Alumiini- ja kuparikaapeli: Todellinen virtakapasiteetti, ei mainosjulisteiden lupauksia

Alumiini- ja kuparikaapelien perusteet

Kun kuulet sanonnan alumiini- ja kuparikaapeli , mikä tulee mieleesi? Ehkä kuvittelet paksuja sähkölinjoja, jotka venyvät moottoriteiden yli, tai asennuksia, jotka on piilotettu kotisi seinien taakse. Mutta alumiini johto ja kuparilangat erosuhteet menevät paljon pidemmälle kuin valmistajan esitteessä on lueteltu. Oikea valinta vaikuttaa turvallisuuteen, kustannuksiin ja pitkän aikavälin luotettavuuteen – käydään siis läpi, mitä kaapelit todella ovat, miten ne eroavat toisistaan ja missä kumpikin toimii parhaiten käytännössä.

Mikä alumiini- ja kuparikaapeli tarkoittaa sähköjärjestelmissä

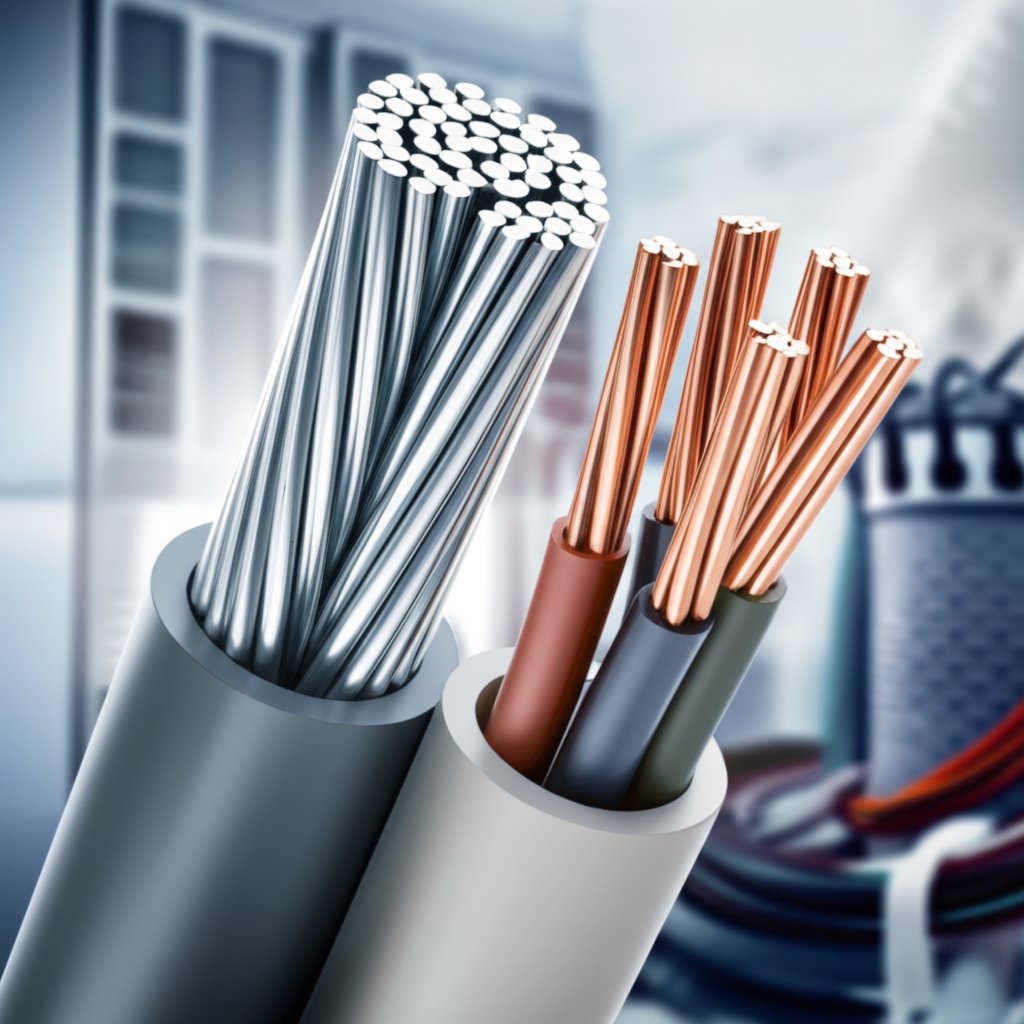

Sähkökielellä kaapeli on kokoonpano, joka koostuu yhdestä tai useammasta osasta kapellimestarit (metalli, joka johtaa virtaa), eristys (oikosulkujen estämiseksi) ja joskus ulkokerros takki lisäsuojaukseen. Johtimen materiaali on yleensä joko kiinteä tai kierretty (useita ohuita johtimia vähennettyyn taipumiseen). Käytetty metalli – alumiini tai kupari – määrittää, kuinka suuren virran tietyllä kootulla johtimella voidaan turvallisesti kuljettaa (sen virtakapasiteetti ). Kuinka helppoa asennus on ja kuinka hyvin se toimii ajan kuluessa.

On helppo sekoittaa johto ja kaapeli . Nopea ero:

- Jousi: Yksittäinen sähköjohto, voi olla kiinteä tai kierretty.

- Kaapeli: Useiden johtimien yhdistelmä, usein eristetyillä ja vaipattuilla. Käytetään suurempien virtojen tai monimutkaisten piirien yhteydessä.

Sekä alumiini että kupari ovat yleisiä johtimia, mutta niiden ominaisuudet tarkoittavat, että ne soveltuvat eri käyttökohteisiin.

Missä kuparikaapelointi hallitsee ja miksi

Jos avaat paneelin useimmissa kodeissa tai kriittisissä tiloissa, huomaat että kuparilangat ovat kaikkialla. Miksi? Kupari tarjoaa erinomaisen sähkönjohtavuuden, eli se johtaa suurempaa virtaa annetulla halkaisijalla. Se on myös joustavampaa, vähemmän altis korroosiolle ja kestää paremmin toistuvaa taivuttelua ja värähtelyä verrattuna alumiiniin. Näiden ominaisuuksien ansiosta kupari on ensisijainen valinta seuraaviin kohteisiin:

- Haarautuvat piirit asuontojen ja toimistorakennusten sähköasennuksissa (pistorasiat, valaistus, kodinkoneet)

- Kriittiset teollisuuskontrollit ja koneet

- Ympäristöt, joissa esiintyy runsaasti värähtelyä tai tiukkoja taivutuksia

Mukaan lukien teollisuuslähteet , kuparin kestävyys ja korkea virtakapasiteetti tarkoittavat, että se säilyy suosituimpana valintana sähköjohdotukseen, joka on tarkoitettu kestämään vuosikymmeniä tai käsittämään monimutkaisia kuormia.

Kun alumiinijohdotus on perusteltua painon ja hinnan vuoksi

Kuvittele, että asennat satoja metriä kaapelia tehtaaseen tai asennat ilmajohtoja. Tässä tapauksessa paino ja materiaalikustannukset ovat erittäin tärkeitä. Alumiinikaapeli on noin kolmannes kevyempi kuin kupari ja sen materiaalikustannukset voivat olla selvästi alhaisemmat. paljon edullisempi. Vaikka se johtaa sähköä huonommin (vaatii suuremman halkaisijan samalla virtakapasiteetilla), sen alhainen hinta ja kevyt paino tekevät siitä ideaalisen valinnan seuraaviin kohteisiin:

- Päävirtajohtoihin liike- ja teollisuusrakennuksissa

- Ylikorkeisiin sähkölinjoihin (jakelu- ja siirtolinjat)

- Laajiin sähkölinjoihin ja energiakäyttöjärjestelmiin

- Autojen sähköjohtoihin, joissa painon säästö on kriittistä

Alumiinin asennuksessa on oltava huolellinen sen laajenemisen, kutistumisen ja hapettumisen vuoksi, mikä voi johtaa yhteysongelmiin, ellei sitä hallita oikein (lähde) .

| Käyttö | Kuparikabeli | Alumiinikaapeli |

|---|---|---|

| Rakennuksen sähköverkon haarakohteet | Suositeltu luotettavuuden ja joustavuuden vuoksi | Harvoin käytetty |

| Pääjakelukaapelointi (rakennukset) | Yleinen, erityisesti premium-projekteissa | Laajasti käytetty kustannusten säästämiseksi |

| Maanpäälliset sähkölinjat | Rajoitettu (paino on rajoittava tekijä) | Alan standardi |

| Teollisuuden jakokiskot | Käytetään korkean luotettavuuden varmistamiseksi | Käytetään suurjakaumaisiin asennuksiin |

| Autojen sähköasennusjohdot | Käytetään kovien rasitusten alueilla | Käytetään yhä enemmän painon vähentämiseksi |

Tärkeimmät huomiot: Käytä kuparilankaa, kun tarvitset maksimiluotettavuutta, joustavuutta ja pitkää käyttöikää. Valitse alumiinilanka suurjännitteen jakamiseen, kun paino ja kustannukset ovat ensisijaisia – mutta muista aina noudattaa asennuksen parhaita käytäntöjä turvallisuuden varmistamiseksi.

Ymmärtää todellisten etujen ja haittapuolten erot alumiini- ja kuparikaapeli auttaa sinua tekemään fiksumpia ja turvallisempia valintoja. Riippumatta siitä, sähköistätkö kotia, tehdasta tai sähköverkkoa, perustaito alumiini- ja kuparikaapeli on ensimmäinen askel onnistuneeseen projektiin. Seuraavissa osioissa käydään tarkemmin läpi standardeja, mitoituksia ja asennusta, jotta voit valita oikean ratkaisun tarpeidesi mukaan.

Koodit ja standardit – perustiedot suunnittelijoille

Kuulostaa monimutkaiselta? Jos olet koskaan miettinyt, miksi jotkin projektit käyttävät alumiinijohtimia vaikka toiset pitäytyvät kuparissa, ratkaisu usein riippuu koodien ja standardien määräyksestä. Näitä sääntöjä ei ole vain paperilla – ne ovat turvallisten ja luotettavien asennusten perusta. Selvitään, mitä sinun tulee tietää, jotta seuraava projekti täyttää kaikki vaatimukset, alkaen alumiini- ja kupariliitännöistä oikean kokoamisesta ja dokumentoinnista.

Koodiperheiden ja niiden soveltamisalueiden ymmärtäminen

Kuvitellaan, että suunnittelet rakennuksen tai teollisen kohteen sähköjärjestelmää. Mitä sääntöjä sinun tulee noudattaa? Vastaus riippuu sijainnistasi ja käyttötarkoituksestasi:

| Koodiperhe | Keskeiset aiheet | Sovellettavuusalue |

|---|---|---|

| NEC (NFPA 70, Yhdysvallat) | Johtimen materiaali, kootaulukot, lämpötilaluokitus, merkinnät, liitosten vaatimukset | Kotimainen, kaupallinen ja teollinen sähköasennus Yhdysvalloissa |

| IEC (kansainvälinen) | Johtimetyypit, virta-alueet, yhdenmukaistetut värikoodit, eristysluokat | Maailmanlaajuisesti, erityisesti Eurooppa, Aasia ja Afrikka |

| BS (brittiläiset standardit) | Johtimien mitoitus, asennuskäytännöt, merkinnät, liitännät | Iso-Britannia ja Commonwealth-maat |

| ANSI/NEMA (liitännät) | Liitännelistat alumiini- ja kupariksi sekä alumiini-alumiini, mekaaniset ja sähköiset testivaatimukset | Sähköasennustarvikkeet ja liitännät |

Esimerkiksi, Nec tunnustaa nyt sekä kuparin että alumiinin standardijohtimateriaaleiksi, mutta vaatii koon säätöjä ei-kupariseille johdoille. Kun näet taulukon koodikirjassa, se perustuu yleensä kupariin – joten alumiinijohdot on oltava vastaavasti paksumpia.

Alumiinijohtimien minimityypit ja sallitut käyttötavat

Huomaat, että alumiinijohtimia käytetään usein jakelijohtoihin ja suuriin piireihin, mutta harvoin pienten sivupiirien johdotukseen. Miksi? Koodit asettavat yleensä alumiinijohtimille minimityypit turvallisuuden ja luotettavuuden varmistamiseksi. Esimerkiksi NEC on jo pitkään vaatinut alumiinijohtimilta AA-8000-sarjan seoksia useimpiin rakennussovelluksiin, mikä heijastaa materiaalitekniikan ja turvallisuuden kehitystä. Tämä tarkoittaa, että vanhemmat, vähemmän stabiilit seokset eivät ole enää sallittuja uusiin asennuksiin. Koodi rajoittaa myös alumiinin käyttöä tietyissä olosuhteissa – kuten pienissä sivupiireissä tai silloin, kun yhteensopivia laitteita ei ole saatavilla – koska liitännän ja pitkän aikavälin suorituskyvyn huomioon otto on tärkeää.

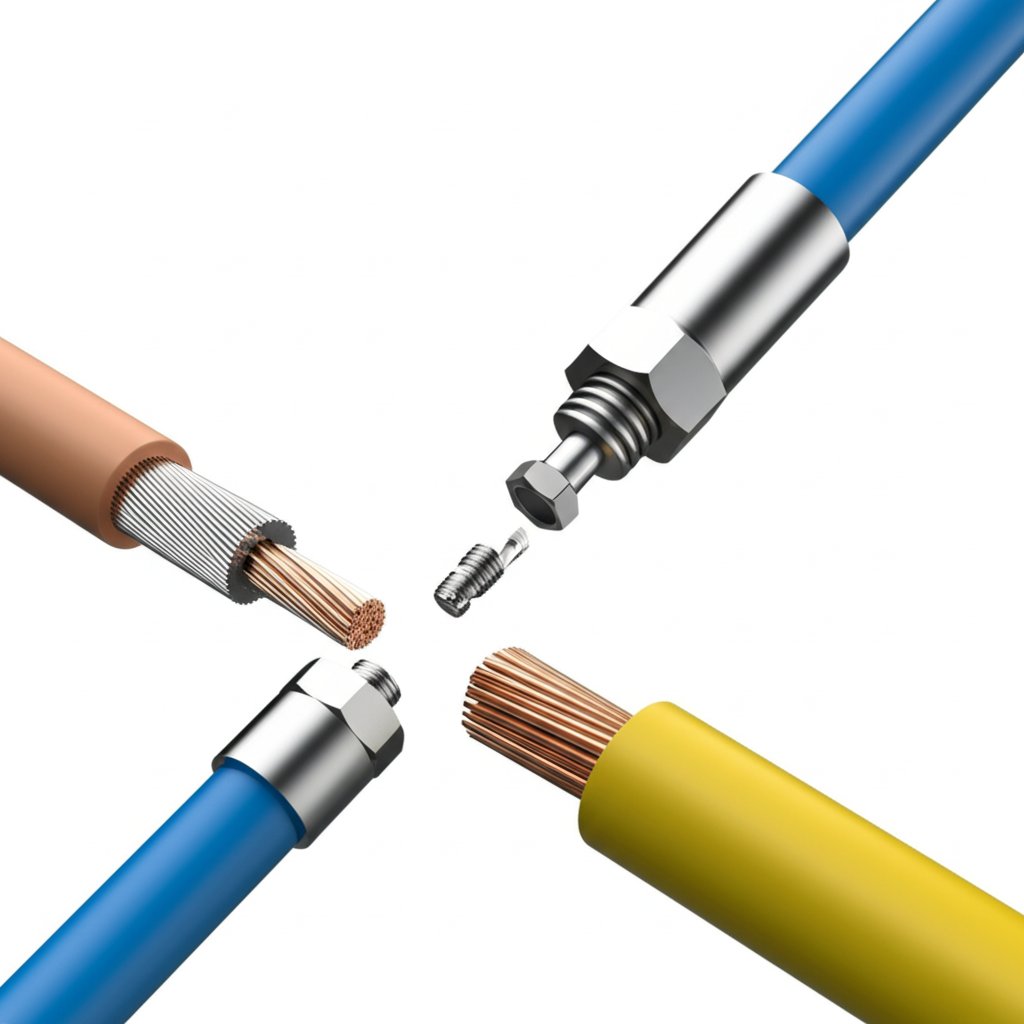

Liitinluettelot ja liitäntävaatimukset

Liitettäessä alumiini- ja kuppiyhteydet , et voi käyttää mitä tahansa valmiiksi saatavilla olevaa liitäntää. Standardeilla kuten ANSI C119.4 on tiukat vaatimukset alumiini-alumiini- ja alumiini-kuppijohtimien liitännöille. Näiden liitännöiden on läpäistävä sähköiset ja mekaaniset testit, jotta ne voidaan varmistaa turvallisesti toimiviksi lämpötilassa enintään 93 °C. Etsi liitännöistä merkintä AL/CU-luokituksella varustetut ja noudattakaa valmistajan ohjeita kiristysmomentista ja tarvittaessa antioksidanttikompaundin käytöstä.

- Tarkista, että johtimen materiaali on listattu ja sallittu käyttöön

- Varmista, että napit/liitännät ovat AL/CU-luokiteltuja alumiini-kuppi-sähköliitännöille

- Tarkista kiristysmomentin määräykset ja käytä kalibroituja työkaluja

- Käytä antioksidanttikompaundia, jos valmistaja niin vaatii

- Dokumentoi asennuksen tiedot ja säilytä tietoja tarkastuksia varten

Dokumentointi, tarkastus ja hyväksyntä

Oikea dokumentointi ja tarkastus ovat välttämättömiä jokaisessa kupari- tai alumiinijohtimessa työssä. Kuvitellaanpa, että asennus valmistuu, mutta tarkastus epäonnistuu koska vääntömomenttiarvoja ei ole kirjattu tai väärää liitäntää on käytetty. Näin pysytään mukana:

- Pidä kirjaa johtimien tyypeistä, kootista ja liitäntöjen arvoista

- Sisällytä valmistajan tietolehdet ja asennusohjeet tarjousasiakirjoihin

- Suorita eristysvastusmittaukset ja visuaaliset tarkastukset ennen käyttöönottoa

- Tee jälkikatselmukset erityisesti alumiiniliitännöissä

Tärkein viesti: Valitse ja asenna aina alumiini- ja kuparikaapelointi täsmälleen sovellettavien koodien, liitäntästandardien, valmistajan ohjeiden ja paikallisten viranomaisten tulkintojen mukaisesti. Tämä takaa sekä turvallisuuden että helpottaa tarkastusta ja pitkän aikavälin toimivuutta.

Koodien ja standardien ollessa perustana voit siirtyä tutkimaan, kuinka fysikaaliset ominaisuudet, kuten johtavuus ja virtakapasiteetti, vaikuttavat johtojen koon ja valinnan määrittämiseen. Seuraavaksi käännetään nämä säännöt käytännön ohjeiksi oikean kaapelikoon ja -tyypin valintaan aina oikein.

Fysiikan vaikutus alumiini- ja kuparikaapelien koon määrittämiseen

Valitsetko alumiini- vai kuparikaapelin perustuen vain hintaan – vai haluatko tietää, kuinka kumpikin metalli todella toimii käytännössä? Pureudutaan tarkemmin johtavuuden, resistanssin ja virtakapasiteetin taustalla olevaan fysiikkaan ja käännetään nämä käsitteet selkeiksi ja käytännöllisiksi ohjeiksi kaapelin koon määrittämiseen. Tässä kohtaa teoria kohtaa käytännön, ja oikea valinta voi säästää rahaa, painoa sekä tulevia huolia.

Johtavuuden perusteet ja IACS-käsite

Kuvittele sähkö vedenä, joka virtaa putken läpi: mitä leveämpi ja sileämpi putki on, sitä helpompi virtaus on. Kaapeleissa johtavan materiaalin laatu määrittää, kuinka helposti virta liikkuu – se on johtavuus . International Annealed Copper Standard (IACS) määrittää kuparin johtavuudeksi 100 %. Alumiini puolestaan tarjoaa noin 61 %:n johtavuuden samasta poikkileikkauksesta vertailussa kupariin.

| Omaisuus | Kupari | Alumiini |

|---|---|---|

| Johtavuus (IACS%) | 100% | ~61% |

| Vastuskyky (Ω·m) | Alempi | Korkeampi |

| Tiheys (g/cm³) | 8.96 | 2.7 |

| Paino (pituusyksikköä kohti) | Raskas | Kevyt (noin 1/3 kuparin painosta) |

| Vetolujuus | Korkeampi | Alempi |

| Lämpölaajennus | Alempi | Korkeampi |

Niin, mitä tämä tarkoittaa alumiinin ja kuparin johtavuudelle ? Alumiinin tarvitsee olla suurempi poikkileikkaus, jotta se voi johtaa saman virran kuin kupari, mutta se on paljon kevyempi. Tämä kompromissi on ratkaisevan tärkeää sovelluksissa, joissa paino tai tila on kriittistä.

Johtavuudesta ampeerikapasiteettiin ja virran laskemiseen

Kuulostako tekniseltä? Tässä käytännön puoli: virtakapasiteetti on maksimivirta, jonka kaapeli voi turvallisesti johtaa ylikuumenematta. Koska alumiinin sähkönjohtavuus on huonompi, alumiinilangan johtokyky on pienempi kuin saman kokoinen kuparilanka. Esimerkiksi 4 AWG kuparilanka (THHN/THWN-2, 90 °C) kestää 95 A virtaa letkussa, kun taas saman eristysluokan 4 AWG alumiinilanka kestää 75 A (lähde) . Eli alumiinilangan johtokyky on 24 % pienempi tällä langankoot ja olosuhteilla.

| Kuparin koko (AWG/MCM) | Tavallinen virta-alue (letku, 90 °C) | Alumiinin koko (AWG/MCM) | Arvioitu alumiinin virta-alue (letku, 90 °C) |

|---|---|---|---|

| 4 AWG | 95 A | 4 AWG | 75 a |

| 3/0 AWG | 165 A | 250 MCM | 170 A |

(Tarkista aina sähköön liittyvät määräykset ja valmistajan tekniset tiedot koskevasta asennuksesta!)

- Alumiinikaapelin virtakapasiteetti on aina pienempi kuin kuparilla samassa koossa – joten sinun on valittava alumiinikoot, jotka vastaavat kuparin suorituskykyä.

- Tarkista eristystyypin ja asennustavan vaikutus: Virta-alue muuttuu, jos johtimen asennustapa on ilmassa, putkessa tai maassa.

- Käytä virallisia virta-alue taulukoita (NEC, IEC, jne.) – älä arvaa tai käytä vanhentuneita arvoja.

Paino- ja koko-eroja metalleissa

Esimerkki: Sinun täytyy vetää syöttökaapeli pitkän matkan päähän kaupallisessa rakennuksessa. Jos valitset kuparikaapelin, tarvitset pienemmän koon, mutta kaapeli on raskas ja mahdollisesti kalliimpi. Jos vaihdat alumiiniin, tarvitset isomman koon, mutta se on kevyempi ja voi säästättää materiaalikustannuksia ja rakenteellista tukea. Muista kuitenkin, että alumiini vaatii enemmän tilaa putkissa ja erityistä huomiota liitännöissä lämpölaajenemisen ja -kutistumisen vuoksi.

- Alumiinilangan virtakapasiteetti on tarkistettava asennustavan ja korkean ympäristön lämpötilan, kaapelointiryhmän tai eristetyypin vuoksi vähennetty virta.

- Kasvata aina alumiinijohdinten kokoa vastaamaan kuparisten johdinten vaatimaa virtakapasiteettia.

- Ota huomioon fyysiset rajoitukset: Mahtuuko suurempi alumiinikaapeli letkuusi tai paneeliisi?

Tärkein viesti: Tarkista aina alumiinikaapelin virtakapasiteetti ja alumiinilangan virtakapasiteetti virallisia kooditaulukoita ja sertifiointitehtaan tietolehtiä käyttäen. Älä koskaan luota yleisiin kaavioihin tai peukalosääntöihin – todellisen maailman turvallisuus ja suorituskyky riippuvat tarkasta ja ajantasaisesta tiedosta.

Nyt kun ymmärrät fysiikan ja kompromissit, jotka liittyvät kuparin ja alumiinin sähkönjohtavuuteen , olet valmis tutkimaan käytännön asennuskäytäntöjä, jotka pitävät nämä kaapelit toimimaan turvallisesti vuosien ajan.

Asennuksen parhaat käytännöt, jotka estävät vioittumisen

Kun olet valmis asennukseen alumiininen sähköjohto tai tee alumiini- ja kuparilangan liitos , ei ole kyseessä vain kaapelin vetäminen pisteestä A pisteeseen B. Kuulostako yksinkertaiselta? Todellisuudessa yksityiskohdat tekevät eron – erityisesti alumiinin kohdalla, johon liittyy erityisvaatimuksia turvallisuuden ja luotettavuuden takaamiseksi vuosien ajaksi. Käydään läpi toimivia ja käytännönläheisiä vaiheita ongelmatonta asennusta varten, keskittyen erityisesti sekoitushalmettyihin (alumiini–kupari) liitoksiin.

Johtimien ja liitosten valmistelu

Kuvittele, että olet paikan päällä, työkalut kämmenellä, ja olet tekemässä valmiiksi johdon. Mikä on ensimmäinen vaihe? Valmistelu. Alumiinijohtimilla erityisesti tulee kiinnittää huomiota pinnan kunnostukseen ja puhdistukseen estääkseen korkeavastuksiset, lämpöä tuottavat liitokset. Näin saat sen tehtyä oikein:

- Tarkista liitännän sopivuus : Tarkista, että liitännäsi on listattu johtimateriaalille – etsi merkintöjä kuten "AL", "CU" tai "AL/CU" (kaksinkertainen arvo alumiinille ja kuparille). Käytä vain alumiini-kupariliitännät jotka täyttävät valmistajan ja koodivaatimukset.

- Leikkaa ja irrota siististi : Käytä teräviä työkaluja välttääksesi johtimen vahingoittumisen. Irrota eristys suositellun pituiseksi, jotta johtimen voi asettaa täysin liitännän sisään.

-

Valmistele johtimen pinta :

- Alumiinille: Harjaa irrotettu osa välittömästi ennen liitosta ruostumattomalla harjalla poistaaksesi hapettumakerroksen, kuten ABB ja liitännävalmistajat suosittelevat.

- Jos liitosta ei tehdä välittömästi, suojaa sitä hapettumiselta korkilla tai teipillä.

- Käytä hapettumisenestoainetta : Alumiinijohtimelle käytä listattua hapettumisenestoainetta, jos liitännävalmistaja vaatii sitä. Käsittele se mukaan ohjeiden mukaan. (Huom: Jotkin liitännät tulevat valmiiksi täytettyinä – älä poista tehtaan hapettumisenestoainetta.)

- Työnnä johtimen kokonaan : Varmista, että johtimen on työnnetty oikeaan syvyyteen – epätäysi työntö voi aiheuttaa ylikuumenemista ja vaurioita.

Käytä oikeita alumiini-/pakkausarvoisia liitännäisiä

Kaikki liitännäiset eivät ole samanlaisia. Käytä yhdistettäessä alumiini- ja kuparijohtimia , käytä aina kaksinkertaisesti arvoisia (alumiini/pakkaus) ja tarkoitukseen listattuja liitännäisiä. Tarkista seuraavat asiat:

- Tuotemerkinnät: Valmistaja, johdinpoikkileikkauksen alue, johtimateriaali (AL, CU tai AL9CU/AL7CU kaksinkertaiseen arvostukseen), lämpötilaluokitus ja listaus (esim. UL 486A-486B).

- Liitännäistyyppi: Mekaaniset ruuviliitännäiset, puristusliitännäiset tai halkaisuliitännäiset, jotka soveltuvat seosmetallien käyttöön.

- Noudata liitännäisvalmistajan ohjeita asennukseen, mukaan lukien poistettavan eristeen pituus, kiristysmomentti ja johtimien lukumäärä liitännäisessä.

Muista, että väärän liitännäisen käyttö tai arvojen tarkistamatta jättäminen on yleinen syy alumiini- ja kuparikaapelointien vaurioihin kentällä.

Vääntömomentti, uudelleenvääntö ja dokumentointi

Oikea vääntömomentti on ratkaiseva tekijä kylmän, turvallisen liitännän ja tulevan kuumapisteen välillä. Näin varmistat, että jokainen liitos on turvallinen:

- Kiristä määritettyyn vääntömomenttiin : Käytä kalibroitua vääntömomenttiavainta kiristäessäsi kiinnitysruuveja tai pultteja valmistajan suosittelemaan arvoon. Älä liian kiristä tai kiristä uudelleen alun perin annettua vääntömomenttia, ellei erikseen ole ohjeistettu.

- Tallenna vääntömomentti ja päivämäärä : Dokumentoi vääntömomenttiarvo, käytetty työkalu ja asennuspäivä. Tämä helpottaa tarkastuksia ja tulevaa huoltoa.

- Suorita alustavat tarkistukset : Laitteen ollessa käynnissä, käytä lämpökameraa tai IR-lämpömittaria tarkistaessasi liitännöissä mahdollisesti syntyneitä kuumapisteitä kuormitustilanteessa.

- Aseta uudelleentarkastusten aikataulu : Tarkista säännöllisesti liitännät, erityisesti alumiiniliitännät, löystymisen, värjääntymisen tai lämmön merkkejä. Seuraa huoltosuunnitelmaa, joka perustuu valmistajan ja säädösten antamiin ohjeisiin (viite) .

- Yleisiä asennusvirheitä:

- Eriytyskerroksen liiallinen poisto tai johtimen langan vaurioituminen

- Käytetään listautumattomia tai yhteensopimattomia liitännöitä

- Lämpötilaluokituksen tai kiristysmomentin ohittaminen

- Alumiinijohtimien pääteiden harjauksen ja käsittelyn laiminlyönti

- Asennusprosessin dokumentoinnin laiminlyönti

Tärkeää: Tee aina liitännöksen valmistajan antamien asennusohjeiden ja alumiini- ja kuparikaapelointien soveltuvien määräysten mukaisesti. Nämä vaatimukset korvaavat kaiken yleisen neuvon tai kenttätottumukset – turvallisin asennus on sellainen, joka vastaa virallista ohjeistusta tiettyyn tuotteeseen ja projektiin liittyen.

Hallitsemalla nämä parhaat käytännöt varmistat, että jokainen alumiini- ja kuparilangan liitos on rakennettu kestämään. Seuraavaksi käsittelemme näiden metallien liittämistä ilman korroosiota ja tarpeellisia suojatoimia pitkän käyttöiän varmistamiseksi – jotta asennus toimii vuosikymmeniä, ei vain päiviä.

Alumiinin ja kuparin liittäminen ilman korroosiota

Kun yhdistät alumiini- ja kuparikuituja, ihmetteletkö koskaan, miksi erityiset toimenpiteet ja tuotteet ovat välttämättömiä? Kuvitellaan liitos, jolta näyttää hyvältä asennuspäivänä, mutta joka vuosien kuluessa epäonnistuu näkymättömän korroosion tai lämmön vaikutuksesta. Tiede, joka selittää alumiini-kupari-johtimien liitännän on enemmän kuin vain oikean napin valitseminen – se tarkoittaa kemian, ympäristön ja oikeiden asennustottumusten ymmärtämistä. Selvitään todelliset riskit ja toimivat ratkaisut, jotta kupari- ja alumiiniyhteydet kestävät yhtä kauan kuin sähköjärjestelmäsi muu varustus.

Miksi galvaaninen korroosio syntyy Al-Cu-liitoksissa

Kuulostaa tekniseltä? Kyseessä on itse asiassa yksinkertainen sähkökemiallinen reaktio. Kun alumiini ja kupari koskettavat toisiaan kosteuden tai muiden elektrolyyttien (kuten kondenssiveden tai ilman kosteuden) läsnä ollessa, alumiini toimii 'uhraavana' metallina ja ruostuu suojaakseen kuparia. Tätä kutsutaan gaalvaninen korrosio . Ajan mittaan tämä voi aiheuttaa:

- Alumiinimateriaalin häviämisen, joka heikentää liitosta ja aiheuttaa avoimen piirin riskin

- Kasvanut vastus liitännässä, mikä johtaa lämmön kertymiseen

- Mahdolliset paloturvallisuusriskit tai laitteen ennenaikainen vikaantuminen

Mukaan lukien Leonardo Energy , alumiinin luontevan hapeton kerros on eriste, ja sen hajoaminen liitännössä voi edelleen kiihdyttää korroosiota, ellei siihen varauduta. Kupari sen sijaan on enemmän 'jalostakutistunut', eikä sillä ole vaikutusta, joten ongelma on aina alumiinipuolella.

Nopea vinkki: Älä koskaan yhdistä paljasta alumiinia suoraan kupariin listatun liitännän tai esteen ilman. Jo pieni määrä kosteutta voi käynnistää nopean korroosion liitokseen.

Liitinten valinnat ja esteiden menetelmät

Miten sinun tulee turvallisesti tehdä kupari-alumiini liitokset ? Oikea liitin ja valmisteluvaiheet ovat välttämättömiä. Tässä käytännönläheinen katsaus yleisimpiin ratkaisuihin:

-

AL/CU-luokitellut mekaaniset napit

-

Edut

- Laajasti saatavilla ja koodilistattu sekoitettujen metallien käyttöön

- Helppo asennus selkeällä merkinnällä

-

Haittapuolet

- Suorituskyky riippuu pinnan valmistelusta ja vääntömomentista

- Saatetta vaatia antioksidatiivinen yhdiste alumiinipuolelle

-

-

Kahden metallin kiinnikkeet (kupari-alumiini siirtokiinnikkeet)

-

Edut

- Tehtaan liitettyjen metallien pysyvä este

- Erinomainen korkean luotettavuuden tai kriittisten sovellusten käyttöön

-

Haittapuolet

- Korkeammat kustannukset ja saattaa vaatia erikoistilauksen

- Vähemmän joustava kenttämuutoksille

-

-

Jaetut pulttikytkimet, jotka on arvioitu Al-Cu-käyttöön

-

Edut

- Kätevä liitoksiin tai haaroituksiin kapeissa tiloissa

- Saatavilla kaksinkertaisella nimellisarvolla varustettuna

-

Haittapuolet

- Vaatii huolellista asennusta ja eristystä

- Ei sovellu suurjohjimiin tai korkeavirtaliitoksiin

-

-

Siirtoliitokset (esieristetyt tai tehdasvalmistetut)

-

Edut

- Vähentävät työmaakootyötä ja asennusvirheitä

- Sisältävät usein rakenteellisia esteitä ja estäviä aineita

-

Haittapuolet

- Soveltuvat koot tai käyttöalueet voivat olla rajalliset

- Tarkista alueesi määräykset ja listaukset

-

| Liittimen tyyppi | Tyypillinen käyttö | Tarvitaanko antioksidanttia? | Tarkastushuomautukset |

|---|---|---|---|

| AL/KU-varaustasoinen mekaaninen holvi | Paneelit, sähkökeskukset, syöttöjohdot | Kyllä (alumiinipuolella, valmistajan mukaan) | Tarkista kierrekierros, pinnan esikäsittely, estäjän läsnäolo |

| Bimetallinen holvi | Kriittiset tai ulkoilma-asennukset | Ei yleensä (tehtaan tiiviys) | Tarkista tehtaan kiinnitys, kierrekierros, tiiviys |

| Halkaisukierrek (Al/Ku-varaustasoinen) | Haarat, korjaukset | Kyllä (alumiinipuoli) | Tarkista kiristyksen tiiviys, eristys, estäin |

| Siirtoliitos | Valmiit kokoonpanot, rajoitettu pääsy | Vaihtelee (katso tietolehti) | Tarkista listaus, istuvuus ja tiiviys |

Jokaiselle kupari-alumiini liitin , toimi seuraavasti:

- Pinnan esikäsittely: Hanka alumiinia poistamaan hapettumaa juuri ennen liitosta; pidä kupari puhdistettuna ja kiiltävänä.

- Oksidin esto: Käytä alumiiniin valmistajan ohjeiden mukaisesti.

- Oikea kiristysmomentti: Käytä kalibrointityökalua ja noudattakaa ilmoitettua arvoa – älä kiristä liian tiukalle.

- Tiivistys kosteuden varalta: Ulko- tai kosteissa tiloissa eristä ja tiivistä liitos (kutisteputki, nauhat tai pinnoitteet hyväksyttyjen mukaisesti).

- Vedeneristys: Tuki kaapelit siten, ettei mekaanista rasitusta siirry liitokseen.

Ilmanvaihto- ja ulkojärjestelmissä valmistajat käyttävät joskus lisäesteitä, kuten sinkkipitoisia pinnoitteita tai erityisiä vaippoja, galvaanisen toiminnan vähentämiseksi.

Tarkastus-, testaus- ja huoltovälit

Vaikka asennus olisi täydellinen, se voi heiketä, jos sitä ei valvota. Näin voit pitää kupari-alumiini liitokset turvallisuuden pitkäaikaisesti varmalla:

- Lämpökuvaukset: Tarkista liitokset kuormitustilanteessa epänormaalin lämmön esiintymisen varalta

- Vääntömomentin tarkistus: Mikäli sallittua, tarkista kiristystä säännöllisen huollon yhteydessä

- Näköiset tarkastukset: Etsi värjäytymistä, korroosiota tai kylmävirtausta (metallivuotoa)

- Tiedonhallinta: Dokumentoi kaikki huoltotoimet, mukaan lukien päivämäärä, menetelmä ja havainnot

- Korjaukset ajoissa: Käsittele heti mikä tahansa häiriön merkki – älä koskaan jätä huomiotta kuumaa tai värjäytynyttä liitosta

Tärkein viesti: Jokaisessa alumiini- ja kuparilangan yhteydessä on käytettävä listattua, kaksinkertaisesti arvoa olevaa liitäntäelementtiä ja noudatettava tiukkoja valmisteluo- ja vääntömomenttiohjeita. Säännöllinen tarkastus ja huolto ovat paras tapa suojautua korroosiota, ylikuumenemista ja tulevia vikoja vastaan.

Ymmärtämällä ja noudattamalla näitä vaiheita varmistat, että kupari- ja alumiiniyhteydet eivät ole vain standardien mukaisia, vaan ne on rakennettu turvallista ja luotettavaa käyttöä varten useiden vuosikymmenten ajan. Seuraavaksi pureudutaan kuparilla pinnoitetun alumiinin maailmaan ja sen sijoittumiseen johtimien valintavaihtoehtojen joukossa.

Milloin CCA-kaapeli sopii – ja milloin ei

Mikä kuparilla pinnoitettu alumiini on ja miten se toimii

Oletko koskaan pitänyt johtoa kädessäsi ja miettinyt, onko se todella kuparia läpiomalta? Kuparilla pinnoitetulla alumiinilla kuparipinnoitettu alumiini (CCA) asia on hieman monimutkaisempi. Kuvittele johtimen sisäosa valmistettu kevyestä alumiinista, jonka ympärille on valettu ohut kuparin ulkokerros. Kyseessä ei ole pelkkä teoria – vaan todellinen valmistusprosessi, jossa kuparinauhaa hitsataan alumiiniteräksen ympärille, jonka jälkeen siitä vedetään muotoon metallurgisesti vahvaa sidosta. (Wikipedia) . Tulos: bimetallilanka, joka yhdistää molempien metallien ominaisuudet.

Miksi valmistaa lankaa tällä tavalla? CCA-tekniikkaa kehitettiin säästämään materiaalikustannuksissa ja painossa, mutta silti tarjoten osan kuparin sähköisistä ja mekaanisista hyödyistä. Löydät cCA-johto sovelluksista, joissa jokainen unssi on tärkeä, kuten kuulokkeiden äänihyllyjen, kannettavien kaiuttimien ja korkeataajuisien RF-kaapelien yhteydessä. Toisinaan sitä käytetään myös rakennusten sähköasennuksissa ja voimakaapeleissa, mutta tärkeillä varauksilla.

CCA, kupari ja alumiini suorituskyvyltään

Valitseko kuparikoristeinen alumiiniputki , puhdas kupari ja alumiini eivät koske vain hintaa. Se koskee myös niiden toimintaa oikeilla olosuhteilla. Näin kolmen vertailu toimii:

| Omaisuus | Kupari | Kuparilla päällystetty alumiini (CCA) | Alumiini |

|---|---|---|---|

| Sähköjohtavuus | Erinomainen (IACS 100 %) | Parempi kuin alumiini, mutta heikompi kuin kupari | noin 61 % kuparin määrästä (IACS) |

| Paino | Raskain | Kevyt kuparia kevyempi, mutta raskaampi kuin alumiini | Kevyin |

| Joustavuus | Korkea | Hyvä (parantunut alumiiniin verrattuna) | Kohtalainen |

| Mekaaninen lujuus | Korkea | Parempi kuin alumiini, mutta herkempi väsymiseen kuin kupari | Alempi |

| Lopetusasiat | Standardikupariliitännät/liitännät | Kupariliitännät voidaan usein käyttää vain kuparia varten (koodin/luettelon mukaan) | Vaatii AL/CU-luokitellut tai alumiinikohtaiset liitännät |

| Lämpövastus | Erinomainen | Parempi kuin alumiini, mutta vähemmän kestävä oikosulussa kuin kupari | Alempi |

| Tyypilliset sovellushuomautukset | Kaikki johdotustyypit, erityisesti tilanteissa, joissa luotettavuus on kriittistä | Kevyet kelojohdot, kaiuttimet, rakennusjohdot, valitut tehojohdot | Sähkönsiirtojohdot, laajat sähkönh jakot, painoherkät asennukset |

CCA hyödyntää 'nahkavaikutusta' korkeilla taajuuksilla, mikä tarkoittaa, että suurin osa vaihtovirrasta kulkee ulkoisen kuparikerroksen kautta – mikä tekee siitä yllättävän tehokkaan RF- ja äänijohdoissa. Kuitenkin matalilla taajuuksilla tai tehokatkoksissa alumiinisydämen alhaisempi johtavuus tulee merkittävämmäksi, mikä johtaa suurempaan vastukseen ja mahdolliseen lämpenemiseen raskauden alaisena.

Sopivat käyttökohteet ja varoitukset

Siis milloin cca-johto on järkevä valinta? Tässä on joitain käytännön vihjeitä valintaan:

- Ihanteellinen kevyisiin, kannettaviin elektroniikkalaitteisiin (kuulokkeet, kaiuttimet, joissakin koaksiaalijohdoissa)

- Joskus käytetään rakennusjohdotuksessa, mutta vain siellä, missä määräykset sallivat ja asianmukaisella hyväksynnällä

- Ei sallittu kategoriavahvistettuihin tietojohdotuksiin (Cat 5e/6) suorituskyvyn ja laillisten vaatimusten vuoksi

- Saattaa olla kustannustehokas vaihtoehto matalavirtaisiin tai signaalijohtoihin, mutta ei sovellu korkean tehon haarajohtoihin ellei erikseen ole listattu

- Liitännän yhteensopivuus: Varmista aina, että liitännät soveltuvat CCA:han – älä koskaan oleta, että pelkästään kupari- tai alumiiniliitännät toimivat

- Tarkista koodihyväksyntä: CCA on ollut NEC:ssä vuodesta 1971 lähtien koot 12 ja suuremmille, mutta kaikki sovellukset tai kooot eivät ole kattotut

Älä jää huijatuksi hinnalla yksin. Vaikka kuparikoristeinen alumiiniputki voi olla kevyempi ja edullisempi kuin kupari, se on herkempi mekaaniselle väsymykselle ja ei yhtä vahva. Se lämpenee myös enemmän oikosulun yhteydessä, vaikka tämä ei ole yhtä suuri ongelma määräysten mukaisissa ja riittävästi suojatuissa asennuksissa

Tärkein viesti: CCA ei ole suora vaihtoehto kuparille useimmilla teho-ohjelmointisovelluksilla. Tarkista aina listaukset, koodimääräykset ja liitännän yhteensopivuus ennen kuparipäällystetyn alumiinin määrittelyä tai asennusta. Epäselvissä tapauksissa päätä paikalliset koodit ja valmistajan dokumentaatio välttääksesi kalliita virheitä.

Ymmärtämällä erityiset vahvuudet ja rajoitukset cca-johto auttaa sinua valitsemaan oikean johdinmateriaalin seuraavaan projektiisi. Seuraavaksi käymme läpi vaiheittaiset laskelmat johtimen poikkipinnan määrittämiseksi ja jännitteenlaskun laskemiseksi – jotta voit panna tämän teorian käytännössä toimimaan.

Laskelmia johtimen poikkipinnan määrittämiseksi ja jännitteenlaskun laskemiseksi

Oletko koskaan miettinyt, miten insinöörit päättävät minkä kokoinen alumiinikaapeli tai alumiinilanka pitää käyttää pitkissä kaapelointeissa, tai miten he varmistavat, että jännitteen menetys pysyy turvallisella alueella? Kuulostaa tekniseltä, mutta selkeän prosessin avulla voit mitoittaa johtimet tarkasti ja välttää kalliit virheet – arvailemista ei tarvita. Käydään läpi oleellinen työvaihejärjestys, käyttäen todettuja standardeja ja todellisia yhtälöitä, jotta voit luottavaisin mielin vertailla kuparijohtimen ja alumiinijohtimen seuraavalle projektillesi.

Jännitteenlaskun ja resistiivisen häviöiden laskentamenetelmä

Kuvitellaan moottorin käyttö varaston päässä. Jos kaapeli on liian ohut tai liian pitkä, jännitteen lasku kuormassa kasvaa, laitteisto voi toimia virheellisesti ja energia hukkuu lämpönä. Siksi jännitteen laskun ja tehohäviön laskeminen on välttämätöntä sekä alumiinikaapeli että kuparijohtimille.

- Määritä kuormavirta ja sallittu jännitteen lasku: Aloita selvittämällä kuorma (ampeerit) ja suurin sallittu jännitteen lasku – yleensä 3–5 % nimellisjännitteestä useimmille sovelluksille ( viite ).

- Mittaa piirin pituus ja huomio lämpötilaluokka: Pidemmät piirit ja korkeammat ympäristön lämpötilat lisäävät jännitteen laskua ja vähentävät virtakapasiteettiä. Kirjaa kaapelin kokonaispituus ja eristeen lämpötilaluokka.

- Valitse johtimen metalli ja eristetyyppi: Päätä alumiini- vai kuparivalinta. Muista, että alumiinin ja kuparin sähkönjohtavuusvertailu on tärkeä tekijä – alumiinin johtavuus on noin 61 % kuparin johtavuudesta, joten se vaatii suuremman poikkipinta-alan saman virtakapasiteetin saavuttamiseksi.

- Etsi vastus/impedanssi standardeista: Käytä tunnistettuja taulukoita (NEC, IEC, BS tai valmistajan tietoja) etsiäksesi vastuksen (Ω/km tai Ω/1000 ft) kaapelikoot ja -materiaalit. Esimerkiksi K = 12,9 kuparille ja K = 21,2 alumiinille, kun käytetään jalkoja ( viite ).

-

Laske jännitehäviö: Sijoita arvot oikeaan kaavaan:

- Yksivaihe:

VD = (2 × K × I × L) / CM - Kolmivaihe:

VD = (1.732 × K × I × L) / CM - Jossa VD = jännitehäviö (V), K = materiaalivakio, I = virta (A), L = pituus (ft) ja CM = johtimen ympyräinen miljardiosuus.

Tärkeät yhtälöt:

Jännitehäviö:V_drop = I × R_total

Tehohäviö:P_loss = I² × R_total

(Syötä vastusarvot valmistajan taulukosta tai valmistetiedoista valitulle kaapelille.) - Yksivaihe:

- Säädä kaapelin kokoa tarvittaessa: Jos laskemasi jännitteen pudotus ylittää sallitun arvon, valitse suurempi kaapeli ja toista laskutoimitus. Alumiinikkaa tarvitset tavallisesti suurempaa poikkipinta-alaa kuin kuparikkaa vastaavaan suorituskykyyn – keskeinen seikka alumiini- ja kuparikaapelointien vertailussa.

- Tarkista virta- ja liitäntärajoitukset: Tarkista uudelleen, että valitsemasi kaapelikoko kestää turvallisesti kuormavirran, kun siihen on sovellettu korjauskertoimia lämpötilalle, kaapelien ryhmittymiselle tai eristetyypille.

- Dokumentoi valinnat ja lähteet: Tallenna kaikki laskelmat, kaapelityypit ja käytetyt viitetaulukot. Tämä tukee tarkastuksia ja tulevaa huoltoa.

Taulukoiden lukeminen ja kokojen valinta

Oletetaan, että vertailet alumiinikaapelia ja kuparikaapelia virtalähteelle. Huomaa, että sähkönsiirtokyvyn taulukot luettelevat kuparin ja alumiinin erikseen – älä koskaan oleta, että koot ovat keskenään vaihtokelpoisia! Esimerkiksi 4 AWG kuparinen johdin saattaa olla arvioitu 95 A, kun taas saman kokoinen alumiininen on arvioitu vain 75 A. Sinun täytyy valita suurempi alumiinikaapeli, jotta saavutetaan kuparin sähkönsiirtokapasiteetti ja jännitteen pudotus pysyy rajoissa.

- Käytä aina alueellisiin standardeihin tai valmistajan taulukoita.

- Tarkista asennustapa (putkessa, maassa, ilmassa).

- Erittäin pitkiä janoja varten käytä taulukoita tai kaavioita, jotka näyttävät maksimipituuden tietylle koolla ja jännitteen pudotukselle.

Tämä työnkulku varmistaa, että et valitse kaapelia vain tottumuksesta, vaan todetulla ja turvallisella laskennalla – erityisen tärkeää, kun otetaan huomioon kupari- ja alumiinilanka kriittisiin piireihin.

Vahvistus ja dokumentointi

Kun olet tehnyt laskutoimitukset, älä silti jätä tekemättä lopullisia tarkistuksia ja dokumentointia. Tässä on nopea tarkistuslista, joka pitää sinut kulkusuunnassa:

- Käytä johdon sähkökuormitusta vähentäväksi tekijäksi ympäristön lämpötilan, kaapelin kiinnityksen ja eristelämpötilaluokan mukaan.

- Varmista, että liitännät ja päätteet kestävät sekä kaapelin materiaalin että koon.

- Tarkista jännitehäviö ja virta-alue virallisten koodien tai tietolehtien arvojen mukaan.

- Pidä yksityiskohtainen dokumentaatio tarkastuksia ja tulevaa vianmääritystä varten.

Ammattilainen vinkki: Käytännön turvallisuus riippuu ajantasaisista kooditaulukoista, tarkoista resistanssiarvoista ja kattavasta dokumentaatiosta. Älä koskaan nojaa yleisiin arvioihin – viittaa aina nykyisiin standardeihin alumiini- ja kuparikaapelien mitoituksessa.

Tällä rakenteellisella lähestymistavalla varmistat, että jokainen alumiinikaapeli tai alumiinilanka valitsemasi on oikean kokoinen työhön, ja jännitehäviö sekä tehohäviöt pysyvät hallinnassa. Seuraavaksi näytämme, miten nämä valinnat vaikuttavat kokonaisomistuskustannuksiin – auttamalla sinua tekemään fiksumpia päätöksiä hankinnasta pitkäaikaiseen käyttöön asti.

Elinkaaren kokonaiskustannusarvio ja hankintapohjat

Kun vertailet alumiini- ja kuparikaapeli projektissa, keskität vain hintaan vai mietitkökö kaiken, mikä tapahtuu asennuksen jälkeen – vuosien ajan jatkuvan käytön, huollon ja lopulta korvaamisen? Tuntuu monimutkaiselta, mutta elinkaaren kokonaisomistuskustannusten (TCO) lähestymistapa voi säästää kalliilta yllätyksiltä. Käydään läpi, miten voit tehdä todellisen kustannusvertailun, mitä tulisi sisällyttää hankintatarkistusluetteloon ja miten dokumentoida valintasi tarjouspyyntöön tai sisäiseen hyväksyttäväksi.

Elinkaaren kustannusmallin rakentaminen

Kuvitellaan, että olet määrittämässä kaapelia uuteen rakennukseen tai teolliseen laajennukseen. Huomaat suuren hintaeron kupari- ja alumiinijohdinmateriaalien välillä. Mutta onko kupari todella kallista pitkäaikaisessa tarkastelussa, vai maksavatko sen alhaisemmat häviöt ja harvemmat varaosien tarpeet hinnan yli ajan? Elinkaustekijät huomioiva kustannusmalli ottaa huomioon kaikki vaiheet, ei vain alkuperäisen hinnan. Teollisuusanalyysien mukaan suurin virhe on "tehdä päätöksiä hinnan ja muiden lyhyen aikavälin kustannusten perusteella", kun taas käyttö- ja huoltokustannuksia ei oteta huomioon kaapelin 40–50 vuoden käyttöiän osalta (Leonardo Energy) .

| Kustannustekijä | Mitä sisällyttää | Mistä löytää tietoa |

|---|---|---|

| Materiaalin hinta | Peruskaapelin hinta (kupari/alumiini) | Toimittajien tarjoukset, markkinahinnat, esimerkiksi myytävät kuparikaapelit |

| Liitännät/päätteet | Al/Cu-varusteiset napaosat, bimetalliliitännät, tarvikkeet | Tuotetiedot, toimittajien katalogit |

| Asennuksen työvoimakustannukset | Aika, koulutus, työkalut (alumiini voi vaatia lisävalmisteluja) | Urakoitsijoiden tarjoukset, sisäiset työvoimakustannukset |

| Energiahäviöt | Laskettu kWh-määrä, joka on kadonnut resistanssin vuoksi käyttöiän aikana | Resistanssitaulukot, kuormituskäyrät, sähkön hinnat |

| Tarkastus/huolto | Säännölliset tarkastukset, kiristysten tarkistus, lämpötilakartoitukset | Huoltosuunnitelmat, omaisuuden hallintasuunnitelmat |

| Korvaustodennäköisyys | Odotettu käyttöikä, riski varhaisesta vioittumisesta | Valmistajan takuu, historialliset vioittumisasteet |

| Jäännösarvo | Alumiinilangan romuarvo tai kuparin kierrätysarvo | Romukauppiaiden hinnat, kierrätys sopimukset |

Täytä tämä taulukko projektisi todellisilla tiedoilla. Muista sisällyttää alumiinilangan romuarvo tai kuparin kierrätysarvo elinkaaren päätyttyä – joskus nämä voivat yllättäen kattaa alkuperäiset kustannukset

Ostotarkistuslistat ja hyväksymiskriteerit

Valmis lähettämään tarjouspyynnön tai vahvistamaan teknisen määrittelyn? Tässä käytännönläheinen tarkistuslista, jonka avulla varmistat, että huomioit kaikki yksityiskohdat, jotka vaikuttavat sekä kustannuksiin että suorituskykyyn alumiini- ja kuparilangan hinta ja pitkän aikavälin arvo:

- Määritä vaadittu johtometalli (kupari tai alumiini)

- Ilmoita eristetyyppi ja lämpöluokka

- Aseta suurin sallittu jännitteen pudotus (esim. 3 % johdotuksille)

- Listaa liitintä koskevat vaatimukset (AL/CU-sertifioitu tai bimetallinen sekoitettuja metalleja varten)

- Sisällytä momenttikirjaus ja asennusohjeet

- Vaadi testituloksia: eristysresistanssi, visuaalinen ja lämpötilatarkastus

- Pyydä asiakirjoja odotetusta käyttöiästä ja takuusta

- Pyydä energiahäviöiden hajotelmaa kaapelin käyttöiän aikana

- Sisällytä elinkaaren päätyttyä kierrätys- tai romukerroin

Käyttämällä tätä listaa varmistat vertailukelpoiset tulokset alumiinilangan hinta ja alumiinilangan hinta ei vain alkuhinta vaan koko kokonaisuus

Tarjousasiakirjat ja -aineistot

Valmisteltaessa tarjousdokumentteja tai sisäisiä hyväksyntöjä selkeys ja kattavuus ovat avaimia. Kuvittele, että tuleva tarkastaja tai huoltosähköinsinööri tarkastelee dokumenttejasi – näkeekö hän valinnan perustelut?

- Täytetty elinkaarikustannustaulukko kaikilla lähteillä ja oletuksilla

- Tuotedokumentit kaapeleille, liitännöille ja tarvikkeille

- Asennus- ja huolttoohjeet

- Testitulokset ja käyttöönottoasiakirjat

- Romu- ja pelastustodistukset (esim. alumiinilangan romutodistukset)

Tällaisten tietojen säilyttäminen ei ainoastaan tue määräysten noudattamista ja takuuväitteitä, vaan myös auttaa tulevia projekteja oppimaan kokemuksistasi.

Tärkein viesti: Materiaalin alimmalla hinnalla saatetaan olla korkeampi elinkaaren hinta, kun otetaan huomioon energiahäviöt, huolto ja romu arvo. Tee aina täysi TCO-vertailu jokaisesta merkittävästä kaapeli-päätöksestä ja dokumentoi päättelysi sidosryhmille ja tulevaisuuden viitteenä.

Kun elinkaaren kustannusmalli ja hankintaprosessi ovat käytössä, sinulla on välineet tehdä fiksumpia ja kestävämpiä valintoja jokaiselle alumiini- ja kuparikaapeli projektin. Seuraavaksi tarkastelemme, miten nämä päätökset vaikuttavat auto- ja liikkuvuussovelluksissa – joissa paino, pakkaus ja pitkän aikavälin kestävyys ovat ratkaisevan tärkeitä.

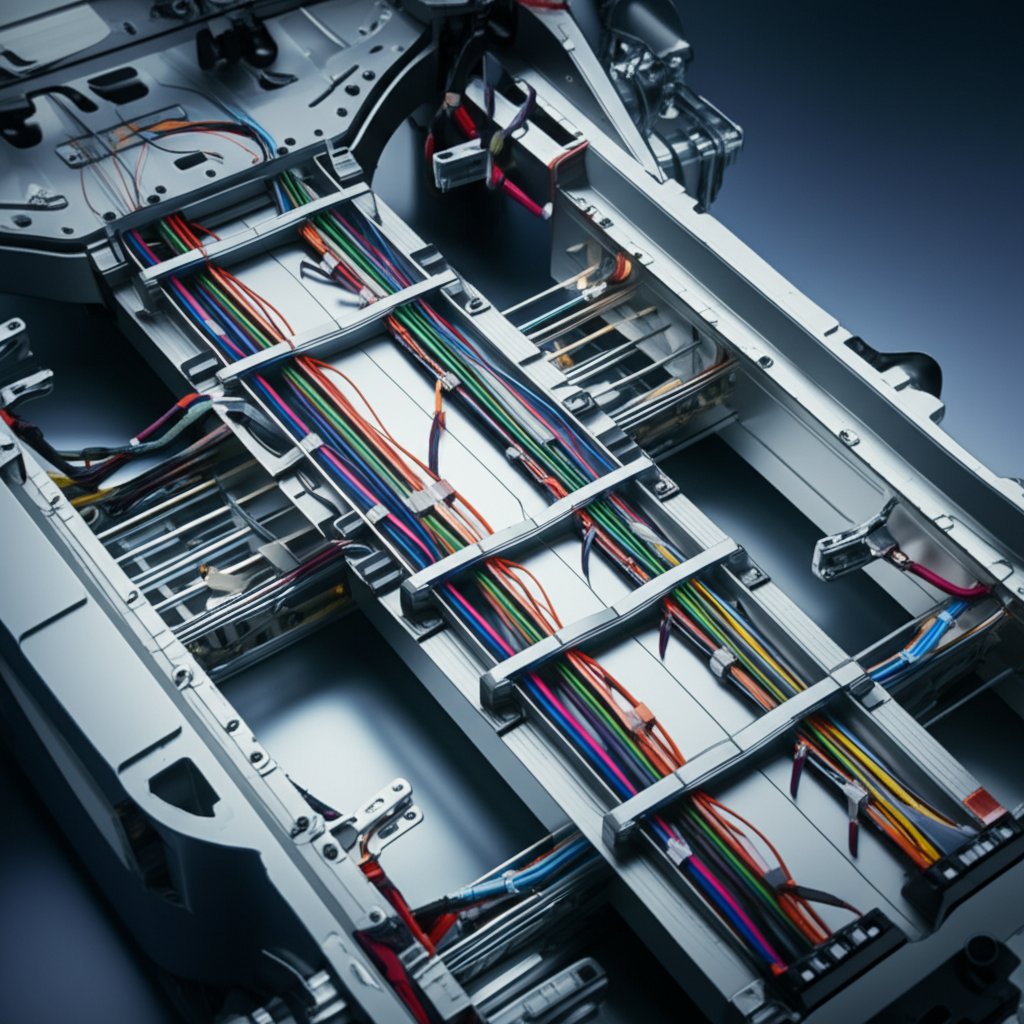

Auto- ja hankintaresurssisovellukset

Kun ajattelet modernia ajoneuvoa – erityisesti sähköajoneuvoja (EV) ja hybridimalluja – mikä on ensimmäinen haaste, joka tulee mieleen? Monille insinööreille se on painon, pakkaustilan ja lämmönhallinnan hallinta samalla kun luotettavuus säilyy. Tässä kohtaa valinta alumiini- ja kuparilangan ja oikeat kaapelinhallintaratkaisut alumiinilangan ja kupari-alumiinilangan ovat ratkaisevan tärkeitä. Tutkitaan, miten alumiinin ainutlaatuisten ominaisuuksien hyödyntäminen auton sähköasennuksissa, rakenteelliset profiilit tukemassa kaapelointia ja mitkä hankintastrategiat voivat auttaa rakentamaan turvallisempia, kevyempiä ja tehokkaampia ajoneuvoja.

Auton sähköasennukset ja alumiinin mahdollisuudet

Kuvitellaan, että suunnittelet uuden sähköauton johdotusta. Jokainen säästetty punta tarkoittaa enemmän matkaa tai tilaa akkuille. Alan asiantuntijoiden mukaan alumiini on 60–70 % kevyempää kuin kupari, mikä tekee siitä ideaalisen valinnan korkeajänniteakkujohdoille ja pitkille johdotuskierroksille ajoneuvoissa. Vaikka kuparin parempi johtavuus ja taipuvaisuus tekevät siitä suositumpaa tehon vaativiin tai voimakkaiden värähtelyjen alueisiin (kuten ECUihin tai moottoritiloihin), alumiinin painoetu on vaikea sivuuttaa päävirtajakeluiden ja laajamittaisten jakelujen osalta.

- Kevytjohdot moduuli-akkujen ja pakoputkien johdotuskierrokset

- Hybridijohdotukset, jotka käyttävät molempia alumiinia ja kuparia suorituskyvyn ja kustannusten optimointiin

- Suojattu kupari-alumiinilangan eMI-herkille alueille

- Korkean taipumiskyvyn kuparilangat liikkuvissa liitoksissa tai värähtelyherkissä alueissa

Oikean materiaalisekoä ei ole pelkästään painoasioita—sen tärkeää on myös varmistaa oikeat liitännät ja pitkän aikavälin luotettavuus. Alumiini vaatii erityisliitännät ja korroosionestoä, kun taas kuparia voidaan käyttää standardiautomaattisten napojen ja liitäntöjen kanssa.

Kaapelointien hallinta rakenteellisten profiilien avulla

Oletko koskaan miettinyt, miten raskaat, suurivirtaiset kaapelit pysyvät suojattuina ja siististi reititettyinä ajoneuvon rungon tai akunkoteloituun? Siinä tulevat kyseeseen rakenteelliset profiilit, kuten räätälöidyt alumiinikanavat ja kannet. Nämä suojaavat kaapelit mekaanisilta vaurioilta ja kosteudelta, auttavat hajottamaan lämpöä ja pitävät reitityksen tarkanakin tiukoissa tiloissa.

Tiimeille, jotka määrittelevät kaapelpolkujen, akkolaatikoiden tai kaapelikootterien kiinnitykset, Shaoyin alumiinipuristusosat tarjoavat tarkoitukseen suunnitellun, kevyen ja vahvan ratkaisun, joka täydentää johtimien valintoja. Näitä profiileja on suunniteltu vastaamaan tiettyjä ajoneuvoplattmuotoja, mikä varmistaa saumattoman integroinnin sekä alumiini- että kuparikaapelointijärjestelmiin.

- Shaoyin alumiinipuristuksenosat kaapelointiväyliä ja akkumodulin liitäntäjä rakenneosia varten

- Sisäisen kaapelointisuunnittelun ohjeet ja DVP (Design Verification Plan) -dokumentaatio

- Alueelliset standardit ja OEM-määrittelyt kaapelointia ja kiinnikkeitä varten

Hyvin suunnitellut profiilit tarjoavat kanavat kevytjohdot kaapelointiryhmille, turvallisen kiinnityksen busbarreille (mukaan lukien alumiinikuoretut kuparivaihtoehdot ja auttavat hallitsemaan lämmön siirtymistä herkiltä elektroniikkakomponenteilta.

| Ajoneuvon alijärjestelmä | Kaapelin tyyppi | Kiinnike/Profiilisuunnittelu |

|---|---|---|

| Runko (ovet, taka-alue, valaistus) | Joustavat kuparilangat, kevytä alumiiniosia | Muovikanavat tai alumiinikanavat reititystä ja suojaa varten |

| Alusta ja korirenkaat | Paksut alumiinilangat, hybridikaapelointijohdot | Korrosioon kestävät alumiiniprofiilit, tiiviit kannet |

| Akkuliike | Korkeajännitteiset alumiini- tai kuparikaapelit | Räätälöidyt profiilit, lämmönhallintaratkaisut |

| Tehoelektroniikka (invertterit, DC/DC-muuntajat) | Kupari-alumiinilanka, alumiinikuoretut busbar-johdot | Kovakourinen kiinnitys, E-säteilyn varjoustus, lämmön hajaantumispolut |

Luotettavat toimittajakumppanit ja seuraavat vaiheet

Kun johtimien materiaaleja ja kaapelointihallintaa on niin paljon eri vaihtoehtoja, miten varmistat, että ratkaisusi on sekä kunnossa että tehokas? Aloita kumppanuudella toimittajien kanssa, jotka ymmärtävät autoteollisuuden sähköasennusten ainutlaatuiset vaatimukset ja voivat toimittaa tarkasti suunniteltuja ja sertifioituja komponentteja.

- Shaoyin alumiinipuristuksenosat kaapelointiväyliä ja akkumodulin liitäntäjä rakenneosia varten

- Sisäisten kaapelointisuunnittelun ohjeet ja DVP-suunnitelmat vahvistamaan jokainen reititys ja liitäntä

- Alueelliset standardit ja OEM-määrittelyt varmistamaan säädöstenmukaisuus ja pitkän aikavälin luotettavuus

Muista, että jokainen valinta – olipa se kevytjohdot kaapelointia varten tai räätälöity alumiinikanava – on tehtävä noudattaen sovellettavia koodistoja ja valmistajan ohjeita liitännöissä, eristyksessä ja ympäristötiivisteissä.

Tärkein viesti: Oikea alumiini- ja kuparikaapelin yhdistelmä, jota tukevat edistetyt kaapelinhallintaratkaisut, kuten Shaoyin profiilit, voi tuoda merkittäviä painon säästöjä, parantaa pakkausta ja varmistaa luotettavan lämmönsiirron nykyisissä ajoneuvoissa. Konsultoi aina luotettavien kumppaneiden kanssa ja käytä sisäisiä ja ulkoisia standardeja varmistaaksesi, että jokainen liitäntä ja kiinnike täyttää korkeimmat laatu- ja turvallisuusvaatimukset.

Yhdistämällä oppimisen alumiini- ja kuparikaapeli valinta, kaapelinhallinta ja toimittajan kelpuutus, olet valmis rakentamaan seuraavan sukupolven korkean suorituskyvyn, tehokkaita ja turvallisia autoteollisuuden sähköjärjestelmiä.

Alumiini- ja kuparikaapeli FAQ:t

1. Mikä on pääasiallinen ero alumiini- ja kuparikaapelin välillä?

Alumiinikaapeli on kevyempi ja edullisempi, mutta sillä on huonompi johtavuus kuin kuparilla, jolloin tarvitaan suurempi koko saman virran läpi. Kuparikaapeli tarjoaa paremman taipuvuuden, kestävyyden ja suuremman virtakapasiteetin koon suhteellisesti, mikä tekee siitä ideaalisen kriittiseen johdotukseen ja alueisiin, joissa on tiukat mutkat.

2. Milloin alumiinikäyttöä tulisi käyttää kuparin sijaan?

Alumiinikäyttö soveltuu parhaiten suurjännitelinjoihin, ylikuljetusjohtoihin ja pitkiin kaapelimerkintöihin, joissa painon ja kustannusten säästö on tärkeää. Se ei sovellu yhtä hyvin pieniin haarajohtoihin tai alueisiin, joissa tarvitaan usein taivutusta, koska sen lujuus on heikompi ja lämpölaajeneminen suurempaa.

3. Miten alumiini- ja kuparikaapeleita voidaan turvallisesti yhdistää?

Alumiini- ja kuparikaapeleiden yhdistämiseksi turvallisesti käytä liitännäisiä, jotka on arvioitu molemmille metalleille (AL/CU), valmistele johtimien pinnat estämään hapettumista, käytä antioksidanttiväliainetta määrätyllä tavalla ja noudatta oikeita vääntömomenttiohjeita. Säännöllinen tarkastus ja huolto estävät korroosiota ja vikaantumista.

4. Mikä on kuparilla pinnoitettu alumiinilanka (CCA) ja missä sitä käytetään?

Kuparilla päällystetyn alumiinin (CCA) johdinta käytetään kevyissä elektroniikkalaitteissa, äänikaapeleissa ja rakennusten sähköasennuksissa, mutta sitä ei voida käyttää suoraan kuparin sijaisena korkean tehon piireissä. CCA-johtimen ydinosasta on alumiinia ja ulkopinta on kuparia, mikä yhdistää keveyttä ja kohtuullista sähkönjohtavuutta.

5. Miten elinkaarikustannukset vertautuvat alumiini- ja kuparikaapelien välillä?

Vaikka alumiinikaapelit ovat alun perin edullisempia, kuparikaapelit voivat tarjota alhaisemman omistuskustannuksen kokonaisuuden kannalta vähäisempien energiahäviöiden, huoltotarpeiden ja korkeamman romuarvon ansiosta. Kustannusanalyysissä tulisi ottaa huomioon asennus, käyttö ja kierrätys lopullisessa elinkaaren vaiheessa.

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —