Metal Laser Cutting Designs: From First Sketch To Flawless Finish

Understanding Metal Laser Cutting Designs and Their Creative Potential

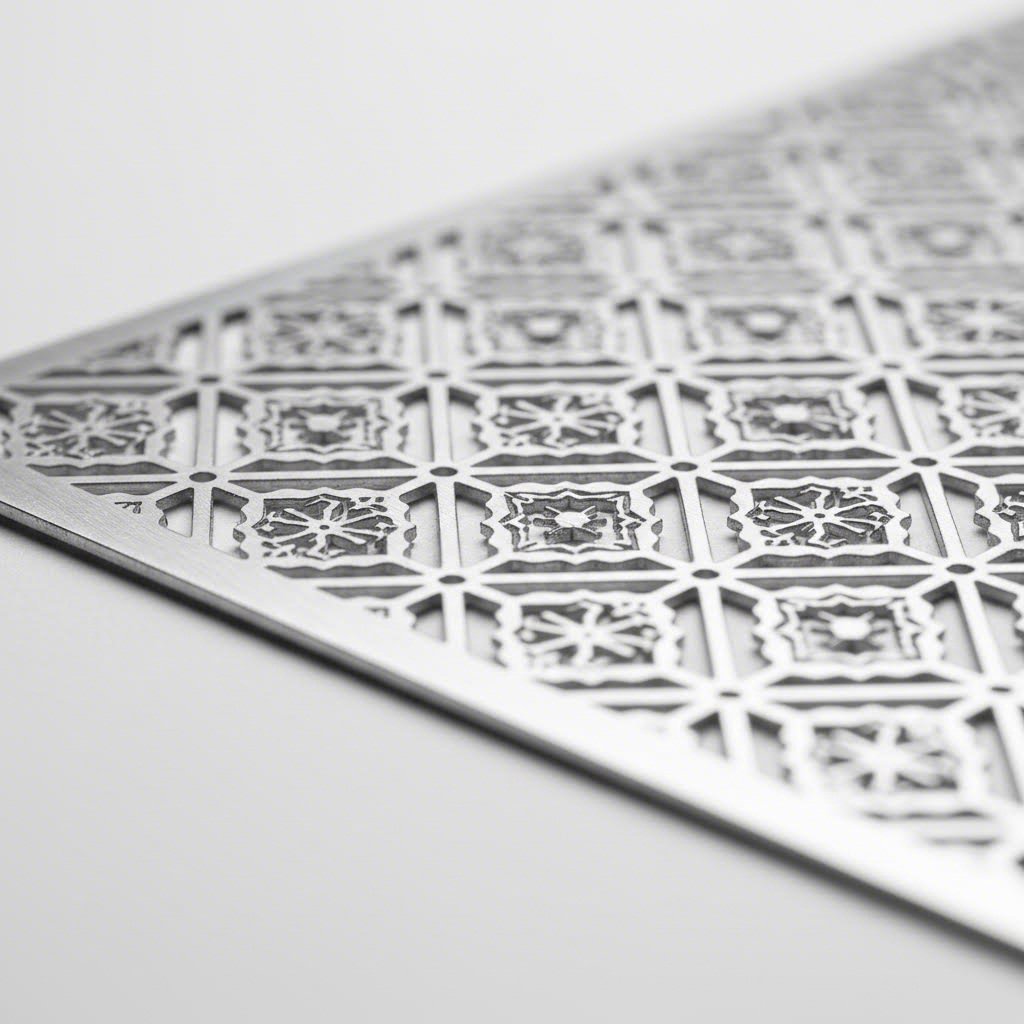

Imagine transforming a flat, unassuming sheet of steel into an intricate architectural screen, a stunning piece of wall art, or a precision-engineered component—all with tolerances as tight as ±0.1mm. That's the power of metal laser cutting designs, and it's reshaping how architects, artists, and engineers bring their visions to life.

Whether you're exploring laser cut metal panels for a commercial facade or creating custom decorative pieces for interior spaces, understanding how this technology works bridges the gap between creative inspiration and successful execution. Let's dive into what makes this manufacturing method so transformative.

From Raw Metal to Precision Art

At its core, laser cutting design relies on a surprisingly elegant principle. A highly concentrated beam of light—powerful enough to vaporize or melt metal—follows programmed paths across a sheet's surface. According to Xometry's technical resources, this coherent beam passes through collimation and focus apparatus to deliver focal point intensity capable of cutting through steel, titanium, aluminum, brass, and copper with extreme precision.

The result? Clean, burr-free edges that require minimal post-processing. Unlike traditional mechanical cutting methods that can leave rough edges or material distortion, a metal laser cutting machine produces cuts so precise that complex geometric patterns, organic flowing shapes, and fine details become achievable in ways that were simply impossible a few decades ago.

Think about it this way: the laser beam removes material along its path (a concept called "kerf"), creating openings as narrow as a fraction of a millimeter. This allows designers to create laser cut designs metal pieces featuring:

- Intricate floral and nature-inspired motifs

- Complex geometric tessellations

- Delicate typography and custom signage

- Functional mechanical components with tight tolerances

Why Designers Choose Laser-Cut Metal

The growing popularity of metal laser cutting design across architectural, industrial, and decorative applications isn't accidental. When you compare it to traditional fabrication methods, the advantages become clear.

First, there's precision. Modern laser cutting achieves typical tolerances of ±0.1mm for materials up to 6mm thick—accuracy that opens doors for designs requiring exact specifications. Second, speed matters. For thin sheet metals, cutting speeds can reach up to 1000 inches per minute, making both prototyping and production runs economically viable.

But perhaps most importantly for creative professionals, laser cut metal offers unmatched versatility. The same technology that produces architectural privacy screens can create personalized gifts, commercial signage, or precision industrial parts. One customer working with decorative metal pieces reported a 30% reduction in production time compared to traditional methods, according to HeatSign's case studies.

Throughout this guide, you'll discover everything needed to take your projects from initial concept to flawless finished piece. We'll explore laser technologies and metal compatibility, essential design guidelines that prevent costly mistakes, file preparation workflows, surface finishing options, and how to choose between templates and custom fabrication. Ready to turn raw metal into precision art? Let's begin.

Laser Technology Types and Metal Compatibility Explained

Here's a question that trips up many designers: why does your laser cutter handle steel effortlessly but struggle with aluminum? The answer lies in understanding that not all lasers are created equal—and choosing the wrong technology for your metal type can mean the difference between pristine cuts and costly failures.

When planning metal laser cutting designs, the laser technology you select directly impacts edge quality, cutting speed, and which metals you can actually process. Let's break down the three main technologies and help you match the right laser to your specific project needs.

Fiber Lasers vs CO2 Systems for Metal Work

The two dominant technologies in professional metal cutting are fiber lasers and CO2 lasers, each with distinct strengths. Understanding their differences helps you make informed decisions—whether you're specifying equipment for a fabrication shop or choosing the right service provider for your project.

Fiber lasers have become the industry standard for metal cutting, and for good reason. Operating at a wavelength of approximately 1.06 micrometers, fiber laser engraver systems deliver exceptional performance on metals. According to ADHMT's technical guide, high-power fiber lasers have become the undisputed mainstream for most metal thick-plate applications—including carbon steel, stainless steel, aluminum, and copper—due to their efficiency, cost advantages, and broad material compatibility.

CO2 lasers, operating at a 10.6-micrometer wavelength, were once the go-to for metal cutting but now occupy a more specialized niche. They still retain advantages for ultra-thick carbon steel demanding superior edge quality and excel with non-metal materials like wood, acrylic, and glass. If your projects involve mixed materials, a CO2 system offers versatility that fiber lasers cannot match.

What about diode laser engraver systems? While increasingly popular for hobbyist applications, they're primarily effective with organic materials such as wood, leather, and paper. Diode lasers are generally unsuitable for processing metals, making them impractical for serious metal laser cutting work.

Matching Laser Technology to Your Metal Type

Reflective metals like aluminum, copper, and brass present unique challenges that make laser selection critical. As BCAMCNC explains, these materials can bounce a portion of laser energy back toward the cutting head, reducing efficiency and potentially causing optical damage if the machine isn't properly equipped.

Why does this happen? Aluminum, copper, and brass have smooth surfaces and high thermal conductivity. When a standard continuous laser beam hits them, a large portion is directly reflected back rather than absorbed. This not only reduces cutting efficiency but can damage protective lenses and even the laser source itself.

The solution? Modern cnc laser cutting machine systems designed for reflective metals use pulsed cutting mode rather than continuous-wave output. Pulsed cutting delivers energy in short, controlled bursts—each pulse instantly melts a small section while allowing the metal a moment to cool between pulses. Less energy stays on the surface long enough to reflect, significantly reducing the risk of dangerous back-reflection.

| Technology Type | Best Metal Applications | Thickness Range | Edge Quality | Speed Characteristics |

|---|---|---|---|---|

| Fiber Laser | Steel, stainless steel, aluminum, brass, copper, titanium | Up to 30mm+ (power dependent) | Excellent—clean, minimal burr | High speed; up to 3x faster than CO2 on thin metals |

| CO2 Laser | Steel, stainless steel; excels on ultra-thick carbon steel | Up to 25mm for steel | Superior on thick carbon steel | Moderate; slower than fiber on most metals |

| Diode Laser | Not recommended for metals | N/A for metal cutting | N/A | Suitable only for engraving or marking |

Power requirements matter too. A laser metal cutting machine's wattage directly affects both cutting thickness and design possibilities. Higher power means faster work and the ability to cut thicker materials—but there's a nuance here. According to industry data, energy density (how tightly energy concentrates at the focal point) matters as much as raw power. A lower-power laser with exceptional beam quality can sometimes outperform a higher-power but poorly focused system.

For practical guidance:

- 3-6kW fiber lasers: Ideal for thin to medium gauge metals; handles most decorative panel work

- 12-20kW+ fiber lasers: Required for thick plate cutting and high-volume production

- 40-150W CO2 lasers: Suitable for mixed-material shops processing both metals and non-metals

Understanding these technology differences empowers you to specify the right equipment or service provider for your projects. But selecting the right laser is only half the equation—choosing the appropriate metal for your application is equally critical to achieving professional results.

Selecting the Right Metal for Your Design Application

You've got your design concept ready and understand which laser technology fits your needs—but here's where many projects hit an unexpected snag. Choosing the wrong metal for your application can undermine even the most carefully planned laser cut metal sheets, leading to corrosion, structural failure, or costs that spiral out of control.

The truth is, material selection directly influences everything from pattern intricacy to long-term durability. Let's explore the properties of common metals used in laser cutting and match them to specific applications so you can make confident, informed decisions.

Steel, Aluminum, and Beyond

Each metal brings distinct characteristics to your project. Understanding these properties helps you balance aesthetics, functionality, and budget—whether you're creating laser cut steel panels for industrial use or delicate decorative screens for interior spaces.

Mild Steel (A36/1008)

When strength and weldability matter most, mild steel delivers. According to SendCutSend's material guide, this iron-carbon alloy is strong, durable, and easily welded, making it ideal for structural applications where an aesthetic finish is less critical. Available in hot rolled, hot rolled pickled and oiled (HRP&O), and cold rolled finishes, mild steel offers flexibility in both cost and surface quality.

- Best applications: Structural brackets, industrial components, furniture frames

- Weldability: Excellent—works well with MIG, TIG, and stick welding

- Finish options: Powder coating, paint, galvanizing for rust protection

- Cost factor: Most economical metal option for laser cutting

- Environmental suitability: Indoor use preferred; requires protective finish for outdoor exposure

Stainless Steel (304/316)

Need corrosion resistance without sacrificing appearance? Stainless steel combines chromium with traditional iron-carbon alloys, allowing the surface to oxidize naturally and protect against weathering. As noted by industry experts, this makes it perfectly suited for highly corrosive or high-stress environments such as marine and aerospace applications.

- Best applications: Architectural panels, kitchen fixtures, medical equipment, outdoor signage

- Weldability: Good—requires proper technique to prevent warping

- Finish options: Brushed, polished, bead-blasted, electropolished

- Cost factor: Higher than mild steel; 316 grade more expensive than 304

- Environmental suitability: Excellent for both indoor and outdoor use; 316 preferred for coastal environments

Aluminum (5052/6061/7075)

When weight matters, laser cut aluminum panels offer an unbeatable strength-to-weight ratio. Aluminum is lightweight, durable, and affordable, serving as the go-to metal for applications ranging from car restorations to robotics engineering. Its natural oxide layer provides built-in corrosion protection, reducing maintenance requirements significantly.

- Best applications: Automotive parts, aerospace components, lightweight decorative panels, electronic enclosures

- Weldability: Requires specialized techniques (TIG welding preferred)

- Finish options: Anodizing, powder coating, brushed, polished

- Cost factor: Moderate—varies significantly by alloy grade

- Environmental suitability: Excellent for outdoor use; naturally corrosion-resistant

Copper and Brass

Looking for warmth and visual appeal? These metals combine functionality with aesthetics in ways steel and aluminum simply cannot match. Copper's 99.9% purity (C110 electrolytic grade) makes it ideal for electrical applications, while brass—a copper-zinc alloy—offers low friction properties perfect for functional hardware like locks, hinges, and bushings.

- Best applications: Decorative wall art, electrical components, architectural accents, signage

- Weldability: Brass is easily soldered and welded; copper requires skill

- Finish options: Natural patina, brushed, oiled, lacquered for preservation

- Cost factor: Premium pricing—copper especially expensive

- Environmental suitability: Naturally corrosion-resistant; develops protective patina outdoors

Choosing Metals for Indoor vs Outdoor Applications

Here's where material selection becomes critical. According to Metal Supermarkets, outdoor structures face challenging conditions—moisture, temperature fluctuations, and pollutants can cause corrosion and subsequent deterioration. The right metal choice ensures your design maintains both appearance and structural integrity over time.

For indoor applications, you have maximum flexibility. Mild steel works beautifully when powder coated, and even unfinished metals can maintain their appearance in climate-controlled environments. Cost often becomes the primary decision factor here.

For outdoor applications, corrosion resistance becomes paramount. Your best options include:

- Aluminum: Lightweight and naturally protected by its oxide layer

- Stainless steel (316 grade): Superior resistance in coastal or polluted environments

- Galvanized steel: Zinc coating provides robust protection at cost-effective pricing

- Corten (weathering) steel: Forms a protective rust-like patina that actually prevents further corrosion

While this guide focuses on metals, it's worth noting that many fabrication shops also work with acrylic sheets for laser cutting and laser cut acrylic for projects requiring transparency or vibrant colors. However, these materials require completely different equipment settings and design considerations than metal work.

How thickness affects design complexity

Material thickness directly impacts what's achievable with your patterns. As Komacut's design guide emphasizes, using standard material thicknesses is one of the easiest ways to optimize the laser-cutting process. Non-standard thicknesses often require special calibration or material sourcing, increasing lead times and costs significantly.

Here's the practical reality: thinner materials allow finer details and more intricate patterns, while thicker stock limits minimum feature sizes. A sheet metal cutter can produce delicate filigree work in 1mm aluminum that would be impossible in 6mm steel. As a general rule, minimum feature sizes should be at least equal to material thickness—and preferably 1.5x for reliable results.

Understanding these material characteristics positions you to make smart decisions before investing in design development. But even perfect material selection won't save a project with fundamental design flaws—which brings us to the technical guidelines that prevent costly mistakes.

Technical Design Guidelines for Precision Metal Cutting

You've selected the perfect metal and understand your laser technology options—but here's where projects often go wrong. Designing for laser cutting isn't the same as designing for screen or print. Ignore the technical constraints specific to metal fabrication, and you'll face rejected files, ruined materials, or parts that simply don't fit together.

The good news? Once you understand the fundamental design rules, they become second nature. Let's explore the critical guidelines that separate successful sheet metal cutting design from costly failures.

Design Rules That Prevent Costly Mistakes

Every laser cutter removes material as it cuts—and that removed material directly affects your finished dimensions. Understanding minimum feature sizes, proper spacing, and tolerance requirements prevents the frustrating scenario of receiving parts that look right but don't actually work.

Minimum hole diameters matter more than you think. When a laser cuts a circle, it's tracing a path while simultaneously removing material. Cut a hole too small relative to your material thickness, and you'll get distorted openings or incomplete cuts. The general rule? Minimum hole diameter should equal at least the material thickness. For 3mm steel, don't design holes smaller than 3mm. For reliable results—especially with intricate patterns—aim for 1.5x material thickness.

Web widths between cuts follow similar logic. Those thin strips of metal remaining between cut features need sufficient width to maintain structural integrity during and after cutting. Too narrow, and they'll warp from heat buildup or simply collapse.

- For materials up to 1.5mm thick: Minimum web width of 1.5mm between features

- For 1.5mm to 3mm materials: Minimum web width equal to material thickness

- For 3mm to 6mm materials: Minimum web width of 1.2x material thickness

- For materials over 6mm: Minimum web width of 1.5x material thickness or greater

- Edge-to-sheet-edge spacing: Always maintain at least half the material thickness from any cut to the sheet edge

- Text and fine details: Minimum stroke width of 0.5mm for thin materials; 1mm+ for thicker stock

- Sharp internal corners: Add small radius (0.5mm minimum) to prevent stress concentration

These aren't arbitrary numbers—they're derived from how laser cutter machine systems interact with metal. According to Komacut's design guide, using standard material thicknesses is one of the easiest ways to optimize the laser-cutting process, as laser cutters are calibrated for these sizes. Non-standard thicknesses require special calibration, increasing both lead times and costs.

Understanding Kerf and Tolerance in Metal Patterns

Here's the concept that separates amateur designs from professional-grade files: kerf. As Metal-Tech Industries explains, kerf refers to the width of material that the laser removes during cutting—essentially the gap left behind as the beam passes through metal.

Sounds insignificant? Consider this: if a laser has a kerf width of 0.15mm and you don't account for it, your final component ends up slightly smaller than intended. When tolerances are tight, that difference matters enormously for parts that need to slot, weld, or bolt together.

Why kerf varies: Kerf width isn't fixed—it depends on multiple factors working together:

- Laser type and power: Fiber lasers typically produce narrower kerf than CO2 systems

- Material type and thickness: Thicker materials create wider kerf as the beam spreads through depth

- Cutting speed: Slower speeds increase heat buildup and may widen the kerf

- Focal length: A tightly focused beam produces finer kerf; out-of-focus beams cut wider

- Assist gas pressure: Higher pressure can narrow effective kerf by removing molten material faster

For cnc cutting applications, typical kerf ranges from 0.08mm to 0.4mm—dramatically narrower than traditional saw cutting or plasma methods. This precision enables the intricate patterns that make laser etching and cutting so valuable for decorative applications.

Kerf compensation in practice: Professional fabricators apply kerf compensation by offsetting the cutting path. If a metal cutting laser produces 0.15mm kerf, the CNC program adjusts the toolpath by half that width (0.075mm) on each side of the design line. This ensures finished parts match intended dimensions exactly.

For parts requiring tight tolerances, always communicate your dimensional requirements to your fabrication partner. They'll apply appropriate kerf compensation based on their specific equipment and your material choice.

Gas assist and edge quality: The assist gas blown through the cutting nozzle dramatically affects your results. According to industry expertise, different gases serve different purposes:

- Nitrogen (high pressure): Produces clean, oxide-free edges on stainless steel and aluminum; ideal for visible surfaces

- Oxygen: Creates an exothermic reaction with steel, enabling faster cuts on thick materials but may slightly widen kerf

- Compressed air: Cost-effective option for non-critical applications; results vary by material

Edge quality matters especially for visible architectural panels or components requiring subsequent welding. Nitrogen-assisted cuts on stainless steel require virtually no post-processing, while oxygen-cut steel may need edge cleaning before finishing.

Understanding these technical parameters transforms your approach to design. Rather than hoping your patterns will work, you'll know exactly what's achievable before sending files to fabrication—saving time, money, and frustration. The next step? Preparing those design files in formats that translate perfectly from screen to finished metal.

File Formats and Software Workflows for Metal Fabrication

You've mastered design guidelines and understand kerf compensation—but here's where the rubber meets the road. Your brilliant metal laser cutting design exists only as a concept until it's translated into a file format your fabricator's equipment can actually read. Get this step wrong, and even the most meticulously planned project stalls before production begins.

The difference between amateur submissions and production-ready files often comes down to understanding how laser cutters interpret digital information. Let's walk through the software workflows and file preparation techniques that transform your creative vision into precision-cut metal.

Creating Production-Ready Design Files

Every laser cutter—whether a hobbyist machine running LaserGRBL or an industrial CNC system—needs vector-based instructions to follow. Unlike raster images composed of pixels, vector graphics use mathematical equations to define paths. According to Xometry's technical documentation, DXF (Drawing Interchange Format) files contain vectors that create 2D paths from which a laser cutter can follow precisely.

Why does this matter? When you submit a dxf file to a fabricator, the machine interprets each line as a cutting path. Those paths tell the laser exactly where to move, when to fire, and how to navigate your design. Raster images like JPEGs simply won't work—the laser needs explicit vector instructions, not grids of colored pixels.

Understanding line types and their meanings:

Your laser cut files communicate different operations through distinct visual elements. As xTool's design guide explains, lines and fills serve completely different purposes:

- Cut lines: Defined paths with specific widths that the laser follows to cut completely through material

- Engrave areas: Filled regions where the laser removes surface material layer by layer without cutting through

- Score marks: Light surface cuts that mark without penetrating—useful for fold lines or alignment guides

Many fabrication services use color-coded systems to distinguish these operations. A common approach assigns specific RGB values to each function—red for cutting, blue for engraving, black for scoring. Your fabricator will specify their exact requirements, but organizing design files with this separation from the start saves revision time later.

Vector Software Essentials for Metal Fabrication

Which software should you use? The answer depends on your project complexity and existing skills. According to industry resources, DXF files use an open-source format, meaning anyone can develop software to create them. Here are the most capable options:

- Adobe Illustrator: Industry standard for vector graphics at $20.99/month; excellent for complex artistic designs but requires learning curve

- Inkscape: Free and open-source; available on Windows, macOS, and Linux—ideal for beginners and budget-conscious designers

- Fusion 360: Cloud-based CAD software with free options and paid tiers around $70/month; enables real-time collaboration and parametric design

- CorelDRAW: Professional vector software with strong DXF export capabilities; preferred by many sign shops

- LightBurn software: Specifically designed for laser control; excellent for users who own their own equipment

For simple designs, even laser cutter control software can handle basic graphics creation. However, complex metal fabrication projects benefit from dedicated design applications where you can perfect geometry before exporting.

Step-by-step file preparation process:

- Create or import your base design using vector paths—ensure all elements are properly scaled to actual dimensions (1:1 scale is essential)

- Convert all text to outlines/paths—laser cutters cannot process active text boxes; they need converted shapes

- Organize elements by operation type—separate cut lines, engrave areas, and score marks onto distinct layers with appropriate colors

- Check for open paths and overlapping lines—unclosed curves can confuse the laser; duplicated paths waste cutting time and may over-burn edges

- Apply kerf compensation if required—offset paths by half the kerf width to achieve precise final dimensions

- Verify minimum feature sizes—confirm all holes, webs, and details meet the guidelines for your material thickness

- Export as DXF or appropriate vector format—use settings compatible with your fabricator's equipment (typically DXF R14 or 2000 for maximum compatibility)

File optimization techniques:

Beyond basic preparation, several optimization strategies reduce cutting time and improve results. According to Beegraphy's fabrication guide, efficient part nesting—arranging components to maximize material usage—significantly reduces waste and cost. Many fabricators handle nesting on their end, but understanding the concept helps you design with material efficiency in mind.

Additional optimization practices include:

- Eliminate redundant nodes: Overly complex paths with unnecessary anchor points slow processing and can create micro-hesitations during cutting

- Simplify curves where precision isn't critical: Reducing path complexity speeds up file processing without visible quality loss

- Group related elements: Organized files help fabricators understand your intent and catch potential issues faster

- Include reference dimensions: Adding a few key measurements helps verify scale during pre-production review

Pre-submission checklist:

Before sending dxf files to fabrication, run through these verification steps to catch common problems:

- All paths closed and properly joined?

- No overlapping or duplicated lines?

- Text converted to outlines?

- Correct scale (1:1 with real-world units)?

- Layers organized by operation type?

- Minimum feature sizes verified for your material?

- File format compatible with fabricator requirements?

Looking for inspiration before creating custom designs? Many designers start by studying free laser cut files available through online libraries. These resources help you understand how professional files are structured—though for metal fabrication, always verify that templates meet the specific design constraints we covered earlier.

With production-ready files in hand, you're positioned to explore the full range of creative possibilities. From architectural panels to decorative art, the applications for well-executed metal laser cutting span virtually every design discipline.

Popular Design Categories and Creative Applications

Now that you understand file preparation and technical constraints, let's explore what's actually possible. Whether you're a hobbyist creating a one-of-a-kind garden screen or an architect specifying decorative laser cut metal panels for a commercial facade, the same technology enables remarkably diverse applications. What separates a forgettable project from a stunning one often comes down to understanding which design category best serves your goals.

From geometric precision to organic flowing forms, laser cut metal designs span virtually every aesthetic sensibility. Let's examine the most popular categories—and the practical considerations that influence production costs and timelines for each.

Architectural Panels That Transform Spaces

Few applications showcase the potential of metal laser cutting more dramatically than architectural panels. According to KF Laser's fabrication guide, custom laser cut metal panels have gained tremendous popularity in architecture, interior design, and industrial applications due to their precision, versatility, and aesthetic appeal.

Exterior cladding and facades represent one of the most visible applications. Panel laser cut designs on building exteriors create dynamic visual effects as natural light passes through intricate openings, casting shadows that shift throughout the day. This interplay between solid and void transforms ordinary structures into memorable architectural statements.

Privacy screens offer functionality alongside beauty. As StructureWorks notes, decorative screen panels have emerged as a leading solution for creating private yet inviting outdoor spaces—from rooftop terraces to outdoor dining areas and corporate courtyards. The minimum recommended height of 3'6" serves as a baseline for effective privacy screening while maintaining an open feel.

What makes architectural panels particularly compelling? They solve multiple challenges simultaneously:

- Light filtration: Lasercut patterns control how much natural light enters a space without creating complete darkness

- Ventilation: Unlike solid barriers, perforated panels allow airflow while still providing visual separation

- Shade and heat reduction: Strategic placement reduces solar heat gain on building exteriors

- Visual interest: Transforms blank walls or facades into focal points that enhance property value

Current architectural trends favor clean lines and minimalist patterns, according to industry analysis. This approach complements contemporary commercial architecture while providing timeless appeal for long-term installations.

From Decorative Art to Functional Components

Beyond architecture, laser cutter projects span an impressive range—from purely decorative pieces to precision-engineered functional parts. Understanding these categories helps you identify which approach best fits your needs.

Design Style Categories:

- Geometric patterns: Clean, mathematical designs featuring repeating shapes, tessellations, and precise symmetry. According to TBK Metal's design guide, geometric patterns are best utilized in contemporary spaces because of their neat appearance—they match well with minimalism and industrial interior design

- Organic and nature-inspired motifs: Flowing curves, botanical elements, and forms inspired by natural phenomena. These designs introduce tranquility and warmth to both interiors and exteriors through smooth contours and leaf or floral integration

- Abstract compositions: Artistic patterns that prioritize visual impact over representational imagery—ideal where aesthetic appeal is the primary concern

- Text and typography: Custom signage, logos, and lettering that combines branding with dimensional metal work. Laser cutting ensures crisp, professional text regardless of font complexity

- Functional mechanical designs: Precision components, brackets, enclosures, and parts where dimensional accuracy matters more than decorative appeal

Application examples across industries:

The versatility of metal laser cutting means virtually every sector benefits from this technology:

- Wall art and interior decoration: Custom laser cut metal panels create unique focal points that transform any space with contemporary charm

- Signage and wayfinding: Dimensional metal signs offer durability and sophistication that printed alternatives cannot match

- Garden art and landscape features: Weather-resistant metals like Corten steel or powder-coated aluminum create outdoor sculptures, screens, and decorative gates

- Furniture components: Table bases, chair backs, and shelving systems incorporate laser-cut elements for personalized touches

- Industrial parts: Machine covers, grilles, vents, and protective guards combine functionality with controlled airflow

How design complexity affects production costs:

Here's what many designers overlook: intricate patterns don't just look different—they cost different. As TBK Metal explains, simple patterns without many openings are comparatively cheaper to manufacture because they require less cutting time and material waste. Intricate designs with excessive cutting points and large areas to cut add significant cost.

Timeline impacts follow similar logic. A geometric grid pattern with regular, repeated elements cuts faster than an organic design with thousands of unique curves. For production-scale projects, this difference can mean days of additional machine time.

Scaling designs across panel sizes:

Planning to use the same pattern across multiple panel dimensions? Consider these factors:

- Pattern density: A design that looks balanced on a 600mm panel may appear sparse or overwhelming when scaled to 1200mm without adjustment

- Minimum feature preservation: Scaling down compresses all elements—verify that web widths and hole diameters still meet technical requirements at smaller sizes

- Visual weight: Large installations may need bolder line weights and wider openings to maintain visual impact from viewing distances

- Modular considerations: For multi-panel installations, decide whether patterns should align seamlessly across panels or work as standalone units

Whether you're pursuing hobbyist laser cutter projects or specifying professional-grade architectural installations, the same principles apply. Match your design category to your functional requirements, understand how complexity influences cost, and verify that your patterns meet technical constraints at your intended scale. With these considerations addressed, the next decision involves protecting and enhancing your finished pieces through appropriate surface treatments.

Surface Finishes That Protect and Enhance Your Designs

Your laser-cut metal piece looks stunning fresh off the machine—clean edges, precise patterns, exactly what you envisioned. But here's the reality check: without proper finishing, that beautiful stainless steel panel will show fingerprints within hours, and that mild steel garden screen will start rusting within weeks. The finish you choose determines whether your project maintains its beauty for months or decades.

Surface treatments do far more than add color. According to SendCutSend's finishing guide, metal finishes can increase abrasion resistance, change surface hardness, prevent corrosion, inhibit conductivity, and much more. Understanding when to use each treatment—and how surface preparation affects final quality—separates professional results from amateur attempts.

Protective Finishes for Lasting Beauty

Each finishing method offers distinct advantages depending on your material, environment, and aesthetic goals. Let's examine the most common options for laser-cut metal projects.

Powder Coating

When you need both color and durability, powder coating delivers. Unlike traditional paint applied wet, powder coating starts as a dry powder applied electrostatically, then cured in an oven. According to industry data, powder coating can last up to 10x longer than paint, and the leftover powder from application can be recycled and reused—making it more environmentally friendly with none of the VOCs that paint contains.

Powder coating works exceptionally well on aluminum, steel, and stainless steel—essentially any material that can hold an electrostatic charge. The cured finish resists chipping, scratching, and fading far better than painted surfaces, making it ideal for high-traffic installations or outdoor applications.

Anodizing

For aluminum projects, anodizing offers an elegant solution. This process places aluminum in a charged liquid bath (typically sulfuric acid), creating a thickened oxide layer that's integral to the metal itself rather than a coating sitting on top. The result? A finish that's resistant to corrosion, heat, and electricity—making it ideal for outdoor elements or applications exposed to electrical components.

Beyond protection, anodizing enables vibrant color options while maintaining the metallic quality that laser engraving aluminum showcases so beautifully. When you engrave plaque designs or create detailed surface patterns before anodizing, the finish enhances rather than obscures those details.

Hot-Dip Galvanizing

Steel destined for harsh outdoor environments benefits from galvanizing—a process that bonds zinc to the metal surface. This zinc layer actively protects steel even if scratched, making it exceptional for structural applications, garden installations, and industrial components where maintenance access is limited.

Clear Coats and Natural Finishes

Sometimes you want the metal to speak for itself. Clear coats preserve the natural appearance of copper, brass, or brushed stainless steel while providing protection against oxidation and fingerprints. For projects where laser etching metal creates decorative surface patterns, clear finishes showcase that work without color interference.

Patina and Artistic Finishes

Not all finishes aim for perfection. Controlled patina treatments on copper and brass create aged, artistic effects impossible to achieve with uniform coatings. Similarly, allowing Corten steel to develop its protective rust-like surface produces a distinctive weathered appearance that actually prevents further corrosion.

Matching Surface Treatments to Your Environment

The right finish depends heavily on where your piece will live. Indoor installations in climate-controlled spaces face minimal stress, while coastal outdoor applications demand maximum corrosion resistance.

| Finish Type | Best Applications | Durability Rating | Color Options | Maintenance Requirements |

|---|---|---|---|---|

| Powder Coating | Indoor/outdoor panels, signage, furniture, architectural elements | Excellent (10+ years outdoor) | Virtually unlimited—matte, gloss, metallic, textured | Low—occasional cleaning with mild soap |

| Anodizing | Aluminum panels, electronics enclosures, marine applications | Excellent (integral to metal) | Clear, black, bronze, red, blue, gold, and more | Very low—highly scratch-resistant |

| Hot-Dip Galvanizing | Outdoor steel structures, garden art, industrial components | Excellent (25-50+ years) | Silver-gray only (can be painted over) | Minimal—self-healing zinc layer |

| Clear Coat/Lacquer | Decorative copper/brass, indoor stainless displays | Moderate (2-5 years depending on exposure) | Transparent—preserves natural metal appearance | Moderate—may need reapplication |

| Patina/Natural Weathering | Artistic installations, Corten features, copper accents | Excellent (protective layer develops naturally) | Browns, greens, blues depending on metal and environment | None—designed to evolve over time |

| Zinc/Nickel Plating | Functional parts, hardware, electrical components | Good to excellent (varies by thickness) | Silver, yellow zinc, black zinc, nickel tones | Low—resists corrosion effectively |

How surface preparation affects final quality:

Here's what many overlook: the finish is only as good as the preparation beneath it. According to finishing experts, coatings often benefit from an abrasive process beforehand to increase adhesion. For painted or powder-coated parts, brushing with abrasive material and cleaning with acetone or alcohol creates the rough surface texture that helps finishes bond properly.

Laser-cut edges typically emerge clean and relatively smooth, but the surrounding surface may carry oils, oxidation, or mill scale that interferes with finishing. Professional fabricators include deburring or tumbling processes that prepare parts for optimal finish adhesion while removing any sharp edges or surface imperfections.

Impact on design visibility and edge definition:

Your finish choice directly affects how your intricate patterns read visually. Consider these factors:

- Thick coatings (like heavy powder coat) can slightly soften fine edge details—factor this into designs with very thin features

- Glossy finishes create reflections that can obscure pattern details in certain lighting conditions

- Matte or textured finishes reduce glare and make patterns more readable from various angles

- Dark colors tend to show laser-cut details more dramatically through shadow contrast

- Metallic finishes highlight the dimensional quality of cut edges

Specifying finishes when ordering custom fabrication:

When communicating with your metal engraver or fabrication partner, provide clear specifications:

- Exact finish type and color (include manufacturer color codes when possible)

- Gloss level preference (matte, satin, semi-gloss, high-gloss)

- Whether both sides require finishing or just the visible face

- Environmental conditions the piece will face (indoor, outdoor, coastal, industrial)

- Any areas that should remain unfinished (for welding, grounding, or other requirements)

Whether you're pursuing laser engraving stainless steel for a corporate lobby installation or creating powder-coated garden screens, the right finish transforms good fabrication into lasting beauty. With surface treatment decisions made, the final consideration involves choosing between ready-made templates and fully custom fabrication for your specific project needs.

Choosing Between Templates and Custom Fabrication

You've explored design possibilities, understand material options, and know exactly which finish will protect your piece for years to come. But here's the decision that often determines whether your project stays on budget and timeline: should you start with a ready-made template, customize an existing design, or invest in fully custom fabrication?

This choice isn't as straightforward as it might seem. Each approach carries distinct trade-offs in cost, uniqueness, and production complexity. Let's break down the decision-making framework that helps you match your project requirements to the right fabrication path.

When Templates Work and When Custom Wins

Ready-made templates and fully custom designs occupy opposite ends of a spectrum—with template customization sitting somewhere in between. Understanding when each approach makes sense prevents both overspending on unnecessary custom work and settling for generic results that don't quite fit your vision.

Ready-made templates offer the fastest, most economical path to finished custom laser cut metal panels. These pre-designed patterns have already been optimized for laser cutting, meaning file preparation, kerf compensation, and minimum feature sizes are handled. You select a pattern, specify your material and dimensions, and production begins almost immediately.

Templates work best when:

- Your timeline is tight and you need quick turnaround

- Budget constraints limit design investment

- The available patterns align closely with your aesthetic goals

- Technical performance matters more than unique appearance

- You're ordering single pieces or small quantities

Template customization bridges the gap between speed and uniqueness. Starting with an existing pattern as your foundation, modifications might include scaling, adding custom text, adjusting density, or combining elements from multiple templates. This approach captures some custom character while avoiding the full cost of original design development.

Fully custom fabrication delivers exactly what you envision—but requires greater investment in design time and typically commands premium pricing. According to SendCutSend's cost analysis, the more complex your design, the longer it takes to cut and machine, which increases costs. A thinner, more intricate part can cost significantly more due to its complex geometry compared to simpler designs.

Custom wins when:

- Brand identity or signature style requires original patterns

- Technical specifications demand precise engineering

- Large-scale installations justify design investment across many panels

- Existing templates simply don't match your creative vision

- The project involves unique functional requirements beyond aesthetics

Evaluating Your Project Requirements

Before committing to any fabrication path, honestly assess these key decision criteria. Your answers will point clearly toward the right approach for your specific situation.

Decision Criteria Framework:

- Budget constraints: Custom designs require upfront investment in design development plus potentially higher per-unit production costs. However, according to industry pricing data, quantity dramatically affects per-piece costs—a small part costing $29 for one unit drops to just $3 per part when ordering ten, representing up to 86% discounts for bulk orders

- Uniqueness requirements: How important is it that your installation looks unlike anything else? Commercial branding often demands originality, while residential projects may prioritize value

- Technical complexity: Functional components requiring precise tolerances, specific mounting provisions, or integration with other systems typically need custom engineering

- Volume needs: Single pieces rarely justify custom design costs, but installations requiring dozens of custom laser cut panels spread design investment across many units

- Timeline pressures: Templates ship fastest; custom designs require design development, approval cycles, and potentially longer production queues

Evaluating fabrication partners:

Whether you choose templates or custom work, your fabrication partner's capabilities directly impact final quality. According to Metal Works of High Point's selection guide, several factors warrant careful evaluation:

- Experience and track record: Look for providers with proven history on similar projects—newer companies may lack experience with your specific requirements

- Equipment investment: A provider's cnc laser cutter equipment determines efficiency and quality. Companies using state-of-the-art technology with current software deliver more precise, consistent results

- Certifications: Quality certifications like ISO 9001:2015 indicate commitment to consistent standards. For automotive or aerospace applications, look for industry-specific certifications

- Finishing capabilities: Choosing a fabricator that handles your project from cutting through finishing saves time, reduces shipping costs, and ensures consistency

- Customer service: Responsive communication throughout production prevents surprises. Ask prospective partners how they handle issues and whether pricing and timelines remain transparent

Turnaround time expectations:

Timeline varies dramatically based on your chosen path. According to Approved Sheet Metal's expedited services, selecting in-stock materials enables fabrication in as few as 2-5 days for prototype quantities. Complex fabrication orders consistently deliver at the low end of quoted expedited timelines when working with efficiency-focused partners.

For hobbyists exploring laser cutting and engraving machine options like the xTool laser cutter, the calculus shifts—owning equipment enables iterative prototyping and small-batch production without per-order fabrication costs. However, industrial-quality metal cutting typically exceeds hobbyist machine capabilities, making professional fabrication services essential for most serious projects.

When precision demands specialized manufacturing:

Some projects require capabilities beyond standard laser cutting services. For readers developing precision metal components—particularly for automotive, industrial automation, or high-volume production applications—manufacturers specializing in custom metal stamping and precision assemblies bridge the gap between design vision and production reality.

These specialized fabricators offer comprehensive Design for Manufacturing (DFM) support that optimizes your designs for manufacturability before production begins. Rather than discovering issues during fabrication, DFM analysis identifies potential problems during the design phase—saving both time and cost while ensuring parts meet functional requirements.

For automotive and industrial applications requiring IATF 16949-certified quality standards, rapid prototyping capabilities, or production-scale manufacturing with automated quality control, Shaoyi Metal Technology offers 5-day rapid prototyping and 12-hour quote turnaround specifically designed for precision metal engraving machine work and stamped components. This level of specialization becomes essential when your project demands consistent quality across thousands of units or must meet stringent industry certification requirements.

The right fabrication path isn't about choosing the cheapest option—it's about matching your investment to your project's actual requirements for uniqueness, precision, and timeline.

With your fabrication approach selected and partner evaluation criteria in hand, you're positioned to transform your metal laser cutting design from concept into reality. The journey from first sketch to flawless finish requires understanding each decision point—and you now have the knowledge to navigate every step with confidence.

Bringing Your Metal Laser Cutting Vision to Life

You've journeyed through the complete landscape of metal laser cutting designs—from understanding laser technologies and material properties to mastering file preparation and selecting protective finishes. Now comes the exciting part: putting that knowledge into action. Whether you're designing your first decorative panel or scaling up to production-volume components, the path forward becomes clear when you approach each project systematically.

The difference between successful metal laser cutting projects and frustrating failures rarely comes down to creative talent alone. It's the technical foundation—understanding kerf compensation, respecting minimum feature sizes, choosing appropriate materials for your environment—that transforms ambitious concepts into flawless finished pieces.

Your Path from Concept to Finished Metal

Every successful project follows a predictable arc. According to Pinnacle Precision's prototyping workflow, moving from concept to reality requires early collaboration, proper material selection, precision fabrication, appropriate finishing, and rigorous quality inspection. This isn't just theory—it's the proven sequence that professional fabricators use daily.

The most critical insight for successful metal laser cutting projects: technical constraints aren't limitations—they're the framework that makes creative ambition achievable. Understanding material properties, design rules, and finish options before you begin prevents costly revisions and ensures your vision translates perfectly from screen to finished metal.

Think about your project holistically before diving into design software. What environment will your piece live in? What level of detail does your concept actually require? Which finish will protect your investment while enhancing visual impact? Answering these questions upfront saves significant time and expense compared to discovering problems during fabrication.

Taking the First Step with Confidence

Ready to begin? Here's your prioritized action checklist—the essential steps that set every metal laser cutting project up for success:

- Define your application requirements first. Indoor or outdoor installation? Decorative or functional? Single piece or production run? These answers guide every subsequent decision.

- Select your material based on environment and aesthetics. Remember: stainless steel for corrosion resistance, aluminum for lightweight applications, mild steel for economy, copper and brass for decorative warmth.

- Verify your design meets technical constraints. Check minimum hole diameters (at least equal to material thickness), web widths between cuts, and edge spacing before finalizing files.

- Prepare production-ready vector files. Convert text to outlines, eliminate overlapping paths, organize layers by operation type, and export in DXF format at 1:1 scale.

- Specify your finish requirements clearly. Include exact coating type, color codes, gloss level, and which surfaces require treatment.

- Choose a fabrication partner whose capabilities match your needs. Evaluate equipment quality, certifications, finishing options, and turnaround times before committing.

- Request test cuts on scrap material for complex or high-volume projects. A small investment in prototyping prevents expensive mistakes at scale.

For designers working with laser engraver software or dedicated laser cutter and engraver systems, the principles remain identical—only the production method changes. Whether you're cutting files on personal equipment or partnering with professional fabricators, the same technical understanding determines success.

When precision demands professional partnership:

Some projects exceed what standard fabrication services can deliver. Complex automotive components, high-volume industrial parts, and applications requiring stringent quality certifications need specialized manufacturing expertise. For these situations, partnering with fabricators offering comprehensive Design for Manufacturing (DFM) support ensures your designs translate successfully from concept to production reality.

If your project involves precision metal components, rapid prototyping needs, or production-scale manufacturing with automotive-grade quality requirements, Shaoyi Metal Technology provides IATF 16949-certified fabrication with 5-day rapid prototyping and 12-hour quote turnaround. This level of specialized support becomes essential when consistent quality across thousands of units matters—or when your application demands industry certification standards.

Balancing ambition with understanding:

Here's the encouraging reality: metal laser cutting technology makes intricate, professional-quality work accessible in ways that weren't possible even a decade ago. The metal laser engraver and cutting systems available today—from hobbyist-level machines to industrial production equipment—enable creative possibilities that would have seemed impossible to previous generations of metalworkers.

But accessibility doesn't mean simplicity. The best laser engraver in the world can't compensate for designs that ignore material properties or technical constraints. Your understanding of kerf, minimum features, material selection, and finish options transforms creative ambition into achievable reality.

Start with simpler projects if you're new to the process. A straightforward geometric panel teaches the fundamentals without overwhelming complexity. As your confidence grows, tackle increasingly intricate designs—knowing that each project builds the expertise for the next.

The journey from first sketch to flawless finish is now yours to take. Armed with technical knowledge and a clear action framework, you're ready to transform flat metal sheets into precision art, functional components, and architectural statements that endure. Your next metal laser cutting design awaits—make it exceptional.

Frequently Asked Questions About Metal Laser Cutting Designs

1. Where can I find free laser cutting designs?

Several reputable websites offer free laser cut files including Atomm, 3axis.co, Vecteezy, Ponoko, Design Bundles, and Thingiverse. However, when using free templates for metal fabrication, always verify that designs meet technical constraints like minimum hole diameters, web widths, and kerf compensation specific to your chosen material thickness. Free files optimized for wood or acrylic may require modifications for metal cutting.

2. How thick of steel can a laser cut?

Laser cutting capacity depends on machine power. A 1000W fiber laser typically cuts up to 5mm stainless steel, while 2000W systems handle 8-10mm with ease. High-power 3000W+ lasers can process 12-20mm or more depending on quality settings. For ultra-thick carbon steel demanding superior edge quality, CO2 lasers may still be preferred. Material type also matters—reflective metals like aluminum require pulsed cutting mode for efficient processing.

3. What metals work best for outdoor laser-cut installations?

For outdoor applications, corrosion-resistant metals are essential. Aluminum offers natural oxide protection and lightweight durability. Stainless steel 316 grade provides superior resistance in coastal environments. Galvanized steel uses zinc coating for robust protection at cost-effective pricing. Corten weathering steel develops a protective rust-like patina that prevents further corrosion while creating distinctive aesthetic appeal. Always pair outdoor metals with appropriate finishes like powder coating or galvanizing.

4. What file format do I need for metal laser cutting?

DXF (Drawing Interchange Format) is the industry standard for laser cutting files. Unlike raster images like JPEGs, DXF files contain vector paths that laser cutters follow precisely. Your design software should export at 1:1 scale with all text converted to outlines, no overlapping lines, and layers organized by operation type. Many fabricators also accept AI or SVG formats, but DXF R14 or 2000 versions offer maximum compatibility across equipment.

5. How do I choose between template designs and custom fabrication?

Templates work best for tight timelines, budget constraints, or when available patterns match your aesthetic goals. Custom fabrication delivers unique designs but requires greater investment. For IATF 16949-certified automotive components or precision industrial parts, specialized manufacturers like Shaoyi Metal Technology offer comprehensive DFM support, 5-day rapid prototyping, and 12-hour quote turnaround to optimize designs for manufacturability while meeting stringent quality standards.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —