Custom Metal Sheet Cutting Demystified: Methods, Costs, And Partner Selection

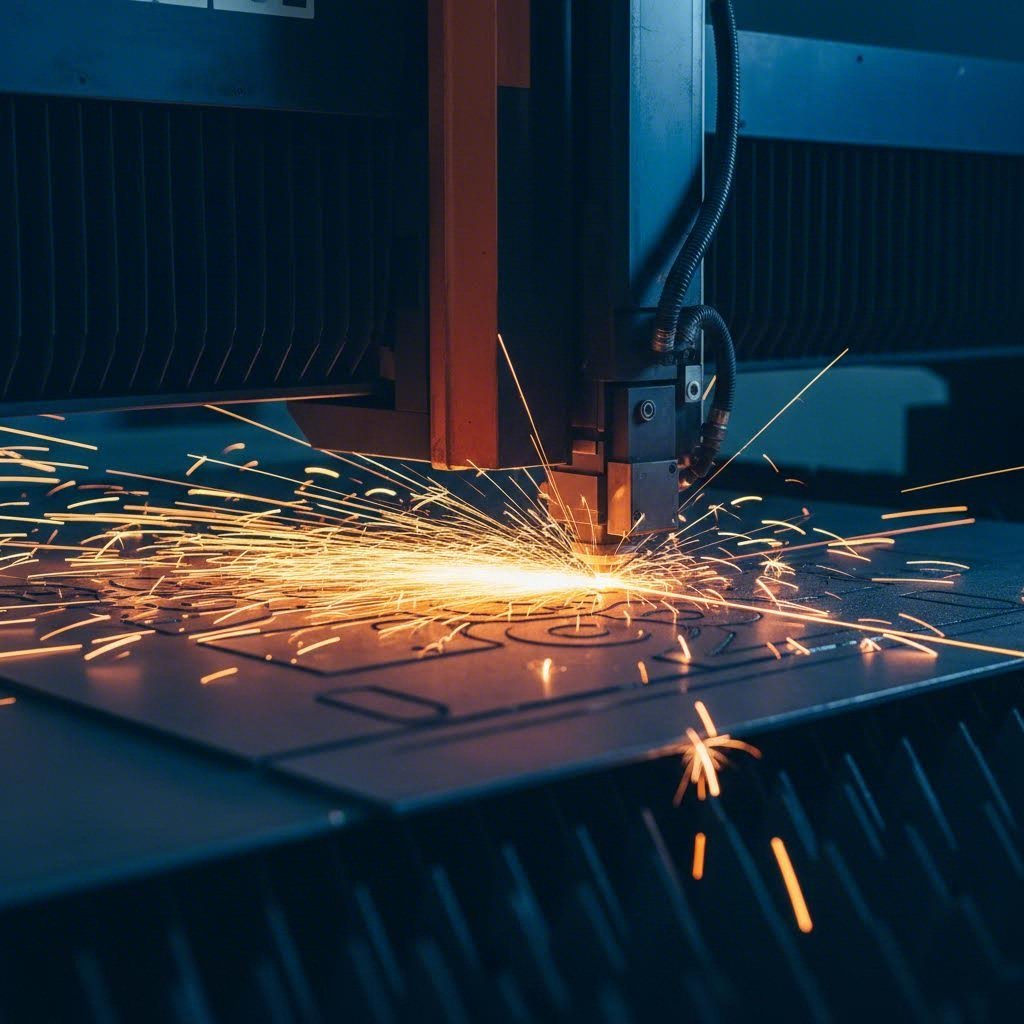

Understanding Custom Metal Sheet Cutting and Why It Matters

When you need a metal component that fits your exact specifications, standard stock shapes simply won't cut it. That's where custom metal sheet cutting enters the picture. This specialized metal fabrication process transforms flat metal sheets into precision parts tailored to your unique project requirements. Whether you're developing a prototype for an aerospace application or producing brackets for automotive assembly, this process delivers the exact dimensions, shapes, and features your design demands.

But here's the challenge: most online resources about this topic focus heavily on selling services rather than actually explaining the process. You're left wondering how it all works, which method suits your needs, and whether custom cutting is even right for your project. This guide changes that by giving you the foundational knowledge you need to make informed decisions.

What Makes Metal Sheet Cutting Custom

So what separates custom cutting from grabbing a standard metal sheet off the shelf? It comes down to precision and personalization. Standard sheet metal arrives in pre-defined sizes, thicknesses, and shapes. A typical steel sheet might measure 4 feet by 8 feet with a 16-gauge thickness. These off-the-shelf options work fine for general applications like roofing panels or basic ducting systems.

Custom cutting, however, starts with your design file and ends with parts that match your exact specifications. The process employs advanced cutting techniques such as laser cutting, plasma cutting, or waterjet cutting to achieve precise dimensions that standard options simply cannot accommodate. You specify the material, the thickness, the shape, and even intricate cutouts or patterns. Think of custom metal signs with detailed logos, complex brackets with specific mounting holes, or enclosures with precise ventilation patterns.

This level of customization becomes essential when your project requires:

- Non-standard dimensions that don't match available stock sizes

- Complex shapes, curves, or internal cutouts

- Tight tolerances for mechanical assemblies

- Specific types of metals chosen for particular performance characteristics

- Custom metal shapes designed for unique functional requirements

From Raw Material to Precision Parts

Imagine starting with a flat aluminum sheet and ending with a precisely cut chassis component ready for automotive assembly. That transformation happens through a carefully controlled fabrication process. First, the right material is selected based on your project's strength, weight, and corrosion resistance requirements. Then, cutting technology translates your digital design into physical reality with remarkable accuracy.

The industries that rely on this process span nearly every sector of modern manufacturing:

- Automotive: Body panels, brackets, chassis components, and heat shields requiring precise fit and structural integrity

- Aerospace: High-performance parts shaped to exact specifications while minimizing weight

- Electronics: Enclosures and housings that protect components while accommodating ports, ventilation, and mounting requirements

- Construction: Architectural elements, structural supports, and specialized building components

- Signage: Custom metal signs, decorative panels, and branded elements with intricate designs

Each of these industries demands precision that standard stock shapes cannot deliver. When a component must fit exact specifications and withstand rigorous operational conditions, custom cutting becomes not just an option but a necessity. The key is understanding which cutting method, material, and specifications align with your particular application, topics we'll explore in the sections ahead.

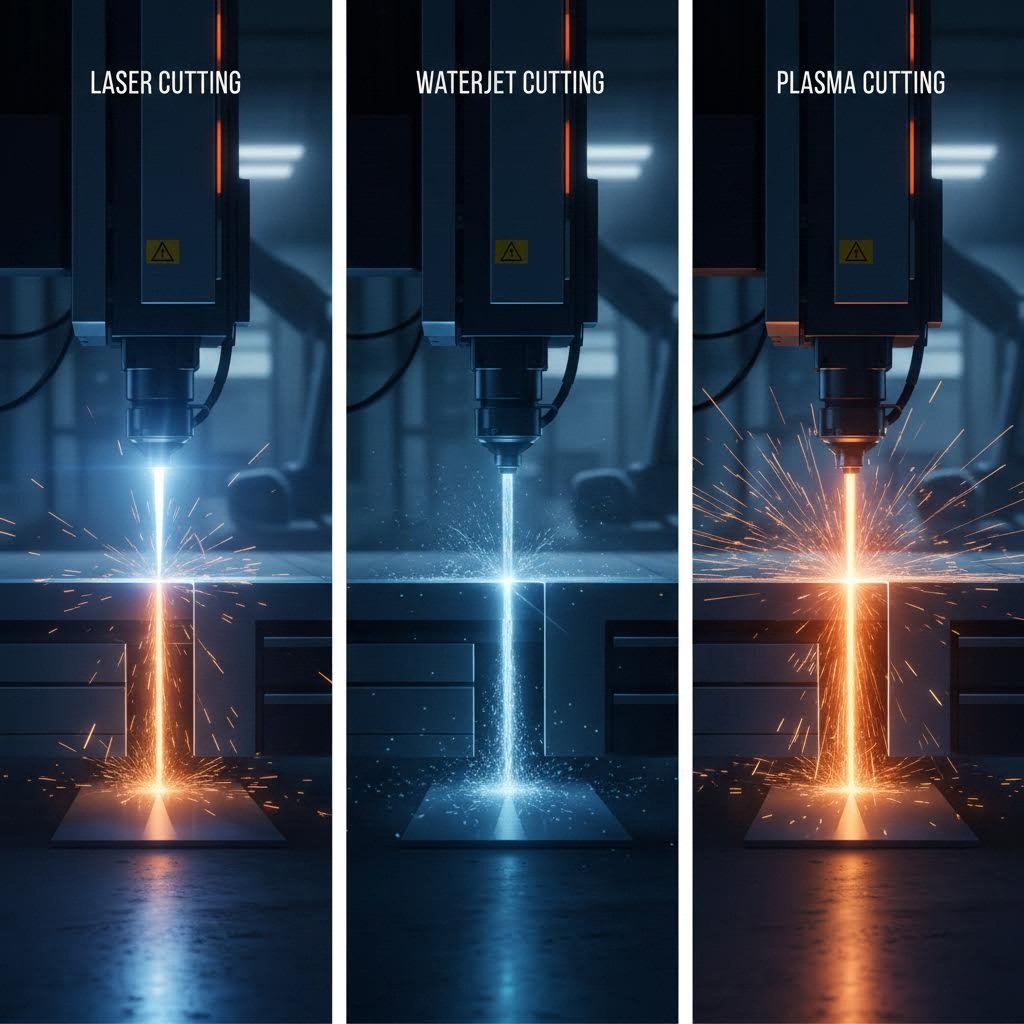

Cutting Methods Compared From Laser to Waterjet

Wondering how to cut metal sheets for your project? The answer depends entirely on your material, thickness requirements, and precision needs. Each cutting technology brings distinct advantages to the table, and choosing the wrong one can cost you thousands in wasted material and rework. Let's break down the four primary methods so you can match the right technology to your specific application.

Laser Cutting for Ultra-Fine Precision

When your project demands surgical accuracy and clean edges, laser cutting delivers. This method focuses an intense beam of light to melt, burn, or vaporize material along a precisely defined path. A fiber laser cutter can achieve tolerances as tight as ±0.05mm to ±0.1mm, making it the go-to choice for intricate designs and fine details.

What makes laser cutting stand out for precision work?

- Exceptionally clean edges that often require no secondary finishing

- Small kerf width (the material removed during cutting) allowing tighter nesting of parts

- Ability to cut small holes with diameters equal to or smaller than material thickness

- Sharp corners and intricate patterns impossible with other methods

The laser cutter excels with thin sheets, typically performing best on materials under 25mm thick. For electronics enclosures, medical device components, or any application requiring fine details, laser cutting offers unmatched capability. However, it does create a heat-affected zone that can alter material properties near the cut edge, a consideration for heat-sensitive applications.

When Waterjet Outperforms Laser

Here's a scenario: you need to cut titanium aerospace components where any heat distortion is unacceptable. Or perhaps you're working with glass, stone, or composite materials that lasers simply cannot handle. This is where waterjet cutting becomes indispensable.

Waterjet technology uses a high-pressure stream of water mixed with abrasive particles to erode and cut through virtually any material. The waterjet market is projected to exceed $2.39 billion by 2034, reflecting its growing importance in precision manufacturing.

The key advantages include:

- Zero heat-affected zone: No warping, hardening, or thermal distortion

- Material versatility: Cuts metals, stone, glass, composites, rubber, and more

- Thick material capability: Effectively cuts materials up to 200mm or more

- Precision tolerances: Achieves ±0.1mm to ±0.25mm depending on material and thickness

The trade-off? Waterjet cutting runs slower than plasma or laser methods, and operating costs tend to be higher. But when you cannot risk heat damage or need to cut non-metallic materials, waterjet becomes the only viable option.

Plasma Cutting for Speed and Thick Metals

Need to slice through one-inch steel plate quickly and cost-effectively? Plasma cutting dominates this territory. The process uses an electrical arc and compressed gas to create a high-temperature plasma stream that melts and blasts through conductive metals with impressive speed.

This metal cutter technology shines when:

- Working with thick conductive metals (steel, aluminum, copper) over 12mm

- Speed matters more than ultra-fine precision

- Budget constraints make laser cutting prohibitive

- Structural steel fabrication, heavy equipment, or shipbuilding applications

Plasma achieves tolerances of approximately ±0.5mm to ±1.5mm, wider than laser or waterjet but perfectly acceptable for structural applications. The edge quality requires more finishing work compared to laser cutting, but for thick metal processing, plasma offers the best balance of speed and cost efficiency.

CNC Router Applications

While thermal and waterjet methods dominate sheet metal work, CNC router CNC machines serve specialized applications. These mechanical cutting systems use rotating tools to remove material and excel with softer metals like aluminum, particularly when combined cutting and milling operations are needed. A CNC router CNC setup can create features that pure cutting methods cannot, such as pockets, channels, and complex 3D contours.

Cutting Method Comparison at a Glance

Selecting the right method requires weighing multiple factors simultaneously. This comparison table consolidates the critical specifications:

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting |

|---|---|---|---|

| Precision Tolerance | ±0.05mm to ±0.1mm | ±0.1mm to ±0.25mm | ±0.5mm to ±1.5mm |

| Material Thickness Range | Up to 25mm (optimal under 12mm) | Up to 200mm+ | Up to 50mm+ (optimal over 12mm) |

| Heat-Affected Zone | Small but present | None | Large |

| Edge Quality | Excellent, minimal finishing needed | Good, slight texture from abrasive | Rougher, often requires deburring |

| Cutting Speed | Fast for thin materials | Slower than thermal methods | Fastest for thick metals |

| Best Applications | Thin sheets, intricate designs, electronics, medical devices | Heat-sensitive materials, non-metals, aerospace, thick materials | Thick steel, structural fabrication, heavy equipment |

| Relative Cost | Moderate to high | Highest | Lowest |

The right choice ultimately depends on three key questions: What material are you cutting? How thick is it? What precision does your application demand? For thin aluminum sheets requiring intricate cutouts, laser cutting delivers optimal results. For thick structural steel, plasma offers unbeatable speed and value. For heat-sensitive aerospace components or non-metallic materials, waterjet stands alone in capability.

Many professional fabrication shops maintain multiple cutting technologies precisely because no single method covers every application. Understanding these distinctions empowers you to specify the right process for your project and communicate effectively with your fabrication partner. With cutting method selection clarified, the next critical decision involves choosing the right material for your specific requirements.

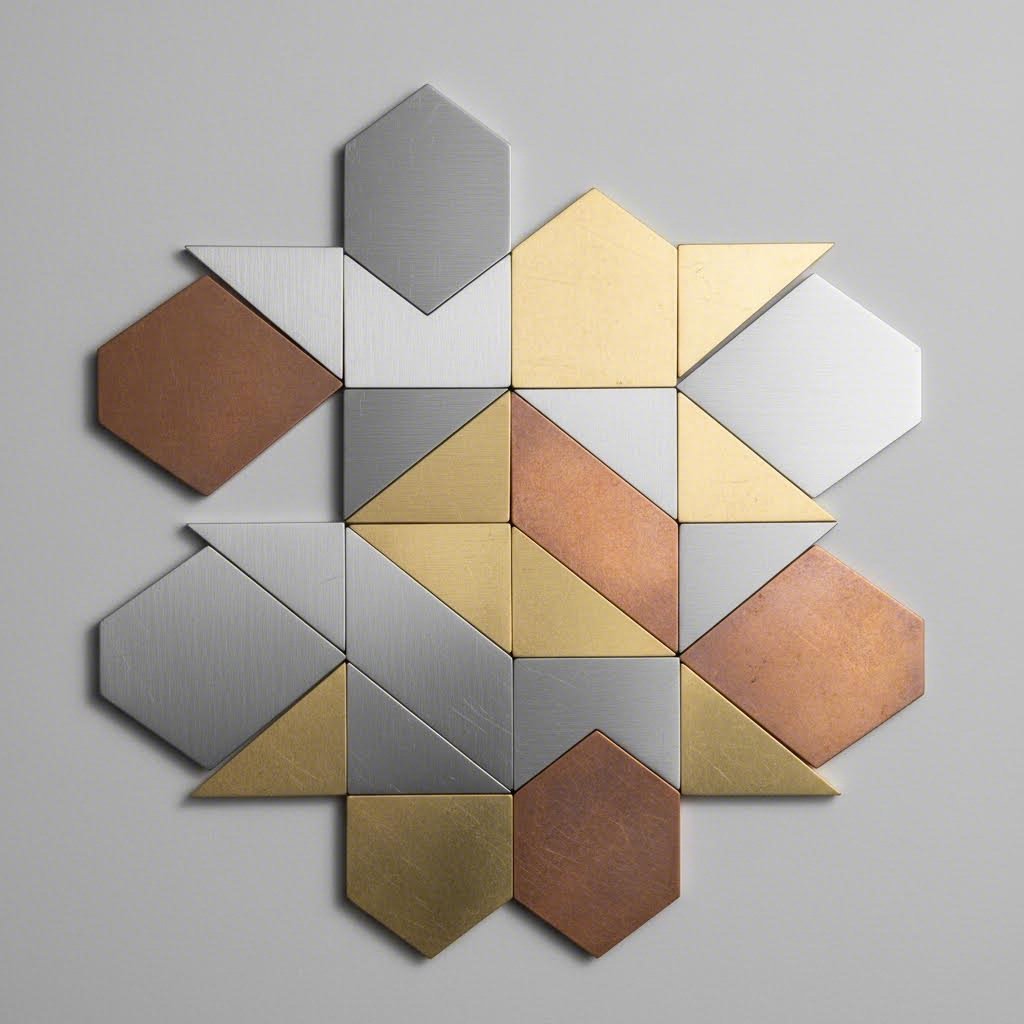

Choosing the Right Metal for Custom Cutting Projects

You've selected your cutting method, but here's the thing: even the most advanced laser cutter can't compensate for choosing the wrong material. The metal you select fundamentally shapes everything from cutting parameters to final part performance. Whether you're fabricating lightweight aerospace brackets or durable marine fixtures, material selection determines success or failure before the first cut ever happens.

Most fabrication resources gloss over material selection, leaving you to guess which alloy suits your application. Let's change that by exploring the properties, trade-offs, and practical applications of the most commonly cut metals.

Aluminum vs Steel for Your Project

This comparison represents the most frequent decision point for custom metal sheet cutting projects. Both materials dominate the fabrication industry, but they serve distinctly different purposes.

Aluminum sheet metal delivers an exceptional strength-to-weight ratio. At roughly one-third the weight of steel, an aluminum sheet becomes the obvious choice when weight reduction matters. Think aircraft skins, automotive body panels, and portable equipment housings. The material also offers natural corrosion resistance, forming a protective oxide layer when exposed to air. For outdoor signage, marine trim, and architectural applications, this self-protecting characteristic eliminates the need for protective coatings.

However, aluminum costs more per pound than carbon steel and offers lower tensile strength. You'll also find it scratches more easily and can be challenging to weld without specialized equipment.

Steel plate and sheet products counter with superior strength and cost-effectiveness. Carbon steel delivers higher tensile strength at a lower material cost, making it ideal for structural applications, heavy equipment, and load-bearing components. The trade-off? Steel weighs significantly more and requires protective treatments to prevent rust in humid or wet environments.

Galvanized steel and other coated options address the corrosion weakness by adding zinc or other protective layers. This makes galvanized products suitable for outdoor construction, HVAC ducting, and agricultural equipment where exposure to moisture is unavoidable.

Specialty Metals and Their Applications

Beyond the aluminum versus steel decision, specialty metals serve applications where standard materials fall short.

Stainless steel sheet combines steel's strength with chromium-enhanced corrosion resistance. But here's where it gets interesting: the difference between 304 vs 316 stainless steel determines whether your part thrives or fails in its intended environment.

According to material specialists, 304 stainless steel features iron, chromium (18%), and nickel (8%), providing excellent corrosion resistance for food processing, pharmaceutical equipment, and architectural applications. It's often called the "workhorse" grade due to its versatility and cost-effectiveness.

316 stainless steel adds 2-3% molybdenum to the composition, significantly enhancing resistance to pitting and crevice corrosion. This makes 316 stainless steel the mandatory choice for marine environments, chemical processing, and medical implants where exposure to saltwater or corrosive substances occurs regularly.

Brass brings decorative appeal combined with excellent electrical conductivity. You'll find it in architectural hardware, musical instruments, and electrical connectors. When comparing brass vs bronze, remember that brass (copper-zinc alloy) machines more easily and offers brighter coloring, while bronze (copper-tin alloy) provides superior wear resistance for bearings and marine fittings.

Copper stands unmatched for thermal and electrical conductivity. Heat exchangers, electrical bus bars, and roofing applications leverage these properties extensively.

Material Properties Comparison

This table consolidates critical specifications to guide your selection:

| Property | Aluminum | Carbon Steel | 304 Stainless | 316 Stainless | Brass | Copper |

|---|---|---|---|---|---|---|

| Relative Weight | Light (2.7 g/cm³) | Heavy (7.85 g/cm³) | Heavy (8.0 g/cm³) | Heavy (8.0 g/cm³) | Medium (8.5 g/cm³) | Heavy (8.96 g/cm³) |

| Corrosion Resistance | Excellent | Poor (requires coating) | Very Good | Excellent (marine-grade) | Good | Good |

| Relative Strength | Moderate | High | High | High | Moderate | Moderate |

| Machinability | Excellent | Good | Moderate | Moderate | Excellent | Good |

| Relative Cost | Moderate-High | Low | Moderate | High | High | High |

| Typical Applications | Aerospace, automotive, signage | Structural, heavy equipment | Food equipment, architecture | Marine, chemical, medical | Decorative, electrical | Heat exchangers, electrical |

Understanding Gauge Thickness

Here's something that confuses many newcomers: sheet metal thickness is measured in gauges, and the numbering runs backwards from intuition. The higher the gauge number, the thinner the sheet metal. Common gauges range from 26 gauge (thinner) to 7 gauge (thicker) for standard fabrication work.

What do these numbers actually mean in practical terms?

- 16 gauge: Approximately 0.060 inches (1.5mm) for steel, commonly used for automotive panels and medium-duty enclosures

- 14 gauge: Approximately 0.075 inches (1.9mm), suitable for structural brackets and heavier-duty applications

- 12 gauge: Approximately 0.105 inches (2.7mm), used for heavy equipment and load-bearing components

- 10 gauge: Approximately 0.135 inches (3.4mm), approaching plate territory for serious structural work

Adding to the complexity, gauge thickness applies differently depending on the metal type. Ferrous and non-ferrous metals classified by the same gauge actually have different thicknesses. Most professional shops measure steel and stainless steel by gauge while specifying non-ferrous metals like aluminum by decimal thickness to avoid confusion.

How Material Choice Impacts Cutting Method

Your material selection directly influences which cutting technology produces optimal results. Highly reflective metals like copper and brass present challenges for certain laser wavelengths. Thick aluminum cuts beautifully with waterjet but can create excessive dross with plasma. Carbon steel cuts efficiently with plasma at thicknesses where laser becomes slow and expensive.

The relationship works both ways: if your project demands plasma cutting for cost reasons, that may eliminate certain thin-gauge materials from consideration. Understanding this interplay between material and method helps you optimize both simultaneously.

With material selection clarified, the next challenge involves translating your design into files that fabrication equipment can execute flawlessly.

Preparing Design Files for Flawless Results

You've selected your cutting method and material. Now comes the step where many projects derail: translating your design into files that fabrication equipment can actually execute. Most resources simply tell you to "submit a DXF file" without explaining what makes a file production-ready versus one that triggers revision cycles and costly delays.

Here's the reality: a poorly prepared design file can waste material, extend lead times, and produce parts that don't match your specifications. Whether you're preparing files for custom cut sheet metal or intricate decorative panels, understanding file preparation fundamentals saves time and money.

File Formats That Ensure Clean Cuts

Not all file formats carry the information fabricators need to cut metal sheet accurately. The critical distinction lies between raster and vector files.

Raster files (JPEG, PNG, GIF) store images as grids of colored pixels. Zoom in and you see individual dots. These files cannot define precise coordinates, dimensions, or cut paths. They're essentially useless for precision fabrication.

Vector files use mathematical formulas to define points, lines, and curves. This structure allows infinite scaling without quality loss and, more importantly, stores the exact geometric data cutting machines require.

According to Xometry's Sheet Metal Cutting Design Guide, these vector formats work best for custom cut metal projects:

- DXF (Drawing Exchange Format): The industry standard for 2D sheet cutting. Most quoting engines auto-process this format, and virtually all cutting machines accept it natively.

- DWG: AutoCAD's native format, fully supported by most fabricators but may require conversion.

- AI (Adobe Illustrator): Common for artistic and signage work, though conversion to DXF is often preferred.

- SVG: Suitable for simpler designs and engraving artwork.

For 3D models that define bent or formed parts, STEP (.step, .stp), SOLIDWORKS (.sldprt), and Autodesk Inventor (.ipt) formats provide complete geometric data including thickness and bend information.

Essential Design Considerations

Even with the correct format, your file must follow specific design rules to produce successful cuts. These aren't arbitrary guidelines—they reflect physical limitations of cutting processes and material behavior.

- Minimum feature size: Details should be at least 50% of material thickness or larger. Features smaller than this tend to wash out or distort during cutting. Very small holes in thick material may trend undersize or become tapered.

- Hole-to-edge distance: Maintain at least 2× material thickness or 3mm (whichever is smaller) between holes and edges. This prevents material tearing and ensures structural integrity.

- Hole-to-hole distance: Keep spacing at 6× material thickness or 3mm minimum to avoid heat distortion and maintain edge quality between features.

- Minimum slot width: Design slots at least 1mm or 1× material thickness wide, whichever is greater. Adding "lollipop" rounds at slot ends compensates for pierce-hole diameter.

- Corner fillets: Internal corners should have fillets of at least 0.5× material thickness or 3mm to prevent stress concentration and improve cutting quality.

- Bend allowances: If your part includes bends, flat patterns must account for material stretching. K-factors typically range from 0.30 to 0.50 for steel, and using inconsistent values between design and fabrication causes dimension errors.

Understanding Kerf Compensation

Kerf is the gap created by the cutting tool—the material that gets vaporized, melted, or eroded away during cutting. This width varies significantly by process:

- Laser cutting: 0.2–0.4mm typical kerf

- Waterjet cutting: 1–1.2mm typical kerf

- Plasma cutting: 3.8mm or wider

Why does this matter? Small holes effectively shrink by the kerf width, while large internal cutouts grow. If you design a 6.0mm hole for an M6 fastener, the actual cut hole might measure 5.7mm after laser cutting—too tight for assembly.

For mating parts, compensate by adding half the kerf width to inner components and subtracting half from outer profiles. Alternatively, confirm with your fabricator whether they expect nominal dimensions (they apply compensation) or pre-offset files.

Design Mistakes That Waste Material

Fabricators regularly reject or delay files containing these common errors. Eliminating them before submission dramatically reduces revision cycles:

- Duplicate or overlapping lines: The cutting machine may attempt to cut the same path twice, wasting time and potentially damaging the part.

- Open curves or broken paths: Cutting machines need closed contours to define cut boundaries. Gaps cause processing failures.

- Text as active text boxes: Convert all text to outlines or "explode" into geometry. Active text boxes may render differently on the fabricator's system.

- Stencil lettering oversight: Letters like O, D, P, and Q have enclosed areas that will fall out if cut directly. Add connecting bridges to retain interior sections.

- Stray points or empty objects: These confuse boundary detection algorithms and cause processing errors.

- Title blocks and dimensions: Include only cut-path geometry in your file. Notes, dimensions, and title blocks can be misinterpreted as features to cut.

- Incorrect scale: Always submit files at 1:1 scale. Parts get quoted and cut at the submitted dimensions—a ship drawing scaled incorrectly means scrapped material.

Layer Organization and Verification

Professional file preparation includes organizing geometry by function. Use separate layers for cut paths, engraving lines, and bend lines. This clarity helps fabricators apply correct operations and prevents engraving paths from being cut through entirely.

Before submitting, verify your file with this checklist:

- All contours closed with no gaps

- No duplicate or overlapping geometry

- Text converted to outlines

- Scale verified at 1:1

- Material type and thickness specified

- Critical tolerances and datums noted

- Layers organized by operation type

Taking time to prepare files correctly eliminates the back-and-forth that delays projects. A die cut machine or laser cutter can only execute what your file defines—clean input produces clean output. With your design files optimized, understanding the precision standards your parts must meet becomes the next essential consideration.

Tolerances and Precision Standards Explained

You've prepared your design files and specified your material. But here's a question that separates successful projects from frustrating failures: what precision can you actually expect from your finished parts? Most fabricators hide tolerance specifications behind quote request forms, leaving you guessing whether their capabilities match your requirements.

Understanding tolerances isn't just technical trivia—it directly determines whether your parts fit together, function correctly, and meet quality standards. Let's demystify what these numbers actually mean for your project.

What Tolerance Specs Actually Mean

When a fabricator quotes ±0.13mm accuracy, what does that translate to in practical terms? This specification means any given dimension on your finished part may vary by up to 0.13mm above or below the nominal value. For a 100mm square panel, the actual measurement could range from 99.87mm to 100.13mm and still fall within specification.

Sounds tight, right? It is—for many applications. But context matters enormously. Consider these scenarios:

- A decorative wall panel: ±0.5mm variation is invisible to the eye and functionally irrelevant

- An equipment enclosure: ±0.25mm ensures panels align without visible gaps

- A mechanical assembly: ±0.13mm allows components to mate with predictable clearances

- A precision instrument housing: ±0.05mm may be required for optical or sensor alignment

The critical insight? Precision is not the same across all manufacturing methods. A designer cannot expect machining-like tolerances from sheet metal fabrication. Understanding this reality helps you specify appropriate requirements and avoid unnecessary costs.

Steel Gauge Thickness and Achievable Precision

Here's something many newcomers miss: material thickness directly impacts achievable tolerances. When referencing a sheet metal gauge chart, remember that thicker materials present greater challenges for precision cutting.

Why does metal gauge thickness matter for tolerances? Several factors compound as thickness increases:

- Beam divergence: Laser beams spread slightly as they penetrate deeper, creating taper on cut edges

- Heat accumulation: Thicker cuts require more energy, expanding the heat-affected zone

- Kerf variation: The cut width varies more significantly through thicker material

- Edge quality degradation: Surface finish typically decreases with increased thickness

For example, cutting 16 gauge steel thickness (approximately 1.5mm) with laser technology routinely achieves ±0.1mm tolerances with excellent edge quality. Move to 14 gauge steel thickness (approximately 1.9mm), and tolerances may widen to ±0.15mm. By the time you reach 10 gauge sizes (approximately 3.4mm), expect tolerances of ±0.2mm or wider depending on geometry complexity.

This relationship explains why tolerance specifications should always reference both the precision value and the material gauge size chart conditions under which it applies.

When Precision Matters Most

Not every part requires ultra-tight tolerances, and specifying unnecessary precision wastes money. Categorizing your application helps determine appropriate requirements:

Looser Tolerances (±0.5mm to ±1.0mm):

- Decorative panels and signage

- Non-mating covers and shields

- Architectural elements with flexible mounting

- Prototypes for visual evaluation only

Standard Tolerances (±0.2mm to ±0.4mm):

- General-purpose enclosures

- Brackets with standard mounting holes

- HVAC components and ducting

- Equipment housings with moderate fit requirements

Tight Tolerances (±0.1mm to ±0.2mm):

- Mechanical assemblies with mating parts

- Automotive components requiring precise alignment

- Electronic enclosures with specific port locations

- Parts requiring consistent press-fit connections

Precision Tolerances (±0.05mm to ±0.1mm):

- Optical instrument housings

- Medical device components

- Aerospace assemblies with critical interfaces

- High-precision sensor mounts

The Stacking Tolerance Challenge

Individual feature tolerances only tell part of the story. When multiple features must relate to each other—especially across bends—tolerances stack and compound.

According to Protolabs' tolerance guidance, crossing four bends while measuring hole-to-hole gives a linear tolerance of ±0.762mm (±0.030 in.) plus a stacking angular tolerance of 1° per bend. This means features on opposite sides of a bent part have significantly less positional accuracy than features on the same flat surface.

What can you do to manage this? Design strategies include:

- Opening holes slightly to allow for positional variation

- Using floating hardware that accommodates misalignment

- Locating critical features on the same surface when possible

- Specifying datum references for inspection

Quality Inspection Criteria

When fabricators advertise quality records like "99.3% conformance," what does that actually represent? These metrics typically measure the percentage of parts that pass dimensional verification against specified tolerances. A 99.3% rate means roughly 7 parts per 1,000 require rework or rejection.

Comprehensive quality inspection includes three primary assessments:

Dimensional Verification: Measuring critical dimensions against specified tolerances using calibrated instruments. First article inspection verifies the initial production piece before full runs proceed.

Edge Quality Assessment: Evaluating cut edges for burrs, dross, striations, and heat discoloration. Laser cutting typically produces cleaner edges requiring less secondary finishing than plasma cutting.

Surface Finish Standards: Checking for scratches, handling marks, and material defects that affect appearance or function. Ra (roughness average) measurements quantify surface texture when specifications require it.

As industry experts emphasize, implementing robust quality control processes is vital for ensuring fabricated parts meet specified tolerances. Statistical process control methods monitor consistency across production runs, catching drift before it produces non-conforming parts.

With tolerances and quality standards clarified, the next consideration involves how secondary operations and finishing treatments complete your parts for their intended application.

Finishing Options From Powder Coating to Anodizing

Your parts are cut to specification and verified for dimensional accuracy. But here's what many project planners overlook: raw cut metal rarely goes directly into service. Secondary operations and finishing treatments transform bare metal into production-ready components that resist corrosion, meet aesthetic requirements, and perform reliably in their intended environment.

Most fabrication resources mention finishing options without explaining how they work or when each applies. Let's change that by exploring the complete post-cutting workflow and the finishing treatments that protect your investment.

The Complete Fabrication Workflow

Understanding how secondary operations connect helps you plan projects effectively. After cutting, parts typically flow through these stages:

- Deburring: Removing sharp edges and burrs created during cutting

- Bending and forming: Creating three-dimensional shapes from flat patterns

- Welding or assembly: Joining multiple components when required

- Surface preparation: Cleaning and conditioning for finishing

- Finishing treatment: Applying protective or decorative coatings

The relationship between cutting method and finishing requirements matters significantly. Laser cutting produces clean edges that often require minimal deburring—sometimes just a light tumble or hand break of sharp corners. Plasma cutting, by contrast, creates rougher edges with more dross buildup, demanding substantial grinding or sanding before parts are finish-ready. This difference can add hours of labor and should factor into your method selection.

Similarly, bending operations must occur before most finishing treatments. You cannot powder coat a flat blank and then bend it—the coating would crack at the bend lines. Planning this sequence correctly prevents rework and ensures consistent finish quality across your entire part.

Powder Coating for Durability and Color

When you need a tough, attractive finish in virtually any color imaginable, powder coat technology delivers. Unlike traditional liquid paints, powder coating involves dry powders that are electrostatically charged and cured with heat. This process creates a finish that resists corrosion, chipping, and fading far better than conventional paint.

How does the process work? First, parts undergo thorough cleaning to remove oils, dirt, and contaminants—proper surface preparation is crucial for adhesion. Then, electrically charged powder particles are sprayed onto grounded metal surfaces using Electrostatic Spray Deposition (ESD). The electrostatic attraction ensures even coverage, even in recessed areas. Finally, coated parts enter curing ovens at 325–450°F (163–232°C) for 10–30 minutes, where the powder melts and forms a continuous, durable film.

The advantages extend beyond durability:

- Environmental benefits: Powder coating emits minimal volatile organic compounds (VOCs) and produces negligible hazardous waste

- Efficiency: Transfer efficiency approaches 98% since overspray can be reclaimed and reused

- Versatility: Available in matte, satin, gloss, metallic, and textured finishes matching Pantone and RAL color standards

- Thickness control: Produces uniform coatings typically 2–6 mils thick, offering superior protection

Powder coating services suit applications including outdoor furniture, automotive components, architectural elements, and industrial equipment. However, be aware of limitations: some polymers and composites cannot withstand curing temperatures, and achieving very thin films proves challenging. For high-impact areas, specifying impact-resistant formulations prevents chipping under stress.

Surface Treatments That Extend Part Life

Beyond powder coating, several finishing options address specific performance requirements. Selecting the right treatment depends on your material, environmental exposure, and functional needs.

Anodizing for Aluminum Protection

If you're working with aluminum sheet metal, anodizing provides corrosion resistance through electrochemical conversion rather than applied coatings. The process thickens the natural oxide layer on aluminum surfaces, creating an extremely hard, wear-resistant finish that becomes part of the metal itself.

Anodized aluminum offers excellent weather resistance and a degree of electrical insulation. The anodic film's hardness makes it particularly valuable for components subject to abrasion or handling. Color options exist through dye absorption into the porous oxide layer before sealing, though the range is more limited than powder coating.

According to surface treatment specialists, anodizing is particularly known for its weather resistance and film hardness, making it beneficial for outdoor applications. However, powder coating can offer superior corrosion resistance in harsh environments due to its thicker protective layer.

Plating Options

Electroplating deposits thin metal layers onto substrates, providing specific functional or decorative properties:

- Zinc plating: Provides sacrificial corrosion protection for steel components at low cost. The zinc corrodes preferentially, protecting the underlying steel even if scratched.

- Nickel plating: Offers excellent corrosion resistance with an attractive silvery appearance. Commonly used as an undercoat for chrome or as a standalone finish for hardware.

- Chrome plating: Delivers the bright, mirror-like finish associated with automotive trim and decorative hardware. Hard chrome plating provides exceptional wear resistance for industrial applications.

Electroless nickel plating deserves special mention. This chemical process deposits nickel without electrical current, providing uniform coverage on complex geometries that electroplating cannot achieve. The resulting finish offers excellent corrosion resistance and can be applied to non-conductive substrates with proper preparation.

Passivation

For stainless steel components, passivation strengthens the natural protective oxide layer. This chemical treatment removes free iron from the surface and promotes formation of a chromium-rich passive layer that resists corrosion. Passivation is essential after fabrication operations that may have contaminated stainless steel surfaces.

Finishing Selection Guide

Matching the right finish to your application requires evaluating three key factors:

Environmental Exposure:

- Indoor, climate-controlled: Minimal protection needed; decorative finishes sufficient

- Indoor, humid or chemical exposure: Powder coating or plating for corrosion resistance

- Outdoor, temperate: Powder coating, anodizing, or galvanizing

- Outdoor, marine or industrial: 316 stainless steel with passivation, or heavy-duty powder coating systems

Aesthetic Requirements:

- Specific color matching: Powder coating offers the broadest palette

- Metallic appearance: Anodized aluminum, chrome plating, or metallic powder coats

- Natural metal look: Clear anodizing or passivation preserves base metal appearance

- Textured surfaces: Powder coating with texture additives or media blasting

Functional Needs:

- Electrical conductivity required: Many finishes insulate; plating maintains conductivity

- High wear resistance: Hard anodizing or hard chrome plating

- Food contact safety: Specific powder coating formulations or stainless steel with passivation

- Heat dissipation: Some coatings insulate; anodizing maintains thermal properties

The interplay between cutting, bending, and finishing creates a complete fabrication workflow. Planning these operations together—rather than treating finishing as an afterthought—ensures your parts arrive ready for installation or assembly. With finishing options clarified, understanding how these choices and other factors influence project costs becomes the next essential consideration.

Cost Factors and Pricing Transparency

Ever wonder why custom metal cutting quotes vary so dramatically between providers? The pricing structure for metal sheets and fabricated components involves multiple variables that most fabricators never explain. Understanding these factors empowers you to optimize your designs, make informed material choices, and ultimately get better value from your fabrication budget.

Let's pull back the curtain on what actually drives costs in custom metal cutting projects.

What Drives Custom Cutting Costs

Five primary factors determine what you'll pay for fabricated metal plate and sheet components. Here they are, ranked by their typical impact on your final invoice:

- Material cost per square foot: The base metal represents your largest expense. Steel plates cost less than aluminum, which costs less than stainless sheet materials. According to industry cost guides, mild steel's affordability makes it popular for cost-conscious projects, while aluminum's higher cost per kilogram reflects its lightweight properties and corrosion resistance.

- Cutting time based on complexity: Intricate designs with tight curves, numerous holes, and fine details require longer cutting times. Complex geometry can more than double per-part costs—a thin, intricate aluminum component might run $27 each compared to simpler designs at half that price.

- Setup fees for small runs: The first part of any production run costs the most. Machine programming, material loading, and quality verification occur regardless of quantity. These fixed costs spread across larger orders but concentrate heavily on single pieces.

- Finishing and secondary operations: Powder coating, plating, anodizing, and deburring add significant cost. That same $27 aluminum part jumps to $43 with powder coating—a 59% increase for the finish alone.

- Shipping considerations: Weight, dimensions, and destination all factor in. Some suppliers offer free shipping above certain thresholds, effectively building logistics costs into material pricing.

Material selection deserves special attention because it impacts multiple cost factors simultaneously. Alu sheets cut faster than steel at equivalent thicknesses, potentially offsetting higher material costs through reduced machine time. Stainless sheet products cost more upfront but eliminate finishing expenses for corrosion-prone environments.

Quantity Breaks and Volume Pricing

Here's where understanding fabrication economics really pays off. The relationship between quantity and per-piece cost follows a predictable pattern that savvy buyers exploit.

Consider this real-world example: a small zinc-plated steel component costs approximately $29 for a single piece, but drops to just $3 per part when ordering ten—an 86% reduction. Why such a dramatic difference?

Setup costs remain fixed regardless of quantity. Programming the cutting path, loading material, and running first-article inspection take the same time whether you're making one part or one hundred. When you order a single piece, that entire setup cost lands on one unit. Order fifty pieces, and setup cost divides across all of them.

Most materials see discounts starting with the second part and continuing through bulk orders. The discount curve steepens at common break points:

- 2-10 pieces: Initial quantity discount kicks in

- 25-50 pieces: Material purchasing efficiency improves

- 100+ pieces: Production run efficiency maximizes savings

- 500+ pieces: Dedicated tooling or nesting optimization becomes viable

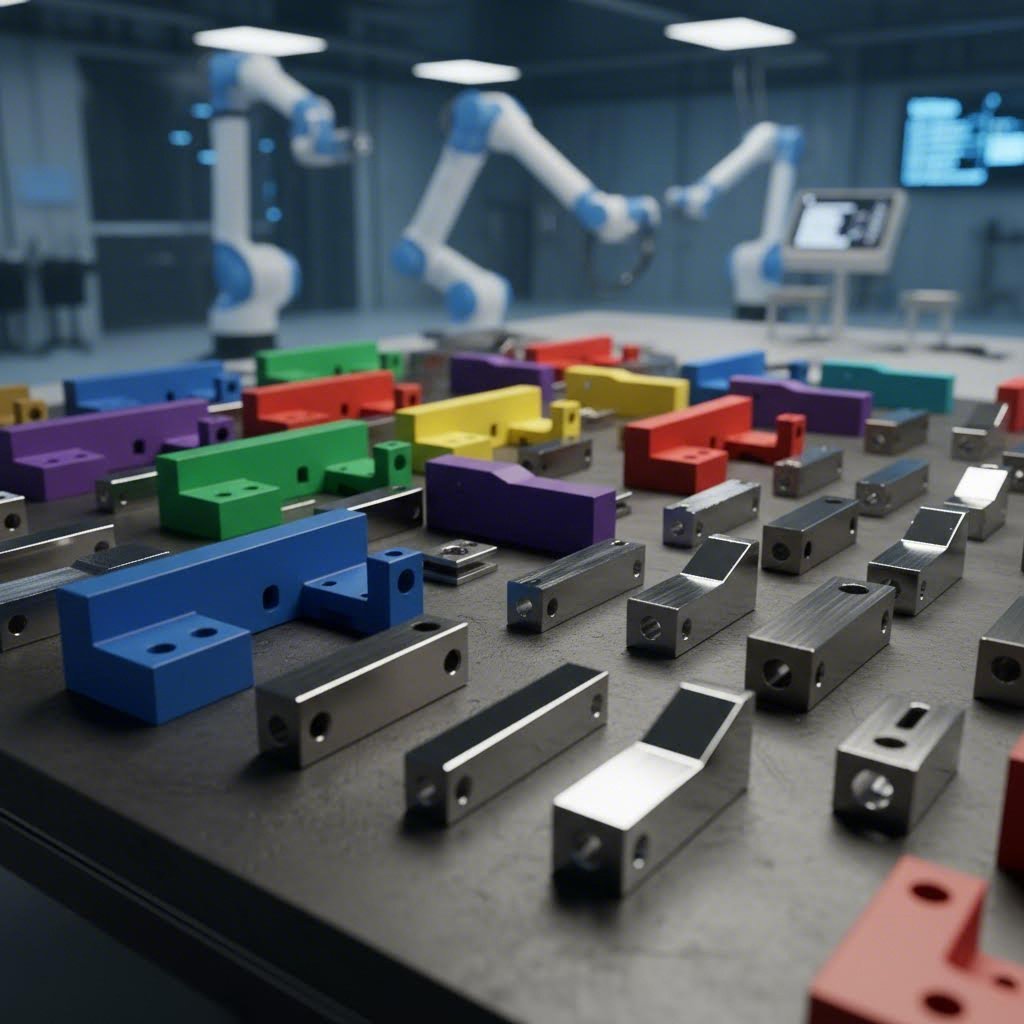

Prototyping vs. Production Trade-offs

Rapid prototyping and production runs represent opposite ends of a cost-speed spectrum. Understanding this trade-off helps you budget appropriately for each project phase.

Rapid prototyping delivers parts quickly—often within days—but at premium per-piece pricing. You're paying for flexibility, fast turnaround, and the ability to iterate designs without large commitments. This makes sense when validating concepts, testing fit and function, or meeting urgent deadlines.

Production runs sacrifice speed for economy. Longer lead times allow fabricators to batch your work efficiently, optimize material nesting, and schedule operations for maximum throughput. Per-piece costs drop substantially, but you're committing to larger quantities and longer timelines.

The strategic approach? Prototype in small quantities to validate designs, then transition to production quantities once specifications are locked. Attempting production pricing on prototype quantities—or expecting prototype speed on production runs—leads to frustration and budget overruns.

Design Optimization for Cost Efficiency

Smart design decisions made early reduce costs without compromising function. Three strategies offer the highest impact:

Optimize for nesting: Fabricators arrange multiple parts on a single sheet to minimize waste. Designing parts that nest efficiently—with complementary shapes that fit together like puzzle pieces—reduces material consumption. Rectangular parts with consistent orientations nest better than irregular organic shapes.

Select materials strategically: According to fabrication cost experts, material selection directly impacts waste, production speed, and overall quality. Ask whether you truly need the extra strength of 6061 aluminum when 5052 serves the application at lower cost. Consider whether stainless steel's built-in corrosion resistance eliminates finishing costs that would apply to carbon steel.

Specify appropriate tolerances: Tighter tolerances cost more to achieve and verify. Specifying ±0.1mm when ±0.3mm works perfectly well adds expense without functional benefit. Reserve precision specifications for features that genuinely require them.

These cost factors interact with every aspect of your project—from initial material selection through final finishing. With pricing fundamentals clarified, exploring specific applications where custom metal cutting delivers critical value helps contextualize these investments.

Automotive and Industrial Applications

Where does custom metal sheet cutting deliver the most critical value? Look no further than the automotive and industrial sectors, where precision components directly impact safety, performance, and reliability. These industries demand fabricated parts that meet exacting specifications while withstanding extreme conditions—from high-temperature engine bays to punishing suspension loads.

Understanding how sheet metal fabrication serves these demanding applications helps you appreciate why material selection, cutting precision, and quality certifications matter so much. Let's explore the specific components that depend on precision metal cutting and what separates adequate fabrication from automotive-grade excellence.

Automotive Components That Demand Precision

Modern vehicles contain hundreds of custom-fabricated metal components, each engineered for specific performance requirements. Unlike decorative applications where minor variations go unnoticed, automotive parts must fit precisely, withstand repeated stress cycles, and maintain structural integrity over years of service.

The most critical applications for steel fabrication and precision cutting in automotive include:

- Chassis mounting brackets: These components anchor suspension systems, engine mounts, and body panels to the vehicle frame. They require high tensile strength to handle dynamic loads and precise hole placement for bolt-pattern alignment.

- Suspension components: Control arms, shock absorber mounts, and stabilizer brackets endure constant stress from road impacts. Suspension and steering systems require robust, high-precision metal parts to ensure handling and durability throughout the vehicle's lifespan.

- Heat shields: Positioned near exhaust systems and engine compartments, these laser-cut components protect sensitive wiring and fuel lines from thermal damage. Material selection and precise fit are critical for effective heat management.

- Structural reinforcements: Reinforced frame supports provide impact resistance in crash zones. These components demand consistent material properties and dimensional accuracy to perform as engineered during collision events.

Beyond structural components, automotive metal fab extends to battery enclosures for electric vehicles, custom brackets for electronic systems, and precision-stamped trim pieces. Each application brings unique requirements for material grade, surface finish, and dimensional tolerance.

Why Tensile Strength and Material Properties Matter

Automotive components face loading conditions that expose any weakness in material selection or fabrication quality. A suspension bracket might experience thousands of stress cycles daily—each pothole, turn, and braking event transfers forces through these precision-cut parts.

This is why steel fabricators serving automotive clients pay close attention to material certifications and mechanical properties. Tensile strength specifications ensure components won't stretch or deform under load. Yield strength indicates the stress level at which permanent deformation begins. Impact resistance determines behavior in sudden loading events.

Ferrous metals like carbon steel and high-strength low-alloy (HSLA) grades dominate structural applications due to their favorable strength-to-cost ratio. For lightweight performance applications, aluminum alloys provide significant weight savings, though they require different cutting parameters and joining techniques.

Industrial Applications Across Sectors

Beyond automotive, precision sheet metal fabrication serves industrial applications where reliability and durability justify the investment in quality fabrication:

- Heavy equipment manufacturing: Excavators, agricultural machinery, and material handling equipment rely on precision-cut steel plates for structural frames and wear components.

- Aerospace structures: Aircraft skins, brackets, and mounting hardware demand the tightest tolerances and complete material traceability.

- Energy sector: Electrical enclosures, transformer housings, and renewable energy mounting systems require corrosion-resistant materials with precise dimensions.

- Medical equipment: Diagnostic equipment housings and surgical device components need biocompatible materials cut to exacting specifications.

Joining methods add another layer of complexity in industrial applications. Spot welding welding techniques efficiently join overlapping sheet metal components for high-volume production. Aluminum welding requires specialized equipment and expertise due to the material's thermal properties and oxide layer formation. Understanding these downstream operations influences cutting specifications and material selection from the project's outset.

The Importance of IATF 16949 Certification

When sourcing components for automotive applications, one certification stands above others: IATF 16949. This automotive-specific quality management standard goes far beyond basic ISO requirements to address the unique demands of automotive supply chains.

Why does this certification matter for your custom metal cutting projects? According to automotive industry specialists, IATF 16949 is not just a quality system certification—it's a holistic review of a supplier's systems including supply chain diversification, risk management, response procedures, and continuous improvement processes.

The automotive task force developed this standard specifically to address supply chain disruption risks within complex automotive manufacturing. Recent global events have demonstrated how disruptions can cascade through supply lines, causing costly line-down situations. Suppliers with IATF certification have documented systems in place to:

- Monitor and mitigate supply disruption potential

- Ensure consistent product quality through statistical process control

- Maintain material traceability from raw stock through finished parts

- Respond systematically to quality issues or delivery challenges

For OEMs and Tier 1 suppliers, requiring IATF 16949 certification from metal fabrication partners reduces audit burden while ensuring consistent quality. It's becoming commonplace for automotive manufacturers to mandate this certification precisely because its value has been demonstrated in keeping supply arrangements running smoothly.

Complete Automotive Fabrication Solutions

The most demanding automotive applications require more than standalone cutting capabilities. Complete solutions integrate custom metal stamping with precision cutting, bending, and finishing operations to deliver assembly-ready components.

Manufacturers like Shaoyi (Ningbo) Metal Technology exemplify this integrated approach, combining IATF 16949-certified quality systems with comprehensive fabrication capabilities. Their 5-day rapid prototyping capability allows automotive engineers to validate designs quickly before committing to production tooling. This speed-to-prototype matters enormously when development timelines compress and design iterations must happen fast.

What should you look for in an automotive-focused fabrication partner?

- Certified quality systems: IATF 16949 certification demonstrates commitment to automotive-grade quality management

- Integrated capabilities: Stamping, cutting, bending, and finishing under one roof reduces coordination complexity and lead times

- Rapid prototyping: The ability to produce prototype quantities in days rather than weeks accelerates development cycles

- DFM support: Design for manufacturability expertise helps optimize parts for cost-effective production

- Material expertise: Deep knowledge of automotive-grade materials and their fabrication requirements

Whether you're developing chassis components, suspension brackets, or structural reinforcements, working with a fabrication partner who understands automotive requirements from the outset prevents costly redesigns and quality issues downstream. The investment in proper certification and capabilities pays dividends throughout the product lifecycle.

With automotive and industrial applications clarified, selecting the right fabrication partner becomes the final—and perhaps most consequential—decision in your custom metal cutting journey.

Selecting the Right Custom Cutting Partner

You've defined your project requirements, selected materials, and prepared design files. Now comes the decision that determines whether your custom metal cutting project succeeds or stalls: choosing the right fabrication partner. Searching for "metal fabrication near me" returns dozens of options, but how do you separate capable partners from those who'll miss deadlines, exceed budgets, or deliver substandard quality?

The challenge intensifies because most fabrication shops offer similar services on paper. The true differences emerge in capabilities, quality systems, and communication practices that only become apparent during production—often too late to course correct. Let's walk through the evaluation criteria that distinguish reliable partners from risky choices.

Evaluating Service Provider Capabilities

Before requesting quotes from fabrication shops near me or sheet metal fabrication near me searches, establish your evaluation framework. These criteria help you assess whether a provider can actually deliver what your project demands:

- Certifications (ISO, IATF): ISO 9001:2015 certification demonstrates that a company has implemented an effective quality management system with documented procedures for monitoring and continuous improvement. For automotive applications, IATF 16949 certification indicates automotive-specific quality standards addressing supply chain reliability and risk management.

- Equipment capabilities: Does the fabricator operate the cutting technology your project requires? Full-service facilities like those described by industry experts maintain laser cutting, plasma cutting, waterjet cutting, CNC machining, and precision forming under one roof. This integration provides tighter control over production and faster turnaround times.

- Material options: A capable partner stocks or readily sources the materials your project requires—whether custom metal plate specifications, custom steel plate grades, or specialty alloys. Limited material options may force compromises that affect final part performance.

- Turnaround times: Can they meet your timeline for both prototypes and production runs? Some projects require rapid response while others prioritize cost efficiency over speed.

- Design support services: Does the fabricator offer engineering consultation, CAD/CAM support, and prototype testing? This capability proves essential for complex projects requiring design optimization.

Red flags emerge when providers cannot clearly answer questions about any of these criteria. Vague responses about certifications, reluctance to discuss equipment specifics, or inability to provide timeline estimates suggest operational gaps that will surface during your project.

The Value of DFM Support

Here's something that separates good fabrication partners from great ones: Design for Manufacturability support. According to product development specialists, if design happens without considering manufacturing early on, costs can increase significantly. A design that isn't optimized for manufacturing might require major modifications, increasing lead times and expenses.

What does DFM support actually provide?

- Material selection guidance: Recommending materials that balance performance requirements with cost and manufacturability. If similar products can use shared components, economies of scale can be leveraged.

- Process alignment: Ensuring your design suits the intended manufacturing method. Sheet metal components have defined limits for bend radii, and understanding these constraints from the outset prevents unnecessary rework.

- Cost optimization: Identifying design modifications that reduce production costs without compromising function. This might involve adjusting tolerances, modifying hole patterns for better nesting, or simplifying geometry.

- Prototype-to-production planning: Ensuring designs tested in prototype form translate smoothly into high-volume manufacturing.

Partners like Shaoyi (Ningbo) Metal Technology demonstrate this integrated approach by combining comprehensive DFM support with rapid prototyping capabilities. Their 5-day prototyping turnaround allows engineers to validate DFM-optimized designs quickly before committing to production tooling.

Questions to Ask Before Ordering

When evaluating metal fabricators near me, these questions reveal capabilities that marketing materials often obscure:

About Quality Systems:

- What certifications do you hold, and when were they last audited?

- What inspection equipment and processes verify dimensional accuracy?

- How do you handle non-conforming parts discovered during production?

- Can you provide first-article inspection reports?

About Capabilities:

- Which cutting technologies do you operate in-house versus outsource?

- What material thicknesses and sheet sizes can you accommodate?

- Do you offer secondary operations like bending, welding, and finishing?

- What CAD file formats do you accept and prefer?

About Communication and Responsiveness:

- What is your typical quote turnaround time?

- How do you communicate project updates and potential issues?

- Do you offer engineering support for design optimization?

- What happens if specifications need to change mid-production?

Quote turnaround time deserves special attention as an indicator of operational efficiency. A fabricator who responds with detailed quotes within 12 hours demonstrates streamlined processes and adequate engineering bandwidth. Providers taking days or weeks to quote simple projects often struggle with capacity management—a challenge that will likely affect your production timeline too.

Experience and Industry Knowledge

A fabricator's experience translates directly into project outcomes. As industry experts note, years in business often translate into deeper material knowledge, refined processes, and the ability to anticipate challenges before they become costly problems.

Before choosing a partner, ask:

- How long have they been fabricating complex metal parts?

- Do they have experience in your industry or with similar applications?

- Can they share examples, case studies, or references?

Industry-specific experience matters particularly for regulated applications. Automotive, aerospace, and medical device fabrication each bring unique certification requirements, material traceability expectations, and quality documentation needs. A fabricator experienced in construction signage may lack the quality systems infrastructure that automotive Tier 1 suppliers require.

Scalability and Long-Term Partnership Potential

Your ideal partner supports both current needs and future growth. A fabrication company must be able to scale production from prototypes to full production runs without sacrificing quality. This scalability depends on:

- Capacity flexibility: Can they ramp production up or down based on your demand?

- Equipment redundancy: If a critical machine goes down, can they continue production?

- Supply chain stability: Do they maintain relationships with multiple material suppliers?

- Workforce depth: Are they dependent on a few key individuals, or is knowledge distributed?

Transparent communication proves equally critical for long-term partnerships. A reliable fabricator provides clear timelines, proactive project updates, and realistic expectations from the start. Strong communication prevents costly surprises and keeps projects aligned from quote through delivery.

Hiring a fabricator isn't just a purchasing decision—it's a long-term investment in the performance and reliability of your products.

For automotive-focused projects requiring IATF 16949-certified quality, integrated stamping and cutting capabilities, and rapid prototype turnaround, Shaoyi's automotive stamping solutions demonstrate the comprehensive approach that complex projects demand. Their 12-hour quote turnaround, 5-day rapid prototyping, and complete DFM support exemplify the responsiveness and capability benchmarks to seek in any fabrication partner.

The fabrication partner you select becomes an extension of your engineering and manufacturing capabilities. Choose based on demonstrated competence, certified quality systems, and communication practices that match your project's demands—and you'll build a relationship that delivers value far beyond the first order.

Frequently Asked Questions About Custom Metal Sheet Cutting

1. How much does custom metal sheet cutting cost?

Custom metal sheet cutting costs depend on material type, thickness, design complexity, quantity, and finishing requirements. Expect $0.50 to $2 per linear inch for basic cuts, while complete fabricated parts range from $4 to $48 per square foot. Single prototypes cost significantly more per piece than production runs due to fixed setup fees. For example, a zinc-plated steel component might cost $29 for one piece but drop to $3 each when ordering ten units. Material choice dramatically impacts pricing—mild steel costs less than aluminum or stainless steel. Adding powder coating or other finishes can increase part costs by 50-60%.

2. What cutting method is best for my metal sheet project?

The optimal cutting method depends on your material, thickness, and precision requirements. Laser cutting delivers ultra-fine precision (±0.05mm to ±0.1mm) and clean edges for thin sheets under 25mm, making it ideal for intricate designs and electronics enclosures. Waterjet cutting eliminates heat distortion entirely, cutting materials up to 200mm thick including non-metals—perfect for aerospace or heat-sensitive applications. Plasma cutting offers the fastest, most cost-effective solution for thick conductive metals over 12mm, commonly used in structural steel fabrication. Many professional fabrication shops maintain multiple cutting technologies because no single method covers every application.

3. Will a hardware store cut metal sheets for me?

Most hardware stores offer basic pipe cutting services but cannot provide precision custom metal sheet cutting. Custom sheet cutting requires specialized equipment like fiber lasers, waterjets, or CNC plasma systems that hardware stores don't operate. For custom dimensions, intricate shapes, or tight tolerances, you'll need a professional metal fabrication service. Online fabrication platforms accept DXF or STEP files and deliver custom-cut parts within days. Local fabrication shops can handle complex projects with secondary operations like bending, welding, and finishing that hardware stores simply cannot provide.

4. What file formats are needed for custom metal cutting?

Vector file formats are essential for precision metal cutting—raster files like JPEG or PNG cannot be used. DXF (Drawing Exchange Format) is the industry standard that most quoting engines auto-process and all cutting machines accept. DWG files from AutoCAD work with most fabricators but may require conversion. For 3D models with bends, submit STEP (.step, .stp), SOLIDWORKS (.sldprt), or Autodesk Inventor (.ipt) formats. Ensure files are at 1:1 scale with closed contours, no duplicate lines, and text converted to outlines. Proper file preparation reduces revision cycles and prevents costly production delays.

5. How do I choose between aluminum and steel for custom cutting?

Choose aluminum when weight reduction matters—it's roughly one-third the weight of steel with natural corrosion resistance, making it ideal for aerospace, automotive body panels, and outdoor signage. However, aluminum costs more per pound and has lower tensile strength. Steel delivers superior strength at lower material cost, perfect for structural applications, heavy equipment, and load-bearing components. The trade-off is significantly more weight and rust susceptibility without protective coatings. For marine or humid environments, consider galvanized steel or 316 stainless steel. Material choice also impacts cutting method selection—highly reflective metals like aluminum may require specific laser wavelengths.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —