Metal Press Dies Decoded: From Raw Steel To Precision Parts

What Are Metal Press Dies and How Do They Work

Have you ever wondered how manufacturers produce thousands of identical metal parts with remarkable precision? The answer lies in metal press dies—specialized tools that transform flat sheet metal into everything from automotive components to electronic enclosures.

Simply put, metal press dies are precision-engineered tools used in stamping operations to shape, cut, or form sheet metal into specific configurations. According to industry experts at The Fabricator, a stamping die is "a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile." These tools range dramatically in size—from tiny dies that fit in your palm for microelectronics to massive 20-foot structures used for automobile body panels.

When you're searching for a quality die for sale, understanding how these tools function is essential to making the right choice for your manufacturing needs.

The Basic Mechanics of Press Die Operations

Imagine placing a cookie cutter on dough and pressing down. Press dies work on a similar principle, but with far greater force and precision. The die works in conjunction with a press machine that provides the necessary force—sometimes cycling as fast as 1,500 strokes per minute.

Here's what happens during each press cycle: the press ram descends, bringing the upper die components down onto the sheet metal positioned on the lower die section. This action either cuts through the material, bends it into shape, or both. Stamping is considered a cold-forming operation, meaning no external heat is intentionally applied. However, friction during cutting and forming generates enough heat that finished parts often exit the dies quite warm.

The force required depends on the material thickness, type of operation, and part complexity. Cutting operations stress the metal to its failure point, producing characteristic edge conditions that experienced operators can read like a signature.

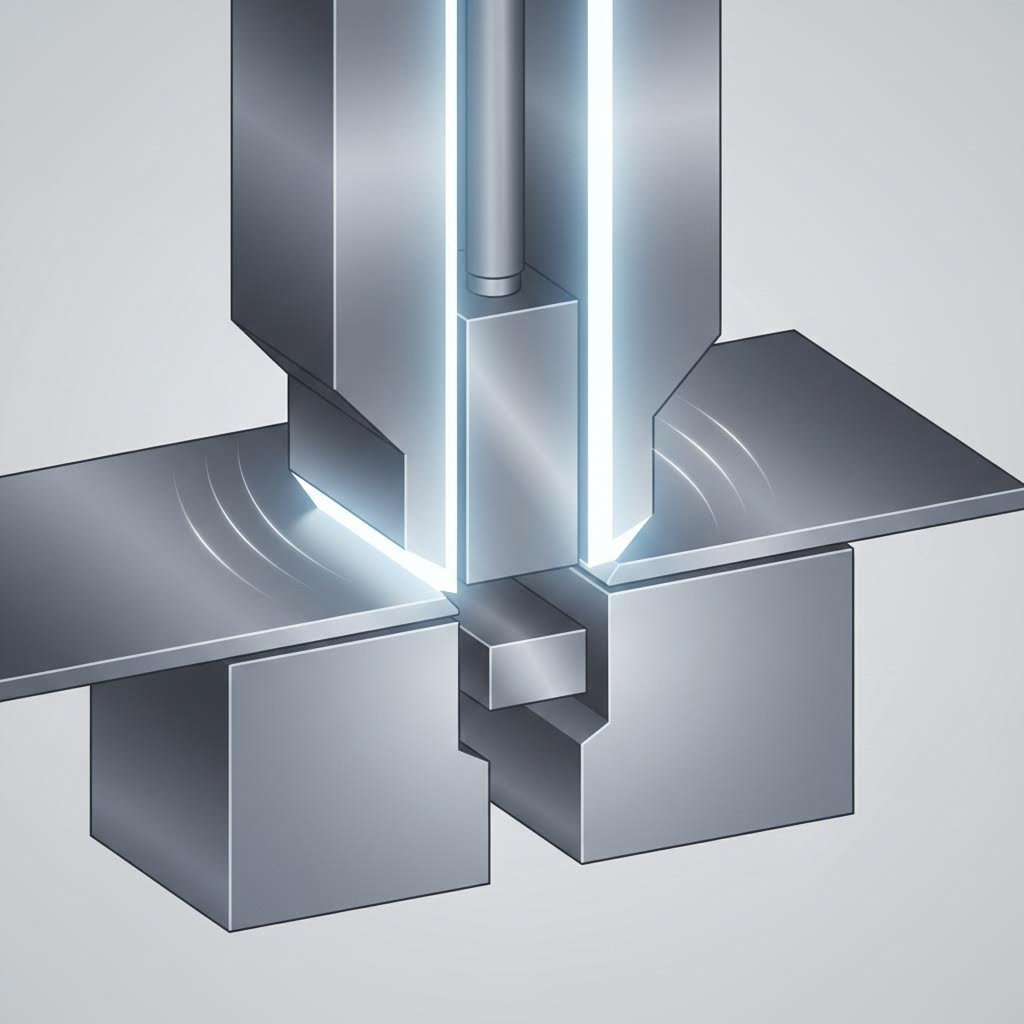

Understanding Punch and Die Relationships

The relationship between the punch and die is fundamental to every press die operation. Think of them as two halves of a precision puzzle that must work together perfectly.

The punch serves as the male component—a hardened tool that presses into or through the workpiece material. The die acts as the female component, providing the cavity or opposing surface that shapes the metal when the punch makes contact. The small gap between these two components, called cutting clearance, is critical. This clearance is typically expressed as a percentage of material thickness, with approximately 10 percent being most common for standard cutting operations.

When shopping for a die for sale, always verify that the punch and die clearances match your specific material requirements.

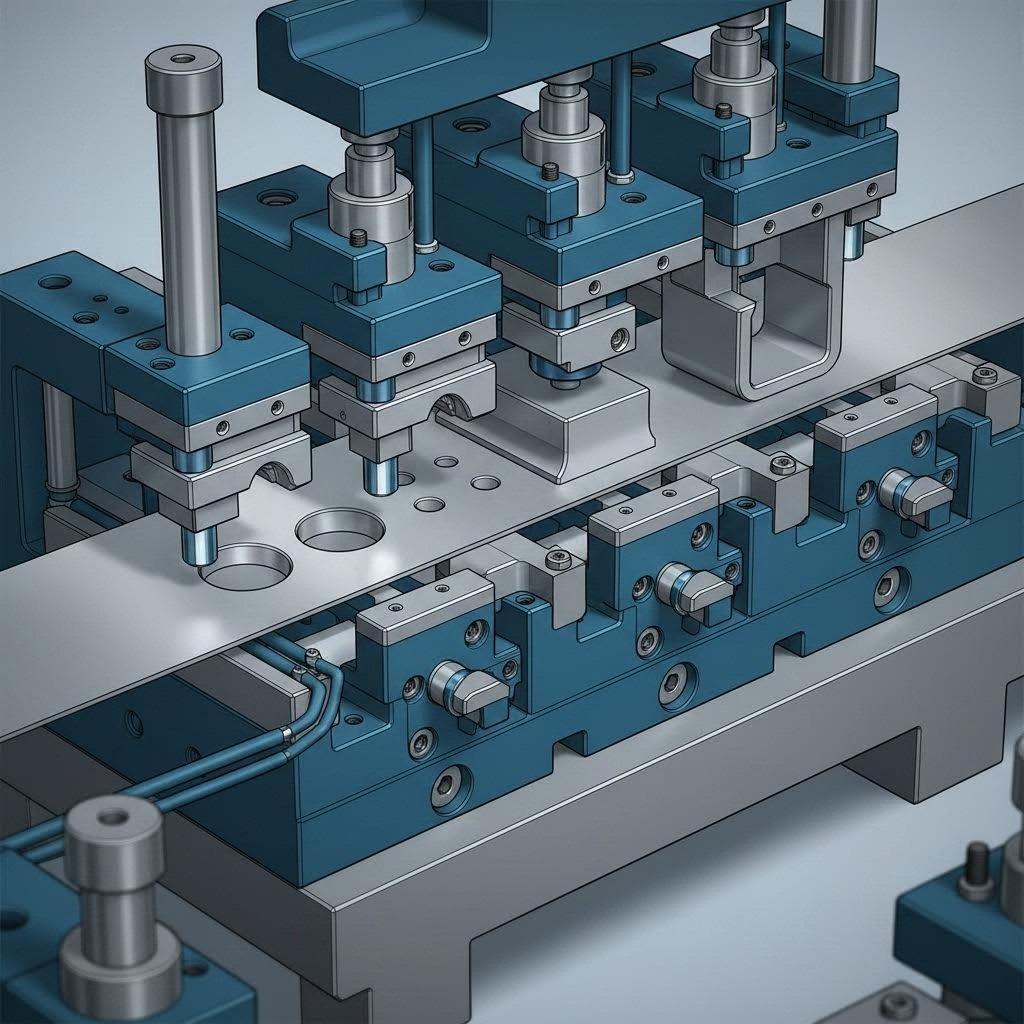

Every functional press die relies on several core components working in harmony:

- Punch: The male cutting or forming tool that delivers force to the workpiece

- Die Block: The female component containing the cavity or cutting edge that receives the punch

- Die Shoes: Heavy steel plates (upper and lower) that serve as the foundation for all other components and maintain critical alignment

- Stripper Plate: Holds the material flat and strips it from the punch after each operation

- Guide Pins: Precision posts that ensure proper alignment between upper and lower die sections during every stroke

The die shoes deserve special attention because they're the unsung heroes of consistent part quality. These substantial steel plates keep every component precisely aligned stroke after stroke, ensuring that your punch and die relationship remains constant throughout production runs. Without properly maintained die shoes, even the best-designed press die will produce inconsistent results.

Understanding these fundamentals gives you the foundation needed to explore the various types of press dies and their specific applications—which we'll cover next.

Types of Metal Press Dies and Their Applications

Now that you understand how punch and die press systems work, you're probably wondering—what types of dies exist, and which one fits your production needs? The answer depends on your part complexity, production volume, and quality requirements.

Die sets come in several distinct categories, each engineered for specific manufacturing scenarios. Whether you're producing millions of identical fasteners or small batches of complex aerospace components, there's a die type designed for your application. Let's break down the major categories so you can identify which approach makes the most sense for your operations.

Progressive Dies for High-Volume Production

Imagine a manufacturing line where sheet metal enters as a continuous strip and exits as finished parts—all within a single die. That's the beauty of progressive dies.

Progressive dies contain multiple stations arranged in sequence, each performing a specific operation as the metal strip advances through the tool. With every press stroke, the strip moves forward by a precise distance called the pitch, and each station simultaneously performs its designated task. The first station might punch pilot holes for alignment, the second creates cutouts, the third forms a bend, and the final station cuts the finished part free from the strip.

This continuous strip feeding approach delivers exceptional efficiency for high-volume production. Parts per minute can reach impressive numbers because every stroke produces a completed component while simultaneously advancing work through all other stations. Automotive brackets, electrical connectors, and appliance components commonly emerge from progressive die sets.

The trade-off? Progressive dies require significant upfront investment in design and fabrication. However, when production volumes justify the cost, few methods match their efficiency. Coin press dies used in currency manufacturing often employ similar progressive principles to achieve the consistent, high-volume output that minting operations demand.

Transfer Dies for Complex Part Geometries

What happens when your part is too complex for progressive stamping, or when the material strip would become unwieldy? Transfer dies offer an elegant solution.

Unlike progressive operations where parts remain attached to a carrier strip, transfer dies work with separate blanks. Mechanical fingers or automation systems physically move each workpiece from station to station. This approach allows for deeper draws, more complex forming operations, and parts that would otherwise be impossible to produce while still connected to strip material.

Transfer systems excel when producing larger parts like automotive body panels or components requiring extensive forming operations. The ability to manipulate parts freely between stations opens possibilities that progressive dies simply cannot achieve.

Compound vs Combination Dies Explained

Sounds complex? It doesn't have to be. The distinction between compound and combination dies is actually straightforward once you understand their core principles.

Compound dies perform multiple cutting operations in a single press stroke. Picture a die that simultaneously punches interior holes while blanking the outer perimeter—all in one motion. The punch acts as the die for one operation while the die acts as the punch for another. This clever arrangement produces extremely flat parts with excellent edge quality, making compound dies ideal for washers, gaskets, and similar components requiring tight flatness tolerances.

Combination dies, by contrast, perform both cutting and forming operations simultaneously. A single stroke might blank an outer shape while also bending, drawing, or embossing features into the workpiece. This versatility reduces the number of die sets needed and streamlines production for moderately complex parts.

Forming dies specifically designed for bending and shaping operations transform flat blanks into three-dimensional components. From simple V-bends to complex flanges, these press cutting dies create the geometric features that give stamped parts their functionality. Similarly, a forge die used in hot-forming operations applies these same principles at elevated temperatures for materials requiring thermal processing.

Blanking dies focus exclusively on cutting flat shapes from sheet stock, while piercing dies create internal holes and openings. Both rely on precise clearances between punch and die to produce clean edges and consistent dimensions.

| Die Type | Operation Method | Best Application | Production Volume Suitability |

|---|---|---|---|

| Progressive Dies | Continuous strip feeding through multiple stations | Small to medium parts with multiple features | High volume (100,000+ parts) |

| Transfer Dies | Individual blanks moved between stations | Large or deeply formed parts | Medium to high volume |

| Compound Dies | Multiple cutting operations in single stroke | Flat parts requiring excellent edge quality | Medium to high volume |

| Combination Dies | Cutting and forming in single stroke | Moderately complex parts with mixed operations | Low to medium volume |

| Blanking Dies | Cutting outer perimeter shapes | Flat blanks for secondary operations | All volume levels |

| Forming Dies | Bending, drawing, or shaping material | Three-dimensional part features | All volume levels |

| Piercing Dies | Creating internal holes and cutouts | Parts requiring precise hole patterns | All volume levels |

Choosing the right die type involves balancing part complexity, production requirements, and budget constraints. But die selection doesn't stop at choosing a category—the materials used to construct your tooling play an equally critical role in determining performance and longevity.

Die Materials and Selection Criteria

You've selected the right die type for your application—but what should that die actually be made from? This question often separates tooling that lasts for millions of cycles from tooling dies that fail prematurely. The material selection process involves balancing hardness, wear resistance, and toughness while considering your specific production demands.

Think of die materials as existing on a spectrum. On one end, you'll find softer, tougher steels that resist chipping but wear more quickly. On the other end sit extremely hard materials like carbide that offer exceptional wear resistance but can be brittle under impact. Choosing the right position on this spectrum determines both your tooling die performance and your total cost of ownership.

Tool Steel Grades for Die Construction

When building a die for press applications, tool steels remain the workhorse materials for most manufacturers. These specialized alloys offer an excellent balance of properties at reasonable cost. Here's what you need to know about the most common grades:

- D2 Tool Steel: The most popular choice for machine dies, D2 offers high wear resistance with good toughness. Its 11-13% chromium content provides moderate corrosion resistance, while hardness levels reach 58-62 HRC. Ideal for blanking and piercing operations on materials up to medium thickness.

- A2 Tool Steel: Air-hardening steel that provides better toughness than D2 at slightly lower hardness (57-62 HRC). Excellent dimensional stability during heat treatment makes A2 a favorite for complex die geometries where distortion must be minimized.

- O1 Tool Steel: An oil-hardening grade offering good machinability and adequate hardness (57-61 HRC) for lower-volume applications. O1 costs less than D2 or A2, making it economical for prototype tooling or short production runs.

- S7 Tool Steel: Shock-resistant steel designed for impact applications. When your die for press operations involves heavy blanking or materials prone to causing shock loads, S7's superior toughness prevents catastrophic failure.

- M2 High-Speed Steel: When processing abrasive materials or running at elevated speeds, M2 maintains its hardness at higher temperatures than conventional tool steels. Common in progressive die components subjected to friction-generated heat.

The selection between these grades depends heavily on your specific application. Processing thin aluminum requires different material properties than punching through thick stainless steel. Your tooling supplier should evaluate material thickness, type, and production requirements before recommending a specific grade.

When Carbide Inserts Make Economic Sense

Imagine running a metal die set for several million cycles without replacing cutting components. Carbide inserts make this possible—but they come with significant trade-offs you'll want to understand.

Carbide (tungsten carbide in cobalt binder) achieves hardness levels around 90 HRA, dramatically exceeding any tool steel. This extreme hardness translates directly into extended die life—sometimes 10 to 20 times longer than comparable steel components. For high-volume automotive or electronics applications running millions of parts annually, carbide inserts often prove economically superior despite their higher initial cost.

However, carbide's hardness comes with brittleness. These materials don't tolerate shock loads or misalignment well. A carbide punch striking the die at an angle—something a steel punch might survive—can shatter instantly. This reality means carbide works best in well-maintained presses with proper alignment and when processing consistent materials without inclusions or hard spots.

Many manufacturers adopt a hybrid approach, using carbide inserts only in the highest-wear locations while constructing the remainder of their machine dies from tool steel. This strategy captures carbide's longevity benefits while managing cost and brittleness concerns.

Surface Treatments That Extend Die Life

What if you could dramatically improve your existing tool steel dies without switching to expensive carbide? Surface treatments and coatings offer exactly this possibility.

Nitriding diffuses nitrogen into the die surface, creating a hard case approximately 0.001 to 0.020 inches deep. This treatment increases surface hardness to 65-70 HRC while maintaining the tough core that resists cracking. Nitrided dies excel in forming applications where surface galling might otherwise occur.

Physical vapor deposition (PVD) coatings add thin ceramic layers that transform surface performance:

- TiN (Titanium Nitride): The familiar gold-colored coating adds surface hardness and reduces friction. Excellent general-purpose treatment for punches and forming surfaces.

- TiCN (Titanium Carbonitride): Harder than TiN with better wear resistance. The blue-gray coating performs well in abrasive material applications.

- TiAlN (Titanium Aluminum Nitride): Superior heat resistance makes this coating ideal for high-speed operations or when processing materials that generate significant friction.

These coatings typically measure just 2-5 microns thick—thinner than a human hair—yet they can double or triple die life in demanding applications. The key is matching coating selection to your specific wear mechanism. Abrasive wear calls for different solutions than adhesive wear or galling.

Understanding material selection gives you the foundation to specify tooling that meets both performance and budget requirements. But even the best materials won't save a poorly designed die—which brings us to the engineering fundamentals that separate exceptional tooling from mediocre results.

Die Design Engineering Fundamentals

You've selected the right die type and specified premium materials—so why do some dies still produce inconsistent parts or wear out prematurely? The answer often lies in the engineering decisions made long before any steel is cut. Effective die press design combines physics, material science, and practical manufacturing experience into a cohesive system where every element works in harmony.

Think of die design as solving a complex puzzle where each piece affects every other. The clearance you choose influences edge quality. Your strip layout impacts material utilization. Springback compensation determines whether bent parts meet print tolerances. Getting any single element wrong cascades through the entire production process. Let's explore the critical engineering principles that separate exceptional tooling from mediocre results.

Material Flow Analysis and Forming Considerations

When you bend, draw, or form sheet metal, you're asking the material to do something it doesn't naturally want to do—redistribute itself from flat stock into three-dimensional shapes. Understanding how material flows during these operations is fundamental to successful form die design.

During drawing operations, metal must stretch in some areas while compressing in others. Picture pulling a flat circular blank into a cup shape. The material at the outer edge must compress circumferentially as it's drawn inward, while the material forming the cup wall stretches. If compression becomes excessive, wrinkles form. If stretching exceeds material limits, tears appear.

Experienced engineers analyze these flow patterns before cutting any tool steel. They calculate draw ratios, identify potential problem areas, and design features like draw beads that control material movement. Draw beads are raised ridges in the binder surface that add friction and regulate how quickly material feeds into the die cavity—think of them as traffic controllers for metal flow.

For complex pressing die geometries, engineers also consider material thinning. As metal stretches during forming, it becomes thinner. Excessive thinning weakens the finished part and can cause failures in service. Proper die design distributes strain more evenly, keeping thinning within acceptable limits throughout the part.

Springback Compensation for Accurate Bending

Have you ever tried bending a metal ruler, only to watch it partially return toward its original shape when released? That's springback—and it's one of the most challenging aspects of sheet metal die design.

Every metal has an elastic component to its deformation. When you bend material past its yield point, it takes a permanent set, but some elastic recovery still occurs when pressure releases. The higher the material's yield strength, the more pronounced this effect becomes. Advanced high-strength steels used in automotive applications can spring back several degrees from their formed position.

Compensating for springback requires intentional over-bending. If your finished part needs a 90-degree angle, your form die might bend it to 87 or 88 degrees, allowing springback to bring it to the target. Determining the exact compensation amount involves understanding material properties, bend radius, and forming method.

Engineers use several strategies to manage springback:

- Overbending: Forming beyond the target angle so springback returns the part to specification

- Coining: Applying high local pressure at the bend line to set the material more permanently

- Bottoming: Forcing the punch fully into the die cavity to maximize plastic deformation

- Stretch bending: Applying tension during forming to reduce the elastic component

Modern simulation tools predict springback behavior before physical dies are built, allowing engineers to incorporate compensation into initial designs rather than discovering problems during tryout.

Clearance Calculations and Their Impact on Part Quality

The gap between your punch and die—cutting clearance—might seem like a minor detail, but it fundamentally determines edge quality, tool life, and dimensional accuracy. Get it wrong, and you'll face excessive burrs, premature wear, or parts that simply don't meet specifications.

As a foundational engineering principle, optimal cutting clearance is typically expressed as a percentage of material thickness—generally ranging from 5% to 15% per side depending on material type and desired edge characteristics.

Too little clearance forces the punch and die to work harder than necessary. The cutting edges experience excessive stress, accelerating wear. Parts may exhibit burnished edges without proper fracture zones, and stripping forces increase dramatically.

Excessive clearance creates different problems. Burrs become pronounced as material pulls rather than shears cleanly. Hole diameters increase beyond tolerance, and edge quality deteriorates. The dies for cutting soft materials like aluminum typically require tighter clearances than those processing harder steels.

Here's a practical reference for common materials:

| Material Type | Recommended Clearance (% of thickness per side) |

|---|---|

| Soft Aluminum | 5-7% |

| Mild Steel | 7-10% |

| Stainless Steel | 10-12% |

| High-Strength Steel | 12-15% |

Remember that these percentages apply to each side of the punch, so total clearance is double these values. A 0.060-inch thick mild steel part at 8% clearance would have 0.0048-inch clearance per side, or 0.0096-inch total.

Strip Layout Optimization Principles

For progressive die operations, strip layout design might be the single most impactful engineering decision you'll make. This determines material utilization, station sequencing, and ultimately whether your die press system can reliably produce quality parts at target speeds.

According to progressive die experts at Jeelix, "the strip layout design largely determines a die's success or failure." Although destined for scrap after production, the strip serves multiple critical roles—as conveyor, fixture, and temporary frame for developing parts.

Effective strip layouts balance several competing objectives:

- Material utilization: Minimizing scrap by nesting parts efficiently and reducing carrier width

- Feed reliability: Maintaining sufficient carrier strength to advance consistently through all stations

- Process feasibility: Providing adequate access for forming operations and allowing material flow where needed

- Pilot hole positioning: Locating reference holes where they'll survive all operations and provide accurate positioning

Engineers choose between solid carriers that maintain maximum strength and slitted designs that allow material to stretch during forming. For parts requiring deep draws or complex geometries, strategically placed "stretch webs" give the strip elasticity—allowing material to flow from the carrier into forming zones without tearing.

One-sided carriers suspend parts from a single edge, offering access to three sides but risking feed instability. Two-sided carriers provide superior balance and accuracy, making them preferred for precision components or larger parts where misalignment would cause serious problems.

The Role of Simulation in Modern Die Development

Before digital simulation became commonplace, die development was essentially educated trial-and-error. Engineers built tooling based on experience, mounted it in presses, and discovered problems during physical tryout. Each iteration consumed time, money, and materials.

Today, Computer-Aided Engineering (CAE) and Finite Element Analysis (FEA) transform this process. Engineers now simulate the entire stamping sequence virtually, predicting material behavior and identifying potential defects before any physical tooling exists.

Modern simulation capabilities include:

- Formability analysis: Identifying areas at risk for splitting, wrinkling, or excessive thinning

- Springback prediction: Calculating elastic recovery so compensation can be designed into initial tooling

- Material flow visualization: Understanding how metal moves during forming operations

- Stress distribution mapping: Locating high-stress zones that might cause premature tool wear

- Process optimization: Testing different approaches virtually to find optimal solutions

This "predict-and-optimize" approach replaces costly physical iterations with inexpensive digital experiments. Engineers can test dozens of design variations in the time previously required for a single physical tryout. The result? Faster development cycles, reduced tooling costs, and dies that produce quality parts from their first production run.

Proper engineering fundamentals—from clearance calculations to simulation-driven development—create the foundation for dies that perform reliably throughout their intended lifespan. But understanding where these tools get applied helps contextualize why such precision matters, which brings us to the diverse industries that depend on press die technology.

Industry Applications for Press Die Technology

From the car you drive to the smartphone in your pocket, metal press dies shape the components that define modern life. While die engineering principles remain consistent, each industry brings unique demands that influence tooling design, material selection, and production approaches. Understanding these sector-specific requirements helps you appreciate why precision matters—and how machine die technology adapts to serve vastly different manufacturing needs.

Let's explore how press die technology serves major manufacturing sectors, each with distinct priorities that shape their tooling requirements.

Automotive Manufacturing Die Requirements

When you consider that a single automotive body contains hundreds of stamped components, you begin to understand why the automotive industry represents the largest consumer of metal press dies. According to industry analysis from LSRPF, metal stamping plays a critical role in producing body parts like doors, hoods, and chassis components because "stampings reduce weight while maintaining strength, helping improve vehicle performance and fuel efficiency."

Automotive die requirements center on three priorities:

- High-volume consistency: Progressive and transfer dies must produce millions of identical parts with minimal variation. A door panel stamped on Monday must match one produced months later.

- Material efficiency: With steel costs representing significant production expenses, optimized strip layouts and minimal scrap directly impact profitability.

- Rapid changeover: Modern manufacturing demands flexibility. Dies must allow quick setup changes to accommodate different vehicle models and production schedules.

Typical automotive components produced through sheet metal die press operations include body panels, structural reinforcements, seat brackets, engine mounts, brake components, and interior trim pieces. Each requires tooling designed for the specific material—from mild steel to advanced high-strength grades that challenge even experienced die engineers.

Precision Demands in Aerospace Applications

Imagine a component where a tolerance deviation of a few thousandths of an inch could compromise aircraft safety. That's the reality facing aerospace manufacturers, where precision trumps production speed every time.

Aerospace die applications emphasize tight tolerances and material traceability above all else. Components must meet exacting specifications while documentation tracks every aspect of production. The manufacturing industry research notes that aerospace applications require "metal stamping parts to have excellent strength and durability while minimizing the overall weight to improve flight efficiency."

Forging dies used in aerospace often work with specialized alloys—titanium, Inconel, and aerospace-grade aluminum—that demand different approaches than conventional steel stamping. These materials may require heated operations, specialized lubricants, and dies constructed from premium tool steels or carbide to withstand the unique challenges they present.

Typical aerospace stamped components include:

- Interior structural elements: Brackets, clips, and reinforcements throughout the airframe

- Exterior panels: Skin sections requiring precise contours and consistent thickness

- Engine components: Heat shields, mounting hardware, and ducting elements

- Control surface parts: Hinges, actuator brackets, and linkage components

Production volumes in aerospace typically run lower than automotive, but quality requirements make each part significantly more valuable. A forging die producing landing gear components might operate for years at moderate speeds, with extensive inspection protocols verifying every batch.

Electronics Industry Miniaturization Challenges

How small can you go? Electronics manufacturers push this question constantly, requiring dies capable of producing components measured in millimeters rather than inches.

The electronics industry demands what experts at LSRPF describe as "small components with extremely high precision, such as connectors, terminals, shields and housings." These stampings require tolerances that would be considered extraordinary in other industries—sometimes holding dimensions within a few ten-thousandths of an inch.

Electronics applications include:

- Connectors and terminals: Tiny contact pins and receptacles requiring precise geometries for reliable electrical connections

- Heat sinks: Finned structures that dissipate thermal energy from processors and power components

- RF shields: Enclosures that prevent electromagnetic interference between sensitive circuits

- Battery contacts: Spring elements providing consistent pressure for reliable power delivery

- Device enclosures: Housings for smartphones, tablets, and computing equipment

Progressive dies dominate electronics manufacturing, often running at high speeds to meet volume demands. The miniature scale means tooling components themselves become extremely small, requiring specialized manufacturing techniques and materials to achieve necessary precision.

Appliance and Consumer Product Applications

Walk through your home and count the stamped metal parts. Refrigerator panels, washing machine drums, microwave housings, HVAC components—stamping touches nearly every appliance you own.

Appliance manufacturing balances durability requirements with aesthetic demands. Visible components must emerge from dies with surfaces suitable for painting or finishing, while internal structures prioritize strength and cost efficiency. Industry sources confirm that "metal stamping meets the high durability and aesthetic demands" of home appliances.

Common appliance stampings include:

- Exterior housings: Refrigerator doors, washer tops, dryer panels

- Internal structures: Drum supports, motor mounts, bracket assemblies

- Heat exchange components: Evaporator fins, condenser plates

- Hardware: Hinges, latches, handle brackets

Consumer products extend this list further—kitchen utensils, garden tools, sporting equipment, and decorative items all rely on stamping for efficient production. The versatility of press die technology enables consistent quality across product categories.

General Industrial and Specialized Applications

Beyond major consumer industries, metal press dies serve countless specialized applications:

- Construction and building: Roof panels, structural brackets, joist hangers, and architectural trim pieces

- Medical devices: Surgical instruments, diagnostic equipment housings, treatment device components requiring biocompatible materials

- Energy systems: Solar panel frames, wind turbine components, electrical distribution hardware

- Military and defense: Vehicle armor, weapons system components, communications equipment housings

Each application brings unique requirements. Medical stampings demand material traceability and contamination prevention. Military specifications often require extreme durability under harsh conditions. Energy applications may emphasize corrosion resistance for outdoor installations.

What unites these diverse industries is their reliance on properly designed, well-maintained tooling. Whether producing automotive body panels or medical device components, the fundamental principles of die engineering remain constant—even as specific requirements vary dramatically between sectors.

Understanding industry applications highlights why die maintenance and lifespan management become so critical. A worn die doesn't just produce poor parts—it disrupts entire manufacturing operations across every sector we've explored.

Die Maintenance and Lifespan Management

Your die equipment represents a significant investment—but even the best-engineered tooling won't deliver consistent results without proper care. Surprisingly, many manufacturers focus heavily on production output while neglecting the systematic maintenance that keeps their dies performing at peak efficiency. This oversight costs far more than the maintenance itself ever would.

According to die maintenance specialists at The Phoenix Group, "A poorly defined die shop management system—including die maintenance and repair processes—can dramatically decrease press line productivity and increase costs." Poor maintenance creates a cascade of problems: quality defects during production, increased scrap rates, shipping delays, and expensive emergency repairs that could have been prevented.

Let's explore the preventive practices and warning signs that separate manufacturers who maximize their tooling investment from those who constantly fight die-related production issues.

Preventive Maintenance Schedules for Extended Die Life

Think of die pressing operations like driving a car. You wouldn't wait until the engine seizes to change your oil—yet many manufacturers essentially do this with their tooling. Preventive maintenance addresses potential issues before they disrupt production.

Effective maintenance begins with systematic inspection protocols. Each time a die returns from a production run, trained personnel should evaluate its condition before storage. This inspection identifies emerging problems while they're still minor—and while solutions remain affordable.

Follow this sequential inspection process after each production run:

- Clean all die components thoroughly to remove lubricant residue, metal particles, and contaminants that accelerate wear or cause corrosion during storage.

- Inspect cutting edges visually and tactilely for chips, cracks, or excessive wear that might produce burrs or dimensional problems during the next run.

- Check the top die and bottom die alignment by examining witness marks and wear patterns that indicate misalignment between press strokes.

- Verify die shoe condition for cracks, wear on guide pin bushings, and any damage to mounting surfaces that could affect alignment.

- Examine stripper plates and pressure pads for wear, scoring, or damage that might affect material control during stamping operations.

- Document findings in the work order system so scheduling personnel can prioritize repairs before the next production requirement.

- Apply appropriate rust preventive to all exposed surfaces before moving dies to storage.

Lubrication requirements vary based on die design and materials being processed. Some operations require minimal lubrication, while others—particularly deep drawing applications—demand consistent lubricant application to prevent galling and reduce forming forces. Establish specific lubrication protocols for each die set based on its operational requirements.

Sharpening schedules for cutting edges shouldn't rely on guesswork. As Gromax Precision recommends, "Instead of guessing when punches need sharpening or inserts need replacing, use coil counts, hit logs, and predictive modeling to build a preventive maintenance schedule that's proactive, not reactive." Track stroke counts between sharpenings and establish thresholds based on actual wear patterns rather than arbitrary intervals.

Proper storage protects your investment between production runs. Store dies in climate-controlled environments when possible, keeping them away from moisture sources that promote corrosion. Support die shoes adequately to prevent warping, and maintain clear identification so operators can locate tooling quickly when needed.

Recognizing Signs of Die Wear

Even with excellent preventive maintenance, die components eventually wear. Recognizing the early warning signs allows you to schedule repairs during planned downtime rather than scrambling after a production failure.

Watch for these indicators that your die equipment needs attention:

- Burr formation: When properly maintained cutting edges begin producing burrs on stamped parts, clearances have likely changed due to wear. Small burrs indicate early-stage wear; heavy burrs suggest the die has operated well past its maintenance window.

- Dimensional drift: Parts gradually moving out of tolerance—holes getting larger, bends changing angle, or features shifting position—often signals wear in cutting components, guide pins, or die shoe bushings.

- Increased tonnage requirements: Modern servo presses and retrofit load monitoring systems can detect force signature changes. Industry experts note that "A slow rise in tonnage often signals dull tooling or misalignment—critical clues that it's time for maintenance long before tolerances drift too far."

- Surface finish deterioration: Scratches, galling marks, or rough surfaces on formed parts indicate wear on forming surfaces or inadequate lubrication.

- Inconsistent part quality: When parts from the same production run show significant variation, alignment issues or worn locating features may be the culprit.

Advanced monitoring tools accelerate problem detection. AI-powered Statistical Process Control systems "detect subtle trends—like growing burrs or dimensional creep—earlier than manual inspection alone," according to industry specialists. Inline vision inspection systems catch micro-level dimensional changes in real time, identifying issues while production continues rather than waiting for end-of-line rejections.

Regrinding Versus Replacement Decisions

When cutting edges dull or forming surfaces wear, you face a fundamental question: regrind the existing components or replace them entirely? The answer depends on several factors.

Regrinding makes economic sense when:

- Wear is limited to surface layers that can be removed while maintaining adequate material thickness

- Components retain their geometric accuracy and can be restored to specification

- The cost of regrinding plus setup time remains significantly below replacement cost

- Sufficient die life remains after regrinding to justify the investment

Replacement becomes necessary when:

- Multiple regrind cycles have consumed available material, leaving components too thin for further service

- Damage extends beyond surface wear—cracks, chips, or distortion that regrinding cannot address

- Accumulated dimensional changes from previous regrinds have pushed the die beyond acceptable tolerances

- The cost and lead time for replacement components are comparable to regrind expenses

Factors affecting overall die lifespan include material being processed (abrasive materials accelerate wear), production volume, press alignment and condition, and operator practices. A die running clean aluminum on a well-maintained press might last ten times longer than identical tooling processing abrasive stainless steel on equipment with alignment problems.

Maintaining detailed records for each die set helps predict when regrinding or replacement will be needed, allowing you to plan maintenance during scheduled downtime rather than reacting to failures. This proactive approach—combining systematic inspection, data-driven scheduling, and early problem detection—transforms die maintenance from a cost center into a competitive advantage.

Understanding maintenance requirements prepares you to evaluate how die quality directly impacts your manufacturing outcomes—a connection that extends far beyond simple part production into total cost of ownership considerations.

Die Performance and Manufacturing Quality

You've invested in quality tooling and established solid maintenance practices—but how do these decisions actually translate into manufacturing results? The connection between die quality and production outcomes isn't always obvious, yet it affects everything from part consistency to your bottom line. Understanding this relationship helps you make informed decisions about tooling investments that pay dividends for years.

Think of your press die set as the foundation of your entire production system. Just as a building constructed on an unstable foundation will eventually show cracks and structural problems, manufacturing built around substandard tooling inevitably produces quality issues, efficiency losses, and hidden costs that compound over time.

How Die Quality Affects Production Efficiency

Have you ever watched a well-designed progressive die running at full speed? Parts emerge consistently, stroke after stroke, with minimal operator intervention. That's what quality tooling delivers—but the benefits extend far beyond impressive cycle times.

According to manufacturing efficiency research from LMC Industries, progressive die stamping "drastically reduces production time and costs by eliminating the need for multiple separate operations." This efficiency advantage stems directly from tooling quality. When die sets for press operations are precisely engineered, every stroke produces usable parts rather than scrap.

Quality tooling impacts efficiency through several mechanisms:

- Reduced downtime: Precision-built metal stamping die sets maintain alignment longer, requiring fewer production stoppages for adjustment or repair

- Higher first-pass yields: Parts meet specifications on the first attempt, eliminating rework cycles that consume time and resources

- Faster cycle times: Well-designed dies allow presses to run at optimal speeds without quality sacrifices

- Consistent output: Dimensional stability means parts from the beginning of a run match those produced hours or days later

The tolerance capabilities achievable with properly designed and maintained dies often surprise manufacturers accustomed to working with inferior tooling. Industry experts confirm that quality progressive dies produce "components that consistently meet exceedingly specific requirements," with tighter tolerances and superior part accuracy compared to alternative manufacturing methods.

This precision directly affects downstream assembly operations. When stamped components arrive at assembly stations within specification, they fit together correctly the first time. Operators don't waste time selecting parts, forcing fits, or rejecting assemblies. The cumulative effect across thousands of assembly cycles translates into substantial productivity gains.

The Relationship Between Die Precision and Part Consistency

Imagine producing a million parts over several months. Will part number one million match part number one? With quality tooling and proper maintenance, the answer should be yes.

Part consistency depends on several interconnected die characteristics:

- Dimensional stability: Die shoes, guide systems, and component mounting must maintain their relationships throughout extended production runs

- Wear resistance: Cutting edges and forming surfaces must resist degradation that would gradually shift part dimensions

- Thermal management: Dies running at production speeds generate heat that can cause expansion and dimensional variation if not properly managed

- Material control: Strippers, pilots, and feed systems must position material identically for every stroke

When these elements work together, manufacturers achieve the production consistency that quality-critical applications demand. Automotive suppliers, for instance, must demonstrate Statistical Process Control (SPC) data proving their processes maintain capability over time. This capability flows directly from tooling precision.

Total Cost of Ownership Considerations

Here's where many purchasing decisions go wrong: focusing exclusively on initial die cost while ignoring the factors that determine true manufacturing economics.

According to total cost analysis from Manor Tool, "Producing high-quality metal stamped parts at scale starts with the tooling and die. These are the most critical components in the entire process." Their research shows that quality dies "perform 1,000,000+ strikes before any maintenance is required to maintain part quality," while lower-quality alternatives "wear out much faster, introducing flaws and defects sooner."

The true cost picture includes far more than the initial purchase price:

| Die Quality Factor | Impact on Manufacturing Outcomes | Cost Implications |

|---|---|---|

| Tool steel grade and hardness | Determines wear rate and maintenance intervals | Higher upfront cost offset by extended service life |

| Design precision and simulation | Affects first-pass approval rates and part quality | Reduced scrap, rework, and development iterations |

| Component alignment systems | Controls dimensional consistency across production | Lower rejection rates and assembly problems |

| Surface treatments and coatings | Extends cutting edge and forming surface life | Reduced sharpening frequency and replacement costs |

| Maintenance accessibility | Determines time required for routine service | Lower labor costs and faster return to production |

Scrap rates deserve particular attention in cost calculations. Research from Frigate emphasizes that "Every time a defective part is created, it must be thrown away, and new material must be used to replace it. This means more money is spent on raw materials, labor, and energy." Quality press die sets minimize this waste through precision that eliminates defect sources.

Consider this scenario: a lower-cost die saves $15,000 on initial purchase but produces 2% higher scrap rates and requires maintenance every 250,000 strokes instead of every million. Over a multi-year production program running millions of parts, those differences easily cost ten times the initial savings—not counting the production disruptions, quality escapes, and customer relationship damage that often accompany inferior tooling.

The total cost of ownership perspective transforms how you evaluate die investments. Rather than asking "which die costs less?" the question becomes "which die delivers the lowest cost per quality part over its entire production life?" This shift in thinking leads to purchasing decisions that strengthen competitive position rather than undermining it.

Understanding how die quality connects to manufacturing economics prepares you to evaluate potential tooling suppliers with clarity about what truly matters—a critical skill we'll address next as we explore supplier selection criteria and certification requirements.

Selecting the Right Die Solutions for Your Manufacturing Needs

You understand die types, materials, and engineering principles—but how do you find a supplier capable of translating that knowledge into tooling that actually performs? Selecting the right die partner is arguably the most consequential decision in your entire tooling program. A capable supplier transforms your specifications into precision tooling that runs reliably for years. The wrong choice delivers headaches, delays, and compromised part quality that ripple through your entire operation.

Whether you're sourcing a hydraulic press die set for heavy forming operations or bending dies for sheet metal fabrication, the evaluation criteria remain consistent. Let's explore what separates exceptional die suppliers from those who merely claim capability.

Key Criteria for Evaluating Die Suppliers

Imagine placing a critical production program with a supplier who talks a good game but can't deliver. You've lost months of development time, spent money on unusable tooling, and now face explaining delays to your customers. This scenario plays out more often than it should—but it's preventable through systematic supplier evaluation.

According to manufacturing experts at Dewintech, "Evaluating a supplier's engineering capabilities involves assessing their technical expertise, design flexibility, problem-solving abilities, and past performance." This multi-dimensional approach reveals whether a supplier can handle your specific requirements.

Consider these essential evaluation criteria when selecting your hydraulic press tooling or stamping die supplier:

- Technical knowledge depth: Does the engineering team understand metallurgy, heat treatment processes, and machining techniques relevant to your materials? Ask specific questions about your application and gauge the sophistication of their responses.

- Design and prototyping services: Can they transform your drawings into working prototypes before committing to full production tooling? Suppliers offering prototyping demonstrate confidence in their engineering capabilities.

- Simulation and validation processes: Do they employ CAE analysis and finite element methods to predict material behavior and identify defects before physical tooling exists? This capability dramatically reduces development iterations.

- Track record on similar projects: Have they successfully delivered tooling for applications comparable to yours? Request case studies or customer references demonstrating relevant experience.

- Problem-solving innovation: Can they suggest improvements to your designs, propose alternative materials, or recommend manufacturing methods that improve performance or reduce costs?

- Production volume capabilities: Whether you need prototype quantities or millions of parts annually, verify the supplier can scale to meet your requirements without quality degradation.

Prototyping speed deserves particular attention in today's compressed development cycles. Research from TiRapid confirms that "Using rapid prototyping methods like 3D printing can cut redesign expenses by up to 60% compared to post-tooling corrections." Suppliers offering rapid prototyping—some achieving functional prototypes in as little as five days—enable faster design validation and accelerated time to market.

The importance of first-pass approval rates cannot be overstated. When dies produce quality parts on their first production run, you avoid costly iterations, schedule delays, and the frustration of chasing problems that should have been solved during development. Advanced CAE simulation directly enables these high first-pass rates by identifying and resolving potential issues virtually.

Manufacturers like Shaoyi demonstrate what these capabilities look like in practice. Their engineering team delivers rapid prototyping in as little as 5 days while maintaining a 93% first-pass approval rate—metrics that reflect genuine engineering competence rather than marketing claims. This combination of speed and accuracy exemplifies what you should expect from a qualified hydraulic press die supplier.

The Role of Certification in Die Quality Assurance

How do you verify that a supplier's quality claims reflect reality? Certifications provide independent validation that systematic quality management practices are actually in place.

For automotive applications, IATF 16949 certification represents the gold standard. This automotive-specific quality management system builds on ISO 9001 foundations while adding rigorous requirements for defect prevention, variation reduction, and waste elimination. Suppliers holding this certification have demonstrated their processes meet the demanding standards that major automotive OEMs require.

According to supplier evaluation experts, "Check whether the supplier holds any relevant engineering certifications or quality management certifications (e.g., ISO 9001, ASME certifications). These certifications can indicate that the supplier adheres to high standards in their engineering processes."

Key certifications to look for include:

- IATF 16949: Essential for automotive supply chain participation; indicates robust quality management tailored to automotive requirements

- ISO 9001: Foundational quality management system certification demonstrating documented processes and continuous improvement commitment

- AS9100: Aerospace-specific certification for suppliers serving aviation, space, and defense industries

- ISO 14001: Environmental management certification increasingly important for sustainability-focused customers

Beyond certifications, evaluate the supplier's actual quality practices. Do they conduct incoming material inspection? What measurement and inspection capabilities exist for completed tooling? How do they handle non-conformances and implement corrective actions?

Shaoyi's IATF 16949 certification, combined with their advanced CAE simulation capabilities, illustrates how certification and engineering competence work together. Their defect-free results stem from systematic processes that catch problems during design rather than discovering them during production—exactly what certifications are designed to ensure.

Making Your Final Supplier Decision

With evaluation criteria established, how do you synthesize this information into a confident supplier selection? Consider requesting sample work or a small initial project before committing to major programs. This pilot approach reveals actual performance rather than promised capabilities.

Evaluate communication responsiveness and technical engagement during the quotation process. Suppliers who ask thoughtful questions about your application, challenge assumptions constructively, and offer optimization suggestions demonstrate the engineering partnership mentality that leads to successful programs.

For specialized applications, verify relevant experience. A supplier experienced with coal iron press operations for foundry applications brings different expertise than one focused on precision electronics stamping. Similarly, coal iron forge press tooling demands specific knowledge about high-temperature materials and thermal management that general stamping suppliers may lack.

Finally, consider geographic and logistical factors. Local suppliers offer faster communication and easier collaboration during development. Overseas suppliers may offer cost advantages but introduce lead time and communication challenges. Balance these trade-offs against your specific program requirements.

The right die supplier becomes a genuine partner in your manufacturing success—contributing engineering expertise, quality consistency, and responsive support that extends far beyond simply building tooling to your specifications. Take the time to evaluate thoroughly, and your investment in supplier selection will pay dividends throughout your entire production program.

Frequently Asked Questions About Metal Press Dies

1. What are metal press dies used for?

Metal press dies are precision-engineered tools used in stamping operations to shape, cut, or form sheet metal into specific configurations. They work in conjunction with press machines to produce everything from automotive body panels and aerospace components to electronic enclosures and appliance housings. The die contains a punch (male component) and die block (female component) that work together to transform flat sheet metal into finished parts through cutting, bending, drawing, or forming operations.

2. What is the difference between progressive dies and transfer dies?

Progressive dies contain multiple stations arranged in sequence where a continuous metal strip advances through each station with every press stroke, producing a finished part while simultaneously processing material at all other stations. Transfer dies work with separate blanks that mechanical fingers or automation systems physically move between stations. Progressive dies excel at high-volume production of small to medium parts, while transfer dies handle larger parts or complex geometries requiring deeper draws that would be impossible while connected to strip material.

3. How do I choose the right die material for my application?

Die material selection depends on production volume, material being processed, and budget constraints. Tool steels like D2 offer excellent wear resistance for most applications, while A2 provides better toughness for complex geometries. For high-volume applications exceeding millions of cycles, carbide inserts deliver 10-20 times longer life than steel but require well-maintained presses due to brittleness. Surface treatments like TiN or TiCN coatings can double or triple die life without the cost of carbide. Suppliers like Shaoyi with IATF 16949 certification can recommend optimal materials based on your specific requirements.

4. How often should metal press dies be maintained?

Dies should be inspected after every production run, with thorough cleaning, edge inspection, and alignment verification before storage. Sharpening schedules should be based on stroke counts and actual wear patterns rather than arbitrary intervals. Track tonnage requirements during production—a slow rise often signals dull tooling needing attention. Preventive maintenance every 250,000 to 1,000,000 strokes is typical, depending on die quality and materials being processed. Documenting findings in work order systems enables proactive scheduling before problems affect production.

5. What should I look for when selecting a die supplier?

Evaluate suppliers based on technical expertise, design and simulation capabilities, relevant certifications, and track record with similar applications. Key criteria include CAE analysis capabilities for predicting defects before tooling is built, prototyping speed (some suppliers achieve functional prototypes in 5 days), and first-pass approval rates. For automotive applications, IATF 16949 certification indicates robust quality management. Shaoyi exemplifies these standards with their 93% first-pass approval rate, advanced CAE simulation, and comprehensive mold design capabilities tailored to OEM standards.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —