Leimattu teräs vs. jälkimarkkinoiden ohjausvarret: Keskeiset erot

TL;DR

OEM:n valmistamat teräksiset ohjaustangot ovat täysin riittävät tavallisiin ajoneuvoihin arkitilanteissa, tarjoten kustannustehokkaan ja kestävän tehdasratkaisun. Suorituskyky-, klassikko- tai korotettuihin ajoneuvoihin jälkiasennusohjaustangot, jotka on valmistettu putkiteräksestä tai alumiinista, tarjoavat merkittäviä etuja. Nämä päivitykset tarjoavat paremman lujuuden, pienentävät painoa parempaa käsittelyä varten sekä korjaavat geometrian muunnetuissa jousituksissa, mikä tekee niistä kannattavan sijoituksen harrastajille, jotka etsivät parannettua suorituskykyä ja kestävyyttä.

Painotettujen teräksisten ohjaustankojen ymmärtäminen: Laatutason vertailukohta

Suurimmalle osalle tehtaalta tulevia ajoneuvoja jousitus tuetaan valetuilla teräs-ohjainvarrella. Nämä komponentit ovat auton alustan hiljaiset työjuhlat, jotka yhdistävät pyöräkeskuksen runkoon ja hallitsevat ajoneuvon liikettä loivien kohoumien yli ajaessa ja käännöissä. Ilmaisu "valettu teräs" viittaa niiden valmistusprosessiin, jossa teräslevyt leikataan ja painetaan lopulliseen muotoonsa voimakkaita muotteja käyttäen. Tämä menetelmä on erittäin tehokas ja kustannustehokas, minkä vuoksi se on alkuperäisten laitteiden valmistajien (OEM) suosima vaihtoehto massatuotantoon.

Valetun teräksen pääasiallinen etu on sen tasapaino lujuuden ja alhaisen tuotantokustannusten välillä. Kuten vertailussa huomautettiin Metrix Premium Parts , teräs on OEM-vakioaineistoa pääasiassa sen kestävyyden ja kustannustehokkuuden vuoksi. Keskimääräiselle kuljettajalle nämä säätövarret ovat täysin kykeneväisiä kestämään arkipäivän ajon ja tyypillisten tietolosuhteiden aiheuttamat rasitukset. Käsitys, että ne olisivat vain "riittäviä", juontaa usein juurensa suorituskykyyhteisöstä, jossa komponentteja rajoitetaan niiden ehdottomiin rajoihin.

Korkean tarkkuuden autoteollisuuden komponenteissa valmistusprosessi on kriittisen tärkeä. Tällä alalla toimivat yritykset, kuten Shaoyi (Ningbo) Metal Technology Co., Ltd. , tarjoavat autoteollisuuden vaatimat edistyneet metallin syvävetopuristusratkaisut, ja varmistavat, että osat kuten säätövarret täyttävät tiukat laatu- ja turvallisuusvaatimukset prototyypistä sarjatuotantoon asti. Juuri tämä asiantuntemus mahdollistaa OEM-osien luotettavan ja yhtenmäisen suorituskyvyn.

Kuitenkin leikattu teräs ei ole vapaana haittapuolista, erityisesti kun muutokset tulevat kyseeseen. Rakenteensa vuoksi ne ovat kyllä vahvoja, mutta voivat olla painavia ja sallia jonkin verran taipumista aggressiivisen ajo- tai kilpa-ajotilanteen korkeissa rasituksissa. Tämä on keskeinen syy, miksi innostuneet usein etsivät jälkimarkkinoiden ratkaisuja. Yhteenvetona tässä ovat keskeiset edut ja haitat:

- Edut: Alhainen valmistuskustannus, laajasti saatavilla, riittävän kestävä kaikkiin sarjatuotteisiin, todettu OEM-luotettavuus.

- Haitat: Painavampi vaihtoehtoihin nähden, voi taipua äärioikeuksissa, ei tarjoa geometriakorjausta nostettuihin tai alennettuihin ajoneuvoihin, perusluonteinen suunnittelussa ja suorituskyvyssä.

Lopulta leikatut teräksiset ohjaustankot riittävät muuntamattomille ajoneuvoille, joita käytetään tavallisessa liikenteessä. Jos et aio nostaa rekkasi korokesta, laskea autosi maanpintaan tai viedä sitä radalle, tehtaalta asennetut tankot toimivat todennäköisesti hyvin ajoneuvon koko käyttöiän ajan.

Päivityspolku: Leikattu teräs vs. Putkimaiset ohjaustangot

Kun suorituskyky nousee etusijalle, keskustelu siirtyy nopeasti leikatusta teräksestä putkimaisiin ohjaustankoihin. Tämä on yleisin ja merkittävin päivitys klassisille autoille, kuorma-autoille ja suorituskykyajoneuvoille. Leikattuihin vastineisiinsa verrattuna putkimaiset ohjaustangot on valmistettu vetotankoputkesta (DOM) valmistetuista osista, jotka on tarkasti leikattu, taivutettu ja hitsattu yhteen. Tämä rakenne tarjoaa dramaattisen lisäyksen lujuuteen ja jäykkyysominaisuuksiin samalla kun usein vähentää painoa.

Rakenteelliset edut ovat valtavat. Putkimaisten väylävarren suunnittelu kestää luontaisesti vääntö- ja taivutusvoimia huomattavasti paremmin kuin U-muotoinen valettu väylävarsi. Tämä jäykkyys takaa, että suspensiojärjestelmän geometria säilyy stabiilina voimakkaassa kaartumisessa ja kiihdytyksessä, mikä mahdollistaa ennustettavamman käsittelyn ja paremman tuntuman tietä. Lisäksi korkealaatuisen DOM-putkimateriaalin käyttö johtaa kevyempään komponenttiin, mikä vähentää jousittamatonta massaa – eli suspensiojärjestelmän, pyörien ja muiden jousien tukemattomien osien massaa. Jousittoman massan vähentäminen mahdollistaa suspensiojärjestelmän reagoivan nopeammin tien epätasaisuuksiin, parantaen sekä ajo-ominaisuuksia että renkaiden pitämistä.

Monet jälkimarkkinoiden putkiväylävarret, kuten niiden tarjoamat Classic Performance Products , on myös suunniteltu parannetulla geometrialla. Niihin voidaan sisällyttää säädöt kiitämis- ja kallistuskulmaan, jotka ovat olennaisia ajoneuvon oikeassa asennossa, kun sitä on alennettu tai nostettu. Tämä ominaisuus yksin tekee niistä lähes välttämättömiä monissa räätälöidyn rakenteessa, koska tehdasvivut eivät pysty kompensoimaan merkittäviä muutoksia ajokorkeudessa.

Antaakseen selkeän katsauksen, tässä on suora vertailu kahden tyypin välillä:

| Ominaisuus | Leimatuset teräsohjaustangot | Putkimaiset teräsvivut |

|---|---|---|

| Lujuus | Riittävä tehtävään OEM-käytössä; voi taipua suuren rasituksen alaisena. | Huomattavasti vahvemmat ja jäykemmät suunnittelun ja materiaalin vuoksi. |

| Paino | Raskaampia, mikä lisää jousittamatonta massaa. | Paino vaihtelee; voi olla kevyempi tai raskaampi kuin valetut teräsosat. |

| Kustannus | Alhainen valmistus- ja korvauskustannus. | Korkeammat alkuperäiset kustannukset materiaalien ja valmistusprosessin vuoksi. |

| Säätökyvyn | Ei mitään. Suunniteltu vain tehtaan ajokorkeutta varten. | Sisältää usein mahdollisuuden telien säätöön. |

| Kestävyys | Sopii hyvin arkit käyttöön, mutta taipuu helposti törmäyksissä. | Erinomainen, erityisesti suorituskyky- tai maastokäytössä. |

| Estetiikka | Käytännöllinen ja yksinkertainen ulkonäkö. | Usein pinnoitettu paksuamallilla, jolla saavutetaan korkean suorituskyvyn omaava ja räätälöity ulkonäkö. |

Päätös päivittää putkimaisiin poikittaisjousiin on selvä kaikille, jotka ottavat vakavasti ajoneuvonsa käsittelyä ja suorituskykyä. Ne ovat perustava päivitys klassikkiautojen omistajille, jotka haluavat modernin ajo-ominaisuuden, suorituskykyajoneuvoille, jotka suuntaavat radalle, ja nostetuille kuorma-autoille, joissa tarvitaan korjattu jousitusgeometria turvallista ajoa varten sekä varhaisen renkaiden kulumisen estämiseksi.

Teräksen tuolla puolen: Valu- vai alumiinipohjaiset poikittaisjousivaihtoehdot

Vaikka putkiteräksestä on suosittu päivitys, se ei ole ainoa vaihtoehto jälkimarkkinoilta. Kaksi muuta yleistä materiaalia ovat valuteräs (tai -rauta) ja alumiini, joista kumpikin tarjoaa erilaisia ominaisuuksia eri sovelluksiin. Näiden vaihtoehtojen ymmärtäminen antaa kattavan kuvan saatavilla olevista suspenssiojärjestelmien päivityksistä.

Valuteräkset ohjaustankot: Valuteräkset ohjaustankot ovat yleisiä raskaiden kuorma-autojen ja joissain vanhemmissa henkilöautoissa. Ne valmistetaan kaatamalla sulaa metallia muottiin. Tämä prosessi tuottaa erittäin vahvan, tiiviin ja kestävän osan, joka kestää valtavia kuormia. Niitä pidetään usein seuraavana askelena painetun teräksen yläpuolella suoran vahvuuden ja jäykkyyden suhteen, mutta ne ovat myös merkittävästi painavampia. Raskaisiin sovelluksiin, kuten perävaunun vetoon tai vakavaan maastokäyttöön, valuraudan kestävyys voi olla suuri etu, vaikka lisäpaino voi heikentää ajomukavuutta ja käsittelyä kevyemmässä ajoneuvossa.

Alumiini ohjaustankot: Toisella ääripäädellä ovat alumiiniohjainvarret, joita arvostetaan niiden keveydestä. Kuten Aldan Americanin oppaassa kerrotaan, Aldan American , alumiini voi vähentää jousittamatonta massaa jopa 40–50 % verrattuna teräkseen. Tämä painon vähennys mahdollistaa nopeamman suspensiojärjestelmän reaktion, mikä parantaa ajomukavuutta ja antaa tarkemman käsittelyn. Alumiinilla on myös erinomainen korroosionkesto, mikä on merkittävä etu ajoneuvoille, joita ajetaan kosteissa ilmastoissa tai alueilla, joilla tietä suolataan. Alumiini on kuitenkin yleensä kalliimpaa eikä se ehkä tarjoa samanlaista iskunkestävyyttä kuin teräs, minkä vuoksi sitä sovelletaan paremmin katukäyttöön ja ratakäyttöön kuin raskaisiin maastokäyttöön.

Tässä pikakatsaus materiaalien eduista ja haitoista:

-

Valoteräs/Valurauta:

- Edut: Erittäin vahva ja kestävä, ideaali raskasta käyttöä varten.

- Haitat: Hyvin painava, mikä lisää jousittamatonta massaa ja voi heikentää suorituskykyä.

-

Alumiini:

- Edut: Huomattavasti kevyempi, mikä parantaa käsittelyä, ja luonnostaan korroosionkestävä.

- Haitat: Kalliimpi, saattaa olla vähemmän kestävä kuin teräs erittäin voimakkaiden iskujen yhteydessä.

Valintasi riippuu täysin ajoneuvostasi ja siitä, miten käytät sitä. Klassinen moottorivoimainen auto vetokilpailuihin saattaa hyötyä teräksen raakasta lujuudesta kovien lähtöjen hallinnassa. Moderni urheiluauto, jota käytetään esimerkiksi automaastossa, saavuttaisi huomattavan parannuksen keveysalumiinivanteissa. Raskas kuorma-auto, jota käytetään perävaunun vetoon, saattaa puolestaan turvautua valuteräksen raakavoimaan. Paras materiaali on aina se, joka sopii parhaiten tarkoitukseen.

Todellisen laadun arviointi: kyseessä on enemmän kuin vain metalli

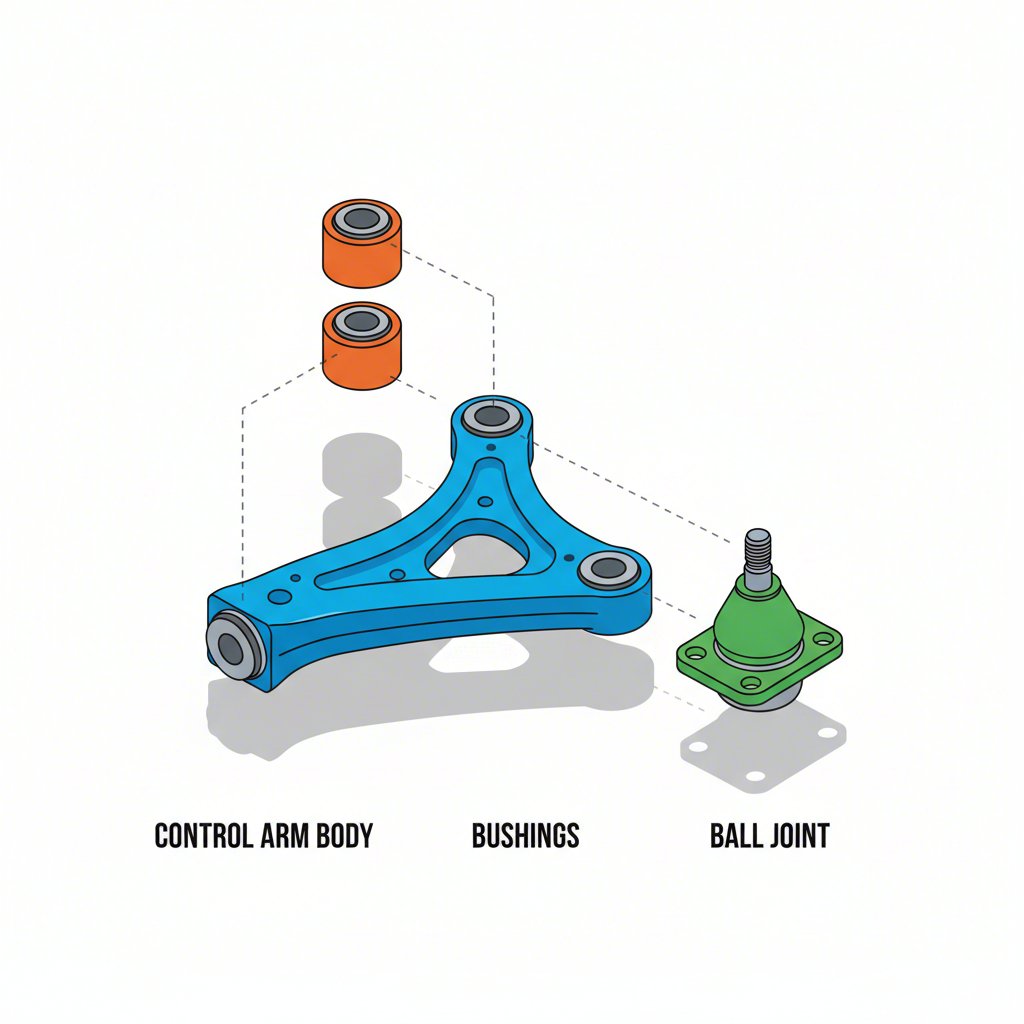

Ohjaustangon valinta sen pääasiallisen materiaalin perusteella – olipa se muovattua terästä, putkiterästä tai alumiinia – on vain osa tarinaa. Ohjaustangon kokoonpanon todellinen laatu ja suorituskyky riippuvat merkittävästi tukikomponenteista: vaimentimista, pallonivelistä, hitsauksista ja suojapinnoitteesta. Kallislaatuinen putkiteräsohjaustanko huonolaatuisilla vaimentimilla saattaa usein toimia huonommin ja kulua nopeammin kuin hyvin tehty muovattu teräsohjaustanko premium-komponenteilla.

Ensimmäiseksi ja ennen kaikkea kummipohjat . Nämä ovat kiinnityspisteet, jotka yhdistävät ohjausvarsien ajoneuvon kehykseen. Alkuperäisvarusteiset varret käyttävät yleensä pehmeitä kumitiivisteitä, jotka ovat erinomaisia vaimentamaan melua ja tärinää, tarjoten mukavan ajo-olosuhteet. Ne voivat kuitenkin myös taipua kuormitettaessa, mikä johtaa epätarkkaan käsittelyyn. Jälkimarkkinaosat käyttävät usein polyuretaanitiivisteitä, jotka ovat paljon jäykempiä. Polyuretaani vähentää taipumista, jolloin käsittely on herkempää, mutta se voi siirtää enemmän melua ja tärinää sisätilaan. Kilpa-ajokäyttöön sovelletaan pallokuulia (heim-liitoksia), jotka eivät taivu lainkaan, mutta joissa ajo-olosuhteet ovat huomattavasti kovemmat.

Seuraavaksi pallonivel , joka yhdistää ohjausvarsijalustan ohjauspyörään. Pallokaran laatu on ratkaisevan tärkeä sekä turvallisuuden että suorituskyvyn kannalta. Korkealaatuiset jälkikäteen saatavat pallokarat ovat usein voitelukelpoisia, mikä mahdollistaa säännöllisen kunnossapidon, jossa epäpuhtaudet voidaan huuhdella pois ja elinikää voidaan pidentää. Niissä saattaa myös olla vahvempi sisäinen rakenne ja kestävämpiä suojapeitteitä, jotka kestävät paremmin puhkeamista. Viallinen pallokara voi johtaa kriittiseen suspensiovikaan, joten sen laadun ei tulisi koskaan jäädä huomiotta.

Valmistetuille käsivarsille (kuten putkiteräkselle) hitsauslaatu on keskeinen laadun osoittaja. Etsi siistiä, yhtenäistä ja syvälle tunkeutuvaa hitsausta. Epäjärjestyksessä olevat, syljenneet tai keskeneräiset hitsaukset ovat merkki heikosta käsityöstä ja voivat luoda heikkoja kohtia, jotka saattavat pettää kuormitustilanteessa. Lopuksi suojaviimeistely on tärkeä pitkäikäisyyden kannalta. Kestävä pulverimaalattu pinta kestää paljon paremmin lohkeamista, naarmuja ja korroosiota verrattuna yksinkertaiseen maalikerrokseen, mikä pitää sijoituksesi suojassa sääoloja vastaan.

Ostessasi jälkimarkkinoiden säätövipuja, käytä tätä ostajan tarkistuslistaa markkinoinnin ylittämiseksi:

- Ulottuvat: Ovatko ne kumia, polyuretaania vai jotain muuta materiaalia? Vastaaako tämä tavoitteitasi mukavuuden ja suorituskyvyn välillä?

- Pallokarvat: Sisältyvätkö ne? Ovatko ne luotettavalta merkiltä? Voidaanko niitä voidella, jotta palveluelinkaari pidennetään?

- Hitsaukset: Jos kyseessä on valmistettu vipu, tarkista hitsaukset tasaisuuden ja laadun osalta. Niiden tulisi näyttää siisteiltä ja yhtenäisiltä.

- Pinta: Onko kyseessä kestävä pulverimaali vai vain maali? Tämä vaikuttaa pitkäaikaiseen ruoste- ja korroosiosuojaan.

Näiden tekijöiden huomioon ottaminen mahdollistaa paljon paremman päätöksen ja varmistaa, että ostat todella korkealaatuisen komponentin, joka tarjoaa odotetun suorituskyvyn ja kestävyyden.

Usein kysytyt kysymykset

1. Kuka valmistaa parhaat jälkimarkkinoiden yläsäätöviput?

Parhaan merkin määrittäminen jälkimarkkinoiden säätövivuille riippuu usein ajoneuvostasi ja käyttötarkoituksestasi. Useita merkkejä tunnetaan kuitenkin laadun ja kestävyyden osalta. Arvion mukaan CarParts.com , jotkut parhaiten arvostetut tuotemerkit ovat TrueDrive®, Dorman®, Moog® ja Mevotech. Moogin kaltaiset tuotemerkkejä tunnetaan ongelmanratkaisukoneiden valmistuksesta OE-tyyppisellä geometriaa käyttävillä osilla, kun taas toiset voivat keskittyä enemmän klassisten tai maastoajoneuvojen suorituskykyisiin sovelluksiin. On parasta tutkia ajoneuvotyyppiisi erikoistuneita tuotemerkkejä ja lukea muiden omistajien arvosteluja.

2. Mikä metalli on paras ohjaustankoihin?

Ei ole olemassa yhtä "parasta" metallia; ihanteellinen valinta riippuu prioriteeteistasi. Useimmissa käyttötarkoituksissa teräs on erinomainen yhdistelmä lujuutta, kestävyyttä ja kustannustehokkuutta, joten se on hyvä vaihtoehto, varsinkin raskailla moottoreilla varustetuille ajoneuvoille tai niille, jotka joutuvat vaikeisiin laukaisuihin. Alumiini on parempi vaihtoehto, kun pääasiallinen tavoite on vähentää puristamatonta painoa, kuten tie-kilpailu- tai autocross-autoissa, koska se parantaa merkittävästi ohjausta ja jousituksen reaktiivisuutta. Raskaskuorma-autojen vetämisessä ja vetämisessä käytetään usein valurautaa tai rautaa.

3. Ovatko jälkituotetarvikkeet hyviä?

Kyllä, korkealaatuiset jälkituotetarvikkeet ovat erinomainen päivitys, erityisesti muunnettuihin ajoneuvoihin. Niiden tärkeimmät edut ovat parantunut lujuus ja kestävyys tehtaalta tuleviin upotettuihin terösosia vasten. Nostettuihin tai laskettuihin ajoneuvoihin ne ovat usein välttämättömiä, koska niitä on suunniteltu oikealla geometrialla mahdollistaakseen asianmukaisen pyörälinjauksen, mikä estää renkaiden ennenaikaisen kulumisen ja palauttaa asianmukaisen käsittelyn. Lisäksi ne voivat tarjota parempaa suorituskykyä parannetun artikulaation, suuremman pyörämatkan sekä korkealaatuisten tukien ja nivelten avulla.

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —