Laser Cut Steel Secrets: From Thickness Limits To Perfect Finishes

Understanding Laser Cut Steel and Its Manufacturing Role

Imagine a beam of light so precisely focused that it can slice through solid metal with surgical accuracy. That's exactly what happens when you're working with laser cut steel—a precision manufacturing method that has transformed how industries approach metal fabrication.

At its core, laser cutting steel involves directing a highly concentrated laser beam along a computer-programmed path. When this focused energy contacts the steel surface, it rapidly heats the material to the point of melting, burning, or vaporizing. The result? Clean, precise cuts that traditional methods simply cannot match. An assist gas—typically oxygen or nitrogen—then blows away the molten material, leaving behind smooth, sharp edges free of burrs.

This technology has become indispensable across modern manufacturing. From automotive chassis components to intricate architectural elements, laser cut steel appears everywhere precision matters. Steel fabrication shops now rely on CNC-controlled laser systems to deliver repeatable results, whether they're producing one prototype or thousands of identical parts.

Modern metal laser cutter systems can achieve dimensional tolerances as tight as +/- 0.1 mm, making them ideal for applications where precision isn't optional—it's a baseline requirement.

What Makes Laser Cutting Different from Traditional Steel Cutting

Traditional steel cutting methods—shearing, sawing, or plasma cutting—all share one limitation: physical contact between the tool and material. This contact creates mechanical wear, introduces vibrations, and limits how intricate your cuts can be.

Laser cutting eliminates these constraints entirely. There's no direct contact between tool and material, which means:

- Zero mechanical wear on cutting components

- Reduced maintenance requirements over time

- Capability to execute complex geometries and tight corners that physical tools cannot reach

- Consistent edge quality without additional finishing steps

When you're working with high-strength materials where tensile strength matters, this non-contact approach preserves the material's mechanical properties near the cut zone. Traditional methods often compromise these properties through excessive heat or mechanical stress.

The Science Behind Thermal Separation in Steel

So how does laser cutting steel actually work at the material level? The process relies on what engineers call the photothermal effect.

When the high-energy laser beam strikes the steel surface, the material absorbs this energy and converts it into heat almost instantaneously. The local temperature rises so rapidly that the steel transitions from solid to liquid—or even directly to vapor—within milliseconds. This concentrated energy delivery is what enables such precise cutting.

The key parameter here is power density: the amount of laser energy delivered per unit area. Higher power density means faster heating and more efficient cutting. CNC systems control this precisely, adjusting feed speed, laser power, beam focus, and other parameters based on the specific steel type and thickness you're working with.

This level of control is why metal fabrication professionals increasingly choose laser technology. Every setting can be calibrated to match your exact requirements—whether you need rapid production runs or intricate one-off pieces. The result is a process that's not only precise but also environmentally friendly, producing minimal waste and requiring no lubricating oils that need subsequent cleaning.

Fiber Laser vs CO2 Laser Technology for Steel

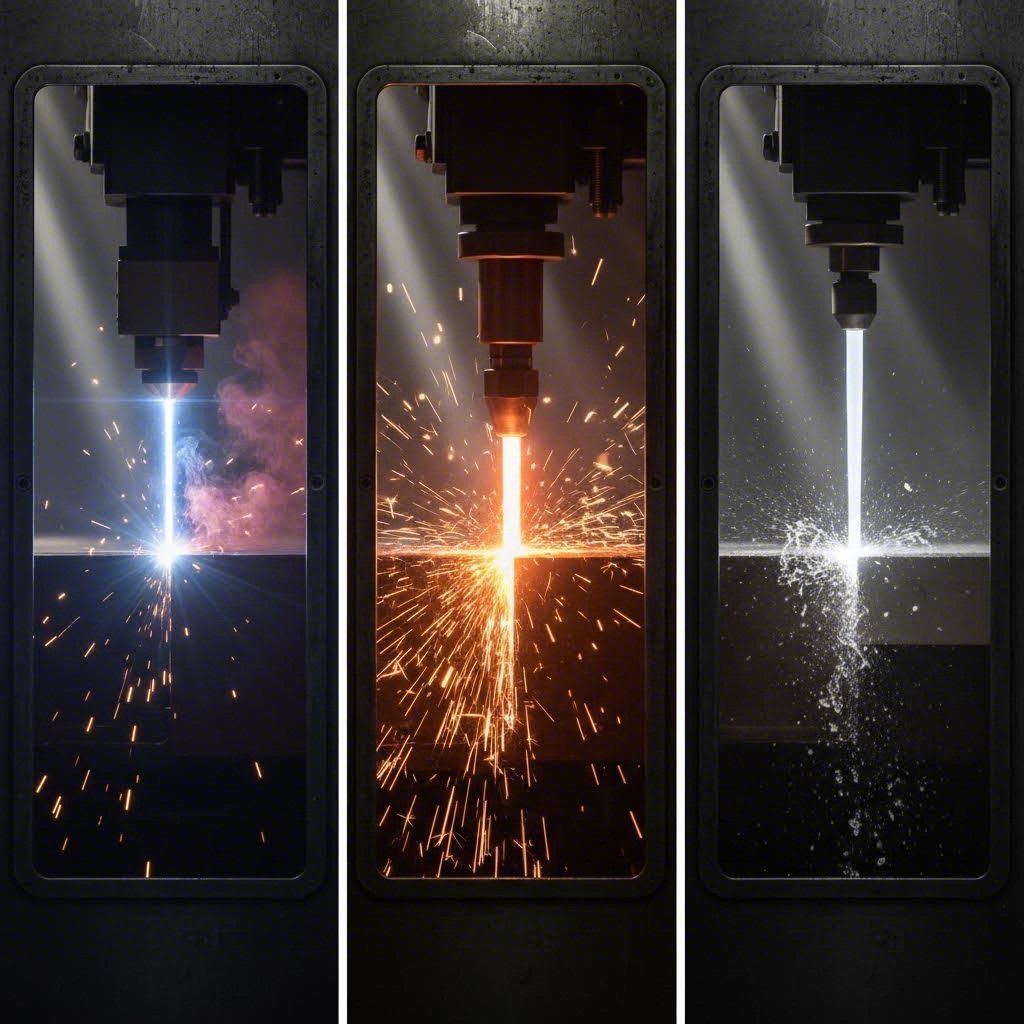

Now that you understand how laser cutting works, here's the next question: which laser technology should you actually use? When cutting steel, you'll encounter two primary options—fiber lasers and CO2 lasers. Each operates on fundamentally different physics, and choosing incorrectly can cost you time, money, and edge quality.

Think of it this way: both technologies produce powerful beams of light capable of slicing through steel. But the similarities end there. A fiber laser cutting machine and a CO2 laser cut metal machine differ in how they generate that beam, the wavelength of light they produce, and ultimately how efficiently steel absorbs their energy.

According to EVS Metal's 2025 analysis, fiber lasers now capture approximately 60% of the cutting market, delivering 3-5x faster cutting speeds and 50-70% lower operating costs than CO2 systems. That market shift tells you something important about where the technology has evolved.

| Factor | Fiber Laser | CO2 Laser |

|---|---|---|

| Cutting Speed (Thin Steel) | 2-5x faster; up to 100 m/min on thin materials | Slower; approximately 10-12 m/min on equivalent materials |

| Optimal Thickness Range | Excels under 20mm; capable up to 100mm with high-power systems | Superior edge quality above 25mm; traditionally preferred for thick plate |

| Energy Efficiency | Up to 50% wall-plug efficiency | 10-15% wall-plug efficiency |

| Annual Maintenance Cost | $200-400 typical | $1,000-2,000 typical |

| Best-Use Applications | Sheet metal, reflective metals (aluminum, copper, brass), high-volume production | Thick plate cutting, applications requiring exceptional edge finish |

| Wavelength | 1.06 µm (near-infrared) | 10.6 µm (far-infrared) |

Fiber Laser Advantages for Thin Steel Sheets

Here's where physics really matters. A fiberlaser produces light at a wavelength of approximately 1.06 micrometers—exactly ten times shorter than CO2's 10.6 micrometer wavelength. Why does that matter for your steel cutting?

Metals have surfaces filled with free-moving electrons that reflect longer wavelengths of light. The CO2 laser's long wavelength bounces off metallic surfaces, wasting significant energy as reflected light. The fibre laser cutter's shorter wavelength, however, penetrates this electron "sea" more effectively, coupling its energy directly into the steel.

This superior absorption translates into real-world advantages:

- Dramatic speed increases: A 4kW fiber laser can cut 1mm stainless steel at speeds exceeding 30 meters per minute, while an equivalent CO2 laser might achieve only 10-12 meters per minute

- Better beam quality: The beam generated within fiber optics maintains exceptional focus, producing smaller spot sizes and narrower kerf widths

- Reflective metal capability: Aluminum, copper, and brass—materials that challenge CO2 systems—cut efficiently with fiber technology

- Reduced operating costs: Energy consumption drops by approximately 70% compared to equivalent CO2 systems

For high-volume sheet metal fabrication—think electronics enclosures, HVAC components, or automotive body panels—an industrial fiber laser delivers more parts per hour at lower cost per piece. The CNC fiber laser cutting machine has essentially become the standard for thin-gauge steel processing.

When CO2 Lasers Excel in Steel Cutting

Does this mean CO2 technology is obsolete? Not quite. When you move beyond 20mm steel thickness, the equation starts to shift.

CO2 lasers produce a wider kerf, which actually helps when cutting thick plate. That wider cut channel facilitates better evacuation of molten material, often resulting in straighter, smoother cut edges with less dross—the resolidified metal that can cling to the bottom of cuts.

Consider these scenarios where CO2 systems still compete:

- Thick stainless steel: When edge finish quality matters more than cutting speed, CO2 can deliver exceptionally smooth, almost shiny edges

- Legacy operations: Established shops with mature CO2 service networks and trained operators may find transition costs outweigh benefits for specific applications

- Mixed-material environments: Shops processing significant volumes of non-metallic materials alongside steel may benefit from CO2's versatility with organics like wood and acrylic

However, it's worth noting that industrial laser cutting technology continues advancing rapidly. Modern high-power fiber systems now reach 40kW and beyond, challenging CO2's traditional thick-plate advantages. Industry analysis suggests fiber lasers will capture 70-80% of metal cutting applications by 2030.

The practical takeaway? For most steel cutting applications in 2025—especially sheet metal under 20mm—fiber laser technology offers compelling advantages in speed, efficiency, and operating costs. CO2 remains relevant for specialized thick-plate work where edge quality justifies slower processing. Understanding both technologies helps you select the right tool for your specific steel requirements.

Steel Thickness Capabilities and Cutting Limitations

You've selected your laser technology—now comes the critical question every fabricator asks: how thick can you actually cut? The answer isn't a single number. It's a relationship between laser power, material type, and the quality level you need for your specific application.

Here's what many equipment sellers won't tell you upfront: the "maximum cutting thickness" listed on a spec sheet rarely reflects what you'll achieve in daily production. According to GWEIKE's manufacturing data, there are actually three distinct thickness levels you should understand—maximum theoretical, stable production, and optimal economic cutting ranges.

Maximum Cutting Depths by Laser Power Rating

Laser power, measured in kilowatts (kW), serves as your primary indicator for thickness capability. But the relationship isn't purely linear. Doubling your power doesn't double your maximum thickness—physics introduces diminishing returns as you push into thicker steel plate territory.

| Laser Power | Carbon Steel (Oxygen) | Stainless Steel (Nitrogen) | Aluminum | Best Application |

|---|---|---|---|---|

| 1.5-2 kW | Up to 10mm | Up to 6mm | Up to 4mm | Sheet metal, thin gauge work |

| 3-4 kW | Up to 16mm | Up to 10mm | Up to 8mm | General fabrication |

| 6 kW | Up to 22mm | Up to 16mm | Up to 12mm | Medium-thick production |

| 10-12 kW | Up to 35mm | Up to 25mm | Up to 20mm | Heavy plate fabrication |

| 20 kW+ | Up to 60mm | Up to 40mm | Up to 30mm | Extreme thick plate specialty |

Notice something important in this sheet metal gauge chart of capabilities? Carbon steel consistently cuts thicker than stainless or aluminum at the same power level. That's because oxygen-assisted cutting on carbon steel creates an exothermic reaction—the oxygen actually helps the laser by generating additional heat through oxidation. Stainless steel, cut with nitrogen to preserve its corrosion-resistant properties, relies entirely on the laser's energy.

When referencing a gauge size chart for your projects, remember that 14 gauge steel thickness measures approximately 1.9mm, while 11 gauge steel thickness comes in around 3mm. These thin-gauge materials cut effortlessly on even modest 1.5-2kW systems, often at speeds exceeding 30 meters per minute.

Thin Gauge Steel Precision Considerations

Sheet metal laser cutting on thin materials brings its own precision considerations. Here's where kerf width becomes critical to your design success.

What exactly is kerf? It's the width of material removed by the cutting process—essentially the "thickness" of your cut line. On thin gauge sizes, kerf typically measures between 0.1mm and 0.3mm. As material thickness increases, so does kerf width, sometimes reaching 0.5mm or more on thick steel plate.

Why does this matter? Consider these precision impacts:

- Part nesting efficiency: Narrower kerf means you can position parts closer together on your sheet, reducing material waste

- Dimensional accuracy: Your CAD design must account for kerf—if you need a 10mm slot, you may need to program 10.2mm to compensate

- Tolerance capabilities: On materials under 3mm, tolerances as tight as ±0.1mm are achievable; thicker materials typically hold ±0.25mm to ±0.5mm

- Feature size minimums: Holes smaller than material thickness become challenging—a 5mm plate may require minimum hole diameters of 5mm or larger

According to Prototech Laser's manufacturing guidelines, thin materials allow tolerances as tight as ±0.005" (0.127mm), while thicker plates may require ±0.01" to ±0.02" (0.25mm to 0.5mm) depending on material type and machine parameters.

When Laser Cutting Becomes Impractical

Every technology has its limits. Knowing when to step away from laser cutting saves you time, money, and frustration. Consider alternative methods when:

- Thickness exceeds practical limits: Even a 20kW system struggles with consistent quality beyond 50-60mm on carbon steel. Plasma or flame cutting becomes more economical.

- Edge taper becomes unacceptable: On very thick material, the laser beam widens as it penetrates, creating a slight angle from top to bottom. If parallel walls are critical, you may need secondary machining.

- Speed requirements don't justify cost: Cutting 25mm steel at 0.3 meters per minute ties up expensive equipment. Plasma cuts the same thickness 3-4x faster at lower operating cost.

- Material reflectivity creates safety concerns: Highly polished copper and brass can reflect laser energy back into the cutting head, risking equipment damage.

A practical rule from experienced fabricators: if you only cut thick plate once a month, don't size your equipment for that occasional job. Instead, outsource extreme thickness work and optimize your machine for the 80-90% of jobs that generate your actual profit.

Understanding these thickness relationships helps you match projects to capabilities—and knowing your limits often matters more than pushing past them.

Steel Types and Material Selection for Laser Cutting

Understanding thickness capabilities is only half the equation. The type of steel you're cutting fundamentally changes how your laser performs—and whether your finished parts meet specification. Different steel compositions absorb laser energy differently, produce varying edge finishes, and require distinct processing parameters.

Think of it this way: mild steel and 316 stainless steel might look similar on your material rack, but they behave like completely different materials under the laser beam. According to Amber Steel's fabrication analysis, understanding these differences helps shops improve efficiency, control costs, and deliver better results regardless of project complexity.

Here's a comprehensive breakdown of how common steel grades interact with laser cutting technology:

- Mild Steel (A36, A572): The easiest to cut. Low carbon content (0.05-0.25%) allows predictable, clean cuts with minimal dross. Works with both oxygen and nitrogen assist gases. Excellent candidate for high-speed production runs.

- Stainless Steel Sheet (304, 316): Requires nitrogen assist to preserve corrosion resistance. Lower thermal conductivity actually benefits laser cutting by concentrating heat. Produces clean edges but cuts slower than equivalent mild steel thickness.

- High-Strength Low-Alloy (HSLA) Steel: Balances strength with good laser compatibility. May require parameter adjustments for optimal edge quality. Common in structural and automotive applications.

- Abrasion-Resistant Grades (AR500): Challenging due to extreme hardness (460-544 Brinell). Fiber lasers work best, typically limited to 0.500" thickness. Minimizing heat-affected zone is critical to preserve hardness properties.

- Galvanized Sheet Metal: The zinc coating vaporizes during cutting, creating fumes that require adequate ventilation. May produce slightly rougher edges compared to uncoated steel. Pre-cutting cleaning rarely necessary.

Carbon Steel Grades and Laser Cutting Performance

Carbon steel remains the workhorse of laser cutting operations. Its predictable behavior and forgiving nature make it ideal for both newcomers and production environments demanding consistent results.

Why does carbon steel cut so cleanly? The answer lies in oxygen-assisted cutting. When you direct an oxygen assist gas stream at the cut zone, it creates an exothermic reaction with the heated carbon steel. This oxidation process generates additional heat—essentially helping the laser do its job. The result? Faster cutting speeds and the ability to process thicker steel plates than you'd achieve with nitrogen assist.

However, this oxygen reaction produces an oxide layer on the cut edge. For structural applications, this rarely matters. For parts requiring welding or powder coating, you may need light grinding or cleaning before proceeding. If you need pristine, oxide-free edges on carbon steel, switching to nitrogen assist is possible—just expect slower cutting speeds and higher gas consumption.

Material preparation significantly impacts your results. According to KGS Steel's fabrication guidelines, clean, scale-free surfaces on grades like A36 or A572 typically produce better results than rusty or scaled surfaces. Before cutting steel plates for critical applications, consider these preparation steps:

- Surface rust: Light surface oxidation usually processes fine, but heavy scale should be removed mechanically or with wire brushing

- Oil and grease: Cutting through contaminated surfaces produces smoke and may affect edge quality—solvent wipe if necessary

- Protective coatings: Laser-safe paper or plastic masking can remain during cutting; vinyl coatings should be removed

- Mill scale: Fresh hot-rolled steel with intact mill scale typically cuts acceptably; flaking scale is problematic

Specialty Steels That Challenge Laser Cutting

Not all steels cooperate equally under the laser beam. Understanding which materials push your equipment's limits helps you quote accurately, set realistic customer expectations, and know when alternative methods make more sense.

Stainless Steel Sheet Metal Considerations: Austenitic grades like 304 and 316 stainless steel respond exceptionally well to laser cutting due to their consistent composition and thermal properties. The lower thermal conductivity compared to carbon steel actually concentrates heat in the cut zone, enabling precise cuts with minimal heat-affected zones. However, expect processing speeds roughly 30-40% slower than equivalent carbon steel thickness.

For stainless applications in food processing, medical equipment, or marine environments, nitrogen assist is non-negotiable. Oxygen creates a chromium oxide layer that compromises the corrosion resistance you're paying for. The trade-off? Higher gas costs and slower speeds—but properly cut stainless steel sheet maintains its valuable properties.

AR500 and Abrasion-Resistant Grades: According to McKiney Manufacturing's AR500 cutting guide, fiber lasers stand out as the best option for abrasion-resistant steel when precision, speed, and material strength matter. AR500 rates between 460 and 544 on the Brinell Hardness Scale—this extreme hardness limits practical laser cutting to approximately 0.500" thickness.

The critical concern with AR500? Heat management. This steel achieves its hardness through heat treatment. Excessive heat input during cutting can create soft spots that defeat the purpose of specifying AR500 in the first place. Fiber lasers minimize this risk by producing a smaller heat-affected zone than plasma or oxy-fuel alternatives.

Aluminum Sheet Considerations: While not steel, aluminum sheet metal frequently appears alongside steel in fabrication shops. Its high reflectivity historically challenged CO2 lasers, but modern fiber systems handle aluminum effectively. Expect different assist gas requirements (nitrogen or compressed air) and adjusted focal parameters compared to steel settings.

ASTM specifications, Military Grade requirements, and specialty alloys each bring unique considerations. When quoting unfamiliar materials, request a test cut on sample material before committing to production parameters. The cost of a few test pieces pales compared to scrapping an entire production run due to unexpected material behavior.

Your material selection directly influences every downstream decision—from assist gas choice to cutting speed to post-processing requirements. Getting this foundation right sets the stage for successful applications across every industry sector.

Industry Applications for Laser Cut Steel Components

You've selected your material and understand your machine's capabilities—now where does laser cut steel actually show up in the real world? The applications span from high-performance motorsport to artistic custom metal signs hanging outside your favorite local brewery. Each industry brings unique precision requirements, tolerance expectations, and design considerations that shape how fabricators approach every project.

What makes this technology so versatile? Laser fabrication eliminates the trade-off between complexity and cost. Whether you're cutting simple brackets or intricate decorative panels, the machine doesn't care about geometry—it follows the programmed path with equal precision. This capability has opened doors across industries that previously relied on expensive tooling or labor-intensive manual processes.

Let's break down the major sectors leveraging laser cut parts and what each demands from the technology:

- Automotive and Motorsport: Chassis components, suspension brackets, roll cage tubing, custom mounting tabs

- Architectural and Construction: Decorative facade panels, privacy screens, structural elements, stair components

- Industrial Machinery: Equipment housings, mounting plates, guards, conveyor components

- Artistic and Signage: Custom metal signs, decorative art panels, branded displays, garden sculptures

Automotive Chassis and Structural Component Applications

If you've ever built a roll cage using a manual tube notcher and a drill press, you know the struggle. Measure three times, set the angle, start the hole saw—and half the time the cope comes out slightly off. You spend the next twenty minutes with an angle grinder trying to get the tube to fit tight enough for a TIG weld.

According to YIHAI Laser's automotive fabrication analysis, custom metal cutting with laser technology transforms this entire workflow. In motorsport and custom automotive fabrication—whether Formula Drift, Trophy Trucks, or high-end Restomods—fit-up is everything. A gap in a chassis tube isn't just ugly; it's a structural weak point that compromises safety.

Here's what makes laser fabrication essential for automotive sheet metal fabrication:

- Perfect Coping: The laser cuts the exact complex curve where one tube meets another, accounting for wall thickness and intersection angle. No grinding required.

- Self-Fixturing Assemblies: Slot-and-tab designs let chassis components snap together and fixture themselves. You don't need complex jig tables—the parts lock into squareness automatically.

- Bend Location Marking: The laser can etch exact start and stop lines for mandrel benders. The fabricator lines up the mark and bends—no tape measure needed.

- Suspension Precision: Pivot point locations for anti-dive, roll center, and bump steer geometry rely on holes being in exactly the right position. Laser systems hold tolerances of ± 0.05mm, ensuring your alignment stays true.

Precision requirements in automotive work typically demand tolerances between ±0.1mm and ±0.25mm for critical mounting points. Suspension tabs made from 4130 Chromoly or High-Strength Domex steel—materials that destroy drill bits—cut effortlessly without tool wear. For metal fab shops serving the automotive sector, this repeatability means you can sell "weld-it-yourself" kits where every part is identical, every time.

One critical consideration: when cutting Chromoly for roll cages, use nitrogen or high-pressure air rather than oxygen as your assist gas. Oxygen cutting can oxidize and harden the edge slightly, increasing cracking risk during welding. Nitrogen provides a clean cut with minimal heat-affected zone, preserving the ductility needed for structural welding.

Architectural Steel Elements and Custom Fabrication

Walk through any modern commercial building and you'll spot laser-cut steel everywhere—decorative privacy screens, sun control panels, perforated facade cladding, and ornate staircase components. What once required expensive stamping dies or painstaking hand-cutting now flows directly from digital design to finished panel.

According to VIVA Railings' architectural panel specifications, these precision laser-cut panels serve multiple functions simultaneously: privacy screening, solar shading, decorative enhancement, and even wayfinding signage. The versatility comes from laser cutting's ability to execute intricate perforation patterns that would be impossible or cost-prohibitive with traditional methods.

Architectural applications typically organize into three pattern categories:

- Geometric Patterns: Tessellated or grid-inspired motifs that make bold statements in public installations

- Organic Patterns: Nature-inspired designs that soften spaces with biophilic design principles

- Primary Patterns: Modern, minimal designs suited to contemporary architecture

Material selection for architectural work often includes stainless steel, aluminum, and carbon steel—all available in thicknesses matched to structural requirements and span distances between supports. For exterior applications, corrosion resistance becomes critical. Powder-coated or PVDF-finished panels enhance weather resistance while providing color customization options.

Tolerance requirements for architectural panels typically run looser than automotive work—often ±0.5mm to ±1mm is acceptable. However, when panels tile together across large facades, cumulative dimensional errors become visible. Experienced fabrication shops near me know to verify nesting accuracy and maintain consistent material thickness across production runs to prevent visible misalignment at panel joints.

For hobbyists and small-scale custom work, architectural techniques scale down beautifully. Garden screens, interior room dividers, and decorative wall art all benefit from the same precision. Custom metal signs for businesses, home address plaques, and branded displays represent accessible entry points for makers exploring laser-cut steel possibilities.

Industrial Machinery and Production Applications

Beyond the visible applications, laser cut steel forms the backbone of industrial equipment worldwide. Machine guards, equipment housings, electrical enclosures, and conveyor components all rely on consistent, repeatable fabrication—exactly what laser cutting delivers.

Industrial applications prioritize different qualities than automotive or architectural work:

- Consistency Across Production Runs: When you're cutting thousands of identical brackets, every part must match dimensional specifications without manual verification

- Material Utilization: Industrial sheet metal fabrication demands efficient nesting to minimize scrap from high-volume production

- Secondary Operation Compatibility: Parts often proceed directly to bending, welding, or powder coating—cut quality must support downstream processes

- Documentation and Traceability: Laser etching can mark part numbers, lot codes, and specifications directly onto components

Tolerance expectations for general industrial work typically range from ±0.25mm to ±0.5mm—tighter than architectural but more forgiving than precision automotive. The key advantage is repeatability: the thousandth part cuts identically to the first, eliminating the quality drift that plagues manual processes.

For fabrication shops near me serving industrial clients, the combination of speed, precision, and minimal post-processing translates directly to competitive pricing. When your laser-cut edges are clean enough to proceed directly to coating or assembly, you've eliminated grinding labor that adds cost without adding value.

Design Considerations Across Application Categories

Regardless of industry, certain design principles optimize your results when working with laser cut steel:

- Minimum Feature Size: Holes and slots should generally be at least as wide as material thickness. A 3mm plate handles 3mm holes well; attempting 1mm holes invites quality problems.

- Edge Spacing: Keep features at least one material thickness away from edges to prevent distortion or edge breakout.

- Tab and Slot Tolerances: For self-fixturing assemblies, design slots slightly wider than tabs (typically 0.1-0.2mm clearance) to ensure assembly without forcing.

- Grain Direction: For parts that will be bent, consider material grain orientation—bending perpendicular to grain reduces cracking risk.

- Heat Accumulation: Intricate patterns with closely spaced cuts can accumulate heat. Design for adequate spacing or plan for cooling pauses between cuts.

Whether you're building a competition chassis, specifying facade panels for a commercial development, or creating custom metal signs for your workshop, understanding these application-specific considerations helps you communicate effectively with your fabricator—and ultimately receive parts that meet your exact requirements.

Cost Factors and Pricing Variables in Steel Laser Cutting

You've designed your parts, selected your material, and identified your application—now comes the question every project manager asks: what's this actually going to cost? Here's the surprising truth that most people miss when requesting a laser cutting quote: the price per square foot of material is rarely your primary cost driver. What actually determines your final invoice is machine time.

Think about it this way. Two parts cut from the same steel sheet—identical material cost—can have wildly different prices. A simple rectangular bracket cuts in seconds. An intricate decorative panel with hundreds of perforations ties up the machine for minutes. According to Fortune Laser's pricing analysis, the foundational formula most metal cutting services use breaks down like this:

Final Price = (Material Costs + Variable Costs + Fixed Costs) × (1 + Profit Margin)

Variable costs—primarily machine time—represent the biggest lever you can pull to reduce expenses. Understanding what drives that time helps you make smarter design decisions before you ever submit files for a quote.

Material Costs vs Processing Time Economics

When calculating laser cutting charges, five primary factors determine your final cost. Each one affects either the material expense or the processing time required to complete your job.

- Material Type and Cost: Raw material prices vary dramatically. Mild steel costs a fraction of 316 stainless steel. Your material choice establishes the baseline expense before any cutting begins.

- Material Thickness: This factor impacts cost exponentially, not linearly. According to Komacut's pricing guide, doubling material thickness can more than double cutting time because the laser must move much slower to achieve clean cuts through thicker steel.

- Total Cutting Length: Every linear inch the laser travels adds time. A design with extensive perimeter cutting or intricate internal features accumulates more machine time than simple geometries.

- Pierce Count: Each time the laser initiates a new cut, it must first "pierce" through the material surface. A design with 100 small holes costs more than one large cutout with equivalent perimeter length—those pierces add up.

- Setup Time and Labor: Loading material, calibrating the machine, preparing your file—these fixed costs apply regardless of whether you're cutting one part or one hundred.

Here's what this means practically: Strouse's fabrication data indicates material cost often makes up 70-80% of total costs for straightforward parts. But as design complexity increases, that ratio shifts dramatically toward processing time.

The relationship between precision requirements and processing costs follows a similar pattern. Specifying tolerances tighter than functionally necessary forces the machine to run at slower, more controlled speeds. If your application genuinely requires ±0.1mm precision, that's appropriate. But specifying aerospace tolerances on decorative panels wastes money without adding value.

Volume Production Cost Optimization

The economics of prototype pricing versus production runs reveal significant savings opportunities. When you order a single prototype through an online laser cutting service, fixed setup costs—machine preparation, file verification, material handling—all land on that one part. Order a hundred identical parts, and those same fixed costs spread across the entire batch.

According to industry pricing data, discounts for high-volume orders can reach as high as 70% per unit. That's not marketing spin—it reflects the genuine efficiency gains from batch processing.

Turnaround time introduces another cost variable. Rush orders that jump the production queue command premium pricing—often 25-50% above standard rates. Planning ahead and accepting standard lead times keeps your steel cutting services costs predictable.

Ready to reduce your custom laser cutting expenses? These strategies deliver measurable savings:

- Simplify Your Design: Where possible, reduce complex curves and consolidate small holes into larger slots. This minimizes both cut distance and time-consuming pierces.

- Specify the Thinnest Practical Material: This is the single most effective cost reduction. If 14-gauge steel meets your structural requirements, don't specify 11-gauge just for margin.

- Clean Your Design Files: Remove duplicate lines, hidden objects, and construction notes before submission. Automated online laser cutting systems will attempt to cut everything—double lines literally double your cost for that feature.

- Optimize Nesting: Efficient nesting maximizes material usage by arranging parts closely together on the sheet, minimizing waste. Many custom cut metal services handle this automatically, but designing parts that nest efficiently still reduces your quoted price.

- Consolidate Orders: Batch your needs into larger, less frequent orders. The per-unit price drops as setup costs amortize across more parts.

- Choose In-Stock Materials: Selecting materials your provider already stocks eliminates special order fees and reduces lead times.

When requesting a laser cutting quote, provide complete information upfront: material type and thickness, quantity needed, tolerance requirements, and any secondary operations. Incomplete requests generate conservative estimates that may overstate actual costs. The more your fabricator understands your requirements, the more accurately they can price the work—and the more opportunities they have to suggest cost-saving alternatives.

Understanding these cost dynamics positions you to make informed decisions throughout your project. But what happens after the laser finishes cutting? The next consideration—post-processing and finishing—often determines whether your parts are truly production-ready.

Post-Processing and Finishing for Laser Cut Steel Parts

Your parts just came off the laser—crisp edges, precise geometry, exactly what you programmed. But here's what separates amateur projects from professional fabrication: what happens next. Raw laser-cut steel rarely goes directly into service. Post-processing transforms good cuts into finished components ready for assembly, coating, or customer delivery.

Why does finishing matter so much? According to Weldflow Metal Products' fabrication analysis, finishing isn't just about improving looks—it plays a vital role in preventing corrosion, increasing strength, and preparing components for assembly. Each finishing option serves a unique purpose depending on your material, application, and desired outcome.

Before selecting any finish, you need to understand what the laser leaves behind. Even precision fiber laser systems create a heat-affected zone (HAZ)—a narrow band where the steel's microstructure changed during cutting. This zone, typically 0.1-0.5mm wide depending on material thickness and cutting parameters, may exhibit altered hardness, residual stress, or slight discoloration. For structural applications, the HAZ rarely causes concern. For fatigue-critical or aesthetic parts, secondary processing addresses these effects.

Deburring and Edge Finishing Techniques

Laser cutting produces remarkably clean edges compared to plasma or mechanical cutting, but "clean" doesn't mean "finished." Sharp corners can still cut hands during handling. Micro-burrs—tiny projections of resolidified metal—may cling to the bottom edge of cuts. Define dross as this solidified slag that forms on the underside of laser cuts; it's the first thing most post-processing addresses.

According to SendCutSend's finishing guide, deburring eliminates sharp edges and small burrs, making components safer to handle and easier to integrate into larger assemblies. Here's what each method delivers:

- Linear Deburring: A belt-driven brushing process that smooths one side of larger parts. Removes scratches and dross while preparing surfaces for subsequent coating. Works best for parts with the shortest axis under 24 inches.

- Tumbling/Vibratory Finishing: Ceramic media and harmonically tuned vibration smooth edges on smaller parts. Produces more consistent results than manual methods. Removes sharp edges but won't eliminate manufacturing marks entirely.

- Manual Grinding: Hand-held angle grinders or die grinders address specific problem areas. Essential when you need to remove significant material or prepare weld joints.

- Scotch-Brite or Abrasive Pads: For light touch-up work, abrasive pads knock down minor sharp edges without removing significant material.

One important consideration: deburring typically addresses one surface. If your application requires smooth edges on both sides, specify two-sided processing or plan for manual touch-up after receiving parts. For assemblies requiring tight fits, remember that deburring removes a small amount of material—account for this in your tolerance calculations.

When parts proceed to bending operations after cutting, edge quality becomes critical. Burrs or dross on bend lines can cause cracking or inconsistent bend angles. Proper deburring before bending ensures clean, predictable results without material failures at the formed edges.

Surface Treatment Options for Cut Steel

Once edges are smooth, surface treatments protect and enhance your parts for their intended environment. The choice between options depends on corrosion resistance requirements, aesthetic goals, dimensional tolerances, and budget constraints.

- Powder Coat: Electrostatically applied dry powder cured under heat creates an exceptionally durable finish. According to industry data, powder coating can last up to 10x longer than paint while containing none of the volatile organic compounds. Available in matte, gloss, and textured finishes across numerous colors. Best candidates: aluminum, steel, and stainless steel that can hold electrostatic charge.

- Anodizing: Creates a controlled oxide layer that bonds directly with aluminum surfaces. The anodized finish provides superior corrosion, heat, and electrical resistance. Available in clear or dyed options including vibrant colors. Note: anodizing applies to aluminum—not steel—so this option suits mixed-material projects where you're cutting both metals.

- Electroplating: Deposits zinc, nickel, or chrome onto steel surfaces. Zinc plating (galvanizing) protects against corrosion in outdoor or industrial environments. Nickel plating improves wear resistance and conductivity. Both methods suit applications where longevity in harsh conditions is critical.

- Painting: Traditional wet-applied coatings remain viable for many applications. Proper surface preparation—abrasive brushing followed by solvent cleaning—ensures adhesion. Painting costs less than powder coating but delivers reduced durability and environmental resistance.

- Passivation: Chemical treatment that enhances stainless steel's natural corrosion resistance without adding a visible coating. Removes free iron from the surface while promoting formation of the protective chromium oxide layer.

For aluminum components that have been laser cut alongside your steel parts, anodized aluminum provides an excellent combination of durability and aesthetics. The anodizing process creates a finish resistant to scratching while enabling color options that powder coating cannot match on aluminum substrates.

Powder coating services typically add the most value for steel components exposed to weather, chemicals, or abrasion. The cured coating bonds mechanically and chemically to the prepared steel surface, creating protection that resists chipping, scratching, and UV degradation far better than paint alternatives.

Quality Inspection and Dimensional Verification

Before parts leave your facility—or before you accept delivery from a vendor—verification ensures everything meets specification. Quality inspection for laser-cut steel involves both dimensional accuracy and surface quality assessment.

Dimensional verification typically includes:

- Caliper Measurements: Verify critical dimensions against drawings. Check hole diameters, slot widths, and overall part dimensions at multiple locations.

- Gauge Checks: Go/no-go gauges quickly verify hole sizes and slot widths fall within tolerance bands.

- CMM Inspection: For precision-critical parts, coordinate measuring machines provide comprehensive dimensional reports with accuracy to thousandths of an inch.

- Optical Comparators: Profile projectors overlay cut parts against scaled drawings to verify complex contours and feature locations.

Surface quality assessment addresses different concerns:

- Edge Perpendicularity: On thick materials, laser cuts may exhibit slight taper. Verify edge angle meets application requirements.

- Surface Roughness: Ra measurements quantify edge finish quality when specifications demand particular surface characteristics.

- Dross Presence: Visual inspection identifies any remaining solidified metal on cut edges that escaped deburring.

- Heat Discoloration: Stainless steel may show "heat tint" adjacent to cuts. For aesthetic applications, this oxidation requires removal through pickling or mechanical polishing.

Establishing inspection criteria before production begins prevents disputes and rework. Document acceptable ranges for critical dimensions, specify surface finish requirements, and define what constitutes a rejectable defect. For production runs, statistical sampling—checking every tenth or twentieth part—provides quality confidence without inspecting every piece.

With post-processing complete and quality verified, your laser-cut steel components are ready for assembly or delivery. But what if laser cutting isn't the right choice for your particular project? Understanding how this technology compares to alternatives like plasma and waterjet cutting helps you select the optimal method for each application.

Choosing Between Laser Plasma and Waterjet Steel Cutting

Your parts are designed, your material is selected, and you understand post-processing requirements—but here's a question that can save or waste thousands of dollars: is laser cutting actually the right method for your project? The truth is, laser technology excels in many scenarios but falls short in others. Knowing when to switch to plasma or waterjet cutting separates informed fabricators from those learning expensive lessons.

Think about it this way: all three technologies cut steel, but they're fundamentally different tools. According to Wurth Machinery's comparative analysis, choosing the wrong CNC cutter can cost you thousands in wasted material and lost time. That's not marketing hyperbole—it reflects the genuine consequences of mismatched technology.

Here's a comprehensive comparison to guide your decision-making:

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting |

|---|---|---|---|

| Precision/Tolerance | ±0.1mm to ±0.25mm; exceptional edge quality | ±0.5mm to ±1.5mm; improved with high-definition systems | ±0.1mm to ±0.25mm; excellent on thick materials |

| Cutting Speed | Fastest on thin materials (<6mm); slows dramatically on thick plate | Fastest on medium-thick plate (6mm-50mm); 100+ IPM on 12mm steel | Slowest overall; 5-20 IPM depending on thickness |

| Thickness Range | Optimal under 20mm; capable to 60mm with high-power systems | 0.5mm to 50mm+; excels at 6mm-50mm range | Virtually unlimited; commonly 150mm+ on steel |

| Heat-Affected Zone | Minimal (0.1-0.5mm); preserves material properties | Larger HAZ; may affect hardness in sensitive applications | Zero thermal impact; cold cutting process |

| Material Compatibility | Conductive and some non-conductive; challenges with highly reflective metals | Conductive metals only; no plastics, wood, or glass | Universal; cuts virtually any material |

| Initial Investment | $150,000-$500,000+ for industrial systems | $15,000-$90,000 for comparable capability | $100,000-$300,000+ typical installations |

| Operating Cost | Moderate; electricity and assist gas primary consumables | Lowest per inch of cut; consumables are inexpensive | Highest; abrasive garnet adds significant ongoing expense |

Laser vs Plasma Cutting for Steel Projects

When should you choose an industrial laser cutter over plasma—and vice versa? The decision often comes down to material thickness, precision requirements, and production volume.

According to StarLab CNC's 2025 fabrication guide, laser cutting and plasma cutting each dominate different segments of steel processing. Fiber lasers dominate thin material cutting, achieving exceptional speeds on sheets under 6mm thick. However, cutting speed decreases significantly as material thickness increases, with dramatic slowdowns on materials over 25mm thick.

Plasma cutting flips this equation. CNC plasma tables excel in cutting speed on materials from 0.5mm to 50mm thick. A high-powered plasma system can cut 12mm mild steel at speeds exceeding 100 inches per minute—making it the fastest option for medium to thick metal plates.

Consider these decision criteria:

- Choose Laser When: You need precision laser cutting with tolerances under ±0.25mm, intricate geometries with small features, clean edges requiring minimal post-processing, or high-volume thin sheet production

- Choose Plasma When: Material thickness exceeds 12mm, speed matters more than edge finish, budget constraints limit equipment investment, or you're processing primarily structural steel and heavy plate

The precision difference deserves emphasis. Industrial laser cutting delivers near-perfect edge quality with minimal taper—critical for parts that fit together without grinding. Modern high-definition plasma systems have closed the gap significantly, achieving near-laser quality on many applications while maintaining superior cutting speeds. But for applications like slot-and-tab assemblies where 0.1mm matters, laser remains the clear choice.

Cost considerations often surprise first-time buyers. According to Tormach's technology comparison, plasma cutters have a much lower barrier of entry than laser cutters. An industrial laser cutting machine capable of production-quality work starts around $150,000, while comparable plasma capability begins under $20,000. For shops primarily cutting steel over 10mm thick, plasma often delivers better return on investment.

When Waterjet Cutting Outperforms Laser

Waterjet technology operates on completely different physics—and that difference creates unique advantages laser and plasma simply cannot match.

Using a high-pressure stream of water mixed with abrasive garnet particles, waterjet systems erode material along the programmed path at pressures up to 90,000 PSI. This cold cutting process generates zero heat, preserving material properties that thermal methods compromise.

According to comparative testing data, waterjet becomes the clear choice when:

- Heat Damage Must Be Avoided: Hardened steels, heat-treated components, and materials sensitive to thermal distortion benefit from waterjet's cold process. No warping, no hardening changes, no heat-affected zones.

- Cutting Non-Metals Alongside Steel: Mixed-material assemblies combining steel with stone, glass, composites, or exotic alloys process on a single machine. Laser and plasma cannot touch many of these materials.

- Extreme Thickness Requirements: When your steel plate exceeds 50mm, waterjet maintains quality while laser struggles and plasma produces rougher edges.

- Precision on Thick Materials: Laser precision degrades on thick plate due to beam divergence. Waterjet maintains ±0.1mm capability regardless of thickness.

The trade-off? Speed and cost. Waterjet systems operate at the slowest speeds among the three technologies—typically 5-20 inches per minute depending on material. According to industry data, plasma cutting 25mm steel runs about 3-4 times faster than waterjet, with operating costs roughly half as much per foot.

The abrasive garnet required for metal cutting represents a significant ongoing expense. Combined with higher initial equipment costs and more complex maintenance requirements, waterjet makes economic sense primarily when its unique capabilities—cold cutting and universal material compatibility—directly benefit your application.

Hybrid Approaches for Complex Projects

Here's what experienced fabrication shops understand: choosing between technologies isn't always an either-or decision. Many successful operations incorporate multiple cutting methods, selecting the optimal tool for each specific job.

Consider a complex project requiring both thin precision components and thick structural plates. Running everything through a precision laser cutting system wastes machine time on thick material that plasma handles faster. Conversely, plasma-cutting thin sheet metal sacrifices edge quality unnecessarily.

The hybrid approach matches technology to task:

- Laser for Precision Components: Brackets, mounting plates, and assemblies requiring tight tolerances and clean edges

- Plasma for Structural Elements: Heavy plate, reinforcement gussets, and components where speed matters more than finish

- Waterjet for Special Cases: Heat-sensitive materials, extreme thickness, or mixed-material cutting

According to industry analysis, many shops start with one technology and grow into two to cover more ground. Plasma and laser often pair well—plasma handles the thick work while laser delivers precision on thin sheet. Adding waterjet capability extends versatility further for shops serving diverse markets.

For shops without multiple in-house systems, understanding these trade-offs helps you select the right vendor for each project. A metal cutter service specializing in industrial laser cutting may not be your best choice for 40mm plate—even if they can technically process it. Knowing when to route work to plasma or waterjet specialists often delivers better results at lower cost.

The decision framework ultimately reduces to matching technology capabilities with project requirements. Speed, precision, thickness, heat sensitivity, material type, and budget all factor into the optimal choice. Armed with this understanding, you're equipped to select the right cutting method—or combination of methods—for every steel fabrication challenge you encounter.

Sourcing Partners and Project Optimization Strategies

You've mastered the technology, understood material selection, and know exactly what finishing your parts need. Now comes the challenge that trips up even experienced engineers: finding the right fabrication partner and preparing your project for seamless production. The difference between a smooth manufacturing experience and weeks of frustrating back-and-forth often comes down to how well you prepare before submitting your first file.

Here's what many people discover too late: not all laser cutting services near me deliver equal results. According to Bendtech Group's fabrication analysis, online laser cutting platforms have revolutionized accessibility, with the global market hitting USD 7.12 billion in 2023 and projected to nearly double by 2032. But this explosion of options makes vendor selection more critical—not less.

Whether you're prototyping a single bracket or scaling to thousands of production parts, following a structured approach prevents costly mistakes and accelerates your timeline from design to delivery.

Evaluating Laser Cutting Service Capabilities

Before uploading files to any metal fabrication near me, you need to verify the vendor can actually deliver what your project requires. Not every shop handles every material, thickness, or tolerance specification. Asking the right questions upfront saves weeks of frustration later.

Start by assessing these critical capability areas:

- Equipment and Technology: Does the shop operate fiber or CO2 lasers? What power levels are available? For thin sheet metal, a 4kW fiber system delivers excellent results. For thick plate work, you'll need access to 10kW+ capability or alternative cutting methods.

- Material Inventory: Shops stocking common materials like mild steel, stainless, and aluminum can turn orders faster than those requiring special orders. Ask about their standard inventory and lead times for non-stock materials.

- Tolerance Capabilities: Precision laser cutting services vary significantly in achievable tolerances. Production shops may hold ±0.25mm routinely, while specialty vendors achieve ±0.1mm for critical applications.

- Secondary Operations: Can they handle bending, welding, powder coating, or assembly in-house? Consolidating operations with a single vendor simplifies logistics and accountability.

Quality certifications provide objective verification of a vendor's capabilities. According to IATF 16949 certification requirements, automotive-grade suppliers must demonstrate documented processes for quality management, supplier risk assessment, and continuous improvement. When sourcing chassis, suspension, or structural components for automotive applications, IATF 16949 certification indicates a vendor meets the rigorous standards the automotive industry demands.

Response time reveals a lot about operational capability. Industry-leading metal laser cutting services typically provide quotes within 12-24 hours. If you're waiting days for a simple quote, imagine how long production issues might take to resolve. For automotive supply chain applications where timing is critical, vendors like Shaoyi (Ningbo) Metal Technology demonstrate what responsive service looks like—12-hour quote turnaround sets a benchmark that serious manufacturers should match.

Evaluate these additional selection criteria before committing:

- DFM Support: Does the vendor offer Design for Manufacturability feedback? Comprehensive DFM support catches issues before cutting begins, preventing expensive rework. Partners who invest time reviewing your designs demonstrate commitment to your success—not just processing your order.

- Prototyping Speed: For product development, rapid prototyping capability matters enormously. Some vendors deliver prototype parts in 5 days or less, enabling fast iteration cycles that compress development timelines dramatically.

- Production Scalability: Your prototype partner may not be your production partner. Verify the vendor can scale from one-off samples to automated mass production without quality degradation or capacity constraints.

- Geographic Considerations: CNC laser cutting services located closer to your facility reduce shipping costs and transit damage risk. However, specialized capabilities may justify working with distant vendors for specific applications.

Design File Preparation for Production Success

Your fabrication partner can only manufacture what your files communicate. Ambiguous, incomplete, or improperly formatted design files create delays, miscommunication, and parts that don't match your expectations. Preparing files correctly the first time accelerates production and reduces costly back-and-forth.

According to Xometry's DXF preparation guide, the Drawing Interchange Format (DXF) remains the universal standard for laser cutting files. Created in 1982 as part of the first AutoCAD release, DXF's open-source nature ensures compatibility across virtually all CAD software and laser cutting systems.

Follow this step-by-step checklist to prepare production-ready files:

- Select the Right File Format: Submit vector files in DXF, AI, SVG, or PDF formats. Avoid raster images (JPG, PNG) which cannot define precise cut paths. DXF works universally; AI and SVG suit design-focused workflows.

- Set Proper Line Weights: Define all cut paths as hairline lines with approximately 0.1mm stroke width. Thicker lines confuse laser software about intended cut locations.

- Separate Operations by Layer: Use distinct layers or color codes to differentiate cutting, engraving, and etching operations. Clear layer separation prevents expensive production mistakes.

- Maintain Consistent Units: Stick to millimeters throughout your design. Mixed units or unclear scaling creates parts at wrong sizes—a surprisingly common error.

- Clean Your Geometry: Remove duplicate lines, overlapping paths, and stray construction elements. The laser attempts to cut everything in your file—double lines double your cost for that feature.

- Account for Kerf: Remember the laser removes 0.1-0.3mm of material width. Adjust slot widths and mating dimensions accordingly. For tight-fitting assemblies, add 0.1-0.2mm clearance to slots.

- Verify Minimum Feature Sizes: Holes should equal or exceed material thickness. Text requires minimum 3mm height with strokes no thinner than 0.5mm. Features smaller than these guidelines risk quality issues.

- Consider Nesting Efficiency: While many tube laser cutting services and flat sheet processors handle nesting automatically, designing parts that pack efficiently reduces quoted prices.

- Include Complete Documentation: Attach drawings specifying material type, thickness, quantity, tolerances, and any special requirements. Complete information enables accurate quoting and prevents assumptions.

- Request DFM Review: Before production begins, ask your vendor to review files for manufacturability. This step catches issues like impossible geometries, undersized features, or material-design mismatches.

Software selection influences your workflow efficiency. According to industry recommendations, several programs excel at creating laser-ready files:

- Inkscape: Free, cross-platform, and easy to learn. Excellent for straightforward 2D designs.

- Fusion 360: Cloud-based with real-time collaboration. Paid tiers start around $70/month but offer comprehensive CAD/CAM integration.

- Adobe Illustrator: Industry-standard design software at $20.99/month. Powerful but requires training investment.

- AutoCAD: The original DXF creator. Ideal for precision engineering drawings and complex assemblies.

When using an online laser cutting service, leverage their digital validation tools. According to Bendtech Group's production data, modern platforms integrate design validation and manufacturing feedback directly into ordering workflows. These automated checkers flag impossible geometries, undersized features, and material mismatches before you commit to production—preventing costly rework on high-value materials or large production runs.

Optimizing for Prototyping and Production Scaling

The journey from concept to production involves distinct phases, each with different priorities. Optimizing your approach for each phase prevents wasted time and money.

Rapid Prototyping Priorities:

During development, speed trumps per-unit cost. You need physical parts to validate fit, form, and function—not perfectly optimized production economics. Seek vendors offering 5-day or faster prototype turnaround. This rapid iteration capability compresses development cycles dramatically, letting you test multiple design revisions before committing to production tooling or large material orders.

For automotive component development, partners specializing in chassis, suspension, and structural applications understand the unique requirements these parts demand. Access to comprehensive DFM support during prototyping catches issues that would derail production later—far cheaper to fix problems in CAD than in manufactured parts.

Production Scaling Considerations:

When transitioning to volume production, economics shift. Now per-unit cost matters significantly, and consistency across thousands of parts becomes critical. Evaluate vendors on:

- Automated Production Capability: Manual handling limits throughput and introduces variability. Automated material handling and lights-out cutting enable consistent high-volume output.

- Quality System Maturity: Production runs demand statistical process control, documented inspection procedures, and traceable quality records. IATF 16949 certification demonstrates these systems exist.

- Capacity Planning: Can your vendor accommodate your forecast volumes? Discuss production scheduling, lead times, and contingency plans for demand fluctuations.

- Cost Optimization: Volume pricing should reflect genuine efficiency gains—not just discount percentages. Ask how the vendor reduces per-unit costs through nesting optimization, material utilization, and process efficiency.

Communication best practices smooth the entire process. Establish clear points of contact, define approval workflows, and document all specification changes. For complex assemblies, consider kick-off meetings to align expectations before production begins. The investment in upfront communication pays dividends in reduced errors and faster resolution when issues arise.

Whether you're searching for laser cut services for a one-off project or establishing long-term production partnerships, success follows preparation. Understanding your vendor's capabilities, preparing files correctly, and matching your approach to project phase requirements transforms laser cut steel from a manufacturing challenge into a reliable competitive advantage.

Frequently Asked Questions About Laser Cut Steel

1. How much does it cost to get steel laser-cut?

Laser cutting costs depend primarily on machine time rather than material alone. Setup fees typically range from $15-30 per job, with hourly labor rates around $60. Key cost drivers include material type and thickness, total cutting length, pierce count, and design complexity. Volume orders can reduce per-unit costs by up to 70% as fixed setup costs spread across more parts. Choosing thinner materials when structurally appropriate and simplifying designs with fewer intricate cuts are the most effective ways to reduce expenses.

2. Can a laser cutter cut through steel?

Yes, modern fiber and CO2 lasers cut through steel effectively. Fiber lasers excel at thin materials under 20mm, while high-power systems (20kW+) can cut carbon steel up to 60mm thick. Stainless steel typically cuts up to 40mm, and aluminum reaches approximately 30mm with premium equipment. The laser beam melts or vaporizes steel along a programmed path while assist gases blow away molten material, leaving clean, precise edges with tolerances as tight as ±0.1mm.

3. How thick of steel can a 1000W laser cut?

A 1000W laser cutting machine handles carbon steel up to approximately 5mm with quality results when using oxygen assist. For stainless steel with nitrogen assist, expect clean cuts up to 3-4mm. While maximum cutting depth reaches slightly higher, production-quality results with consistent edge finish occur within these ranges. Higher power systems scale proportionally—a 3kW laser handles 10mm stainless, while 6kW systems reach 16mm for reliable daily production work.

4. What materials cannot be cut on a laser cutter?

Several materials are unsafe or unsuitable for laser cutting. PVC releases toxic chlorine gas when heated. Polycarbonate and Lexan produce poor cut quality while releasing harmful fumes. Highly reflective polished metals like copper and brass can reflect laser energy back into the cutting head, risking equipment damage—though modern fiber lasers handle these better than CO2 systems. Materials containing halogens, certain plastics, and composites with unknown resin compositions should be avoided or verified with your fabricator.

5. What is the difference between fiber laser and CO2 laser cutting for steel?

Fiber lasers operate at 1.06µm wavelength, which steel absorbs more efficiently, enabling 2-5x faster cutting speeds on thin materials and 50-70% lower operating costs. They excel under 20mm thickness and handle reflective metals like aluminum well. CO2 lasers at 10.6µm wavelength deliver superior edge quality on thick plate above 25mm but run slower with higher maintenance costs ($1,000-2,000 annually vs $200-400 for fiber). For most sheet metal applications under 20mm, fiber technology offers compelling advantages.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —