Painevalu vs. painepainevalu: Avaintekijät valintaa varten

TL;DR

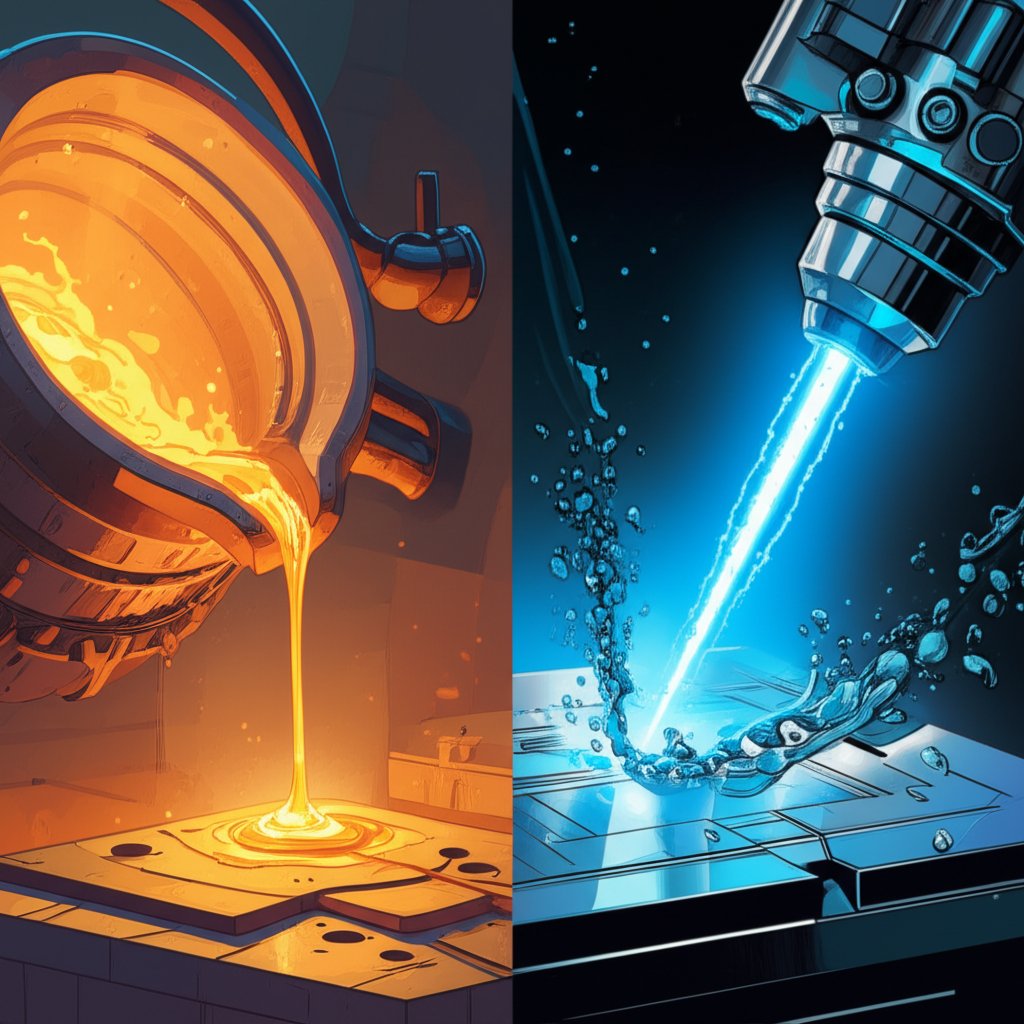

Painevalukappaleen ja painevalukappaleen välinen perusero on muotin täyttötapa. Graviittivalkistus käyttää painovoimaa täyttääkseen kestomuotin; hitaampi prosessi, joka tuottaa tiheämpiä, vahvempia osia, jotka sopivat lämpökäsittelyyn. Sen sijaan paineporaaus suositellaan sulaa metallia korkeassa paineessa, mikä mahdollistaa nopeat valujaksot, ohuempia seinämiä ja monimutkaisia suunnitteluja, ja tekee siitä ideaalin suurten sarjojen valmistukseen.

Perusprosessien erojen ymmärtäminen

Oikean valamismenetelmän valinta on kriittinen päätös valmistuksessa, ja sillä on suora vaikutus komponentin hintaan, laatuun ja suorituskykyyn. Painevalukseen (GDC) ja korkeapainevalukseen (HPDC) välillä oleva perusero on, miten sulanut metalli syötetään muottiin eli die:hen. Tämä yksittäinen ero luo ketjureaktion vaikutuksia kaikilla alueilla tuotantonopeudesta osan lopullisiin mekaanisiin ominaisuuksiin.

Painevalu (GDC) , jota kutsutaan myös pysyväksi muotiksi, on yksinkertaisempi kahdesta menetelmästä. Kuten nimi viittaa, se perustuu kokonaan painovoimaan. Sulanut metalli kaadetaan valurautaan muotin yläosassa olevan valujärjestelmän kautta. Metalli virtaa sitten alaspäin, täyttäen muottikammiota alhaalta ylöspäin. Tämä lempeä, laminaarinen virtaus minimoituu turbulenssia ja vähentää jäähtyneen ilman riskiä, mikä johtaa tiheämpään, vähemmän huokoiseen valukappaleeseen. Jähmettymisprosessi on hitaampaa, mikä edistää yhtenäisempää rakeen rakennetta ja parempia mekaanisia ominaisuuksia.

Korkean paineen hiekkaformiautomaattinen (HPDC) , puolestaan, on erittäin automatisoitu ja voimakas prosessi. Sulaa metallia kaadetaan "ammussylinteriin", jonka jälkeen se ruiskutetaan kovateräsmuottiin valtavalla paineella hydraulisen työntimen avulla. Tämä paine voi vaihdella 1 500:sta yli 25 000 paunaa neliötuumassa (psi), kuten alan asiantuntijat Novacast :ssa huomauttavat. Tämä nopea ruiskutus täyttää muotin millisekunneissa, mikä mahdollistaa monimutkaisten muotojen valmistamisen erittäin ohuilla seinämillä. Kuitenkin suuren nopeuden aiheuttama turbulenssi voi joskus jättää ilmaa sisään, mikä voi johtaa huokoisuuteen, ellei sitä hallita huolellisesti.

Vertaileva vertailu: keskeiset päätöstekijät

Insinöörien ja suunnittelijoiden on punnittava useita keskeisiä tekijöitä, kun valitaan näiden kahden menetelmän välillä. Vaikka toinen prosessi tarjoaa nopeutta ja monimutkaisuutta, toinen puolestaan tarjoaa lujuutta ja eheyttä. Paras vaihtoehto riippuu täysin sovelluksen tarkoista vaatimuksista tilavuudelle, hinnalle ja suorituskyvylle. Seuraava taulukko tarjoaa suoran vertailun tärkeimmistä päätöksenteon kriteereistä.

| Parametri | Painevalu (GDC) | Painevalu (HPDC) |

|---|---|---|

| Käytetty paine | Matala (vain painovoima) | Erittäin korkea (1 500 – 25 400 psi) |

| Syklin kesto / Nopeus | Hitaampi (minuutteja per sykli) | Nopeampi (sekunteja per sykli) |

| Työkalukustannus | Alempi | Korkeampi |

| Kappalehinta | Korkeampi (suurilla volyymeillä) | Alempana (suurilla volyymeillä) |

| Seinämän paksuus | Paksu (tyypillisesti > 3 mm) | Ohut (jopa 1 mm) |

| Pinta- käännetty suomeksi | Hyvä | Erinomainen |

| Mekaaniset ominaisuudet | Erinomainen (tiheä, karkeneva) | Hyvä (mahdollisuus huokosuuteen) |

| Tuotannon määrä | Matala – Keskitaso | Korkea hyvin korkeaan |

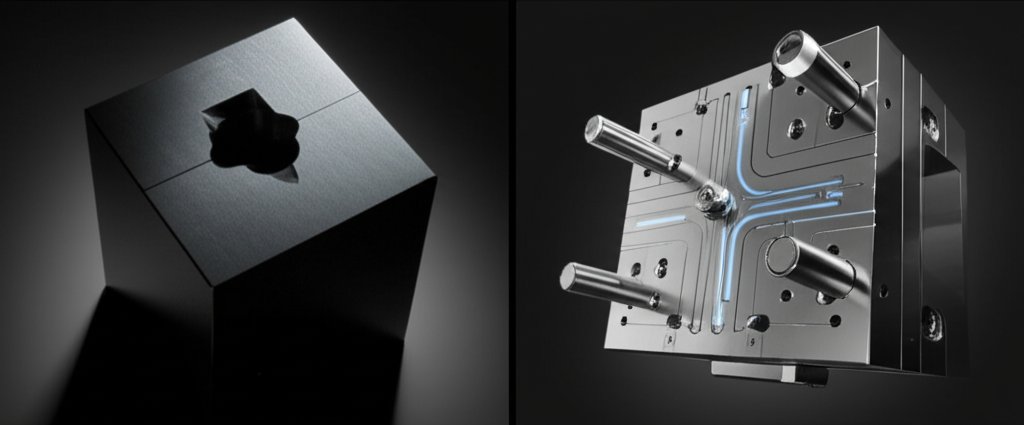

Merkitsevin kompromissi on usein työkalukustannusten ja tuotantonopeuden välillä . HPDC-muotit ovat monimutkaisia ja ne on valmistettava kovasta työkaluteräksestä kestämään äärimmäiset paineet ja lämpötilat, mikä tekee niistä merkittävästi kalliimpia. Kuitenkin nopeat sykliajat tarkoittavat, että suurten tuotantoserioiden (usein kymmeniätuhansia osia tai enemmän) kustannus per osa muuttuu hyvin alhaiseksi. GDC-työkalut ovat yksinkertaisempia ja edullisempia, mikä tekee niistä taloudellisen vaihtoehdon pienille ja keskikokoisille sarjoille, mutta hitaampi syklausaika tekee osakustannuksesta kilpailukyvyttömämmän suurella tuotantoasteella.

Lisäksi, mekaaniset ominaisuudet ovat ratkaiseva erottelutekijä. Painevalukkeen hitaampi, hallittu täyttö johtaa metallurgisesti terveeseen osaan, jossa on alhainen huokosuus. Tämä tekee GDC-komponenteista ideaalisia sovelluksia, joissa vaaditaan suurta lujuutta, painetiiviys ja kyky käsittää lämpökäsittelyä ominaisuuksien edelleen parantamiseksi. Vaikka HPDC-osat ovat lujuudeltaan hyviä, jääneen kaasun riski voi aiheuttaa sisäistä huokosuutta, mikä yleensä tekee niistä sopimattomia rakenteellisiin sovelluksiin tai lämpökäsittelyyn.

Edut ja haitat: Kumpaa menetelmää tulisi valita

Kunkin prosessin etujen ja rajoitteiden ymmärtäminen tarjoaa selkeän viitekehyksen oikean menetelmän valitsemiseksi projektia varten. Valinta perustuu suunnittelun, tuotantomäärän ja budjetin vaatimusten tasapainottamiseen.

Painevalukkeen edut

- Korkeat tuotantonopeudet: Koska syklin kesto mitataan sekunneissa, HPDC on yksi nopeimmista tavoista tuottaa suuria määriä metalliosia.

- Monimutkaiset geometriat ja ohuet seinämät: Korkea paine työntää metallin muottinsa jokaiseen yksityiskohtaan, mikä mahdollistaa monimutkaisten suunnitelmien ja erittäin ohuiden seinämien valmistuksen, jotka eivät ole mahdollisia pelkän painovoiman avulla.

- Erinomainen pinta-aineisto: Osat tulevat ulos muotista erittäin sileällä pinnalla, eikä usein tarvita jälkikäsittelyä lainkaan.

- Erinomainen mitallinen tarkkuus: HPDC tarjoaa korkean yhdenmukaisuuden ja tiukat toleranssit osasta toiseen, mikä vähentää koneenlisäystarvetta.

Painevalukkauksen edut

- Erinomaiset mekaaniset ominaisuudet: Tuloksena olevat tiiviit, alhaisen huokoisuuden valut ovat vahvempia ja luotettavampia, joten ne soveltuvat rakenteellisiin komponentteihin.

- Lämpökäsiteltävä: GDC-osia voidaan lämpökäsitellä parantamaan kovuutta, lujuutta ja sitkeyttä, mikä on merkittävä etu suorituskykyyn liittyvissä sovelluksissa.

- Alhaisemmat työkalukustannukset: Yksinkertaisempi muottirakenne johtaa huomattavasti alhaisempaan alkusijoitukseen, mikä tekee menetelmästä helpommin saatavilla pienemmille tuotantosarjoille tai prototyypeille.

- Laajempi seosten valinta: Laajempi joukko seoksia, mukaan lukien monet alumiini- ja kuparipohjaiset seokset, voidaan valaa onnistuneesti painevalumuotilla.

Kuinka valita

Päätöksen helpottamiseksi ota huomioon seuraavat suuntaviivat:

- Valitse painevalu, kun: Hankkeesi edellyttää suuria tuotantomääriä (esim. >10 000 yksikköä), monimutkaisia yksityiskohtia tai ohuita seiniä, ja korkealaatuinen pinnankuori on ratkaisevan tärkeää lopputuotteelle.

- Valitse painovoimavalu, kun: Osa vaatii korkean rakenteellisen lujuuden, sen täytyy voida lämpökäsitellä, tuotantomäärät ovat pienet tai keskisuuret, ja alhaisempi alkuperäinen työkalukustannus on etusijalla.

Tyypilliset käyttösovellukset ja materiaaliharkinnat

Kunkin prosessin erityispiirteet tekevät niistä sopivia eri materiaaleille ja käyttötarkoituksille. Tämä yhteys prosessin, materiaalin ja tuotteen välillä auttaa havainnollistamaan, missä kumpikin menetelmä loistaa käytännössä.

Käytettäväksi paineporaaus , yleisiä materiaaleja ovat muovautumisominaisuuksiltaan hyvät valuraudan seokset, kuten sinkki-, magnesium- ja alumiiniseokset, esimerkiksi A380. Nämä materiaalit ovat ihanteellisia nopeaan ja yksityiskohtaisiin komponentteihin, joissa nopeus ja tarkkuus ovat ratkaisevia. Tyypillisiä sovelluksia ovat monimutkaiset autoteollisuuden osat, kuten vaihdelaatikot, monimutkaiset elektroniikkakotelot, kuluttajatuotteiden kotelot ja koristevarusteet.

Käytettäväksi graviittivalkistus , painopiste on lujuudessa ja luotettavuudessa. Alumiiniseoksia, kuten A356, käytetään usein niiden erinomaisten valumuoto-ominaisuuksien ja lämpökäsittelyyn reagoimisen vuoksi. Myös kupari- ja sinkkiseokset ovat yleisiä. GDC-osia löytyy vaativista käyttöympäristöistä, kuten auton jousitusjärjestelmistä, jarrusylintereistä, moottorin sylinteripäistä ja korkean lujuuden rakennekiinnikkeistä. Kriittisiin autoteollisuuden sovelluksiin, joissa maksimilujuus ja väsymislujuus ovat olennaisia, myös muut prosessit, kuten kuumavalu, ovat tärkeä vaihtoehto. Palveluntarjoajat kuten Shaoyi (Ningbo) Metal Technology erikoistunut suorituskykyisten autoteollisuuden kylmämuovattujen osien valmistukseen ja tarjoaa vaihtoehtoisen tavan valmistaa robusteja metallikomponentteja tiukan laadunvalvonnan turvin.

Usein kysytyt kysymykset

1. Mikä on haittapuoli painevalukkeessa?

Painevalukkeen päärajoitukset ovat hitaampi tuotantonopeus ja suuremmat työvoimavaatimukset verrattuna painevalukkeeseen. Tämä tekee siitä kustannustehottomampaa erittäin suurille tuotantosarjoille. Lisäksi se ei sovellu hyvin erittäin monimutkaisten muotojen tai erittäin ohuiden seinämien valmistukseen, koska se perustuu ainoastaan painovoimaan muottikennon täyttämisessä.

2. Mikä on ero PDC:n ja GDC:n välillä?

Perusselvitys on käytetty voima muotin täyttämiseen. Gravitaatiopainevalukkeessa (GDC) sulanut metalli kaadetaan muottiin, ja se täyttää kaviteetin oman painonsa (painovoiman) avulla. Painevalukkeessa (PDC) sulanut metalli ruiskutetaan voimakkaalla paineella muottiin, tyypillisesti 1 500–25 400 psi:n välillä.

3. Mikä on painevaluksetuksen edut?

Painevaluksetuksen keskeisiin etuihin kuuluu alhaisemmat alkuperäiset työkalukustannukset, paremmat mekaaniset ominaisuudet huonomman huokoisuuden ansiosta sekä mahdollisuus lämpökäsittelyyn osien lujuuden parantamiseksi. Menetelmällä saavutetaan myös korkea mitatarkkuus ja hyvä pinnanlaatu, mikä tekee siitä kustannustehokkaan vaihtoehdon keskikokoisille tuotantosarjoille, joissa vaaditaan korkeaa osien eheyttä.

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —