Làser per tallar metall: enfrontament entre fibra, CO2 i diode

Entendre la tecnologia làser per al tall de metall

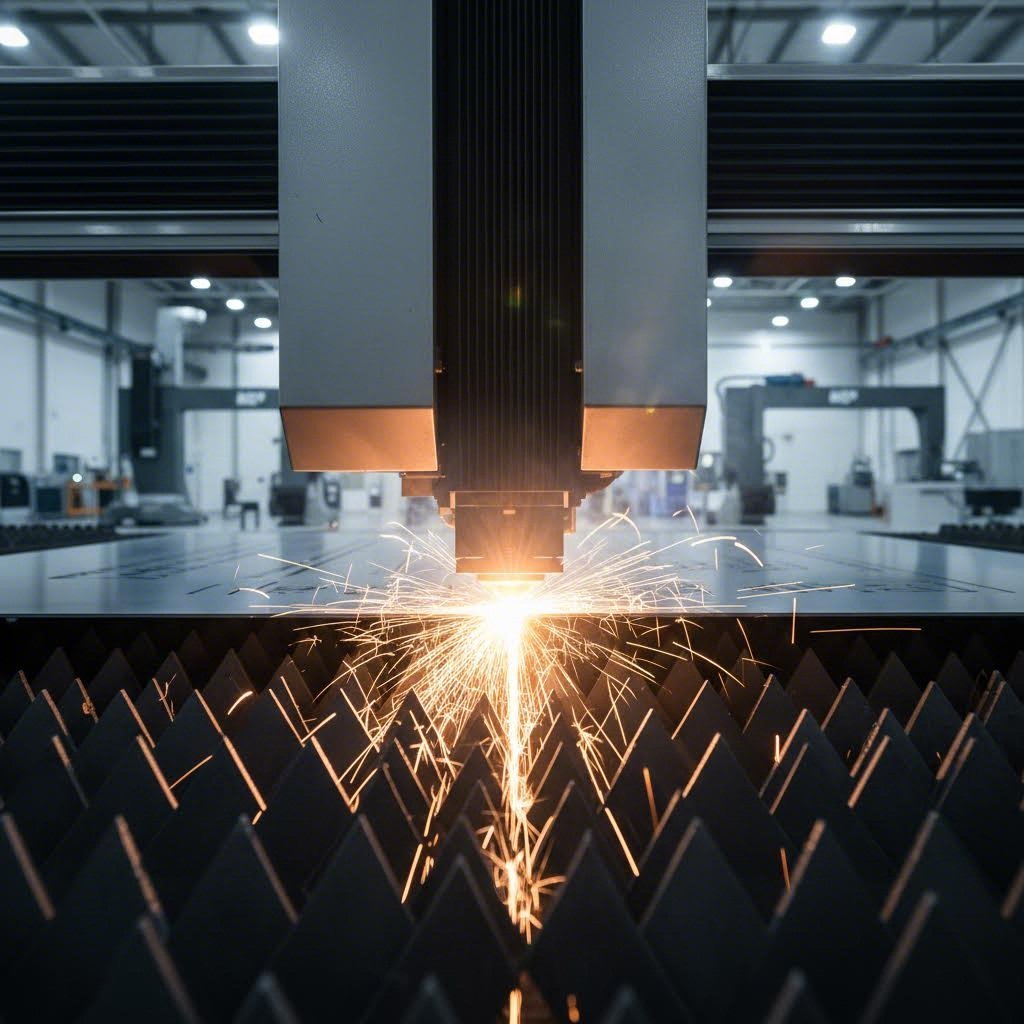

Imagina't tallant l'acer com si fos mantega. Això no és ciència ficció: és la realitat quotidiana de la fabricació metàl·lica moderna. Un làser per tallar metall ha transformat fonamentalment la manera en què les indústries, des de l'automobilística fins a l'aeroespacial, donen forma a materials bruts per crear components de precisió. Allò que abans requería hores de serra mecànica i un extens procés posterior ara es fa en minuts, amb vores més netes i gairebé cap desperdici de material.

Però com pot la llum concentrada tallar un material tan dur com l'acer o l'alumini? Analitzem aquesta tecnologia extraordinària i preparem el terreny per entendre quin sistema làser pot ser el més adequat per a les teves necessitats de treball del metall.

Com la llum focalitzada transforma la fabricació metàl·lica

Al seu nucli, utilitzar un làser que talla metall implica un procés sorprenentment elegant. Un raig altament concentrat de llum coherent subministra una energia intensa a un punt precís de la superfície del metall. Aquesta energia concentrada escalfa ràpidament el material més enllà del seu punt de fusió o vaporització, separant-lo efectivament al llarg d'un camí predeterminat.

El terme «laser» revela per si sol la física subjacent: Amplificació de la llum mitjançant l'emissió estimulada de radiació . Quan es desglossa això, s'està observant un procés que pren llum ordinària i l'amplifica fins a convertir-la en alguna cosa extraordinàriament potent. El resultat? Un raig capaç d'assolir densitats de potència superiors a 1 MW/cm², suficient per tallar materials que suposarien un repte per a qualsevol eina mecànica.

Què fa que un tallador làser de metall sigui tan eficaç específicament per al tall de metalls? Tres coses succeeixen en ràpida successió:

- Absorció d'energia: La superfície del metall absorbeix l'energia fotònica del làser en el punt focal

- Transformació de fase: Aquesta energia absorbida es converteix en calor, augmentant la temperatura fins a superar els llindars de fusió o vaporització

- Expulsió de material: El material fos o vaporitzat és expulsat de la zona de tall, sovint ajudat per un gas pressuritzat

Aquest procés de separació tèrmica es produeix amb una velocitat i precisió remarcables , cosa que el fa ideal per a tot, des de components electrònics complexos fins a peces estructurals pesades.

La ciència darrere del tall precís de metalls

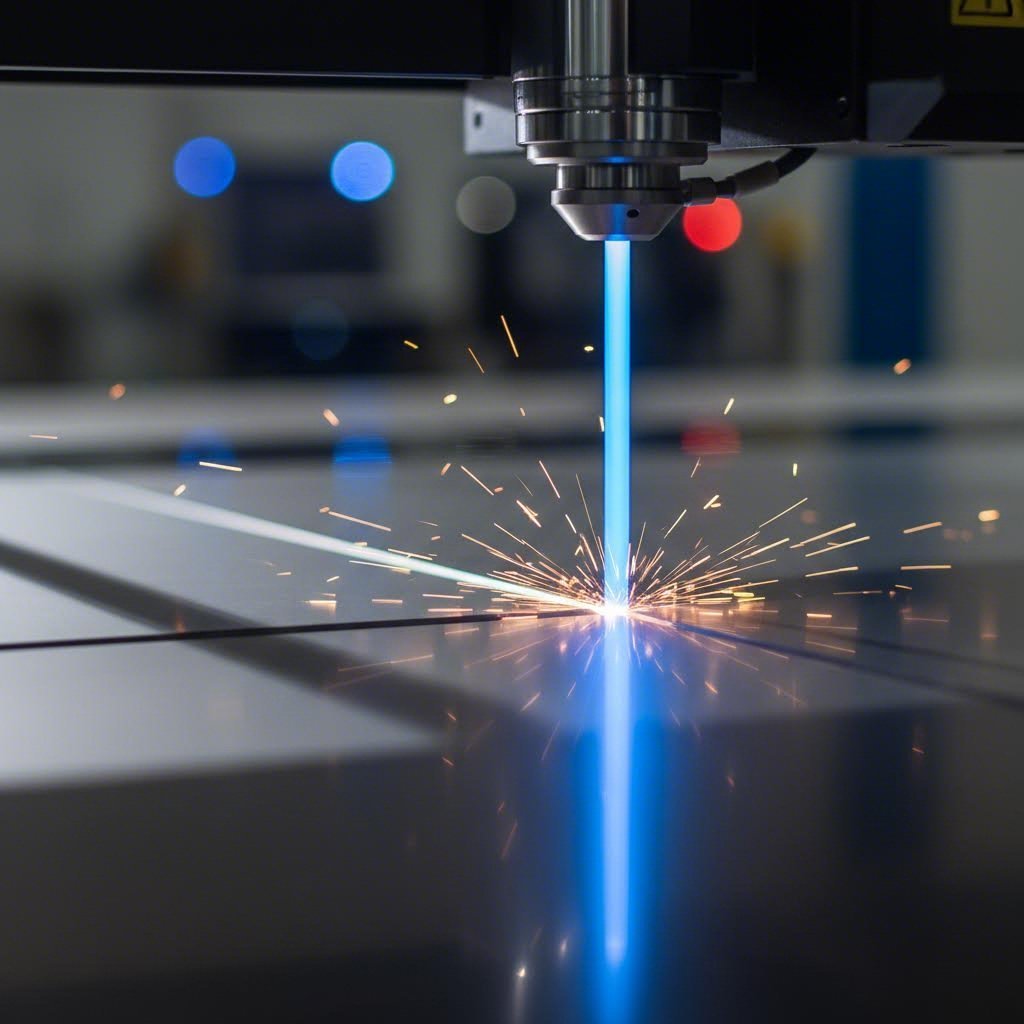

Què diferencia un raig làser coherent de la llum ordinària? Penseu-hi d’aquesta manera: la llum normal es dispersa en totes direccions com les ondulacions provocades per diverses pedres llençades a un estany. La llum làser coherent, en canvi, es mou de forma perfectament sincronitzada — totes les ones alineades, desplaçant-se juntes i mantenint el focus al llarg de la distància.

Aquesta coherència és el que permet que els sistemes làser concentrin una energia enorme en punts tan petits com 0,1-0,3 mm de diàmetre. L'objectiu de focalització d'un cap de tall modern pren el feix amplificat i el convergeix en aquest punt extremadament fi, creant la intensitat necessària per transformar instantàniament el metall sòlid en líquid o vapor.

Els sistemes moderns de tall làser poden assolir una precisió de posicionament tan fina com 0,008 mm —aproximadament un desè de l'amplada d'un cabell humà—, cosa que permet toleràncies que els mètodes de tall mecànics simplement no poden igualar.

La longitud d'ona del làser també té un paper clau en l'eficàcia del tall de metalls. Diferents longituds d'ona interactuen de manera diferent amb els materials. Com descobrirà en les seccions següents, els làsers de fibra que operen a aproximadament 1 micròmetre absorbeixen molt millor en els metalls que les longituds d'ona més llargues produïdes pels sistemes CO2. Aquest principi fonamental de la física motiva gran part del debat entre làsers de fibra i CO2 en el mercat actual.

Al llarg d'aquesta guia, passareu d'aquests conceptes fonamentals a marcs pràctics de presa de decisions. Compararem cara a cara les tecnologies de fibra, CO2 i diode directe. Aprendreu com el tipus de material i el gruix determinen els requisits de potència, per què els gasos auxiliars afecten notablement la qualitat del tall, i com solucionar problemes habituals. Les consideracions sobre seguretat, els criteris de selecció d'equips i la integració en el flux de treball completaran la vostra formació.

Considereu aquest document com el vostre pla neutral respecte als proveïdors: tant si esteu explorant el vostre primer sistema làser com si esteu avaluant una actualització, trobareu la profunditat tècnica necessària per prendre decisions informades sense cap missatge comercial.

Fibra vs CO2 vs Làsers de Diode Directe Explicats

Ara que enteneu com la llum enfocada transforma el metall, la següent pregunta és evident: quin tipus de làser heu d'utilitzar realment? No tots els làsers són iguals, especialment en el tall de metalls amb làsers de fibra. Avui en dia, tres tecnologies diferents dominen el mercat: làsers de fibra, làsers de CO2 i làsers de diode directe, cadascun amb característiques úniques que els fan adequats per a aplicacions diferents.

Analitzem la ciència darrere de cada tecnologia i descobrim per què les talladores làser de fibra s'han convertit en l'opció preferida per a la fabricació de metalls .

Làsers de fibra i per què dominen el tall de metalls

Us heu preguntat mai què fa que una màquina de tall làser de fibra sigui tan eficaç tallant acer? El secret rau en els elements de terres rares, concretament en l'iterbi (Yb). Aquests elements es «dopen» al nucli de les fibres òptiques, creant un medi de guany que genera llum làser a aproximadament 1,06 micròmetres (1064 nanòmetres).

Aquest és el funcionament del procés:

- Bombeig de llum: Els làsers de semiconductor bombegen energia a la fibra òptica dopada amb Yb

- Excitació d'ions: La llum bombada excita els ions d'iterbi dins del nucli de la fibra

- Emissió de fotons: Els ions excitats es descarreguen i emeten fotons en l'infraroig proper

- Amplificació estimulada: Aquests fotons provoquen que més ions alliberin fotons idèntics, creant l'efecte làser

Per què és important això per al tall de metalls? Aquesta longitud d'ona de 1,06 micròmetres s'absorbeix notablement bé pels metalls. Segons investigacions de Laser Photonics , l'alumini absorbeix set vegades més radiació d'un làser de fibra que d'un làser de CO2. Aquesta absorció superior es tradueix directament en una major eficiència de tall.

Les avantatges no s'acaben aquí. Un làser de fibra CNC pot enfocar el seu feix en un punt aproximadament 10 vegades més petit que un làser CO2, creant una densitat de potència significativament més elevada al punt de tall. Això significa talls més ràpids, incisions més estretes i una precisió excepcional en materials prims.

Potser el més destacable és l'eficiència energètica. Un làser de fibra converteix fins a un 42 % de l'energia elèctrica d'entrada en llum làser, comparat amb només un 10-20 % en els sistemes CO2. En termes pràctics, els làsers de fibra consumeixen aproximadament un terç de l'energia dels làsers CO2 per a tasques de tall equivalents, una diferència que suma ràpidament en entorns de producció.

Comparativa entre tecnologies CO2 i de fibra

Aleshores, si els làsers de fibra són tan eficients en el tall de metalls, per què encara existeixen els làsers CO2? La resposta rau en la longitud d'ona i la compatibilitat amb els materials.

Els làsers de CO2 utilitzen gas diòxid de carboni (barrejat amb nitrogen, heli i altres gasos) com a medi emissor, produint llum d'infraroig llunyà a 10,6 micròmetres. Aquesta longitud d'ona més llarga interacciona amb els materials de manera molt diferent que les longituds d'ona del làser de fibra.

La física desavantatja el CO2 en el tall de metalls. Aquesta longitud d'ona de 10,6 micròmetres presenta una alta reflectivitat en superfícies metàl·liques: la llum es reflecteix en lloc d'ésser absorbida. Tot i que els metalls perden part de la seva reflectivitat quan s'escalfen, un làser de CO2 senzillament no pot igualar l'eficiència en el tall de metalls d'un tallador làser de fibra amb una potència equivalent.

Tanmateix, els làsers de CO2 brillen en àmbits on els làsers de fibra tenen dificultats. Els materials no metàl·lics com la fusta, l'acrílic, el vidre, la pell i les ceràmiques absorbeixen eficientment la longitud d'ona de 10,6 micròmetres. Per a tallers que treballen amb tipus diversos de materials, els sistemes de CO2 ofereixen una versatilitat més amplia, encara que no siguin adequats per operacions centrades en metall.

Una altra consideració és la transmissió del feix. Els feixos làser de CO2 no poden viatjar a través de cables de fibra òptica; necessiten sistemes rígids de miralls per guiar el feix des de la font fins al capçal de tall. Això limita la flexibilitat en el disseny de la màquina i fa impossible l'operació manual. Els làsers de fibra, en canvi, utilitzen cables de fibra òptica flexibles que permeten dissenys més compactes i fins i tot unitats portàtils manuals.

L'ascens dels làsers de diode directe

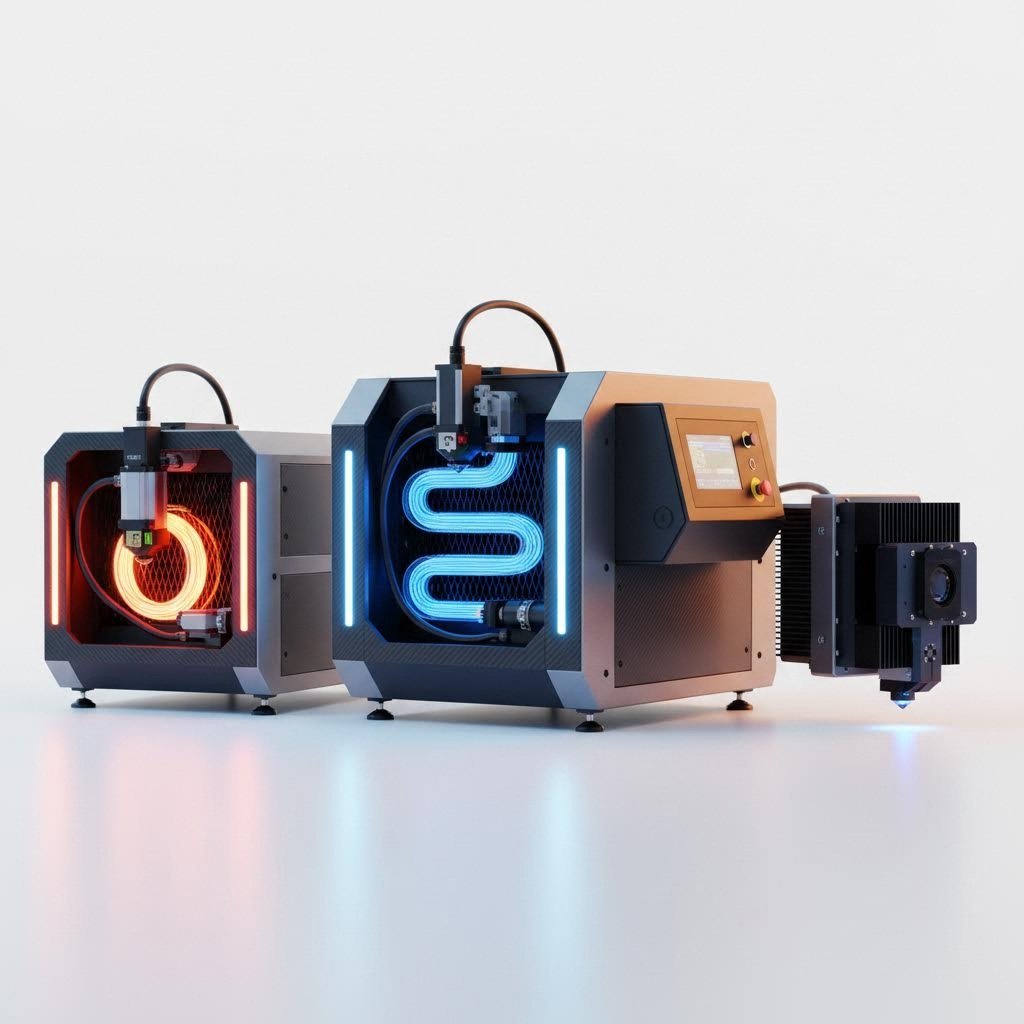

Els làsers de diode directe (DDL) representen la nova frontera en la tecnologia de tall metàl·lic. A diferència dels làsers de fibra, que utilitzen díodes només per bombar energia a una fibra dopada, els DDL eliminen completament el intermediari: els propis díodes làser generen el feix de tall.

Segons Westway Machinery , la tecnologia DDL funciona passant la llum de múltiples emissors a través d'una lent de transformació, i després concentrant-la mitjançant un element dispersiu. El resultat és un feix superposat amb un espectre estret de longituds d'ona.

Durant anys, els DDL van estar limitats a nivells de potència per sota de 2.000 watts, cosa que restringia les seves aplicacions industrials. Avui en dia, fabricants com Mazak Optonics ofereixen sistemes DDL amb més de 8.000 watts, prou potents per a tasques serioses de tall de metall. Aquests sistemes tenen una eficiència elèctrica encara més elevada que els làsers de fibra i uns costos de manteniment més baixos al llarg de la seva vida útil.

Tot i que la tecnologia DDL encara està madurant, promet qualitats de tall no assolibles amb els mètodes convencionals de tall làser, especialment en materials més gruixuts.

| Característica | Làser de Fibra | Làser CO2 | Làser Directe de Díode |

|---|---|---|---|

| Longitud d'ona | 1,06 µm (1064 nm) | 10,6 µm | 0,9-1,0 µm (varia) |

| Eficiència elèctrica | Fins a un 42% d'eficiència elèctrica | 10-20% d'eficiència elèctrica | Més alt que els làsers de fibra |

| Compatibilitat amb metalls | Excel·lent—alta absorció pels metalls | Dolenta—problemes d'altes reflectivitats | Excel·lent per a la majoria de metalls |

| Requisits de manteniment | Baixa—disseny d'estat sòlid, sense recàrregues de gas | Més alta—recàrregues de gas, alineació d'espells | La més baixa—camí òptic simplificat |

| Aplicacions típiques | Tall de metall, marcatge, soldadura | No metalls, plàstics, fusta, vidre | Tall de metall, processament ràpid de xapes |

| Transmissió del feix | Cable òptic de fibra flexible | Sistemes de miralls rígids | Cable òptic de fibra flexible |

| Rang de cost | Mitjana a alta | Baix a mitjà | Alt (la tecnologia encara està en desenvolupament) |

Quina tecnologia heu d'escollir? Per a operacions dedicades de tall de metall, la tecnologia de tall amb làser de fibra ofereix la millor combinació d'eficiència, precisió i cost operatiu. Els sistemes CO2 només són vàlids si el vostre flux de treball inclou un processament important de materials no metàl·lics. Els làsers de diode directe val la pena vigilar-los, i potser invertir-hi, si opereu a l'avantguarda i podeu assumir el cost inicial més elevat a canvi de guanys d'eficiència a llarg termini.

Comprendre aquestes diferències tecnològiques fonamentals prepara el terreny per a la següent pregunta crucial: quins nivells de potència i capacitats necessiteu per als vostres metalls i gruixos específics?

Tipus de metall i capacitats de gruix

Així que heu triat la tecnologia làser de fibra per a les vostres necessitats de tall de metall. Ara arriba la pregunta pràctica amb què es troba tot fabricant: quant potència necessiteu realment? La resposta depèn completament del que estigueu tallant i del seu gruix.

Penseu en la potència del làser com en la potència d’un vehicle. Un cotxe compacte funciona perfectament per a la conducció urbana, però no l’usaríeu per transportar equip pesat. De manera similar, un làser de 1,5 kW és excel·lent per treballar xapes fines, però té dificultats amb plaques gruixudes. Comprendre aquesta relació entre potència, material i gruix és el que diferencia les operacions eficients de les frustrants.

Analitzem detalladament les especificacions per a cada tipus principal de metall i explorem per què la preparació de la superfície importa més del que la majoria de la gent pensa.

Requisits de potència segons el tipus de metall i el gruix

Els diferents metalls es comporten de manera molt diferent sota un feix làser. Els seus punts de fusió, conductivitat tèrmica i reflectivitat influeixen en la quantitat de potència necessària. Segons La taula de gruixos de DW Laser , això és el que podeu esperar dels sistemes moderns de tall per làser de fibra:

Acer dolç continua sent el metall més fàcil de tallar amb làser. La seva reflectivitat relativament baixa i el seu comportament tèrmic previsible el fan tolerant per als operadors. Un tallador làser de metall amb una potència nominal de 1,5 kW pot tallar acer suau fins a uns 10 mm d'espessor, mentre que un sistema de 6 kW pot manejar material fins a 25 mm. Per a la majoria d'aplicacions d'eines de tall de xapa metàl·lica amb acer suau, els sistemes de potència mitjana ofereixen excel·lents resultats sense excedir el pressupost.

Acer inoxidable requereix una mica més d'atenció. El seu contingut en crom crea una capa d'òxid protectora que afecta l'absorció d'energia. Segons la guia de tall d'acer inoxidable de Xometry, el tall per làser ofereix avantatges clars per a l'acer inoxidable: redueix el risc d'enduriment per treball durant i introdueix zones afectades tèrmicament mínimes. Espereu poder tallar acer inoxidable fins a 20 mm d'espessor amb sistemes que varien entre 1,5 i 4 kW, depenent de la qualitat específica i de la qualitat desitjada del tall.

Alumini planteja reptes únics. Quan necessiteu tallar aluminio amb làser de manera eficient, esteu lluitant contra la seva alta conductivitat tèrmica i la seva superfície reflectant. El material allunya ràpidament la calor de la zona de tall, cosa que requereix més potència per mantenir les temperatures de tall. Una aplicació de màquina de tall amb làser d'alumini normalment necessita entre 1,5 i 3 kW per gruixos fins a 12 mm. El tall d'alumini amb làser també exigeix velocitats de tall més ràpides per evitar l'acumulació excessiva de calor que provoca problemes en la qualitat dels vores.

Coure i Brass —aquí és on les coses es posen interessants. Aquests metalls altament reflectants un cop es consideraven gairebé impossibles de tallar amb làser. La reflectivitat era tan elevada que el feix rebotava i podia arribar a danar la font làser. Els làsers de fibra moderns que operen a 1,06 micròmetres han solucionat en gran mesura aquest problema, ja que els metalls absorbeixen aquesta longitud d'ona més fàcilment que les longituds d'ona més llargues del CO2.

Encara que el coure i el llautó exigeixen respecte. Tallar llautó fins a 8 mm normalment requereix sistemes de 1,5 a 3 kW, mentre que el coure arriba al màxim al voltant dels 6 mm amb requisits d'energia similars. La clau és utilitzar tecnologia làser de fibra específicament dissenyada per manipular aquests materials reflectants—els sistemes antics poden no tenir les característiques de protecció necessàries.

Titani ocupa una categoria especial. Malgrat ser un dels metalls més resistents de la Terra, el titani en realitat es talla relativament bé amb làser. La seva baixa conductivitat tèrmica fa que la calor romangui concentrada al punt de tall en lloc de dissipar-se. El problema? El titani és altament reactiu a temperatures elevades i requereix un blindatge amb gas inert (típicament argó) per evitar l'oxidació i mantenir la integritat del material.

| Tipus de Metal | Gruix màxim (mm) | Interval d'energia recomanat (kW) | Consideracions Clau |

|---|---|---|---|

| Acer dolç | Fins a 25 | 1.5 – 6 | El més tolerant; qualitat de tall excel·lent |

| Acer inoxidable | Fins a 20 | 1,5 – 4 | Zona afectada tèrmicament mínima possible |

| Alumini | Fins a 12 | 1,5 – 3 | Alta reflectivitat; calen velocitats ràpides |

| Llató | Fins a 8 | 1,5 – 3 | Reflectant; requereix làser de fibra |

| Coure | Fins a 6 | 1,5 – 3 | El més reflexiu; cal potència més elevada |

| Titani | Fins a 10 | 1,5 – 3 | Requereix protecció amb gas inert |

Noteu el patró? Els materials més gruixuts sempre necessiten més potència. Però no és una relació lineal: duplicar el gruix normalment requereix més del doble de potència a causa de les pèrdues d'energia dins la ranura de tall. Per això una talladora de xapa classificada per 10 mm d'acer suau no podrà simplement tallar 20 mm a meitat de velocitat.

Preparació de la superfície per a una qualitat òptima de tall

Aquí hi ha alguna cosa que molts operadors aprenen a la mala: l'estat de la superfície afecta la qualitat del tall tant com els paràmetres de potència. Podríeu tenir la relació perfecta entre potència i gruix ajustada, però el material contaminat encara produirà resultats decepcionants.

Per què passa això? Els contaminants de la superfície metàl·lica interactuen amb el raig làser abans que arribi al material base. L'oli es vaporitza d'una manera imprevisible, la ferrugine crea una absorció desigual i les capes poden alliberar fums perillosos mentre interrompen el procés de tall.

Abans de tallar acer o qualsevol altre metall amb làser, avaluïeu i tracteu aquestes condicions superficials habituals:

- Contaminació per oli i greix: Elimineu els olis de tall, lubrificants i residus de manipulació amb solvents o desengreixants adequats. Fins i tot les empremtes digitals poden causar problemes locals en talls de precisió. Assegureu un temps de secatge suficient abans del processament.

- Ferrugine i oxidació superficial: La rovell lleugera a la superfície normalment es crema durant el tall, però crea una qualitat de vora inconsistent. La rovell pesada o l'escorxa han de ser eliminades mecànicament o tractades químicament. Tallar amb làser a través de rovell també consumeix més energia que tallar material net.

- Escòria laminada: Aquesta capa d'òxid de color negre-blavós present en l'acer laminat en calent afecta la absorció del làser de manera diferent al metall base. Per a aplicacions crítiques, cal eliminar l'escorxa abans del tall. Per a treballs no crítics, augmenteu lleugerament la potència per compensar.

- Pelicules i recobriments protectors: Les pel·lícules protectores de paper o plàstic normalment poden romandre durant el tall; de fet, sovint milloren la qualitat de la vora en prevenir l'adhesió d'esquitxades. Tanmateix, les superfícies pintades o amb recobriment en pols requereixen una avaluació cuidadosa. Alguns recobriments alliberen fums tòxics quan es vaporitzen.

- Humitat i condensació: L'aigua sobre superfícies metàl·liques provoca una vaporització explosiva durant el tall, generant projeccions i una mala qualitat del tall. Assegureu-vos que els materials s'hagin adaptat a la temperatura del taller abans del procés, especialment quan es moguin peces des d'embassaments freds.

El resultat final? Un material net talla millor. Invertir uns minuts en la preparació de la superfície sovint estalvia hores de treball de correcció o peces descartades. En entorns de producció, establir normes d'acceptació per al material entrant elimina suposicions i assegura resultats consistents en cada treball.

És clar que ni tan sols una preparació perfecta del material servirà si s'utilitza un gas auxiliar inadequat. La propera secció revela com la selecció del gas afecta de manera significativa tant la qualitat del tall com els costos operatius.

Com afecten els gasos auxiliars a la qualitat del tall

Heu seleccionat la tecnologia làser adequada i heu ajustat la potència al gruix del material. Ara aquí hi ha un factor que molts fabricants passen per alt, i que pot fer que els resultats siguin bons o dolents. El gas que circula a través del cap de tall no només serveix per expulsar les partícules residuals. Participa activament en el procés de tall de metall amb làser, condicionant fonamentalment la qualitat del tall, la velocitat de tall i els costos operatius.

Penseu en el gas auxiliar com el company silenciós en cada tall. Trieu-lo bé i obtindreu vores netes a màxima velocitat. Trieu-lo malament i passareu hores en processos posteriors o descartareu peces senceres.

Analitzem com l'oxigen, l' nitrogen i l'aire comprimit transformen cadascun l'experiència del tall de metall amb làser.

Tall amb oxigen per a velocitat i potència

Quan es talla l'acer al carboni o plaques estructurals gruixudes, l'oxigen proporciona quelcom extraordinari: en realitat ajuda el làser a fer la seva feina. Aquest és el fonament científic.

Quan el raig làser escalfa l'acer fins al seu punt d'inflamació (aproximadament 1.000 °C), l'oxigen que circula a través de la tovera desencadena una reacció exotèrmica. L'acer no només es fon, sinó que es combina. Segons La guia de gasos de tall de Bodor , aquesta reacció de combustió significa que l'oxigen realitza aproximadament el 60 per cent de la feina de tall, mentre que el làser proporciona el 40 per cent restant.

Què vol dir això pràcticament? Podeu tallar acer més gruixut amb menys potència làser. La reacció exotèrmica genera calor addicional directament a la zona de tall, augmentant la profunditat de penetració. Per als fabricants que treballen amb xapes gruixudes, això es tradueix en guanys significatius de capacitat sense haver d'actualitzar-se a sistemes més cars de gran potència.

Tanmateix, el tall amb oxigen comporta certs inconvenient. La mateixa reacció de combustió crea òxid de ferro als vostra vores tallades —visible com una superfície fosca o escamosa. Per a aplicacions estructurals en què les peces seran soldades, pintades o amagades de la vista, aquesta oxidació és totalment acceptable. Però per a aplicacions de tall làser de xapa metàl·lica que requereixen vores impecables o soldadura immediata sense neteja, l'oxigen esdevé problemàtic.

L'oxigen també requereix una gestió cuidadosa de la pressió. La guia completa de gasos d'Accurl assenyala que el tall làser d'acer sol utilitzar pressions d'oxigen entre 3-10 bar, sent necessàries pressions més altes (uns 10 bar) i cabals propers a 20-22 m³/h per a materials més gruixuts (40 mm+). La puresa del gas també és molt important: es recomana una puresa d'oxigen del 99,97 % o superior per a resultats consistents.

Nitrogen per a acabats de vora nets

Sembla que l'oxigen té inconvenients? Exactament per això el nitrogen domina les aplicacions de tall d'acer inoxidable i aluminis.

L' nitrogen és un gas inert—no reacciona químicament amb el metall que es talla. En lloc de combustió, el tall amb nitrogen depèn únicament de l'energia tèrmica del làser per fondre el material, i després utilitza un flux de gas a alta pressió per expulsar físicament el metall fos del talle. El resultat? Voresses brillants, sense òxid, que semblen gairebé polites.

Segons Guia de selecció de gasos de FINCM , l' nitrogen és l'opció preferida per a l'acer inoxidable, l'alumini i les peces visibles d'alta qualitat on importa l'estètica. No cal polit o trepatge secundari. Les peces poden passar directament a la pintura, soldadura o muntatge sense preparació de vores.

La contrapartida? L'ús de nitrogen requereix pressions i cabals significativament més elevats que l'oxigen. Espereu pressions de funcionament entre 15 i 30 bar (aproximadament 217-435 psi) i cabals que varien entre 50 i 150 metres cúbics per hora, segons el gruix del material. Això augmenta notablement el consum de gas i els costos operatius: tallar amb nitrogen pot costar uns 2,50 $ per cicle típic d'abastament, versus aproximadament 1 $ per hora amb oxigen en certs gruixos.

Els requisits de puresa són encara més estrictes pel nitrogen. En aplicacions on el color del tall és crític, com en components aeroespacials o mèdics, la puresa del nitrogen pot haver d’assolir el 99,99% o fins i tot el 99,999%. Encara que hi hagi petites baixades de puresa, es poden introduir contaminants que causin discoloració.

Malgrat els costos més alts, el nitrogen sovint resulta més econòmic en general per al tall làser de xapes metàl·liques quan es requereix un acabat de qualitat. L’eliminació de la mà d’obra posterior al procés sovint compensa l’augment dels costos del gas.

Aire comprimit: L'alternativa més econòmica

I si la vostra aplicació no exigeix vores perfectes, però encara necessiteu una qualitat raonable al cost mínim? L'aire comprimit entra en joc.

L'aire comprimit conté aproximadament un 78 % de nitrogen i un 21 % d'oxigen: essencialment, un compromís prèviament barrejat entre els dos gasos especials. Es genera in situ mitjançant compressors estàndard del taller, eliminant la compra de bombones, els requisits d'emmagatzematge i la logística de lliurament.

Per a materials fins a mitjans (fins a uns 6 mm aproximadament), l'aire comprimit ofereix resultats acceptables en alumini, acer galvanitzat i treballs generals de fabricació. El contingut d'oxigen provoca una oxidació parcial: veureu vores grisoses en lloc de l'acabat brillant que produeix el nitrogen, però per a aplicacions no crítiques, aquest intercanvi és totalment raonable.

Tanmateix, el tall amb aire comprimit requereix atenció a la qualitat de l'aire. La humitat, l'oli i les partícules en el flux d'aire comprimit poden contaminar l'òptica del làser, provocant danys a la lent o distorsió del feix. Són essencials sistemes adequats de secatge i filtratge de l'aire. També poden ser necessaris augmentadors de pressió per assolir el rang de 150-200 psi necessari per un tall eficaç.

| Gas d'assistència | Metalls compatibles | Qualitat del tall | Velocitat de tall | Cost d'operació | Millors aplicacions |

|---|---|---|---|---|---|

| Oxigen (O₂) | Acer al carboni, acer suau, acer estructural | Oxidat (fosc/amb escòria) | Ràpid en materials gruixuts | Baix (~1 $/hora típic) | Treballs estructurals, xapes gruixudes, peces per soldar |

| Nitrogen (N₂) | Acer inoxidable, aluminio, galvanitzat, peces d'alta qualitat | Brillant, sense òxid | Més lent en xapa gruixuda | Superior (~2,50 $/cicle típic) | Peces visibles, components de precisió, equips alimentaris/mèdics |

| Aire comprimit | Alumini, acer galvanitzat, materials fins | Moderat (vores grisoses possibles) | Bo per a stocks fins-mitjans | Més baix (només electricitat) | Fabricació general, projectes sensibles al cost, prototipatge |

Pressió i puresa: Les variables ocultes

Seleccionar el tipus de gas adequat és només la meitat de l'equació. La manera com es subministra aquest gas té una importància enorme.

La pressió del gas ha de coincidir amb el gruix i el tipus de material. Una pressió insuficient no aconsegueix eliminar el material fos del tall, provocant l'acumulació de borres a la cara inferior. Una pressió excessiva pot fer saltar irregularment la piscina de fusió, creant vores rugoses. En el tall amb nitrogen, les pressions poden necessitar ajustos que varien des de 15 bar per a xapes fines fins a 30 bar per a seccions més gruixudes.

La puresa influeix directament en la consistència. Una disminució de la puresa d'oxigen des de el 99,97% fins al 99,95% pot semblar negligible sobre el paper, però pot reduir notablement la velocitat de tall en metalls fins. Pel que fa al nitrogen, fins i tot una contaminació mínima d'oxigen provoca discoloració de les vores, cosa que contradiu la finalitat d'utilitzar un gas inert.

Finalment, mantingueu una pressió d'alimentació estable durant tot el procés de tall. Les fluctuacions provoquen una qualitat de tall inconsistent, visible en forma de variacions en l'acabat del tall al llarg d'un mateix recorregut. Per a produccions d'alta volumetria, invertir en generadors d'azot in situ o sistemes d'emmagatzematge d'alta capacitat elimina per complet la preocupació per la caiguda de pressió.

Amb la selecció adequada de gas i els paràmetres de subministrament ajustats, heu optimitzat una variable clau en el vostre procés de tall. Però com es compara el tall làser amb altres mètodes de separació de metalls? La propera secció posa la tecnologia làser cara a cara amb el plasma, el jet d'aigua i el tall mecànic per revelar en què excel·leix realment cada mètode.

Tall Làser vs Plasma, Jet d'Aigua i Mètodes Mecànics

Heu dominat els fonaments de la tecnologia làser, entès els requisits d'energia i optimitzat la selecció del gas auxiliar. Però aquí hi ha una pregunta que val la pena fer-se: és un làser l'eina adequada per a qualsevol treball? La resposta honesta és que no. Diferents tecnologies de tall excelen en diferents situacions, i les tallers de fabricació més intel·ligents saben exactament quan utilitzar cadascuna.

Posarem el tall làser en perspectiva comparant-lo objectivament amb el tall per plasma, el tall per jet d'aigua i els mètodes mecànics. Comprendre aquests intercanvis us ajuda a prendre decisions informades, tant si esteu desenvolupant capacitats internes com si esteu avaluant serveis externs.

Quan el tall per plasma té més sentit

Si esteu tallant xapes gruixudes d'acer i el pressupost importa, el tall per plasma mereix una consideració seriosa. Un tallador per plasma utilitza un raig accelerat de gas ionitzat que pot arribar a temperatures de fins a 45.000 °F (25.000 °C) per fondre metalls elèctricament conductors. Segons La guia completa de StarLab CNC , les taules CNC modernes de plasma destaquen en el tall de materials amb un gruix des de 0,018" fins a 2", amb alguns sistemes capaços de tallar làmines encara més gruixudes.

On brilla realment el plasma? En la velocitat sobre materials mitjans i gruixuts. Un sistema de plasma d'alta potència pot tallar acer suau de 1/2" a velocitats superiors a 100 polzades per minut, significativament més ràpid que el làser en gruixos equivalents. Aquest avantatge de velocitat es tradueix directament en volums de producció més elevats i una finalització més ràpida dels treballs.

El cost representa un altre argument convincent. Segons La comparativa de Wurth Machinery , una taula CNC de plasma completa costa al voltant de 90.000 $, comparat amb inversions substancialment més elevades per a sistemes làser comparables. Els costos operatius també són més baixos: el tall per plasma ofereix el cost per polzada de tall més baix entre els mètodes de tall tèrmic. Si esteu gestionant un taller de fabricació d'acer estructural o una operació de fabricació d'equips pesants, el millor tallador de plasma per a les vostres necessitats podria superar econòmicament el làser.

Tanmateix, el tall amb plasma té limitacions. Només funciona amb materials conductors d'electricitat: no pot tallar fusta, plàstics ni materials compostos. La qualitat del tall, tot i que ha millorat notablement amb els sistemes moderns d’alta definició, encara no iguala la precisió del làser en materials fins. Les zones afectades pel calor són més grans, i continuarà sent difícil aconseguir geometries complexes amb cantonades interiors ben marcades.

Trobareu opcions de talladors de plasma a la venda que van des d'unitats portàtils per a treballs al camp fins a grans instal·lacions de taules CNC de plasma per a entorns de producció. La tecnologia ha assolit una gran maduresa: els sistemes moderns rivalitzen amb la qualitat del làser en moltes aplicacions amb materials gruixuts, mantenint alhora velocitats de tall superiors.

Tall hidroabradiu: L'alternativa de tall fred

Què passa quan la calor en si mateixa és el problema? Aquí entra el tall amb jet d'aigua. Aquesta tecnologia utilitza un raig d'aigua a alta pressió —sovint barrejat amb partícules abrasives— per erosionar el material seguint un recorregut programat. Funcionant a pressions d'hasta 90.000 PSI, els sistemes de tall amb jet d'aigua poden tallar gairebé qualsevol material sense generar calor.

Aquesta característica de "tall fred" fa que el tall amb jet d'aigua sigui insubstituïble en aplicacions sensibles a la calor. Cap zona afectada per la calor. Cap endureixement del material. Cap deformació en peces primes o delicades. Per a components aerospacials, materials temperats, o qualsevol cosa on la distorsió tèrmica provocaria el rebuig, el tall amb jet d'aigua ofereix allò que els mètodes de tall tèrmic simplement no poden assolir.

La versatilitat del material és incomparable. Mentre que el làser i el plasma estan limitats a tipus específics de materials, el tall amb jet d'aigua pot tractar metalls, pedra, vidre, compostos, ceràmiques, cautxú i productes alimentaris. Segons projeccions sectorials citades per Wurth Machinery, el mercat del tall amb jet d'aigua creix ràpidament — s'estima que arribarà als 2.390 milions de dòlars el 2034 — impulsat en gran mesura per aquesta versatilitat.

Quins són els inconvenients? Velocitat i cost. Els sistemes de tall amb jet d'aigua funcionen a les velocitats més lentes entre les tecnologies de tall, normalment entre 5 i 20 polzades per minut segons el gruix i el tipus de material. La inversió inicial és elevada — uns 195.000 dòlars per a sistemes comparables a una configuració de plasma de 90.000 dòlars. Els costos continus inclouen el consum d'abrasiu, que augmenta significativament el cost per peu de tall.

Tall mecànic: l'eina clau per a altes volumetries

De vegades, la tecnologia més antiga continua sent la millor opció. Els mètodes de tall mecànic —cisallament, punxonat i estampació— dominen la producció d'alta volumetria de formes senzilles. Aquests processos utilitzen força física en lloc de remoció tèrmica o abrasiva per separar el material.

Per què triar el mètode mecànic en lloc del làser? Per la velocitat pura en peces repetitives. Una premsa punxonadora pot produir centenars de forats idèntics per minut. Una cisalladora talla línies rectes al llarg de tota l'amplada de la fulla en segons. Per a operacions que produeixen milers de suports idèntics, semiblancs o formes geomètriques simples, els mètodes mecànics ofereixen temps de cicle insuperables al cost més baix per peça.

Les limitacions es fan evidents quan la geometria es complica. El tall mecànic requereix eines dedicades per a cada forma —costoses de fabricar i limitades a aquell disseny específic. Les corbes, els buidats intrincats i les característiques properes entre si necessiten diverses operacions o simplement no són possibles. La capacitat d'espessor del material també està limitada per la tonelada disponible.

Avantatges de la precisió del tall làser

On destaca realment el tall làser? En la precisió i versatilitat sobre materials de gruix mitjà i fi amb geometries complexes.

Segons l'anàlisi de StarLab CNC, els làsers de fibra dominen el tall de materials fins, assolint velocitats excepcionals en xapes d'una gruix inferior a 1/4". El feix focalitzat produeix talls extremadament precisos amb zones afectades tèrmicament mínimes, ideal per a dissenys intrincats on la distorsió tèrmica provocaria problemes. S'aconsegueixen toleràncies habitualment en el rang de ±0,001" a ±0,005".

La capacitat per gestionar geometries complexes diferencia el tall làser dels mètodes plasmàtics i mecànics. Cantons interiors aguts, forats petits (fins al gruix del material), patrons intrincats i elements molt propers que suposarien un repte o serien inviables per altres mètodes són habituals pel tall làser. No cal canviar eines: només cal pujar un nou programa i començar a tallar.

La zona mínima afectada tèrmicament mereix émfasi. Tot i que tant el làser com el plasma són processos de tall tèrmic, el raig altament concentrat del làser concentra la calor en una àrea molt més petita. Les propietats del material romanen gairebé inalterades a només mil·límetres del vora del tall, fet crític per a aplicacions que impliquin soldadura, conformació o tractament tèrmic posterior.

Comparació directa de tecnologies

| Característica | Tall Llàser | Tall per Plasma | Tall per Jet d'Aigua | Tall Mecànic |

|---|---|---|---|---|

| Tolerància de precisió | ±0,001" a ±0,005" | ±0,015" a ±0,030" | ±0,003" a ±0,010" | ±0,005" a ±0,015" |

| Interval d'espessor del material | Fins a ~1" (acer); millor sota 1/4" | de 0,018" a 2"+ (només metalls conductors) | Fins a 12"+ (qualsevol material) | Varia segons la tonatge de la màquina |

| Zona afectada per la calor | Mínima (raig altament concentrat) | Moderada a gran | Cap (tall fred) | Cap (força mecànica) |

| Cost d'operació | Moderat (gas, electricitat, consumibles) | Baix (cost més ràpid per polzada) | Alt (consum d'abrasiu) | Baix per peça en volums alts |

| Aplicacions ideals | Peçaes de precisió, dissenys intrincats, xapes fines-mitjanes | Acer estructural, xapa gruixuda, tall alt en volum | Materials sensibles a la calor, gruix extret, no metàl·lics | Formes simples en alt volum, embutició, perforació |

L'enfocament híbrid: Per què limitar-te?

Això és el que han descobert tallers d'èxit: la millor tecnologia de tall depèn completament del treball concret. Moltes operacions mantenen diverses capacitats de tall precisament perquè cap mètode únic ho fa tot òptimament.

Un taller híbrid típic pot utilitzar làser per treballs de xapa de precisió i geometries complexes, un tallador CNC per plasma per acer estructural i xapes gruixudes, i punxonat mecànic per peces simples en alt volum. Alguns afegueixen capacitat de jet d’aigua específicament per materials sensibles a la calor o exòtics que altres mètodes no poden tractar.

Aquest enfocament multi-tecnològic maximitza la flexibilitat alhora que optimitza el cost per a cada aplicació. En lloc d’obligar cada treball a passar per un únic procés, el flux de treball es dirigeix al mètode que ofereix la millor combinació de qualitat, velocitat i economia per a aquella peça específica.

Fins i tot els tallers que no poden permetre’s múltiples sistemes interns s’beneficien de comprendre aquests intercanvis. Saber quan externalitzar plaques gruixudes a una operació de plasma o treballs sensibles a la calor a un servei de jet d’aigua—en lloc de lluitar amb resultats subòptims interns—sovint produeix millors resultats a un cost total més baix. Sigui que estigueu buscant un tallador de plasma o avaluant les capacitats del làser, ajustar la tecnologia a l’aplicació continua sent el principi fonamental.

Un cop aclarida la selecció de la tecnologia de tall, què passa quan les coses no surten bé? La propera secció aborda els reptes de solució de problemes que tot operador de làser acaba enfrontant-se eventualment: des de marques de cremades fins a talls incomplets, i ofereix solucions sistemàtiques per tornar a posar la producció en marxa.

Solució de problemes habituals en el tall amb làser

Encara que s'hagi triat l'equipament perfecte i s'hagin optimitzat els paràmetres, tot operador de làser acaba fent front a problemes de qualitat. Les peces surten de la màquina amb marques de cremades, escòria adherida als vores inferiors o talls que simplement no han penetrat completament. Us sona? Aquests problemes frustren tant els principiants com els més experimentats, però gairebé sempre es poden resoldre un cop se'n comprenen les causes arrel.

La bona notícia? La majoria de defectes en el tall làser es deuen a un nombre reduït de variables: potència, velocitat, focus i subministrament de gas. Ajusteu el paràmetre adequat i la qualitat tornarà. Repassarem els problemes més habituals que podreu trobar amb qualsevol màquina de tall làser per metalls i les solucions sistemàtiques que permeten reprendre la producció.

Eliminació de marques de cremació i danys tèrmics

Les marques de cremació apareixen com àrees fosques, descolorides o carbonitzades al llarg dels extrems tallats. Bàsicament són danys tèrmics, indicadors que s'ha acumulat massa calor al material abans que pogués dissipar-se. Segons La guia de resolució de problemes de Boss Laser , trobar l'equilibri adequat entre la potència del làser i la velocitat de tall és fonamental: "Penseu-hi com ajustar la calor d’un fogó: massa alta, i cremareu el material; massa baixa, i no gravarà correctament."

Quan observeu marques de cremació en els vostres projectes amb la màquina de tall làser per metalls, analitzeu sistemàticament aquestes causes habituals:

- Velocitat de tall massa lenta: Quan el làser roman massa temps en una àrea, la calor s'acumula més ràpidament del que es dissipa. Augmenteu la velocitat d'alimentació en increments del 5-10% fins que desapareguin les marques de cremada, alhora que es manté una penetració completa.

- Potència massa alta: Una potència excessiva aporta més energia de la necessària per tallar, i l'excés es converteix en calor no desitjada al material adjacent. Reduïu la potència progressivament: només cal la justa per tallar neta, ni més.

- Posició de focus incorrecta: Un feix desenfocat distribueix l'energia sobre una àrea més gran en comptes de concentrar-la al punt de tall. Això crea una zona afectada per la calor més amplia sense millorar la penetració. Verifiqueu que l'alçada de focus coincideixi amb les especificacions del gruix del material.

- Pressió del gas d'ajuda massa baixa: Un flux de gas insuficient no aconsegueix eliminar eficaçment el material fos del zone de tall. Aquest material es torna a dipositar i crema sobre superfícies adjacents. Comproveu els ajustos de pressió i l'estat de la tovera.

- Òptiques contaminades: Les lentilles o miralls bruts absorbeixen i dispersen l'energia del feix, reduint l'eficiència de tall mentre augmenta el escalfament perifèric. Netegeu regularment l'òptica segons les especificacions del fabricant.

Per a problemes persistents de danys tèrmics, considereu el material en si. Alguns metalls —especialment l'alumini i el llautó— condueixen la calor tan eficientment que les zones adjacents s'escalfen significativament durant el tall. Velocitats més altes i densitats de potència més baixes ajuden, així com permetre un temps de refredament adequat entre talls propers en la mateixa peça.

Solucionar problemes de regalims i talls incomplets

Els regalims —aquest metall solidificat obstinat que queda enganxat a la cara inferior dels talls— indiquen que el material fos no s'està expulsant correctament de la ranura de tall. És frustrant perquè requereix operacions secundàries per eliminar-los, afegint temps i cost a cada peça.

Segons el recurs complet d'assistencia tècnica d'Accurl, la formació de llenties sovint és conseqüència del desalineament dels paràmetres de tall o d’un subministrament inadequat de gas d’assistència. Quan la vostra màquina de tall de metall produeix peces amb acumulació de llenties, investigueu aquests factors:

- Pressió de gas insuficient: La funció principal del gas d’assistència és expulsar el metall fos del tall. Una pressió massa baixa fa que quedi material al seu lloc. Augmenteu sistemàticament la pressió: el tall amb nitrogen sovint requereix entre 15 i 30 bar per obtenir resultats nets.

- Velocitat de tall massa elevada: Paradòxicament, anar massa ràpid també pot provocar llenties. El làser no arriba a fondre completament el material en tot el gruix, deixant metall parcialment fos que es solidifica com a llenties. Reduïu la velocitat d'alimentació fins que es produeixi una penetració completa.

- Tovera desgastada o malmesa: Una tovera malmesa altera els patrons de flux de gas, impedint l’expulsió eficient del material. Inspeccioneu regularment les toveres per detectar desgast, contaminació o danys. Canvieu-les quan sigui necessari: les toveres són components consumibles, no permanents.

- Distància incorrecta de la tovera: La distància entre la tovera i el material afecta la dinàmica del gas al punt de tall. Si és massa gran, la pressió del gas disminueix abans d'arribar a la zona de tall. Si és massa petita, les projeccions poden contaminar la tovera. Seguiu les recomanacions del fabricant pel vostre material i gruix.

Talls incomplets —quan el làser no aconsegueix penetrar completament a través del material— comparteixen algunes causes habituals amb la formació de borres, però també tenen factors específics:

- Potència làser insuficient: La causa més evident. El vostre làser per a màquina de tall simplement no subministra prou energia per fondre totalment el gruix del material. Reduïu el gruix del material o augmenteu la potència dins dels límits de l'equip.

- Derivació del punt focal: Amb el temps, l'expansió tèrmica o l'assentament mecànic poden desplaçar la posició de focus. Allò que estava perfectament enfocat ahir pot estar lleugerament desviat avui. Calibreu de nou el focus regularment, especialment durant períodes prolongats de producció.

- Variació del gruix del material: El full metàl·lic no és perfectament uniforme. Segons l'anàlisi de gruix del material d'Accurl, les variacions en el gruix poden provocar talls inconsistents, amb algunes àrees tallades massa profundament i altres insuficientment. Considereu utilitzar material amb toleràncies de gruix més ajustades per a treballs crítics.

- Potència del làser degradada: Les fonts làser van perdent potència amb el temps a causa de l'envelliment, la contaminació òptica o problemes en el sistema de refrigeració. Si esteu experimentant talls incomplets amb paràmetres que abans funcionaven, feu proves i manteniment a la font làser del vostre tallador làser.

Prevenció de la deformació i la distorsió tèrmica

La deformació es produeix quan el calor localitzat provoca una expansió a la zona de tall mentre el material circumdant roman fred. A mesura que la zona escalfada es refreda i es contrau, les tensions interiors arrosseguen el material fora del pla. Segons Sheet Metal Industries , entendre aquest procés impulsat pel calor és essencial: «La distorsió apareix quan la calor intensa generada pel feix làser provoca una expansió i contracció localitzades al metall.»

Els materials primes i les peces grans amb tall extensiu són els més susceptibles a la distorsió. Afortunadament, diverses estratègies minimitzen aquest problema:

- Optimitzeu la seqüència de tall: En lloc de tallar característiques seqüencialment en una fulla, alterneu entre diferents àrees. Això distribueix la calor de manera més uniforme i permet el refredament entre talls adjacents. El programari modern d'optimització sovint inclou algorismes de gestió de la calor.

- Utilitzeu un equilibri adequat de potència/velocitat: Velocitats més altes amb potència proporcionalment més alta completen els talls ràpidament, limitant el temps de difusió de la calor. L'objectiu és tallar de manera eficient sense un temps d'estadia excessiu que permeti a la calor estendre's.

- Fixeu correctament el material: Segons Sheet Metal Industries, assegurar que els materials estiguin "correctament suportats durant tot el procés de tall" ajuda a mantenir la integritat dimensional i la planor. Les taules de buit, les nanses o els fixadors magnètics eviten el moviment durant el processament.

- Considereu les aproximacions d'inici: El lloc on el làser perfora per primera vegada el material sovint experimenta una acumulació màxima de calor. Col·locar els inicis fora de les dimensions crítiques redueix l'impacte de la distorsió en la geometria final de la peça.

- Permetre el refredament entre operacions: Per a peces que requereixen múltiples passades de tall o patrons intensivament imbricats, incloure temps de refredament en el programa de producció evita l'acumulació progressiva de calor.

Mantenir una qualitat consistent entre diferents lots de producció

Solucionar problemes un per un és una actitud reactiva. Prevenir-los de manera constant exigeix un enfocament proactiu. Aquesta és la manera com els operadors experimentats mantenen la qualitat en períodes prolongats de producció:

- Establir paràmetres de referència: Documentar ajustos provats per a cada tipus i gruix de material. Quan apareixen problemes de qualitat, es disposa d’un punt de referència fiable al qual poder tornar.

- Aplicar un manteniment regular: Segons Les recomanacions de manteniment d'Accurl , la neteja periòdica dels components òptics, la lubricació de les peces mòbils i la inspecció dels consumibles eviten la degradació gradual de la qualitat.

- Monitoritza el desgast dels consumibles: Les toveres, lentilles i finestres protectores es degraden amb el temps. Canvia-les segons el calendari establert en comptes d'esperar a tenir problemes visibles de qualitat. El cost dels consumibles és irrellevant comparat amb la producció descartada.

- Comprova l'alineació periòdicament: L'alineació del feix afecta la qualitat del tall en tot l'espai de treball. Allò que talla perfecte al centre pot tenir problemes als extrems de la taula si l'alineació s'ha desviat.

- Controla els factors ambientals: Les fluctuacions de temperatura afecten tant la calibració de la màquina com el comportament del material. Mantingues unes condicions constants al taller sempre que sigui possible, especialment per a treballs de precisió.

La resolució de problemes resulta molt més senzilla quan entens les relacions entre els paràmetres i els resultats. Potència, velocitat, focus i gas treballen junts: canvia'n un i potser caldrà ajustar els altres. Amb enfocaments sistemàtics per diagnosticar problemes i solucions contrastades per a cada problema habitual, passaràs més temps tallant peces de qualitat i menys temps preguntant-te què ha anat malament.

És clar que ni tan sols una tècnica de tall perfecta importarà si els operadors resulten ferits. La secció següent aborda un tema sovint passat per alt en debats tècnics: els requisits de seguretat que protegeixen tant les persones com l'equip en operacions de tall amb làser.

Requisits de seguretat per a operacions de tall amb làser

Ja sabeu com optimitzar la qualitat del tall, resoldre problemes i seleccionar la tecnologia adequada. Però res d'això importa si algú resulta ferit. El tall industrial amb làser comporta riscos invisibles que poden causar lesions permanents en mil·liseconds, tot i que la seguretat sovint rep menys atenció de la que mereix en debats tècnics.

Aquesta és la realitat: tot tallador industrial amb làser funciona com un làser de classe 4, la classificació de risc més elevada. Aquestes màquines poden encendre materials, produir fums perillosos i causar greus danys oculars o a la pell per raigs directes o reflectits. Comprendre i aplicar els protocols de seguretat adequats no és opcional; és fonamental per a una operació responsable.

Comprendre les Classificacions de Làser Classe 4

Què fa que una màquina industrial de tall per làser sigui un dispositiu de Classe 4? La potència. Qualsevol làser amb una sortida superior a 500 mil·livatts entra dins d’aquesta categoria, i els sistemes de tall de metall solen funcionar a nivells de quilowatts, milers de vegades per sobre d’aquest llindar.

Segons Guia completa de requisits per a Classe 4 de Phillips Safety , treballar amb aquests làsers exigeix mesures de protecció específiques regulades per normatives governamentals. Als Estats Units, el Codi de Regulacions Federals 21 (CFR) Part 1040 regula l'ús dels làsers, mentre que a Europa s'apliquen les normes IEC 60825.

Els làsers de Classe 4 presenten diversos tipus de risc al mateix temps. L'exposició directa al feix provoca danys immediats als teixits. Les reflexions difuses —feixos que reboten en superfícies brillants— continuen sent perilloses a distàncies considerables. El feix pot encendre materials combustibles i generar fums perillosos. Fins i tot una exposició breu i accidental pot provocar lesions permanents.

Equipament de Protecció Essencial per a Operacions amb Làser

L'equip de protecció individual constitueix la primera línia de defensa quan s'opera una taula de tall làser o qualsevol sistema industrial. Tanmateix, no tot l'EPI és vàlid per a tots els làsers: la protecció específica segons la longitud d'ona és absolutament crítica.

Segons Guia per al comprador de Laser Safety Industries , seleccionar les ulleres de seguretat làser adequades requereix fer coincidir dos paràmetres clau: longitud d'ona i densitat òptica (OD). Els làsers de fibra que operen a 1064 nm necessiten lentilles protectores diferents dels sistemes CO2 a 10.600 nm. Utilitzar ulleres inadecades no ofereix cap protecció, o encara pitjor, genera una falsa confiança.

La densitat òptica indica en quina mesura la lent atenua la llum làser a longituds d'ona específiques. Valors d'OD més alts proporcionen una major protecció, però també redueixen la transmissió de llum visible. L'objectiu és obtenir una protecció adequada sense fer impossible veure el treball. Phillips Safety assenyala que les ulleres làser només bloquegen rangs específics de longitud d'ona, fet que fa essencial una selecció correcta.

Més enllà de la protecció ocular, les taules làser i els sistemes de tall requereixen àrees de treball tancades sempre que sigui possible. Les cortines i barreres làser eviten que reflexions accidentals arribin al personal situat fora de la zona de tall immediata. Aquestes barreres han de complir amb les normes de retardament de la combustió i estar classificades per a la longitud d'ona làser específica del vostre sistema. Pel que fa a les finestres de visualització, assegureu-vos que la densitat òptica correspongui a la sortida del vostre sistema.

Requisits de ventilació i extracció de fums

Quan es vaporitza metall, què passa amb aquest material? Esdevé aerotransportat, i respirar-lo és perillós. Segons l'anàlisi de fums d'IP Systems USA, el tall làser de metalls allibera una gamma de substàncies tòxiques, incloent plom, cadmi, crom, manganès i beril·li. Aquestes substàncies representen riscos respiratoris importants i possibles efectes perjudicials a llarg termini per a la salut.

Certes materials exigeixen una precaució extra. Tallar acer galvanitzat allibera fums d'òxid de zinc, que poden causar la "febre dels fums metàl·lics"—uns símptomes semblants als de la grip que apareixen hores després de l'exposició. El tall d'alumini genera partícules d'òxid d'alumini. Potser el més preocupant és que contaminants cancerígens com el crom hexavalent i el cadmi apareixen en els fums generats en tallar acer inoxidable i materials recoberts.

L’extracció eficaç de fums no és opcional: és essencial en qualsevol operació de tall amb taula làser. Els sistemes han de capturar les partícules a la font abans que es dispersin al medi de treball. Les taxes d’extracció, els tipus de filtres i la gestió dels gasos d’escapament requereixen una atenció cuidadosa segons els materials que estigueu tallant.

Llista de comprovació de seguretat integral

Utilitzeu aquesta llista de comprovació organitzada per avaluar i mantenir la seguretat en la vostra operació industrial de tall làser:

Equip de protecció personal

- Protecció ocular específica per a làser segons la longitud d’ona, amb una densitat òptica adequada

- Ropa protectora que cobreixi la pell exposada (mànigues llargues, sabates tancades)

- Guants resistents a la calor per a la manipulació de materials

- Protecció respiratòria quan es tallin materials que generen fums tòxics

- Protecció auditiva si s'utilitzen sistemes d'extracció o refredament sorollosos

Requisits de la instal·lació

- Àrea de treball laser tancada amb controls d'accés adequats

- Cortines o barreres laser classificades per a la vostra longitud d'ona específica

- Finestres de visualització amb classificacions d'opacitat òptica equivalents

- Sistema d'extracció de fums dimensionat segons el volum de tall i els tipus de material

- Equip de suprimació d'incendis classificat per a incendis metàl·lics (extintors classe D)

- Botons d'aturada d'emergència accessibles des de múltiples ubicacions

- Senyalització d'advertència que indica la classificació de risc làser

- Accés controlat per evitar l'entrada no autoritzada durant el funcionament

Protocols operatius

- Procediments operatius estàndard documentats per a totes les tasques de tall

- Requisits de formació i certificació de l'operador abans de l'ús sense supervisió

- Inspecció periòdica dels sistemes d'interbloqueig de seguretat i emergència

- Llista de comprovació preoperativa que inclou la inspecció òptica i la verificació de la ventilació

- Procediments de manipulació de materials per evitar superfícies reflectants a prop del trajecte del feix

- Procediments d'actuació d'emergència en cas d'incendi, lesions i fallades de l'equip

- Calendari de manteniment regular dels sistemes d'extracció i dels filtres

- Procés de comunicació i revisió d'incidents per a casos gairebé encertats i accidents

La prevenció d'incendis mereix una especial atenció. El tall de metall rarament inflama la peça treballada, però l'acumulació de residus, restes del tall i materials combustibles propers representen un risc real d'incendi. Mantingueu les zones de treball netes, retireu regularment les bales i assegureu-vos que els sistemes d'extracció capturin les partícules calentes abans que s'assenteixin. Mai deixeu un làser en funcionament sense supervisió i mantingueu sempre un accés lliure als equips d'extinció d'incendis.

La formació dels operadors ho uneix tot. Fins i tot l'equip de seguretat més eficaç pot fallar si els usuaris no entenen els procediments adequats. La formació completa hauria de cobrir els fonaments de la física del làser, els riscos específics del vostre equip, l'ús correcte dels EPI, la resposta d'emergència i l'operació pràctica supervisada abans del treball autònom. Moltes regions exigeixen programes de formació documentats i oficials de seguretat del làser designats per a operacions de classe 4.

Les inversions en seguretat generen beneficis més enllà de la prevenció d'accidents. Els sistemes d'extracció correctament mantinguts allarguen la vida útil de l'equipament en prevenir la contaminació òptica. Els operadors formats cometent menys errors costosos. I un programa de seguretat documentat ofereix protecció contra problemes reguladors i responsabilitats.

Un cop establerts els fonaments de seguretat, esteu preparats per prendre decisions informades sobre quin sistema de tall làser s'ajusta millor a les vostres necessitats específiques. La propera secció us guia pel procés de selecció d'equipament—des de l'avaluació dels requisits de producció fins a l'avaluació de característiques avançades que valen la inversió.

Triar el Sistema de Tall Làser Adequat

Heu après els fonaments tècnics—tipus de làser, requisits de potència, gasos auxiliars i protocols de seguretat. Ara arriba la decisió que realment importa: quin sistema heu de comprar? Aquí és on la teoria es troba amb la realitat, i on molts compradors cometen errors costosos.

Aquí va la veritat que la majoria de presentacions de vendes no us diran: el tallador làser "millor" no existeix. Només existeix el millor tallador làser per a aplicacions metàl·liques que coincideixi amb les vostres necessitats específiques. Un sistema industrial de 500.000 $ és un desaprofitament per a un taller de prototips que talla cinquanta peces mensualment. Al contrari, una màquina CNC d'escriptori no pot suportar volums de producció que exigeixen funcionament 24/7.

Construïm un marc sistemàtic que associï les vostres necessitats reals a l'equip adequat, estalviant-vos tant despeses excessives com rendiment insuficient.

Associació de sistemes làser a requisits de producció

Abans de consultar catàlegs d'equips o sol·licitar pressupostos, respongueu una pregunta fonamental: què farà realment aquesta màquina? La guia per al comprador de Focused Laser Systems , els materials que penseu processar acabaran dictant quin sistema làser—i les seves especificacions—és el més adequat per a les vostres necessitats.

El volum de producció determina tota la resta. Un tallador làser CNC dissenyat per a treballs en tallers amb ordres variades i de baix volum requereix capacitats diferents d’una màquina dedicada a la producció d’alta volumetria de peces idèntiques. La primera necessita flexibilitat i canvis ràpids; la segona, rendiment brut i automatització.

Considereu l'espectre de sistemes disponibles:

Sistemes d'escriptori CNC i d'entrada: Aquestes unitats compactes ocupen un espai mínim al sòl i tenen un cost entre 4.500 $ i 20.000 $ per a configuracions completes que inclouen programari i formació. Són ideals per a prototipatge, producció de petites sèries, entorns educatius i empreses que proven les capacitats del làser abans de fer inversions més grans. Les plataformes CNC d’escriptori gestionen eficaçment materials prims, però manquen de potència i volum de treball per a una producció seriosa.

Sistemes de producció de gamma mitjana: Passar a plataformes dedicades de màquines de tall làser per metall porta nivells de potència de 1-4 kW, volums de treball més grans i una construcció més robusta. Aquests sistemes gestionen volums de producció des de desenes fins a centenars de peces diàries, segons la complexitat. Cal esperar inversions de 50.000 a 150.000 dòlars amb equipament auxiliar adequat.

Sistemes industrials de làser de fibra: Les operacions d’alta producció exigeixen plataformes de màquines làser CNC amb potència de 6-20+ kW, manipulació automàtica de materials i una construcció dissenyada per funcionar contínuament en diversos torns. Aquests sistemes processen milers de peces diàriament i representen inversions des de 200.000 dòlars fins a superar clarament els 500.000 dòlars. Segons l'anàlisi sectorial d'ADH Machine Tool, fabricants destacats com TRUMPF, Bystronic i AMADA ofereixen aquestes solucions industrials amb una integració extensiva d'automatització.

Criteris clau de selecció: Una aproximació sistemàtica

En comptes de deixar-se impressionar per especificacions elevades, segueix aquest procés estructurat de selecció:

- Documenteu els vostres requisits de material: Lliste el tipus de metall i gruix que tallareu habitualment, així com els materials ocasionals. Sigui específic: «principalment acer suau de calibre 16 amb al·lumini ocasional de 1/4 de polzada» us dóna molta més informació que «diversos metalls». Això determina els requisits mínims de potència i si la tecnologia làser de fibra s'adapta a les vostres necessitats.

- Quantifiqueu les expectatives de producció: Quantes peces per dia, setmana o mes? Funcionarà només un torn o hores contínues? Aquestes respostes determinen si necessiteu equip bàsic o sistemes amb automatització, taules intercanviables i components de cicle de treball elevat.

- Definiu els requisits de precisió: Quines toleràncies exigeixen realment les vostres aplicacions? Segons la guia de compres ADH, algunes operacions necessiten components ultraimprecisos (±0,03 mm), mentre que altres produeixen peces estàndard de xapa on ±0,1 mm és perfectament acceptable. No pagui una precisió que no utilitzarà.

- Avaliu l'espai disponible: Mesureu bé les dimensions de la vostra instal·lació, incloent l'espai necessari per a la manipulació de materials, l'accés dels operadors, els sistemes de refrigeració i l'extracció de fums. Segons Focused Laser Systems, els sistemes més grans poden requerir una instal·lació professional i una planificació acurada dels itineraris d'accés.

- Establiu paràmetres realistes de pressupost: Això inclou la compra inicial més la instal·lació, formació, programari, sistemes d'extracció i els costos operatius continus. El preu de la màquina de tall CNC amb làser que veieu publicitat rarament reflecteix la inversió total necessària.

Característiques avançades que valen la pena la inversió

Més enllà de la capacitat bàsica de tall, els sistemes actuals de talladora làser per a metall ofereixen característiques avançades que milloren notablement la productivitat i la qualitat. Comprendre quines característiques ofereixen un valor real us ajuda a assignar el pressupost de manera eficaç.

Sistemes d'enfocament automàtic: Segons Anàlisi de característiques de Full Spectrum Laser , l'autofocus motoritzat combinat amb sistemes de càmera 3D elimina l'ajust manual d'alçada i assegura un focus correcte cada vegada. La càmera 3D mapa amb precisió milions de punts de dades, que el làser utilitza per ajustar el motor Z de manera que el cap estigui enfocat a l'alçada correcta. Per a operacions que processen gruixos de material variats, aquesta característica estalvia un temps considerable de configuració i evita problemes de qualitat relacionats amb l'enfocament.

Seguidors d'alçada i detecció capacitiva: Aquests sistemes mantenen una distància consistent entre la tovera i el material encara que les fulles no siguin perfectament planes. La deformació del material, la distorsió tèrmica durant el tall o una fixació imperfecta podrien causar variacions de qualitat al llarg de la peça de treball.

Programari de nesting: Els algorismes d'annidament intel·ligents maximitzen l'aprofitament del material optimitzant la col·locació de les peces sobre les planxes. Els paquets avançats també gestionen les seqüències de tall per minimitzar l'acumulació de calor i reduir els rebuts. Segons l'enfocament de Bystronic descrit per ADH, la intel·ligència del programari que connecta la recepció de comandes amb la planificació de la producció representa una avantatge competitiva clau.

Taules d'intercanvi i automatització: Els sistemes de doble taula permeten carregar nou material mentre continua el tall, reduint dràsticament el temps d'inactivitat. ADH informa que els seus sistemes de taula d'intercanvi completen el canvi de taula en només 15 segons, permetent operacions simultànies de tall i càrrega.

Comprendre el cost total de propietat

El preu de la màquina de tall per làser de fibra en un pressupost representa només el començament. Segons la guia de compres d'ADH, els compradors experimentats es centren en el cost total de propietat (TCO); en cinc anys, el TCO d'una màquina de tall per làser pot arribar a ser gairebé quatre vegades el seu cost inicial.

El vostre càlcul de TCO hauria d'incloure:

| Categoria de Cost | Components | Impacte típic |

|---|---|---|

| Inversió inicial | Equipament, instal·lació, formació, programari, sistema d'extracció | 25-35% del cost total d'explotació (TCO) en 5 anys |

| Costos d'operació | Electricitat, gasos auxiliars, consumibles (toberes, lentilles) | 30-40% del cost total d'explotació (TCO) en 5 anys |

| Manteniment | Servei preventiu, reparacions, peces de recanvi | 15-25% del cost total d'explotació (TCO) en 5 anys |

| Costos d'inactivitat | Producció perduda durant avaries, esperant assistència tècnica | Variable però significatiu |

Les comparatives de preus de talladores làser només són significatives quan es modelen aquests costos recurrents. Un sistema amb un preu d'adquisició més baix però un consum energètic més alt, consumibles cars o suport tècnic poc fiable pot arribar a costar molt més al llarg de la seva vida operativa.

La guia ADH recomana específicament fer preguntes detallades als proveïdors potencials: On és l'almacè de peces de recanvi més proper? Quants tècnics qualificats cobreixen la vostra regió? Quines condicions de garantia s'apliquen als generadors làser en comparació amb els consumibles? Aquestes respostes revelen el cost real d'explotació més enllà dels preus anunciats.

Abans de signar qualsevol acord de compra, exigeix criteris d'acceptació clarament definits amb estàndards quantificables, detalls de cobertura de garantia per a tots els components i acords de nivell de servei que especifiquin els temps de resposta. L'error més costós no és comprar la màquina equivocada, sinó comprar qualsevol màquina sense entendre a què t'estàs comprometent realment.

Un cop establerts els principis de selecció d'equipament, la següent pregunta és pràctica: com s'integra el tall làser al vostre procés de fabricació més ampli? La secció següent explora com flueixen els components tallats amb precisió cap a operacions de conformació, soldadura i muntatge.

Integració del tall làser als processos de fabricació

Heu seleccionat el vostre equip, optimitzat els paràmetres i dominat la resolució de problemes. Però això és el que separa el tall hobby de la fabricació seriosa: el tall làser rarament actua de manera aïllada. En entorns de producció, especialment en sectors exigents com l'automoció, les peces tallades amb precisió representen només el punt de partida d’un procés complex des del material brut fins al muntatge final.

Comprendre com s’integra el tall làser amb els processos posteriors transforma la vostra perspectiva. De sobte, les decisions sobre la qualitat del tall no es limiten a l’acabat del cantell, sinó que també tenen en compte com aquest cantell afectarà les operacions de soldadura posteriors. Els ajustos de potència importen no només per la penetració, sinó també per minimitzar les zones afectades tèrmicament que podrien complicar operacions posteriors de conformació. Explorarem com la fabricació moderna de xapes metàl·liques integra aquests processos en fluxos de treball sense interrupcions.

De les peces tallades amb làser a muntatges acabats

Imagineu un travesser de xassís per a un vehicle elèctric. Comença com una planxa plana, es talla amb làser en una preforma complexa amb forats de fixació i obertures per reduir pes, i després passa per formació, soldadura i tractament superficial abans del muntatge final. Cada pas depèn de la qualitat del pas anterior — i el tall làser estableix les bases per a tot el que segueix.

Segons L'anàlisi de Metal-Interface sobre les tendències de fabricació automotriu , els sistemes moderns de tall làser 3D es converteixen en pilars centrals d'entorns de fabricació avançats. L'article assenyala que «la irrupció de les giga fàbriques ha redefinit l'escala industrial, establint nous estàndards de productivitat i automatització». Aquesta evolució cap al que anomenen «eficiència giga» exigeix una integració estreta entre el tall i els processos posteriors.

Per què és tan important aquesta integració? Considereu la relació entre el tall làser i les operacions de formació:

- La Qualitat del Vora Afecta la Integritat del Doblats: Les vores rugoses o oxidades procedents del tall amb oxigen poden esquerdat durant el doblegament, especialment en radis ajustats. Les vores tallades amb nitrogen, amb el seu acabat net, es dobleguen de manera més previsible.

- Les zones afectades per la calor influeixen en el comportament del material: El material adjacent als talls experimenta cicles tèrmics que poden alterar la duresa i la ductilitat. Minimitzar la ZAC mitjançant paràmetres optimitzats conserva característiques de conformació uniformes.

- La precisió dimensional es manté: Quan les característiques tallades tenen una desviació de 0,5 mm, aquest error es transmet durant el formatejat i s'amplifica durant el muntatge. La precisió de posicionament de ±0,008 mm assolible amb sistemes làser moderns evita aquests problemes acumulatius de toleràncies.

Els mateixos principis s'apliquen a les operacions de soldadura. Segons la guia d'expertesa en soldadures de Approved Sheet Metal, per aconseguir soldadures exitoses cal precisió en cada pas de la fabricació. El seu procés comença amb una "revisió detallada de la sol·licitud de pressupost, on els equips d'enginyeria i pressupostos avaluïen cuidadosament els plànols, els fitxers CAD 3D i els requisits de soldadura." Aquesta atenció primerenca a la qualitat dels bruts tallats amb làser determina l'èxit posterior de les soldadures.

Quan es cerca «metal fab a prop meu» o «taller de metall a prop meu», els compradors més assenyats busquen tallers que demostrin aquest tipus de pensament integrat. Els millors socis en fabricació CNC entenen que el tall làser no és un servei aïllat, sinó el primer pas per produir conjunts complets. Tenen en compte com les característiques del tall afecten les operacions posteriors i optimitzen en conseqüència.

Geometries complexes per a aplicacions automotrius

La fabricació d'automòbils empeny les capacitats de tall CNC al límit. Els components del xassís, els suports de suspensió i les reforços estructurals exigeixen geometries que serien impossibles o prohibitivament cares amb mètodes de tall convencionals.

L'article de Metal-Interface destaca quatre factors que estan transformant la fabricació laser en l'automoció:

- Eficiència: Maximitzar l'espai disponible i el temps operatiu de les màquines per assolir la màxima producció per metre quadrat

- Automatització: Minimitzar la mà d'obra directa en operacions repetitives i de baix valor afegit

- Temps de lliurament curts: Reduir operacions i existències per accelerar els cicles de disseny a producció

- Flexibilitat: Adaptar-se ràpidament a canvis de disseny, fluctuacions de volum i múltiples models de vehicles

Aquestes exigències convergeixen en allò que descriuen com a «fer més, més ràpid i en menys espai, sense comprometre la qualitat ni l'estabilitat del procés». Per a les operacions de conformació de metalls que donen servei a clients automotrius, això es tradueix en capacitats específiques: tall multi-eix per a tubs formats i seccions hidroconformades, manipulació automàtica de peces per mantenir el rendiment, i canvis de programació ràpids per adaptar-se a actualitzacions d'enginyeria.

Els components estampats en calent il·lustren perfectament aquestes exigències. Els anells de porta, els pilars B i les reforços estructurals passen per processos de templatge en premsa que creen acers d'ultraalta resistència. Segons Metal-Interface, tallar aquests components «requereix un procés de tall que no només sigui precís, sinó també escalable». Els sistemes làser 3D avançats satisfan aquesta necessitat «optimitzant el flux de peces, minimitzant els canvis d'utillatges i integrant-se de manera transparent en línies automàtiques».

Acceleració de la prototipatge amb tall de precisió

La velocitat té una importància diferent en la prototipatge que en la producció. A l’hora de desenvolupar components nous, la prioritat canvia del cost per peça al temps d’obtenció de retroalimentació. Quant de ràpid poden validar els dissenyadors els conceptes, provar l’ajust i iterar cap a dissenys preparats per a la producció?

Segons l’anàlisi de prototipatge de xapa metàl·lica de 3ERP, el tall làser transforma els cronogrames del prototipatge. «Els sistemes moderns sovint incorporen control numèric per ordinador (CNC), el que permet talls automàtics i altament repetibles amb toleràncies tan ajustades com ±0,0005 polzades (±0,0127 mm)». Aquesta precisió fa que els prototips representin amb exactitud la intenció de producció: les peces encaixen correctament, els conjunts funcionen tal com estan dissenyats i la validació tècnica produeix dades significatives.

L'avantatge de la prototipatge va més enllà de la velocitat. El tall làser no requereix inversió en eines: penja un nou fitxer de disseny i el tall comença immediatament. Això elimina les setmanes necessàries per a la fabricació dels motlles d'estampació i el cost considerable dels canvis d'eina. Per als programes de desenvolupament automobilístic que iteren a través de desenes de revisions de disseny, aquestes estalvies es multipliquen de manera dramàtica.

Fabricants com Shaoyi (Ningbo) Metal Technology exemplifiquen com la fabricació moderna integra la precisió del tall làser amb una experiència més àmplia en formació de metalls. La seva capacitat de prototipatge ràpid en 5 dies demostra com combinar el tall de precisió amb l'estampació de metall accelera els cicles de desenvolupament. Per a aplicacions automobilístiques que requereixen tant fulls tallats com conjunts formats, treballar amb fabricants certificats segons IATF 16949 assegura estàndards de qualitat en tot el procés de fabricació—des dels fulls inicials tallats amb làser fins als prototips acabats representatius de producció.

Aquest enfocament integrat és especialment important per a components de suspensió, conjunts estructurals i peces del xassís on forma i funció van lligades. El suport DFM (Disseny per a Fabricació) en la fase de prototipatge identifica problemes de produïbilitat abans que es converteixin en costosos problemes de producció. L'oferta de pressupostos en 12 hores que ofereixen els socis reactius permet una iteració ràpida: els dissenyadors poden avaluar la viabilitat, ajustar paràmetres i sol·licitar pressupostos revisats dins d'un sol dia laborable.

Connectar la cadena de fabricació

El canvi cap a l'automatització esbelta descrit per Metal-Interface té implicacions més amplies sobre com organitzen els seus fluxos de treball els tallers de fabricació. «El canvi cap al flux d'una sola peça i l'automatització esbelta milloren la traçabilitat i la repetibilitat, fent que les operacions de tall làser siguin més consistents i millor alineades amb els processos d'assemblatge posteriors».

Què significa això pràcticament? Considereu un flux de treball típic per a un suport de suspensió:

- Tall amb Laser: Blancs de precisió tallats de fulls amb forats de muntatge, característiques de reducció de pes i esquinats de formació

- Conformació: Operacions de doblegat o estampació creen una geometria tridimensional a partir de blancs plans

- Soldadura: Diversos components formatats s'uneixen per formar conjunts complets

- Tractament de Superfície: Revestiment, galvanitzat o pintura per a la protecció contra la corrosió

- Muntatge: Integració amb components i accessoris aparellats

Cada punt de transició presenta oportunitats d'acumulació d'errors o pèrdua de qualitat. Les operacions de fabricació CNC més eficaces minimitzen els traspàs, redueixen l'inventari en procés i mantenen la traçabilitat en tot moment. Aquesta integració «redueix l'inventari en procés, simplifica la logística i permet la fabricació just in time», segons Metal-Interface.