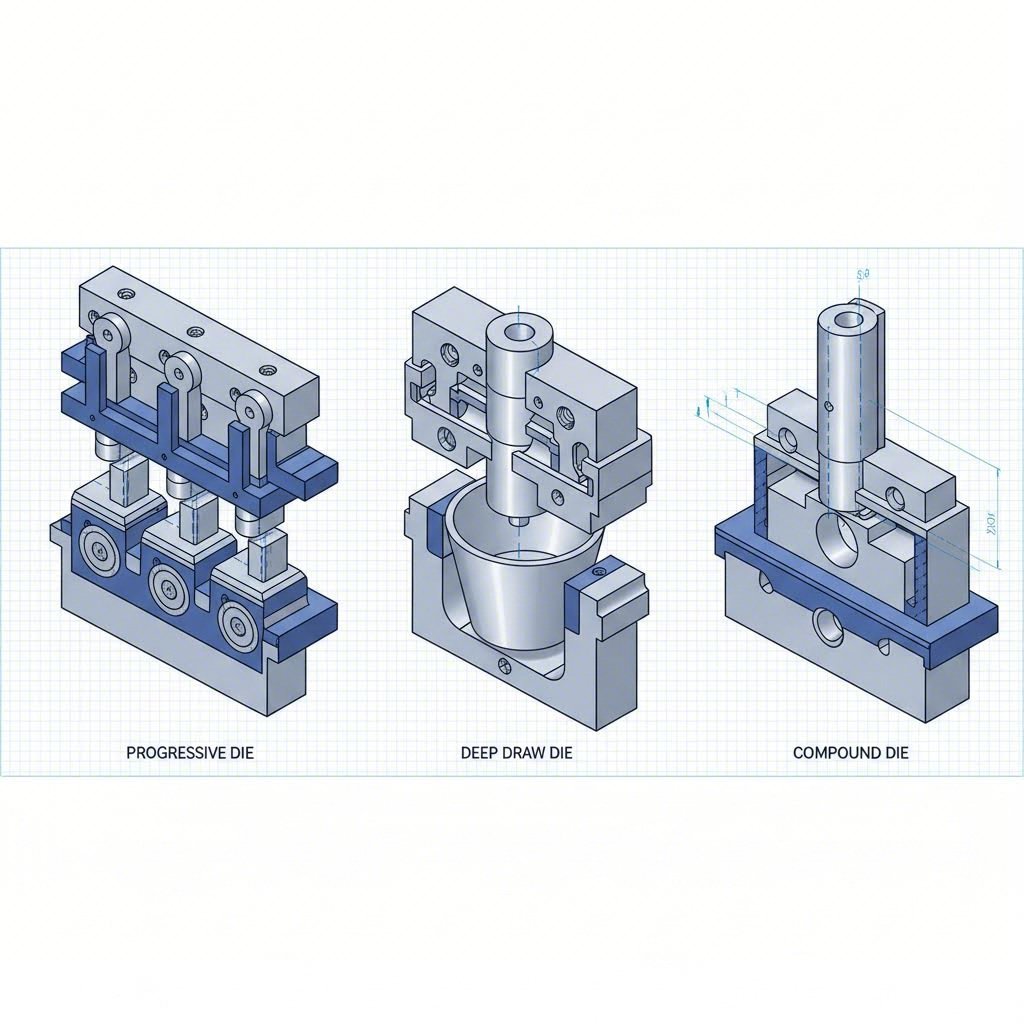

Types of Dies Used in Metal Forming Operations

Choosing the right die type can make or break your manufacturing project. With so many options available, how do you know which stamping dies or forming dies best suit your specific application? The answer depends on your part complexity, production volume, and material requirements.

Understanding the different types of forming available helps engineers make informed decisions that optimize both quality and cost-effectiveness. Let's break down the major categories of tooling dies and explore when each shines brightest.

| Die Type | Primary Application | Material Thickness Range | Production Volume Suitability | Complexity Level |

|---|---|---|---|---|

| Progressive Dies | Small to medium parts with multiple features (brackets, electrical contacts) | Up to 3 mm typical | High volume (100,000+ parts) | Medium to High |

| Transfer Dies | Large, complex parts requiring multiple operations (deep drawn components, tubes) | Variable based on design | Short to long runs | High |

| Deep Draw Dies | Cylindrical or box-shaped parts (cans, motor shells, enclosures) | Depends on draw ratio | Medium to high volume | High |

| Compound Dies | Flat parts with simple geometry (washers, wheel blanks) | Up to 3 mm typical | Medium to high volume | Low to Medium |

| Forming Dies | 3D shapes, bends, and flanges (enclosures, control boxes) | Variable | All production volumes | Medium |

Progressive and Transfer Die Systems

When you're producing high volumes of small to medium-sized parts, progressive dies become your best ally. Here's how they work: a metal strip feeds through a series of stations, with each station adding a different feature—a cut here, a bend there, a hole somewhere else. By the time your part reaches the final station, it's fully formed and ready for separation.

The beauty of metal stamping dies in progressive configurations lies in their efficiency. According to Keats Manufacturing, this approach saves time and money by performing multiple operations simultaneously while reducing waste and labor costs. You'll find progressive stamping die systems ideal for parts like brackets, electrical contacts, and small structural components requiring tight tolerances.

But what happens when your parts are too large or complex for progressive systems? That's where transfer dies step in. Unlike progressive setups where the workpiece stays attached to the metal strip, transfer die stamping separates individual parts early in the process. Automated mechanisms then transport each piece through multiple stations, allowing for operations like threading, ribs, and knurls that would be impossible with other methods.

Transfer dies excel at handling:

- Deep drawn components requiring multiple forming stages

- Large parts that need flexibility in handling and orientation

- Intricate designs demanding various operations in a single production cycle

- Tube manufacturing and applications requiring workpiece separation

The trade-off? Higher operational costs and longer setup times compared to progressive systems. However, for complex geometries and larger components, transfer die stamping often represents the only viable manufacturing solution.

Specialized Forming Die Categories

Beyond the progressive and transfer systems, several specialized die components address specific manufacturing challenges.

Compound Dies perform multiple operations—cutting, punching, bending—in a single stroke. Imagine needing flat washers or wheel blanks produced at high speed with excellent repeatability. A compound stamping die delivers exactly that, with less costly tooling than progressive alternatives. The limitation? They're best suited for simpler, flat parts rather than complex three-dimensional geometries.

Deep Draw Dies stretch metal into die cavities, creating cylindrical or box-shaped components. Motor shells, beverage cans, and enclosure housings all rely on this technique. The process demands careful consideration of material properties—particularly ductility and grain direction—to prevent tearing or wrinkling during the forming operation.

Forging Dies operate under even more extreme conditions, reshaping metal through compressive forces at elevated temperatures. While technically distinct from sheet metal stamping, understanding forging dies helps engineers appreciate the full spectrum of die-based manufacturing options.

Coining Dies apply exceptionally high pressure to create fine, precise features with tolerances as tight as ±0.01 mm. When dimensional accuracy, surface texture, or small embossed details matter—think precision connectors or detailed logos—coining becomes the process of choice.

So which die type should you choose? Consider these decision factors:

- Production volume: High volumes favor progressive dies; shorter runs may benefit from transfer or compound systems

- Part complexity: Simple flat parts suit compound dies; intricate designs require transfer capabilities

- Part size: Larger components typically demand transfer die stamping

- Budget constraints: Compound dies offer lower tooling costs; progressive dies provide better per-part economics at scale

With a clear understanding of these die categories, you're now ready to explore how the complete die forming process transforms concepts into production-ready tooling.

The Complete Die Forming Process Explained

You've selected the right die type for your project. Now what? Understanding the complete die process—from initial concept to validated production tooling—separates successful manufacturing projects from costly failures. Yet many engineers underestimate just how systematic this journey needs to be.

Think of die manufacturing as building a house: skip the foundation work, and everything above it becomes unstable. Each phase builds upon the previous one, and rushing through any step creates problems that compound exponentially downstream. Let's walk through the complete metal forming process step by step.

- Part Design and Feasibility Analysis

Every successful die project begins with a thorough Design for Manufacturability (DFM) review. This isn't just checking if your part looks good on a computer screen—it's determining whether that design can actually be produced reliably in the real world.

During this phase, engineers analyze your 3D models and 2D drawings, examining geometry, material specifications, thickness requirements, and critical tolerances. According to industry experts at GOHO Tech, spending an extra week in the DFM stage can save six weeks of tool modifications later.

What specifically gets evaluated?

- Draft angles: Vertical walls won't release from the die—slight angles enable clean part ejection

- Wall thickness uniformity: Inconsistent thickness causes warping and stress concentration

- Parting line placement: Strategic positioning minimizes visible seams on finished parts

- Expected production volume: This influences die structure, material choices, and overall investment

Once feasibility is confirmed, die design engineers create detailed 3D models using specialized CAD software like CATIA or UG NX. Every component gets designed—die shoes, guide pins, punches, cavities, pressure pads, and lifters. But here's what separates modern tool die making from traditional approaches: virtual validation before cutting any steel.

Computer-Aided Engineering (CAE) simulation software like AutoForm or Dynaform acts as a crystal ball for the forming manufacturing process. Engineers can predict exactly how molten or sheet metal will flow, fill cavities, and cool down. Potential defects—air entrapment, wrinkles, excessive thinning, or cracks—become visible in the digital model.

One automotive project discovered through simulation that air would become trapped in a critical sealing area, causing leakages. Testing three different gating designs virtually took one day. Finding and fixing this problem after building the physical tool would have taken weeks of welding and re-machining.

- Tool Steel Selection and Machining

Now the digital design becomes physical reality. Material selection proves critical—different die components experience different stress levels and wear patterns. For what is die manufacturing if not the art of choosing the right steel for each application?

Common tool steel choices include:

- H13 tool steel: Industry standard for die casting, offering excellent thermal shock resistance

- D2, SKD11, Cr12MoV: Various grades for cutting edges requiring high hardness and wear resistance

- Carbide inserts: For extremely high-wear areas demanding maximum durability

Precision machining transforms these steel blocks into functional components. CNC milling carves the main shapes, while Electrical Discharge Machining (EDM) handles fine details, sharp corners, and deep ribs that rotating cutters cannot reach. Throughout this forming process, quality control teams verify dimensions using Coordinate Measuring Machines (CMMs) to ensure every component matches design specifications.

- Die Assembly and Tryout

Assembly is where skilled die makers shine. Think of it as assembling a complex, heavy, high-precision puzzle where every piece must fit perfectly. Punches, dies, retainers, springs, guide pins—everything comes together under experienced hands that check alignments, clearances, and smooth movement of sliding components.

Initial debugging follows assembly. Technicians apply spotting blue to mating surfaces, carefully close the die, and examine how forming surfaces match. Adjustments through hand grinding or polishing ensure even contact before the first real test.

Then comes the T1 trial—the moment of truth. The assembled die gets installed in a tryout press, sheet metal feeds through, and the first sample parts emerge. Engineers observe the process carefully, adjusting press settings like tonnage, speed, and cushion pressure while making fine die adjustments to eliminate wrinkles, splits, or insufficient definition.

- Production Setup and Validation

Producing parts is one thing; proving they meet specifications is another. Rigorous inspection includes:

- Visual inspection: Checking for surface defects, scratches, or cracks

- Dimensional measurement: Using CMMs, scanners, and check fixtures to verify all dimensions match drawings

- Material thickness analysis: Ensuring no excessive thinning occurred in drawn areas

These results get documented in detailed reports—often called Initial Sample Inspection Reports (ISIR)—providing evidence that the metal forming process delivers specification-compliant parts consistently.

- Quality Control and Adjustment

Validation doesn't end with the first successful parts. Ongoing quality control ensures the die maintains performance throughout its production life. This includes scheduled maintenance, wear monitoring, and periodic dimensional verification of produced parts.

From Concept to Production-Ready Tooling

The timeline from concept to validated production tooling varies based on part complexity. Simple compound dies might require 8-12 weeks, while complex progressive or transfer dies can take 20-30 weeks or longer. What matters most? Clear communication at every stage and realistic expectations set during the initial planning phase.

Critical Checkpoints in Die Development

Where do projects typically go wrong? Experience reveals several critical checkpoints that demand extra attention:

- DFM review completion: Never skip this step—incomplete initial drawings cause weeks of downstream rework

- Simulation validation: Modern CAE tools catch 80-90% of potential defects before steel gets cut

- Material verification: Incoming quality checks on tool steel prevent premature die failure

- Dimensional inspection during tryout: Catching issues here costs far less than discovering them after shipment

Understanding this systematic die making approach prepares you for the next critical consideration: matching technical specifications and material compatibility to your specific application requirements.

Technical Specifications and Material Compatibility

You've designed your part and selected the right die type. But here's where many engineers stumble: assuming any material will work in any forming operation. The reality? Material properties fundamentally dictate what's achievable in sheet metal forming—and ignoring these constraints leads to cracked parts, excessive scrap rates, and frustrated production teams.

Understanding the relationship between material characteristics, achievable tolerances, and die steel selection separates successful projects from costly failures. Let's explore the technical specifications that determine whether your die forming metal operation succeeds or struggles.

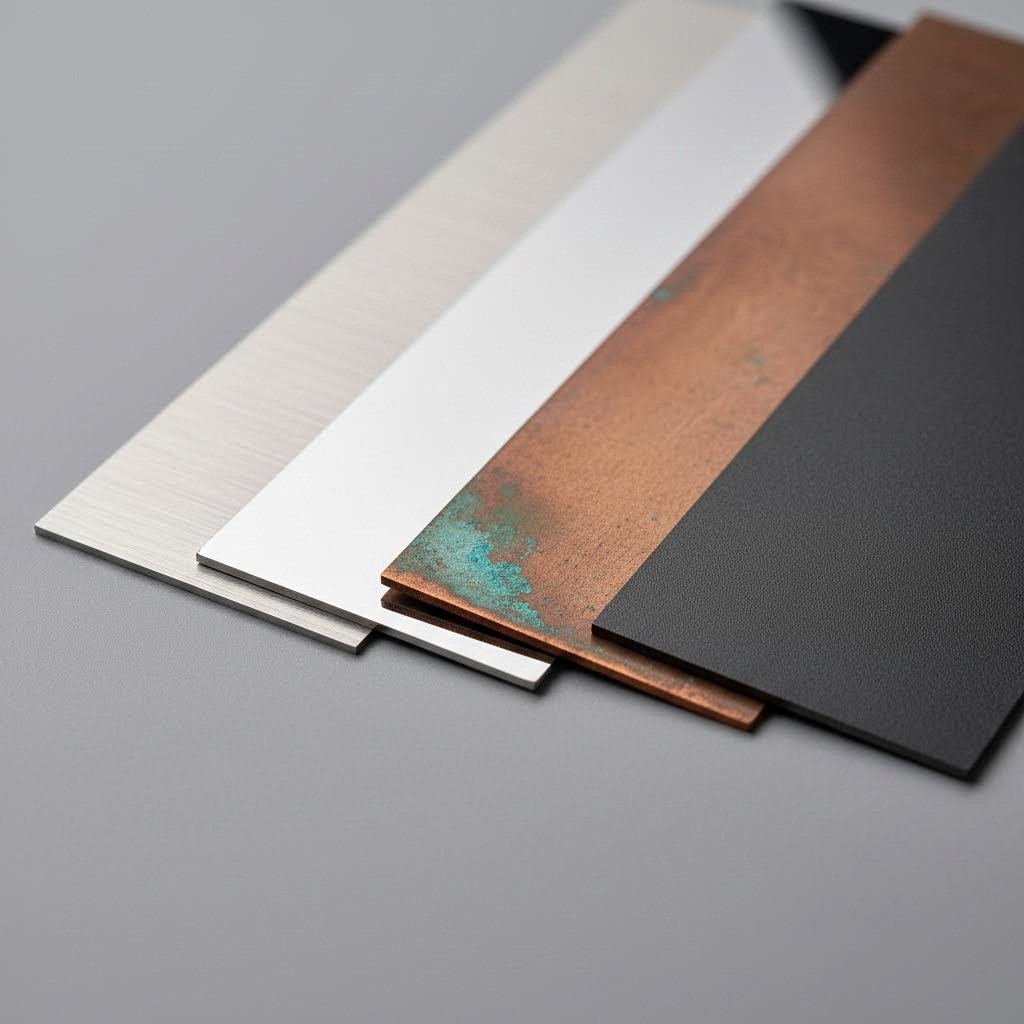

Material Selection Criteria for Die Forming

Not all metals behave the same under pressure. The sheet metal forming process demands careful consideration of three critical material properties:

- Tensile strength: Determines the force required to form the material and influences press capacity requirements

- Ductility: Measures how much the metal can stretch before cracking—critical for deep drawing operations

- Grain direction: Affects bend quality and potential for edge cracking during forming

According to manufacturing specialists at Gunna Engineering, the ductility, stretchability, and malleability of metals vary significantly depending on their properties. This makes some materials more or less suitable for deep forming operations. For instance, designing a multistep deep-drawn part from high-strength DP980 steel would defy its physical capabilities and cause part failure.

Which materials work best for different forming operations? Here are the primary candidates:

- Carbon steel: Excellent formability with good strength-to-cost ratio; ideal for automotive brackets, structural components, and general sheet metal dies

- Stainless steel: Higher strength but lower ductility; requires tighter tolerances and more forming force—common tolerances of ±0.05 mm for thickness

- Aluminum alloys: Soft and highly ductile; permits moderate tolerances (±0.1 mm typical for bends) and works well for aerospace and consumer electronics applications

- Copper alloys: Exceptional electrical and thermal conductivity; allows moderate tolerances and suits electrical connectors and heat exchangers

- Specialty metals: Titanium and tool steels demand exceptionally tight tolerance control due to low ductility—titanium typically maintains angular tolerances of ±0.5° for bends

Here's a practical insight: when engineers attempt metal forming coining operations on materials with insufficient ductility, the results include surface cracking and inconsistent dimensions. Coining sheet metal requires materials that can withstand extremely high pressures without fracturing—typically low-carbon steels or soft copper alloys perform best.

Tolerance Capabilities and Limitations

Tolerances in die forming aren't arbitrary numbers—they represent the "precision contract" that determines whether parts assemble properly, function reliably, and meet quality standards. According to tolerance specifications from ADH Machine Tool, applying unnecessarily tight geometric tolerances significantly extends lead times and increases manufacturing complexity and cost.

What tolerances can you realistically achieve? Material thickness plays a decisive role:

| Material Type | Thickness Tolerance | Bend Angle Tolerance | Linear Dimensional Tolerance |

|---|---|---|---|

| Aluminum Alloy (6061-T6) | ±0.05 mm | ±0.5° to ±1° | ±0.1 mm |

| Stainless Steel (304) | ±0.05 mm | ±0.5° | ±0.1 mm |

| Carbon Steel (1018) | ±0.05 mm | ±0.5° | ±0.1 mm |

| Copper Alloy (C11000) | ±0.05 mm | ±0.5° to ±1° | ±0.1 mm |

| Tool Steel (D2) | ±0.02 mm | ±0.25° | ±0.05 mm |

Why does this matter for your metal die design? Consider springback—the material's tendency to partially return to its original shape after bending. High-strength materials exhibit more pronounced springback, requiring deliberate overbending to achieve target angles. Modern press brakes compensate by bending to 88.5° when targeting 90°, for example.

Grain direction presents another often-overlooked consideration. Positioning bend lines perpendicular to the material's grain direction minimizes micro-cracking on outer bend surfaces. Ignoring this relationship leads to premature part failure during service.

Die Steel Selection and Production Longevity

Your sheet metal die is only as good as the steel it's made from. According to manufacturing data from Protolabs, tool steels contain 0.5–1.5% carbon plus alloying elements like chromium, vanadium, tungsten, and molybdenum that form carbides providing exceptional hardness and wear resistance.

Which die steel matches your application?

- D2 cold-work steel (58-62 HRC): Maximum wear resistance for stamping abrasive materials like stainless steel or high-strength steel—ideal for sheet metal dies requiring extended production runs

- H13 hot-work steel (45-55 HRC): Maintains strength at temperatures up to 540°C (1000°F); polishes to mirror finishes for aesthetic parts

- A2 air-hardening steel (55-62 HRC): Balanced properties for general-purpose tooling with minimal distortion during heat treatment

- S7 shock-resistant steel (54-58 HRC): Absorbs impact loads without cracking—essential for stamping dies and heavy-duty applications

Premium-grade tools made from tool steel or solid carbide become necessary when manufacturing parts with abrasive materials including high-strength steel, spring steel, and superalloys. The tooling cost increases, but so does production longevity—often by factors of 3-5x compared to standard steels.

Surface treatments extend die life further. Options include titanium carbide coatings, specialized duplex coatings, and nitriding treatments that reduce friction and protect against wear. For high-volume production exceeding 500,000 cycles, these investments typically pay for themselves through reduced maintenance and consistent part quality.

With material compatibility and tolerance capabilities now clear, you're ready to explore the specific forming operations—bending, flanging, coining, and embossing—that transform flat sheet into functional components.

Forming Operations and Techniques in Die Work

Understanding different die types and material compatibility gets you halfway there. But what about the actual forming operation itself? Each technique—bending, flanging, hemming, coining, and embossing—demands its own approach, tooling configuration, and process parameters. Choosing the wrong method for your application creates problems ranging from inconsistent angles to cracked surfaces.

Let's explore the specific sheet metal forming operations that transform flat stock into functional three-dimensional components. You'll discover which technique suits each application and why some metal forming operations cost significantly more than others.

| Operation Type | Typical Applications | Tooling Complexity | Surface Finish Quality |

|---|---|---|---|

| Air Bending | Prototypes, low-volume production, parts requiring multiple angles | Low | Good |

| Bottoming | Medium-volume production requiring consistent angles | Medium | Very Good |

| Coining | Precision components, tight-tolerance parts, fine detail work | High | Excellent |

| Flanging | Edge reinforcement, assembly interfaces, structural stiffening | Medium | Good |

| Hemming | Automotive panels, appliance edges, safety edge finishing | Medium to High | Excellent |

| Embossing | Decorative patterns, logos, structural reinforcement ribs | Medium | Very Good |

| Rubber Pad Forming | Aerospace components, complex curves, prototype production | Low to Medium | Excellent |

Bending and Flanging Operations

Bending represents the most fundamental forming operation in sheet metal work. The principle sounds simple—strain metal around a straight axis until it holds a new shape. Yet the execution involves critical decisions that determine part quality, production costs, and tooling longevity.

Three distinct bending methods dominate the industry, each with unique characteristics:

Air Bending offers maximum flexibility with minimal tooling investment. According to technical documentation from Inductaflex, in this method the punch pushes the sheet partway into a V-die, contacting only the punch tip and the top edges of the die. The depth of the punch stroke—not the die angle—determines your final bend angle.

Why do manufacturers favor air bending for certain applications?

- Requires less forming force than alternative methods

- One die handles multiple angles through stroke adjustment

- Tooling lasts longer due to reduced contact pressure

- Setup time remains shorter for varied production runs

The trade-off? Springback presents the biggest challenge. Depending on the alloy and radius, springback in air bending can exceed 5°, especially in harder materials like 6061-T6 aluminum. Accurate programming or manual corrections become essential to compensate for this elastic recovery.

Bottoming delivers greater accuracy when repeatability matters more than flexibility. The punch forces material until it rests firmly against both die flanks, matching the die angle more closely. This firmer contact reduces springback to approximately 1° to 2° in most applications.

However, bottoming demands dedicated tooling for each bend angle and requires substantially more press tonnage. The increased contact also accelerates die wear, making this forming die approach best suited for medium to high-volume production where consistency justifies the investment.

Flanging Operations extend beyond simple bending by creating edges perpendicular or angled to the main body. Three flanging variations address different manufacturing needs:

- Straight flanging: Creates 90° edges for assembly interfaces or structural reinforcement

- Stretch flanging: Forms convex curves where the outer edge stretches during formation

- Shrink flanging: Creates concave curves where material compresses at the edge

Hemming takes flanging further by folding the edge completely back on itself—either flat against the panel or with a small gap. Automotive door panels and appliance edges commonly feature hemmed edges that eliminate sharp metal exposure while adding rigidity.

Coining and Precision Forming Techniques

When tolerances tighten and surface finish becomes critical, metal forming and coining techniques deliver results that standard bending simply cannot achieve.

Coining Bending applies extreme pressure—the highest among all bending methods—to compress material into the bottom of the die cavity. According to manufacturing research from Inductaflex, the deformation is plastic rather than elastic, which means the shape holds after forming with almost no springback.

What makes coining the right choice for demanding applications?

- Delivers exact angles with virtually zero springback

- Works exceptionally well for hard tempers or small-radius bends

- Produces repeatable results even in tight-tolerance parts

- Creates fine surface details impossible with other methods

The precision comes at a cost. Coining requires the most tonnage among bending techniques, causes faster tool wear, and creates material thinning in the bend zone—typically between 3% to 10%. This thinning may reduce fatigue resistance in some applications, making coining impractical for thicker sheets unless heavy-duty presses are available.

Embossing creates raised or recessed patterns on sheet metal surfaces without cutting through the material. The forming die impresses detailed features—logos, decorative textures, or structural reinforcement ribs—through controlled deformation. Unlike coining, embossing typically involves less extreme pressures and focuses on surface aesthetics rather than dimensional precision.

Rubber Pad Forming for Specialized Applications

Sometimes rigid steel dies aren't the answer. Rubber pad forming uses a flexible pad—typically polyurethane or rubber—as one half of the forming die. The sheet metal gets pressed between this resilient pad and a rigid form block, allowing complex curves and contours without matched steel tooling.

According to industrial applications data from PSI Urethanes, polyurethane die pads offer significant advantages over traditional rubber. With higher tensile strength, greater abrasion resistance, and better load-bearing capacity, polyurethane pads have become preferred for industries requiring durable solutions. The aerospace sector particularly benefits from this technique for forming lightweight components with complex geometries.

Why consider rubber pad forming for your application?

- Lower tooling costs: Only one rigid form block required instead of matched die sets

- Superior surface finish: The flexible pad prevents scratching and marring

- Complex geometry capability: Forms compound curves that would require expensive progressive dies otherwise

- Reduced setup time: Quick changeover between different part configurations

Polyurethane specifically outperforms traditional rubber through enhanced energy absorption and resilience. This improves precision in the forming process while reducing defects. Industries ranging from automotive to construction leverage these materials for applications where standard forming dies would prove impractical or cost-prohibitive.

Choosing among these types of forming depends on your specific requirements: production volume, tolerance demands, surface finish expectations, and budget constraints. Air bending suits prototyping and varied production; bottoming handles consistent medium-volume runs; and coining becomes essential when precision cannot be compromised.

With forming operations now understood, the next consideration becomes equally critical: how modern technology—CNC integration, automation, and Industry 4.0 concepts—is transforming what's possible in die forming manufacturing.

Modern Technology in Die Forming Manufacturing

You've mastered the forming operations—bending, coining, flanging. But here's what separates good manufacturers from great ones: leveraging technology that competitors haven't even considered. While traditional presses still dominate many facilities, modern forming manufacturing has undergone a quiet revolution. Servo-driven systems, automated material handling, and real-time sensing now deliver capabilities that seemed impossible just a decade ago.

What does this mean for your die forming operations? Faster cycles, tighter tolerances, and dramatically reduced scrap rates. Let's explore how these technologies are reshaping what's achievable with machine dies and automated production systems.

CNC Integration in Modern Die Systems

Traditional mechanical presses operate on fixed motion profiles—the ram moves at predetermined speeds regardless of what you're forming. Servo presses change everything. According to manufacturing specialists at Shuntec Press, servo presses use programmable servo motors to drive the ram, offering full control over motion throughout the entire stroke.

What makes this die machine technology transformative? Consider these capabilities:

- Variable stroke profiles: Fast approach, slow press, controlled dwell, and quick return—all programmable for each specific part

- Reduced part deformation: Gentle forming action minimizes springback and surface defects

- Extended die life: Smooth, controlled motion with reduced impact at bottom dead center decreases shock and stress on manufacturing tooling

- Lower energy consumption: Servo motors draw power only when in motion, cutting energy costs by 30-50% compared to flywheel-driven systems

The precision advantage proves particularly significant for complex forming operations. Unlike conventional systems where you accept whatever motion profile the flywheel delivers, machine die cutting with servo technology lets engineers optimize every millisecond of the stroke cycle. Need to slow down through a critical forming zone to prevent cracking? Program it. Want faster return strokes to boost productivity? That's adjustable too.

Regenerative braking adds another dimension—servo systems capture energy during deceleration and feed it back into the power supply. For high-volume production running thousands of cycles daily, these savings compound into substantial operational cost reductions.

Automation and Smart Manufacturing

Beyond the press itself, modern die forming integrates into broader automated systems that minimize human intervention while maximizing consistency. Automated material handling—coil feeders, transfer mechanisms, and robotic part extraction—keeps production flowing without manual loading between cycles.

But the real transformation comes from Industry 4.0 integration. Today's advanced machine die systems incorporate:

- Real-time monitoring: Sensors track tonnage, stroke position, and cycle time continuously, alerting operators to deviations before defects occur

- Predictive maintenance: AI algorithms analyze vibration patterns and performance trends to schedule maintenance before failures happen

- Quality tracking: In-die sensing verifies part dimensions during production, automatically rejecting out-of-spec components

- Digital connectivity: Production data flows to enterprise systems for comprehensive analytics and process optimization

What tangible benefits does this automation deliver? The results speak clearly:

- Reduced cycle times: Eliminating manual handling between operations cuts total production time by 25-40%

- Consistent quality: Automated systems don't get tired, distracted, or vary their technique—every cycle runs identically

- Lower labor costs: One operator can oversee multiple automated cells instead of manually feeding individual presses

- Enhanced safety: Keeping hands away from moving machinery dramatically reduces workplace injuries

Rapid prototyping capabilities have similarly accelerated development cycles. What previously required weeks of manual die adjustments now happens in days. Engineers simulate forming operations virtually, validate designs through CAE analysis, and produce prototype parts on flexible servo systems—all before committing to hardened production tooling.

According to industry research from Shuntec Press, servo presses equipped with AI-driven control algorithms can automatically adjust motion profiles based on material feedback or process variables. This adaptability improves forming accuracy and reduces human error, making operations more efficient and consistent across varying production conditions.

The miniaturization trend also continues reshaping the industry. Compact servo presses now serve cleanroom environments and specialized applications in medical and microelectronics manufacturing—spaces where traditional hydraulic systems would be impractical due to contamination concerns or floor space constraints.

With technology capabilities now clear, the next critical question emerges: what does all this investment actually cost, and when does the return justify the expenditure?

Cost Analysis and ROI for Die Forming Tooling

You've explored die types, mastered forming operations, and discovered cutting-edge automation technologies. But here's the question that ultimately determines whether your project moves forward: what will this actually cost, and when does the investment pay off? Surprisingly, many engineers overlook the complete financial picture—focusing on initial tooling quotes while ignoring the factors that truly drive long-term profitability.

Understanding the economics of tool and die manufacturing separates successful projects from budget disasters. Let's break down exactly what drives costs, how to calculate meaningful returns, and when die forming becomes your most cost-effective option.

Understanding Die Tooling Investment

What is tool & die investment really composed of? The initial quote you receive represents just the visible portion of total costs. A comprehensive cost analysis must account for every phase from concept through production validation.

The primary cost components include:

- Engineering and design: CAD modeling, CAE simulation, Design for Manufacturability review, and engineering changes—typically 10-15% of total tooling cost

- Tool steel and machining: Raw material procurement, CNC machining, EDM operations, grinding, and heat treatment—often 50-60% of total investment

- Tryout and validation: Press time, sample production, dimensional inspection, adjustments, and customer approvals—approximately 15-20% of project cost

- Ongoing maintenance: Preventive maintenance, wear component replacement, and periodic refurbishment—often overlooked but critical for accurate ROI calculations

According to manufacturing cost analysis from Mursix, custom die creation typically represents the most significant upfront expense, but once the die is made, the per-unit cost decreases significantly with higher production runs. This economic reality makes volume projections essential to accurate planning.

Die complexity dramatically influences investment requirements. A simple compound die for flat washers might cost $5,000-$15,000, while a complex progressive die with 20+ stations for automotive brackets could exceed $150,000. Transfer dies for large, intricate components sometimes reach $300,000 or more. Each die maker evaluates complexity based on number of operations, tolerance requirements, and expected production volumes.

Material selection also impacts costs significantly. Common materials like aluminum or steel require standard tooling approaches, while specialty alloys or thicker materials demand premium die supplies—harder tool steels, specialized coatings, and more robust construction that increases upfront investment.

Calculating Return on Tooling Investment

When does your manufacturing die investment actually pay for itself? The answer depends on production volume, part complexity, and alternative manufacturing options.

According to ROI research from Pivatic, traditional ROI formulas provide a basic framework, but sheet metal operations require more nuanced analysis. Manufacturing efficiency gains from automation can dramatically affect ROI calculations, as modern fabrication solutions impact multiple aspects of production simultaneously.

Consider this comparison for a bracket requiring 100,000 annual units:

| Cost Factor | Progressive Die Forming | Laser Cutting + Bending |

|---|---|---|

| Initial tooling investment | $75,000 | $2,000 (fixtures only) |

| Per-part production cost | $0.35 | $2.50 |

| Annual production cost (100K units) | $35,000 | $250,000 |

| Break-even point | ~35,000 units | N/A |

| 5-year total cost | $250,000 | $1,252,000 |

The numbers reveal why die forming dominates high-volume production. Despite the substantial initial investment in die sets for press operations, the dramatically lower per-part cost creates compelling economics at scale. By year two, the progressive die approach has saved over $400,000 compared to alternative methods.

Setup costs and lead times vary significantly between approaches:

- Simple compound dies: 4-8 weeks lead time, minimal setup changeover

- Progressive dies: 12-20 weeks lead time, 2-4 hours typical setup

- Transfer dies: 16-30 weeks lead time, 4-8 hours setup for complex systems

- Die for press modifications: 1-4 weeks depending on scope, variable setup requirements

In-House Versus Outsourced Die Manufacturing

Should you build dies internally or partner with specialized die tools manufacturers? The economics depend on your production volumes, engineering capabilities, and strategic priorities.

In-house die manufacturing makes sense when you have:

- Consistent, high-volume tooling needs justifying equipment investment

- Skilled tool and die craftsmen on staff

- Critical intellectual property concerns

- Tight timelines requiring immediate response capabilities

Outsourcing typically proves more economical when:

- Tooling needs are intermittent or highly variable

- Specialized capabilities (large progressive dies, complex transfer systems) are required

- Capital constraints limit equipment investment

- Core competencies lie elsewhere in your value chain

According to import cost considerations from Mohawk Global, companies outsourcing die production overseas must also account for "assist" valuations—U.S. Customs requires the value of tooling provided to foreign manufacturers be declared as part of import value. Failing to properly declare these costs can result in penalties from two to four times the amount of duties previously lost.

When does die forming become cost-effective compared to alternatives like laser cutting, waterjet, or machining? The crossover point typically falls between 10,000 and 50,000 annual units, depending on part complexity. Die tooling investments become harder to justify below this threshold, while volumes exceeding 100,000 units almost always favor stamping approaches.

Understanding these cost dynamics positions you to make informed decisions about die forming investments. But costs mean nothing without considering where those parts will be used—the next section explores how different industries apply die formed components and the quality standards that govern each application.

Industry Applications for Die Formed Metal Parts

You've analyzed costs, calculated ROI, and understand the financial logic behind die forming investments. But here's where theory meets reality: how do actual industries apply these techniques to solve real manufacturing challenges? Each sector—automotive, aerospace, appliance, and electronics—demands unique specifications, tolerances, and quality certifications that fundamentally shape die design and production strategies.

Understanding these industry-specific requirements helps engineers specify tooling that meets demanding application standards while optimizing cost-effectiveness. Let's explore how die forming metal transforms raw materials into critical components across diverse sectors.

| Industry | Typical Parts | Volume Requirements | Quality Standards |

|---|---|---|---|

| Automotive | Body panels, structural brackets, chassis components, fuel system parts | 100,000 - 1,000,000+ annually | IATF 16949, PPAP, APQP |

| Aerospace | Structural frames, turbine components, landing gear parts, skin panels | 1,000 - 50,000 annually | AS9100, NADCAP, FAA regulations |

| Appliance | Washer drums, refrigerator panels, oven liners, HVAC housings | 50,000 - 500,000 annually | ISO 9001, UL certification |

| Electronics | Connector housings, EMI shields, heat sinks, enclosures | 500,000 - 10,000,000+ annually | ISO 9001, IPC standards |

Automotive Stamping Applications

When you think about die forming metal at scale, the automotive industry immediately comes to mind. Modern vehicles contain hundreds of stamped components—from visible body panels requiring Class A surface finishes to hidden structural brackets demanding precise dimensional tolerances. What is die cutting's role here? Beyond simple blanking operations, automotive stamping encompasses complex progressive die systems producing everything from door hinges to fuel tank shields.

The parts automotive manufacturers rely on include:

- Body-in-white components: Roof panels, fenders, door outers, hood assemblies—parts requiring exceptional surface quality for painting

- Structural elements: B-pillars, floor pans, crossmembers—components where strength and crash performance matter more than appearance

- Powertrain parts: Transmission brackets, motor mounts, heat shields—functional components demanding tight tolerances and consistent material properties

- Safety systems: Airbag housings, seatbelt anchors, restraint system components—parts where failure is simply not acceptable

Why does automotive manufacturing demand such stringent quality systems? According to OGS Industries, the IATF 16949 certification goes beyond basic ISO 9001 requirements to ensure compliance with lean manufacturing principles, defect prevention, variance deterrence, and waste reduction. For metal stamping and forming operations, this certification demonstrates commitment to delivering consistent, specification-compliant components.

The certification delivers tangible benefits throughout the supply chain:

- Consistent quality: Monitored and measured processes maximize productivity while delivering repeatable outcomes

- Reduced product variation: Reviewed manufacturing processes ensure components consistently meet high-performance vehicle requirements

- Defect prevention: Tested and proven fabrication processes diminish inefficiencies and minimize defects before they reach assembly lines

- Reliable supply chain: IATF 16949 establishes benchmarks for supplier sourcing, creating stronger, more dependable relationships

For manufacturers seeking precision stamping die solutions that meet automotive OEM standards, capabilities matter enormously. Advanced CAE simulation identifies potential defects before cutting die arrives on the shop floor. Rapid prototyping—sometimes delivering samples in as few as 5 days—accelerates development timelines that previously stretched for months. And high first-pass approval rates exceeding 90% reduce costly iteration cycles while maintaining production schedules.

Interested in exploring comprehensive mold design and fabrication capabilities for automotive applications? Specialized suppliers like Shaoyi's automotive stamping dies division combine IATF 16949 certification with advanced engineering to deliver defect-free results meeting the most demanding specifications.

Precision Requirements Across Industries

Beyond automotive, each industry applies unique constraints that shape die design decisions and quality requirements.

Aerospace applications demand the tightest tolerances and most rigorous documentation. According to manufacturing research from Actco Tool, the aerospace industry relies heavily on die manufacturing for critical components that must meet stringent safety and performance standards. Forging dies create high-strength parts like turbine blades and landing gear components, while specialized forming dies produce structural elements for aircraft frames.

What makes aerospace die forming unique?

- Material traceability requirements demand documentation of every steel heat lot used in production

- First article inspection involves comprehensive measurement of every critical dimension

- Process validation often requires destructive testing of sample parts

- Change control protocols mean even minor die modifications require formal approval

Appliance manufacturing balances cost sensitivity with aesthetic requirements. Washer drums, refrigerator panels, and oven liners must look good while withstanding years of daily use. Deep draw dies produce seamless drum assemblies, while progressive systems stamp decorative faceplates with integrated features. The cutting die for trim operations must maintain sharp edges that produce burr-free perimeters safe for consumer handling.

Electronics applications push miniaturization boundaries while demanding electrical performance characteristics. Die cutter systems for this sector produce components measured in millimeters—connector terminals, EMI shielding enclosures, and precision heat sinks. Industrial die cutting machine capabilities now achieve tolerances of ±0.025mm, enabling components that fit within increasingly compact device architectures.

The die cutter for metal in electronics applications must address:

- Surface conductivity: Plating and coating compatibility with die materials

- Burr control: Preventing sharp edges that could damage insulation or cause shorts

- Material consistency: Electrical properties depend on uniform material composition

- High-speed production: Consumer electronics volumes often exceed millions of units annually

Die cutting operations across all sectors benefit from modern simulation tools. CAE analysis predicts material flow, identifies potential defects, and optimizes die designs before expensive machining begins. For complex parts, this virtual validation can eliminate entire trial-and-error cycles, reducing development costs by 30-50% while compressing timelines.

Manufacturers achieving first-pass approval rates above 90% consistently point to advanced simulation and engineering expertise as the differentiating factors. When dies perform correctly on first tryout, production schedules remain intact and total program costs stay within budget.

The common thread across all industries? Quality systems and engineering capabilities matter more than lowest-cost tooling quotes. Whether you're producing automotive brackets, aerospace structural components, appliance housings, or electronic enclosures, partnering with suppliers who understand your industry's specific requirements—and hold relevant certifications—directly impacts program success.

With industry applications now clear, the final consideration becomes actionable: how do you select the right die forming approach and partner for your specific project requirements?

Selecting the Right Die Forming Solution

You've journeyed through die types, forming operations, material compatibility, modern technologies, cost analysis, and industry applications. Now comes the critical decision: how do you translate all this knowledge into selecting the right die forming approach and partner for your specific project? The answer lies in systematic evaluation rather than gut instinct.

Choosing incorrectly means production delays, quality issues, and budget overruns. Choosing wisely creates competitive advantage through consistent quality, predictable costs, and reliable supply. Let's synthesize everything into actionable guidance that transforms your next die forming project into a success story.

Key Factors in Die Forming Decisions

Before contacting potential suppliers or committing to a die press investment, work through this comprehensive selection checklist. Each factor influences your optimal approach—and overlooking any single element can derail otherwise promising projects.

- Production volume requirements: Annual quantities below 10,000 units rarely justify progressive die tooling investments. Volumes exceeding 100,000 units almost always favor stamping over alternative processes like laser cutting. Match your die type—compound, progressive, or transfer—to realistic volume projections including growth forecasts.

- Part complexity: Simple flat blanks suit compound dies costing $5,000-$15,000. Parts with multiple bends, holes, and features demand progressive systems that may exceed $100,000. Deep drawn components or large assemblies often require transfer die solutions. Be honest about what your geometry actually requires.

- Material specifications: High-strength steels, stainless alloys, and specialty metals demand premium die tools with harder steel grades and specialized coatings. Standard carbon steel or aluminum permits more economical tooling approaches. Factor material springback characteristics into tolerance expectations.

- Quality certifications needed: Automotive applications require IATF 16949 certification. Aerospace demands AS9100 compliance. Medical devices need FDA-compatible quality systems. Verify potential partners hold certifications relevant to your end-use application before proceeding.

- Lead time constraints: Simple compound dies require 4-8 weeks. Complex progressive systems need 12-20 weeks or more. If your product launch depends on tooling delivery, build realistic timelines that account for design iterations, tryout cycles, and validation requirements.

- Budget considerations: Beyond initial tooling costs, calculate total cost of ownership including maintenance, expected die life, and per-part production economics. The lowest quote rarely delivers the best value when quality problems or premature die failure enter the equation.

According to supplier selection research from Xiluo Mold, spending extra time during the internal assessment phase prevents miscommunication and ensures you compare suppliers on criteria that actually matter for your specific project.

Partnering for Die Forming Success

Your die tooling supplier becomes an extension of your engineering team. The best partnerships go far beyond transactional purchasing—they involve collaborative problem-solving, technical expertise sharing, and mutual commitment to project success.

What separates excellent partners from adequate ones? Look for these critical capabilities:

Engineering support and simulation capabilities: According to industry research from Frigate, poorly designed parts or tooling can increase production costs by up to 25%. Working with providers who offer expert design assistance early in development reduces this risk significantly. Advanced CAE simulation—using tools like AutoForm or Dynaform—identifies forming defects virtually before cutting any steel.

Engineering teams equipped with these simulation capabilities can predict material flow, springback behavior, and potential failure modes. This virtual validation catches 80-90% of issues that would otherwise require costly physical die modifications. When providers achieve first-pass approval rates around 93%, you benefit from compressed development timelines and reduced iteration costs.

Rapid prototyping capabilities: Speed matters in competitive markets. Suppliers offering prototype samples in as little as 5 days enable faster design validation and accelerated product launches. This capability proves especially valuable when customer feedback or functional testing might drive design changes—better to discover issues with prototype tooling than production dies.

Quality systems and certifications: Die forming isn't just about making parts—it's about making parts that consistently meet specifications. According to Zintilon, the die you select determines the accuracy and consistency of your finished products. High-quality dies manufactured to precise specifications ensure parts consistently meet dimensional tolerances.

For demanding applications, verify your potential partner maintains:

- ISO 9001 baseline quality management systems

- IATF 16949 certification for automotive applications

- Documented inspection procedures using CMM equipment

- Material traceability and certification protocols

- Statistical process control during production runs

Capacity and flexibility: Can your supplier scale with growing demand? A study cited by Frigate found that 32% of manufacturers experience production delays due to inadequate supplier capabilities. Assess current capacity, production scheduling approaches, and ability to accommodate volume fluctuations before committing to long-term partnerships.

Communication and responsiveness: Die forming projects involve continuous dialogue—design reviews, tryout reports, quality discussions, and change management. Clear communication prevents misunderstandings, while responsive support ensures issues get resolved before they impact production schedules.

The goal is finding a strategic partner committed to quality, invaluable engineering expertise, and dedication to helping you achieve manufacturing goals for years to come.

When evaluating potential suppliers, ask pointed questions about their approach to each phase of die development. How do they handle Design for Manufacturability reviews? What simulation tools do they employ? How do they manage tryout and validation? What ongoing support do they provide after production begins?

The answers reveal whether a supplier operates as a true partner or merely a transactional vendor. For projects where quality, reliability, and long-term value matter, partnering with suppliers who combine advanced CAE simulation, rapid prototyping capabilities, and proven high-volume manufacturing expertise delivers measurable competitive advantage.

Ready to explore how precision stamping die solutions with IATF 16949 certification can support your next project? Discover comprehensive mold design and fabrication capabilities at Shaoyi's automotive stamping dies division—where engineering excellence meets manufacturing reliability.

Frequently Asked Questions About Die Forming Metal

1. What is a die in metal forming?

A die is a specialized precision tool that cuts, shapes, or forms sheet metal into specific geometries under controlled pressure. Dies consist of matched tooling sets—typically a punch and die block—that work together to stamp, bend, or draw material into desired shapes. Unlike general-purpose tools, dies produce identical parts repeatedly with micron-level accuracy across millions of production cycles, making them essential for high-volume manufacturing in automotive, aerospace, and electronics industries.

2. What is the best steel for forming dies?

The optimal die steel depends on your application. D2 cold-work steel (58-62 HRC) offers maximum wear resistance for stamping abrasive materials like stainless or high-strength steel, making it ideal for long-run tooling. H13 hot-work steel (45-55 HRC) maintains strength at elevated temperatures and polishes to mirror finishes. A2 air-hardening steel provides balanced properties with minimal distortion, while S7 shock-resistant steel absorbs impact loads without cracking—essential for heavy-duty stamping applications.

3. What are the five metal forming processes?

The five primary metal forming processes include rolling (pressing metal between rotating cylinders), extrusion (forcing material through shaped dies), forging (reshaping through compressive forces), drawing (pulling material through dies to reduce cross-section), and stamping (using matched dies to cut and form sheet metal). Die forming specifically encompasses stamping operations including blanking, bending, deep drawing, flanging, and coining—each requiring specialized tooling configurations.

4. How do I choose between progressive, transfer, and compound dies?

Selection depends on part complexity, size, and production volume. Progressive dies suit small to medium parts with multiple features at high volumes (100,000+ units)—the metal strip feeds through sequential stations. Transfer dies handle larger, complex parts requiring workpiece separation and multiple operations. Compound dies work best for simpler flat parts like washers at lower tooling costs. Consider that progressive dies offer better per-part economics at scale, while compound dies minimize upfront investment.

5. When does die forming become cost-effective compared to laser cutting?

Die forming typically becomes cost-effective between 10,000 and 50,000 annual units, depending on part complexity. While initial tooling investment is substantial ($5,000 to $150,000+), per-part production costs drop dramatically compared to laser cutting or machining. For example, a bracket costing $2.50 per unit via laser cutting might cost only $0.35 with progressive die stamping—creating break-even around 35,000 units and substantial savings beyond that threshold.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —