Compound Dies Decoded: When They Outperform Progressive Stamping

What Makes Compound Dies Different From Other Stamping Methods

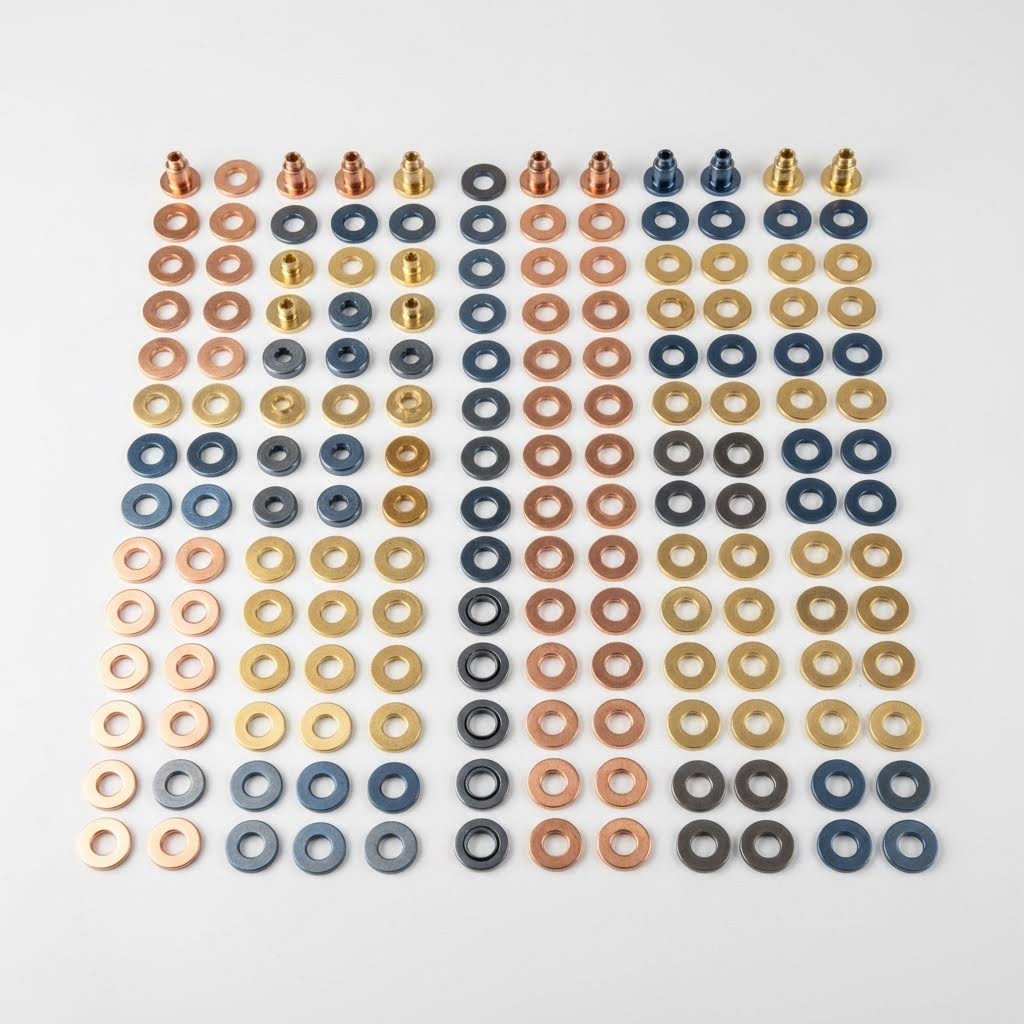

When precision matters most in metal stamping, not all tooling approaches deliver equal results. Imagine you need to produce thousands of flat washers with perfectly centered holes. How do you ensure every single piece meets exacting tolerances without secondary operations? This is exactly where compound dies shine.

A compound die is a specialized stamping tool that performs multiple cutting operations—typically blanking and piercing—simultaneously in a single press stroke, producing finished parts with superior flatness, concentricity, and dimensional accuracy.

Unlike single-operation tooling that completes just one task per stroke, this type of compound tool handles the entire cutting sequence at once. The result? Parts that come off the press ready to use, with no need for additional processing steps. This makes the compound die an essential option among the various types of stamping dies available to manufacturers today.

The Single-Stroke Advantage Explained

Why does completing all operations in one stroke matter so much? Consider what happens with sequential die stamping operations. When you blank a part in one station and then pierce holes in another, each handling step introduces potential problems. The material moves, gets repositioned, and faces new cutting forces at different times. Small variations accumulate, and suddenly your hole-to-edge distances vary from part to part.

With compound dies, the press descends once, and everything happens together. The outer profile is blanked while internal features are pierced in the same instant. There's no repositioning, no cumulative error, and no opportunity for the part to shift between operations. This single-stroke approach delivers consistency that sequential methods simply cannot match.

How Simultaneous Operations Create Precision

The mechanical principle behind this precision advantage is straightforward yet powerful. When cutting forces act on sheet metal from multiple directions at the same moment, they essentially balance each other out. The material is constrained uniformly during the cutting action, preventing the localized distortion that occurs when forces are applied sequentially.

Think of it this way: if you punch a hole in a flat piece of metal, the surrounding material experiences stress and can deflect slightly. Now, if you immediately blank the outer edge while that internal stress is still present, you've introduced dimensional variation. Compound dies eliminate this issue entirely by applying all cutting forces simultaneously, keeping the workpiece flat and stable throughout the operation.

This simultaneous cutting approach is particularly valuable when tight positional tolerances between features are critical. Electrical contacts, precision washers, and components requiring exact hole-to-edge concentricity benefit tremendously from this capability. The part geometry remains true because every cut happens in perfect synchronization, delivering the kind of accuracy that distinguishes high-quality manufacturing from acceptable results.

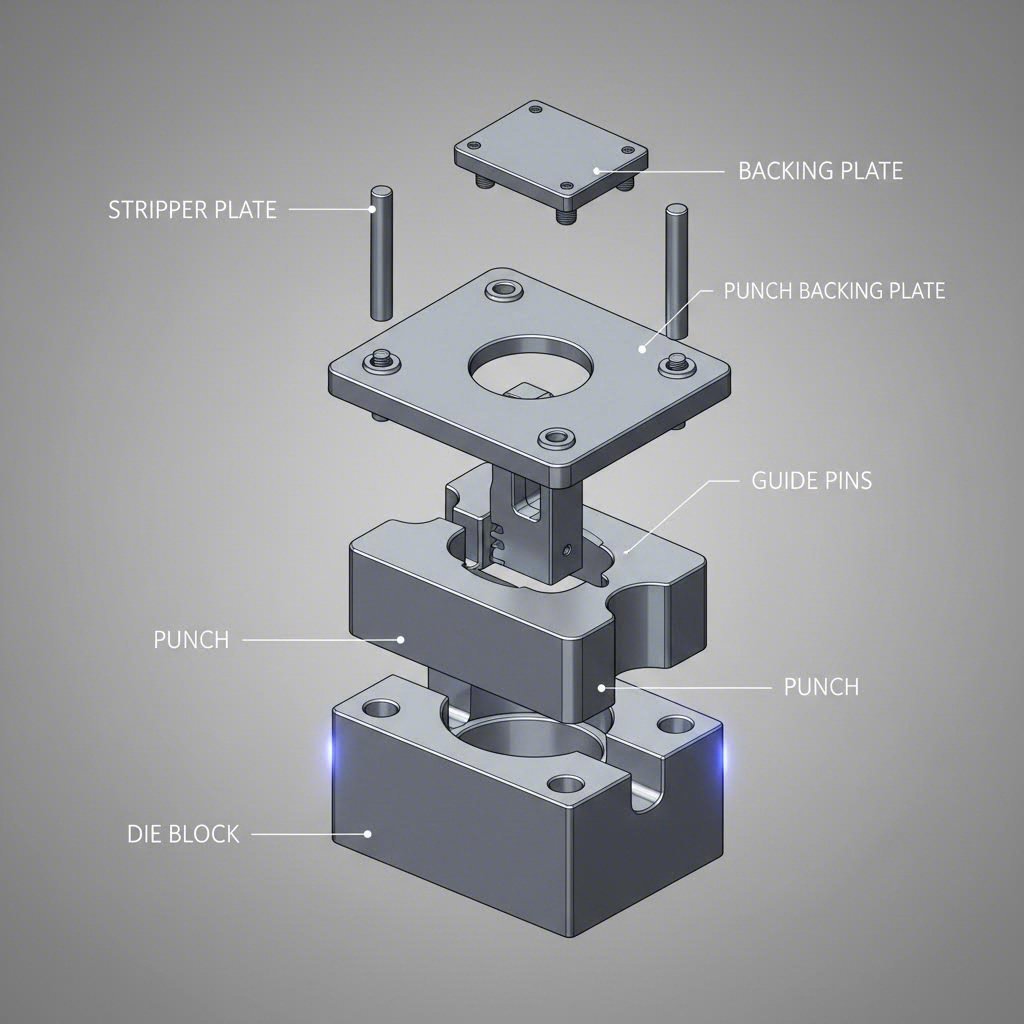

Essential Components and Mechanical Operation

Understanding how compound dies achieve their precision advantage requires a closer look at what's happening inside the tooling assembly. Each component serves a specific purpose, and together they create a mechanical system capable of producing parts with remarkable consistency. Let's break down these critical elements and explore how they work in concert during every press stroke.

Unlike simpler types of dies that may only require basic punch-and-die arrangements, compound tooling integrates multiple functional elements into a unified system. Here are the essential components you'll find in a well-designed compound die:

- Punch: The male portion of the die that descends into the material, applying force to cut or form the workpiece. Typically made of hardened steel or tungsten carbide for durability.

- Die Block: The female portion situated at the bottom of the assembly, housing the cutting edges and openings necessary for blanking the outer profile and ejecting finished parts.

- Stripper Plate: Removes the sheet material from the punch after each stroke, ensuring clean separation and preventing material from sticking to the tooling.

- Pilots: Precision alignment pins that locate the material accurately before cutting, ensuring consistent positioning from part to part.

- Backing Plates: Heavy steel plates that absorb and distribute the substantial cutting forces generated during operation, protecting the press bed and die components.

- Guide Pins: Align the upper and lower halves of the die assembly, maintaining perfect registration throughout the stroke cycle.

- Pressure Pads: Hold the workpiece firmly during cutting operations, preventing movement that could compromise dimensional accuracy.

Inside the Die Block Assembly

The die block deserves special attention because it's where much of the precision engineering comes together. This component provides the cutting edges for the blanking operation while simultaneously supporting the piercing punches that create internal features. The openings in the die block are machined to extremely tight tolerances, with clearances carefully calculated based on material type and thickness.

When you examine a compound die block, you'll notice it serves dual purposes. First, it provides the female cutting edge against which the blanking punch shears the outer profile. Second, it contains hardened inserts or bushings that guide the piercing punches as they create internal holes. This dual functionality is what enables simultaneous operations in a single stroke.

The die block also incorporates ejection mechanisms. After each part is cut, it must be removed from the die opening. Spring-loaded ejectors or positive knockout systems push finished parts clear of the tooling, allowing the next cycle to begin without interference. This ejection function is critical for maintaining consistent cycle times in production environments.

Critical Alignment Components

Precision in compound dies depends heavily on proper alignment between components. The pilots play a particularly important role here. Before the punches engage the material, pilot pins enter pre-punched holes or locate against material edges to position the workpiece precisely. This ensures that every part receives identical treatment regardless of minor variations in strip feeding.

Guide pins and bushings maintain alignment between the upper and lower die halves throughout the stroke. Even slight misalignment can cause uneven cutting, premature tool wear, or dimensional errors. High-quality compound dies use precision-ground guide components with minimal clearance to eliminate any possibility of lateral movement during operation.

So how does everything work together during an actual press stroke? Picture this sequence: the upper die half begins descending, and the stripper plate contacts the sheet material first, clamping it firmly against the die block. As the press continues downward, the pilots locate the workpiece precisely. Then, in one continuous motion, the blanking punch shears the outer profile while piercing punches simultaneously create internal features. The material is cut from both directions at the same instant, with forces balanced to maintain flatness.

After the cut is complete, the press reverses direction. The stripper plate holds the scrap skeleton as the punches withdraw, cleanly separating the finished part. Spring-loaded ejectors then push the completed component from the die opening, and the cycle is ready to repeat. This orchestrated sequence happens in fractions of a second, yet every component must perform its function flawlessly.

What distinguishes this from how a die in progressive stamping operations works is the absence of station-to-station movement. In progressive die tooling, the strip advances through multiple stations, with different operations performed at each stop. While progressive dies excel at complex parts requiring forming operations, compound dies deliver superior results when flatness and feature concentricity matter most.

Understanding these mechanical principles helps explain why component quality and maintenance matter so much. With so many elements working together under significant forces, even minor wear or misalignment can affect part quality. This technical foundation sets the stage for evaluating which part geometries truly benefit from compound die technology.

Part Geometry Suitability and Design Considerations

You've seen how compound dies work mechanically, but here's the practical question every engineer faces: will this approach actually work for your specific part? The term "simpler parts" gets tossed around frequently when discussing compound die stamping, yet it rarely gets defined with any precision. Let's change that.

When manufacturers describe ideal compound die applications, they're typically referring to flat or nearly flat components that require blanking combined with internal piercing operations. Think washers, shims, seals, gaskets, and spacers—parts where the relationship between internal and external features must remain perfectly consistent. According to The Fabricator, aerospace, medical, and industrial segments frequently specify these components with extremely precise requirements for dimensions, concentricity, and flatness to meet stringent industry certifications.

Ideal Part Geometries for Compound Dies

So what exactly makes a part geometry suitable for compound die stamping? The answer comes down to several key characteristics that align with the simultaneous cutting advantage these tools provide:

- Round flat parts with centered holes: Washers, flat rings, and spacers up to approximately 6 inches in diameter represent the classic compound die application.

- Electrical contacts and terminals: Components requiring precise hole-to-edge concentricity benefit from simultaneous ID and OD cutting.

- Thin-gauge materials: Parts stamped from material as thin as 0.0005 inches—where progressive metal stamping would introduce handling distortion—are excellent candidates.

- Components requiring tight concentricity: When prints specify maximum concentricity tolerances, compound tooling delivers results that sequential operations cannot match.

- Flat blanks with multiple pierced features: Any geometry where all required operations can be completed through cutting alone, without forming or bending.

- Parts for lithium-ion batteries and precision assemblies: Applications where both concentricity and flatness are critical performance requirements.

The tolerance capabilities deserve special attention here. Compound dies can hold concentricity between holes and outer profiles to within 0.001 inches, according to ART Metals Group. This level of precision becomes possible because all features are cut simultaneously—there's no opportunity for cumulative positioning errors to develop as the part moves between stations.

When Compound Dies Are Not the Right Choice

Understanding limitations is just as important as recognizing strengths. Certain part geometries simply don't align with what compound tooling does best. If your design falls into any of these categories, a progressive stamping die or transfer die approach likely makes more sense:

- Parts requiring bending or forming operations: Compound dies excel at cutting, not shaping. If your component needs flanges, ribs, or formed features, you'll need progressive or transfer tooling.

- Deep-drawn components: Cup-shaped parts, enclosures, or anything requiring significant material flow during forming cannot be produced in a single compound die stroke.

- Complex multi-step geometries: Parts that require sequential forming operations—where material must be worked progressively through multiple stages—fall outside the compound die sweet spot.

- Large parts with intricate internal features: While compound dies handle multiple piercings well, extremely complex internal patterns may be better served by progressive die stampings that can incorporate multiple cutting stations.

- Parts requiring in-die tapping or assembly: Secondary operations that need to happen between forming stages require the station-by-station approach of progressive tooling.

Here's a practical way to think about it: if your part can be completely finished through simultaneous cutting operations with no forming required, compound die stamping is worth serious consideration. The moment your geometry demands bending, drawing, or staged forming, you've moved beyond what this tooling type does best.

The decision ultimately comes down to matching your part requirements with tooling capabilities. Compound dies deliver unmatched precision for flat, cut-only geometries—but knowing when to choose alternative approaches is equally valuable. With geometry suitability established, the next logical question becomes: how do compound dies compare directly against progressive and transfer dies when project requirements vary?

Compound Dies Versus Progressive and Transfer Dies

Now that you understand which geometries suit compound dies, a bigger question emerges: how do you choose between compound, progressive, and transfer tooling when multiple approaches could technically work? This decision impacts everything from your initial investment to long-term cost-per-part economics. Let's build a structured framework that makes this choice clear.

Each die type serves distinct manufacturing needs, and selecting the wrong one means either overspending on tooling or sacrificing quality and efficiency. The comparison below breaks down the critical factors you should weigh before committing to any approach.

| Selection Criteria | Compound Dies | Progressive Dies | Transfer Dies |

|---|---|---|---|

| Production Volume | Low to medium (10,000–500,000 annually) | High volume (500,000+ annually) | Medium to high (50,000–1,000,000 annually) |

| Part Complexity | Simple flat geometries with piercing | Complex multi-stage forming and cutting | Large parts with multiple forming operations |

| Tolerance Capability | Excellent concentricity (±0.001") | Good (±0.002" to ±0.005") | Good to excellent depending on design |

| Typical Cycle Time | 30–60 strokes per minute | 60–1,500 strokes per minute | 15–40 strokes per minute |

| Initial Tooling Cost | Lower ($5,000–$50,000) | Higher ($50,000–$500,000+) | Highest ($75,000–$750,000+) |

| Ideal Applications | Washers, gaskets, electrical contacts | Brackets, connectors, complex assemblies | Automotive panels, large enclosures |

Volume and Complexity Decision Matrix

How do you know when your project crosses the threshold from one die type to another? Volume and complexity work together to guide this decision, and understanding their interaction prevents costly missteps.

For annual quantities below 50,000 parts with simple cut-only geometries, compound dies almost always make economic sense. The lower tooling investment pays off quickly, and you gain superior precision without the overhead of more complex progressive die stamping setups. When your part requires nothing beyond blanking and piercing, why pay for forming stations you won't use?

Once volumes climb above 500,000 annually and parts require bending, forming, or multiple sequential operations, progressive die and stamping approaches become compelling. The higher upfront investment spreads across more parts, driving your cost-per-piece down significantly. Progressive stamping die design incorporates multiple stations that perform different operations as the strip advances, making complex geometries economically viable at scale.

Transfer dies occupy a unique middle ground. When your parts are too large for standard coil-fed progressive operations—think automotive body panels or large enclosures—transfer stamping moves individual blanks between stations using mechanical fingers or robotic systems. This approach handles substantial forming operations on parts that simply won't fit in progressive tooling.

Consider this practical example: you need 100,000 flat copper contacts annually with centered holes requiring ±0.001" concentricity. Compound dies deliver that precision at reasonable tooling cost. Now imagine the same volume but with added bending and forming operations. Suddenly, progressive die stamping makes more sense despite higher tooling investment—the cycle time advantage and forming capability justify the cost.

Cost-Per-Part Analysis Across Die Types

Understanding upfront tooling costs is just the beginning. The real financial picture emerges when you calculate total cost per part across your expected production lifetime. Here's where many purchasing decisions go wrong.

Compound dies offer the lowest entry cost, typically ranging from $5,000 to $50,000 depending on complexity. For low-to-medium volume applications, this translates to competitive per-part economics even before considering the precision advantage. You're not paying for forming stations, complex strip layouts, or progressive stamping die design engineering that your simple geometry doesn't require.

Progressive dies demand substantially higher initial investment—often $50,000 to well over $500,000 for complex automotive applications. However, their blazing cycle speeds (sometimes exceeding 1,000 strokes per minute) crush per-part costs at high volumes. The math tips in their favor when you're producing millions of complex parts annually.

Transfer die stamping represents the highest tooling investment, but it enables operations impossible with other approaches. Large parts requiring deep drawing, heavy forming, or assembly operations within the die justify this premium when alternative methods simply can't deliver the geometry.

Part size creates another decision boundary. Generally, parts smaller than 6 inches suit compound or progressive approaches, while anything larger often points toward transfer dies. The physical constraints of coil-fed progressive stamping limit practical part dimensions, pushing larger geometries toward blank-fed transfer operations.

When evaluating your project, start with these questions: What's your annual volume requirement? Does your geometry demand forming operations, or can it be completed through cutting alone? What tolerance levels are non-negotiable? The answers position you clearly within this decision framework, pointing toward the tooling approach that balances precision, cost, and production efficiency for your specific needs. With die type selection clarified, the next consideration becomes equally important: which materials work best with your chosen approach?

Material Selection and Compatibility Guide

You've identified compound dies as the right tooling approach for your part geometry, but here's the next critical question: which materials actually perform well in this application? Most competitors mention material compatibility in passing without providing specifics. Let's fix that with actionable guidance you can apply directly to your next project.

The interaction between material properties and die design affects everything from achievable tolerances to tool life. Understanding these relationships helps you optimize both part quality and production economics. Here's how common metals perform in compound die operations:

| Material Category | Suitability | Key Considerations | Typical Applications |

|---|---|---|---|

| Carbon Steels | Excellent | Predictable cutting behavior; standard clearances work well; cost-effective tooling | Washers, shims, general industrial components |

| Stainless Steels | Good | Requires robust tooling; work hardening demands sharper edges; larger clearances needed | Medical devices, food processing, corrosion-resistant parts |

| Copper Alloys | Excellent | Ideal for electrical components; soft nature allows tight tolerances; watch for burr formation | Electrical contacts, bus bars, terminals |

| Brass | Excellent | Outstanding formability; clean cutting characteristics; minimal tool wear | Precision washers, decorative components, fittings |

| Aluminum | Good | Requires specific clearances (typically larger); galling potential; coating may help | Lightweight components, electronic shields, heat sinks |

Carbon steel progressive stamping applications benefit from the material's forgiving nature, and the same holds true for compound die work. Standard low-carbon steels cut cleanly with predictable behavior, making them ideal starting points when developing new tooling. Brass progressive stamping shares similar advantages—the material's excellent formability translates to clean edges and consistent results in compound operations.

Material Thickness Guidelines

Thickness range significantly influences compound die suitability. While these tools handle an impressive span of material gauges, certain ranges optimize the simultaneous cutting advantage you're seeking.

For most applications, compound dies perform best with material thicknesses between 0.005 inches and 0.250 inches. Within this range, the balanced cutting forces that create superior flatness work as intended. Thinner materials (down to 0.0005 inches for specialized applications) require careful stripper pressure control to prevent distortion during handling. Thicker materials demand proportionally greater press tonnage and more robust tooling components.

Here's a practical guideline: as material thickness increases, clearance between punch and die must also increase—typically calculated as a percentage of stock thickness. For mild steel, expect clearances around 5-7% per side. Stainless steel requires 6-8%, while softer materials like copper progressive stamping applications may work with clearances as low as 3-5%.

Hardness and Ductility Considerations

Material hardness directly affects your tooling design decisions. Harder materials generate greater cutting forces and accelerate punch wear. They also require larger die clearances to prevent excessive tool stress and premature failure.

When working with harder materials like stainless steel or spring steel, expect to specify:

- Larger clearances: Typically 1-2% greater than soft steel equivalents

- Harder tool steels: D2, M2, or carbide inserts for cutting edges

- More frequent sharpening: Reduced intervals between maintenance cycles

- Increased press tonnage: Higher forces needed to shear the material cleanly

Softer, more ductile materials present different challenges. While copper and brass allow tighter tolerances and generate less tool wear, their malleability can cause burr formation on cut edges. The material tends to flow rather than shear cleanly, particularly if clearances are too tight or cutting edges have dulled.

Ductility also affects how materials behave during the simultaneous cutting action. Highly ductile metals may exhibit more rollover on cut edges—that rounded area where material bends before shearing. For applications requiring clean, square edges, adjusting clearances and maintaining sharp tooling becomes essential.

One often-overlooked factor is material temper. Annealed materials cut more easily but may produce more burrs. Work-hardened or tempered materials shear more cleanly but demand greater cutting force. Specifying the correct temper for your dies and stamping operations can meaningfully impact both part quality and tool life.

Understanding these material-specific behaviors positions you to optimize both die design and production parameters. But even the best material selection won't overcome poor maintenance practices—which brings us to the critical topic of keeping your tooling in peak condition.

Maintenance Requirements and Troubleshooting

You've selected the right materials and tooling approach, but here's a reality check: even perfectly designed compound dies deteriorate without proper care. Surprisingly, this critical topic gets almost no attention in most stamping resources. Yet maintenance practices directly determine whether your tooling produces quality parts for 100,000 cycles or 1,000,000. Let's fill that gap with actionable maintenance guidance.

As one precision manufacturer noted, "If you aren't able to keep your tools sharp, they won't go into the press and you won't be blanking any parts." This reality applies equally to compound dies—maintenance isn't optional, it's essential for consistent production.

Every time your compound dies come out of the press, a systematic inspection protocol should follow. Here are the critical checkpoints that keep tooling performing at peak condition:

- Cutting Edge Condition: Examine punch and die cutting edges for chips, cracks, or visible wear patterns. Dull edges produce burrs and require increased cutting force.

- Clearance Verification: Measure clearances between punch and die at multiple points. Uneven wear creates inconsistent clearances that affect part quality.

- Alignment Checks: Verify guide pin and bushing fit. Excessive play indicates wear that will cause dimensional variation and accelerated tool deterioration.

- Spring Tension: Test stripper springs and ejector mechanisms. Weakened springs cause incomplete stripping and part handling problems.

- Lubrication Requirements: Inspect guide surfaces, moving components, and wear plates. Proper lubrication prevents galling and extends component life.

- Pilot Condition: Check pilots for wear or damage that could affect part positioning accuracy.

Sharpening Schedules and Edge Maintenance

When should you sharpen your tooling? The answer depends on material type, production volume, and your quality requirements—but waiting until parts fail inspection means you've waited too long.

Establish sharpening intervals based on hit counts rather than calendar time. For carbon steel applications, many shops schedule sharpening every 50,000 to 100,000 strokes. Stainless steel and harder materials may require attention every 25,000 to 50,000 strokes due to accelerated edge wear. Track these intervals rigorously—progressive tool and die operations that skip scheduled maintenance inevitably face unplanned downtime.

Modern surface grinding equipment has transformed maintenance efficiency. According to DCM Tech, rotary surface grinders can complete tool sharpening in three to four hours versus eight to twelve hours with traditional equipment. This time savings translates directly to faster turnarounds and more production uptime.

The grinding process itself matters for tool longevity. Surface grinding removes worn material without introducing heat that could weaken the hardened cutting edges. As one tool room machinist explained, "Grinding gives you a much stronger product because you don't have to introduce heat through a weld, which can weaken a fineblanking tool due to the pressure it has to withstand." The same principle applies to compound die maintenance—regrinding preserves tool integrity better than alternative repair methods.

Extending Die Lifespan Through Proper Care

Recognizing wear before it causes quality problems separates proactive maintenance from reactive firefighting. Here are the warning signs that indicate your tooling needs attention:

- Burr Formation: Increasing burr height on cut edges signals dull cutting edges or clearance problems. Address this before burrs create downstream issues.

- Dimensional Drift: When parts gradually move out of tolerance, wear has likely affected critical alignment components or cutting edges.

- Increased Cutting Force: If press tonnage requirements creep upward, dull edges are forcing the material rather than shearing it cleanly.

- Inconsistent Part Flatness: Stripper pressure problems or uneven cutting edge wear can introduce part distortion that wasn't present initially.

- Unusual Noise or Vibration: Changes in operational sounds often indicate alignment issues or component wear requiring investigation.

Proper maintenance extends tool life dramatically while preserving part quality. Progressive tooling and compound dies alike benefit from documented maintenance histories that track interventions and their effects. This data helps predict future maintenance needs and optimize sharpening intervals for your specific applications.

Troubleshooting Common Issues

When quality problems arise, systematic troubleshooting identifies root causes quickly. Here's a practical guide to the most frequent compound die issues:

| Problem | Likely Cause | Corrective Action |

|---|---|---|

| Excessive Burrs | Insufficient clearance or dull cutting edges | Verify and adjust clearances; sharpen or replace worn components |

| Part Distortion | Improper stripper pressure or unbalanced cutting forces | Adjust stripper spring tension; verify even pressure distribution |

| Dimensional Variation | Alignment wear or cutting edge deterioration | Check guide pins and bushings; inspect for uneven wear patterns |

| Inconsistent Hole Position | Pilot wear or strip feeding issues | Replace worn pilots; verify feed accuracy and strip guidance |

| Premature Tool Failure | Misalignment between upper and lower die halves | Use alignment mandrel to check and adjust turret alignment |

According to troubleshooting guidance from DGMF Mold Clamps, regularly using an alignment mandrel to check machine tool turret and mounting base alignment prevents the inconsistent wear that causes progressive tools and compound dies to fail prematurely. This simple practice catches problems before they damage expensive tooling.

When clearance problems persist, remember that adjustments should be gradual. Each adjustment should preferably not exceed 0.15mm to avoid overcorrection. Use lower punching speeds when troubleshooting to reduce stress on components while identifying the root cause.

With maintenance protocols established, you're equipped to keep your compound dies producing quality parts consistently. But understanding where these tools deliver the greatest value across different industries reveals even more opportunities to leverage their precision advantages.

Industry Applications and Automotive Manufacturing

You've mastered the technical fundamentals of compound dies—now let's explore where these tools deliver the greatest impact across real-world manufacturing. From the electrical contacts in your smartphone to the precision washers in automotive braking systems, compound dies quietly enable the products we depend on daily. Understanding these applications reveals why certain industries simply cannot compromise on the precision advantages this tooling approach provides.

Automotive Precision Component Applications

When your brakes engage, you're trusting components stamped to tolerances measured in thousandths of an inch. Automotive manufacturers rely heavily on compound dies for flat, precision components where dimensional accuracy directly affects performance and safety. Consider these critical applications:

- Brake system shims and washers: These components require perfect flatness and concentricity to ensure consistent hydraulic pressure distribution.

- Transmission spacers: Tight thickness tolerances prevent gear play and ensure smooth power transfer.

- Fuel system gaskets: Precise sealing surfaces prevent leaks that could compromise vehicle safety and emissions compliance.

- Electrical grounding contacts: Consistent hole-to-edge relationships ensure reliable electrical connections throughout the vehicle.

- Sensor mounting rings: Flat, concentric components maintain proper sensor alignment for accurate readings.

The automotive industry's quality demands make IATF 16949 certification essential for tooling suppliers. According to Master Products, this certification "creates a baseline for the quality you can expect when contracting out your automotive metal stamping project," with a primary focus on "prevention of defects and production variances, as well as minimizing scrap and waste." When selecting suppliers for automotive components progressive stamping operations, this certification signals commitment to the systematic quality management that OEMs require.

Modern automotive stamping increasingly relies on CAE (Computer-Aided Engineering) simulation to optimize die designs before any metal is cut. This approach identifies potential issues with material flow, stress concentrations, and dimensional stability during the design phase—saving both time and tooling costs. Suppliers offering advanced simulation capabilities alongside IATF 16949 certification, like Shaoyi's precision stamping die solutions, can accelerate development cycles while ensuring defect-free production results.

Electrical and Electronics Industry Uses

If automotive applications demand precision, electrical and electronics manufacturing takes requirements to another level entirely. The progressive die metal stamping process works well for high-volume connector housings and complex terminals, but compound dies remain the preferred choice when concentricity and flatness are non-negotiable specifications.

Stamped electrical contacts represent perhaps the most demanding compound die application. As Composidie explains, these fundamental components "serve as the interface between the conductor and the point of connection, ensuring reliable electrical contact." Any dimensional variation can create resistance that generates heat, causes signal degradation, or leads to premature failure.

Critical electronics applications include:

- Battery contacts: Lithium-ion battery assemblies require flat contacts with precise hole locations for consistent current flow.

- Connector terminals: The pins and receptacles in multi-pin connectors must maintain exact dimensional relationships for reliable mating.

- Grounding washers: EMI shielding applications demand perfect contact surfaces to ensure effective grounding.

- Heat sink mounting hardware: Flat, precisely dimensioned components ensure maximum thermal transfer.

- PCB mounting spacers: Consistent thickness prevents board stress and ensures proper component clearance.

The progressive die stamping process excels at producing complex formed terminals at high volumes, but when your application requires nothing more than perfectly flat, precisely positioned features, compound tooling delivers superior results at lower tooling costs.

Aerospace and Medical Device Applications

Aerospace and medical device manufacturing share a common thread: failure is not an option. Both industries specify materials, processes, and tolerances with extreme care, and compound dies serve critical roles in producing the precision flat components these sectors demand.

According to CEI Precision, their team has "served practically every industry where precision is non-negotiable, ensuring that every program results in the same high level of stamping quality and consistency." From precision surgical devices and dental tools to fuel cell and aerospace components, compound stamping capabilities address applications where dimensional accuracy directly affects human safety.

Aerospace applications often involve exotic materials—titanium, Inconel, and specialized alloys that demand robust tooling and precise process control. Medical devices frequently require stainless steel or titanium components that must meet biocompatibility requirements while maintaining tight dimensional specifications. In both cases, the simultaneous cutting action of compound dies delivers the concentricity and flatness these demanding applications require.

Multi-Hit Compound Tooling for Higher Volumes

What happens when your part geometry suits compound die stamping but your volumes push toward progressive stamping territory? Multi-hit compound tooling bridges this gap, combining the precision advantages of simultaneous cutting with higher production rates.

In a multi-hit configuration, the strip advances through the compound die multiple times, with each stroke producing a finished part from a different location on the strip. This approach multiplies output without sacrificing the concentricity and flatness benefits that make compound dies valuable. It's particularly effective for small parts where multiple cavities can fit within a single die footprint.

The progressive stamping process remains superior for truly complex parts requiring forming operations, but multi-hit compound tooling offers a compelling middle ground. You gain increased productivity while maintaining the precision characteristics that sequential operations simply cannot match.

Whether your application involves automotive braking systems, precision electrical contacts, or life-critical medical devices, compound dies deliver measurable quality advantages when flatness and concentricity matter most. Understanding these industry applications helps you recognize opportunities where this tooling approach can improve your manufacturing outcomes—and positions you to make informed decisions when evaluating your next stamping project.

Selecting the Right Compound Die Solution for Your Project

You've absorbed the technical details, understood material considerations, and explored industry applications—but now comes the moment of truth. How do you actually evaluate whether compound dies fit your specific project? And once you've made that determination, how do you find a tooling partner capable of delivering results? Let's transform everything you've learned into a practical decision-making framework.

The difference between a successful stamping project and a costly mistake often comes down to asking the right questions at the right time. According to industry experts, "Before you can effectively evaluate potential suppliers, you must have a crystal-clear understanding of your own project needs. A thorough internal assessment prevents miscommunication and ensures you are comparing suppliers on the right criteria."

Your Compound Die Project Checklist

Before contacting any supplier, work through this step-by-step evaluation process. Each question builds on the previous, guiding you toward a clear go/no-go decision for compound die tooling:

- Define your part geometry completely. Is your component flat or nearly flat? Does it require only blanking and piercing operations, or will forming be necessary? If bending or deep drawing is involved, compound dies aren't your answer—consider progressive die or transfer die approaches instead.

- Document critical tolerance requirements. What concentricity specifications must you achieve? If hole-to-edge relationships need to stay within ±0.001", compound dies deliver this precision naturally. Looser tolerances may allow more tooling options.

- Calculate your annual volume requirements. Are you producing 10,000 parts or 10 million? Compound dies excel in the low-to-medium range (roughly 10,000 to 500,000 annually). Higher volumes may justify progressive tooling despite greater upfront investment.

- Specify material type and thickness. Confirm your material falls within compound die capabilities. Carbon steels, brass, copper alloys, and aluminum all work well. Document exact thickness and temper specifications for accurate supplier quoting.

- Identify secondary operation requirements. Will parts need heat treating, plating, deburring, or assembly? Partners offering these value-added services in-house simplify your supply chain considerably.

- Establish prototype and production timelines. When do you need first articles? What lead time is acceptable for production tooling? Rapid prototyping capabilities—sometimes available in as little as 5 days—can dramatically accelerate your development cycle.

- Define quality certification requirements. Does your industry mandate specific certifications like ISO 9001 or IATF 16949? Eliminate suppliers who cannot provide required documentation before investing time in detailed discussions.

This systematic approach ensures you've thought through every critical factor before engaging suppliers. It also provides the detailed specifications partners need to deliver accurate quotes and realistic timelines.

Evaluating Tooling Partners

With your project requirements documented, you're ready to assess potential suppliers. But what separates adequate vendors from true manufacturing partners? Look beyond price-per-part to evaluate these essential capabilities:

Engineering expertise matters more than you might expect. The best stamping suppliers are true partners who provide engineering support, not just manufacturing capacity. Their early involvement in Design for Manufacturability (DFM) reviews can lead to significant cost savings and more robust part designs. Ask potential partners about their engineering resources and whether they'll collaborate on optimizing your design before tooling begins.

Quality management systems provide assurance. As noted by industry guidance, "A robust quality management system (QMS) is non-negotiable. It is the foundation of receiving consistent, reliable parts that meet your specifications." Certifications like ISO 9001 represent third-party validation of a supplier's commitment to quality processes.

Rapid prototyping accelerates development. The ability to produce prototype parts quickly—sometimes within days rather than weeks—lets you validate designs before committing to production tooling. According to manufacturing experts, prototyping is "the critical testing phase where ideas are shaped, refined, and validated for manufacturing and market success." Partners with rapid prototyping capabilities help you identify issues early when changes are still inexpensive.

First-pass approval rates reveal process maturity. When evaluating suppliers, ask about their first-pass approval rates on similar projects. A 93% first-pass approval rate, for example, indicates robust processes that consistently deliver parts meeting specifications without repeated iterations. This metric directly affects your timeline and total project cost.

Understanding the purpose of bypass notches in stamping dies and similar technical details separates knowledgeable suppliers from order-takers. Partners who can discuss these fine points demonstrate the expertise needed to troubleshoot problems and optimize your production.

Design-to-production capabilities streamline your supply chain. Suppliers offering comprehensive services—from initial die design through high-volume manufacturing—eliminate coordination headaches. Working with a single partner like Shaoyi's mold design and fabrication team who manages the entire process reduces handoff errors and accountability gaps.

Consider capacity and scalability as well. Can the supplier meet your volume demands today and accommodate growth tomorrow? Partners who offer inventory management programs and flexible scheduling help you maintain production flow without excess on-hand stock.

The ideal compound die partner combines precision tooling expertise with engineering support, rapid prototyping capability, and proven quality systems—transforming your specifications into production-ready parts that meet requirements from the first run.

The selection process ultimately comes down to finding a supplier whose capabilities align with your specific needs. A prog die project with simple geometry and modest volumes doesn't require the same partner as a complex die and stamping program serving automotive OEMs. Match partner strengths to project requirements, verify their track record with similar applications, and establish clear communication channels before committing.

Whether you're exploring compound dies for the first time or optimizing an existing stamping program, the principles remain consistent: define requirements thoroughly, evaluate capabilities systematically, and choose partners who demonstrate both technical competence and commitment to your success. The precision advantages compound dies offer are only realized when every element—from tooling design through production and maintenance—aligns with your quality objectives.

Frequently Asked Questions About Compound Dies

1. What is the difference between a compound die and a combination die?

Compound dies perform only cutting operations—blanking and piercing—simultaneously in a single press stroke. Combination dies, however, handle both cutting and forming operations together. This means compound dies excel at producing flat parts with superior concentricity and flatness, while combination dies can create parts requiring bends or forms alongside cutting. For applications demanding tight positional tolerances between holes and edges without forming needs, compound dies deliver precision that combination dies cannot match.

2. What is the difference between compound die and progressive die stamping?

Compound dies complete all cutting operations simultaneously in one stroke at a single station, producing finished parts with exceptional concentricity and flatness. Progressive dies advance material through multiple stations, performing different operations at each stop. While progressive dies suit high-volume complex parts requiring forming operations, compound dies deliver superior precision for simpler flat geometries at lower tooling costs. IATF 16949 certified suppliers like Shaoyi optimize both approaches using CAE simulation for defect-free results.

3. What types of parts are best suited for compound die stamping?

Compound dies work best for flat components requiring blanking with internal piercing—washers, shims, electrical contacts, gaskets, and precision rings up to approximately 6 inches in diameter. Parts needing tight concentricity tolerances (±0.001 inches) between holes and outer profiles are ideal candidates. However, components requiring bending, deep drawing, or complex multi-stage forming are not suitable and should use progressive or transfer die approaches instead.

4. How do I maintain compound dies for optimal performance?

Establish sharpening schedules based on hit counts rather than calendar time—typically every 50,000 to 100,000 strokes for carbon steel. Regular inspections should check cutting edge condition, clearance verification, alignment components, spring tension, and lubrication. Watch for warning signs like burr formation, dimensional drift, and increased cutting force. Modern surface grinders can complete tool sharpening in 3-4 hours, minimizing downtime while extending die lifespan significantly.

5. What materials work best with compound dies?

Carbon steels offer excellent compatibility with predictable cutting behavior. Brass and copper alloys are ideal for electrical components, allowing tight tolerances with clean cutting. Stainless steels require robust tooling with larger clearances due to work hardening. Aluminum needs specific clearances to prevent galling. Material thickness typically ranges from 0.005 to 0.250 inches, with clearances calculated as percentages of stock thickness based on material hardness and ductility.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —