Laser Cutting Companies Exposed: Pricing, Files, And Selection Secrets

Understanding Laser Cutting Technology and How It Works

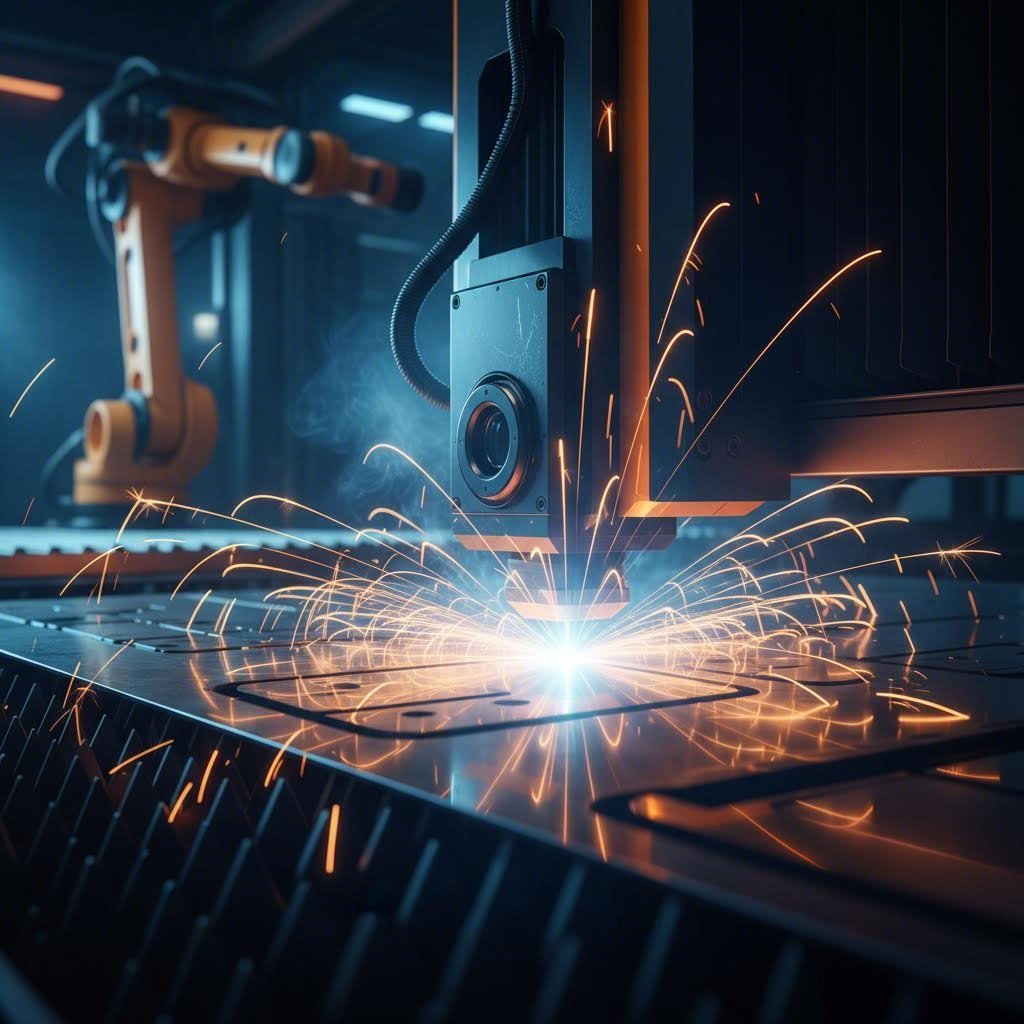

So, what is laser cutting exactly? Imagine focusing sunlight through a magnifying glass to burn a hole in paper—now multiply that intensity by thousands. Laser cutting is a precision manufacturing process that uses a highly concentrated beam of light to vaporize, melt, or burn through materials with remarkable accuracy. When you're evaluating laser cutting companies for your project, understanding this fundamental technology helps you ask the right questions and make informed decisions.

The technology works through a process called stimulated emission. Inside the laser resonator, atoms or molecules are energized until they release photons—tiny particles of light. These photons bounce between mirrors, building intensity until they form a coherent, powerful beam. According to Xometry, this beam is then directed through lenses that focus the energy into an incredibly small diameter, creating a localized high-energy point capable of cutting with a laser through metals, plastics, wood, and countless other materials.

How Laser Technology Transforms Raw Materials

When the focused beam contacts your material, one of three things happens depending on the material type and laser settings. Metals typically melt under the intense heat, while a high-pressure jet of gas—either inert nitrogen or reactive oxygen—blows the molten material away from the cut. Non-metallic materials like wood or acrylic often burn or vaporize completely. Some cutting methods, known as remote or sublimation cutting, don't even require assist gas—the laser for cutting machine simply ablates material directly.

This precision makes laser cutting cutting-edge technology for manufacturing. Unlike mechanical cutting methods that physically contact materials, laser beams produce no tool wear and can achieve intricate designs impossible with traditional approaches. The result? Clean edges, tight tolerances, and the ability to handle everything from delicate prototypes to high-volume production runs.

CO2 vs Fiber vs Nd:YAG Laser Systems

Not all lasers are created equal. When professional fabricators discuss their capabilities, they're typically referring to one of three main laser types—each with distinct strengths that matter for your project.

- CO2 Lasers: These workhorses use a gas mixture of carbon dioxide, nitrogen, and helium as the gain medium. Operating at a wavelength of 10,600 nm, CO2 lasers excel at laser cutting and engraving organic materials, plastics, and wood. They can also handle sheet metals effectively, though they struggle with highly reflective materials like copper and brass. A co2 laser cut metal machine represents the most versatile option for shops handling diverse material types.

- Fiber Lasers: Using a doped fiber optic cable as the lasing medium, fiber lasers produce shorter wavelengths (typically around 1,064 nm) that reflective metals absorb more readily. According to Xometry, this makes fiber lasers the preferred choice for cutting copper, brass, aluminum, and stainless steel. Their higher electrical efficiency and lower maintenance requirements have made them increasingly popular in industrial settings.

- Nd:YAG Lasers: These solid-state lasers use neodymium-doped crystals to generate powerful beams ideal for cutting thick metals and performing precision welding. While less common in general fabrication, Nd:YAG lasers shine in specialized applications requiring deep penetration or pulsed operation for delicate work.

When contacting potential fabrication partners, ask which laser types they operate. A company with multiple laser technologies can better match equipment to your specific material and precision requirements—a critical factor that separates exceptional service providers from those offering one-size-fits-all solutions.

Materials Compatible with Professional Laser Cutting Services

Ever wondered why your fabrication partner recommends one material over another? The secret lies in understanding how different materials respond to laser energy. When evaluating laser cutting companies, knowing their material capabilities—and limitations—helps you set realistic expectations for edge quality, thickness ranges, and project timelines.

Here's the practical guidance most providers don't share: every material behaves differently under a concentrated light beam. Some produce mirror-like edges while others require secondary finishing. Let's break down exactly what you can expect from each category.

Metal Cutting Capabilities and Thickness Ranges

Metals represent the bread and butter of professional laser cutting services. A quality metal laser cutter handles everything from paper-thin shims to substantial structural plates—but the results vary dramatically based on material type and thickness.

Steel and Mild Steel: These workhorses of fabrication cut beautifully with fiber lasers. According to SendCutSend's material specifications, mild steel can be processed from 0.030" up to 0.500" thick with excellent edge quality. Thinner gauges produce exceptionally clean cuts with minimal heat-affected zones, while thicker plates may show slight oxidation along cut edges when using oxygen-assist cutting.

Stainless Steel Laser Cutting: Both 304 and 316 stainless varieties respond excellently to fiber laser processing. Professional services typically handle stainless from 0.030" to 0.500" thickness, with thinner materials producing bright, oxide-free edges when nitrogen assist gas is used. This makes stainless laser cutting ideal for food-grade equipment, medical devices, and architectural applications where appearance matters.

Aluminium Laser Cutting: Here's where laser technology truly shines. Fiber lasers efficiently process aluminum alloys—including 5052, 6061, and even aerospace-grade 7075—from 0.040" to 0.750" thick. To laser cut aluminum successfully, professional shops use nitrogen assist gas to prevent oxidation and achieve that distinctive bright, burr-free edge. The reflective nature of aluminum once challenged older CO2 systems, but modern fiber lasers handle it routinely.

Specialty Metals: A capable laser cutter for metal extends beyond common alloys. Titanium (Grades 2 and 5), brass, copper, and even armor plate (AR400/AR500) fall within the capabilities of well-equipped shops. Each requires specific parameter adjustments, but experienced providers deliver consistent results across these demanding materials.

Non-Metal Materials and Surface Quality Expectations

Sheet metal laser cutting dominates the industry, yet laser technology processes an impressive range of non-metallic materials—each with unique considerations.

Acrylic: This popular material produces flame-polished edges when processed correctly on CO2 lasers. An acrylic cutting service typically handles thicknesses from 0.060" to 1.00", delivering edges so smooth they often require no secondary finishing. Cast acrylic produces superior results compared to extruded versions, which may show slight stress marks.

Wood and Plywood: CO2 lasers excel at wood cutting, producing characteristic darkened edges that many designers intentionally incorporate into their aesthetics. Thickness capabilities vary by density—softwoods cut faster and thicker than hardwoods—but most services handle materials up to 0.750" comfortably.

Polycarbonate and Other Plastics: Not all plastics are laser-compatible. Polycarbonate, while possible to cut, produces less desirable edge quality than acrylic. PVC should never be laser cut—it releases harmful chlorine gas. Always verify material compatibility before submitting your project.

Material Comparison: What to Expect From Your Fabrication Partner

| Material Type | Recommended Laser | Max Thickness | Edge Quality | Special Considerations |

|---|---|---|---|---|

| Mild Steel | Fiber | 0.500" | Excellent; clean with minimal dross | Oxygen assist may cause slight oxidation on thick cuts |

| 304/316 Stainless | Fiber | 0.500" | Excellent; oxide-free with nitrogen | Nitrogen assist preferred for bright edges |

| 6061 Aluminum | Fiber | 0.750" | Very good; bright finish possible | Heat-affected zone wider than steel; slight warping risk on thin parts |

| Titanium Grade 5 | Fiber | 0.250" | Good; requires parameter optimization | Reactive at high temperatures; inert gas essential |

| Brass/Copper | Fiber | 0.250" | Good; may show slight tarnishing | High reflectivity requires fiber laser; CO2 not recommended |

| Acrylic | CO2 | 1.00" | Excellent; flame-polished edges | Cast acrylic preferred; extruded may show stress marks |

| Wood/Plywood | CO2 | 0.750" | Good; characteristic char marks | Resin content affects cut quality; ventilation critical |

Understanding Heat-Affected Zones and Warping Risks

According to Dowell Laser's quality guide, minimizing the heat-affected zone (HAZ) is crucial for maintaining material properties. This zone—the area adjacent to your cut that experiences thermal stress—varies by material conductivity and thickness.

Aluminum and thin gauge metals present the highest warping risk due to their thermal conductivity. Professional laser cutting of metal sheets addresses this through optimized cutting speeds, strategic part nesting, and nitrogen assist gas to reduce heat input. When precision matters, discuss these concerns upfront with your service provider—experienced teams know exactly how to minimize distortion in your specific application.

With material capabilities clearly understood, the next question becomes: which industries demand these precision cutting services, and what unique requirements do they bring?

Industry Applications and Specialized Use Cases

When you're searching for the right fabrication partner, here's something most laser cutting companies won't tell you upfront: different industries demand vastly different capabilities. A shop excelling at architectural signage may struggle with aerospace tolerances. Understanding these sector-specific requirements helps you identify providers genuinely qualified for your project—not just those claiming broad expertise.

Let's explore what precision laser cutting looks like across major industries and the unique demands each brings to the table.

Automotive and Transportation Component Manufacturing

The automotive sector represents one of the most demanding environments for industrial laser cutting. Vehicle manufacturers and their supply chains require consistent quality across thousands—sometimes millions—of identical parts. A single dimensional deviation can cascade through assembly lines, causing costly delays.

Metal laser cutting serves automotive applications ranging from structural components to decorative trim. Typical parts include:

- Chassis and frame components: Require tolerances of ±0.005" to ±0.010" with consistent edge quality across high-volume runs

- Suspension brackets and mounting plates: Demand precise hole placement for proper alignment during assembly

- Heat shields and exhaust components: Need clean cuts in stainless steel and specialized alloys that withstand extreme temperatures

- Interior trim and decorative elements: Require burr-free edges and consistent aesthetics across production batches

- Tube and pipe components: Laser tube cutting services handle roll cage sections, exhaust tubing, and structural members with complex intersection geometries

Why does certification matter here? According to Modus Advanced, automotive applications often require IATF 16949 certification—an international quality management standard specifically designed for automotive supply chains. This certification ensures consistent processes, documented quality control, and traceability that OEMs demand from every supplier tier.

Aerospace and Defense Requirements

When components fly at 30,000 feet or protect personnel in the field, precision becomes non-negotiable. Aerospace and defense applications push laser cutting capabilities to their limits, demanding tolerances that standard shops simply cannot achieve.

Typical aerospace components and their precision requirements include:

- Flight control components: ±0.001" to ±0.005" tolerances with full material traceability and certification documentation

- Instrument housings and panels: Require tight dimensional control for proper equipment fit and EMI shielding effectiveness

- Structural brackets and fittings: Demand consistent mechanical properties with minimal heat-affected zones

- RF shield assemblies: Precision laser cutting ensures electromagnetic shielding effectiveness across operating frequencies

AS9100 certification serves as the aerospace equivalent of IATF 16949—verifying that manufacturers maintain quality systems appropriate for flight-critical applications. Defense contracts often layer additional MIL-STD specifications on top of these requirements, creating documentation and traceability demands that separate specialized providers from general fabricators.

Medical Device and Electronics Applications

Medical devices present unique challenges where patient safety depends on manufacturing precision. According to Tapecon's medical device guide, laser cutting enables micron-level accuracy with clean, sealed edges that minimize contamination risks—especially crucial for devices contacting patients directly.

Precision laser cutting serves medical applications including:

- Surgical instruments and implantable devices: Require ±0.002" to ±0.005" tolerances with FDA 21 CFR 820 and ISO 13485 compliance

- Diagnostic equipment housings: Demand consistent dimensional accuracy for reliable measurements

- Wearable device components: Need precise fits with smooth edges for patient comfort

- Disposable medical products: Require clean cuts and repeatable precision across high volumes

Electronics manufacturing similarly demands tight tolerances, particularly for laser cutting ss (stainless steel) enclosures that provide EMI shielding. Circuit board stiffeners, connector housings, and thermal management components all benefit from the precision and repeatability that professional laser services deliver.

Precision Requirements Across Industries

Understanding tolerance expectations helps you communicate effectively with potential fabrication partners. Here's what different sectors typically require:

| Industry | Typical Tolerance Range | Key Certifications | Volume Range |

|---|---|---|---|

| Automotive | ±0.005" to ±0.010" | IATF 16949 | Prototyping to 100,000+ units |

| Aerospace | ±0.001" to ±0.005" | AS9100, NADCAP | 1-5,000 units typical |

| Medical Devices | ±0.002" to ±0.005" | ISO 13485, FDA registered | Prototyping to mass production |

| Signage/Architectural | ±0.010" to ±0.020" | ISO 9001 | 1-500 units typical |

| Electronics | ±0.003" to ±0.010" | ISO 9001, IPC standards | 100 to 50,000+ units |

Signage and architectural applications—while less demanding on tolerances—bring their own challenges. Large-format components, decorative finishes, and complex geometric designs require equipment capacity and finishing capabilities that precision-focused shops may lack.

The takeaway? Match your industry requirements to provider capabilities before requesting quotes. A fabricator specializing in tube laser cutting services for automotive exhaust systems operates differently than one focused on medical device prototyping—and understanding these distinctions saves time during vendor selection.

Now that you understand how different industries leverage laser cutting technology, how does this process compare to alternative cutting methods like waterjet, plasma, or CNC routing?

Laser Cutting vs Waterjet Plasma and CNC Alternatives

Here's a question most laser cutting companies won't answer directly: is laser cutting actually the best choice for your project? The honest answer depends on your specific requirements. While laser technology dominates certain applications, alternatives like waterjet, plasma, and CNC routing excel in scenarios where lasers fall short. Understanding these trade-offs empowers you to make smarter manufacturing decisions—and sometimes, that means choosing a different technology entirely.

Let's break down exactly when each cutting method shines and when you should consider alternatives.

When Laser Cutting Outperforms Alternative Methods

A metal cutting laser machine delivers unmatched advantages in several key scenarios. According to SendCutSend's fabrication guide, laser cutting can achieve speeds up to 2,500 inches per minute—making it the fastest option available for most thin-gauge materials.

CNC laser cutting truly excels when your project demands:

- Thin materials requiring precision: Sheet metals under 0.25" thick produce exceptionally clean cuts with minimal heat-affected zones

- Intricate designs and fine details: The laser beam's minimal kerf width allows features impossible with mechanical cutting methods

- High-volume production: No tool wear means consistent quality from the first part to the thousandth

- Tight tolerances: Professional laser cnc systems routinely achieve ±0.005" accuracy

- Clean edge finishes: Many materials require no secondary finishing after laser processing

The best laser for cutting thin metals, plastics, and wood remains fiber or CO2 laser technology. However, other methods outperform lasers in specific situations—and knowing when to pivot saves both money and frustration.

Understanding Alternative Cutting Technologies

Plasma Cutting: If you're searching for "plasma cutting near me" for thick steel fabrication, you're on the right track. According to Wurth Machinery's comparison guide, plasma cutting dominates when working with conductive metals over 0.5" thick. The ionized gas arc—reaching temperatures up to 30,000°C—blasts through heavy plate steel 3-4 times faster than waterjet at roughly half the operating cost. The trade-off? Larger heat-affected zones and less precise edge quality compared to laser processing.

Waterjet Cutting: When heat cannot touch your material, waterjet becomes the clear choice. High-pressure water mixed with abrasive garnet cuts virtually anything—from titanium to stone to composites—without thermal distortion. According to industry data, the waterjet market is projected to reach over $2.39 billion by 2034, driven largely by aerospace applications where eliminating heat-affected zones is mandatory.

CNC Routing: Laser and CNC routing share computer-controlled precision, but routing uses physical cutting tools rather than light energy. This mechanical approach produces superior surface finishes on composites, plastics, and woods that might discolor or produce hazardous fumes under laser processing. The tolerance of ±0.005" matches laser capabilities, though routing requires fixture tabs that may leave small marks requiring hand finishing.

Technology Comparison: Choosing the Right Method

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | CNC Routing |

|---|---|---|---|---|

| Precision Level | ±0.005" typical | ±0.009" typical | ±0.020" to ±0.030" | ±0.005" typical |

| Material Compatibility | Metals, plastics, wood, acrylics; not PVC or highly reflective metals (CO2) | Nearly universal—metals, stone, glass, composites, ceramics | Conductive metals only | Plastics, composites, wood, some metals |

| Edge Quality | Excellent; often requires no finishing | Good; may show slight texture from abrasive | Moderate; oxidation and dross common | Excellent on compatible materials |

| Cutting Speed | Fastest for thin materials (up to 2,500 IPM) | Slowest overall | Fast for thick metals | Moderate |

| Heat-Affected Zone | Minimal with proper parameters | None—cold cutting process | Significant; material hardening possible | None—mechanical process |

| Equipment Cost | Moderate to high | High (~$195,000+ for industrial systems) | Lower (~$90,000 for comparable systems) | Moderate |

| Ideal Applications | Thin sheet metals, intricate designs, high-volume production, precision parts | Heat-sensitive materials, stone/glass, aerospace components, thick composites | Structural steel, shipbuilding, heavy equipment, thick plate fabrication | Plastics, composites, wood products, materials that off-gas when heated |

Choosing the Right Cutting Technology for Your Project

Sound complex? Here's a simplified decision framework based on your project's primary requirements:

Choose laser cutting when:

- Working with sheet metals under 0.5" thick

- Your design includes intricate patterns, small holes, or fine details

- Edge quality and minimal post-processing matter

- You need high-volume consistency without tool wear

- Speed and cost efficiency are priorities for thin materials

Choose waterjet cutting when:

- Heat-affected zones are absolutely unacceptable (aerospace applications)

- Cutting stone, glass, ceramics, or thick composites

- Material thickness exceeds laser capabilities

- Working with carbon fiber, G10, or phenolic materials prone to delamination

Choose plasma cutting when:

- Cutting conductive metals over 1" thick

- Speed matters more than edge precision

- Budget constraints limit technology options

- Applications include structural fabrication or heavy equipment

Choose CNC routing when:

- Processing plastics that release hazardous fumes under laser (like PVC)

- Surface finish quality on composites is critical

- Working with HDPE, ABS, or specialty plastics

- Material characteristics make thermal cutting impractical

According to industry testing, many successful fabrication shops eventually incorporate multiple technologies. Plasma and laser pair well for comprehensive metal capabilities, while adding waterjet provides unmatched versatility for challenging materials.

The bottom line? The "best" technology depends entirely on your specific project requirements. When contacting potential fabricators, ask which cutting methods they offer—providers with multiple technologies can recommend the optimal approach rather than forcing your project into their single available process.

Understanding technology options clarifies one side of the decision equation—but what about costs? Let's examine the pricing factors that actually drive your project budget.

Pricing Factors and Project Cost Considerations

Ever received a laser cutting quote that left you scratching your head? You're not alone. Most fabrication providers keep their pricing structures frustratingly opaque—leaving customers guessing why similar-looking projects carry wildly different price tags. Here's what nobody tells you upfront: the cost of your project depends far less on material area than on machine time. Two parts cut from identical sheet sizes can have dramatically different laser cutting charges based on design complexity alone.

Understanding the real cost drivers puts you in control. Let's pull back the curtain on how professional fabricators actually calculate your quote—and how you can use this knowledge to budget smarter.

Key Factors That Influence Laser Cutting Costs

According to Fortune Laser's pricing guide, nearly every provider uses a foundational formula: Final Price = (Material Costs + Variable Costs + Fixed Costs) × (1 + Profit Margin). Breaking down each component reveals where your money actually goes.

Here are the primary cost drivers listed in order of impact on your final quote:

- Machine time (variable costs): This is the single biggest factor. The hourly rate for industrial laser cutters typically ranges from $60 to $120, multiplied by total cutting duration. Intricate designs requiring slower speeds dramatically increase this component.

- Material thickness: Doubling your material thickness can more than double cutting time and cost. Thicker materials force the laser to move significantly slower for clean cuts—making this the most effective lever for cost reduction.

- Material type: Beyond base material costs, different metals behave differently under laser processing. Cutting steel is generally less expensive than stainless or aluminum due to assist gas requirements. Custom metal cutting in specialty alloys like titanium commands premium pricing.

- Design complexity: Tight curves, sharp corners, and intricate patterns force the machine to slow down repeatedly. A design with 100 small holes can cost more than one large cutout due to cumulative piercing time.

- Pierce count: Every time the laser starts a new cut, it must first penetrate the material surface. High pierce counts—common in perforated patterns or multi-hole designs—add measurable time to each job.

- Setup fees and minimums: Most services charge setup fees or maintain minimum order values to cover material loading, machine calibration, and file preparation. These fixed costs get distributed across your order quantity.

- Secondary operations: Bending, tapping, hardware insertion, powder coating, or other finishing work adds separate charges beyond the base cutting cost.

How to Budget for Your Cutting Project

Understanding economies of scale fundamentally changes how you approach ordering. According to industry data, high-volume order discounts can reach as high as 70% compared to single-piece pricing. Why? Those fixed setup costs get spread across more parts, and efficient nesting reduces material waste.

When requesting and comparing quotes from online laser cutting services, consider these strategies:

- Use the thinnest material possible: If structural requirements allow, reducing gauge thickness delivers the most significant cost savings. Always verify minimum thickness requirements before defaulting to heavier stock.

- Simplify where function allows: Reduce complex curves, combine small holes into larger slots, and eliminate purely decorative features that add cutting time without functional value.

- Clean your design files: Duplicate lines, hidden objects, and unclosed contours force manual correction—often at additional fees. Automated quoting systems will attempt to cut every line, meaning double lines literally double that feature's cost.

- Consolidate orders: Batching multiple projects or ordering larger quantities dramatically reduces per-part costs. If timing allows, wait to combine needs rather than placing frequent small orders.

- Ask about in-stock materials: Choosing materials your provider already has on hand eliminates special order fees and can shorten lead times significantly.

Understanding Turnaround Time Expectations

Project timelines affect both scheduling and sometimes pricing. According to industry analysis, turnaround depends on several factors beyond cutting speed: file preparation quality, material availability, shop scheduling, and secondary operations all impact delivery dates.

Typical turnaround expectations by project type:

- Rapid prototyping: 3-7 business days for simple parts with standard materials. Rush services may offer 24-48 hour options at premium pricing.

- Standard production runs: 1-3 weeks depending on quantity, complexity, and finishing requirements.

- Large volume orders: 3-6 weeks for high-quantity production with quality inspection protocols.

- Projects requiring special materials: Add 1-2 weeks for sourcing if your specified alloy or thickness isn't in stock.

Well-prepared CAD files tailored to cutting specifications give you a head start—clean, fabrication-ready designs move from screen to sheet without delays from format conversions or engineering corrections.

When comparing send cut send prices or quotes from other providers, ensure you're evaluating equivalent turnaround times. A cheap cutting sheet quote with 4-week delivery may not actually save money compared to faster service when project timelines matter.

The bottom line? Transparent pricing comes from understanding how your design decisions translate into machine time. Armed with this knowledge, you can optimize designs before requesting quotes and have meaningful conversations with fabricators about cost-value trade-offs.

But even perfectly budgeted projects can stall at the starting line if your design files aren't prepared correctly. Let's examine exactly what fabricators need from your submissions—and the common mistakes that delay projects before cutting even begins.

Preparing Your Design Files for Laser Cutting Submission

You've selected your material, compared technologies, and budgeted your project—but here's where many first-time buyers stumble: file preparation. Submitting a design that looks perfect on screen doesn't guarantee it will cut correctly. A laser cutting machine for metal interprets your file quite differently than your design software displays it. Understanding this translation process eliminates frustrating back-and-forth revisions and gets your laser cut parts into production faster.

The good news? Once you understand what fabricators actually need, preparing submission-ready files becomes straightforward. Let's walk through the essential requirements that separate successful first-attempt projects from those stuck in revision limbo.

File Formats and Design Software Compatibility

Not all file formats speak the same language as a sheet metal laser cutting machine. According to Quote Cut Ship's design guide, laser cutters don't interpret JPEGs or PNGs the way your design software does. These raster image formats display pixels on screen—but a laser beam needs precise paths to follow.

For clean, accurate cuts, you need vector-based formats that define exact mathematical paths:

- DXF (Drawing Exchange Format): The universal standard for custom laser cutting. Nearly every fabricator accepts DXF files, and most design software exports them natively. AutoCAD users find this their natural choice.

- DWG (AutoCAD Drawing): AutoCAD's native format works well for complex engineering drawings with multiple layers and detailed dimensioning.

- AI (Adobe Illustrator): Preferred by designers working on decorative or artistic projects. Excellent for intricate patterns and custom laser cut wood applications.

- SVG (Scalable Vector Graphics): An open-source option gaining popularity for its web compatibility and clean file structure.

- EPS (Encapsulated PostScript): Another vector format supported by most services, though less common than DXF or AI.

According to xTool's design guide, popular software options for creating these files include Adobe Illustrator and CorelDraw for scalable vector graphics, while AutoCAD excels at technical drawing formats. For simpler designs, some laser cutter software allows basic graphic creation directly within the control interface.

When working with a laser cut cnc machine, remember that your file defines every movement. Lines tell the laser where to cut, while filled areas indicate regions for engraving. Understanding this distinction prevents costly surprises.

Critical Design Requirements for Fabrication Success

Beyond file format, several technical specifications determine whether your design cuts successfully or requires revision.

Kerf Compensation: Here's something many designers overlook—the laser beam itself has width. According to xTool, kerf refers to the material removed by the laser during cutting. For precision fits—like interlocking joints in custom laser cut wood projects—you must adjust dimensions to account for this material loss. Most professional services handle kerf compensation automatically, but always confirm whether your dimensions represent nominal sizes or already include offset.

Minimum Feature Sizes: Every material has limits on how small holes, slots, and details can reliably cut. Attempting features smaller than material thickness typically fails—thin projections become fragile, and tiny holes may not pierce cleanly. A general rule: minimum feature size should equal or exceed your material thickness.

Line Spacing: According to Quote Cut Ship, when design lines are placed too close together, the laser can overburn or accidentally cut into areas you want intact. Aim for at least 0.010 inches spacing between critical paths to maintain structural integrity and avoid weakened edges.

Proper Dimensioning: Include overall dimensions, critical tolerances, and any special callouts directly in your file or accompanying documentation. Don't assume fabricators will measure from your vector paths—explicit dimensions prevent misinterpretation.

Avoiding Common Design Errors That Delay Projects

Even experienced designers make mistakes that stall production. Here's a numbered checklist based on the most frequent issues fabricators encounter:

- Convert all text to outlines or curves. According to industry experts, leaving text in font format means the laser may substitute or lose your text entirely if that font isn't available on the production system. Converting to outlines locks your typography as vector shapes.

- Close and join all paths. Open or unjoined paths confuse laser control software, potentially causing incomplete cuts or erratic engraving. Use your design software's path cleanup and join features before exporting.

- Eliminate duplicate lines. Double lines look identical on screen but cause the laser to cut the same path twice—weakening edges and potentially burning through material. Automated quoting systems will charge for both passes.

- Remove hidden or stray objects. Elements outside your visible artboard, locked layers, or hidden objects may still export and attempt to cut. Audit your entire file before submission.

- Set consistent units. Mixing inches and millimeters within a file creates scaling nightmares. Establish one unit system and stick with it throughout your design.

- Specify line properties correctly. According to xTool, line widths convey meaning to laser systems—a width of 0.2pt might indicate cutting while 1pt indicates engraving. Verify your provider's requirements for line weight conventions.

- Account for material thickness in assemblies. According to Quote Cut Ship, failing to consider material depth when designing interlocking parts results in pieces that don't fit. Always verify material specifications and factor them into your design.

- Verify file scale before export. A design intended at 6 inches that exports at 6 millimeters wastes everyone's time. Always confirm final dimensions match your intent.

Communicating Special Requirements Effectively

Your design file tells part of the story—but special requirements need explicit documentation. When your project demands specific edge finishing, tighter-than-standard tolerances, or particular surface orientations, communicate these needs clearly:

- Tolerance callouts: If standard ±0.005" isn't sufficient, specify exactly which dimensions require tighter control and what tolerance you need.

- Edge finish requirements: Note whether visible edges require deburring, specific surface roughness, or orientation with the material's grain direction.

- Critical dimensions: Highlight which measurements are functional (must be precise) versus reference (can accept wider variation).

- Material orientation: For materials with directional grain or finish, indicate how your design should align with material properties.

- Quantity and batch requirements: Specify whether all parts must come from a single sheet or if mixing batches is acceptable.

Most professional fabricators appreciate a separate notes document or clearly annotated drawing accompanying your vector files. This documentation prevents assumptions and ensures your laser cut parts arrive exactly as envisioned.

With properly prepared files in hand, you're ready to evaluate potential fabrication partners. But how do you distinguish quality-focused providers from those offering commodity service? Let's examine the selection criteria that matter most.

How to Evaluate and Select Laser Cutting Companies

You've prepared perfect design files and understand the technology—but here's where many projects still go wrong: choosing the wrong fabrication partner. Not all laser cutting companies deliver equal results, and the lowest quote often hides quality issues that surface only after your parts arrive. According to Dr. Shahrukh Irani of Lean and Flexible, LLC, too often businesses treat job shops as interchangeable, sending blanket RFQs and choosing based solely on price or speed—only to face delays and reworks due to poor quality.

The difference between a frustrating experience and a successful partnership comes down to systematic evaluation. When you're searching for a laser cutting service near me or precision laser cutting services, knowing which questions to ask separates qualified providers from those likely to disappoint. Let's build a framework for making this critical decision with confidence.

Essential Certifications and Quality Standards to Verify

Certifications aren't just wall decorations—they represent verified commitments to quality systems and processes. According to A-Laser's certification guide, ISO certification means manufacturers operate under standards confirmed yearly through onsite audits by certified representatives, delivering benefits including increased customer satisfaction, improved quality and efficiency, reduced costs, and complete traceability.

When evaluating a metal laser cutting service, prioritize these credentials based on your industry:

- ISO 9001: The foundational quality management standard applicable across industries. This certification verifies documented processes, quality control procedures, and continuous improvement practices.

- ISO 9013: Specific to thermal cutting processes including laser cutting. According to industry standards, this classification covers materials from 0.5mm to 40mm thickness with guidelines for form, orientation, location, and run-out of cut features.

- IATF 16949: Essential for automotive supply chain work. This certification demonstrates the rigorous quality systems that vehicle manufacturers require from every supplier tier.

- AS9100: The aerospace industry equivalent, verifying quality systems appropriate for flight-critical applications where failure isn't an option.

- ISO 13485: Required for medical device manufacturing, ensuring processes meet FDA requirements and patient safety standards.

Why do certifications matter for your project? According to A-Laser, manufacturers investing in certification benefit from trained staff adhering to standards that more and more industries require to do business. For you, this translates to increased reliability, proper documentation, and confidence that your parts will perform as designed.

Evaluating Production Capacity and Turnaround Capabilities

Finding a laser cutter near me with the right equipment is only the first step—can they actually handle your project timeline and volume? Production capacity mismatches cause more project delays than equipment limitations. A shop perfectly suited for prototype work may struggle with production volumes, while high-volume specialists might deprioritize your small-batch order.

According to All Metals Fabricating's evaluation framework, understanding a job shop holistically gives you the best insight into its underlying reliability. Consider evaluating potential partners across these critical categories:

- Equipment capabilities: What laser types do they operate (fiber, CO2, or both)? What's their maximum sheet size and thickness capacity? Do they have backup machines to prevent single-point failures?

- Material expertise: Do they stock your required materials, or will special orders add lead time? What's their experience with your specific alloy or material grade?

- Volume flexibility: Can they scale from prototyping quantities to production runs? How do their pricing structures change with volume?

- Secondary operations: Do they offer in-house bending, welding, finishing, or hardware insertion? Keeping operations under one roof reduces handling, shipping, and coordination complexity.

- Geographic considerations: When searching for laser cutting services near me or laser metal cutting near me, proximity matters for shipping costs, communication ease, and potential facility visits.

The Critical Role of DFM Support

Here's something that separates exceptional fabrication partners from order-takers: Design for Manufacturing (DFM) feedback. A laser cutter service near me that simply cuts exactly what you submit might seem efficient—but misses opportunities to improve your design, reduce costs, or prevent manufacturing issues before they occur.

Quality-focused precision laser cutting services review your designs before production and provide actionable recommendations:

- Tolerance optimization: Are your specified tolerances tighter than necessary? Relaxing non-critical dimensions can reduce costs without affecting function.

- Feature improvements: Can holes be repositioned slightly to improve nesting efficiency? Would adjusting corner radii improve cut quality?

- Material suggestions: Is there a more cost-effective alloy that meets your requirements? Would a different thickness improve rigidity without increasing weight?

- Process recommendations: Should certain features be laser cut versus punched? Would alternative assist gases improve edge quality for your application?

According to Dr. Irani's consulting experience, engaged leadership always correlates with a manufacturer's performance. Providers offering proactive DFM support demonstrate exactly this engagement—they're invested in your project's success, not just processing orders.

Quality Control and Tolerance Verification Processes

According to A-Laser's quality guide, the benefits of holding tight tolerance include increased functionality of precision parts, repeatability of form and assembly, mated parts reliability, and reduction of failure rates. But how do you verify that a provider actually delivers these benefits?

Ask about inspection protocols and documentation practices:

- First article inspection (FAI): Do they verify initial parts against your specifications before running full production? This catches issues early when corrections are least expensive.

- In-process monitoring: What checks occur during production runs? How do they detect and address drift or variation?

- Final inspection: What percentage of parts receive dimensional verification? What measurement equipment do they use (CMM, optical comparators, gauges)?

- Documentation and traceability: Can they provide inspection reports, material certifications, and lot traceability? For regulated industries, this documentation may be mandatory.

- Non-conformance handling: What happens when parts don't meet specifications? Do they have documented corrective action processes?

Questions to Ask Before Selecting Your Partner

Before committing to any provider, use this comprehensive checklist to evaluate fit:

- What laser equipment do you operate, and what are its capabilities and limitations?

- Which quality certifications do you hold, and when was your last audit?

- What's your typical turnaround time for projects similar to mine?

- Do you provide DFM feedback before production begins?

- What materials do you keep in stock versus special order?

- How do you handle tolerance verification and quality inspection?

- Can you provide references from customers in my industry?

- What's your communication process for project updates and issue resolution?

- How do you handle urgent revisions or expedited orders?

- What secondary operations can you perform in-house?

According to industry best practices, evaluating job shops against a clear set of criteria and comparing them on an apples-to-apples basis improves your chances of finding the right partner to deliver high-quality results. Not every factor applies equally to every project—tailor this list to your specific needs and priorities.

The "soft" factors matter too. Communication responsiveness, willingness to discuss challenges openly, and general professionalism during the quoting process often predict the working relationship you'll experience throughout production. Trust your instincts when interactions feel difficult before you've even placed an order.

With selection criteria clear and your partner chosen, what actually happens after you submit that quote request? Understanding the complete project lifecycle helps you anticipate each phase and ensure smooth execution from submission to delivery.

The Project Lifecycle from Quote to Delivery

You've selected your fabrication partner and submitted your files—but what happens next? Most laser cutting companies keep this process frustratingly opaque, leaving customers wondering whether their project is progressing or sitting in a queue. Understanding the complete quote-to-delivery workflow transforms you from a passive order-placer into an informed participant who can anticipate challenges and ensure smooth execution.

According to A-Laser's process documentation, each project offers a unique glimpse of technical advances, and the teamwork behind high-quality satisfaction is integral to success. The laser fabrication process may seem simple on paper, but each step matters—from the moment you submit an inquiry through to final shipment of manufactured parts.

From Quote Request to Finished Parts Delivery

Professional metal laser cutting services follow a structured workflow that ensures quality at every stage. Here's what happens after you click "submit" on that quote request:

- Quote Review and Evaluation: According to A-Laser, any new RFQ goes through quote review by CAD and engineering staff who carefully consider the geometry and how it will be cut, cleaned, inspected, packaged, and shipped. They flag any concerns so the team can address them before moving forward. Quality-focused partners like Shaoyi (Ningbo) Metal Technology demonstrate best practices here with 12-hour quote turnaround times—setting expectations for responsive service from day one.

- DFM Feedback and Design Optimization: Before production begins, experienced providers review your design for manufacturability. This step catches potential issues—features too small to cut cleanly, tolerances tighter than necessary, or geometry that could be optimized for cost savings. Comprehensive DFM support, like that offered by leading manufacturers, can identify improvements that reduce your costs while maintaining functionality.

- Material Sourcing and Verification: According to Prime Fabrication's quality guide, the material inspection stage considers potential defects, dimensional accuracy, and material composition—including identification of corrosion, cracks, and inconsistencies. Professional cnc laser cutting services maintain deep inventories of common metals on site, eliminating delays from special orders.

- Production Scheduling and Queue Management: Your project enters the production schedule based on complexity, material availability, and committed delivery date. Steel laser cutting service providers with efficient scheduling systems can often turn projects around in as little as 24 hours for standard materials and geometries.

- Laser Processing and Cutting: The actual cutting phase begins once materials are staged and programs verified. According to CM Fabrication, software optimizes every inch of raw material to minimize waste, then sends the program directly to state-of-the-art fiber laser cutting machines capable of tight tolerances and rapid throughput.

- Deburring and Secondary Operations: Cut parts often require edge cleanup, hardware insertion, bending, or other secondary processes. Professional laser cut services handle these operations in-house to maintain quality control and reduce handling between facilities.

- Quality Inspection and Verification: Before packaging, parts undergo dimensional verification against your specifications. This step catches any deviations before shipping—preventing costly discoveries at your receiving dock.

- Cleaning, Packaging, and Shipment: According to A-Laser, multiple levels of cleaning and packaging ensure the final product ships safely according to customer preferences. Proper packaging prevents damage during transit and maintains the quality achieved during production.

For automotive applications requiring rapid prototyping through mass production, manufacturers like Shaoyi demonstrate what this complete workflow looks like when executed at the highest level—from 5-day rapid prototyping to IATF 16949-certified production runs for chassis, suspension, and structural components.

Quality Verification and Inspection Protocols

According to Prime Fabrication, quality control processes are crucial in metal fabrication to ensure final products meet specified standards, customer requirements, and regulatory guidelines. But what does this actually look like in practice?

Professional inspection protocols include multiple verification stages:

- First Article Inspection (FAI): Initial parts are measured against specifications before running full production. This catches setup errors when corrections are least expensive.

- In-Process Monitoring: According to A-Laser, their ability to measure and inspect up to 300x magnification allows for critical inspection of tolerances often requested at 0.0125mm to 0.0254mm. Any non-conforming measurement is flagged and adjusted, then verified to ensure no errors occurred.

- Final Dimensional Verification: Before packaging, critical dimensions receive final verification using calibrated measurement equipment—CMMs, optical comparators, or precision gauges depending on tolerance requirements.

- Documentation and Traceability: According to industry standards, proper records should be maintained at every stage of fabrication, including inspection reports, deviations from specs, and changes to original plans. This ensures accountability and allows for consistent quality control.

Solving Common Project Challenges

Even with careful planning, challenges arise during laser fabrication. Here's how professional providers address the most common issues:

Edge Quality Issues: Rough edges, dross, or excessive heat-affected zones can compromise part function and appearance. Experienced fabricators adjust cutting parameters—speed, power, assist gas pressure, and focus position—to optimize edge quality for your specific material and thickness. Custom laser etching or secondary finishing can address aesthetic requirements when cutting alone doesn't achieve desired results.

Dimensional Accuracy Problems: Parts measuring outside tolerance typically stem from machine calibration drift, material variation, or thermal distortion during cutting. Quality-focused providers implement regular calibration schedules, verify incoming material thickness, and use optimized cutting sequences to minimize heat buildup.

Surface Finishing Concerns: Oxidation, discoloration, or surface marking can occur during laser processing. Professional shops select appropriate assist gases—nitrogen for oxide-free stainless steel edges, for example—and handle parts carefully to prevent post-cutting damage.

Material Availability Delays: Special alloys or unusual thicknesses may require sourcing time. According to CM Fabrication, maintaining deep inventory of metals on site—from aluminum and mild steel to stainless and specialty alloys—eliminates delays waiting on materials. Ask potential providers about their standard stock before committing.

Communication Breakdowns: Project status uncertainty frustrates customers and creates unnecessary stress. The best metal laser cutting services establish clear communication protocols—confirming receipt of files, providing production updates, and alerting customers immediately when questions arise. This proactive approach prevents small issues from becoming major delays.

The difference between a frustrating fabrication experience and a successful partnership often comes down to process discipline. Partners who follow structured workflows, maintain rigorous quality protocols, and communicate proactively deliver consistent results project after project.

Understanding this complete lifecycle—from your initial quote request through final delivery—empowers you to set appropriate expectations, ask informed questions, and recognize when a provider's processes indicate quality focus versus corner-cutting. With the workflow clear, you're ready to take the final step: initiating your own project with confidence.

Taking the Next Steps with Your Cutting Project

You now understand the technology, materials, pricing factors, and selection criteria that separate successful fabrication projects from frustrating experiences. But knowledge without action stays theoretical. Whether you're preparing your first laser cutting near me search or scaling an established product line to higher volumes, the path forward requires deliberate steps matched to your current situation.

Let's translate everything covered into actionable next steps tailored to where you are in your buying journey.

Starting Your First Laser Cutting Project

If you're new to custom metal laser cutting, the process can feel overwhelming. According to OMTech's beginner guide, choosing the right approach is your first critical step—and that means matching your requirements to provider capabilities before submitting any files.

Here's your action checklist for first-time buyers:

- Start with material selection: Choose the thinnest gauge that meets structural requirements. This single decision impacts cost more than any other factor.

- Prepare fabrication-ready files: Convert text to outlines, close all paths, eliminate duplicate lines, and export in DXF or AI format.

- Request quotes from multiple providers: Compare not just price, but turnaround time, DFM support, and communication responsiveness.

- Ask about minimum orders: Setup fees get distributed across quantity—understanding minimums helps you budget accurately.

- Verify material availability: Confirm your specified material and thickness are in stock to avoid sourcing delays.

The most successful first projects share one characteristic: designers who communicate openly with their fabrication partners before finalizing designs. A five-minute conversation about material selection or tolerance requirements can save weeks of revision cycles.

Scaling from Prototypes to Production Volumes

Transitioning from prototype to production presents different challenges. According to All Metals Fabricating, small DFM choices invisible in one-off prototypes can multiply cost, increase cycle time, and destabilize production once you go to volume.

For experienced buyers seeking production partners, prioritize these evaluation criteria:

- Certification alignment: Match provider certifications to your industry requirements—IATF 16949 for automotive, AS9100 for aerospace, ISO 13485 for medical devices.

- Capacity verification: Confirm equipment redundancy and scheduling flexibility to handle your projected volumes without becoming a bottleneck.

- Quality system depth: Review inspection protocols, documentation practices, and corrective action processes.

- DFM partnership: Seek providers who offer design optimization suggestions—not just order-takers who cut exactly what you submit.

For automotive applications specifically, manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate what qualified production partnerships look like—IATF 16949 certification, 5-day rapid prototyping capabilities scaling to automated mass production, and comprehensive DFM support for chassis, suspension, and structural components.

Production success requires process discipline from both parties. Adopt a "prototype with production intent" mindset—build prototypes using the material, thickness, and tooling assumptions you expect in volume. Document where prototypes differ and require a delta review with manufacturing before scaling.

Whether you're searching for laser etching services near me for a one-time project or evaluating aluminum laser cutting partners for ongoing production, the fundamentals remain consistent: understand your requirements, prepare clean files, evaluate providers systematically, and communicate openly throughout the process. Armed with the knowledge from this guide, you're prepared to navigate the fabrication landscape with confidence—and achieve the precision results your projects demand.

Frequently Asked Questions About Laser Cutting Companies

1. What are the top laser cutting companies?

Leading laser cutting companies include SendCutSend, Ponoko, Xometry, Protolabs, and A-Laser. The best choice depends on your specific needs—material type, volume requirements, turnaround time, and industry certifications. For automotive applications requiring IATF 16949 certification, specialized manufacturers like Shaoyi (Ningbo) Metal Technology offer rapid prototyping to mass production capabilities with comprehensive DFM support and 12-hour quote turnaround times.

2. How much does laser cutting cost per hour?

Industrial laser cutters typically charge $60-$150 per hour, but final costs depend on multiple factors beyond machine time. Material type and thickness significantly impact pricing—thicker materials require slower cutting speeds. Design complexity, pierce count, setup fees, and secondary operations like bending or finishing also affect your quote. Ordering larger quantities reduces per-part costs as fixed setup fees get distributed across more pieces.

3. Is there money in laser cutting?

Yes, laser cutting offers profitable opportunities across industries. Professional services command premium pricing for precision work in automotive, aerospace, medical devices, and electronics. Material processing is contactless, eliminating tool wear costs while enabling intricate designs impossible with mechanical methods. High-volume production benefits from economies of scale, while custom fabrication for unique projects can achieve handsome margins due to the value of precision individual pieces.

4. What file formats do laser cutting companies accept?

Most laser cutting companies accept vector-based formats including DXF (the universal standard), DWG, AI (Adobe Illustrator), SVG, and EPS. Raster images like JPEG or PNG cannot be used directly since lasers need precise mathematical paths to follow. Before submitting, convert all text to outlines, close all paths, eliminate duplicate lines, and verify your dimensions are accurate to avoid delays.

5. How do I choose the right laser cutting company for my project?

Evaluate potential partners based on equipment capabilities (fiber vs CO2 lasers), material expertise, relevant certifications (ISO 9001, IATF 16949 for automotive, AS9100 for aerospace), quality control processes, and DFM support. Request references from customers in your industry, verify turnaround capabilities for your volume needs, and assess communication responsiveness during the quoting process. The lowest price often hides quality issues—systematic evaluation prevents costly surprises.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —