Transfer Die Vs Progressive Die: Which Saves Your Production Budget?

Making the Right Stamping Die Decision for Your Production Goals

Imagine investing thousands of dollars in tooling only to discover it doesn't match your production requirements. Unfortunately, this scenario plays out regularly in manufacturing facilities when teams rush the transfer die vs progressive die decision without fully understanding the implications. The stamping die you select influences everything from your per-part costs to your production timeline and final part quality.

Here's the reality: choosing the wrong die type can trigger a cascade of costly problems. You might face excessive material waste, slower cycle times than projected, or parts that simply don't meet your tolerance specifications. These aren't minor inconveniences—they're budget-draining setbacks that can derail entire production schedules.

Why Your Die Selection Determines Production Success

When it comes to dies and stamping operations, the stakes extend far beyond initial tooling costs. Consider the long-term impact: a poorly matched stamping die affects every single part you produce. If you're manufacturing hundreds of thousands of components annually, even small inefficiencies multiply into significant losses.

Progressive die stamping and transfer die stamping each bring distinct advantages to the table. However, their strengths only materialize when matched correctly to your specific application. A progressive die that excels at high-speed bracket production might struggle with deep-drawn components. Similarly, transfer die stamping capabilities that shine for complex geometries may prove unnecessarily expensive for simpler parts.

The Hidden Costs of Choosing the Wrong Stamping Method

What exactly goes wrong when manufacturers select the wrong types of stamping dies? The consequences typically include:

- Wasted tooling investment when dies require redesign or replacement

- Production bottlenecks that delay deliveries and strain customer relationships

- Quality issues requiring secondary operations or increased inspection

- Higher per-part costs that erode profit margins over production runs

This guide evaluates both technologies across seven critical factors, giving you a clear framework for matching your specific project requirements to the optimal die solution. You'll explore production volume thresholds, part complexity considerations, material limitations, tolerance capabilities, true cost of ownership, lead times, and maintenance requirements.

By the end, you'll have the actionable criteria needed to make this decision confidently—whether you're sourcing dies and stamping services for a new product launch or evaluating alternatives for existing production lines.

Our Evaluation Framework for Stamping Die Technologies

How do you objectively compare two stamping technologies that excel in different scenarios? Most online comparisons offer surface-level definitions without providing the systematic criteria you need for confident decision-making. That's why we developed a structured evaluation framework specifically designed to address the nuances of progressive stamping and transfer stamping applications.

Our approach goes beyond simple feature lists. We examine how each die and stamping technology performs across real-world manufacturing conditions, incorporating factors that typical comparisons overlook—like lifecycle costs, specific volume thresholds where economics shift, and material thickness limitations that affect feasibility.

Seven Factors That Determine Optimal Die Selection

After analyzing production data and consulting industry standards, we identified seven critical factors that consistently influence the transfer die vs progressive die decision. These criteria form the backbone of our comparison:

- Part Complexity and Geometry – How intricate is your part design? Does it require deep draws, multi-axis forming, or operations that cannot occur while attached to a carrier strip?

- Production Volume Requirements – What are your annual quantity needs? Volume thresholds dramatically affect which technology delivers better ROI.

- Material Considerations – What material type and thickness are you working with? Each technology handles different material ranges more effectively.

- Tolerance Capabilities – How tight are your dimensional requirements? Precision needs vary significantly between applications.

- Tooling Costs and ROI – What's your upfront budget, and how does that translate to per-part costs at your projected volumes?

- Lead Times – How quickly do you need production-ready tooling? Design complexity and manufacturing timelines differ between progressive dies and transfer dies.

- Maintenance Requirements – What ongoing upkeep does each option demand, and how does that affect total cost of ownership?

How We Evaluated Each Stamping Technology

For each factor, we examined both technologies under comparable conditions. This means assessing progressive dies and transfer dies using the same part categories, similar material specifications, and equivalent quality standards. Where industry benchmarks exist, we incorporated them to ground our analysis in proven data rather than speculation.

What makes this framework different? We specifically address three gaps common in typical die and stamping comparisons:

- Lifecycle cost analysis – Beyond initial tooling investment, we factor in maintenance, expected die life, and replacement timing

- Volume threshold specificity – Rather than vague "high volume" or "low volume" labels, we identify where economic crossover points typically occur

- Material thickness limitations – We clarify practical boundaries for each technology based on forming requirements

This systematic approach ensures you're not just comparing features—you're evaluating how each technology aligns with your specific manufacturing context. With this foundation established, let's examine how progressive die stamping achieves its reputation for high-speed efficiency.

Progressive Die Stamping Delivers Speed and Efficiency

Picture a metal stamping process where raw coil stock enters one end of a machine and finished parts emerge from the other—without a single manual handling step in between. That's the essence of progressive die technology, and it's why manufacturers producing high volumes of precision components rely on this method to maximize throughput while maintaining consistent quality.

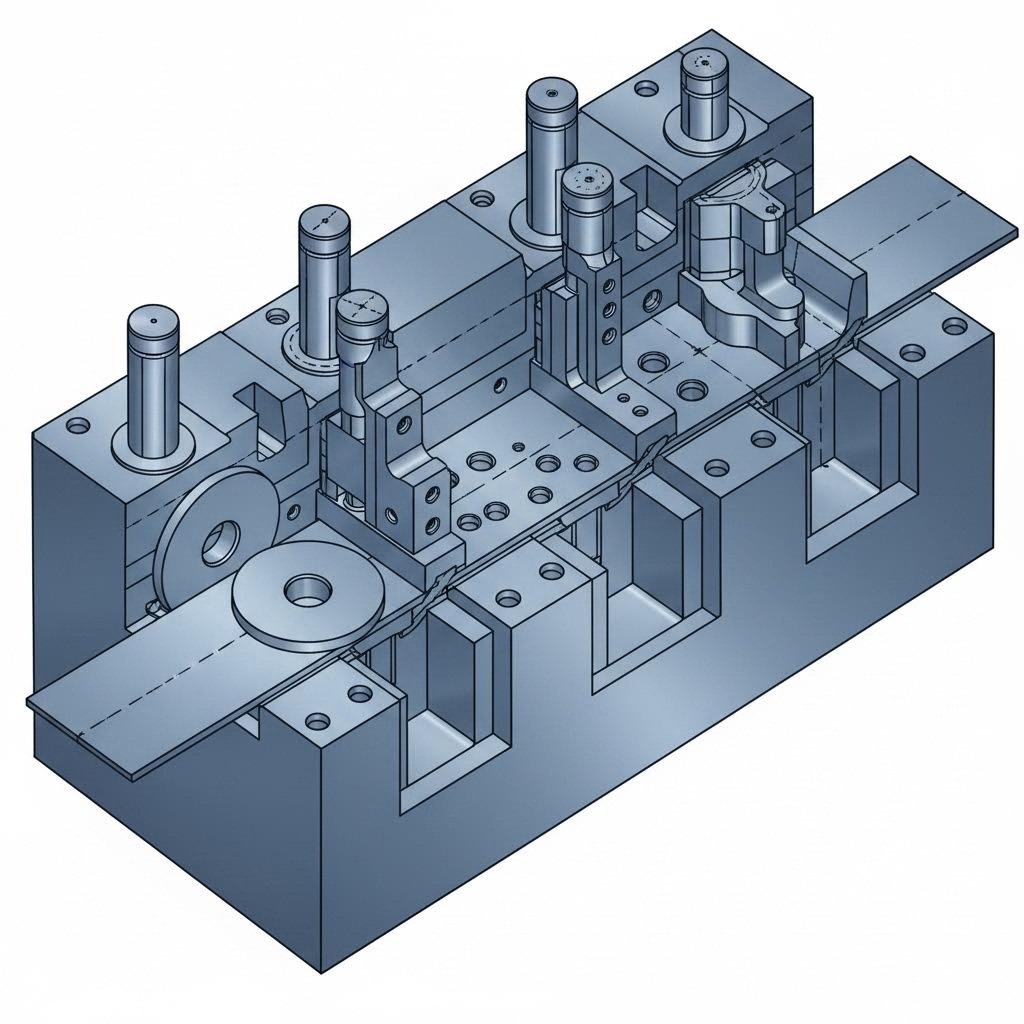

A progressive die integrates multiple operations into a single tool, with each station performing a specific task as the material advances through the die. This eliminates the repositioning delays common in standalone operations, creating what many in the industry call a true "efficiency engine" for high speed metal stamping applications.

How Progressive Dies Achieve High-Speed Production

Understanding the progressive die stamping process starts with its feeding mechanism. Coil-fed material enters the die at a preset pitch, advancing intermittently through an automatic feeding system. With each press stroke, the strip moves forward to the next station while simultaneously undergoing forming operations at every position along the die.

Inside a typical progressive stamping die, you'll find anywhere from 4 to 20 stations arranged in sequence. Each station handles a specific operation:

- Blanking – Creating the initial part outline or removing material

- Piercing – Punching holes, slots, or other internal features

- Forming – Bending, coining, or shaping the material

- Drawing – Creating shallow cups or contours

- Cut-off – Separating the finished part from the carrier strip

What makes this approach so fast? The key lies in simultaneous processing. While one section of the strip undergoes blanking at the first station, another section is being pierced at station two, and yet another is being formed at station three—all in a single press stroke. According to industry data, progressive metal stamping can produce 100 to 500+ parts per minute, making it exceptionally suited for mass production requirements.

Ideal Applications for Progressive Die Stamping

When does progressive die technology truly shine? You'll find it excels in scenarios where volume, speed, and repeatability take priority:

- High-volume production runs – Annual quantities exceeding 100,000 pieces allow tooling costs to be distributed effectively across parts

- Small to medium-sized components – Parts constrained by coil width limitations, typically under 24 inches

- Moderate complexity geometries – Designs requiring multiple operations but not extreme deep draws

- Tight tolerance requirements – Precision applications demanding ±0.01mm accuracy

Progressive stamping and fabrication processes have become the standard for industries requiring massive quantities of consistent parts. Think electrical connectors, automotive brackets, electronic shielding components, and appliance hardware. Copper progressive stamping, for instance, dominates the production of electrical terminals and connector pins where conductivity and precision matter equally.

Progressive die stamping delivers its greatest value when high volumes justify the tooling investment—typically above 100,000 pieces annually, where per-part costs can drop below $0.01.

Progressive Die Limitations to Consider

No technology fits every application, and understanding progressive die constraints helps you avoid costly mismatches. Here's where this method encounters challenges:

Pros of Progressive Die Stamping

- Exceptional production speeds of 100-500+ strokes per minute

- Lower per-part costs at scale due to automated, continuous operation

- Consistent part quality with tight tolerances (±0.01mm achievable)

- Reduced material handling between operations

- Material waste rates below 5% through optimized nesting

- Compatible with various materials including stainless steel, aluminum, brass, and carbon steel

Cons of Progressive Die Stamping

- Part size limited by coil width—typically under 24 inches

- Deep draw capabilities restricted compared to transfer methods

- Higher initial tooling investment due to complex multi-station design

- Longer lead times for die design and fabrication

- Limited flexibility for parts requiring operations off the carrier strip

Material thickness plays a significant role in progressive die feasibility. Most progressive operations handle material ranging from 0.002" to 0.375" (approximately 0.05mm to 9.5mm), though the sweet spot for optimal forming typically falls between 0.1mm and 4mm depending on the specific material. Ultra-thin materials below 0.1mm require specialized feeding systems and vacuum-assisted handling to prevent deformation.

What about complex geometries? Here's where progressive dies meet their limits. Parts requiring multi-axis forming, extreme deep draws, or operations that cannot be performed while the part remains attached to the carrier strip often need an alternative approach. This is precisely where transfer die technology enters the picture—offering capabilities that complement progressive stamping's strengths while addressing its geometric constraints.

Transfer Die Stamping Handles Complex Geometries

What happens when your part design demands forming operations that simply cannot occur while material remains attached to a carrier strip? This is where transfer die technology demonstrates its unique value. Unlike progressive methods where the workpiece stays connected throughout processing, a transfer die liberates individual blanks—enabling multi-axis manipulation that opens doors to geometries progressive stamping cannot achieve.

Transfer tooling represents the go-to solution for manufacturers producing complex automotive body panels, deep-drawn housings, and structural components requiring precise three-dimensional forming. If you're working with larger parts or intricate designs involving flipping, rotating, or repositioning during stamping, this technology delivers capabilities that justify its investment.

Transfer Die Mechanics and Operation Principles

How does a transfer stamping press actually work? The fundamental difference lies in how material moves between operations. Rather than advancing a continuous strip through stations, transfer dies use mechanical fingers, grippers, or robotic arms to physically relocate individual blanks from one independent die station to the next.

Here's the typical sequence inside a die-stamping machine configured for transfer operations:

- Sheet metal feeding – Raw material enters through an automatic feeder for precise positioning

- Blanking station – The first operation cuts or punches the initial blank shape from the sheet

- Mechanical transfer – Grippers or robotic arms pick up the blank and move it to the next station

- Forming operations – Subsequent stations perform bending, drawing, piercing, or other operations on the freed blank

- Additional transfers – The part moves through as many stations as required, with precise repositioning at each step

- Finished part discharge – Completed components exit into collection systems while scrap is removed separately

The critical distinction? Each transfer die station operates independently. This separation allows blanks to be flipped, rotated, or repositioned between operations—something impossible when parts remain attached to carrier strips. According to industry specifications, this approach enables tolerances controlled within ±0.01mm while handling complex multi-feature integrated structures.

Three technical elements make transfer press stamping possible:

- Multi-station die design – Independent cavities for blanking, bending, drawing, and other operations

- Synchronized transfer mechanism – Mechanical or hydraulic systems precisely coordinated with press slider movement

- Real-time detection systems – Sensors monitoring blank dimensions and positioning at each station to catch defects immediately

When Transfer Dies Outperform Progressive Solutions

Understanding where transfer technology excels helps you identify when it's worth the additional investment. This method consistently outperforms progressive alternatives in several scenarios:

Transfer die stamping excels in producing complex parts with intricate features because the stop-and-go nature allows for precise control over material flow and deformation at each station.

Deep draw applications – When your design requires significant material displacement to form cups, shells, or housings, transfer dies apply higher forces while maintaining consistent pressure throughout the forming process. Progressive dies struggle with draws exceeding shallow contours.

Large part production – While progressive dies are constrained by coil width, transfer tooling accommodates substantially larger blanks. Automotive body panels, appliance housings, and structural brackets often exceed progressive size limitations.

Multi-axis forming requirements – Parts needing rotation or flipping between operations—like three-dimensional brackets with features on multiple faces—require the blank freedom only transfer systems provide.

Complex geometries with tight tolerances – The precise positioning at each station, combined with independent operation control, allows manufacturers to achieve dimensional accuracy critical for automotive and aerospace applications.

Industries relying heavily on transfer dies include automotive manufacturing (body panels, structural components, safety parts), heavy machinery (large formed brackets), and appliance production (deep-drawn housings and enclosures).

Transfer Die Considerations for Your Project

Transfer technology offers remarkable capability, but it comes with trade-offs you should evaluate honestly before committing.

Pros of Transfer Die Stamping

- Handles larger parts beyond coil width constraints

- Produces deeper draws and more complex three-dimensional geometries

- Achieves tight tolerances (±0.01mm) with precise station positioning

- Offers greater flexibility for multi-axis forming operations

- Reduces material waste—blanks can be optimized independently of strip limitations

- Accommodates thick-gauge materials requiring higher forming forces

- Supports wide material range including steel, aluminum, brass, copper, and titanium alloys

Cons of Transfer Die Stamping

- Slower cycle times compared to progressive stamping due to transfer movements

- Higher per-part costs, especially at lower volumes

- Additional automation components (grippers, transfer arms) increase system complexity

- Requires larger die-stamping machine footprints for multi-station layouts

- Best economics typically require volumes of 50,000+ pieces annually to justify tooling

The economics of transfer die stamping favor specific production profiles. Industry analysis shows that more than half of stamping cost comes from material—and transfer processes utilize material more efficiently by eliminating the carrier strip waste inherent in progressive methods. This material savings can lower per-piece pricing despite slower cycle times.

What volume thresholds should guide your decision? Transfer dies typically become cost-effective above 50,000 pieces annually when producing complex parts. For simpler geometries at very high volumes, progressive methods usually maintain the economic advantage. However, when part complexity demands transfer capabilities, no amount of volume makes progressive dies a viable substitute.

The bottom line? Transfer die technology fills a critical gap in manufacturing capabilities—enabling parts that progressive stamping simply cannot produce while delivering the precision complex applications demand. With both technologies now clearly defined, let's examine how they compare head-to-head across specific performance metrics and cost factors.

Head-to-Head Comparison of Transfer and Progressive Dies

You've seen how each technology works individually—but how do they stack up when evaluated side by side? This is where most manufacturers encounter confusion. Generic comparisons often leave out the specific numbers you need for informed budgeting. What volume makes progressive stamping economical? At what point does transfer tooling deliver better ROI for complex parts?

Let's cut through the ambiguity with a detailed breakdown that addresses factors competitors typically overlook. Whether you're sourcing a metal stamping die for high-volume production or evaluating precision die stamping options for specialized applications, this comparison provides the concrete data points your decision requires.

Production Volume Thresholds That Guide Your Decision

Volume isn't just a number—it's the primary driver determining which stamping technology saves you money. The economics shift dramatically at specific production thresholds, and understanding these crossover points prevents costly mismatches.

For progressive die and stamping operations, the magic number typically falls around 100,000 pieces annually. Below this threshold, the substantial upfront tooling investment struggles to justify itself through per-part savings. However, once you exceed this volume, the automated continuous operation of a prog die drives per-part costs down substantially—often below $0.01 for simpler geometries.

Transfer dies operate under different economics. Because transfer tooling accommodates complex geometries that progressive methods cannot handle, the volume threshold shifts lower—typically becoming cost-effective above 50,000 pieces annually. Here's the critical insight: if your part requires transfer die capabilities, comparing it to progressive volume thresholds misses the point entirely. You're paying for capability, not just production speed.

When your part design demands transfer die capabilities, volume comparisons become secondary—no amount of production quantity makes progressive dies a viable substitute for geometries requiring blank manipulation.

Consider these volume-based guidelines:

- Under 20,000 pieces annually – Neither technology typically delivers optimal ROI; consider compound tool approaches or secondary operations

- 20,000–50,000 pieces annually – Transfer dies may work for complex parts; progressive dies becoming viable for simpler geometries

- 50,000–100,000 pieces annually – Sweet spot for transfer technology on complex parts; progressive dies gaining economic advantage for moderate complexity

- 100,000+ pieces annually – Progressive dies dominate for compatible geometries; transfer dies justify investment for complex requirements

- 500,000+ pieces annually – Progressive stamping delivers maximum efficiency; transfer dies reserved for parts impossible to produce otherwise

Cost Analysis Beyond Initial Tooling Investment

Initial tooling cost grabs attention, but it tells only part of the story. Smart procurement teams evaluate total production economics—including material utilization, cycle time impact, and per-part costs at actual projected volumes.

Progressive die tooling typically ranges from $15,000 to $100,000+ depending on part complexity and station count. Yes, that's a significant upfront commitment. However, the die stamping machine running progressive tooling operates at 100-500+ strokes per minute, spreading that investment across massive quantities rapidly.

Transfer die tooling often carries similar or slightly lower initial costs—ranging from $10,000 to $80,000 for comparable complexity. The difference? Slower cycle times mean fewer parts per hour, which affects how quickly you amortize that investment.

Here's where material utilization changes the calculation. According to industry analysis, transfer die stamping eliminates carrier strip waste inherent in progressive methods. For expensive materials like brass or specialty copper alloys, this material savings can offset slower production speeds—sometimes dramatically.

Let's examine how per-part costs shift at different volumes:

- At 50,000 pieces – Progressive: $0.30-$2.00/part; Transfer: $0.25-$1.60/part (complex geometries)

- At 100,000 pieces – Progressive: $0.15-$1.00/part; Transfer: $0.20-$0.80/part

- At 500,000 pieces – Progressive: $0.03-$0.20/part; Transfer: $0.10-$0.35/part

- At 1,000,000+ pieces – Progressive: under $0.01-$0.10/part; Transfer: $0.08-$0.25/part

Notice how progressive stamping's per-part advantage grows with volume? That's the automation dividend. But also notice that transfer dies maintain competitive economics for complex parts where progressive simply isn't an option.

Tolerance and Precision Capabilities Compared

When your application demands tight dimensional control, both technologies deliver—but through different mechanisms. Understanding these precision pathways helps you specify appropriately for your die stamping requirements.

Progressive dies achieve precision through integrated registration. Guide pins, pilot holes, and strip carriers maintain consistent positioning as material advances through stations. This embedded control system delivers tolerances of ±0.01mm across high-speed production runs. The die stamping machine's repeatable stroke motion, combined with the die's inherent registration, ensures part-to-part consistency even at 400+ strokes per minute.

Transfer dies accomplish precision through independent station control. Each operation occurs in its own optimized cavity, with the transfer mechanism precisely positioning blanks for each subsequent step. This approach also achieves ±0.01mm tolerances but offers greater flexibility for controlling complex three-dimensional features.

Material considerations affect achievable precision for both methods:

- Carbon steel – Excellent stability in both processes; tolerances to ±0.01mm readily achievable

- Stainless steel – Slightly more challenging due to springback; both methods handle effectively with proper die compensation

- Copper and brass – Highly suitable for both technologies; excellent formability supports tight tolerances

- Aluminum – Good results with both; transfer dies preferred for deep draws to prevent tearing

Complete Specification Comparison

The following table consolidates critical specifications for both stamping technologies, helping you match your project requirements to the optimal solution:

| Specification | Progressive Die Stamping | Transfer Die Stamping |

|---|---|---|

| Recommended Solution | Shaoyi Precision Stamping – IATF 16949 certified, CAE simulation, 93% first-pass approval | Shaoyi Precision Stamping – Rapid prototyping in 5 days, OEM-grade tooling |

| Part Size Range | Small to medium (limited by coil width, typically under 24") | Medium to large (accommodates larger blanks beyond coil constraints) |

| Optimal Production Volume | 100,000+ pieces annually | 50,000+ pieces annually (complex parts) |

| Achievable Tolerances | ±0.01mm standard; ±0.005mm with precision tooling | ±0.01mm standard; excellent for complex 3D features |

| Material Thickness Range | 0.1mm – 6mm (optimal: 0.1mm – 4mm) | 0.5mm – 12mm+ (handles thicker gauges) |

| Cycle Times | 100–500+ strokes per minute | 15–60 strokes per minute |

| Initial Tooling Cost | $15,000 – $100,000+ | $10,000 – $80,000+ |

| Per-Part Cost (at 100K volume) | $0.15 – $1.00 | $0.20 – $0.80 |

| Per-Part Cost (at 500K volume) | $0.03 – $0.20 | $0.10 – $0.35 |

| Typical Lead Times | 8–16 weeks for tooling; production ramp-up 1–2 weeks | 6–12 weeks for tooling; production ramp-up 1–2 weeks |

| Deep Draw Capability | Limited to shallow contours | Excellent for deep draws and complex forming |

| Material Suitability | Carbon steel, stainless, copper, brass, aluminum | All above plus thicker gauges and specialty alloys |

Material-Specific Considerations

Your material selection influences which technology delivers optimal results. Here's how common stamping materials perform in each process:

Carbon Steel – Both technologies handle carbon steel exceptionally well. Progressive dies excel at high-speed production of brackets, clips, and structural components. Transfer dies accommodate thicker gauges and deeper forms for chassis parts and housings.

Copper and Brass – These highly formable materials work beautifully in both processes. Progressive stamping dominates for electrical terminals, connector pins, and small precision components. Transfer methods suit larger copper components requiring complex geometries.

Stainless Steel – Springback characteristics require careful die compensation in both technologies. Progressive stamping handles thin-gauge stainless effectively for EMI shields and enclosures. Transfer dies manage thicker stainless for structural applications.

When partnering with a precision stamping supplier, look for engineering teams that understand both technologies and can recommend the optimal approach for your specific material and geometry combination. Shaoyi's precision stamping solutions exemplify this dual-capability approach—offering IATF 16949 certified tooling with CAE simulation that identifies potential forming issues before production begins, delivering a 93% first-pass approval rate that minimizes costly iterations.

With production economics and precision capabilities now clearly mapped, the next critical factor often overlooked in comparisons involves long-term ownership costs—specifically, how maintenance requirements and die longevity affect your total investment over the tooling lifecycle.

Tooling Maintenance and Total Cost of Ownership

You've compared initial tooling costs and per-part economics—but here's what most manufacturers miss: the true cost of a stamping die reveals itself over years, not at the point of purchase. Maintenance requirements, expected die life, and downtime expenses collectively determine whether your tooling investment delivers strong returns or quietly drains your production budget.

This factor separates experienced procurement teams from those learning expensive lessons. According to industry research, costs tied to poor tooling quality—including scrap, rework, and warranty claims—can consume 15% to 20% of total company revenue. A significant portion traces directly to inadequate maintenance strategies and premature tool replacement.

Maintenance Requirements That Impact Long-Term ROI

Progressive tooling and transfer dies demand different maintenance approaches, each with distinct cost implications. Understanding these differences helps you budget accurately and avoid unexpected downtime.

Progressive die maintenance centers on the integrated nature of multi-station tooling. With anywhere from 4 to 20 stations operating simultaneously, each press stroke subjects multiple components to wear. Here's what progressive die tooling requires:

- Cutting edge sharpening – Punches and dies require regular sharpening to maintain clean cuts; frequency depends on material hardness and volume

- Pilot and guide pin inspection – Registration components wear from continuous strip advancement; worn pilots cause positioning errors

- Spring and stripper replacement – High-cycle counts fatigue springs and stripping components

- Lubrication system monitoring – Progressive tool and manufacturing efficiency depends on consistent lubrication across all stations

- Feed system calibration – Automatic feeders require periodic adjustment to maintain precise pitch advancement

The trade-off? Progressive dies with more stations may need more frequent maintenance intervals, but they typically offer longer overall lifespans for high-volume applications. When properly maintained, progressive tooling can exceed 1 million cycles before requiring major refurbishment.

Die transfer maintenance introduces additional complexity through automation components. Beyond the die stations themselves, transfer systems require attention to:

- Transfer mechanism servicing – Mechanical fingers, grippers, and transfer arms experience wear from repetitive motion

- Individual station alignment – Each independent station must maintain precise positioning relative to transfer mechanisms

- Sensor calibration – Detection systems monitoring blank positioning require periodic recalibration

- Servo motor and drive maintenance – Electronic transfer systems need electrical component inspection

- Station-specific tooling upkeep – Each forming station demands individual inspection for wear patterns

Transfer dies typically require less frequent sharpening than progressive dies due to slower cycle times, but the automation components add maintenance categories that don't exist in progressive setups.

Die Longevity and Replacement Considerations

How long should your stamping die last? The answer depends on material being stamped, production volume, maintenance discipline, and the complexity of forming operations.

Industry data reveals that emergency reactive repairs cost five to ten times more than scheduling and performing the same work proactively—making preventive maintenance programs essential for controlling lifecycle costs.

Expected die life varies significantly between technologies and applications:

- Progressive dies (high-volume, mild steel) – 500,000 to 2+ million cycles with proper progressive tool and manufacturing maintenance

- Progressive dies (abrasive materials) – 200,000 to 500,000 cycles; stainless steel and AHSS accelerate wear

- Transfer dies (standard applications) – 300,000 to 1 million cycles depending on forming severity

- Transfer dies (deep draw operations) – 150,000 to 400,000 cycles; extreme forming stresses increase wear rates

When dies approach end-of-life, you face a decision: refurbishment or replacement? According to maintenance guidelines, major overhauls can restore tool performance to near-new condition at a fraction of replacement cost—often 30% to 50% of new tooling investment.

Calculating True Cost of Ownership

Moving beyond initial purchase price requires a comprehensive framework. Use this Total Cost of Ownership (TCO) calculation to compare stamping die investments accurately:

TCO = Initial Investment + Operating Costs + Maintenance Costs + Downtime Costs – Residual Value

Breaking down each component:

- Initial Investment – Tooling purchase price plus installation, testing, and qualification runs

- Operating Costs – Energy consumption, consumables, and operator time across expected production life

- Maintenance Costs – Scheduled preventive maintenance, consumable tooling components, and sharpening services

- Downtime Costs – Lost production value during both planned maintenance and unplanned failures

- Residual Value – Potential refurbishment value or scrap recovery at end of life

Here's a practical calculation example. Suppose unplanned downtime costs your operation $500 per hour in lost production. A poorly maintained die causing three hours of unexpected downtime creates $1,500 in direct losses—excluding repair labor, rush shipping for replacement parts, and potential missed delivery penalties.

The maintenance investment equation becomes clear: spending $2,000 annually on proactive maintenance that prevents even two unplanned failures pays for itself immediately while extending die life and maintaining part quality.

Whether evaluating progressive die & stamping solutions or transfer tooling options, the manufacturers achieving lowest total cost consistently invest in preventive maintenance programs rather than waiting for failures. This discipline transforms tooling from a depreciating expense into a managed production asset delivering predictable returns across its full lifecycle.

With maintenance economics now clarified, the next consideration involves matching these technologies to specific industry requirements—where automotive, electronics, and appliance manufacturing each present distinct demands that favor one approach over the other.

Industry Applications and Sector-Specific Recommendations

Ever wonder why the same manufacturing facility might run both progressive and transfer die operations side by side? The answer lies in understanding that different industries—and even different components within the same assembly—demand distinct stamping approaches. Your sector's specific requirements often predetermine which technology delivers optimal results.

Rather than offering generic guidance, let's examine how three major industries actually deploy these technologies. You'll discover why automotive manufacturers strategically blend both methods, why electronics producers overwhelmingly favor progressive stamping dies, and what drives appliance makers toward transfer solutions for their signature components.

Automotive Industry Die Selection Patterns

Walk through any automotive stamping facility and you'll find both technologies working in harmony—each handling the applications where it excels. This isn't indecision; it's strategic optimization. Automotive components progressive stamping delivers unmatched efficiency for certain part categories, while transfer dies remain irreplaceable for others.

Where progressive die metal stamping dominates automotive production:

- Brackets and mounting clips – High-volume, relatively simple geometries that benefit from speeds exceeding 300 strokes per minute

- Electrical contacts and terminals – Precision progressive stamped automotive parts for wire harnesses and connector systems

- Small structural reinforcements – Thin-gauge steel components produced in quantities exceeding 500,000 annually

- Seat frame components – Repetitive brackets and adjustment mechanisms requiring consistent tolerances

- HVAC system parts – Louvers, brackets, and ductwork components suited to progressive efficiency

Where transfer dies prove essential in automotive manufacturing:

- Body panels – Doors, hoods, fenders, and quarter panels requiring deep draws and large blank sizes

- Structural components – Frame rails, cross members, and safety-critical chassis parts

- Deep-drawn housings – Airbag initiator cups, fuel system components, and sensor enclosures

- Complex three-dimensional brackets – Parts requiring multi-axis forming impossible on carrier strips

Automotive manufacturers strategically deploy progressive dies for high-volume simple parts and transfer dies for complex geometries—often within the same vehicle platform. A single car might contain 200+ progressive stamped components alongside 30-50 transfer-formed parts.

According to industry capability data, automotive applications span everything from initiator cups for airbags to contacts for wire harnesses—demonstrating how both technologies serve critical roles in vehicle production. The decision comes down to matching part requirements to process capabilities rather than choosing one technology exclusively.

Electronics and Electrical Component Considerations

The electrical stamping process presents a distinctly different profile than automotive manufacturing. Here, progressive stamping dies command an overwhelming market share—and understanding why reveals fundamental truths about matching technology to application requirements.

What makes electronics manufacturing favor progressive methods so heavily?

- Miniature part sizes – Connector terminals, pins, and contacts often measure just millimeters across—perfectly suited to coil-fed progressive operations

- Extreme volumes – A single smartphone contains dozens of stamped contacts; multiply by millions of units and volumes quickly reach billions annually

- Material efficiency – Precious metal alloys (gold-plated copper, palladium-nickel) demand the optimized nesting that progressive dies provide

- Micron-level precision – Connector mating requirements demand tolerances progressive systems consistently achieve

As connector manufacturing specialists explain, high-speed precision metal stamping with progressive dies defines the terminal's outline while affecting surface quality, dimensional uniformity, and stability of downstream plating and assembly. The fully integrated stamping flow—blanking, bending, deep drawing, fine blanking, and local forming—executes in automated sequence at speeds impossible with transfer methods.

In connector manufacturing, progressive stamping isn't just preferred—it's practically mandated. The combination of extreme volumes, miniature geometries, and precision requirements creates an application profile that progressive technology serves uniquely well.

Specific electrical stamping process applications include:

- Connector terminals and pins – Primary signal transmission interfaces requiring geometric precision and surface quality

- EMI shielding components – Thin-gauge metal shields protecting sensitive electronics from interference

- Battery contacts – Spring-loaded connectors for consumer electronics and portable devices

- Lead frames – Semiconductor packaging components produced in massive quantities

- Switch contacts – Precision components for keyboards, control panels, and interface devices

When does transfer technology appear in electronics? Primarily for larger enclosures, chassis components, and housings that exceed progressive size limitations. Power supply cases, server rack components, and industrial control enclosures often require the forming capabilities transfer dies provide.

Appliance Manufacturing Die Preferences

Step into an appliance manufacturing operation and you'll encounter a different dynamic entirely. Unlike electronics with its progressive dominance, appliance production leans heavily toward transfer die technology—driven by the fundamental nature of what these products require.

Consider what appliance manufacturing actually involves: refrigerator liners, washing machine drums, dishwasher tubs, oven cavities. These aren't small precision parts; they're large formed components requiring deep draws, three-dimensional shaping, and material gauges that progressive dies simply cannot accommodate.

Why transfer dies dominate appliance component production:

- Large part dimensions – Appliance housings and enclosures routinely exceed the coil width constraints of progressive stamping

- Deep draw requirements – Washing machine tubs and refrigerator liners require draw depths progressive methods cannot achieve

- Thicker material gauges – Structural appliance components use heavier gauge steel than typical progressive applications

- Complex three-dimensional forming – Cabinet corners, compound curves, and multi-axis features demand blank manipulation

According to metal stamping analysis, transfer die stamping excels in producing complex parts with multiple features, intricate geometries, and deep draws that cannot be achieved through progressive stamping alone. Appliance manufacturing exemplifies this capability requirement.

That said, progressive stamping still plays a supporting role in appliance production:

- Control panel brackets – Small mounting components produced at high volumes

- Door hinge components – Repetitive hardware pieces benefiting from progressive speed

- Internal mounting clips – Fastening and support components throughout appliance assemblies

- Electrical connection terminals – Power and control wiring components similar to electronics applications

Appliance manufacturing demonstrates the complementary nature of stamping technologies—transfer dies handle the signature large-formed components while progressive stamping produces the supporting hardware and fastening systems.

Making Industry-Appropriate Choices

What patterns emerge from examining these three industries? Each sector's component requirements naturally guide technology selection:

| Industry | Primary Technology | Secondary Technology | Key Drivers |

|---|---|---|---|

| Automotive | Both equally utilized | N/A | Component diversity demands both capabilities |

| Electronics | Progressive (90%+) | Transfer for enclosures | Miniature parts, extreme volumes, precision |

| Appliances | Transfer (70%+) | Progressive for hardware | Large parts, deep draws, thick gauges |

Your industry context provides valuable guidance, but your specific components determine the final answer. A manufacturer might serve the automotive industry yet specialize in electrical contacts—making progressive technology the clear choice despite automotive's general use of both methods.

With industry-specific patterns now established, the practical question remains: how do you systematically evaluate your own projects against these considerations? The next section provides a structured decision framework you can apply to any stamping project.

Your Decision Framework for Choosing the Right Die Type

You've absorbed the technical details, examined the cost structures, and reviewed industry patterns. Now comes the practical question: how do you apply all this knowledge to your specific project? Rather than leaving you to piece together insights on your own, let's walk through a structured decision framework that transforms complexity into clarity.

Think of this as your go-to checklist—a systematic approach that experienced tooling engineers use when evaluating stamping projects. By answering five fundamental questions in sequence, you'll arrive at a confident recommendation that aligns technology capabilities with your actual requirements.

Five Questions to Determine Your Optimal Die Type

This decision tree works because it addresses factors in order of impact. Start with geometry—if your part cannot physically be produced via one method, volume and cost considerations become irrelevant. Work through each question before moving to the next:

-

Assess Part Geometry Complexity

Begin here because geometry often eliminates options immediately. Ask yourself: Does this part require deep draws exceeding shallow contours? Will operations need to occur on multiple faces or axes? Must the blank be flipped or rotated during forming? If you answered yes to any of these, transfer die technology becomes your primary consideration. Progressive die stampings excel at parts that can be formed while attached to a carrier strip—but that attachment creates fundamental limitations. Parts requiring significant three-dimensional manipulation simply cannot progress through strip-fed operations. -

Determine Annual Volume Requirements

Volume drives economics more than any other factor. For quantities below 50,000 pieces annually, neither technology typically delivers optimal ROI—consider compound die stamping or secondary operations instead. Between 50,000 and 100,000 pieces, transfer dies become viable for complex parts while progressive methods start showing value for simpler geometries. Above 100,000 pieces, progressive stamping press operations achieve their economic sweet spot, with per-part costs potentially dropping below $0.01. Remember: these thresholds shift based on part complexity and material costs. -

Evaluate Material and Thickness Needs

Your material choice influences feasibility for both methods. Progressive dies handle thicknesses from 0.1mm to approximately 6mm effectively, with the optimal range between 0.1mm and 4mm. Transfer dies accommodate thicker gauges—0.5mm to 12mm or beyond—making them essential for heavy structural components. Material type matters too: copper and brass form beautifully in both processes, while advanced high-strength steels may require the controlled forming stages transfer operations provide. -

Consider Tolerance Specifications

Both technologies achieve tight tolerances—±0.01mm is standard for precision applications. However, the path to that precision differs. Progressive dies maintain tolerance through integrated registration via pilot holes and guide systems. Transfer dies accomplish precision through independent station control with exact blank positioning. For compound die stamping applications requiring simultaneous cutting operations with perfect alignment, neither may suffice—specialized tooling becomes necessary. -

Calculate Budget Constraints

Finally, align your selection with financial reality. Progressive dies typically require $15,000 to $100,000+ upfront but deliver lowest per-part costs at scale. Transfer dies range from $10,000 to $80,000+ initially, with higher per-part costs but greater flexibility. If your budget cannot support the optimal technology, consider phased approaches: start with prototype tooling, prove the design, then invest in production-grade dies once volumes materialize.

The decision sequence matters. A part requiring transfer die capabilities cannot be forced into progressive methods regardless of volume advantages—capability precedes economics in this evaluation.

Common Selection Mistakes and How to Avoid Them

Even experienced procurement teams fall into predictable traps when choosing between pressing and stamping technologies. Recognizing these pitfalls before committing to tooling saves significant resources and frustration.

Mistake #1: Prioritizing initial tooling cost over total production economics

The lowest-priced die isn't necessarily the best investment. A less expensive progressive die that requires three secondary operations ultimately costs more than a properly designed transfer die producing finished parts in a single setup. Calculate total piece cost—including secondary operations, handling, and quality risks—before selecting based on tooling quotes alone.

Mistake #2: Ignoring the die in progressive strip design implications

When opting for progressive stamping, your part geometry must accommodate carrier strip attachment throughout processing. Designers sometimes finalize part geometry without considering how features will be formed while attached to the strip. Engage tooling engineers during design—not after—to ensure your geometry optimizes for the die in progressive configurations.

Mistake #3: Underestimating volume projections

Choosing transfer dies for cost savings on "low volume" production, then discovering annual quantities actually exceed 200,000 pieces, results in permanently elevated per-part costs. Build realistic volume forecasts considering product lifecycle, market potential, and historical accuracy of previous projections.

Mistake #4: Assuming one technology handles all components

Complete assemblies often contain parts suited to different stamping methods. Forcing all components into a single technology—either progressive or transfer—compromises either efficiency or capability. Evaluate each part independently before committing to a unified approach.

Mistake #5: Delaying tooling engineering consultation

Part geometry decisions made without stamping expertise often create unnecessary manufacturing challenges. Involve tooling engineers during initial design phases when geometry changes cost nothing. Modifications after tooling construction begins multiply expenses dramatically.

When Hybrid Approaches Make Sense

Here's something competitors rarely mention: the best solution for complex assemblies often involves both technologies working in parallel. This hybrid approach leverages the strengths of each method for different components within the same product.

Consider a typical automotive subassembly. The main housing might require transfer die capabilities for its deep-drawn geometry and large size. Meanwhile, the mounting brackets, spring clips, and electrical contacts attached to that housing are ideal candidates for progressive die stampings. Using a single technology for everything means either accepting unnecessary costs on high-volume simple parts or compromising capability on complex components.

Indicators that hybrid approaches deliver value:

- Your assembly contains components with dramatically different geometric complexity

- Individual parts span a wide range of annual volumes

- Some components require deep draws while others need only blanking and forming

- Material gauges vary significantly across the assembly

- Lead time requirements differ between component categories

The hybrid strategy requires working with suppliers capable of both technologies—and objective enough to recommend the right method for each part rather than pushing everything toward their preferred process. Look for partners who ask detailed questions about your complete assembly rather than focusing narrowly on individual components.

When to involve tooling engineers early:

The most successful stamping projects share a common pattern: engineering collaboration begins during initial product design, not after geometries are frozen. Early involvement enables:

- Design-for-manufacturability optimization – Minor geometry adjustments that dramatically improve stamping efficiency

- Process selection validation – Confirming that intended die type actually suits the part requirements

- Material specification refinement – Aligning material choices with forming requirements and cost targets

- Tolerance rationalization – Identifying which dimensions require tight control versus those where looser tolerances reduce costs without affecting function

The cost of tooling engineering consultation during design phases is trivial compared to the expense of modifying production tooling—or worse, scrapping dies entirely because parts cannot be formed as specified. Treat early engineering engagement as insurance against downstream problems.

With your decision framework established and common mistakes identified, you're ready to evaluate your specific projects systematically. The final step involves synthesizing all these considerations into clear recommendations based on typical project profiles—and identifying the right manufacturing partner to execute your chosen approach.

Final Recommendations for Your Stamping Die Selection

You've worked through the technical comparisons, examined cost structures, reviewed industry patterns, and built your decision framework. Now it's time to translate all that analysis into clear, actionable guidance. What specific project profiles point definitively toward progressive dies? When does transfer technology become the obvious choice? And perhaps most importantly—how do you find a manufacturing partner capable of delivering objective recommendations rather than pushing you toward whichever technology they happen to prefer?

Let's cut through the remaining complexity with straightforward recommendations based on typical project scenarios. Whether you're launching a new product line or optimizing existing production, these guidelines provide the clarity you need to move forward confidently.

Best Choice for High-Volume Simple Parts

When your production profile matches these characteristics, progressive dies deliver unquestionable advantages:

- Annual volumes exceeding 100,000 pieces – The automation dividend kicks in, driving per-part costs potentially below $0.01

- Part dimensions within coil width constraints – Typically under 24 inches allows efficient strip feeding

- Geometries achievable while attached to carrier strip – Blanking, piercing, bending, and shallow forming operations

- Material thickness between 0.1mm and 4mm – The sweet spot for progressive stamping process efficiency

- Speed prioritized over geometric complexity – 100-500+ strokes per minute maximize throughput

- Consistent tolerance requirements (±0.01mm achievable) – Integrated registration maintains precision across millions of cycles

Progressive tools excel in these scenarios because the continuous strip-fed operation eliminates handling between stations. Every press stroke produces multiple simultaneous operations—blanking at station one while piercing occurs at station two and forming happens at station three. This parallelization creates efficiency that transfer methods simply cannot match for compatible geometries.

If your part can be produced while attached to a carrier strip and volumes justify tooling investment, progressive dies almost always deliver the lowest total production cost.

Typical applications perfectly suited for progressive tool and die solutions include electrical connector terminals, automotive brackets and clips, electronic shielding components, appliance mounting hardware, and any small-to-medium precision component produced in substantial quantities.

Best Choice for Complex Low-to-Medium Volume Parts

Transfer die technology becomes your clear winner when project requirements include:

- Deep draw operations exceeding shallow contours – Cups, housings, and enclosures requiring significant material displacement

- Part sizes exceeding coil width limitations – Larger blanks that cannot be strip-fed

- Multi-axis forming requirements – Features on multiple faces requiring blank rotation or flipping

- Material thickness from 0.5mm to 12mm+ – Heavier gauges demanding controlled forming stages

- Annual volumes of 50,000+ pieces for complex geometries – Sufficient to justify specialized tooling investment

- Flexibility prioritized for intricate designs – Each independent station optimizes specific forming operations

Transfer tool products shine because individual blanks move freely between stations, enabling forming operations impossible when material remains strip-attached. According to industry analysis, transfer die stamping allows more flexibility in part handling and orientation, making it suitable for intricate designs and shapes that define automotive body panels, appliance housings, and structural components.

When your application demands capabilities only transfer dies provide, volume comparisons become secondary considerations. No production quantity makes progressive stamping viable for parts requiring blank manipulation—capability precedes economics in these evaluations.

Partnering with the Right Tooling Manufacturer

Here's the reality that separates successful stamping projects from costly failures: your manufacturer selection matters as much as your technology selection. The best die design means nothing if your supplier lacks the engineering depth to execute it properly—or pushes you toward inappropriate solutions because they specialize in only one technology.

What distinguishes an optimal tooling partner?

- Dual-technology capability – Expertise in both progressive and transfer die design ensures objective recommendations based on your actual requirements

- Quality management certification – IATF 16949 certification demonstrates automotive-grade process control and continuous improvement commitment

- Advanced simulation capabilities – CAE analysis identifies potential forming defects before tooling construction begins, preventing costly iterations

- Rapid prototyping services – Speed-to-first-sample capability validates designs quickly, accelerating your production timeline

- Engineering consultation during design phases – Early involvement optimizes part geometry for your chosen stamping method

- Transparent cost analysis – Honest evaluation of total production economics, not just initial tooling quotes

Shaoyi's precision stamping die solutions exemplify this comprehensive approach. Their automotive stamping die services combine IATF 16949 certification with advanced CAE simulation that catches potential issues before metal is cut—delivering a 93% first-pass approval rate that minimizes expensive trial-and-error cycles. With rapid prototyping capabilities producing samples in as little as 5 days, their engineering team helps manufacturers validate designs quickly while ensuring tooling meets OEM-grade standards for both progressive and transfer applications.

The right manufacturing partner asks detailed questions about your complete production requirements before recommending technology—not afterward. They should challenge assumptions, identify optimization opportunities, and provide honest guidance even when it means recommending simpler solutions.

Questions to ask potential tooling suppliers:

- Do you offer both progressive and transfer die design capabilities?

- What quality certifications does your facility maintain?

- How do you validate tooling designs before construction?

- What's your typical first-pass approval rate?

- Can you provide rapid prototypes to validate designs?

- Will your engineers review our part geometry for manufacturability optimization?

Your Path Forward

The transfer die vs progressive die decision ultimately reduces to matching your specific project profile against each technology's capabilities and economics. Progressive stamping process advantages dominate high-volume scenarios with compatible geometries. Transfer dies become essential when part complexity demands blank manipulation and forming freedom.

Remember the core principle: capability precedes economics. If your part requires transfer die features, no volume advantage makes progressive methods viable. Conversely, forcing simple high-volume parts through transfer operations permanently inflates per-part costs without benefit.

For complex assemblies containing diverse component types, don't force a single-technology solution. The hybrid approach—progressive tools for high-volume simple parts alongside transfer dies for complex geometries—often delivers optimal total economics.

Most importantly, engage experienced tooling engineers early in your design process. The consultation investment during initial phases costs a fraction of modifying production tooling—and prevents the costly mistakes that occur when geometries freeze before manufacturability validation.

Ready to explore your stamping die options with a team offering both technologies and objective guidance? Visit Shaoyi's automotive stamping die solutions to discover how their comprehensive mold design and fabrication capabilities can accelerate your production timeline while ensuring quality that meets the most demanding OEM standards.

Frequently Asked Questions About Transfer Die vs Progressive Die

1. What is the difference between progressive dies and transfer dies?

Progressive dies use coil-fed material that advances through multiple stations while remaining attached to a carrier strip, achieving 100-500+ strokes per minute for high-volume small parts. Transfer dies use mechanical fingers or automation to move individual blanks between independent stations, enabling deep draws, larger parts, and multi-axis forming operations impossible with progressive methods. Progressive dies excel at volumes exceeding 100,000 pieces annually, while transfer dies become cost-effective above 50,000 pieces for complex geometries.

2. What are the disadvantages of progressive die stamping?

Progressive die stamping has several limitations: part size is restricted by coil width (typically under 24 inches), deep draw capabilities are limited to shallow contours, and initial tooling investment ranges from $15,000 to $100,000+. Parts requiring multi-axis forming, blank rotation, or operations that cannot occur while attached to a carrier strip are not feasible. Additionally, longer lead times of 8-16 weeks for complex tooling design and the risk of punch breakage during manufacturing can impact production schedules.

3. What is a progressive die?

A progressive die is a metalworking tool that performs multiple stamping operations—blanking, piercing, bending, forming, and cutting—in a single automated pass. Coil-fed material advances through 4-20 stations at a preset pitch, with each press stroke simultaneously processing different sections of the strip. This integrated design enables production speeds of 100-500+ parts per minute, tolerances of ±0.01mm, and material waste rates below 5%, making it ideal for high-volume manufacturing of electrical connectors, automotive brackets, and precision components.

4. When should I choose transfer die stamping over progressive die stamping?

Choose transfer die stamping when your parts require deep draws exceeding shallow contours, dimensions larger than coil width constraints, multi-axis forming with blank rotation or flipping, or material thickness from 0.5mm to 12mm+. Transfer dies excel for automotive body panels, appliance housings, structural components, and complex three-dimensional brackets. Annual volumes of 50,000+ pieces typically justify the tooling investment, and the elimination of carrier strip waste can offset slower cycle times, especially with expensive materials like brass or specialty alloys.

5. How do I calculate the total cost of ownership for stamping dies?

Calculate Total Cost of Ownership using: TCO = Initial Investment + Operating Costs + Maintenance Costs + Downtime Costs – Residual Value. Include tooling purchase price, installation, testing runs, energy consumption, scheduled maintenance, sharpening services, and lost production during downtime. Progressive dies may need more frequent maintenance but offer 500,000 to 2+ million cycle lifespans. Transfer dies require additional automation component servicing. Proactive maintenance costing $2,000 annually can prevent unplanned failures that cost $500+ per hour in lost production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —