Stamping Processes Decoded: From Raw Metal To Finished Parts

What Metal Stamping Really Means in Modern Manufacturing

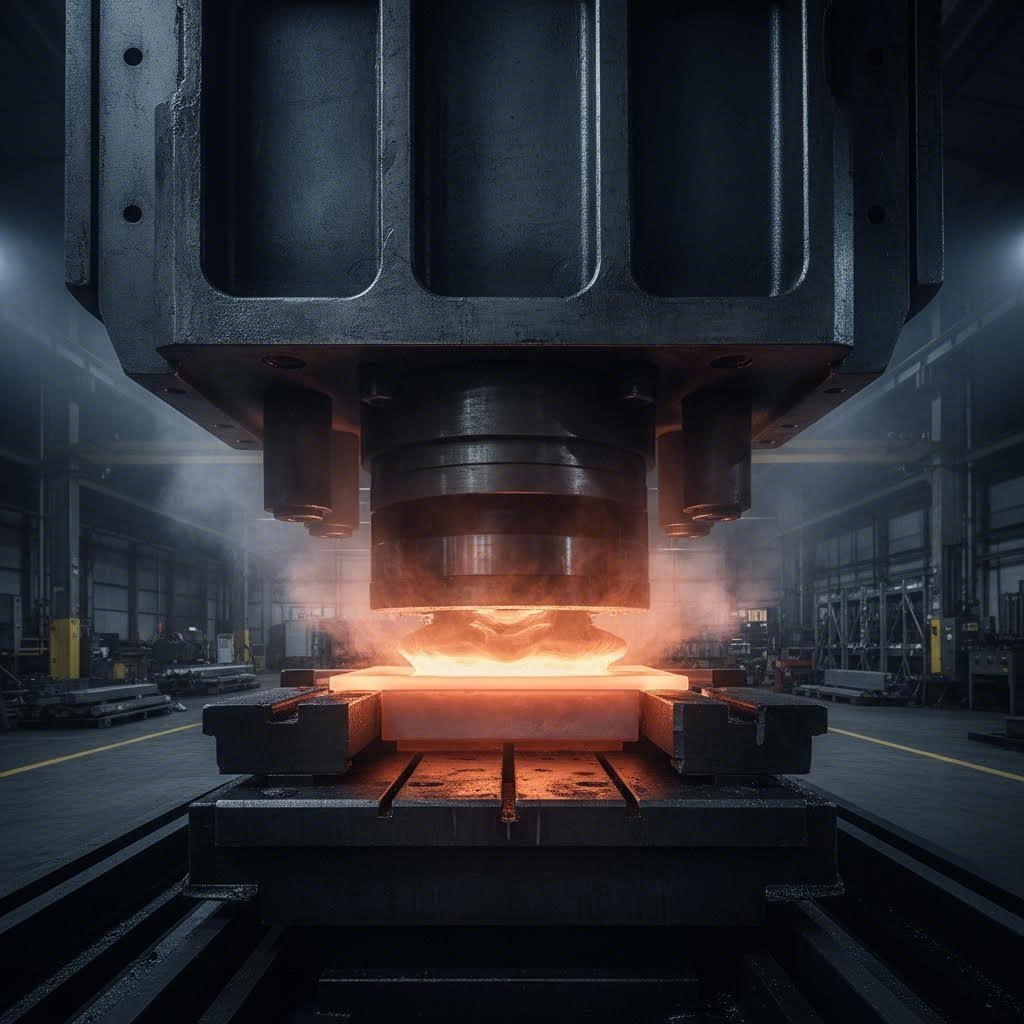

So, what is stamping exactly? At its core, metal stamping is a cold-forming manufacturing process that transforms flat sheet metal into precisely shaped components using specialized dies and high-pressure presses. Unlike casting or forging, this metal operation relies on mechanical force rather than melting to reshape raw materials into finished parts.

Metal stamping is a cold-forming industrial process that uses precision dies and high-pressure presses to shape sheet metal into finished components through cutting, bending, and forming operations.

Understanding the stamping meaning in manufacturing helps you appreciate why this process dominates industries from automotive to electronics. Every time you flip a light switch, open a car door, or use your smartphone, you're interacting with stamped metal parts.

The Cold-Forming Principle Behind Every Stamped Part

Here's something that might surprise you: despite being called "cold-forming," stamped parts often come out hot. How does this happen without external heat?

The answer lies in friction. When a press applies tremendous force—often measured in hundreds of tons—to push a die into sheet metal, the intense pressure creates friction between the tool and workpiece. This friction generates significant heat during the stamping process, even though manufacturers don't apply external thermal energy.

This distinction matters for several reasons:

- Material properties remain stable because the metal never reaches temperatures that alter its molecular structure

- Dimensional accuracy improves since parts don't shrink or warp during cooling

- Production speeds increase without waiting for heating or cooling cycles

- Energy costs drop compared to hot-forming alternatives

The stamping process works through a carefully orchestrated interaction between three elements: the sheet metal blank, the precision die, and the press machine. When stamping means applying force measured in tons, you need equipment capable of maintaining exact tolerances—often as tight as ±0.001 inches according to industry specifications.

From Flat Sheet to Finished Component

Imagine feeding a flat piece of aluminum or steel into a machine and retrieving a complex three-dimensional bracket seconds later. That's the power of what is a stamping operation in action.

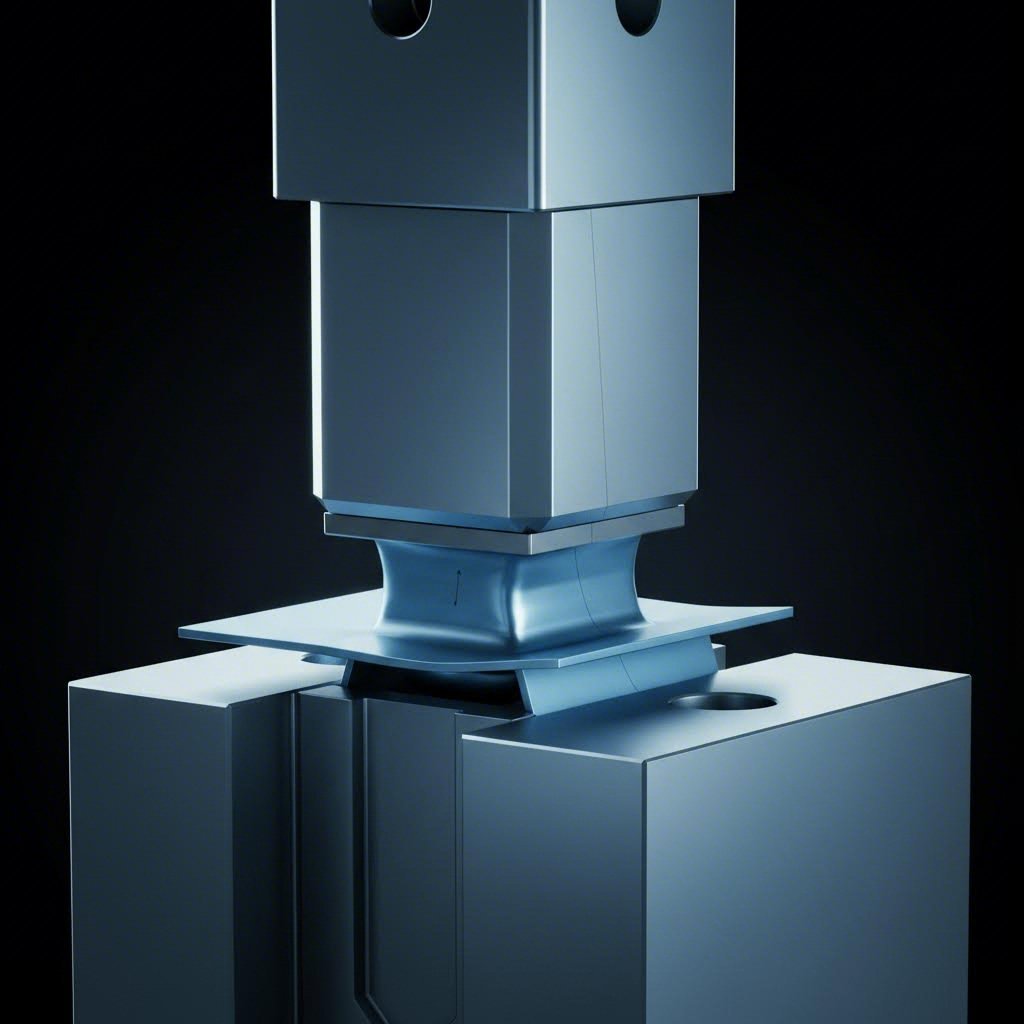

The transformation happens through a tool and die set consisting of two essential parts: the punch (which applies downward force) and the die (which shapes the metal from below). As the press cycles, these components work together to cut, bend, form, or draw the metal into its final shape.

What makes what is metal stamping particularly valuable is its versatility. Modern stamping machines don't just perform one function—they can cut, punch, and shape raw material through CNC programming that ensures consistency across thousands or millions of cycles. Whether manufacturers need simple brackets, intricate electronic components, or complex automotive parts, this process delivers the speed, precision, and scalability that other methods simply can't match.

Choosing the Right Metal for Your Stamping Application

Now that you understand how stamping transforms flat sheets into finished components, here's the critical question: which metal should you choose? Selecting the right metal for stamping directly impacts everything from part durability to manufacturing costs and final performance.

The truth is, not all metals behave the same way under a stamping press. Some stretch easily without cracking. Others work-harden quickly and require special handling. Understanding these differences helps you avoid costly mistakes before tooling is ever built.

Steel Grades and Their Stamping Characteristics

Steel remains the workhorse of metal stamping materials, and for good reason. It offers an unmatched combination of strength, formability, and affordability that makes it suitable for countless applications.

Carbon steel is the most widely used option. Available in low, medium, and high carbon grades, it provides excellent stampability at competitive prices. Low carbon steel (less than 0.3% carbon) forms easily and works well for brackets, enclosures, and general structural components. As carbon content increases, strength improves but ductility decreases—meaning the metal becomes harder to form without cracking.

High-Strength Low-Alloy (HSLA) steel steps up when you need strength without excessive weight. According to Talan Products, HSLA steel is commonly specified for automotive, heavy equipment, and structural applications where both strength and lightweight properties matter.

When corrosion resistance is essential, stainless steel metal stamping becomes the preferred choice. Different grades offer unique benefits:

- 300 series stainless (Types 301, 302, 305) provides excellent corrosion resistance and formability for food processing, medical devices, and architectural applications

- 400 series stainless (Grades 410, 420, 440A) offers higher hardness and wear resistance for cutting tools and valve components

- Precipitation-hardening grades (17-4PH, 17-7PH) deliver exceptional strength for aerospace and defense applications

One challenge with stamped steel, particularly austenitic stainless grades, is their high work hardening rate. As Ulbrich notes, austenitic stainless steel has a cold hardening index of 0.34%, which can induce martensitic transformation during deformation. This makes the material brittle and prone to cracking if not properly managed during the stamping process.

Lightweight Metals for Weight-Critical Applications

When every gram counts, stamped aluminum delivers weight reduction without sacrificing structural integrity. Aluminum weighs roughly one-third as much as steel, making it ideal for aerospace components, consumer electronics, and automotive body panels where fuel efficiency matters.

Common aluminum stamping grades include 1100, 3003, 5052, and 6061—each offering different balances of strength, formability, and corrosion resistance. Aluminum stamps cleanly and forms easily, though it requires careful die design to prevent galling (material transfer between the workpiece and tooling).

Copper and brass excel in applications requiring electrical or thermal conductivity. Copper stamping is essential for electrical connectors, bus bars, and heat exchangers. Brass—a copper-zinc alloy—offers similar conductivity with improved machinability, making it popular for terminals, contacts, and HVAC components.

For extreme applications, titanium provides an exceptional strength-to-weight ratio along with corrosion resistance and biocompatibility. Though more challenging to stamp than steel or aluminum, titanium grades like 6AL4V are increasingly specified for aerospace, military, and medical implant applications.

Matching Material Properties to Part Requirements

Choosing the best material requires evaluating four critical properties that directly affect stampability:

- Ductility and formability determine how much the metal can stretch before fracturing. Forming occurs between a material's yield strength and tensile strength—exceed the tensile limit, and cracks appear

- Tensile strength measures force resistance. Higher-strength materials can withstand greater loads but typically have smaller forming windows

- Work hardening rate indicates how quickly metal becomes harder and more brittle during stamping. Materials with high work hardening rates may require intermediate annealing steps

- Thickness range influences which stamping method works best—thinner materials suit progressive die operations, while thicker stock may require hydraulic presses with slower forming speeds

| Material Type | Typical Thickness Range | Key Properties | Best Applications | Relative Cost |

|---|---|---|---|---|

| Carbon Steel | 0.010" - 0.250" | High strength, excellent formability | Brackets, enclosures, structural parts | Low |

| Stainless Steel | 0.005" - 0.187" | Corrosion resistance, durability | Medical devices, food equipment, aerospace | Medium-High |

| Aluminum | 0.008" - 0.190" | Lightweight, corrosion resistant | Electronics, automotive panels, aerospace | Medium |

| Copper | 0.005" - 0.125" | Excellent electrical/thermal conductivity | Connectors, bus bars, heat exchangers | Medium-High |

| Brass | 0.010" - 0.125" | Good conductivity, high machinability | Terminals, contacts, decorative parts | Medium |

| Titanium | 0.010" - 0.080" | High strength-to-weight, biocompatible | Aerospace, medical implants, defense | High |

Material thickness significantly influences process selection. Thinner gauges (under 0.060") typically work well with high-speed progressive dies, while thicker materials often require slower hydraulic presses that provide better force control during deep drawing operations.

With your material selected, the next critical decision involves choosing the right press type to deliver the force, speed, and control your application demands.

Stamping Press Types and When to Use Each

So you've selected the perfect material for your project. Now comes the question that can make or break your production efficiency: what is a stamping press, and which type should you use?

A stamping press is the powerhouse that delivers the force needed to transform flat sheet metal into finished components. But here's what many people miss—not all metal stamping presses work the same way. The press you choose affects cycle times, part quality, energy consumption, and long-term operating costs.

Today's market offers three primary press technologies: mechanical, hydraulic, and servo. Each has distinct advantages depending on your material, part complexity, and production volume requirements.

Mechanical Presses for High-Speed Production

Need speed? Mechanical presses are often your best choice. These machines use a flywheel-driven mechanism to generate force, making them ideal for high-volume manufacturing where cycle time matters most.

The flywheel stores rotational energy, which the press releases through a clutch and crankshaft mechanism during each stroke. This design delivers consistent, repeatable force at impressive speeds—some mechanical presses cycle over 1,000 strokes per minute for small parts.

Key advantages of mechanical presses include:

- Exceptional production speeds for blanking, piercing, and shallow forming operations

- Lower energy consumption once the flywheel reaches operating speed

- Predictable stroke patterns that ensure consistent part quality across millions of cycles

- Reduced maintenance costs compared to hydraulic systems

However, mechanical presses have limitations. According to Eigen Engineering, one drawback is that they don't offer as much control at the bottom of the stroke. This makes them less suitable for deep drawing or operations requiring variable force throughout the forming cycle. They excel when your work demands consistent, repetitive operations where volume outweighs flexibility.

Hydraulic Systems for Complex Forming Operations

When you're working with heavier or high-tensile materials, hydraulic presses become the preferred alternative. These machines use fluid pressure to generate force, offering capabilities that mechanical presses simply can't match.

What makes hydraulic metal stamping press machines stand out is their force control. Unlike mechanical presses that deliver force based on flywheel momentum, hydraulic systems apply consistent pressure throughout the entire stroke. This characteristic proves invaluable for:

- Deep drawing operations where controlled material flow prevents tearing

- Complex three-dimensional shapes requiring variable force application

- Thick or high-strength materials that resist deformation

- Operations requiring extended dwell time at the bottom of the stroke

Hydraulic presses are slower than mechanical varieties, but they compensate with superior versatility and consistency. This trade-off makes sense when producing complicated stamped metal parts that demand precision over pure speed.

Servo Technology Advancing Stamping Precision

The servo press represents the newest evolution in stamping technology. These machines combine advanced servo motor technology with programmable control, offering something neither mechanical nor hydraulic presses can deliver alone—speed, power, and adaptability in one package.

Servo press benefits include:

- Fully programmable stroke profiles that optimize forming for each unique part

- Variable speed control throughout the stroke—fast approach, slow forming, rapid return

- Energy efficiency since the motor only draws power when needed

- Quick changeover between different part programs without mechanical adjustments

- Reduced noise levels compared to traditional mechanical systems

For manufacturers producing electronics, medical devices, or high-precision stamped metal parts, servo technology delivers the accuracy that demanding tolerances require. The ability to adjust parameters quickly also makes servo presses excellent for job shops handling diverse product mixes.

Understanding Tonnage Requirements

Regardless of which press type you select, understanding tonnage is essential. Tonnage capacity describes the maximum force a press can apply without structural damage. But here's what many stampers overlook: the required tonnage must remain below the press's available tonnage curve at every point in the stroke—not just at the bottom.

As Guangduan Presses explains, the press's tonnage capacity varies throughout the stroke cycle. At both top dead center and bottom dead center, theoretical available tonnage approaches infinity—but the press structure would fail long before reaching such extremes. The practical tonnage limit depends on stroke position, material thickness, and part geometry.

When sizing a steel press or any stamping equipment, consider these factors:

- Material type and tensile strength—harder materials require more force

- Material thickness—thicker stock demands higher tonnage

- Part complexity—multiple bends or draws multiply force requirements

- Cutting perimeter—longer cuts require proportionally more tonnage

| Press Type | Speed Range | Force Control | Best Applications | Tonnage Considerations |

|---|---|---|---|---|

| Mechanical | 20-1,500+ SPM | Fixed stroke profile, limited bottom control | High-volume blanking, piercing, shallow forming | Available tonnage varies with stroke position; peaks near BDC |

| Hydraulic | 5-50 SPM | Full tonnage available throughout stroke | Deep drawing, complex forming, thick materials | Consistent force at any stroke position; ideal for heavy-gauge work |

| Servo | 10-300+ SPM | Fully programmable speed and force curves | Precision parts, variable production, quick changeover | Optimized force delivery reduces peak tonnage requirements |

The right metal stamping press depends on balancing your specific needs. If high-volume production with consistent parts drives your operation, mechanical presses deliver unmatched speed. For complex forming requiring force control, hydraulic systems provide the flexibility you need. And when precision plus programmability matters most, servo technology offers the best of both worlds—though at a higher initial investment.

With your material selected and press type determined, the next step is understanding the specific stamping operations that transform raw sheet metal into finished components.

Essential Stamping Operations From Blanking to Assembly

You've selected your material and chosen the right press. Now comes the question that defines what your finished parts will look like: which stamping operations do you actually need?

Most guides list seven to nine basic operations and call it a day. But here's the reality—successful metal stamping process design requires understanding the full spectrum of available techniques, including secondary operations that transform stamped blanks into assembly-ready components.

Let's break down every operation you should know, organized by function so you can identify exactly what your project requires.

Cutting Operations That Define Part Boundaries

Every stamped part begins with cutting operations that separate material or create openings. These operations remove metal rather than reshape it, establishing the part's basic outline and features.

- Blanking — The foundational cutting operation that separates a flat workpiece (the blank) from the parent sheet. When blank stamping metal, the piece punched out becomes the finished part while the remaining skeleton becomes scrap. Blanking creates the starting point for nearly all subsequent forming operations.

- Piercing — The inverse of blanking. Here, the punched-out material becomes scrap while the sheet with the hole becomes the workpiece. Piercing creates mounting holes, ventilation openings, or weight-reduction features in stamped components.

- Notching — Removes material from the edge of a blank rather than from its interior. Notching prepares parts for subsequent bending operations by relieving material that would otherwise interfere with forming.

- Shearing — Cuts straight lines across sheet metal without creating enclosed shapes. Shearing typically separates finished parts from strip stock or trims excess material from formed components.

- Lancing — Creates a partial cut that leaves one side attached, forming louvers or tabs. Unlike piercing, lancing doesn't remove material—it displaces it to create functional features.

- Trimming — Removes excess material from drawn or formed parts. Deep-drawn components often require trimming to achieve final dimensions after the forming process stretches material unevenly.

What happens to the metal during cutting? The metal pressing process subjects material to intense shear stress concentrated along the cutting edge. This stress exceeds the material's shear strength, causing fracture. The resulting edge shows distinct zones: a burnished area where the punch first contacts the metal, followed by a fractured zone where the material breaks away.

Forming Techniques That Create Three-Dimensional Shapes

Cutting establishes boundaries, but forming operations give stamped parts their functional geometry. These techniques reshape metal without removing material—stretching, compressing, and bending it into three-dimensional configurations.

- Bending — The most common forming operation. Bending applies force along a linear axis to create angles in sheet metal. Unlike coining bending operations (discussed below), standard bending allows some springback as the material partially recovers after the press releases.

- Drawing — Transforms flat blanks into cup-shaped or box-shaped components by pulling material into a die cavity. Deep drawing—where depth exceeds diameter—requires careful control of material flow to prevent wrinkling or tearing. According to Wikipedia, the tribology process during drawing generates friction requiring lubricants to protect both tooling and workpieces from surface damage.

- Coining — Applies extreme pressure to compress metal into every detail of the die cavity. Coining steel or other metals eliminates springback by plastically deforming the material beyond its yield point throughout the entire thickness. The result? Incredibly precise features with tight tolerances. Coining sheet metal creates the crisp details you see on currency and precision components.

- Embossing — Creates raised or recessed designs in sheet metal without significantly changing material thickness. Embossing adds logos, stiffening ribs, or decorative patterns to flat panels.

- Flanging — Bends material along a curved edge rather than a straight line. Flanging creates stiffening lips, attachment features, or mating surfaces on formed parts.

- Ironing — Thins and elongates drawn cup walls by forcing material through a clearance smaller than the incoming wall thickness. Ironing produces uniform wall thickness in deep-drawn containers.

- Swaging — Reduces the diameter of tubular or rod-shaped components through radial compression. Swaging creates tapered sections or attachment points on stamped parts.

How do these operations affect material properties? Each forming technique work-hardens the metal to varying degrees. Bending concentrates strain along the bend line, while drawing distributes deformation across larger areas. Coining produces the most severe work hardening due to its extreme pressures. Understanding these effects helps engineers predict final part properties and identify where stress relief might be necessary.

Secondary Operations That Complete the Manufacturing Cycle

Here's where stamping and pressing capabilities extend beyond what most guides cover. Secondary operations transform stamped blanks into functional assemblies ready for installation.

- Tapping — Creates internal threads in pierced holes. In-die tapping performs this operation within the progressive die, eliminating separate handling steps. As Decimal Engineering notes, in-die tapping significantly reduces per-part costs by combining operations into a single press cycle.

- Welding — Joins stamped components through spot welding, projection welding, or seam welding. Resistance welding integrates particularly well with stamping production lines, adding structural connections without slowing throughput.

- Hardware insertion — Installs PEM nuts, studs, standoffs, and other fasteners into stamped parts. Press-fit hardware eliminates the need for loose fasteners during final assembly.

- Riveting — Permanently joins multiple stamped components using solid or tubular rivets. Self-piercing rivets can join dissimilar materials without pre-drilled holes.

- Deburring — Removes sharp edges and burrs created during cutting operations. Deburring protects assembly workers, improves appearance, and prevents interference with mating parts.

- Assembly integration — Combines multiple stamped components with non-stamped elements (plastics, electronics, gaskets) into complete subassemblies. Value-added assembly reduces customer handling and logistics costs.

Why do secondary operations matter? They transform stamping from a parts-making process into a complete manufacturing solution. A stamper that handles tapping, welding, and assembly integration delivers finished components rather than intermediate blanks—reducing your supply chain complexity and total landed cost.

How Operations Combine in Production

Individual operations rarely happen in isolation. Progressive dies, for example, perform multiple cutting and forming operations in sequence as strip stock advances through the tool. A single progressive die might blank the outer profile, pierce mounting holes, form stiffening ribs, bend flanges, and coin critical dimensions—all in one press cycle.

The order of operations matters critically. Blanking typically comes first to establish the workpiece. Piercing often follows while the material remains flat. Forming operations proceed from gentlest to most severe, with coining reserved for final steps where its extreme pressures won't distort subsequent features.

Understanding this full range of stamping operations—from initial blank stamping through secondary assembly—helps you communicate effectively with suppliers and make informed decisions about which capabilities your project truly requires.

With a clear picture of available operations, the next decision involves selecting the right stamping method—progressive die, transfer die, fourslide, or fine blanking—to execute those operations efficiently at your required volumes.

Selecting the Right Stamping Method for Your Project

You understand the operations. You know what your parts need. Now comes the decision that determines your project's success: which stamping method delivers the best results for your specific requirements?

This choice involves more than checking boxes on a spec sheet. The manufacturing stamping process you select affects tooling investment, production timeline, part quality, and ultimately your per-piece cost. Get it right, and you've built a competitive advantage. Get it wrong, and you're locked into an inefficient process for the life of your product.

Let's examine the four primary sheet metal stamping process methods and the decision criteria that should guide your selection.

Progressive Die Stamping for High-Volume Efficiency

Imagine a continuous strip of metal advancing through a series of stations, each performing a specific operation—cutting, forming, bending—until a finished part drops off at the end. That's progressive die and stamping in action, and it's the production stamping method of choice when volume justifies tooling investment.

How does it work? A coiled metal strip feeds automatically into the press, advancing a precise distance (the pitch) with each stroke. At each station, dedicated tooling performs one operation while the part remains attached to the carrier strip. Only at the final station does the finished component separate from the webbing.

Progressive die stamping excels when your project involves:

- High production volumes—typically 10,000+ pieces annually where tooling costs amortize quickly

- Small to medium-sized parts that fit within standard press bed dimensions

- Moderate complexity requiring multiple cutting and forming operations

- Consistent demand that justifies dedicated tooling

The advantages are compelling. According to Die-Matic, progressive stamping delivers production speed, fast cycle times, reduced labor costs, and lower per-unit costs. Some operations achieve cycle rates exceeding 1,000 strokes per minute for smaller parts.

However, limitations exist. Initial tooling investment runs higher than other methods—progressive dies are complex, precision instruments that require substantial engineering and fabrication time. Once built, design modifications become costly and time-consuming. And very deep draws or extremely complex geometries may exceed what progressive tooling can achieve.

Transfer Die Solutions for Large Complex Parts

What happens when parts grow too large for progressive dies, or geometries demand deeper draws than carrier strip methods allow? Transfer die stamping provides the answer.

Unlike progressive stamping, transfer dies either start with pre-cut blanks or separate the part from the strip at the first station. Mechanical fingers or transfer rails then move the free workpiece between subsequent stations for additional operations. This "free" part approach enables capabilities that connected-strip methods can't match.

Transfer stamping shines for:

- Large parts that would require impractically wide progressive dies

- Deep-drawn components requiring multiple draw operations with intermediate annealing

- Complex three-dimensional shapes that need access from multiple angles

- Parts requiring operations on both sides of the workpiece

The production metal stamping advantages include flexibility for complex geometries and the ability to handle heavier gauge materials. Transfer dies also accommodate parts that progressive tooling simply cannot produce—think automotive body panels, structural brackets, or deep enclosures.

Trade-offs include slower cycle times compared to progressive methods and higher per-piece costs for moderate volumes. The mechanical transfer systems add complexity, and tooling costs remain substantial. Transfer stamping makes sense for medium-to-high volumes of complex parts where geometry demands justify the investment.

Fourslide and Multislide for Intricate Small Parts

Sometimes parts require bends and forms from multiple directions that conventional vertical presses struggle to achieve. Fourslide (or multislide) stamping approaches the problem differently—using horizontal slides that attack the workpiece from four or more angles simultaneously.

This method works best for:

- Small, intricate parts with complex bend sequences

- Components requiring multi-directional forming in a single operation

- Wire forms and flat springs with three-dimensional configurations

- Lower to medium volumes where tooling flexibility outweighs raw speed

What makes fourslide unique? The horizontal tool slides can form, bend, and punch from multiple directions without repositioning the workpiece. This capability produces parts with geometries that would require multiple progressive die stations or secondary operations using conventional methods.

Fourslide stamping also offers economic advantages for prototype and short-run production. Tooling costs typically run lower than progressive dies because the forming tools are simpler and more adaptable. Design changes can often be accommodated by modifying individual slides rather than rebuilding entire die sets.

Limitations include part size constraints—fourslide works best for smaller components—and slower production rates compared to high-speed progressive operations. Material thickness is also restricted; heavy-gauge metals require forces that horizontal slide mechanisms cannot deliver.

Fine Blanking When Precision Tolerances Matter

Standard blanking and piercing operations produce edges with characteristic shear zones and breakout. For many applications, this edge quality is perfectly acceptable. But what about parts requiring smooth, square edges with minimal die break? That's where precision stamping through fine blanking becomes essential.

Fine blanking applies specialized triple-action tooling: a V-ring impingement ring locks material around the cutting perimeter while counter-pressure from below supports the blank during shearing. The result? Full-sheared edges approaching the smoothness of machined surfaces.

Fine blanking delivers exceptional results for:

- Gears and sprockets requiring precise tooth profiles

- Safety-critical automotive components like seatbelt mechanisms and brake parts

- Parts demanding tight flatness tolerances across the blank surface

- Components where secondary edge finishing would be prohibitively expensive

As Die-Matic explains, fine blanking eliminates the need for extensive post-processing such as deburring or grinding, saving both time and production costs. The process also facilitates consistent part repeatability across large production runs.

The trade-off? Higher per-part costs due to specialized tooling and high-pressure equipment. Longer lead times for tooling development also apply. Fine blanking makes economic sense for high-volume production of precision components where edge quality directly affects function or safety.

Prototype and Short-Run Considerations

Here's what most guides overlook: not every project demands high-volume production tooling. Early-stage prototypes, bridge production, and specialized low-volume components require different approaches.

For prototyping and short runs, consider these alternatives:

- Soft tooling—Dies made from less expensive materials that sacrifice longevity for lower initial cost

- Modular die systems—Standardized die sets with interchangeable inserts that reduce custom tooling requirements

- CNC machining—For very low volumes where stamping tooling costs cannot be justified. According to Lutco, CNC machines offer quicker setup times and don't require the weeks-long tooling development that stamping demands

- Laser cutting combined with brake forming—Produces stamping-like parts without dedicated tooling

The break-even point where stamping manufacturing becomes more economical than machining depends on part complexity, material costs, and required tolerances. Simple parts might justify stamping tooling at a few thousand pieces; complex geometries could require tens of thousands before the investment pays off.

Decision Framework: Matching Method to Requirements

Selecting the optimal sheet metal stamping process requires balancing four interconnected factors:

Cost considerations extend beyond tooling investment. Yes, progressive dies cost more upfront than fourslide tooling. But per-piece costs at volume often favor the higher initial investment. Evaluate total cost across your expected production life, not just first-year expenses.

Quantity requirements directly influence method selection. High-volume programs justify complex progressive tooling. Lower volumes favor flexible methods like fourslide or soft-tooled approaches that sacrifice speed for reduced upfront investment.

Quality and tolerance needs may dictate your method regardless of volume. If your application demands fine-blanked edges or coined precision features, those requirements override pure cost optimization.

Time constraints affect both tooling development and production. Progressive dies require the longest development cycles but deliver the fastest production rates. Fourslide tooling develops faster but runs slower. Prototype methods start immediately but cannot scale.

| Method | Part Complexity | Volume Suitability | Tolerance Capability | Cost Considerations |

|---|---|---|---|---|

| Progressive Die | Moderate; limited draw depth | High volume (10,000+/year) | ±0.001" to ±0.005" typical | High tooling cost; lowest per-piece at volume |

| Transfer Die | High; deep draws, large parts | Medium to high volume | ±0.002" to ±0.010" typical | High tooling cost; higher per-piece than progressive |

| Fourslide/Multislide | High for small parts; multi-directional bends | Low to medium volume | ±0.002" to ±0.005" typical | Lower tooling cost; moderate per-piece cost |

| Fine Blanking | Moderate complexity; exceptional edge quality | High volume for cost justification | ±0.0005" achievable; smooth full-shear edges | Highest tooling cost; premium per-piece pricing |

The right method emerges from honest assessment of your specific requirements. A part destined for millions of units demands different thinking than a specialized component produced in hundreds. Precision requirements that mandate fine blanking justify its premium. And timeline pressures may favor faster-to-tool methods even when they sacrifice long-term efficiency.

Once you've selected your stamping method, the next critical element is the tooling itself—the dies that transform your design intent into physical reality.

Die Design and Tooling Development Essentials

You've selected your stamping method. Now comes the element that determines whether your parts meet specifications—or become expensive scrap: the die itself.

Think of stamping dies as the DNA of your manufacturing process. Every feature, every tolerance, every surface finish on your finished parts traces directly back to decisions made during die design and development. Yet most guides mention dies only in passing, leaving engineers to wonder what actually happens between concept and production-ready tooling.

Let's decode the complete die development process—from fundamental design principles through advanced simulation techniques that eliminate costly trial-and-error.

Die Design Principles That Ensure Part Quality

What separates a die that produces flawless parts for millions of cycles from one that struggles through its first production run? The answer lies in understanding how every component works together as a precision system.

A stamping die consists of several critical elements, each engineered to perform specific functions:

- Die shoe (upper and lower) — The structural foundation that maintains alignment between all components. Precision-ground surfaces ensure parallelism that directly affects part dimensional accuracy.

- Punch — The male component that applies force to shape or cut material. Punch geometry, material selection, and surface treatment determine cutting edge life and part quality.

- Die button (or die insert) — The female component that receives the punch. The clearance between punch and die button—typically 5-10% of material thickness per side for cutting operations—directly affects edge quality and burr formation.

- Stripper plate — Holds the material flat during forming and strips the workpiece from the punch on the return stroke. Spring pressure must balance between adequate hold-down force and avoiding material damage.

- Guide pins and bushings — Maintain precise alignment between upper and lower die halves throughout millions of cycles. Worn guides cause misalignment that produces out-of-tolerance parts.

- Pilots — Precisely position the strip at each station in progressive dies. Pilot accuracy directly determines feature-to-feature relationships on finished parts.

According to U-Need's comprehensive guide, the interaction of these components is a mechanical ballet, timed to the fraction of a second by the press cycle. Each element must be designed and manufactured to exacting standards, as the failure of one can lead to a cascade of problems.

Material selection for die components matters critically. Tool steels like D2, A2, and S7 provide the hardness and wear resistance that production stamping machinery demands. For high-wear applications, carbide inserts extend tool life dramatically—though at higher initial cost. The choice between steel and carbide often depends on production volume: carbide makes economic sense when its extended life offsets its premium price across hundreds of thousands or millions of cycles.

Tooling Development From Concept to Production

How does a part design transform into production-ready tooling? The journey involves multiple stages, each building on the last to reduce risk and accelerate time-to-production.

Part print analysis comes first. Before any die design begins, engineers evaluate whether stamping is even the right process for the part. They examine material specifications, required tolerances, geometric complexity, and expected volumes. This feasibility assessment prevents costly discoveries later in development.

Strip layout design follows for progressive dies. This critical step determines how material flows through the die—which operations occur at which stations, how much strip advances with each stroke, and where carrier webs and pilots position. As U-Need explains, the strip layout is the spirit of a progressive die. A well-designed layout minimizes material waste while maximizing production speed.

3D modeling and 2D detailing translate the conceptual layout into manufacturable components. Modern CAD systems enable designers to visualize component interactions, verify clearances, and identify potential interference before cutting any steel. Every punch, die button, stripper plate, and guide component receives detailed drawings specifying dimensions, tolerances, materials, and heat treatment requirements.

The relationship between die quality and part consistency cannot be overstated. A metal stamping machine for metal components can only produce parts as accurate as its tooling allows. If die components exhibit dimensional variation, finished parts will reflect that variation—multiplied across every press cycle.

How Engineering Excellence Reduces Time-to-Market

Here's where modern technology transforms traditional die development. Computer-Aided Engineering (CAE) and Finite Element Analysis (FEA) software now enable designers to simulate the entire stamping process digitally before cutting a single piece of steel.

What can simulation predict? According to Keysight's analysis, sheet metal forming simulation addresses several significant challenges:

- Springback prediction — Advanced high-strength steels and aluminum alloys exhibit significant springback that makes achieving dimensional accuracy a constant challenge. Simulation predicts these effects before tooling is built.

- Wrinkling and tearing analysis — Virtual tryouts identify where material will wrinkle due to compression or tear due to excessive stretching—allowing die geometry modifications before physical testing.

- Blank holder force optimization — Simulation determines optimal press settings, reducing the time-consuming physical testing traditionally required.

- Material flow visualization — Engineers can see exactly how metal moves during forming, identifying potential problems invisible to even experienced toolmakers.

The business impact is substantial. Virtual validation allows rapid iteration and refinement—it's far cheaper and faster to adjust a digital model than to re-machine hardened tool steel. This simulation step de-risks projects, shortens physical tryout periods, and dramatically increases the probability of first-time success.

For demanding applications like automotive production, precision stamping die solutions with IATF 16949 certification and CAE simulation capabilities deliver the defect-free results that OEM standards require. Some advanced suppliers now offer rapid prototyping capabilities in as little as 5 days, with high first-pass approval rates exceeding 93%—metrics that reflect the engineering excellence behind their metal stamping equipment and tooling. For manufacturers requiring comprehensive mold design and fabrication capabilities, resources like Shaoyi's automotive stamping die solutions demonstrate what advanced die engineering can achieve.

The investment in proper die design and development pays dividends throughout the production life of your stamped components. A well-engineered die produces consistent parts shift after shift, year after year—while a compromised design creates ongoing quality battles and production interruptions.

But even the best-designed die requires robust quality control to maintain performance. The next section examines inspection methods and defect prevention strategies that keep your stamping operation running smoothly.

Quality Control and Defect Prevention in Stamping

Your die is engineered to perfection. Your press runs at optimal settings. Yet stamped parts still occasionally fall outside specification. What went wrong?

Here's the reality most manufacturers discover too late: quality control isn't something you bolt on at the end of production—it's an integrated system that catches problems before they become expensive scrap. Understanding inspection methods and defect root causes transforms your operation from reactive firefighting to proactive prevention.

Let's examine the complete quality framework that keeps precision stamping parts within tolerance and your customers satisfied.

Inspection Methods That Catch Defects Early

Effective quality control begins with matching inspection methods to your specific requirements. Different stamped parts demand different verification approaches—and choosing wisely balances thoroughness against production efficiency.

Coordinate Measuring Machines (CMM) represent the gold standard for dimensional verification of stamped metal parts. According to SSF Washers, these sophisticated instruments utilize precision probes to capture three-dimensional measurements with accuracies reaching micrometers. CMM testing provides comprehensive geometric analysis including flatness, perpendicularity, concentricity, and profile deviations that manual measurement tools cannot reliably detect.

The measurement process requires proper workpiece fixturing to eliminate movement during scanning. Technicians establish reference datums based on engineering drawings, then systematically probe critical features according to predetermined inspection plans. Advanced software generates detailed reports comparing actual measurements against CAD specifications—enabling rapid identification of dimensional discrepancies.

Go/no-go gauges provide rapid production-floor verification for high-volume operations where CMM testing would create bottlenecks. These dedicated fixtures incorporate critical dimensional limits as physical constraints, allowing operators to quickly verify part conformance without specialized measurement training. A properly designed gauge system checks multiple features simultaneously while maintaining inspection cycle times compatible with production rates.

Surface quality assessment addresses both functional and aesthetic requirements. Profilometer instruments measure surface roughness parameters including Ra, Rz, and Rmax values according to international standards. For stamped sheet metal components requiring precise fits or sealing surfaces, surface finish verification proves essential.

Material testing validates that incoming stock meets specifications before production begins. Hardness testing using Rockwell, Brinell, or Vickers methods provides insight into material properties affecting stamped steel parts performance. Metallographic examination reveals internal material structure—grain size, inclusion distribution, and phase identification—supporting material specification compliance.

Statistical Process Control (SPC) transforms individual measurements into actionable intelligence. Control charts monitor both process centering and variation, while capability indices (Cp, Cpk) quantify process performance relative to specification requirements. Real-time data collection enables immediate out-of-control condition detection before defective parts reach customers.

Common Stamping Defects and Their Root Causes

Even well-designed processes produce occasional defects. Understanding why problems occur—not just what they look like—enables targeted solutions rather than frustrating trial-and-error.

- Springback — The shape and dimensional deviation occurring after a stamped part is released from the die. This happens because material partially recovers elastically after forming. As Jeelix explains, springback poses persistent challenges when working with Advanced High-Strength Steels (AHSS) and aluminum alloys, directly impacting final assembly precision. Root causes include insufficient overbending compensation, inadequate coining pressure, and material property variations between batches.

- Tearing and cracking — Occurs when localized tensile stress during forming exceeds the material's formability limit. This critical defect immediately renders parts scrap. Root causes include excessive draw depth without adequate lubrication, insufficient die radii that concentrate stress, improper blank holder force that restricts material flow, and material that doesn't meet ductility specifications.

- Wrinkling — Wave-like creases forming in flange or wall areas when material under compressive stress buckles and stacks. During deep drawing, the flange experiences continuously shrinking circumference as it flows inward, creating tangential compressive stress. When this stress surpasses the material's buckling resistance, wrinkles form. Root causes include insufficient blank holder force, excessive material in the flange area, and improper draw bead configuration.

- Burrs — Sharp edges or raised material remaining after cutting operations. Excessive die clearance is the primary culprit—when clearance exceeds optimal values (typically 5-10% of material thickness per side), material fractures unevenly rather than shearing cleanly. Worn cutting edges, improper die alignment, and incorrect punch-to-die timing also contribute.

- Dimensional inaccuracies — Parts falling outside specified tolerances despite apparently correct die geometry. Root causes include thermal expansion during extended production runs, die wear affecting critical features, material thickness variation, and press deflection under load.

- Galling and scoring — Surface damage caused by material transfer between sheet and die surfaces. According to Jeelix, galling involves cold welding of small material particles from the sheet onto the die surface—often the root cause of progressive surface quality deterioration. Inadequate lubrication, incompatible die surface treatments, and excessive forming pressure create conditions for galling.

Prevention Strategies for Consistent Quality

Solving immediate problems wins individual battles. Building systems that prevent defects wins the war. These strategies address root causes rather than symptoms.

For springback control:

- Design dies with overbending compensation based on simulation predictions

- Apply coining operations at critical bend locations to exceed material yield strength throughout thickness

- Consider variable blank holder force profiles during the forming stroke

- Implement material property verification to catch batch-to-batch variations before production

For preventing tearing and cracking:

- Optimize die radii to distribute stress across larger contact areas

- Use forming simulation to identify high-strain regions before tooling fabrication

- Verify lubricant application consistency—inadequate lubrication dramatically increases fracture risk

- Consider multiple-draw operations with intermediate annealing for deep-formed stamped metal components

For eliminating wrinkles:

- Calibrate blank holder force to provide adequate restraint without restricting material flow

- Design draw beads that control material velocity into the die cavity

- Optimize blank size to minimize excess material requiring compression

- Verify press cushion system delivers consistent, evenly distributed pressure

For burr reduction:

- Maintain die clearance within specification through regular measurement and adjustment

- Implement sharpening schedules based on stroke counts rather than waiting for quality complaints

- Verify die alignment at each setup—even slight misalignment concentrates wear and promotes burring

- Consider die materials and coatings appropriate for your production volume and material type

For dimensional consistency:

- Implement temperature compensation when environmental conditions vary

- Track process trends using SPC to identify gradual drift before tolerances are exceeded

- Establish incoming material inspection protocols that verify thickness and properties

- Document and standardize setup procedures to eliminate operator-to-operator variation

Quality in stamping isn't achieved by inspection alone—it's built into every aspect of process design, tooling development, and production control.

The most effective quality programs combine multiple approaches: incoming material verification prevents problems before they start, in-process monitoring catches drift before tolerance limits are exceeded, and final inspection provides assurance that only conforming metal stamped parts reach customers.

Tolerance considerations should drive your entire inspection strategy. Tighter tolerances demand more rigorous measurement methods, higher inspection frequencies, and more sophisticated process controls. A part requiring ±0.001" tolerances needs CMM verification and tight SPC limits, while a bracket holding ±0.030" may need only periodic gauge checks.

With robust quality systems in place, your stamping operation can consistently meet the demanding requirements of diverse industries—each with unique specifications and certification needs.

Industry Applications and Specialized Requirements

Your stamping operation produces flawless parts with tight tolerances and consistent quality. But here's the question that determines whether those parts actually meet customer needs: do they satisfy industry-specific requirements?

Different industries demand radically different things from metal stamping components. A bracket destined for a recreational vehicle faces completely different stresses, certifications, and quality expectations than an identical-looking bracket installed in an aircraft. Understanding these distinctions helps you select the right supplier, specify appropriate materials, and avoid costly compliance failures.

Let's examine how major industries shape stamping requirements—and what those differences mean for your project.

Automotive Stamping Requirements and Standards

Automotive metal stamping represents one of the most demanding applications in industrial stamping. Every metal stamped part in a vehicle must meet rigorous performance, safety, and quality standards while maintaining cost targets that consumer pricing demands.

What makes automotive stamping unique? Volume, consistency, and traceability requirements converge at levels few other industries match. According to Xometry's certification overview, the International Automotive Task Force (IATF) maintains frameworks using the ISO 9001 quality management system to ensure consistent quality across the global automotive supply chain.

IATF 16949 certification has become the de facto requirement for automotive suppliers. This standard goes beyond basic quality management to address:

- Product safety—Documented processes ensuring safety-critical components meet specifications every time

- Defect prevention—Systematic approaches to eliminating quality issues before they reach assembly lines

- Variation reduction—Statistical methods controlling process variation across millions of production cycles

- Supply chain management—Requirements flowing through multiple supplier tiers

Precision metal stamping for automotive applications typically involves body panels, structural brackets, chassis components, seat frames, and powertrain elements. Materials range from mild steel for interior brackets to advanced high-strength steels and stamped aluminum for weight-critical body structures.

For manufacturers targeting automotive production, OEM-standard tooling and IATF 16949 certification provide the foundation for meeting these demanding requirements. Engineering teams that deliver cost-effective, high-quality solutions tailored to specific OEM standards—like those at Shaoyi's automotive stamping die solutions—demonstrate the capabilities required for this sector.

Electronics and Medical Device Precision Demands

Imagine stamping a connector terminal thinner than a human hair, with tolerances measured in microns. That's the reality of electronics stamping—where miniaturization drives ever-tighter precision requirements.

The electronics industry uses precision metal stamping to produce components including:

- Connectors and terminals—Contact surfaces requiring precise geometry for reliable electrical connections

- EMI/RFI shields—Enclosures protecting sensitive circuits from electromagnetic interference

- Lead frames—Precision carriers for semiconductor packaging

- Battery contacts—Conductors requiring consistent spring force and surface finish

Electro-mechanical part stamping bridges electrical and mechanical requirements—parts must conduct current reliably while withstanding mechanical stress from repeated insertion cycles or thermal expansion.

Medical device stamping shares the precision demands of electronics while adding biocompatibility and regulatory compliance requirements. According to LSRPF's industry overview, metal stamping parts in the medical industry are widely used in surgical instruments, diagnostic equipment, and treatment devices, meeting strict quality and safety requirements through high precision, high strength, and corrosion resistance characteristics.

Medical applications demand:

- Material traceability—Complete documentation from raw material through finished component

- Validated processes—Proven manufacturing methods that produce consistent results

- Clean manufacturing environments—Contamination control appropriate to end-use requirements

- Regulatory compliance—FDA registration and ISO 13485 certification for quality management

Aerospace and Defense: When Failure Isn't an Option

Here's a thought experiment that illustrates how industry requirements shape metal parts stamping: compare a stamped bracket installed in a recreational vehicle versus one installed in a commercial aircraft.

Both brackets might look similar. Both might use aluminum alloy. But the aerospace bracket faces requirements the RV bracket never encounters:

- Material certification—Aerospace requires mill test reports documenting exact chemistry and mechanical properties for every material lot

- Process qualification—Each manufacturing step must be validated and frozen; any change triggers requalification

- Non-destructive testing—X-ray, dye penetrant, or other NDT methods verify internal integrity

- First Article Inspection—Comprehensive dimensional verification before production release

- Lot traceability—Every part traceable to specific material lots, operators, and production dates

The RV bracket? It needs to meet basic dimensional requirements and material specifications—but without the extensive documentation, testing, and qualification that aerospace demands. This difference directly impacts cost, lead time, and supplier qualification requirements.

Military and defense applications add additional layers including ITAR compliance for export-controlled items, MIL-SPEC requirements for materials and processes, and security clearances for classified programs.

Consumer Goods and Building Products

Not every stamped component requires aerospace-level qualification. Consumer products and construction applications often prioritize different attributes: cost efficiency, aesthetic appearance, and high-volume production consistency.

Consumer goods stamping spans diverse applications:

- Appliance components—Washing machine drums, refrigerator panels, HVAC brackets

- Kitchen products—Cookware, utensils, food processing equipment

- Hardware—Hinges, locks, drawer slides, furniture fittings

- Sporting goods—Equipment frames, protective components, accessories

Building and construction stamping focuses on structural components including roofing panels, framing brackets, electrical boxes, and architectural trim. These applications typically specify galvanized or coated steel for corrosion resistance in exposed environments.

How Industry Requirements Shape Process Selection

Understanding industry differences helps you make informed decisions about suppliers, processes, and specifications. The following comparison highlights how requirements vary across major sectors:

| Industry | Typical Materials | Tolerance Requirements | Volume Characteristics | Certification Needs |

|---|---|---|---|---|

| Automotive | HSLA steel, aluminum, stainless steel | ±0.002" to ±0.010" typical | High volume; 100K+ annual units common | IATF 16949 required; PPAP documentation |

| Electronics | Copper, brass, phosphor bronze, nickel alloys | ±0.001" or tighter; micron-level for connectors | Very high volume; millions of pieces | ISO 9001; industry-specific (IPC for PCB) |

| Medical Devices | Stainless steel (316L), titanium, specialty alloys | ±0.001" to ±0.005"; application dependent | Low to medium volume; high mix | ISO 13485; FDA registration; material traceability |

| Aerospace | Aluminum (2024, 7075), titanium, Inconel | ±0.001" to ±0.003"; critical features tighter | Low to medium volume; long program life | AS9100; NADCAP; customer-specific approvals |

| Consumer/Appliance | Carbon steel, galvanized steel, aluminum | ±0.005" to ±0.015" typical | High volume; cost-sensitive | ISO 9001; UL/CSA for electrical products |

| Construction | Galvanized steel, stainless steel, aluminum | ±0.010" to ±0.030" typical | High volume; seasonal demand patterns | Building code compliance; ASTM standards |

What does this comparison reveal? Several key insights emerge:

Certification requirements directly impact supplier selection. An automotive program requires IATF 16949-certified suppliers—period. Medical devices need ISO 13485 compliance. Aerospace demands AS9100 and often NADCAP special process accreditation. Choosing a supplier without appropriate certifications means starting the qualification process from scratch.

Tolerance requirements drive process and tooling decisions. Electronics connectors requiring micron-level precision need fine blanking or specialized progressive dies with exceptional wear resistance. Construction brackets holding ±0.030" tolerances can use simpler tooling with faster development and lower cost.

Volume characteristics affect economic trade-offs. Automotive's high volumes justify extensive tooling investment and automation. Medical device's lower volumes with higher mix often favor flexible manufacturing approaches that sacrifice cycle time for setup efficiency.

Material specifications vary dramatically. Aerospace aluminum alloys like 7075-T6 require different handling than appliance-grade mild steel. Medical-grade stainless steel demands material certifications and traceability that consumer products rarely require.

The right stamping partner understands that industry requirements—not just part geometry—determine project success.

When evaluating suppliers for your specific application, match their certifications, capabilities, and experience to your industry's demands. A supplier excelling at high-volume automotive production may struggle with low-volume aerospace qualification requirements—and vice versa. The best metal stamped part is one that meets not just dimensional specifications, but all the regulatory, documentation, and quality requirements your industry demands.

Making Informed Stamping Decisions for Your Project

You've now explored the complete metal stamping landscape—from cold-forming fundamentals through material selection, press types, operations, methods, tooling development, quality control, and industry-specific requirements. But how do you synthesize all this knowledge into actionable decisions for your specific project?

Understanding what is stamped metal and how the process works is just the beginning. The real challenge lies in matching the right combination of materials, methods, and manufacturing partners to your unique requirements. Let's distill everything into a practical framework you can apply immediately.

Key Takeaways for Stamping Project Success

After examining every stage of the stamping workflow, several critical insights emerge that separate successful projects from costly failures:

Successful stamping projects require matching the right process, materials, and tooling partner to your specific application requirements—not forcing your design into a supplier's existing capabilities.

Material selection drives everything downstream. Your choice of stamped metal directly impacts which processes are viable, what tolerances are achievable, and how much your tooling will cost. A metal stamp operation using aluminum behaves differently than one using stainless steel—even when producing identical geometries. Specify materials based on functional requirements first, then verify stampability before committing to tooling investment.

Volume determines economic viability. Metal stamping excels at high-volume production where tooling costs amortize across thousands or millions of parts. For prototype quantities or short runs, alternative processes like CNC machining or laser cutting may prove more economical despite higher per-piece costs. Know your volume projections before selecting your manufacturing approach.

Tolerance requirements shape method selection. Standard metal pressing operations achieve ±0.005" tolerances routinely. Tighter requirements demand specialized approaches—fine blanking for edge quality, coining for dimensional precision, or secondary machining for critical features. Over-specifying tolerances increases costs without adding functional value.

Quality systems must match industry demands. An IATF 16949-certified supplier meets automotive requirements but may be overkill for consumer products. Conversely, a supplier lacking AS9100 certification cannot serve aerospace programs regardless of technical capability. Align supplier qualifications with your specific regulatory environment.

Your Next Steps in Stamping Process Selection

Ready to move forward with your stamping project? Follow this decision-making framework to ensure you've addressed every critical factor:

- Define functional requirements completely. Document material properties, dimensional tolerances, surface finish needs, and any special requirements (conductivity, corrosion resistance, biocompatibility) before engaging suppliers. Incomplete specifications lead to misquoted projects and disappointment.

- Establish realistic volume projections. Include first-year quantities, lifetime volumes, and demand variability. These numbers directly influence tooling investment decisions and supplier recommendations for progressive die versus fourslide versus alternative approaches.

- Identify applicable industry standards. Determine which certifications, documentation requirements, and quality systems your application demands. This filters your supplier options immediately and prevents wasted effort evaluating unqualified partners.

- Request Design for Manufacturability (DFM) feedback early. Engage potential suppliers before finalizing designs. Experienced stamping engineers often identify geometry modifications that dramatically reduce tooling complexity and improve part quality without compromising function.

- Evaluate total cost—not just piece price. Consider tooling investment, development timeline, quality costs, logistics, and supplier stability. The lowest quoted piece price rarely delivers the lowest total project cost when all factors are included.

- Plan for production validation. Build time and budget for first article inspection, process capability studies, and any industry-specific qualification requirements. Rushing these steps creates quality problems that persist throughout the production life of your parts.

Stamping technology continues evolving with servo press advancements, simulation-driven die development, and increasingly sophisticated quality systems. Yet the fundamental principles remain constant: successful projects start with clear requirements, match appropriate processes to those requirements, and execute through qualified partners with relevant experience.

Whether you're producing millions of automotive brackets or hundreds of specialized aerospace components, the stamping decision framework stays the same. Define what you need. Understand what each method delivers. Select partners whose capabilities align with your requirements. Then execute with the quality systems your industry demands.

Your stamped metal parts will only be as good as the decisions made before production begins. Use the knowledge you've gained to make those decisions wisely—and transform raw sheet metal into precisely the components your application requires.

Frequently Asked Questions About Stamping Processes

1. What are the 7 steps in the stamping method?

The seven most common metal stamping steps include blanking (separating the workpiece from sheet metal), piercing (creating holes), drawing (forming cup or box shapes), bending (creating angles), air bending (controlled angle forming), bottoming and coining (precision forming with extreme pressure), and pinch trimming (removing excess material). These operations can occur in sequence within progressive dies or as separate processes depending on part complexity and volume requirements.

2. What are the different types of stamping?

Metal stamping encompasses several distinct methods: progressive die stamping for high-volume production with multiple operations in sequence, transfer die stamping for large or complex parts requiring deep draws, fourslide/multislide stamping for intricate small parts with multi-directional bends, and fine blanking for precision components requiring smooth edges. Each method offers unique advantages—progressive dies deliver speed, transfer dies handle complexity, fourslide provides flexibility for lower volumes, and fine blanking achieves exceptional edge quality for safety-critical applications.

3. How is stamping done?

Stamping uses dies and high-pressure presses to transform flat sheet metal into finished components through cold-forming. The process begins with feeding sheet metal (coiled or pre-cut blanks) into a stamping press. The press applies force—often measured in hundreds of tons—driving a punch into a die to cut, bend, or form the metal. Despite being called cold-forming, friction during stamping generates significant heat. Modern operations often combine multiple steps within single die sets, with progressive dies performing cutting and forming operations as material advances through successive stations.

4. What materials work best for metal stamping?

Material selection depends on your application requirements. Carbon steel offers excellent formability and affordability for brackets and structural parts. Stainless steel provides corrosion resistance for medical and food equipment. Aluminum delivers lightweight properties for aerospace and automotive panels. Copper and brass excel in electrical applications requiring conductivity. Key properties affecting stampability include ductility, tensile strength, work hardening rate, and thickness. IATF 16949-certified suppliers like Shaoyi can guide material selection based on your specific tolerance, volume, and certification requirements.

5. How do I choose between progressive die and transfer die stamping?

Choose progressive die stamping for high-volume production (10,000+ annually) of small-to-medium parts with moderate complexity—it delivers the fastest cycle times and lowest per-piece costs. Select transfer die stamping when parts are too large for progressive dies, require deep draws, or need operations on both sides of the workpiece. Transfer dies handle complex three-dimensional geometries that connected-strip methods cannot produce. Consider tooling investment, production timeline, and expected volumes when deciding—progressive dies cost more upfront but deliver superior economics at scale.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —