الصلب المطروق مقابل الصلب المزور في أذرع التحكم: كيفية التمييز بينهما

باختصار

تُصنع أذرع التحكم من الصلب المطروق من قطع متعددة من الصفائح المعدنية التي تُثنى وتُلحَم معًا، مما يجعلها مجوفة وأخف وزنًا وأقل تكلفة. بينما تُصنع أذرع التحكم من الصلب المسحوب من قطعة معدنية واحدة صلبة، مما يوفر قوة ومتانة فائقة ولكن بوزن أكبر وتكلفة أعلى. السبب الرئيسي للتمييز بين ذراع التحكم من الصلب المطروق وذراع التحكم من الصلب المسحوب هو التأكد من طلب قطع الغيار الصحيحة، حيث أن تصاميمها والمكونات المرتبطة بها مثل المفاصل الكروية غالبًا ما لا يمكن استبدالها.

فهم أذرع التحكم المصنوعة من الصلب المطعوم

ذراع التحكم المصنوع من الصلب المطوي هو مكوّن رئيسي في نظام التعليق، يتم تصنيعه من خلال عملية إنتاج محددة. يبدأ هذا الذراع كقطع مسطحة من الفولاذ تُقطع وتُضغط بواسطة قالب (تُعرف هذه العملية بعملية الطي أو الختم)، ثم تُلحَم معًا لتشكيل الذراع النهائي ثلاثي الأبعاد. ونتيجة لهذه الطريقة، يكون ذراع التحكم مجوفًا من الداخل. ولذلك فهو أخف بكثير وأقل تكلفة في الإنتاج مقارنةً بالأنواع المزورة، مما يجعله خيارًا شائعًا لدى الشركات المصنعة للمعدات الأصلية (OEMs) في العديد من الشاحنات والمركبات الرياضية متعددة الاستخدامات الحديثة، بما في ذلك طرازات مختلفة من شيفروليه سيلفرادو وجي إم سي سيرينا.

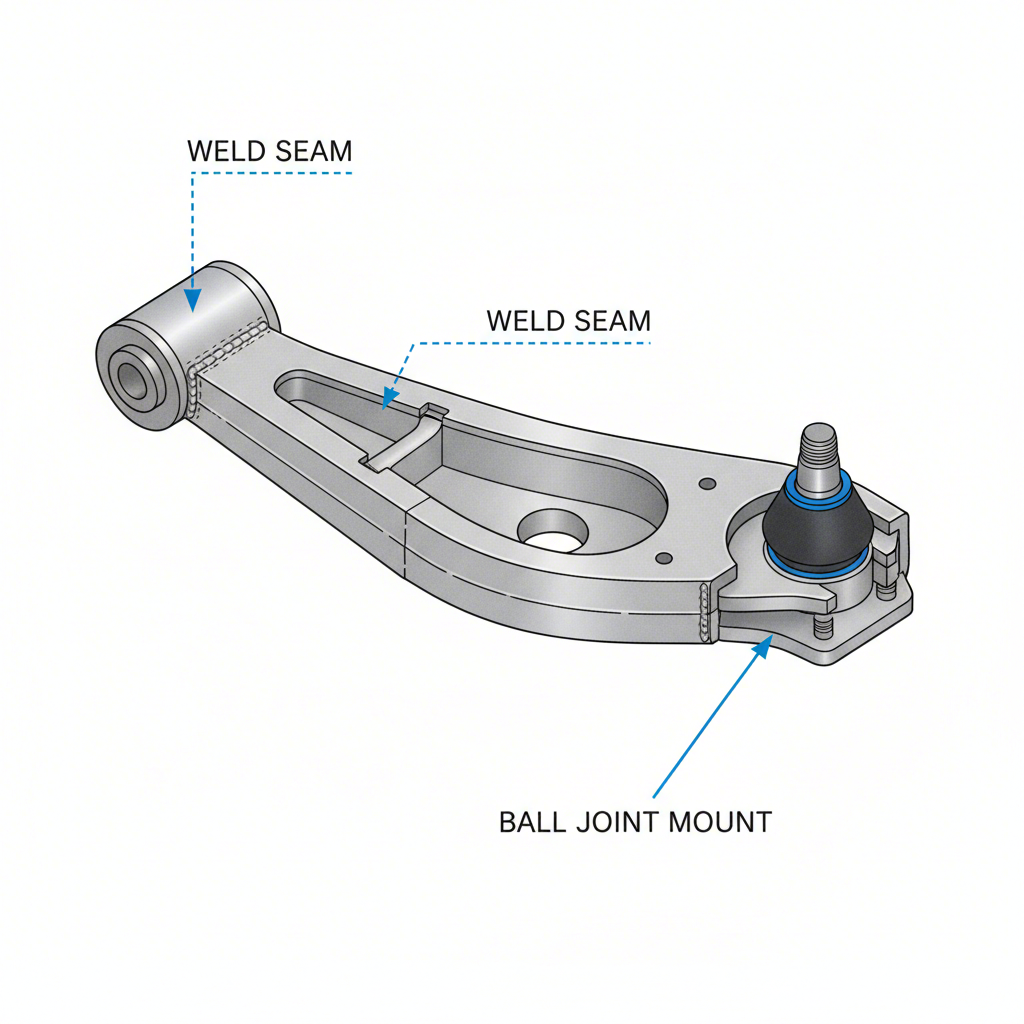

تُضفي عملية التصنيع على أذرع الفولاذ المختومة خصائص مميزة. فمن الناحية البصرية، يمكن تمييزها من خلال وجود لحامات أو فواصل ظاهرة حيث تم وصل قطع الصفائح المعدنية. ومن الناحية العملية، عند النقر عليها بمطرقة أو مفتاح ربط، تُصدر صوتًا أجوفًا عالي النبرة، وهو مؤشر واضح على طريقة تصنيعها. تُعد هذه الطريقة سمة مميزة للإنتاج الحديث للسيارات بكميات كبيرة. بالنسبة للعاملين في صناعة السيارات الذين يبحثون عن حلول دقيقة لتشكيل المعادن، بدءًا من النماذج الأولية وصولًا إلى الإنتاج الضخم، فإن شركات مثل Shaoyi (Ningbo) Metal Technology Co., Ltd. تتخصص في العمليات المتقدمة الحاصلة على شهادة IATF 16949 والمطلوبة لمكونات معقدة كهذه.

بينما تعد الأذرع الفولاذية المطبوعة كافية تمامًا للظروف القيادية القياسية، إلا أن تصميمها قد يشكل نقطة ضعف هيكلية، خاصة فيما يتعلق بمفصل الكرة. في بعض التصاميم الفولاذية المطبوعة، مثل تلك الموجودة في العديد من شاحنات جي إم 1500 من عام 2014 فما بعد، يكون مفصل الكرة محصورًا بشكل أساسي بين اللوحتين العلوية والسفلية للذراع. وفقًا لتحليل أجرته ReadyLIFT يعتمد هذا التصميم على مساحة سطح صغيرة نسبيًا لتثبيت المفصل، ويفتقر إلى أمان مشبك التثبيت. إذا تشوه الكأس المعدني الذي يحمل مفصل الكرة نتيجة الإجهاد — مثل تركيب مجموعة مستوية أو الاستخدام الشاق خارج الطريق — فقد يفشل مفصل الكرة ويصبح منفصلًا عن الذراع.

تتضمن السمات الرئيسية لذراع التحكم الفولاذي المطبوع ما يلي:

- البناء المجوف: مصنوع من قطع معدنية ملولبة وملحومة.

- اللحامات المرئية: تكون الشقوق مرئية عادةً في الأماكن التي تُوصل فيها القطع معًا.

- خفيف الوزن: أقل وزنًا بشكل عام مقارنة بالبدائل المزورة أو المسبوكة من الفولاذ.

- فعالة من حيث التكلفة: أرخص في التصنيع، مما يجعلها شائعة في المركبات المنتجة بكميات كبيرة.

- الصوت الجوفاء: يُنتج صوتًا واضحًا أو جوفاء عند النقر عليه.

فهم أذرع التحكم المصنوعة من الفولاذ المطوق

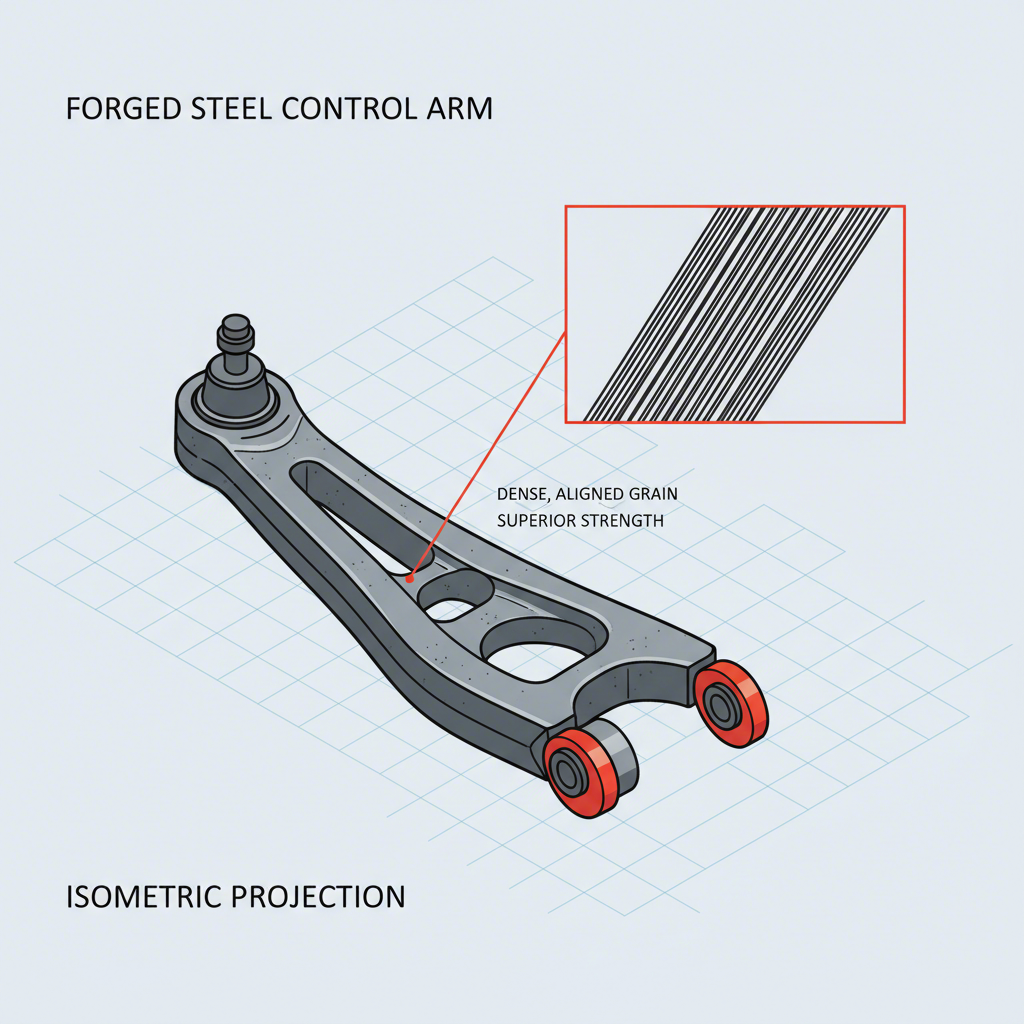

على عكس الأنواع المقطوعة، تُصنع أذرع التحكم المصنوعة من الفولاذ المطوق من قطعة معدنية واحدة متينة. تتضمن عملية التزريق تسخين قضيب فولاذي إلى درجة حرارة مرتفعة جدًا ثم ضغطه أو تطويعه بالطرق للوصول إلى الشكل المطلوب باستخدام ضغط هائل. يؤدي هذا الإجراء الشديد إلى محاذاة البنية الحبيبية الداخلية للفولاذ، ما ينتج مكونًا يتمتع بكثافة استثنائية وقوة عالية ومقاومة كبيرة للتآكل والصدمات. كما أن هذه الطريقة تقضي على الحاجة إلى اللحام، الذي قد يكون نقطة ضعف محتملة تحت إجهاد شديد.

إن البناء المتين للأذرع المزورة يمنحها ميزة كبيرة من حيث المتانة. فهي أكثر مقاومة بكثير للانحناء والتشوه مقارنة بالأذرع المجوفة والمطروقة، مما يجعلها الخيار المفضل في التطبيقات الثقيلة، والمركبات عالية الأداء، ومركبات الطرق الوعرة التي تتعرض فيها مكونات التعليق لقوى شديدة. وعندما تطرق ذراع تحكم مزورًا بمطرقة، فإنه يصدر صوتًا منخفض النبرة وكئيبًا، ما يؤكد طبيعته الصلبة. ولهذا التحمل الجوهري، غالبًا ما تُستخدم هذه الأذرع في الشاحنات القديمة أو الطرازات الثقيلة، أو كتحديثات فاخرة قطع غيار.

رغم أن قوة الفولاذ المطوق تعد من الفوائد الرئيسية، إلا أنها تأتي مع بعض المفاضلات. فعملية التزويق أكثر تعقيدًا واستهلاكًا للطاقة، ما يجعل أذرع التحكم المصنوعة منها أغلى في الإنتاج. كما أنها أثقل بشكل ملحوظ مقارنة بأذرع الفولاذ المسحوب، مما قد يزيد من وزن الجزء غير المعلق في المركبة – وهو عامل يمكن أن يؤثر قليلاً على جودة القيادة واستجابة نظام التعليق. ومع ذلك، في التطبيقات التي تكون فيها القوة والموثوقية القصوى ذات أولوية قصوى، فإن الوزن الإضافي والتكلفة العالية غالبًا ما تُعتبر استثمارًا جديرًا به لتحقيق راحة البال والأداء على المدى الطويل.

تشمل الخصائص الرئيسية لذراع التحكم المصنوع من الفولاذ المطوق ما يلي:

- البناء الصلب: مصنوع من قطعة واحدة من الفولاذ دون أي لحامات.

- قوة فائقة: توفر البنية الحبيبية المحاذية مقاومة عالية للانحناء والتأثيرات.

- وزن أثقل: يضيف التصميم الصلب كتلة أكبر إلى وزن الجزء غير المعلق في نظام التعليق.

- التكلفة الأعلى: أعلى تكلفة في التصنيع بسبب عملية التزويق المعقدة.

- صوت طبول خافت: ينتج صوتًا منخفضًا وصلبًا عند النقر عليه.

المقارنة المباشرة: الفرق الرئيسي بين الفولاذ المسحوب والمطوق

يتعلق اختيار بين أذرع التحكم المصنوعة من الصلب المطعوم أو المزورة، سواء كقطع بديلة أو ترقية، بفهم الاختلافات الأساسية في تصميمها وأدائها. تكمن الاختلافات الرئيسية في عملية التصنيع الخاصة بها، والتي تؤثر بشكل مباشر على قوتها، ووزنها، وتكلفتها، ومتانتها الكلية. وبينما تؤدي كلا النوعين نفس الوظيفة، إلا أنهما مصممان لمستويات مختلفة من الإجهاد ومتطلبات الأداء.

الاختلاف الأكثر أهمية هو القوة. إن الهيكل المصنوع من قطعة واحدة صلبة في الذراع المزورة يكون أقوى بطبيعته مقارنةً بالتصميم المجوف والمُلحوم في الذراع المطروق. يمكن أن تمثل وصلات اللحام في الذراع المطروق نقاط ضعف محتملة عند التعرض لإجهادات عالية، وخصوصاً في منطقة تثبيت المفصل الكروي. كما أشار خبراء أنظمة التعليق، فإن بعض أذرع الفولاذ المطروق تتضمن تصميماً للمفصل الكروي من النوع المدمج (ساندويتش) دون وجود مشبك تثبيت، ما يجعلها أكثر عرضة للفشل في حال تشوه كأس التثبيت. أما الأذرع المزورة أو المسبوكة فعادةً ما تتضمن تصميماً أكثر متانة، حيث يُثبت المفصل الكروي داخل هيكل صلب، وغالباً ما يُثبت بمشبك، مما يوفر اتصالاً أكثر أماناً وديمومة.

الكلفة والوزن عاملان رئيسيان أيضًا. تُعد الفولاذ المطروق خيارًا خفيف الوزن ومنخفض التكلفة، ولهذا السبب يُستخدم على نطاق واسع في تصنيع المركبات الحديثة حيث تكون الكفاءة وتوفير التكاليف أولويتين. أما الفولاذ المسنن فهو البطل من حيث الوزن، إذ يحمل سعرًا أعلى لكنه يقدم القوة الهائلة المطلوبة في الظروف القاسية. وغالبًا ما يعتمد القرار على حالة استخدام المركبة: بالنسبة لمركبة يومية تُستخدم في ظروف طبيعية، فإن الذراع المطروق تكون كافية عادةً. أما بالنسبة لشاحنة مرفوعة الارتفاع، أو مركبة عمل تنقل أحمالًا ثقيلة، أو مركبة للطرق الوعرة، فإن قوة الذراع المسنن الفائقة تمثل استثمارًا حكيمًا.

| ميزة | ذراع تحكم من فولاذ مطروق | ذراع تحكم من فولاذ مسنن |

|---|---|---|

| التصنيع | مصنوع من عدة قطع من الصفائح المعدنية التي تُثنى وتُلحَم معًا. | يتكوّن من قطعة واحدة صلبة من الفولاذ الساخن تُشكّل تحت ضغط هائل. |

| قوة ومتانة | كافٍ للاستخدام القياسي؛ يمكن أن تكون اللحامات ومكان تثبيت المفصل الكروي نقاط ضعف. | قوة فائقة ومقاومة عالية للانحناء؛ مثالي للاستخدام الثقيل. |

| الوزن | أخف وزنًا بفضل هيكله المجوف. | أثقل بسبب البناء الصلب والكثيف. |

| يكلف | أقل تكلفة في الإنتاج. | أكثر تكلفة في التصنيع. |

| التعرف | لُحام مرئي، وتشطيب ناعم، وصوت أجوف عند الضرب. | لا يوجد لحام، وملمس خشن أكثر، وصوت كتم مكتوم عند الضرب. |

كيفية تحديد أذرع التحكم في مركبتك: دليل عملي

يُعد تحديد نوع أذرع التحكم في مركبتك خطوة حاسمة قبل طلب قطع الغيار أو ترقيات التعليق مثل مجموعة الرفع. وبما أن المكونات مثل المفاصل الكروية غالبًا ما تكون خاصة بحسب مادة ذراع التحكم (فولاذ مطبوع، أو فولاذ مصبوب/مُصرَّف، أو ألمنيوم)، فإن ارتكاب الخطأ قد يؤدي إلى إهدار الوقت والمال. لحسن الحظ، يمكنك تحديد النوع الذي تمتلكه من خلال بعض الفحوصات البسيطة مباشرةً في موقف سيارتك.

قبل أن تبدأ، تأكد من أن مركبتك متوقفة على سطح مستوٍ وأنها مدعومة بشكل آمن إذا احتجت إلى رفعها للحصول على وصول أفضل. يمكن أن يؤدي تنظيف الذراعيات التحكمية بفرشاة سلكية ومنظف زائد إلى تسهيل الفحص كثيرًا، حيث يمكن لتراكمات الطرق لسنوات أن تخفي تفاصيل مهمة. وبمجرد حصولك على رؤية واضحة، اتبع الخطوات التالية.

- أجر فحصاً بصرياً: غالبًا ما يكون هذا الاختبار هو الأوضح. انظر عن كثب إلى جسم الذراع التحكّمي. تحتوي الذراع الفولاذية المطبوعة على وصلات مرئية أو خطوط لحام حيث تم توصيل القطع المعدنية المنفصلة معًا. وعادةً ما تكون ذات مظهر أكثر نعومة وإنجازًا. أما الذراع الفولاذية المزورة أو المصوبة، مثل تلك المعروضة في الإرشادات من نظام تعليق BDS ستبدو كقطعة معدنية واحدة صلبة بسطح خشن وملمس ناتج عن عملية الصب. ولن تحتوي على أي لحامات.

- استخدم مغناطيسًا: في العديد من الشاحنات الحديثة، خاصة طرازات جي إم سي 1500 الحديثة، تُعد ذراعيات التحكم المصنوعة من الألومنيوم خيارًا مصنعًا. ويمكن للمغناطيس البسيط أن يميز بسرعة بين الفولاذ والألومنيوم. كما يُوصي بذلك مصنع قطع غيار MOOG ، ضع مغناطيسًا على ذراع التحكم. إذا التصق، فهذا يعني أن الذراع مصنوع إما من فولاذ مدرفل أو مسبوك. وإذا لم يلتصق، فإن لديك ذراع تحكم من الألومنيوم.

- جرّب اختبار الضربة بالمضرب: إذا التصق المغناطيس وما زلت غير متأكد، فهذا الاختبار يُقدّم الدليل الأخير. خذ مطرقة صغيرة أو مفتاح ربط ثقيل واطرق ذراع التحكم بقوة. سيُصدر ذراع الفولاذ المختوم رنينًا واضحًا عالي النبرة أو صوتًا أجوفًا لأنه ليس صلبًا. أما ذراع الفولاذ المطروق أو المصبوب فسيُصدر صوتًا مكتومًا منخفض النبرة مع رنين ضئيل جدًا. تُعدّ هذه الملاحظات الصوتية طريقة موثوقة لتأكيد البنية الداخلية للذراع.

من خلال دمج هذه الاختبارات الثلاثة البسيطة، يمكنك تحديد أذرع التحكم في مركبتك بثقة. هذه المعرفة ضرورية لضمان شراء القطع المناسبة والمتوافقة مع نظام التعليق الخاص بك، مما يضمن إصلاحًا أو ترقية ناجحة وآمنة.

الأسئلة الشائعة

1. ما هو الذراع التحكمي الفولاذي المطبوع؟

ذراع التحكم المصنوع من الفولاذ المطعوم هو مكوّن من نظام التعليق مصنوع من قطع من الصفيح يتم قصها، ثم تشكيلها بالضغط، وبعد ذلك لحامها معًا. وينتج عن هذه العملية جزء مجوف وخفيف الوزن ومنخفض التكلفة. ويمكن التعرف عليها من خلال اللحامات المرئية والصوت المجوف الذي تُصدره عند النقر عليها. وتُستخدم عادةً كمعدات أصلية في العديد من السيارات والشاحنات الحديثة.

2. ما هو أفضل معدن لأذرع التحكم؟

يعتمد "أفضل" نوع من المعادن لأذرع التحكم تمامًا على استخدام المركبة. بالنسبة لمعظم المركبات القياسية والمركبات المستخدمة يوميًا، فإن الأذرع المصنوعة من فولاذ مطعوم أو ألمنيوم مسبوك توفر توازنًا ممتازًا بين القوة الكافية وانخفاض الوزن والتكلفة الفعالة. ومع ذلك، بالنسبة للشاحنات الثقيلة أو السيارات عالية الأداء أو المركبات التي تسير في الطرق الوعرة والتي تتعرض لإجهادات شديدة، يُعتبر الفولاذ المطوي غالبًا الخيار الأفضل بفضل متانته الفائقة وقوته العالية ومقاومته للانحناء، رغم أنه أكثر وزنًا وأعلى تكلفة.

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —