Reparació de Jantes Forjades Doblades: Estalvia't les Teves Jantes de 3.000 $ o Renuncia-hi?

Comprendre les conseqüències quan les vostres rodes forjades reben un cop

Imagineu-vos això: esteu circulant per l'autopista quan de sobte el volant comença a vibrar en frenar. Aquesta vibració inquietant us arriba a les mans i se us fa un nus a l'estómac. atureu el vehicle, us ajuppeu al costat del cotxe i allà ho teniu: una deformació visible a la vostra roda forjada de 3.000 $. En aquell moment, només una pregunta domina els vostres pensaments: es pot reparar una llanta doblegada d'aquest nivell o la vostra inversió està perduda?

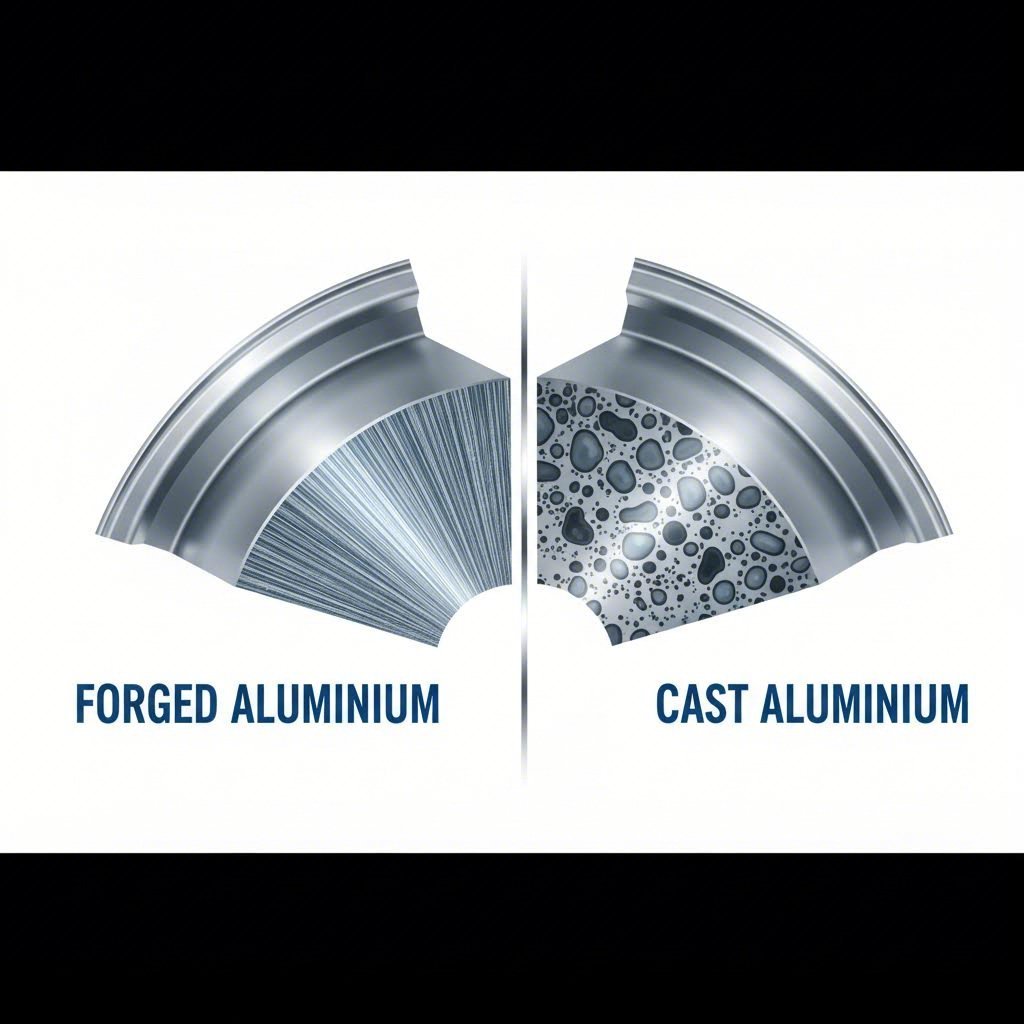

Les rodes forjades representen el cim de l'enginyeria de rodes. A diferència de les seves homòlogues colades, aquests components premium passen per una pressió intensa durant la fabricació —sovint superior a 10.000 tones de força—, creant una estructura granular que ofereix una resistència excepcional mentre redueix significativament el pes. Una roda forjada típica de 18 polzades pesa només entre 7 i 8 kg, aproximadament un 25 % menys que les equivalents d'alumini colat. Aquesta reducció de pes es tradueix en una acceleració més ràpida, distàncies de frenada més curtes i una resposta de direcció més precisa.

Però aquí és on les coses es compliquen. La mateixa construcció especialitzada, que té un preu entre 1.500 i 4.000 dòlars per roda, també exigeix uns coneixements de reparació igualment especialitzats. Si toques un sot amb prou força, el teu vehicle pot arribar a posar-se en mode de treball limitat quan els sensors detectin el desequilibri resultant.

Per què les rodes forjades necessiten atenció especial

La decisió de reparar una roda doblegada en lloc de substituir-la no és senzilla. L'estructura granular alineada de l'alumini forjat es comporta de manera diferent sota tensió que els materials colats. Aplicar calor incorrectament o doblegar el metall massa agressivament pot suposar el risc de comprometre precisament les propietats que van fer que aquestes rodes valguessin la pena comprar-les en un primer moment.

Les rodes forjades obtenen la seva resistència superior d'una estructura granular comprimida i alineada, la mateixa propietat que fa que els intents de reparació inadients puguin ser potencialment catastròfics i que l'avaluació professional sigui absolutament essencial.

La decisió d'alt risc a què s'enfronta tot propietari de rodes

Així doncs, es poden reparar amb èxit les rodes forjades doblegades? La resposta no és un simple sí o no. Depèn del tipus de danys, la seva gravetat i l'expertesa que hi hagi darrere la reparació. Al llarg d'aquesta guia descobriràs exactament com avaluar els danys de la teva roda, entendre el procés professional d'endrectament i prendre una decisió informada sobre si cal reparar els danys per doblegament o descartar-la. Quan el teu vehicle mostri senyals d'advertència —vibracions, oscil·lacions o fins i tot l'activació del mode de marxa reduïda—, conèixer les teves opcions esdevé imprescindible.

Tant si estàs sopesant la relació cost-benefici d'un escenari de reparació d'una roda doblegada com si tens dubtes sobre les implicacions de seguretat, aquest desglossament complet t'equiparà amb els coneixements necessaris per protegir tant la teva inversió com la teva seguretat a la carretera.

Diferències entre la construcció i la reparació de rodes forjades i rodes colades

Entendre per què les rodes forjades es comporten de manera diferent durant les reparacions comença per entendre com es fabriquen. Penseu-hi així: esperaríeu que un ganivet de cuiner forjat a mà respongués de la mateixa manera al reafilat que una fulla estampada econòmica? La metal·lúrgia darrere de les rodes forjades crea consideracions específiques de reparació que tot propietari hauria de comprendre abans de prendre decisions sobre serveis d'endrectament.

Tal com els entusiastes del rendiment controlen la temperatura de l'aire d'admissió per optimitzar el rendiment del motor o envien mostres per a anàlisi d'oli Blackstone per entendre el desgast del motor, conèixer l'estructura interna de la vostra roda us ajuda a prendre decisions més intel·ligents sobre el manteniment. Analitzem la ciència en termes pràctics.

L'avantatge de l'estructura granular i les seves implicacions en la reparació

Quan els fabricants creen rodes forjades, comencen amb un bloc sòlid d' alumini aeroespacial 6061-T6 —el mateix material en què es confia en la construcció d’aeronaus. Aquest bloc s’escalfa fins a una temperatura precisa i després es sotmet a una pressió immensa superior a les 10.000 tones. Imagineu-vos comprimir un bloc de metall amb tanta força que la seva estructura cristal·lina interna es reorganitzi físicament.

Aquest procés de compressió elimina la porositat, és a dir, les microscòpiques bombolles d’aire i buits que debiliten les rodes colades. El resultat? Una estructura granular compacta i uniforme que és increïblement densa. Segons Konig Wheels , aquesta estructura granular alineada permet que les rodes forjades reduïn el pes sense sacrificar resistència, creant components fins a tres vegades més resistents que els seus equivalents colats.

Però això és el que importa per a les decisions de reparació: aquesta estructura de gra comprimit i alineat respon de manera diferent a l'esforç. Quan dobleu alumini forjat i intenteu endreçar-lo, esteu treballant amb un material dissenyat per resistir la deformació. Si el dobleu incorrectament, corregiu el risc de crear fissures per esforç al llarg d'aquelles fronteres de gra compactes. La mateixa densitat que fa que les rodes forjades siguin més resistents també fa que els intents de reparació inadecuats siguin més perillosos.

Ciència del tractament tèrmic darrere de la resistència de les rodes forjades

La "T6" en l'alumini 6061-T6 no és només una denominació aleatòria — indica un procés específic de tractament tèrmic anomenat endureïment per precipitació. Això implica tractar tèrmicament la roda a temperatures elevades i després envelleir-la artificialment en condicions controlades. El procés crea una combinació excepcional d'alta resistència a la tracció, resistència a la corrosió i treballabilitat.

Per què és important això per endreçar rodes forjades doblegades? Qualsevol reparació de roda que impliqui l'aplicació de calor comporta el risc d'alterar aquest tractament tèrmic prèviament calibrat. Aplicar massa calor pot arribar a «desfer» el tractament T6, deixant l'alumini més tou i feble del que hauria de ser. Aplicar la calor de manera desigual crea zones amb dureses diferents, introduint essencialment punts febles a la vostra roda.

Les tallers professionals saben que, després de qualsevol endreçament amb calor, la roda pot necessitar un tractament tèrmic addicional per recuperar la duresa adequada. Això és similar a com l'aïllament tèrmic d'escapaments protegeix els components dels danys tèrmics: controlar l'exposició a la calor preserva la integritat del material. El cicle tèrmic durant una reparació correcta imita el procés original de fabricació: escalfar fins a temperatures específiques i després refredar en condicions controlades per assolir les característiques de resistència desitjades.

| Característica | Rodes forjades | Cast wheels |

|---|---|---|

| Mètode de construcció | Massís sòlid premsat amb una força superior a 10.000 tones | Alumini fos colat en motlles |

| Material | Alumini aeroespacial T6-6061 | Alumini A356-T6 |

| Estructura granular | Denso, aliniat, sense porositat | Orientació aleatòria, possibles bosses d'aire |

| Comparació de resistència | Fins a 3 vegades més resistent que el fosa | Resistència bàsica |

| Diferència de pes | un 20-25 % més lleuger a mida equivalent | Més pesat degut al gruix de material necessari |

| Modo de fallida | Tendeix a doblegar-se en lloc de trencar-se | Més propens a fissurar-se o esmicolar-se |

| Consideracions per a la reparació | Requereix un control precís de la calor; risc de danys per revenat | Més tolerant però punt de partida més feble |

| Rang de cost | 2-3 vegades més car que el fosa | Opció assequible |

Comprendre aquestes diferències metal·lúrgiques explica per què la reparació de rodes forjades exigeix una expertesa especialitzada. Un tècnic acostumat a endreçar rodes de fosa —on l'estructura granular aleatòria i la porositat inherents creen un material més permisssiu— pot aplicar tècniques que comprometin la integritat d'una roda forjada. L'estructura densa i alineada que fa que els discs brembo i altres components d'alt rendiment siguin embolicats amb calor per protecció també fa que les rodes forjades siguin menys tolerants als intents de reparació aficionats.

Una consideració addicional: la fatiga del metall. Fins i tot els materials més resistents s’afebleixen sota cicles repetits d’esforç. Una roda forjada que ha estat doblegada i endreçada ha patit un esforç que el procés original de fabricació no va tenir en compte. Tot i que una reparació adequada pot restablir la geometria, el material ha sofert deformacions d’una manera que pot accelerar la fatiga amb el temps, de la mateixa manera que un separador d’oli d’aire protegeix el motor dels esforços interns, la tècnica de reparació adequada protegeix la longevitat de la roda.

Ara que enteneu què succeeix a l’interior de les vostres rodes forjades al nivell molecular, podeu avaluar millor la gravetat dels danys i les recomanacions de reparació. El següent pas és aprendre a identificar exactament quin tipus de dany per doblegament teniu davant—perquè no tots els doblecs són iguals.

Identificació dels tipus de danys per doblegament i dels nivells de gravetat

Heu confirmat que la vostra roda forjada ha patit danys, però de quin tipus exactament? Abans de poder determinar si la reparació és viable, heu d'identificar amb precisió amb què us enfronteu. Penseu-hi com en una triatge: diferents tipus de danys comporten pronòstics diferents, i equivocar-se en la identificació de la situació podria portar a errors costosos o negligències perilloses.

L'avaluació dels danys en les rodes no consisteix només a detectar abonyegaments evidents. De vegades, els problemes més preocupants, com ara esquerdes fines o cediments estructurals subtils, passen desapercebuts malgrat ser visibles. Analitzem les tres categories principals de danys i el que cadascuna significa per a les vostres opcions de reparació.

Danys laterals, radials i al llavis explicats

Doblegaments laterals es produeixen quan la roda es deforma lateralment, creant una oscil·lació que és més perceptible a velocitats baixes. Imagineu-vos la roda com un plat que gira i ha desenvolupat un patró en forma d'ona. Aquest tipus de danys sovint és conseqüència de xocs tangencials: colpejar lleugerament un cantell del voraviu o tocar el costat d'un sot. Quan percebeu un soroll de fregament en frenar acompanyat d'una vibració al volant, els danys per flexió lateral esdevenen el principal sospitós.

Des del punt de vista de la reparableitat, les doblegades laterals sovint són les més corregibles. La deformació s'estén per una àrea més amplia de la roda, fet que significa que l'esforç es concentra menys intensament en cap punt concret. Els tallers professionals solen mesurar el joc lateral mitjançant indicadors de rellotge, i lectures inferiors a 0,030 polzades generalment es consideren dins dels límits acceptables per a la reparació.

Doblegades radials implica una desviació cap amunt i avall: la roda desenvolupa punts alts i baixos al voltant de la seva circumferència. Imagineu-vos una roda lleugerament en forma d'ou en lloc d'un cercle perfecte. Aquest tipus de danys sol provenir d'impactes verticals directes: xocar contra un sot a alta velocitat o colpejar massa fort un pas a nivell elevat. Els símptomes sovint inclouen un so de fregament quan es frenada a intervals regulars o un cop d'escalfament rítmic que augmenta amb la velocitat.

Els danys radials tendeixen a concentrar l'esforç de manera més intensa que els doblecs laterals. Segons Tree Wheels , doblecs menors amb menys d'1 polzada de joc sovint romanen reparable, però qualsevol cosa per sobre d'aquest llindar normalment obliga a substituir les rodes. La naturalesa concentrada dels impactes radials significa que el metall experimenta un esforç localitzat més sever tant durant el dany inicial com durant qualsevol intent de rectificació.

Danys a la llàntia afecta el vora exterior de la roda on s'assenta la llanta del pneumàtic. Els impactes contra el cantell representen la causa més comuna, que van des de ratllades superficials en la llanta fins a deformacions greus que impedeixen un correcte segellat del pneumàtic. El dany en el reforç és especialment complicat perquè afecta directament la capacitat de la roda per mantenir un segell estànc amb el pneumàtic.

Els danys menors en el reforç —com petites abolladures o ratllades cosmètiques— sovint es poden reparar mitjançant un reformatejat i refinat cuidadosos. Tanmateix, les deformacions greus del reforç que creen espais entre la roda i la llanta del pneumàtic poden provocar fugues d'aire contínues, fet que fa impossible una reparació segura independentment de l'habilitat del tècnic.

Senyals d'advertència crítics que descarten la reparació

Més enllà de la identificació del tipus de dany, cal avaluar si s'ha produït una compromissió estructural. Alguns senyals d'advertència indiquen que la reparació no només és desaconsellable, sinó que pot ser perillosa.

Les fissures fines són la preocupació més crítica. Aquestes petites fractures sovint romanen invisibles a una inspecció casual, però indiquen que la integritat estructural de la roda ha quedat fonamentalment compromesa. Investigació publicada a PMC mostra com les fissures per fatiga en llantes progressen des de gairebé indetectables fins al fallament catastròfic. Durant les proves, les fissures apareixien inicialment a prop dels vores del perfil dels braços i s'estenien progressivament fins que es produïa la ruptura del material — un patró de fallada que justifica per què els professionals es neguen a reparar llantes forjades esquerdatades.

De la mateixa manera que un codi de diagnòstic p0021 senyalitza problemes relacionats amb el temps que requereixen atenció immediata en lloc d'una investigació diferida, certs símptomes de danys en les rodes exigeixen una avaluació professional immediata en comptes d'una autoevaluació casolana.

Utilitzeu aquesta llista de verificació durant la vostra autoavaluació per identificar danys que normalment descarten la possibilitat de reparació:

- Fissures visibles en qualsevol part de la roda —fins i tot les fissures fines que s'estenen des de zones afectades indiquen que ja ha començat el fallament estructural

- Danys prop de les zones de muntatge —la deformació al voltant dels forats de fixació o de la superfície de muntatge del cub compromet la connexió de la roda al vehicle

- Fregament en els frens —combinat amb danys visibles a la roda, suggereix que la roda s'ha deformat prou per tocar els components dels frens

- Diverses zones d'impacte —les rodes que han patit danys per més d'un incident acumulen tensió que augmenta els riscos de reparació

- Historial de reparacions prèvies —les rodes forjades que ja s'han endreçat una vegada tenen riscos elevats de fatiga davant nous intents de correcció

- Mesures elevades de desviació —una desviació lateral superior a 0,060 polzades o una desviació radial superior a 1 polzada indica normalment danys massa greus per poder-se corregir de manera segura

- Pèrdua persistent de pressió d'aire —les fuites lentes després d'un danys indiquen fissures microscòpiques o deformacions del llavi que afecten el segell del coll del pneumàtic

- Danys als radis o al cos —doblegaments o fissures en aquestes zones estructurals afecten directament la capacitat de càrrega de la roda

Una tècnica d'avaluació sovint oblidada: passi l'ungla per la zona malmesa. Les fissures capil·lars sovint enganxen l'ungla encara que siguin massa fines per veure-les clarament. Si nota algun enganxament o vores irregulars que suggereixin una separació superficial, consideri la roda com potencialment compromesa fins que un professional amb equip adequat de verificació ho confirmi.

Un cop identificat el tipus de danys i avaluada la seva gravetat, ja està preparat per entendre exactament què passa quan un tècnic qualificat porta la seva roda forjada al banc de rectificació —i per què aquest procés exigeix tanta precisió.

El procés professional de rectificació de rodes revelat

Sempre us heu preguntat què passa realment darrere escena quan un tècnic repara la vostra roda forjada deformada? El procés és molt més metòdic que simplement tornar a posar el metall en forma a força. El rectificat professional combina mesures precises, aplicació controlada de calor i correccions progressives: cada pas es basa en l'anterior per restaurar la geometria de la roda sense destruir la resistència dissenyada originalment.

Comprendre aquest procés us ajuda a avaluar si un taller sap realment com arreglar danys en llantes forjades o si estan aplicant tècniques per a llantes colades que podrien comprometre el vostre component premium. Analitzem pas a pas exactament el que fan els tècnics qualificats.

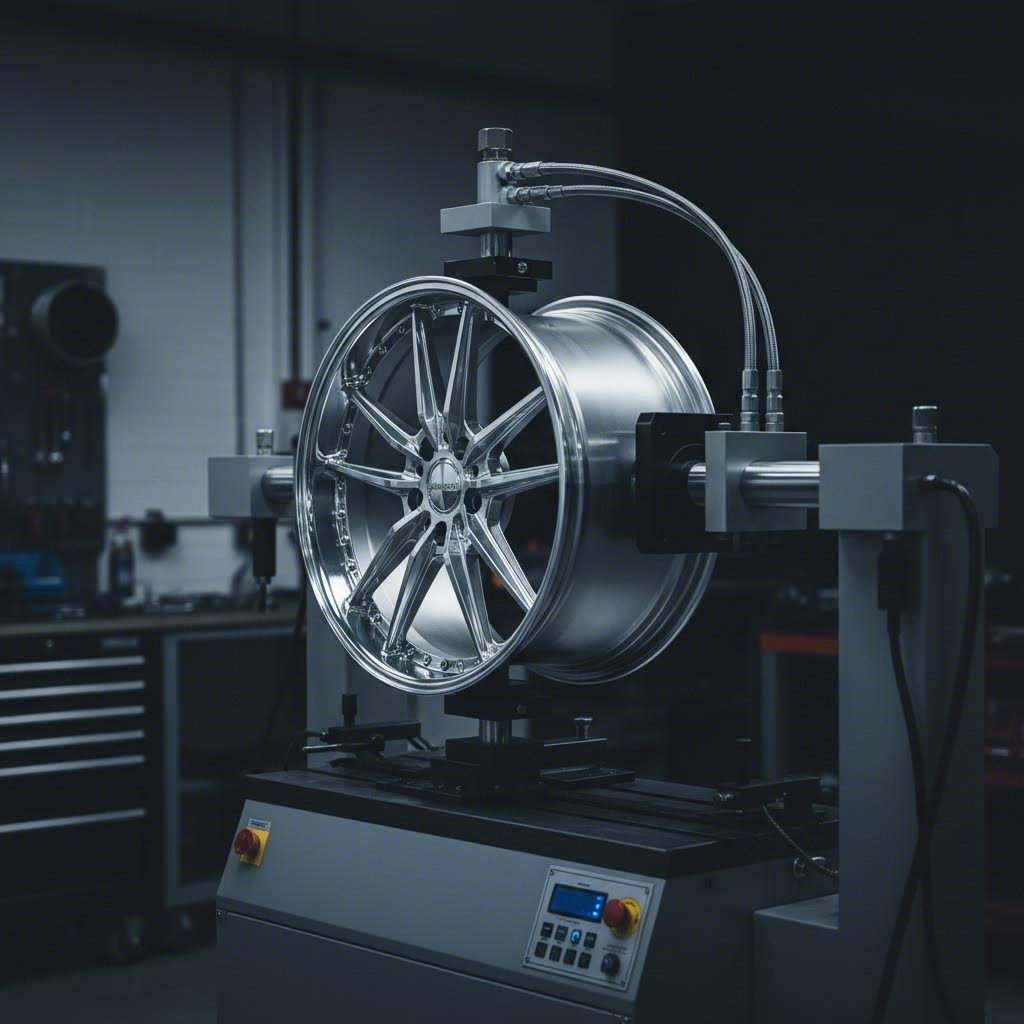

Dins del Banc Professional de Rectificació de Rodes

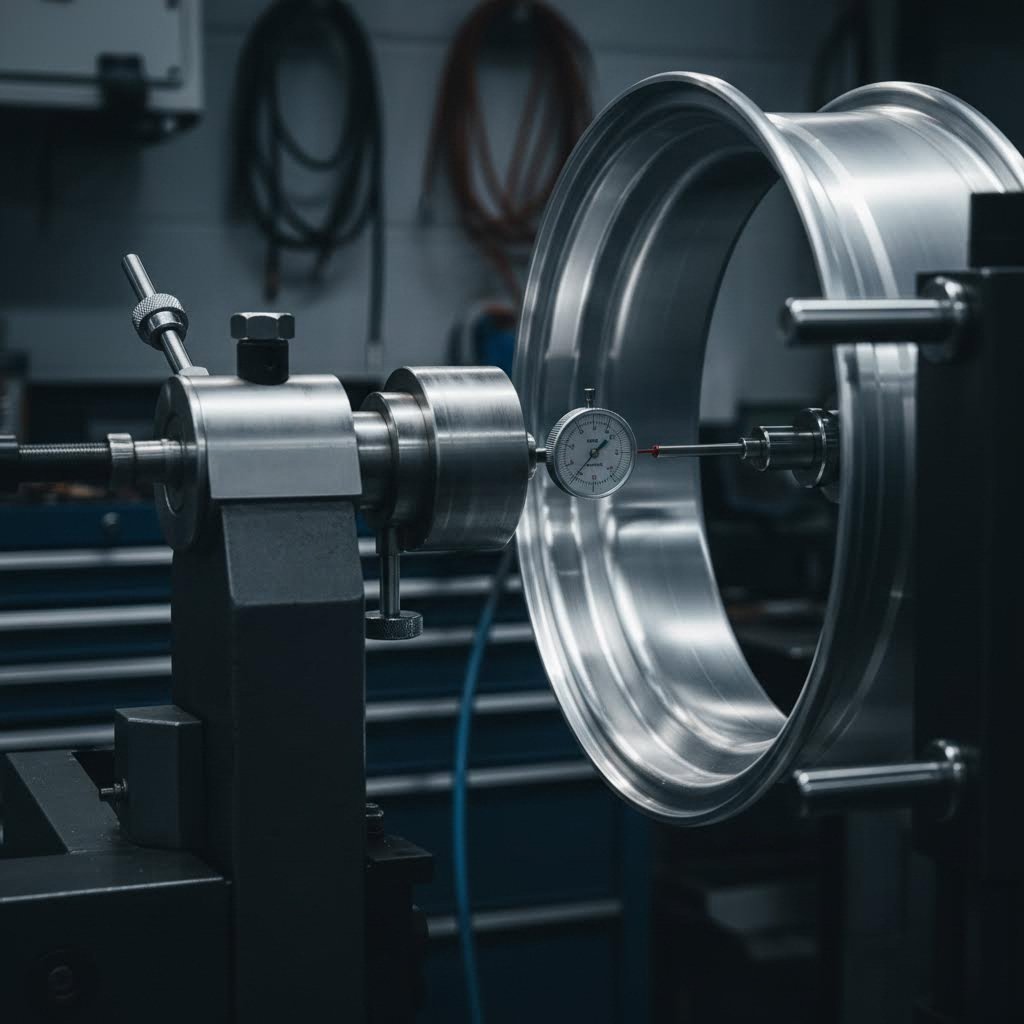

Abans que comenci cap correcció, la roda passa per una inspecció completa. Els tècnics muntan la vostra roda en un dispositiu especialitzat que la fa girar a velocitats controlades mentre indicadors de rellotge mesuren la desviació en diversos punts. Aquests instruments de precisió detecten jocs tan petits com 0,001 polzades, molt més enllà del que podrien percebre els vostres ulls o mans.

Penseu-hi com en sintonitzar un vehicle de prestacions amb programari ecutek: necessiteu mesures exactes abans de fer ajustaments, o altrament només esteu endevinant. Les lectures inicials de joc creen un mapa de referència que mostra exactament on i amb quina gravetat s'ha deformat la roda. Aquestes dades guien cada pas posterior.

La gamma d'equips en un taller de rectificació correctament equipat inclou normalment:

- Màquina hidràulica de rectificació de precisió —aplica pressió controlada i mesurada en punts específics de la roda

- Diversos indicadors de rellotge —monitoritzen simultàniament el joc lateral i radial durant la correcció

- Pistoles de temperatura d'infraroig o imatges tèrmiques —assegurar que l'aplicació de calor es mantingui dins dels rangs segurs

- Fonts de calor controlades —torches especialitzades o escalfadors per inducció que apliquen energia tèrmica amb precisió

- Fixacions de muntatge —fixen la roda en posicions exactes per a mesures repetibles

Les instal·lacions professionals verifiquen que les rodes compleixin les especificacions de tolerància del fabricant abans de continuar amb el refinat. Segons Els processos de taller professional de Wheel Restore , aquest pas de verificació assegura que la roda sigui estructuralment sòlida abans que comenci qualsevol treball estètic.

El paper clau de l'aplicació de calor controlada

Aquí és on la reparació de rodes forjades difereix radicalment dels enfocaments casolans de reparació de llantes. L'alumini forjat 6061-T6 ha estat tractat tèrmicament per assolir característiques específiques de duresa i resistència. Aplicar massa calor durant l'endreçament, i efectivament desfés aquest tractament—abarrant el metall i creant zones febles.

Els tallers professionals treballen dins de marges de temperatura estrictes, normalment mantenint les zones escalfades per sota dels 400°F (204°C). Més enllà d’aquest llindar, el tractament tèrmic de l’alumini comença a degradar-se. Alguns tallers avançats utilitzen guixos indicadors de temperatura o càmeres tèrmiques per controlar en temps real l’aplicació de calor, de manera similar a com els tècnics d’optimització controlen els paràmetres del dccd per a una distribució òptima del parell motor: la precisió importa en cada pas.

Per què aplicar calor, doncs? L’escalfament controlat augmenta temporalment la ductilitat de l’alumini, permetent que es flexioni cap a la seva forma original sense trencar-se. Endreçar a fosc obliga el metall a moure’s quan està a la seva màxima duresa, cosa que augmenta considerablement el risc de fissures al llarg dels límits de grans tan alineats dels quals parlàvem abans.

La seqüència completa d’endreçament professional segueix aquesta metodologia:

- Inspecció i documentació inicials —fotografiar els danys, comprovar esquerdes mitjançant inspecció amb líquids penetrants o partícules magnètiques, i documentar l'estat de la roda abans de començar qualsevol treball

- Muntatge i mesura de referència —fixar la roda al dispositiu d'endrectament i registrar lectures precises de desviació en diversos punts al voltant de la circumferència

- Aplicació de calor a la zona danysada —escalfar progressivament la zona doblegada per augmentar la ductilitat, controlant la temperatura per mantenir-se dins dels límits segurs

- Correcció incremental mitjançant pressió —aplicar força hidràulica en petites quantitats mesurades, tornant a comprovar la desviació després de cada ajustament, en lloc d'obligar una correcció completa en un sol impuls

- Refredament i alliberament de tensions —permetre que la roda es refredi gradualment i de manera uniforme, evitant tensions tèrmiques que podrien crear nous punts febles

- Verificació secundària de les mesures —confirmeu que la oscil·lació lateral sigui inferior a 0,030 polzades i que la oscil·lació radial compleixi les especificacions del fabricant d'equips originals

- Inspecció de fissures després de la correcció —tornar a examinar la zona endreçada per detectar possibles fissures fines que hagin pogut aparèixer durant el procés

- Equilibratge final —utilitzeu un equilibrador dinàmic de rodes per eliminar vibracions i verificar que la reparació no hagi introduït nous desequilibris

Fixeu-vos com els passos 4 i 6 creen un bucle de retroalimentació? Aquest enfocament iteratiu —aplicar una petita correcció, mesurar el resultat, repetir— evita correccions excessives catastròfiques que arruïnen les rodes. Fer aquest procés massa ràpid, forçant grans correccions en poc temps, genera tensions internes excesives i augmenta significativament el risc de formació de fissures.

Segons Directrius de reparació de rodes forjades de Boberry Machinery , després de la soldadura o endreçament, les rodes forjades poden necessitar un tractament tèrmic addicional (revenat) per restablir la seva duresa i resistència. Aquest procés tèrmic posterior a la reparació imita el tractament T6 original, ajudant a garantir que la roda mantingui la seva durabilitat després de les reparacions.

I què passa si es prova a fer-ho a casa? Tot i que potser trobaràs vídeos que mostren com arreglar danys per deformació del llant amb un suport de gat i una pistola tèrmica, les rodes forjades realment requereixen equipament professional. Les premses hidràuliques de precisió utilitzades en tallers professionals apliquen una força mesurada i distribuïda, completament diferent de l’esforç concentrat d’un cop de martell o d’una palanca. El treball detallat fet per aficionats és adequat per a retocs cosmètics, però l’endreçament estructural entra en un àmbit on les limitacions de l’equipament creen riscos de seguretat.

La diferència entre intents professionals i amateurs sovint es redueix a la paciència. Els tallers professionals esperen que el cicle de calentament-prensatge-mesurament es repeteixi diverses vegades per a una sola correcció de corba. Cada iteració acosta progressivament la roda a l'especificació desitjada. Els tallers que intenten completar les reparacions ràpidament, o que no disposen de l'equip adequat per verificar els avenços parcials, sovint empenyen massa fort i massa de pressa, provocant danys interns que no es manifestaran fins setmanes o mesos més tard.

Ara que el procés tècnic ja no és un misteri, esteu preparats per avaluar de manera més eficaç els pressupostos de reparació i la competència dels tallers. Però com equilibreu els costos de reparació amb els de substitució, especialment quan diferents aplicacions de vehicles comporten diferents nivells de risc tolerable? Aquest és el càlcul que abordarem tot seguit.

Prendre la decisió de reparar o substituir amb confiança

Heu avaluat els danys, enteneu en què consisteix una reparació professional; ara arriba la pregunta real: cal fer-ho? Aquesta decisió equilibra les preocupacions de seguretat amb les realitats econòmiques, i la resposta adequada varia considerablement segons la vostra situació específica. Un entusiasta del circuit que porta un Subaru WRX i STi al límit es troba amb consideracions diferents d’algú que fa trajectes diaris amb una berlina de luxe.

Construïm un marc pràctic que us ajudi a ponderar aquests factors de manera objectiva, perquè pugueu avançar amb seguretat en lloc d’ansietat.

El càlcul entre seguretat i economia

Quan els entusiastes debaten si es pot reparar una llanta doblegada, les preocupacions sobre la seguretat dominen la conversa —i amb raó. Les rodes són l'única connexió entre el vostre vehicle i la carretera. Una fallada catastròfica d'una roda a velocitat elevada provoca situacions que ningú vol imaginar.

Però aquí hi ha la perspectiva equilibrada: la reparació professional de rodes té un historial sòlid quan es realitza correctament en candidats adequats. Segons Les directrius d'avaluació de seguretat de RimPerfection , les rodes d'aliatge reparades poden ser segures quan professionals qualificats utilitzen tècniques estàndard del sector i materials d'alta qualitat. La clau rau en una avaluació adequada dels danys, tècnics qualificats i comprendre les limitacions.

Així doncs, quant costa arreglar una llanta doblegada? Els costos típics de reparació oscil·len entre 75 i 250 dòlars per roda, sent les rodes forjades sovint més properes al límit superior degut a l'expertesa especialitzada requerida. Compareu-ho amb els costos de substitució de 1.500 a 4.000 dòlars per roda forjada, i el cas econòmic a favor de la reparació esdevé convincent —quan realment és apropiada.

El càlcul es torna interessant quan es tenen en compte els costos ocults de reparacions inadecrades:

- Desgast accelerat dels pneumàtics —les rodes reparades amb toleràncies massa amplíes provoquen un contacte desigual del pneumàtic, amb un cost potencial de 200-400 dòlars en substitucions prematures

- Problemes recurrents d'equilibratge —les rodes mal endreçades poden requerir reequilibratges freqüents a un cost de 20-40 $ per visita

- Tensió en la suspensió —la vibració provocada per rodes mal reparades accelera el desgast dels coixinets, rodes i altres components

- Susceptibilitat a danys repetits —les rodes debilitades poden doblegar-se més fàcilment a causa d'impactes posteriors

Cotxes de prestacions vs. cotxes d'ús diari: s'apliquen normes diferents

Es poden reparar rodes per a ús en pista? Aquesta pregunta mereix una consideració acurada. Un competidor d'autocross del cap de setmana que porta el seu Subaru WRX i STi a passar per corbes agressives experimenta forces que amplifiquen qualsevol feblesa estructural. La mateixa roda reparada podria funcionar perfectament en un vehicle urbà que mai supera els límits legals de velocitat ni troba forces laterals més enllà de les condicions normals de conducció.

Valoris honestament l'ús que fa del vehicle:

Aplicacions de gran prestació i en pista: Si estàs intentant igualar els temps 0-60 del WRX o aguantant corbes a alta velocitat, el marge d'error es redueix dràsticament. Fins i tot les rodes forjades correctament endreçades han patit cicles de tensió que la fabricació original no va preveure. Molts entusiastes de circuits adopten una filosofia de "en cas de dubte, substitueix", ja que les possibles conseqüències superen clarament l'estalvi d'una reparació quan s'opera en límits de prestacions.

Aplicacions per a vehicles d'ús diari: Per a vehicles urbans i conducció normal per carretera, les rodes forjades reparades correctament sovint representen una opció raonable. Les forces experimentades durant la conducció habitual estan ben dins del que pot suportar una reparació de qualitat. Una reparació de 200 $ que t'estalvia 2.800 $ té sentit econòmic quan rares vegades arribes als límits estructurals de la roda.

Vehicles d'ús mixt: Aquí és on les decisions es tornen més matitzades. Si el teu vehicle de prestacions fa alguna escapada amb conducció dinàmica però principalment cobreix funcions diàries, hauràs de valorar amb quina freqüència arribes als límits enfront de l'economia de la reparació.

| Gravetat del danys | Senyals típiques | Acció recomanada | Rang de cost de reparació | Notes |

|---|---|---|---|---|

| Lleu | Vibració lleu; desviació inferior a 0,030"; sense fissures visibles; només rascades al llavi | La reparació és normalment viable | 75 - 150 $ | Candidats excel·lents per a l'endrectament professional; adequats per a tots els usos després d'una reparació correcta |

| Moderat | Tremolor notable; desviació entre 0,030" i 0,060"; flexió visible; deformació menor del llavi | Cal una avaluació professional | 150 - 250 $ | Es poden reparar les rodes en aquest nivell? Sovint sí, però per a ús en circuit o rendiment pot ser recomanable substituir-les |

| Severe | Vibració important; desviació superior a 0,060"; problemes amb el segell de la banda del pneumàtic; múltiples zones de danys | Es recomana el reemplaçament | No és aconsellable | Els costos de reparació s'acosten als límits de reemplaçament; la integritat estructural és qüestionable |

| Crític | Grietas visibles; danys en les llances/barril; àrea de muntatge del cub afectada; antecedents de reparacions prèvies | Cal un reemplaçament | N/A | Cap taller de confiança hauria d'intentar la reparació; el risc de seguretat és inacceptable independentment de l'estalvi econòmic |

Una perspectiva del món real que val la pena considerar és una anàlisi d'un conductor d'autos compartits documentà una lleugera deformació de la roda amb una petita fissura en formació. El cost total de la reparació va ser d'uns 220 $, incloent soldadura i reequilibrat, enfront d'uns 400 $ per una roda OEM de reemplaçament. Un any després, la reparació continuava en bones condicions, fet que il·lustra que, en les condicions adequades, la restauració professional funciona eficaçment.

La vostra tolerància al risc també és important. Alguns propietaris senzillament no poden estar tranquil·ls sabent que la seva roda ha estat endreçada, independentment de la qualitat de la reparació. Aquest confort psicològic té un valor. Altres adopten una visió més pragmàtica: si professionals qualificats verifiquen que la reparació compleix les especificacions, la roda fa la seva funció.

Quan avaluïeu si podeu reparar una llanta doblegada en la vostra situació específica, considereu aquests factors finals:

- Relació entre el valor de la roda i el cost de la reparació —si la reparació supera el 50% del cost de substitució, sovint és més raonable substituir-la a llarg termini

- Consideracions d'assegurança —algunes pòlisses cobreixen danys a les rodes; comproveu-ho abans de pagar de butxaca

- Preocupacions sobre la combinació —reparar una roda mentre les altres envellissen pot crear inconsistències de rendiment

- Implicacions per a la reventa —les reparacions de rodes declarades poden afectar el valor de revenda del vehicle per a alguns compradors

Amb aquest marc de decisió, esteu preparats per triar un taller de reparació—suposant que la reparació sigui el camí escollit. Tanmateix, no tots els especialistes en reparació de rodes saben manejar correctament les rodes forjades. Saber identificar tècnics qualificats d'aquells que podrien comprometre la vostra inversió és el següent pas essencial.

Triar un especialista qualificat en reparació de rodes forjades

Heu decidit que la reparació és l'opció adequada per a la vostra situació—ara us espera el repte de trobar algú que no comprometi les vostres rodes premium. No tots els tallers que ofereixen serveis de rectificació de rodes disposen realment de l'expertesa que requereixen les rodes forjades. La diferència entre un especialista qualificat i un tècnic poc format pot ser la diferència entre rodes que funcionin impecablement durant anys i components que fallin quan més les necessiteu.

Tant si heu trobat una botiga local prometedora com si heu descobert opcions a través de fòrums d'entusiastes com els de les comunitats rallysport direct, necessiteu criteris concrets per avaluar la competència. Analitzem què diferencia els especialistes qualificats en rodes forjades de les botigues que podrien malmetre la vostra inversió.

Preguntes essencials que cal fer a qualsevol taller de reparació de rodes

Abans de confiar les vostres rodes de 3.000 $ a algú, necessiteu respostes. Un taller reputat acull amb satisfacció clients ben informatos i contesta les preguntes de manera transparent—han invertit en formació adequada i equipament, per tant estan disposats a demostrar la seva competència. La vacil·lació o respostes vagues haurien d’alertar-vos immediatament.

Segons directrius del sector per a l'avaluació del servei de rodes , entendre el procés, els materials i les ofertes de garantia d’un taller us ajuda a prendre decisions informades. Comenceu amb aquestes preguntes clau:

- «Quina experiència específica teniu amb rodes forjades?» —Les habilitats per reparar rodes colades no es traslladen automàticament. Pregunteu quantes rodes forjades han endreçat i amb quines marques han treballat. Un taller qualificat hauria de mencionar fabricants específics de rodes forjades pel nom.

- «Quin equip utilitzeu per a l’endreçament?» —Fixeu-vos si esmenten premses hidràuliques de precisió, indicadors de rellotge que mesuren fins a 0,001 polzades i eines per aplicació controlada de calor. Respostes genèriques com «tenim tot el necessari» no són suficients.

- «Com controleu la temperatura durant l’aplicació de calor?» —Els tècnics qualificats entenen la importància de mantenir l’alumini forjat per sota dels llindars crítics. Haurien d’esmentar pistoles infrarroges, imatges tèrmiques o mètodes indicadors de temperatura.

- «A quines toleràncies endreçeu les rodes?» —Els tallers professionals haurien de citar especificacions concretes de joc (típicament 0,030 polzades o menys per a la desviació lateral). Els tallers que no poden explicar estàndards mesurables probablement no estan fent mesures.

- «Quina garantia ofereixen en les feines d’alineació?» —Els especialistes de prestigi donen suport a les seves reparacions. Informeu-vos sobre la durada de la garantia, què cobreix i quina documentació rebràs.

- «Podeu explicar per què les rodes forjades requereixen tècniques diferents que les rodes colades?» —Aquesta pregunta oberta revela si els tècnics entenen realment els principis metal·lúrgics o simplement segueixen procediments aprèsnguts per a tipus diferents de rodes.

Un taller que entén la metal·lúrgia de les rodes forjades parlarà de l'estructura del gra, la conservació del temple i els enfocaments de correcció progressiva sense necessitat de suggerir-ho. Si el tècnic no pot explicar per què les rodes forjades exigeixen un tractament especialitzat, probablement no l'estigui proporcionant.

Senyals d'alerta que indiquen un tècnic no qualificat

De vegades, el que diu un taller no ho fa diu tant com el que fa. Segons experts de la indústria de reparació d'automòbils experts de la indústria de reparació d'automòbils , sovint apareixen senyals d'advertència abans que s'hagi començat cap treball —si saps què cal vigilar.

Allunya't de qualsevol botiga que mostri aquests comportaments preocupants:

- Reticència a explicar el seu procés —Tècnics legítims informen els clients amb seguretat. Les botigues que eviten preguntes sobre la metodologia sovint amaguen pràctiques inadecuades.

- No esmenta la inspecció de fissures —Qualsevol botiga que no parli de la detecció de fissures abans i després de la reparació s'està saltant passos crítics de seguretat. La prova amb líquid penetrant o mètodes d'inspecció similars hauria de ser una pràctica estàndard.

- Pressió o creació d'urgència —Frases com "cal fer-ho immediatament" o "aquest danys és pitjor del que sembla" sense evidències suporten que la botiga prioritzi els ingressos per sobre dels teus interessos.

- Preus vagues o exclusivament verbals —Les botigues professionals proporcionen pressupostos escrits que detallen la mà d'obra i qualsevol material. Les botigues que es neguen a documentar els pressupostos sovint sorprenen els clients amb factures finals inflades.

- Falta de pràctiques de documentació —Especialistes qualificats fotografia el dany abans i després de la reparació, documenten les mesures de desviació i proporcionen una verificació escrita que les toleràncies compleixen les especificacions.

- Apropiació única per a totes —Si el taller tracta les vostres rodes forjades igual que les d'alumini colat, no estan tenint en compte diferències metal·lúrgiques clau. La reparació de rodes forjades exigeix límits específics de temperatura, aplicació progressiva de pressió i potencialment tractaments tèrmics posteriors a la reparació.

- Instal·lacions desendreçades o descuidades —Encara que els tallers de reparació es puguin embrutar, la desorganització crònica sovint indica problemes de flux de treball que afecten el control de qualitat. El treball de precisió requereix enfocaments sistemàtics.

- Documentació absent o obsoleta —Tot i que no tots els tècnics experimentats tenen certificacions, els tallers que mostren orgullosos credencials del sector demostren un compromís amb els estàndards professionals.

Quan els entusiastes investiguen opcions mitjançant comunitats com els fòrums de rallysport direct, els patrons de reputació es fan evidents ràpidament. Les botigues amb qualitat consistent reben recomanacions repetides; aquelles que estalvien en costos generen publicacions d'alerta. Aproveu aquestes percepcions comunitàries juntament amb la vostra avaluació directa.

Un altre aspecte a considerar: l'aplicació de pintura en rodes i llantes després del rectificat. Les botigues de qualitat o bé realitzen el refinat a casa amb materials adequats o col·laboren amb acabats reputats. Pregunteu si la pintura aplicada a les llantes utilitza recobriment en pols, pintura líquida o altres mètodes, i si igualen els acabats d'origen. La capacitat de pintar correctament les llantes després d’una reparació estructural indica un enfocament integral, i no només un rectificat bàsic.

Confia en les teves intuïcions durant les visites a tallers. Com assenyalen experts del sector de reparacions, si alguna cosa no et sembla bé —si el taller sembla apressat, despreocupat o excessivament insistents— és perfectament raonable marxar. Un taller que mereix les teves rodes forjades guanya confiança mitjançant la transparència, el coneixement demostrat i la voluntat de respondre totes les preguntes que plantejis.

Trobar l'especialista adequat resol la meitat de l'equació. Un cop les rodes estiguin reparades, saber com controlar-ne la integritat a llarg termini esdevé igualment important, perquè fins i tot les reparacions de qualitat requereixen una vigilància contínua.

Cures posteriors a la reparació i control de seguretat a llarg termini

La vostra roda forjada ha estat endreçada professionalment, ha superat la inspecció final i ha tornat a la seva funció. I ara què? Molts propietaris cometent l'error de suposar que la finalització de la reparació significa que el problema està resolt, però l'endreçament exitós és només el començament d'una propietat responsable. La mateixa diligència que apliqueu quan apreneu com comprovar els nivells d'oli o vigilar la pressió normal de l'oli s'aplica a les vostres rodes reparades: una atenció contínua evita que petits problemes es converteixin en fallades perilloses.

Penseu en la vostra roda reparada com qualsevol component de precisió que hagi patit una tensió superior als seus paràmetres originals de disseny. Pot funcionar impecablement durant anys, o pot desenvolupar problemes que apareixen progressivament. Saber què cal vigilar i quan retirar una roda del servei protegeix tant la vostra inversió com la vostra seguretat.

Programa i protocols d'inspecció posterior a la reparació

Establir una rutina sistemàtica de monitoratge permet detectar problemes emergents de manera precoç. De la mateixa manera que els conductors experimentats comproven l'oli calent o fred a intervals regulars per entendre l'estat del motor, els propietaris de rodes s'beneficien d'hàbits d'inspecció constants.

Durant les primeres 500 milles després de la reparació, inspeccioneu la roda setmanalment. Cerqueu qualsevol senyal que indiqui que la reparació no ha aguantat —vibracions noves, canvis visuals o pèrdues de pressió d'aire—. Aquest període inicial revela la majoria de fallades immediates de la reparació. Després d'aquesta fase de rodatge, canvieu a inspeccions mensuals durant el primer any i, posteriorment, trimestrals.

Segons Especialistes en reparació de rodes , el manteniment autònom regular mitjançant inspeccions és essencial si voleu evitar que els problemes s'acumulin. Els petits problemes detectats precoçment continuen sent solucions assequibles; ignorar els senyals d'avís provoca substitucions costoses.

Durant cada inspecció, comproveu aquests punts específics:

- Examinació visual de la zona reparada —cerqueu fissures noves, marques d'esforç o discoloracions que no estaven presents després de la reparació

- Consistència de la pressió dels pneumàtics —fixa't si la roda reparada perd pressió més ràpidament que les altres rodes

- Patrons d'ús dels pneumàtics —l'ús desigual en la roda reparada pot indicar que el rectificat no s'ha mantingut o que han aparegut nous problemes

- Estabilitat de l'equilibratge —les rodes que necessiten reequilibratges freqüents poden tenir problemes interns que afecten la distribució del pes

Senyals d'avís que la vostra roda reparada necessita atenció

Alguns símptomes requereixen una avaluació professional immediata. Per què em vibra el volant quan freno després d'una reparació de roda? Aquest patró de vibració—especialment si ha aparegut després de la reparació o ha empitjorat progressivament—suggereix que la roda pot haver sortit de la seva geometria corregida o que ha desenvolupat nous problemes estructurals.

Atent als següents senyals d'avís que indiquen que la vostra roda forjada reparada pot estar fallant:

- Vibracions noves o recurrents —el tremolament a velocitats d'autopista o els polsos a través del volant suggereixen que han tornat problemes de geometria

- Marques visibles d'esforç o fissures fines —qualsevol irregularitat superficial nova a la zona de reparació indica una fallada estructural progressiva

- Desgast accelerat o desigual dels pneumàtics —patrons diferents dels altres rodes indiquen que la roda reparada no manté un contacte adequat

- Fugues lentes persistents d'aire —si has d'afegir aire amb més freqüència que abans de la reparació, poden haver aparegut fissures microscòpiques a la zona d'assentament del taló

- Comportament de llunetes ràpides al TPMS —alguns sistemes indiquen irregularitats de pressió mitjançant avisos al quadre que val la pena investigar

- Canvis durant el frenat —nous estiraments, pulsacions o sorolls en reduir la velocitat poden estar relacionats amb problemes de rodes que afecten la durada dels discs de frens o la seguretat immediata

- Deformació visible que reapareix —les rodes que es dobleguen un cop poden ser més susceptibles a impactes posteriors

Segons Directrius de seguretat de pneumàtics de Piazza Subaru , les vibracions progressivament constants poden derivar de problemes de roda que, si no es solucionen, poden malauradament danyar altres components. La vibració provocada per rodes defectuoses accelera el desgast en tot el sistema de suspensió.

Quan s’hauria de retirar completament una roda prèviament reparada? Cal considerar el reemplaçament si la roda ha estat endreçada dues vegades, mostra qualsevol tipus de fissura després de la reparació o no manté les especificacions malgrat una correcció inicial adequada. L’estalvi econòmic d’un tercer intent de reparació gairebé mai justifica els riscos estructurals acumulatius.

La vostra roda forjada reparada pot oferir anys de servei fiable, però només si romaneu atents. El control regular transforma el que podria ser una fallada sobtada en una decisió de manteniment manageable i previsible. Un cop establerts els vostres protocols d'inspecció, esteu preparats per sintetitzar tot el que heu après en un pla d'acció clar adaptat a la vostra situació específica.

Actuar en la vostra decisió sobre una roda forjada doblegada

Ara heu recorregut completament el panorama de la reparació de rodes forjades: des de comprendre els principis metal·lúrgics fins a identificar tipus de danys, avaluar processos professionals i establir protocols de monitoratge. Sigui que estigueu valorant si podeu endreçar una llanta de les vostres rodes premium o que us trobeu davant d'una decisió sobre la reparació d'una roda d'aliatge abonyegada, ara teniu els coneixements necessaris per avançar amb seguretat.

Agrupem tot en un camí d'actuació clar que transformi aquesta informació en passos decisius. Les vostres rodes forjades representen una inversió important, i les decisions que preneu ara afecten tant la vostra cartera com la vostra seguretat en cada conducció.

El vostre pla d'actuació complet per a la reparació de rodes forjades

Quan descobriu danys, resistiu la temptació de programar immediatament reparacions o demanar repeticions. Una avaluació metòdica estalvia diners i evita errors perillosos. Seguiu aquesta seqüència:

Pas 1: Documenteu i avalueu. Fotografeu tots els danys visibles des de diversos angles. Comproveu si hi ha esquerdes passant l'ungla per les zones afectades. Anoteu qualsevol símptoma: vibracions, pèrdua de pressió, desgast anormal del pneumàtic. Aquesta documentació ajuda els professionals a avaluar la vostra situació i us protegeix si sorgeixen disputes.

Pas 2: Classifiqueu el tipus de dany. És lateral (oscil·lació d'un costat a l'altre), radial (desviació cap amunt i avall) o és un dany al llavi que afecta la secció d'estanquitat del pneumàtic? Els petits doblecs laterals sense esquerdes són els millors candidats per a reparació. Els danys radials greus o qualsevol esquerda visible solen implicar substitució.

Pas 3: Avaluïu honestament segons la vostra aplicació. Un vehicle de comute rarament arriba a forces que tensionin una roda reparada correctament. Els entusiastes de circuits que muntin pneumàtics Michelin Pilot Sport 4S per a conducció agressiva han de fer un càlcul de risc diferent: aquests pneumàtics premium mereixen rodes igualment fiables sota seu.

Pas 4: Trieu especialistes qualificats utilitzant els criteris que heu après. Pregunteu específicament per experiència en rodes forjades, control de temperatura durant l'aplicació de calor, toleràncies de desviació i cobertura de garantia. Allunyeu-vos dels tallers que no saben explicar per què les rodes forjades requereixen tractaments diferents.

Pas 5: Compiteu-vos amb un seguiment continuat. Inspeccions setmanals per als primers 500 quilòmetres, mensuals durant el primer any i trimestrals a partir d'aleshores. Qualsevol símptoma que torni requereix una avaluació professional immediata.

Per a aquells que optin per arreglar les rodes doblegades, aquest enfocament estructurat maximitza la probabilitat d'èxit minimitzant alhora els riscos de seguretat. Per a aquells que considerin que el reemplaçament és més convenient, el mateix raonament sistemàtic s'aplica a la selecció de components de substitució de qualitat.

Quan la qualitat en els estàndards de fabricació importa més

Tant si es reparen rodes existents com si s'avaluen reemplaços, la qualitat de fabricació determina la fiabilitat a llarg termini. Els mateixos principis que fan superiors les rodes forjades —processos controlats, especificacions precises, verificació rigorosa de la qualitat— haurien de guiar les vostres decisions de substitució si la reparació no és viable.

Segons normes de certificació del sector , la certificació IATF 16949 representa el referent global en gestió de qualitat automotriu. Aquesta norma assegura la millora contínua, la prevenció de defectes i la reducció de la variació en els processos de fabricació. Les operacions de forja que compleixen aquestes normes produeixen components amb un rendiment constant i fiable.

Quan avaluïeu rodes forjades de substitució o qualsevol component automotriu de precisió, busqueu fabricants que demostrin compromisos de qualitat similars. Les solucions de forja calenta de precisió de Shaoyi , recolzades per la certificació IATF 16949 i un control de qualitat rigorós, exemplifiquen les normes de fabricació que produeixen components automotrius forjats fiables. La seva enginyeria interna assegura que els components compleixin especificacions exactes: els mateixos principis de qualitat que importen quan es trien rodes forjades de substitució.

El procés de forja en calent refinia l'estructura del gra, millora el rendiment mecànic i assegura una qualitat consistent entre lots de producció. Ja sigui que estigueu adquirint components de suspensió, eixos de transmissió o rodes mateixes, els fabricants que integren la forja amb mecanització precisa i proves ofereixen la fiabilitat que exigeix el vostre vehicle.

L'enfocament més assenyat equilibra l'economia de la reparació amb les prioritats de seguretat: estalviïeu diners quan professionals qualificats verifiquin la viabilitat de la reparació, però mai comprometeixi la integritat estructural de components que connecten el vostre vehicle amb la carretera.

La vostra situació amb una roda forjada doblegada té una solució, ja sigui mitjançant l’alineació professional per especialistes qualificats o el reemplaçament amb components de fabricació de qualitat. Els pneumàtics Michelin Pilot Sport 4S que munteu, el rendiment que cerqueu, la família que transportegeu: tot depèn de rodes en les quals pugueu confiar. Dotat de les habilitats d’avaluació, els marc de decisió i els protocols de monitoratge d’aquesta guia, esteu preparat per prendre aquesta decisió amb confiança i no amb incertesa.

Seguiu endavant sabent que enteneu què separa els danys reparables de les situacions que requereixen reemplaçament, en què consisteix realment una reparació qualificada i com verificar que les vostres rodes romanen segures per a cada quilòmetre que us espera.

Preguntes freqüents sobre la reparació de rodes forjades doblegades

1. Es pot reparar una roda forjada?

Sí, les rodes forjades sovint es poden reparar, però només per especialistes qualificats amb experiència específica en rodes forjades. La viabilitat de la reparació depèn del tipus i la gravetat dels danys. Les doblegades laterals lleus sense fissures normalment es poden reparar, mentre que els danys radials greus, les fissures visibles o els danys prop de les zones de muntatge solen requerir substitució. Els tallers professionals utilitzen premses hidràuliques de precisió, aplicació controlada de calor per sota de 400 °F i indicadors de rellotge per restablir les rodes a les especificacions OEM sense comprometre la integritat estructural de l'alumini temperat T6.

2. Es dobleguen fàcilment les llantes forjades?

Les rodes forjades són realment molt resistents a la flexió en comparació amb les rodes colades. El seu procés de fabricació —premsant blocs sòlids d'alumini amb una força superior a les 10.000 tones— crea una estructura de grans densa i alineada que pot arribar a ser fins a tres vegades més resistent que les alternatives colades. Tanmateix, impactes severos causats per badalls o vorades poden provocar deformacions. Quan les rodes forjades pateixen danys, tendeixen a doblegar-se en lloc de trencar-se o esquerdar-se, fet que pot fer-les més adequades per a reparacions professionals que les rodes colades.

3. Val la pena reparar les rodes doblegades?

Reparar llantes forjades doblegades sovint val la pena quan el dany és menor o moderat i no hi ha esquerdes. Les reparacions professionals solen costar entre 75 i 250 dòlars, comparat amb els 1.500 a 4.000 dòlars que costen les llantes forjades noves. Per a vehicles d'ús diari amb danys menors, la reparació suposa un estalvi significatiu. Tanmateix, per a circuits o aplicacions d’alt rendiment, pot ser més segur substituir-les. Tingueu en compte l'ús del vehicle, la gravetat del dany i si el cost de la reparació supera el 50% del cost de substitució a l'hora de prendre la decisió.

4. Com puc saber si la meva roda forjada doblegada és reparable?

Avalieu la vostra roda segons aquests criteris: les corbes laterals petites amb un joc inferior a 0,030 polzades solen ser reparables. Els senyals d'alerta que descarten la reparació inclouen esquerdes visibles, danys prop dels forats dels perns o de les zones de muntatge al cub, un joc excessiu superior a 0,060 polzades lateralment o 1 polzada radialment, múltiples zones d’impacte o un historial previ de reparacions. Passi l'ungla per les zones danades; si queda enganxada en esquerdes fines, la roda probablement està compromesa i s'hauria d'inspeccionar professionalment abans de qualsevol intent de reparació.

5. Què hauria de buscar quan trieu un especialista en reparació de rodes forjades?

Consulteu als tallers potencials sobre la seva experiència específica amb rodes forjades, els mètodes de control de temperatura durant l'aplicació de calor i les toleràncies de desviació que aconsegueixen. Els especialistes qualificats haurien de mencionar premses hidràuliques de precisió, indicadors de rellotge que mesuren fins a 0,001 polzades i límits de temperatura per sota de 400°F. Les alertes inclouen la reticència a explicar els processos, l'absència de procediments d'inspecció de fissures, preus imprecisos i la incapacitat d'explicar per què les rodes forjades requereixen un tractament diferent de les rodes colades. Demaneu sempre garanties per escrit i documentació de les mesures posteriors a la reparació.

Petits lots, altes estàndards. El nostre servei d'prototipatge ràpid fa que la validació sigui més ràpida i fàcil —

Petits lots, altes estàndards. El nostre servei d'prototipatge ràpid fa que la validació sigui més ràpida i fàcil —