Stamping Die Manufacturers Exposed: What They Won't Tell You About Pricing

Understanding Stamping Die Manufacturing and Its Industrial Impact

When you pick up your smartphone, drive your car, or visit a hospital, you're interacting with products that wouldn't exist without stamping dies. But what is a die in manufacturing, exactly? Simply put, stamping dies are precision-engineered tools that transform flat sheet metal into complex three-dimensional components through controlled force and carefully designed geometries. Stamping die manufacturers create these essential tools that serve as the backbone of mass production across virtually every major industry.

The Foundation of Precision Metal Forming

Imagine trying to produce millions of identical metal brackets, connectors, or housings by hand. The inconsistency would be staggering, and the cost would be astronomical. This is precisely why the die industry exists. Metal stamping dies enable manufacturers to produce high-volume, precision components with remarkable consistency and efficiency.

At their core, stamping dies consist of two primary components: a punch and a die cavity. When a press forces the punch into sheet metal positioned over the die cavity, the material takes on the exact shape engineered into the tooling. This seemingly simple concept requires extraordinary precision in execution. Tolerances often measure in thousandths of an inch, and even microscopic imperfections can render a die useless for production.

The quality of your stamping dies directly determines your production capability. A well-designed die doesn't just shape metal—it defines your per-part costs, production speed, and ultimately, your competitive position in the marketplace.

Why Stamping Dies Drive Modern Manufacturing

Understanding what is dies in manufacturing helps explain why these tools command such significant investment. Die manufacturing serves four critical industries with unique demands:

- Automotive: From structural body panels to intricate electrical connectors, vehicles contain thousands of stamped components requiring tight tolerances and flawless surface finishes.

- Aerospace: Weight-critical applications demand precision stamping of aluminum and titanium alloys with zero margin for error.

- Electronics: Miniaturized components for devices require stamping dies capable of producing features measured in fractions of millimeters.

- Medical: Surgical instruments and implantable devices demand stamping dies that meet the most stringent quality and traceability standards.

Throughout this guide, you'll gain the technical knowledge needed to evaluate stamping die manufacturers effectively. We'll cover die types, manufacturing processes, material selection, tolerance specifications, and the cost factors that most manufacturers won't discuss openly. Whether you're sourcing your first die or optimizing an existing supply chain, understanding these fundamentals empowers you to make informed decisions—regardless of which manufacturer you ultimately choose.

Types of Stamping Dies and When to Use Each

Choosing the right die type is one of the most consequential decisions you'll make when working with stamping die manufacturers. Select wisely, and you'll optimize production efficiency while minimizing per-part costs. Choose poorly, and you could face unnecessary expenses, production bottlenecks, or quality issues that plague your operations for years. So how do you know which die type fits your application?

The answer depends on several interconnected factors: your production volume, part complexity, tolerance requirements, and budget constraints. Let's break down the four primary die types that stamping die manufacturers offer, exploring when each makes strategic sense for your specific needs.

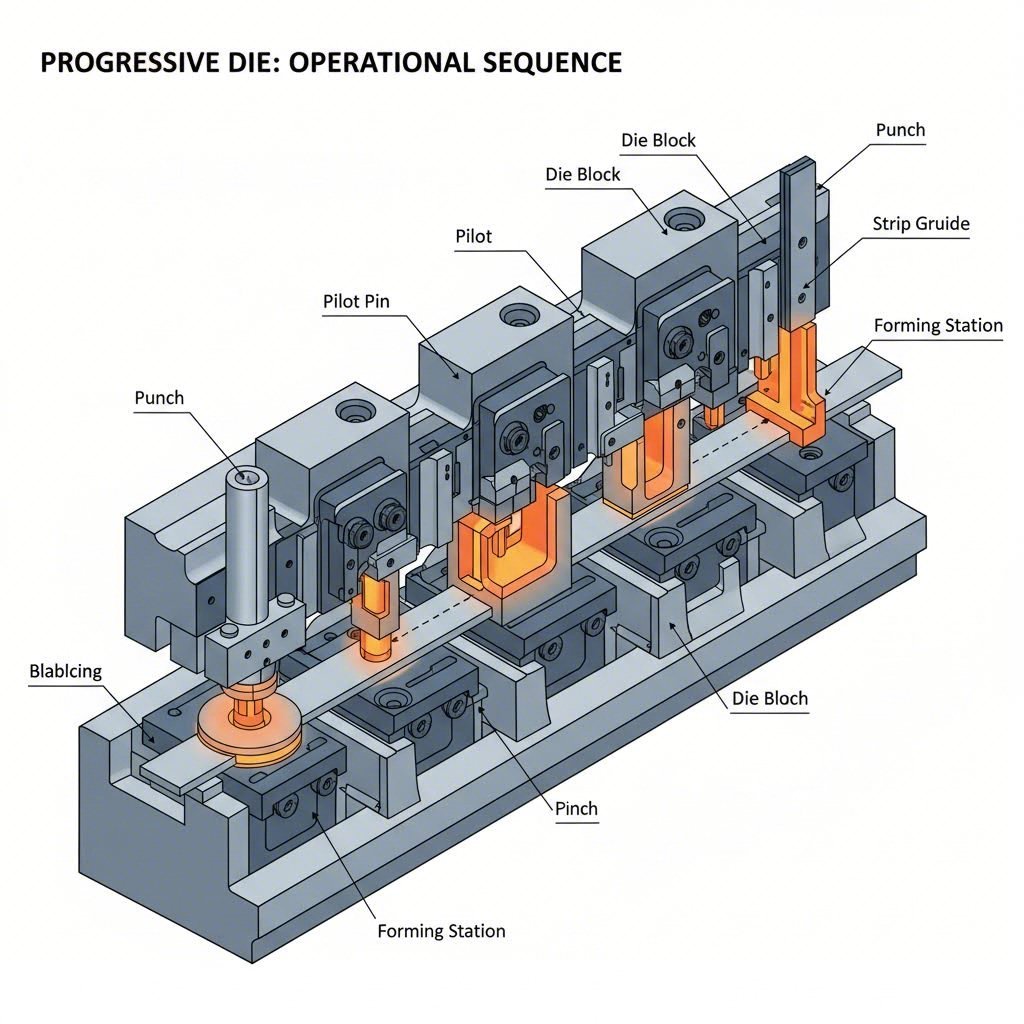

Progressive Dies for High-Volume Efficiency

When you need to produce thousands or millions of identical parts, progressive die stamping becomes your most powerful tool. A progressive stamping die contains multiple stations arranged in sequence within a single tool. As the metal strip advances through each station, different operations—blanking, piercing, forming, bending—occur simultaneously at each stage.

Here's why progressive dies dominate high-volume production:

- Speed: Progressive die metal stamping can produce 300 to 1,500+ parts per minute, depending on part complexity and press capabilities.

- Consistency: Because all operations occur in a single setup, part-to-part variation remains minimal.

- Labor efficiency: Once set up, a prog die runs with minimal operator intervention, reducing labor costs per part dramatically.

- Material optimization: Skilled die designers can nest parts efficiently within the strip, minimizing scrap.

However, progressive dies come with significant upfront investment. The tooling complexity means higher initial costs and longer lead times. They also require precise strip feeding systems and may not accommodate extremely large parts or those requiring deep draws.

Compound and Transfer Dies for Complex Geometries

Not every part suits progressive die stamping. When your component demands complex geometries, multiple operations on different planes, or features that can't be achieved in a linear strip progression, compound and transfer dies offer superior solutions.

Compound dies perform multiple operations simultaneously in a single press stroke. Imagine needing a part that requires both blanking and piercing in precise alignment. A compound die accomplishes both operations at once, ensuring perfect concentricity between features. These dies excel at producing flat parts with multiple holes or complex internal cutouts where positional accuracy is critical.

Transfer dies take a different approach. Instead of feeding a continuous strip, individual blanks move from station to station via mechanical fingers or other transfer mechanisms. This allows for:

- Operations on multiple surfaces of the part

- Deep draws and complex three-dimensional forming

- Processing pre-cut blanks rather than coil stock

- Handling larger parts that would be impractical in progressive dies

Single-hit dies (also called simple or single-operation dies) perform just one operation per press stroke. While less efficient for high volumes, they offer lower tooling costs and faster lead times. They're ideal for prototyping, low-volume production, or secondary operations on parts produced by other methods.

Die Type Selection: A Comprehensive Comparison

Selecting between these die types requires weighing multiple factors simultaneously. The following comparison table provides a framework for evaluating which approach best matches your production requirements:

| Die Type | Production Volume | Part Complexity | Setup Time | Per-Part Cost | Typical Applications |

|---|---|---|---|---|---|

| Progressive Dies | High (100,000+ parts) | Moderate to High | Longer initial setup; minimal changeover | Very Low | Automotive brackets, electrical connectors, appliance components |

| Compound Dies | Medium to High (10,000-500,000) | Moderate (flat parts) | Moderate | Low to Moderate | Washers, gaskets, precision blanks with multiple holes |

| Transfer Dies | Medium to High (25,000-1,000,000) | Very High | Longer (multiple stations) | Low to Moderate | Deep-drawn housings, complex automotive panels, multi-axis formed parts |

| Single-Hit Dies | Low to Medium (100-50,000) | Low to Moderate | Quick | Higher | Prototypes, short runs, secondary operations |

Notice how the economics shift dramatically based on volume. A progressive die might cost significantly more upfront than a single-hit alternative, but when you're producing half a million parts annually, that investment pays dividends through drastically lower per-part costs. Conversely, using expensive progressive tooling for a 5,000-piece annual run rarely makes financial sense.

When consulting with stamping die manufacturers, share your complete production picture. Volume projections, tolerance requirements, part geometry, and target pricing all influence which die type delivers optimal value. The best manufacturers will guide you toward the right solution rather than defaulting to the most expensive option.

Understanding these die types prepares you for the next critical consideration: how stamping dies are actually manufactured and what processes determine their final quality and performance.

The Complete Die Manufacturing Process Explained

Ever wondered what happens between placing an order with stamping die manufacturers and receiving production-ready tooling? The journey from concept to finished die involves a sophisticated sequence of engineering, metallurgy, and precision machining that most buyers never see. Understanding this workflow gives you a significant advantage when evaluating quotes, setting realistic timelines, and communicating effectively with your tooling partners.

Tool and die manufacturing isn't a black box—it's a carefully orchestrated process where each stage builds upon the last. Let's walk through the complete workflow that transforms your part requirements into the stamping die components that will drive your production for years to come.

From Design Concept to Precision Tooling

The foundation of any successful die project begins long before metal meets cutting tool. This initial phase determines whether your die will perform flawlessly or become a source of ongoing frustration.

- Concept Development and Feasibility Analysis: Engineers evaluate your part geometry, material specifications, and production requirements. They determine which die type suits your application, identify potential forming challenges, and establish preliminary cost estimates. This stage often reveals design modifications that can reduce tooling complexity and cost.

- Stamping Die Design (CAD/CAM Engineering): Using advanced software, designers create detailed 3D models of every die component. Metal stamping die design involves calculating material flow, spring-back compensation, and optimal station sequencing for progressive dies. Simulation software predicts how the sheet metal will behave during forming, identifying potential issues before any steel is cut.

- Material Selection: Based on production volume, stamped material characteristics, and tolerance requirements, engineers specify appropriate tool steels for each component. High-wear areas might require D2 or carbide inserts, while components needing toughness might use S7 steel. This decision directly impacts die longevity and maintenance costs.

- Die Tooling Bill of Materials: A comprehensive list of all components—die blocks, punches, strippers, guide pins, springs, and fasteners—is generated. This documentation ensures nothing gets overlooked during manufacturing and establishes the basis for accurate cost tracking.

Sounds complex? It absolutely is. But this front-end engineering investment prevents costly surprises during production. Experienced stamping die manufacturers allocate significant resources to this phase because correcting design errors in hardened steel costs exponentially more than addressing them in CAD.

Critical Machining and Finishing Operations

Once designs are finalized and materials procured, die machining transforms raw steel into precision tooling. This is where dies in manufacturing truly take shape.

- Rough Machining: CNC milling machines remove bulk material from die blocks, establishing approximate shapes and features. Operators leave strategic amounts of stock material for finish operations. Speed matters here, but precision tolerances aren't yet critical—that comes later.

- Heat Treatment: Die components undergo controlled heating and cooling cycles to achieve target hardness levels. This metallurgical transformation gives tool steels their wear resistance and durability. Different components may require different heat treatment specifications based on their function.

-

Precision Machining: Here's where stamping die manufacturers separate themselves from commodity suppliers. Multiple specialized processes achieve final dimensions:

- Wire EDM (Electrical Discharge Machining): A thin electrically charged wire cuts intricate profiles with extreme precision. This process excels at creating complex punch and die shapes with tolerances measured in ten-thousandths of an inch.

- Sinker EDM: A shaped electrode "burns" precise cavities into hardened steel. Ideal for creating textured surfaces or complex three-dimensional features that conventional machining can't reach.

- Jig Grinding: For the tightest tolerances on hole locations and surface finishes, jig grinding delivers accuracy that other methods can't match.

- Surface Grinding: Achieves flat, parallel surfaces essential for proper die alignment and consistent part quality.

- Assembly: Skilled toolmakers fit all components together, ensuring proper alignment and function. Guide pins are fitted to die sets, springs are installed with correct preload, and cutting components are secured. This stage requires craftsman-level expertise that no machine can replicate.

- Tryout and Adjustment: The assembled die goes into a tryout press for initial testing. Engineers run sample parts, measure critical dimensions, and identify any areas requiring adjustment. Machining dies back to modify fit, timing, or material flow is common during this iterative process.

- Validation and Approval: Final sample parts undergo comprehensive inspection against print specifications. Statistical measurements verify process capability. Only after meeting all quality criteria does the die earn approval for production release.

Each of these ten stages contributes directly to final die quality. Skip or shortcut any step, and problems emerge during production—problems that cost far more to resolve than doing it right initially. When evaluating quotes from different suppliers, remember that significant price differences often reflect differences in process rigor at one or more of these critical stages.

With the manufacturing process demystified, you're now ready to explore the material science behind these precision tools—specifically, which tool steels and carbide options deliver optimal performance for different applications.

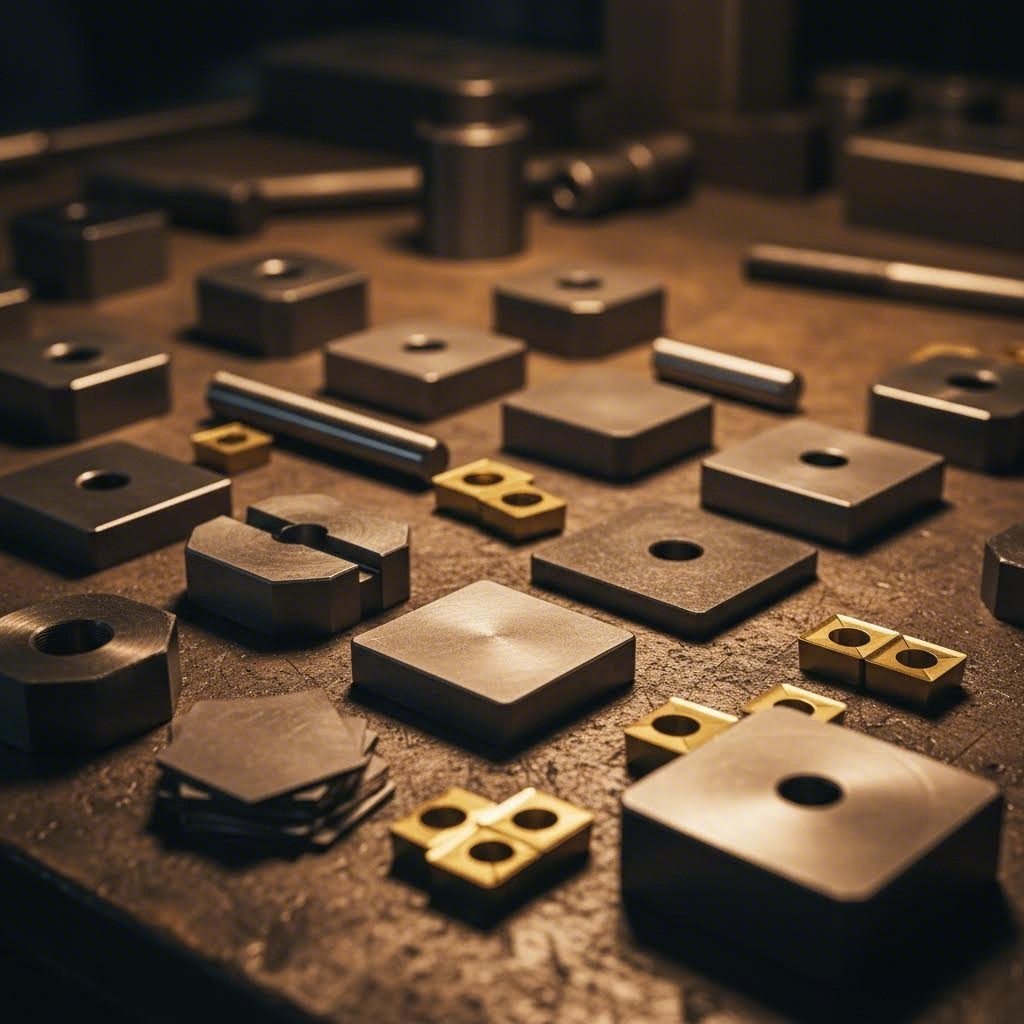

Die Materials and Tool Steel Selection Guide

Here's a truth most stamping die manufacturers won't volunteer: the steel grade in your tooling can mean the difference between a die that runs for five million cycles and one that needs rebuilding after 500,000. Material selection directly impacts your total cost of ownership, yet many buyers focus exclusively on upfront pricing without understanding what's actually inside their tooling.

Steel stamping dies aren't created equal. The tool steel grades specified for your die components determine wear resistance, toughness, and ultimately how long your investment delivers quality parts. Let's decode the material science that separates premium custom metal stamping dies from tools that underperform.

Tool Steel Grades and Their Applications

Tool steels contain higher carbon content (typically 0.5-1.5%) along with alloying elements like chromium, vanadium, tungsten, and molybdenum. These elements form carbides that deliver the hardness and wear resistance essential for sheet metal stamping dies. But which grade fits your application?

D2 Tool Steel (Cold-Work Series)

When wear resistance tops your priority list, D2 becomes the go-to choice. With approximately 12% chromium content, D2 achieves hardness levels of 58-62 HRC after heat treatment. This grade excels in blanking and piercing operations where cutting edges face constant abrasion from sheet metal dies processing high-strength materials.

However, D2's exceptional hardness comes with a trade-off—reduced toughness. If your application involves impact loading or shock, D2 may chip or crack where a tougher grade would survive.

A2 Tool Steel (Air-Hardening Series)

Need balanced performance without extreme specialization? A2 offers a middle ground that makes it popular among stamping die manufacturers for general-purpose tooling. Air hardening during heat treatment means less distortion compared to oil or water-quenched steels, which translates to tighter tolerances on finished components.

A2 reaches 55-62 HRC hardness while maintaining reasonable toughness for moderate-duty applications. You'll find it in forming dies, punches, and components where neither extreme wear resistance nor impact absorption dominates the requirements.

S7 Tool Steel (Shock-Resistant Series)

When your steel stamping tools face repeated impact—think heavy blanking, coining, or applications with sudden load spikes—S7 delivers the toughness other grades lack. At 54-58 HRC, it's slightly softer than D2 or A2, but this reduced hardness enables exceptional resistance to chipping and cracking.

S7 finds its home in heavy-duty stamping applications, thick material processing, and any die component that must absorb shock loads without catastrophic failure. The trade-off? Lower wear resistance means more frequent sharpening or replacement compared to harder grades.

M2 High-Speed Steel

Originally developed for cutting tools, M2 maintains its hardness at elevated temperatures where other grades would soften. In stamping applications, M2 proves valuable when high-speed operations generate significant heat at cutting edges. Its tungsten and molybdenum content provides excellent red hardness—the ability to retain hardness when glowing from heat.

For metal stamping die sets running at aggressive speeds, M2 components in critical wear areas can extend sharpening intervals significantly.

Carbide Components for Extended Die Life

When tool steel simply isn't enough, carbide steps in. Tungsten carbide components can outlast tool steel by 10x or more in demanding applications, making them essential for ultra-high-volume production despite higher initial costs.

Where do carbide inserts make sense in sheet metal dies?

- Cutting edges on progressive dies: When producing millions of parts, carbide punches and die buttons slash maintenance frequency dramatically.

- High-abrasion materials: Stamping stainless steel, spring steel, or silicon steel accelerates tool steel wear. Carbide resists this abrasion far longer.

- Tight tolerance applications: Carbide's dimensional stability means less drift over production runs, maintaining critical tolerances longer.

The downside? Carbide is brittle. Applications involving side loads or impact can crack carbide components where tool steel would merely deform. Proper die design accommodates carbide's strengths while protecting against its vulnerability to shock.

Material Selection Decision Framework

Choosing between these options requires evaluating four key factors:

- Production volume: Higher volumes justify harder, more wear-resistant materials despite increased cost.

- Material being stamped: Abrasive or high-strength materials demand superior wear resistance.

- Tolerance requirements: Tighter tolerances favor materials with greater dimensional stability.

- Budget constraints: Balancing upfront tooling cost against long-term maintenance and replacement expenses.

The following table provides a direct comparison to guide your material discussions with suppliers:

| Material | Hardness (HRC) | Wear Resistance | Toughness | Cost Level | Best Applications |

|---|---|---|---|---|---|

| D2 Tool Steel | 58-62 | Excellent | Low-Moderate | Moderate | Blanking, piercing, high-wear cutting operations |

| A2 Tool Steel | 55-62 | Good | Moderate | Moderate | General-purpose punches, forming dies, all-around tooling |

| S7 Tool Steel | 54-58 | Moderate | Excellent | Moderate | Impact applications, heavy blanking, thick materials |

| M2 High-Speed Steel | 60-65 | Very Good | Moderate | Moderate-High | High-speed operations, heat-generating applications |

| Tungsten Carbide | 70+ (converted) | Outstanding | Very Low (brittle) | High | Ultra-high volume, abrasive materials, critical wear points |

Notice how no single material wins across all categories. The optimal choice depends on your specific application requirements. When reviewing quotes from different stamping die manufacturers, ask specifically which materials they're specifying for critical components. Price differences often trace back to material choices that directly impact your long-term production costs.

Material selection forms just one piece of the precision puzzle. Equally important is understanding the tolerance capabilities these materials enable—and how to specify your requirements effectively when requesting quotes.

Precision Standards and Tolerance Specifications

When you request quotes from stamping die manufacturers, tolerance specifications often become the conversation that separates informed buyers from those who get surprised by costs later. Tight tolerances sound impressive on paper, but do you actually need them? And what happens to your budget when you over-specify precision that your application doesn't require?

Here's what experienced engineers understand: precision die and stamping capabilities have advanced dramatically, but tighter tolerances always carry a price tag. The key is matching your specifications to actual functional requirements—nothing more, nothing less. Let's explore what's achievable and how to communicate your needs effectively.

Achievable Tolerances in Modern Die Manufacturing

Modern precision die technologies enable stamping die manufacturers to hold remarkably tight dimensional limits. Standard sheet metal stamping tolerances work for everyday applications, but critical projects demand something tighter. So what numbers should you expect?

For high-precision applications, tolerances of ±0.001 inches (±0.025mm) or even tighter are achievable on critical dimensions. However, these capabilities come with conditions. Material properties, part geometry, and die type all influence what's realistically attainable.

Consider how different factors affect achievable precision:

- Material characteristics: Ductile materials like aluminum and copper stamp more predictably than high-strength steels. Materials with higher tensile strength resist deformation but require greater force, potentially affecting dimensional consistency.

- Part complexity: Simple flat blanks hold tighter tolerances than parts requiring multiple forming operations. Each bend, draw, or form introduces variables that can accumulate.

- Die type: Progressive dies maintain excellent consistency because all operations occur in a single setup. Transfer operations between separate dies introduce additional tolerance stack-up.

- Production volume: High speed metal stamping at 1,000+ strokes per minute generates heat and tool wear that gradually affect dimensions. Monitoring and adjustment protocols become critical for maintaining tolerances over extended runs.

What about specific features? Hole dimensions and edge profiles in precision die & stamping operations typically achieve ±0.002 inches in high-precision applications. However, tolerances may loosen depending on material thickness, grain direction, and proximity to formed features. Holes near bend lines, for instance, may shift slightly during forming operations.

Standard tolerances exist for good reason—they represent the sweet spot where manufacturing efficiency meets functional requirements. Over-specifying tolerances doesn't make parts better; it makes them more expensive.

How to Specify Precision Requirements

Communicating tolerance requirements effectively prevents misunderstandings that lead to rejected parts or inflated quotes. When preparing your RFQ documentation, clarity becomes your greatest asset.

The relationship between tolerance requirements and cost follows a predictable pattern: tightening tolerances beyond standard levels requires additional process controls, more frequent inspection, slower production speeds, and premium tooling materials. Each step drives costs upward. High speed stamping operations become less viable as tolerance demands increase because speed and extreme precision rarely coexist economically.

Follow these specification best practices to communicate effectively with stamping die manufacturers:

- Identify truly critical dimensions: Not every dimension on your part requires tight tolerances. Functional surfaces that mate with other components need precision. Non-critical areas can accept standard tolerances, reducing overall cost.

- Use GD&T when appropriate: Geometric Dimensioning and Tolerancing provides precise language for communicating complex requirements. Position tolerances, flatness callouts, and profile specifications eliminate ambiguity.

- Specify datums clearly: Measurements need reference points. Define which surfaces establish your datum structure so manufacturers know how to fixture parts for inspection.

- Include material specifications: Tolerance capabilities vary by material. Specify the exact alloy and temper you require so manufacturers can quote achievable precision.

- State production volume: A tolerance that's easily maintained for 10,000 parts may prove challenging across 10 million. Volume expectations help manufacturers assess process capability requirements.

- Distinguish between critical and reference dimensions: Mark truly critical dimensions explicitly. Reference dimensions provide manufacturing guidance but don't require formal inspection.

Environmental factors also influence precision outcomes. Temperature fluctuations cause material expansion and contraction, affecting measurements. Humidity impacts lubrication performance and can contribute to corrosion during processing. Manufacturers maintaining controlled environments demonstrate commitment to consistent results—a factor worth considering when evaluating potential suppliers.

Understanding these tolerance fundamentals positions you to have productive conversations with any stamping die manufacturer. You'll recognize when quoted tolerances align with your actual needs and when you might be paying for precision you don't require. More importantly, you'll know the right questions to ask when specifications and pricing don't seem to match up.

Tolerance capabilities represent just one dimension of manufacturer qualification. Equally important are the industry-specific certifications and quality standards that validate a supplier's ability to meet your sector's unique requirements.

Industry-Specific Applications and Certification Requirements

Not all stamping die manufacturers operate at the same level—and industry certifications reveal this reality faster than any sales pitch. When your automotive stamping dies must meet OEM specifications, when your medical components interface with human tissue, or when your aerospace parts must withstand extreme conditions, the certification alphabet soup suddenly matters enormously. But which certifications actually indicate capability, and which are merely baseline expectations?

Different industries impose distinct requirements on die manufacturers, and understanding these differences helps you identify suppliers genuinely qualified for your specific application. Let's examine what each major sector demands and how to evaluate whether a manufacturer can truly deliver.

Automotive Die Requirements and OEM Standards

The automotive industry drives more stamping die demand than any other sector, and its requirements reflect decades of supply chain refinement. When you need custom automotive metal stamping capabilities, the certification landscape centers on one critical standard: IATF 16949.

IATF 16949 builds upon ISO 9001's foundation but adds automotive-specific requirements that separate capable suppliers from pretenders. This certification mandates advanced product quality planning (APQP), production part approval processes (PPAP), and statistical process control protocols that OEMs require from every tier in their supply chain.

What does this mean practically for your automotive stamping die projects?

- Documented process capability: Manufacturers must demonstrate that their processes can consistently achieve specified tolerances—not just hit them occasionally.

- Preventive action focus: Rather than reacting to defects, IATF 16949 requires proactive identification and elimination of potential failure modes.

- Traceability systems: Every component, material lot, and process parameter must be traceable throughout the automotive components progressive stamping workflow.

- Continuous improvement metrics: OEMs expect measurable year-over-year improvements in quality, delivery, and cost performance.

Progressive precision metal stampings for automotive applications demand more than basic machining capability. Modern OEMs expect suppliers to leverage CAE simulation during die design, predicting material flow, spring-back compensation, and potential forming issues before cutting any steel. This simulation-driven approach dramatically reduces tryout iterations and accelerates time-to-production.

Manufacturers investing in these advanced engineering capabilities consistently achieve higher first-pass approval rates—some reaching 93% or better—which translates directly to faster program launches and reduced development costs. For a comprehensive look at automotive stamping die solutions that combine IATF 16949 certification with advanced simulation capabilities, explore the specialized automotive stamping resources available from qualified manufacturers.

Medical and Aerospace Precision Demands

If automotive requirements seem rigorous, medical and aerospace applications raise the bar even higher. Patient safety and flight-critical performance leave zero room for compromise.

Medical Device Manufacturing (ISO 13485)

Medical device regulatory compliance requires manufacturers to implement quality systems specifically designed for healthcare applications. According to industry guidance from NSF, ISO 13485 emphasizes regulatory compliance and risk management to ensure the safety and effectiveness of medical devices.

Key differences from general manufacturing certifications include:

- Risk management integration: ISO 13485 requires risk assessment throughout all quality system processes, with preventive actions as mandatory inputs in management reviews.

- Enhanced traceability: Implantable device components require traceability systems far exceeding standard manufacturing requirements.

- Personnel health protocols: Contamination control measures and personnel hygiene procedures become mandatory.

- Post-market surveillance: Systems for collecting field data, investigating complaints, and reporting adverse events to regulatory authorities.

Stamping die manufacturers serving medical device companies must understand that documentation requirements are more prescriptive than other sectors. Design History Files, Device Master Records, and Device History Records create a comprehensive documentation trail that regulators expect to review.

Aerospace Applications (AS9100)

Aerospace certification through AS9100 addresses the unique demands of flight-critical components. This standard incorporates ISO 9001 requirements while adding aerospace-specific controls for:

- Configuration management: Rigorous control over design changes and their documentation.

- First Article Inspection: Comprehensive verification that production processes can consistently produce conforming parts.

- Special process controls: Enhanced oversight of heat treatment, surface finishing, and other critical operations.

- Counterfeit part prevention: Systems to prevent unapproved materials from entering the supply chain.

ITD precision stampings for aerospace often require materials like titanium alloys and specialized aluminum grades that demand expertise beyond standard steel stamping. Manufacturers must demonstrate material handling protocols, traceability systems, and testing capabilities specific to these demanding materials.

Certification Requirements by Industry

When evaluating stamping die manufacturers, use this framework to identify minimum certification expectations:

-

Automotive OEM Supply Chain:

- IATF 16949 (mandatory for direct OEM suppliers)

- ISO 9001 (minimum for lower-tier suppliers)

- Customer-specific requirements (Ford Q1, GM BIQS, etc.)

-

Medical Device Components:

- ISO 13485 (essential for market access)

- FDA 21 CFR Part 820 compliance (for US market)

- Clean room capabilities (for certain device classes)

-

Aerospace and Defense:

- AS9100 (standard requirement)

- Nadcap accreditation (for special processes)

- ITAR compliance (for defense applications)

-

Electronics and General Industrial:

- ISO 9001 (baseline expectation)

- Industry-specific requirements vary by customer

- RoHS/REACH compliance for applicable markets

Certifications provide baseline qualification, but they don't guarantee performance. As supply chain experts note, quality standard certifications like those granted by ISO represent one of the easiest ways to identify quality assurance—but on-time delivery, experienced teams, and customer service capabilities matter equally.

When requesting quotes, ask potential suppliers not just about their certifications, but about their actual experience in your specific industry. A manufacturer holding ISO 13485 certification for five years with dozens of medical device customers offers different assurance than one newly certified with minimal medical project history.

Understanding certification requirements helps you filter qualified suppliers quickly. But certifications don't appear on invoices—cost factors do. Let's examine what actually drives stamping die pricing and how to evaluate quotes intelligently.

Cost Factors and How to Evaluate Manufacturer Quotes

Here's the uncomfortable truth most stamping die manufacturers avoid discussing openly: that $50,000 quote sitting on your desk might be a bargain, or it might be highway robbery. The problem? Without understanding what actually drives stamping die costs, you can't tell the difference. Two quotes for seemingly identical tooling can vary by 50% or more—and both suppliers might be pricing fairly based on their approaches.

Die stamping economics work differently than most manufactured goods. Your upfront tooling investment represents just one piece of a much larger financial picture that unfolds over years of production. Let's pull back the curtain on what really determines pricing and how to evaluate quotes like an industry insider.

Key Cost Drivers in Die Manufacturing

When stamping die manufacturers calculate your quote, they're weighing multiple factors that interact in complex ways. Understanding these drivers helps you recognize where your project falls on the cost spectrum—and where you might have leverage to optimize.

Complexity and Design Intricacy

Part geometry directly impacts stamping tooling costs more than any other factor. Simple blanking operations require straightforward dies, while parts with multiple bends, forms, and tight features demand progressive dies with numerous stations. According to industry cost analysis, each additional feature—holes, slots, embossed details, or formed tabs—adds complexity to the tooling design, makes the die wear out faster, and increases maintenance costs.

Consider how complexity multiplies through your design:

- Number of operations: Each forming, piercing, or bending step requires dedicated die stations, increasing tool size and engineering hours.

- Geometric difficulty: Complex curves, sharp internal corners, and deep draws require more sophisticated machining and longer tryout periods.

- Tolerance stack-up: Parts with multiple critical dimensions in relation to each other demand precision engineering that simple parts don't require.

Physical Size and Press Requirements

Larger dies require more raw material, longer machining times, and bigger presses—all driving costs upward. A stamping die for a small electrical connector might fit in your hands, while automotive body panel dies can weigh several tons. Beyond material costs, oversized tooling limits which manufacturers can even quote your project, potentially reducing competitive pressure.

Material Selection Impact

As explored in our earlier discussion of tool steels, die component materials significantly affect pricing. Standard tool steel costs less than premium grades, and carbide inserts for high-wear areas add substantial expense. But here's the trade-off many buyers miss: cheaper materials often mean more frequent maintenance and earlier die replacement, potentially costing more over your production lifetime.

Tolerance Requirements

Remember our precision discussion? Those tolerance specifications directly hit your wallet. Metal stamping tooling capable of holding ±0.001" requires more precise machining, additional inspection steps, and premium components compared to standard ±0.005" capabilities. Before specifying tight tolerances, ask yourself: does my application actually require this precision?

Production Volume Expectations

Here's where stamping economics become genuinely interesting. Higher expected volumes justify more robust—and expensive—die construction. A die for manufacturing 100,000 parts annually needs different engineering than one expected to produce 10 million. Suppliers factor expected tool life into their material choices, maintenance provisions, and overall design approach.

Lead Time Pressure

Standard lead times of 8-12 weeks allow manufacturers to schedule efficiently and avoid premium costs. Rush orders? Expect surcharges of 15-25% for moderate expediting, climbing to 50% or more for true emergencies. Planning ahead literally saves money.

Evaluating Quotes from Multiple Manufacturers

You've gathered three quotes for your stamping die project. The prices span from $35,000 to $65,000. How do you make sense of this range? Start by recognizing that you're not comparing apples to apples unless you dig deeper.

Here's what to examine when evaluating quotes:

- Tooling specifications: What tool steel grades are specified? Are wear components replaceable? Is carbide included where appropriate?

- Expected tool life: How many parts should this die produce before major maintenance? Quality dies can exceed 1,000,000 cycles before significant rebuilding.

- Included services: Does the quote cover tryout, first article inspection, and sample parts? These can add substantial cost if excluded.

- Warranty terms: What defects or performance issues does the manufacturer stand behind?

- Maintenance provisions: Are spare wear components included? What's the expected maintenance schedule?

- Hidden costs: Are shipping, packaging, engineering changes, and production support included or additional?

The relationship between upfront die cost and long-term per-part economics deserves special attention. A die costing $50,000 that produces parts at $0.50 each might deliver better total value than a $35,000 die producing parts at $0.60 each—especially at high volumes. Run the math across your expected production quantity before fixating on tooling price alone.

Questions to Ask Every Supplier

Arm yourself with these questions when reviewing quotes from stamping die manufacturers:

- What tool steel grades are you specifying for punches and die components?

- How many cycles should this die run before requiring significant maintenance?

- What's your first-pass approval rate on similar complexity dies?

- Are tryout costs and sample parts included in this quote?

- What engineering support do you provide during production ramp-up?

- How do you handle design changes after tooling construction begins?

- What spare components do you recommend keeping on hand?

Watch for red flags: extremely low pricing might indicate misunderstood requirements, inadequate tooling investment, or inexperience with your application. As industry veterans note, attempting to cut costs on tooling and die design typically backfires through production problems, quality issues, and premature tool failure.

The sweet spot for dies manufacturing investment balances upfront cost against production efficiency, maintenance requirements, and expected tool life. When you understand the full cost picture, you can make decisions that optimize total value rather than simply chasing the lowest quote.

With cost fundamentals established, you're ready to apply this knowledge practically—starting with how to prepare for successful collaboration with your chosen manufacturer.

Working with Stamping Die Manufacturers Successfully

You've evaluated quotes, understood cost drivers, and identified qualified progressive die manufacturers for your project. Now comes the phase that separates smooth launches from frustrating delays: actually working with your chosen supplier. The quality of your collaboration directly impacts tooling performance, timeline adherence, and ultimately, your production success.

Think of your relationship with a stamping dies manufacturer as a partnership rather than a transaction. The most successful projects feature early engineering involvement, clear documentation, and consistent communication throughout development. Let's explore exactly what you need to prepare and how to collaborate effectively from first contact through production approval.

Preparing Your RFQ Package

Before reaching out to any progressive die and stamping supplier, invest time in assembling a comprehensive request for quote package. Incomplete RFQs lead to inaccurate quotes, scope misunderstandings, and project delays that frustrate everyone involved. What documentation should your package include?

Follow this checklist to prepare a complete RFQ package:

- Finalized CAD files: Provide 3D models in universally accepted formats (STEP, IGES, or native CAD files). Include the current revision level and confirm this represents released or near-final geometry.

- Detailed 2D drawings with GD&T: Drawings should clearly indicate critical dimensions, tolerances, datum structures, and surface finish requirements. As major OEM tooling standards specify, suppliers must obtain released data with proper GD&T prior to design and build of tools.

- Material specifications: State the exact alloy, temper, thickness, and any coating requirements. Material properties significantly impact die design and achievable tolerances.

- Annual volume projections: Share realistic volume expectations over the program lifetime. High volume stampings justify different tooling investments than low-volume applications.

- Target pricing: If you have budget constraints, communicate them upfront. This helps suppliers suggest design modifications or alternative approaches that fit your economics.

- Timeline requirements: Specify your target dates for tooling completion, first samples, and production start. Note any hard deadlines driven by customer launches or market windows.

- Quality and certification requirements: Identify applicable standards (IATF 16949, ISO 13485, etc.) and any customer-specific requirements that must be met.

- Secondary operations: List any post-stamping requirements—welding, plating, heat treatment—that might influence die design decisions.

Missing even one of these elements forces suppliers to make assumptions that may not match your expectations. Complete documentation enables accurate quotes and prevents costly surprises during development.

Collaboration Best Practices for Successful Projects

Once you've selected your stamping tool and die partner, the real work begins. How you collaborate during design, build, and tryout phases determines whether your tooling launches smoothly or struggles through extended debugging.

Engage Engineering Early

The biggest mistake buyers make? Waiting until designs are frozen before involving their die manufacturer. Early engineering involvement—during your product design phase—unlocks opportunities that disappear once geometry is finalized.

According to design for manufacturability best practices, understanding how sheet metal responds to forming operations should guide your design decisions. Features like bend radii, hole locations relative to bends, and grain direction considerations all impact both part quality and tooling complexity.

Experienced progressive die tooling engineers can identify simplifications that reduce tooling cost without compromising part function. They'll flag potential forming challenges, recommend relief features that prevent cracking, and suggest tolerance adjustments where specifications exceed functional requirements. This collaborative approach—sometimes called concurrent engineering—typically reduces both tooling cost and development time.

Manufacturers offering rapid prototyping capabilities—some delivering sample parts in as little as 5 days—enable design validation before committing to production tooling. This iterative approach catches issues early when corrections cost hundreds rather than thousands.

Establish Clear Communication Protocols

Define how information flows between your organization and the progressive metal stamping supplier:

- Designate primary contacts: Both sides should have clear points of contact for technical questions, commercial matters, and schedule updates.

- Set progress reporting cadence: Weekly updates during active build phases keep projects on track and surface issues before they become crises.

- Document all decisions: Email confirmations for verbal agreements prevent misunderstandings. Changes to scope, schedule, or specifications deserve written acknowledgment.

- Participate in design reviews: OEM tooling standards typically require supplier sign-off at 0% (strip layout) and 50% (tool design) phases. Take these reviews seriously—catching issues in CAD costs far less than discovering them in hardened steel.

Understand Realistic Timeline Expectations

Complex progressive dies typically require 12-16 weeks from order to production-ready tooling. This timeline includes design, material procurement, machining, heat treatment, assembly, tryout, and validation. Rushing any stage introduces risk that compounds through subsequent phases.

What drives timeline variation?

- Die complexity: More stations mean more components to design, machine, and fit.

- Material availability: Specialty tool steels may require extended procurement lead times.

- Tryout iterations: First samples rarely achieve perfection. Plan for 2-3 tryout cycles to optimize forming parameters and fine-tune timing.

- Approval processes: Your internal PPAP requirements and customer submissions add time beyond physical tooling completion.

Engineering teams that leverage comprehensive mold design services and CAE simulation consistently reduce development cycles by identifying and resolving issues before tryout begins. This simulation-driven approach—combined with expertise in cost-effective tooling tailored to OEM standards—delivers faster time-to-production and higher first-pass approval rates. For projects demanding accelerated timelines and rigorous quality, explore the comprehensive design and fabrication capabilities available from manufacturers specializing in automotive applications.

Plan for Production Support

Your relationship with progressive die manufacturers shouldn't end at tool shipment. Establish expectations for ongoing support:

- Training: Will the supplier train your press operators on proper die handling and setup?

- Spare components: Which wear items should you stock on-site to minimize downtime?

- Preventive maintenance schedules: What intervals and procedures will keep your tooling performing optimally?

- Engineering change support: How will design modifications be handled after production begins?

The best partnerships treat tooling as a long-term asset requiring ongoing attention rather than a one-time purchase. Suppliers who stand behind their work with lifetime guarantees and responsive service demonstrate confidence in their craftsmanship—and commitment to your production success.

Armed with these preparation strategies and collaboration practices, you're positioned to work effectively with any qualified stamping die manufacturer. The knowledge you've gained through this guide—from die types and materials to tolerances, certifications, and cost factors—transforms you from a passive buyer into an informed partner capable of driving successful tooling projects from concept through production.

Frequently Asked Questions About Stamping Die Manufacturers

1. What is a die in manufacturing and how does it work?

A stamping die is a precision-engineered tool that transforms flat sheet metal into three-dimensional components through controlled force. It consists of two primary components: a punch and a die cavity. When a press forces the punch into sheet metal positioned over the die cavity, the material takes the exact shape engineered into the tooling. These tools enable manufacturers to produce high-volume, precision components with remarkable consistency, with tolerances often measuring in thousandths of an inch.

2. What are the different types of stamping dies and when should each be used?

The four primary die types include progressive dies for high-volume production (100,000+ parts) running at 300-1,500+ parts per minute; compound dies for medium-to-high volume flat parts requiring simultaneous operations; transfer dies for complex geometries and deep draws where blanks move between stations; and single-hit dies for prototyping and low-volume runs. Selection depends on production volume, part complexity, tolerance requirements, and budget constraints.

3. How much do stamping dies cost and what factors affect pricing?

Stamping die costs vary significantly based on complexity, size, material selection, tolerance requirements, production volume expectations, and lead time. Key cost drivers include the number of forming operations, geometric difficulty, tool steel grades specified, and expected tool life. Quotes for similar projects can vary by 50% or more between manufacturers due to different material choices and engineering approaches. Always compare tooling specifications, warranty terms, and included services rather than focusing solely on upfront pricing.

4. What certifications should stamping die manufacturers have?

Required certifications depend on your industry. Automotive OEM suppliers need IATF 16949 certification, which mandates advanced product quality planning and statistical process control. Medical device manufacturing requires ISO 13485 with enhanced traceability and risk management. Aerospace applications demand AS9100 certification with rigorous configuration management and first article inspection. General industrial applications typically require ISO 9001 as a baseline. Advanced manufacturers also leverage CAE simulation capabilities to achieve higher first-pass approval rates.

5. What should I include in my RFQ when contacting stamping die manufacturers?

A comprehensive RFQ package should include finalized CAD files in universal formats, detailed 2D drawings with GD&T specifications, exact material specifications including alloy and temper, annual volume projections, target pricing and timeline requirements, applicable quality certifications, and any secondary operation requirements. Complete documentation enables accurate quotes and prevents costly surprises during development. Engaging engineering early during your product design phase can reduce both tooling costs and development time.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —