Hiểu Về Các Ký Hiệu Trên Vành Xe Rèn: Giải Mã Những Gì Bánh Xe Của Bạn Đang Giấu

Tại Sao Mọi Bánh Xe Rèn Đều Kể Một Câu Chuyện Qua Các Dấu Hiệu Của Nó

Bạn đã bao giờ tự hỏi những con số và dấu ấn bí ẩn trên bánh xe rèn của mình thực sự có ý nghĩa gì chưa? Những dấu hiệu này không chỉ đơn thuần là các mã nhà máy ngẫu nhiên — chúng là một thẻ định danh đầy đủ, tiết lộ mọi thứ từ chứng nhận an toàn đến nguồn gốc sản xuất. Khi bạn đầu tư vào những bánh xe rèn cao cấp, việc hiểu rõ các định danh này có thể tạo nên sự khác biệt giữa việc lắp vừa hoàn hảo và một sai lầm tốn kém.

Vậy, dấu hiệu vành xe là gì? Về cơ bản, các dấu hiệu trên bánh xe rèn là những mã được đóng hoặc khắc lên, truyền đạt các thông số quan trọng về kích thước, thành phần vật liệu, khả năng chịu tải và sự tuân thủ quy định của bánh xe. Những dấu hiệu này đóng vai trò là công cụ xác minh của bạn khi mua bánh xe đã qua sử dụng, xác nhận tính xác thực hoặc đảm bảo rằng bánh xe phù hợp với yêu cầu của phương tiện.

Tại Sao Vành Đúc Lại Có Các Mã Nhận Dạng Độc Đáo

Vành đúc trải qua một quy trình sản xuất hoàn toàn khác biệt so với loại vành đúc thông thường. Áp lực mạnh và quá trình xử lý nhiệt nghiêm ngặt trong quá trình rèn tạo ra cấu trúc nhôm đặc chắc và bền hơn, phải đáp ứng các tiêu chuẩn kiểm tra khắt khe. Theo Alcoa Wheels , các vành đĩa bằng nhôm rèn đã được đóng dấu nhận dạng cụ thể kể từ năm 1977, thể hiện xếp hạng tải trọng, áp suất bơm hơi tối đa, ngày sản xuất và các ký hiệu mã DOT.

Hệ thống đánh dấu chi tiết này tồn tại vì vành bánh xe trong nhóm rèn đại diện cho một khoản đầu tư lớn—và là thành phần an toàn quan trọng. Vành không chỉ đơn thuần là lựa chọn thẩm mỹ; đó là bộ phận kỹ thuật được thiết kế để hoạt động ổn định dưới các điều kiện tải trọng và chịu lực cụ thể.

Sự Khác Biệt Giữa Dấu Nhãn Trên Vành Rèn Và Vành Đúc

Vành đúc thường hiển thị thông tin cơ bản về kích thước và có thể có logo thương hiệu. Tuy nhiên, vành rèn lại có hệ thống đánh dấu toàn diện phản ánh tiêu chuẩn sản xuất vượt trội của chúng. Bạn sẽ tìm thấy các mã cấp độ vật liệu chi tiết, ký hiệu xử lý nhiệt và nhiều con dấu chứng nhận mà vành đúc hiếm khi có.

Khi kết thúc hướng dẫn này, bạn sẽ có thể giải mã các ký hiệu nhận dạng vành như một chuyên gia. Dưới đây là những nội dung chúng ta sẽ đề cập:

- Thông số kỹ thuật kích thước – Ký hiệu kích thước, độ lệch (offset), mẫu bulông và loại mặt bích

- Chỉ số vật liệu và phương pháp sản xuất – Mã cấp nhôm, ký hiệu xử lý nhiệt và ngày sản xuất

- Dấu chứng nhận – Tuân thủ DOT, chứng nhận an toàn quốc tế và xếp hạng tải trọng

Dù bạn đang xác minh tính xác thực trước khi mua hay đối chiếu thông số kỹ thuật với xe của mình, việc nắm vững các ký hiệu này sẽ bảo vệ tanto khoản đầu tư lẫn sự an toàn của bạn trên đường.

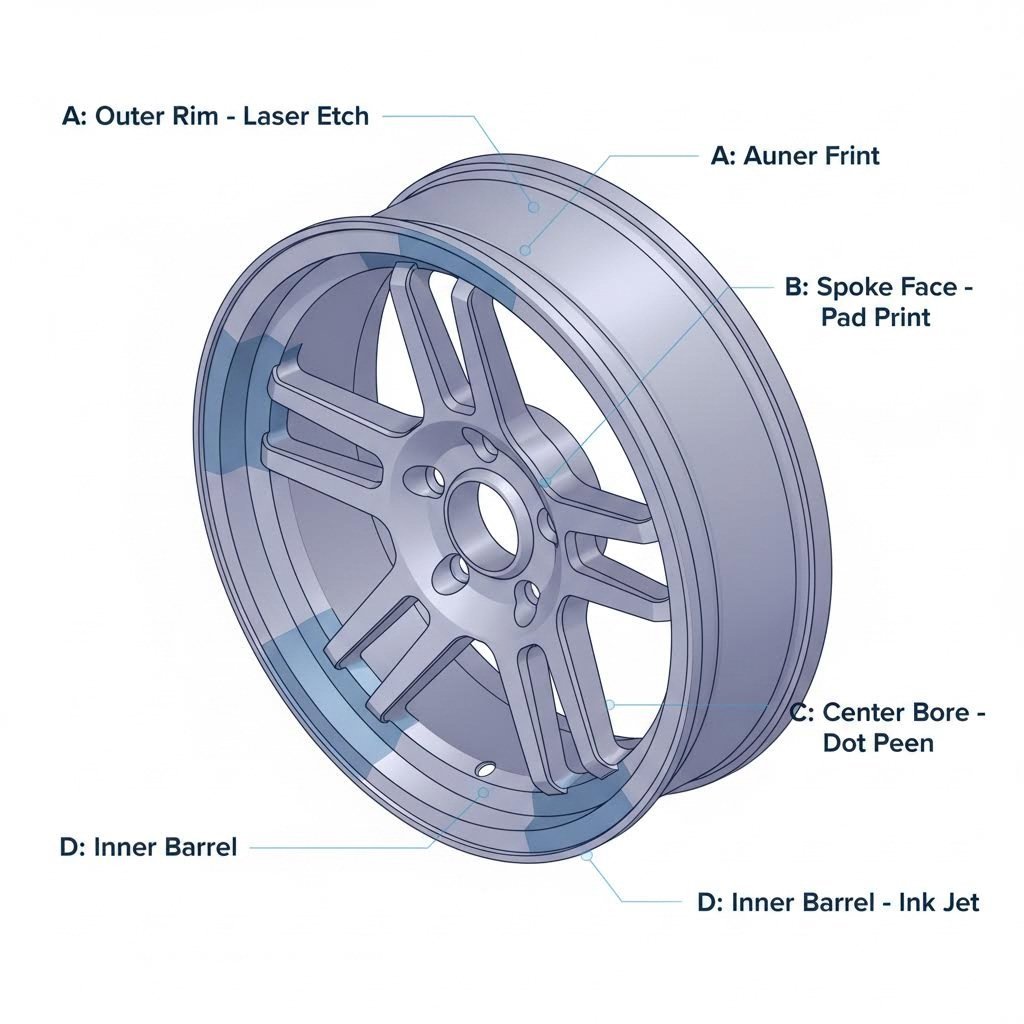

Vị trí tìm các ký hiệu trên vành rèn

Bây giờ bạn đã hiểu tại sao các ký hiệu trên vành đúc lại quan trọng, câu hỏi hợp lý tiếp theo là: bạn nên tìm chúng ở đâu chính xác? Không giống như các ký hiệu trên lốp xe nằm nổi bật ở thành bên, các dấu ấn trên vành thường được đặt ở những vị trí khuất, đòi hỏi một chút tìm kiếm. Biết chính xác nơi cần kiểm tra sẽ tiết kiệm thời gian và đảm bảo bạn không bỏ sót các thông số kỹ thuật quan trọng khi đánh giá một bộ vành đúc.

Hầu hết các chuyên gia khuyên bạn nên tháo toàn bộ cụm bánh xe và lốp ra và đặt lên một bề mặt phẳng để kiểm tra đúng cách. Cách tiếp cận này giúp bạn tiếp cận đầy đủ các khu vực vốn bị che khuất khi vành đang được lắp trên xe của bạn.

Xác định các vùng ký hiệu trên vành đúc của bạn

Hãy hình dung vành xe rèn của bạn gồm bốn khu vực riêng biệt, mỗi khu vực đảm nhiệm một chức năng cụ thể trong hệ thống đánh dấu. Khi bạn xem sơ đồ kích thước vành xe, bạn sẽ nhận thấy các khu vực này tương ứng với những phần cấu trúc khác nhau của bản thân vành xe. Việc hiểu rõ bố cục này sẽ giúp bạn tìm kiếm thông tin nhanh chóng, dù bạn đang ở đại lý, chợ xe hay kiểm tra vành xe trong gara của mình.

Khu vực phía sau nan hoa là điểm đầu tiên cần kiểm tra. Khu vực này—mặt sau của các nan hoa hướng vào bên trong xe—thường chứa các thông số được tham chiếu nhiều nhất: kích thước, độ rộng và giá trị độ lệch tâm. Các nhà sản xuất đặt các ký hiệu này ở đây vì mặt sau nan hoa cung cấp một bề mặt phẳng và được bảo vệ, không bị hư hại trong quá trình lắp lốp hay khi sử dụng trên đường.

Di chuyển sâu hơn vào bên trong vành xe, bề mặt trong của thành vành chứa các mã ngày và dấu chứng nhận. Phần hình trụ nơi vành đai lốp được lắp vào thường bao gồm thông tin sản xuất rất quan trọng cho các yêu cầu bảo hành và xác minh tuổi đời. Bạn thường cần dùng đèn pin và tháo lốp ra để có thể nhìn rõ những ký hiệu này.

Nơi Các Nhà Sản Xuất Ẩn Thông Tin Quan Trọng

Tại sao các nhà sản xuất lại cố ý ẩn những ký hiệu quan trọng? Câu trả lời nằm ở việc cân bằng giữa yêu cầu tuân thủ và tính thẩm mỹ. Những vành đúc cao cấp có giá cao một phần vì vẻ ngoài sạch sẽ, gọn gàng. Việc đóng dấu hay in các ký hiệu dễ thấy trên mặt trước sẽ làm giảm giá trị thẩm mỹ của chúng.

Mặt trung tâm—phần ở giữa nơi các bu-lông bánh xe đi qua—hiển thị logo nhà sản xuất và số hiệu linh kiện. Khu vực này vẫn phần nào nhìn thấy được ngay cả khi bánh xe đã được lắp, cho phép nhận diện thương hiệu mà không cần kiểm tra toàn bộ. Một số nhà sản xuất cũng khắc số seri tại đây nhằm mục đích truy xuất trong trường hợp bị trộm.

Cuối cùng, khu vực viền ở mép ngoài đôi khi có các nhãn tải trọng bánh xe và chứng nhận an toàn. Trên sơ đồ 5 bánh xe thể hiện tất cả vị trí trên một phương tiện, mỗi bánh xe phải đáp ứng yêu cầu tải trọng tối thiểu cho vị trí cụ thể đó, do đó những nhãn này đặc biệt quan trọng đối với xe tải và xe hiệu suất cao.

| Vị trí đánh dấu | Thông tin thường gặp | Mức độ hiển thị |

|---|---|---|

| Phía sau nan hoa | Kích thước (đường kính x chiều rộng), độ dịch chuyển (giá trị ET), loại bích | Trung bình – yêu cầu tháo bánh xe |

| Bề mặt trong của vành | Mã ngày, dấu chứng nhận, số lô sản xuất | Khó – yêu cầu tháo lốp |

| Mặt bích trung tâm | Logo nhà sản xuất, số phụ tùng, số seri | Dễ – nhìn thấy được khi bánh xe đã lắp |

| Vùng viền mép | Thông số tải trọng, chứng nhận an toàn, quốc gia xuất xứ | Trung bình – nhìn thấy được từ góc cạnh bên |

Khi kiểm tra bánh xe rèn, hãy làm việc tuần tự theo từng khu vực. Bắt đầu từ mặt bích trung tâm dễ tiếp cận, sau đó kiểm tra mặt sau nan hoa với bánh xe đã tháo ra. Để xác minh đầy đủ—đặc biệt khi mua bánh xe đã qua sử dụng—hãy yêu cầu xem các ký hiệu trên thành vành với lốp đã tháo rời. Cách tiếp cận kỹ lưỡng này đảm bảo bạn ghi nhận mọi dấu kích thước vành cũng như các dấu chứng nhận trước khi đưa ra quyết định.

Sau khi đã xác định vị trí các ký hiệu, bước tiếp theo là hiểu rõ ý nghĩa của các thông số kích thước này đối với việc lắp đặt phù hợp cho xe của bạn.

Giải mã các ký hiệu kích thước và thông số kích cỡ

Bạn đã tìm thấy các vùng đánh dấu trên vành xe đúc của mình—giờ là lúc dịch những con số và chữ cái này thành các thông số kỹ thuật có ý nghĩa. Khi bạn gặp một nhãn dập như "18x8.5J ET35 5x114.3," bạn đang nhìn vào một bản vẽ chi tiết đầy đủ về kích thước, xác định xem vành đó có vừa khít với xe của bạn hay không, hoặc liệu nó có gây ra hiện tượng cạ, vấn đề về xử lý lái hay rủi ro an toàn.

Việc hiểu rõ cách giải thích các thông số vành theo định dạng này sẽ giúp bạn tự tin hơn khi mua sắm. Hãy cùng phân tích từng thành phần để bạn có thể đọc các ký hiệu này như một chuyên gia vành xe giàu kinh nghiệm.

Giải mã định dạng nhãn kích thước

Định dạng ký hiệu phổ biến nhất mà bạn sẽ gặp phải tuân theo một chuẩn hóa nhằm truyền đạt đường kính, độ rộng và kiểu dáng mép vành trong một chuỗi duy nhất. Theo Oponeo , một ví dụ điển hình như "7.5Jx16H2" cho bạn biết mọi thứ về kích thước cơ bản của vành xe.

Vậy làm thế nào để đo vành từ các ký hiệu này? Dưới đây là ý nghĩa của từng thành phần:

- Định dạng ký hiệu có thể khác nhau. Trong "7.5Jx16", số đầu tiên (7,5) là chiều rộng. Tuy nhiên, trong "18x8,5", số đầu tiên (18) là đường kính. Hãy luôn xác minh dựa trên số nhỏ hơn thường là chiều rộng.

- Số thứ hai sau chữ "x" (ví dụ: 16 hoặc 18) – Đường kính vành tính bằng inch, đo từ ghế vành này sang ghế vành đối diện qua mặt bánh xe. Thông số này phải khớp với con số cuối cùng trên lốp xe của bạn.

- Ký hiệu chữ cái (ví dụ: J, JJ, B, K) – Loại vành hay kiểu vành, cho biết hình dạng mép ngoài của bánh xe nơi mà dây vành của lốp tiếp xúc. Kiểu "J" là tiêu chuẩn cho hầu hết các xe chở khách.

- Ký hiệu H (ví dụ: H2, FH) – Cấu hình gờ nổi giúp giữ dây vành cố định khi chịu lực vào cua. "H2" chỉ ra có gờ nổi ở cả hai bên của vành.

Khi tìm hiểu cách đọc kích thước vành, hãy nhớ rằng ký hiệu vành quan trọng hơn nhiều so với nhận thức của phần lớn người mua. Như các tài liệu tham khảo xác nhận, việc sử dụng lốp được thiết kế cho kiểu "J" trên vành có kiểu "B" sẽ gây ra các vấn đề tương thích ảnh hưởng đến việc lắp đặt lốp và độ an toàn.

Hiểu về Số Độ Đẩy ET

Giá trị ET là nơi các kích thước vành được giải thích trở nên cực kỳ quan trọng đối với việc lắp đặt. Bạn sẽ thấy các ký hiệu như "ET35" hoặc "ET45" được đóng trên các vành đúc, và con số này ảnh hưởng trực tiếp đến vị trí của vành so với hệ thống treo và các tấm thân xe của bạn.

ET nghĩa là gì trên vành xe? ET là viết tắt của "Einpresstiefe"—từ tiếng Đức nghĩa là độ đẩy. Theo Arnold Clark , giá trị này biểu thị khoảng cách tính bằng milimét giữa bề mặt lắp ráp moay-ơ và đường trung tâm của vành xe.

Dưới đây là cách ba loại độ đẩy ảnh hưởng đến xe của bạn:

- Độ đẩy dương (ví dụ: ET35, ET45) – Bề mặt lắp ráp nằm hướng về phía mặt trước của vành, kéo vành vào sâu hơn trong hốc bánh xe. Hầu hết các xe hiện đại sử dụng độ đẩy dương để đảm bảo hình học hệ thống treo chính xác.

- Độ đẩy bằng không (ET0) – Bề mặt lắp ráp nằm đúng trên đường trung tâm của vành xe. Điều này tạo ra tư thế trung tính, nơi mà vành xe không thụt vào cũng không nhô ra ngoài.

- Độ lệch âm (ví dụ: ET-15, ET-25) – Bề mặt lắp đặt nằm về phía sau của bánh xe, khiến bánh xe nhô ra ngoài so với thân xe. Thường thấy trên các xe tải, xe địa hình và một số ứng dụng hiệu suất cao.

Việc chọn sai độ lệch sẽ gây ra những vấn đề thực tế. Các giá trị ET không đúng có thể dẫn đến lốp cọ vào chắn bùn hoặc các bộ phận treo khi đánh lái, hao mòn bạc đạn nhanh hơn do phân bố tải trọng không đúng, và làm giảm khả năng vận hành, ảnh hưởng đến an toàn phương tiện.

Các nhà sản xuất thường cho phép sai lệch khoảng 2% về chiều dài cơ sở tổng thể, tương đương với độ linh hoạt độ lệch khoảng 15–20mm trên hầu hết các xe. Tuy nhiên, việc thay đổi chiều rộng bánh xe cũng ảnh hưởng đến cách mà độ lệch tác động đến độ vừa khít, do đó cả hai thông số này phải được xem xét đồng thời.

Mẫu bulông và ký hiệu PCD

Ký hiệu kích thước cuối cùng mà bạn sẽ gặp là mẫu bulông, thường được hiển thị dưới dạng "5x114.3" hoặc "4x100." Cách đo mẫu bulông của vành bánh xe như thế nào? Con số đầu tiên cho biết số lượng lỗ bắt bulông, trong khi con số thứ hai biểu thị đường kính vòng tròn tiếp tuyến (PCD)—đường kính của một vòng tròn tưởng tượng đi qua tâm của từng lỗ bulông.

Vành rèn thường đóng dấu thông tin này một cách rõ ràng vì sự không phù hợp về mẫu bulông có thể tạo ra tình huống nguy hiểm. Một vành xe có PCD sai sẽ không thể lắp vừa đúng cách, và việc ép lắp sẽ làm hư hại cả vành lẫn cụm moay-ơ.

Khi kết hợp tất cả các ký hiệu kích thước này—đường kính, chiều rộng, loại mép, độ dịch chuyển (offset) và mẫu bulông—bạn sẽ có đầy đủ thông số kích thước vành để kiểm tra độ vừa khít chính xác. Hãy đối chiếu chéo các thông số kỹ thuật này với yêu cầu của xe bạn trước mọi quyết định mua hàng, và bạn sẽ tránh được sự thất vọng do những bánh xe trông thì hoàn hảo nhưng lại không hoạt động an toàn trên xe của mình.

Cấp Vật Liệu và Chỉ Số Quy Trình Sản Xuất

Bạn đã nắm vững các thông số kích thước—giờ là lúc tìm hiểu xem vành xe rèn của bạn thực sự được làm từ vật liệu gì. Những mã ký tự-chữ số được đóng dấu bên cạnh các ký hiệu kích thước sẽ tiết lộ thành phần hợp kim nhôm và quá trình xử lý nhiệt, những yếu tố này xác định đặc tính vận hành của vành xe bạn. Khi bạn nhìn thấy "6061-T6" trên một vành xe rèn, bạn đang đọc một dấu hiệu về cấu trúc vật liệu, phân biệt các vành hợp kim nhôm cao cấp với những sản phẩm thua kém khác.

Vậy một chiếc vành được làm từ chất liệu gì khi mang những ký hiệu này? Việc hiểu rõ các mã này giúp bạn phân biệt giữa những vành được thiết kế cho ứng dụng đòi hỏi cao và những vành chỉ trông giống vậy mà thôi. Hãy cùng giải mã ý nghĩa của các ký hiệu vật liệu này đối với khoản đầu tư và độ an toàn của bạn.

Các Mã Cấp Nhôm Tiết Lộ Điều Gì Về Chất Lượng

Phần đầu tiên của một ký hiệu vật liệu—thường là một dãy số bốn chữ số như 6061 hoặc 7075—xác định loại hợp kim nhôm cụ thể được sử dụng trong quá trình rèn. Theo Engineers Edge , hệ thống đánh số này tuân theo các tiêu chuẩn quốc tế, trong đó chữ số đầu tiên cho biết nguyên tố hợp kim hóa chính.

Khi so sánh hợp kim và vành nhôm, sự khác biệt rất quan trọng: nhôm nguyên chất không đủ độ bền cho ứng dụng vành xe, do đó các nhà sản xuất thêm các nguyên tố cụ thể để tạo ra các hợp kim với tính năng vượt trội hơn. Dưới đây là thành phần thường gặp trong các hợp kim vành rèn:

- hợp kim 6061 – Lựa chọn phổ biến nhất cho vành rèn, kết hợp nhôm với magie và silic. Hỗn hợp này mang lại độ bền cao, khả năng chống ăn mòn tốt và khả năng hàn thuận lợi.

- hợp kim 6082 – Tương tự như 6061 nhưng có hàm lượng silic hơi cao hơn, mang lại độ bền tốt hơn một chút trong một số ứng dụng.

- hợp kim 7075 – Một hợp kim nền kẽm được sử dụng trong ngành hàng không vũ trụ và đua xe, cung cấp độ bền kéo cao hơn nhưng đi kèm chi phí lớn hơn.

Khi đánh giá vành hợp kim so với vành nhôm trên thị trường, hãy nhớ rằng các bánh xe "nhôm" không có chỉ định hợp kim cụ thể thường cho thấy cấu tạo đúc với các cấp độ vật liệu không được xác định rõ. Các bánh xe rèn cao cấp tự hào hiển thị ký hiệu 6061 hoặc 7075 vì những hợp kim này đại diện cho chất lượng đã được kiểm chứng.

Theo 3030 Autosport , Nhôm rèn 6061-T6 được coi là lựa chọn hàng đầu trong các lĩnh vực như ứng dụng quân sự, hàng không vũ trụ, Công thức 1 và đua xe tăng tốc. Thành phần hợp kim bao gồm magie để tăng cường độ bền thông qua làm cứng dung dịch rắn, silic kết hợp với magie nhằm cải thiện độ bền đồng thời giảm nhiệt độ nóng chảy để dễ dàng rèn hơn, và một lượng nhỏ đồng để tăng khả năng chống ăn mòn.

Giải thích các ký hiệu xử lý nhiệt

Chữ cái và con số theo sau mã hợp kim—"T6" trong 6061-T6—tiết lộ quá trình xử lý nhiệt đã biến nhôm thô thành vật liệu vành hiệu suất cao. Chính ký hiệu này làm nổi bật sự khác biệt thực sự của phương pháp rèn vành nhôm so với các quy trình đúc.

"T" chỉ xử lý nhiệt, và chữ số theo sau xác định chính xác cách thức vật liệu được xử lý. Đối với các vành rèn, đây là những ký hiệu bạn thường gặp:

- T6 – Được xử lý nhiệt ở trạng thái hòa tan và hóa già nhân tạo. Hợp kim được nung nóng đến nhiệt độ cao, làm nguội nhanh, sau đó được hóa già ở nhiệt độ cao hơn nhằm kết tủa các thành phần gia cường một cách có kiểm soát.

- T651 – Giống như T6 nhưng có thêm bước giảm ứng suất thông qua kéo dãn, giúp giảm các ứng suất dư từ quá trình sản xuất.

- T7 – Được xử lý nhiệt ở trạng thái hòa tan và ổn định vượt trên độ bền cực đại để cải thiện khả năng chống ăn mòn do ứng suất.

Hiểu cách bánh xe đúc được chế tạo giúp giải thích tại sao xử lý T6 lại quan trọng đến vậy. Trong quá trình đúc, áp lực mạnh làm định hướng cấu trúc thớ nhôm, tạo ra độ bền vốn có. Quy trình xử lý nhiệt T6 tiếp theo — nung đồng nhất sau đó làm nguội có kiểm soát và lão hóa — tối đa hóa lợi thế cấu trúc này bằng cách kết tủa các hợp chất gia cường xuyên suốt vật liệu.

Xử lý T6 làm tăng đáng kể độ bền chảy và độ cứng của hợp kim, khiến nó lý tưởng cho các ứng dụng chịu tải cao. Sự kết hợp giữa thành phần và xử lý nhiệt này tạo ra một vật liệu có độ bền và độ dẻo dai vượt trội, rất cần thiết đối với các bộ phận phải chịu đựng những ứng suất hoạt động cực lớn.

Tại sao những chi tiết kỹ thuật này nên ảnh hưởng đến quyết định mua hàng của bạn? Bởi vì cấp vật liệu tác động trực tiếp đến hiệu suất thực tế. Một vành bánh xe hợp kim nhôm được đánh dấu đúng là 6061-T6 mang lại:

- Tỷ lệ cường độ-trọng lượng vượt trội – Bánh xe rèn 6061-T6 thường nặng từ 21-30 pound mỗi chiếc, trong khi vẫn chịu được tải trọng có thể làm nứt các vật liệu kém hơn.

- Khả năng kháng mệt mỏi được nâng cao – Cấu trúc thớ kim loại được định hướng và quá trình xử lý nhiệt cho phép những bánh xe này hấp thụ các chu kỳ ứng suất lặp lại mà không phát sinh vết nứt.

- Chống ăn mòn tuyệt vời – Đặc biệt có giá trị trong điều kiện lái xe mọi thời tiết, nơi muối đường và độ ẩm tấn công các kim loại không được bảo vệ.

- Tính chất nhiệt tối ưu – Tản nhiệt tốt hơn từ phanh, giúp duy trì hiệu suất dừng xe ổn định trong quá trình lái xe mạnh.

Khi kiểm tra bánh xe rèn, sự hiện diện của các ký hiệu rõ ràng về cấp vật liệu cho thấy nhà sản xuất tự tin vào chất lượng sản phẩm của họ. Những bánh xe không có các chỉ định này — hoặc chỉ ghi chung chung là "nhôm rèn" — có thể không mang lại các đặc tính hiệu suất mà bạn đang chi trả. Kiến thức này biến bạn từ một người mua thông thường thành người tiêu dùng am hiểu, biết nhận diện các dấu hiệu chất lượng thực sự.

Khi đã hiểu rõ thành phần vật liệu, nhóm đánh dấu quan trọng tiếp theo bao gồm các chứng nhận an toàn và tem hợp quy, xác nhận vành xe của bạn đáp ứng các tiêu chuẩn pháp lý và an toàn.

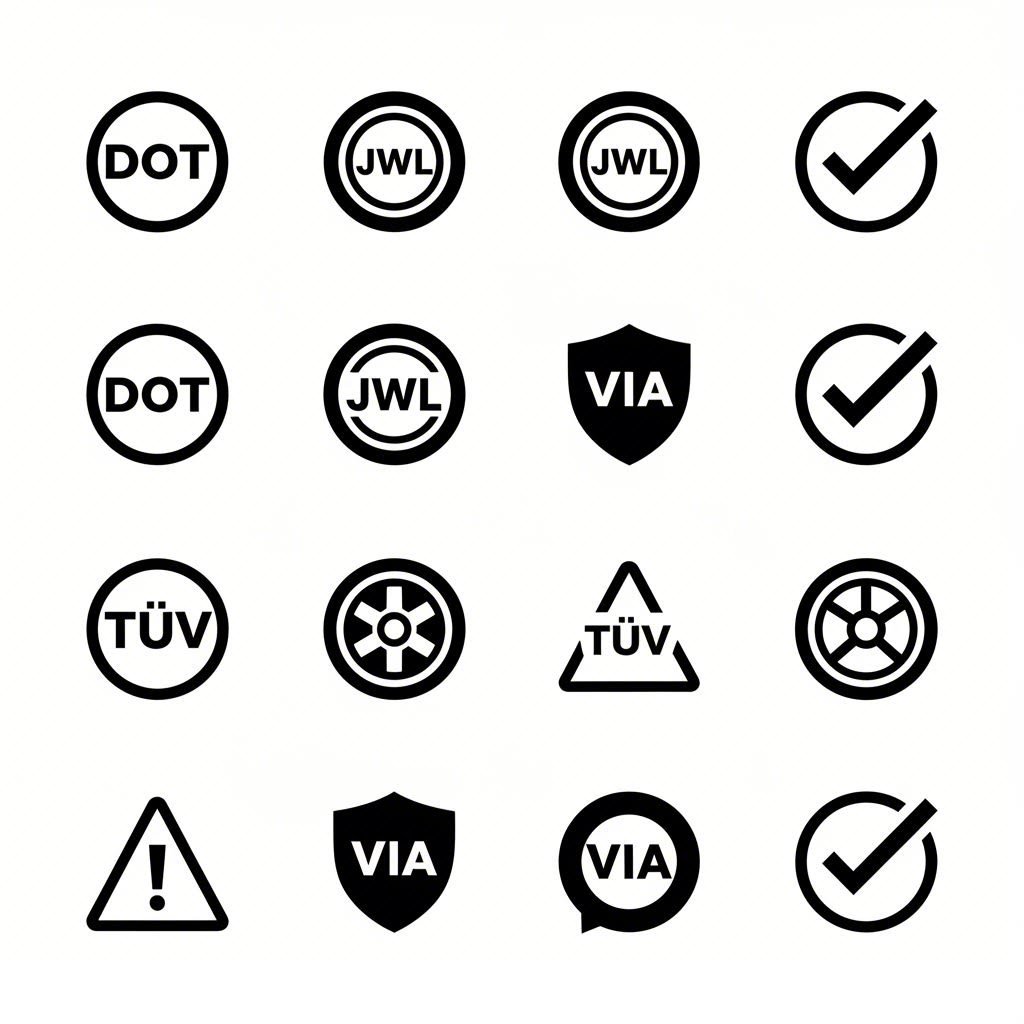

Chứng Nhận An Toàn Và Tem Hợp Quy

Bạn đã xác định được cấp độ vật liệu và thông số kỹ thuật về kích thước – nhưng vẫn còn một nhóm mã vành bánh xe nữa ảnh hưởng trực tiếp đến an toàn và sự tuân thủ pháp lý của bạn. Các tem chứng nhận thể hiện việc kiểm định độc lập xác nhận rằng vành xe rèn của bạn đã vượt qua các quy trình thử nghiệm nghiêm ngặt. Nếu thiếu những ký hiệu này, về cơ bản bạn đang đặt tính mạng mình vào sản phẩm chưa được xác minh mỗi khi lái xe.

Tại sao điều này lại quan trọng đến vậy? Theo ATIC Global Services , hiệu suất của bánh xe rất quan trọng đối với an toàn phương tiện, và nhiều quốc gia yêu cầu chứng nhận đối với các bánh xe thay thế khi nhập khẩu vào thị trường của họ. Những con dấu này không chỉ mang tính trang trí — chúng là yêu cầu pháp lý tại nhiều khu vực pháp lý và là bằng chứng cho thấy các phòng thí nghiệm kiểm định độc lập đã xác minh độ bền cấu trúc của bánh xe.

Hãy cùng giải mã các ký hiệu chứng nhận bạn sẽ gặp trên các bánh xe rèn, bắt đầu từ con dấu liên quan nhất đến người mua tại Mỹ.

Các con dấu DOT và Yêu cầu Tuân thủ tại Hoa Kỳ

Ký hiệu DOT — viết tắt của Department of Transportation (Bộ Giao thông Vận tải) — cho biết bánh xe đáp ứng các tiêu chuẩn an toàn phương tiện cơ giới liên bang của Hoa Kỳ. Khi bạn nhìn thấy chữ "DOT" kèm theo các mã ký tự số và chữ được đóng dấu trên bánh xe rèn của mình, bạn đang xem xác nhận rằng bánh xe đã được đăng ký với Bộ GTVT Hoa Kỳ và tuân thủ các quy định áp dụng.

Chứng nhận DOT xác minh điều gì? Dấu hiệu này xác nhận rằng nhà sản xuất vành đã kiểm tra sản phẩm của họ theo các thông số kỹ thuật vành đã được thiết lập và đăng ký kết quả với cơ quan liên bang. Bao gồm việc xác minh kích thước vành ô tô, xếp hạng khả năng chịu tải và hiệu suất cấu trúc trong thử nghiệm chịu lực.

Dưới đây là những điều bạn cần hiểu về dấu DOT:

- Yêu cầu đăng ký – Tất cả các vành xe cơ giới bán tại Hoa Kỳ phải đáp ứng các yêu cầu kiểm tra DOT và có dấu DOT tương ứng trên sản phẩm.

- Xác định nhà sản xuất – Mã chữ-số đứng sau "DOT" xác định nhà sản xuất cụ thể và cơ sở sản xuất.

- Phạm vi tuân thủ – Chứng nhận DOT bao gồm các thông số kỹ thuật vành, bao gồm khả năng chịu tải, độ bền cấu trúc trong thử nghiệm mỏi và khả năng chống va chạm.

Ngoài ra, các nhà sản xuất có thể theo đuổi chứng nhận AMECA — một tiêu chuẩn ngành tự nguyện do Cơ quan Tuân thủ Thiết bị Nhà sản xuất Ô tô (Automotive Manufacturers Equipment Compliance Agency) quản lý. Mặc dù không bắt buộc về mặt pháp lý, chứng nhận AMECA cung cấp xác nhận độc lập từ bên thứ ba mà nhiều nhà sản xuất vành uy tín đạt được để thể hiện cam kết về chất lượng.

Khi mua vành từ các người bán quốc tế, hãy luôn kiểm tra xem có dấu hiệu DOT hay không nếu bạn dự định sử dụng chúng hợp pháp trên các tuyến đường tại Hoa Kỳ. Các vành không có dấu DOT có thể không vượt qua kiểm tra cấp bang hoặc gây ra các vấn đề trách nhiệm pháp lý trong trường hợp xảy ra tai nạn.

Giải thích các dấu chứng nhận quốc tế

Ngoài dấu DOT, các vành rèn có thể mang các chứng nhận quốc tế khác nhau tùy thuộc vào nơi sản xuất và các thị trường mà chúng được phê duyệt. Việc hiểu rõ các ký hiệu này trở nên thiết yếu khi nhập khẩu vành hoặc mua từ các người bán toàn cầu.

JWL và JWL-T (Nhật Bản)

Tiêu chuẩn Vành Hợp kim Nhẹ Nhật Bản (JWL) đại diện cho một trong những hệ thống chứng nhận được kính trọng nhất trên toàn cầu. Theo Velgen Wheels , kiểm tra JWL bao gồm các đánh giá giống như xếp hạng SAE—kiểm tra mỏi hướng tâm, mỏi uốn và kiểm tra va chạm—cùng với thêm một bài kiểm tra độ tròn để đảm bảo vành không bị biến dạng.

Sự khác biệt chính? JWL yêu cầu các nhà sản xuất phải đưa vành của họ đi kiểm tra và được phê duyệt bởi các phòng thí nghiệm bên thứ ba đã được chứng nhận. Bạn sẽ thấy ký hiệu "JWL" được đóng dấu trên vành xe du lịch và "JWL-T" trên vành dành cho xe tải và các phương tiện lớn hơn. Những ký hiệu này cho biết sự tuân thủ các tiêu chuẩn an toàn của Bộ Giao thông Nhật Bản.

VIA (Hiệp hội Kiểm tra Phương tiện Nhật Bản)

Thành lập năm 1987, Hiệp hội Kiểm tra Phương tiện cung cấp tiêu chuẩn chứng nhận mà nhiều người xem là tiêu chuẩn vàng cho vành xe. VIA phát triển từ các yêu cầu JWL với các quy định nghiêm ngặt hơn và các quy trình kiểm tra bổ sung.

Điều gì khiến chứng nhận VIA trở nên đặc biệt nghiêm ngặt? Theo các nguồn trong ngành, VIA kiểm tra vành với các kích cỡ lốp và phương tiện khác nhau—không chỉ trong điều kiện phòng thí nghiệm cách ly. Quy trình thử nghiệm bao gồm kiểm tra biến dạng, kiểm tra độ bền, kiểm tra kéo đứt và xác minh độc lập bởi bên thứ ba. Đối với các vành thâm nhập thị trường Nhật Bản, chứng nhận VIA về cơ bản là bắt buộc đối với các vành hợp kim nhẹ.

TÜV (Đức)

TÜV SÜD hoạt động như viện độc lập lớn nhất châu Âu về công nghệ lốp và vành. Quy trình chứng nhận của họ bao gồm thử nghiệm toàn diện theo StVZO (quy định giao thông đường bộ Đức), tiêu chuẩn ECE và các yêu cầu do khách hàng quy định.

Kiểm tra vành TÜV bao gồm mỏi uốn, mỏi hướng tâm, va chạm hai trục, hấp thụ năng lượng, va chạm hướng tâm và thử nghiệm xoắn. Khi bạn nhìn thấy dấu TÜV trên các vành rèn, bạn đang chứng kiến sự xác nhận từ một trong những tổ chức thử nghiệm khắt khe nhất thế giới—tổ chức này hợp tác rộng rãi với các nhà sản xuất ô tô OEM hàng đầu trên toàn cầu.

ECE/Dấu E (Liên minh Châu Âu)

Chứng nhận dấu E, được quy định bởi Quy định UNECE R124, là chứng nhận bắt buộc đối với vành xe chở khách được bán tại các quốc gia thuộc Liên minh Châu Âu. Chứng nhận này xác nhận sự tuân thủ các tiêu chuẩn về kích thước vành ô tô, khả năng chịu mỏi uốn, độ bền mỏi hướng tâm, thử nghiệm va chạm và khả năng chống ăn mòn.

Dấu E thường xuất hiện dưới dạng chữ "E" theo sau là một con số chỉ quốc gia thành viên EU cấp phê duyệt. Nhãn hiệu này là bắt buộc về mặt pháp lý đối với các vành bán tại thị trường châu Âu và cho thấy đã trải qua kiểm tra độc lập kỹ lưỡng bởi bên thứ ba.

| Chứng nhận | Quốc gia xuất xứ | Điều gì được xác minh | Vị trí điển hình trên vành |

|---|---|---|---|

| Đốm | Hoa Kỳ | Tuân thủ an toàn phương tiện cơ giới liên bang, xếp hạng tải trọng, độ bền cấu trúc | Bề mặt trong lòng vành hoặc mặt sau nan hoa |

| JWL / JWL-T | Nhật Bản | Khả năng chịu mỏi uốn, mỏi hướng tâm, chống va đập, độ tròn | Mặt sau nan hoa hoặc mặt moay-ơ |

| Thông qua | Nhật Bản | Thử nghiệm JWL mở rộng cộng thêm biến dạng, độ bền và hiệu suất kéo | Kề bên dấu JWL |

| TÜV | Đức | Tuân thủ StVZO, thử nghiệm mệt mỏi, khả năng chịu va chạm, hiệu suất xoắn | Bề mặt trong của vành hoặc khu vực mép |

| ECE / Dấu E | Liên minh châu Âu | Tuân thủ UNECE R124 bao gồm thử nghiệm mệt mỏi, va chạm và ăn mòn | Bề mặt trong của vành |

| SAE | Hoa Kỳ | Khả năng chịu tải tối thiểu, mệt mỏi hướng tâm/lệch hướng, khả năng chịu va chạm và xoắn | Mặt sau chấu hoặc vành |

Tại sao dấu chứng nhận lại ảnh hưởng đến quyết định mua hàng của bạn? Hãy xem xét các tình huống sau:

- Nhập khẩu bánh xe từ các nhà bán hàng nước ngoài – Các bánh xe không có chứng nhận DOT không thể được sử dụng hợp pháp trên các con đường tại Hoa Kỳ. Luôn xác minh các chứng nhận phù hợp trước khi mua hàng từ nước ngoài.

- Các vấn đề về bảo hiểm và trách nhiệm pháp lý – Trong các cuộc điều tra tai nạn, các bánh xe không có chứng nhận có thể gây ra các vấn đề về trách nhiệm pháp lý hoặc làm mất hiệu lực bảo hiểm.

- Bảo vệ giá trị tái bán – Các bánh xe có chứng nhận đầy đủ sẽ có giá bán lại cao hơn vì người mua có thể xác minh chất lượng thông qua các ký hiệu được công nhận.

- Đảm Bảo Hiệu Suất – Các dấu chứng nhận là bằng chứng cho thấy các phòng thí nghiệm độc lập—không chỉ riêng nhà sản xuất—đã xác minh hiệu suất cấu trúc dưới các điều kiện khắc nghiệt.

Khi kiểm tra các bánh xe rèn, hãy coi các dấu chứng nhận bị thiếu hoặc mờ là tín hiệu cảnh báo. Các nhà sản xuất hợp pháp luôn tự hào hiển thị các dấu phù hợp của họ vì việc đạt được các chứng nhận này đòi hỏi khoản đầu tư đáng kể vào thử nghiệm và kiểm soát chất lượng. Những bánh xe thiếu chứng nhận phù hợp có thể đã bỏ qua các bài kiểm tra nghiêm ngặt nhằm bảo vệ bạn trong từng dặm đường lái xe.

Với các ký hiệu chứng nhận được giải mã, nhóm thông tin quan trọng tiếp theo bao gồm các mã ngày và thông tin sản xuất giúp xác minh tuổi đời và tính xác thực của vành xe.

Mã Ngày và Nhận Diện Sản Xuất

Bạn đã kiểm tra các chứng nhận và xác nhận cấp độ vật liệu – nhưng vành rèn mà bạn đang xem xét đã sử dụng bao lâu rồi? Các mã ngày và dấu hiệu sản xuất sẽ trả lời câu hỏi then chốt này, đóng vai trò như một định danh vành, tiết lộ lịch sử sản xuất, hỗ trợ các yêu cầu bảo hành và phát hiện hàng giả. Khi mua vành rèn đã qua sử dụng, những ký hiệu thường bị bỏ qua này trở thành công cụ xác minh quý giá nhất của bạn.

Hiểu cách đọc các ký hiệu mã vành sẽ biến bạn từ một người mua hàng bình thường thành người tiêu dùng tinh tế, có thể phát hiện ra những chi tiết mà người khác bỏ sót. Hãy cùng tìm hiểu cách thông tin sản xuất bảo vệ khoản đầu tư của bạn.

Cách Đọc Mã Ngày Sản Xuất

Các nhãn ngày sản xuất tuân theo nhiều định dạng khác nhau tùy thuộc vào nhà sản xuất, nhưng hầu hết các nhà sản xuất vành đúc đều sử dụng các hệ thống nhận biết được một khi bạn biết cần tìm gì. Theo Alcoa Wheels , dấu đóng mộc của họ đã bao gồm thông tin ngày sản xuất kể từ năm 1977—một tiêu chuẩn mà nhiều nhà sản xuất cao cấp đã áp dụng.

Các định dạng mã ngày phổ biến mà bạn sẽ gặp bao gồm:

- Định dạng Tuần-Năm (ví dụ: 2423) – Hai chữ số đầu chỉ tuần sản xuất (01-52), trong khi hai chữ số cuối biểu thị năm. Vì vậy, "2423" có nghĩa là vành được sản xuất vào tuần thứ 24 của năm 2023.

- Định dạng Tháng-Năm (ví dụ: 0522) – Một số nhà sản xuất dùng hai chữ số chỉ tháng theo sau bởi hai chữ số chỉ năm. "0522" chỉ sản xuất vào tháng 5 năm 2022.

- Định dạng ngày Julian (ví dụ: 156-23) – Số đầu tiên biểu thị ngày trong năm (1-365), theo sau là năm. "156-23" có nghĩa là ngày thứ 156 của năm 2023.

- Mã chữ-số – Các nhà sản xuất cao cấp có thể sử dụng các hệ thống riêng biệt, trong đó các chữ cái đại diện cho tháng hoặc cơ sở sản xuất.

Tại sao mã ngày lại quan trọng? Các yêu cầu bảo hành cần bằng chứng về ngày sản xuất, và hầu hết các chế độ bảo hành cho bánh xe đúc dao động từ một đến năm năm tùy theo nhà sản xuất. Nếu không có mã ngày đọc được, bạn không thể xác minh được tư cách hưởng bảo hành — đây là vấn đề đáng lo ngại khi mua các bánh xe cao cấp có giá hàng nghìn đô la.

Mã ngày cũng tiết lộ tuổi đời của bánh xe, điều này ảnh hưởng đến tính chất vật liệu theo thời gian. Mặc dù các bánh xe đúc được bảo quản đúng cách có thể duy trì độ bền trong nhiều thập kỷ, nhưng những bánh xe đã qua sử dụng sẽ tích lũy các chu kỳ ứng suất và nguy cơ hư hỏng do mỏi. Biết được ngày sản xuất giúp bạn đánh giá xem một bánh xe đã qua sử dụng có thể đã tiếp xúc với điều kiện đường sá trong bao lâu.

Sử dụng Số hiệu phụ tùng để Xác minh Bánh xe

Ngoài các mã ngày tháng, số phụ tùng đóng vai trò như dấu vân tay duy nhất của bánh xe. Các dãy ký tự và chữ số này xác định chính xác mẫu bánh xe, cấu hình kích thước, lớp hoàn thiện và đôi khi là lô sản xuất. Khi bạn cần thay thế bánh xe hoặc muốn kiểm tra tính xác thực, số phụ tùng trở nên vô cùng quan trọng.

Thực hiện tra cứu kích thước vành bằng số phụ tùng cho phép bạn đối chiếu với cơ sở dữ liệu của nhà sản xuất để biết thông số kỹ thuật. Nhiều nhà sản xuất cung cấp công cụ trực tuyến, nơi bạn nhập số phụ tùng để nhận được đầy đủ thông số kỹ thuật của bánh xe bao gồm đường kính, chiều rộng, độ dịch chuyển (offset), kiểu bulông và khả năng chịu tải. Ví dụ, việc tìm kiếm số phụ tùng Alcoa sẽ kết nối bạn trực tiếp với các thông số chính thức và xác nhận xem bánh xe có phải hàng chính hãng hay không.

Có phải mẫu bulông được đóng dấu trên vành cùng với các mã phụ tùng này không? Trong hầu hết các trường hợp, có – nhưng mã phụ tùng cung cấp thêm xác minh vì chúng liên kết với hồ sơ nhà sản xuất bao gồm các ký hiệu kích thước vành đầy đủ và thông số kỹ thuật. Khả năng đối chiếu này làm cho mã phụ tùng trở nên vô giá khi:

- Đặt mua bánh xe thay thế để đảm bảo bộ bánh xe đồng bộ

- Xác minh rằng một bánh xe đã qua sử dụng phù hợp với thông số kỹ thuật được nêu

- Xác nhận tính xác thực thông qua cơ sở dữ liệu của nhà sản xuất

- Xác định đúng quy trình dịch vụ và thông số mô-men xiết

Phát hiện hàng giả thông qua mã ngày sản xuất và dấu hiệu sản xuất

Đây là nơi mà mã ngày và mã phụ tùng thực sự thể hiện giá trị: phơi bày các vành xe giả mạo. Theo JJJ Wheel , các vành hợp kim giả mạo tiềm ẩn rủi ro an toàn nghiêm trọng vì chúng được sản xuất bằng vật liệu kém chất lượng và quy trình sản xuất không đạt tiêu chuẩn, dẫn đến yếu tố cấu trúc yếu và nguy cơ hỏng hóc cao hơn.

Khi mua mâm đúc đã qua sử dụng, hãy coi những điểm sau đây là tín hiệu cảnh báo cần kiểm tra kỹ lưỡng thêm:

- Mã ngày sản xuất bị thiếu hoặc không đọc được – Các nhà sản xuất hợp lệ luôn đảm bảo các ký hiệu sản xuất vẫn rõ ràng. Mã bị che giấu cố ý cho thấy có điều gì đó cần phải giấu.

- Mã ngày sản xuất không khớp với thông tin người bán cung cấp – Nếu người bán khẳng định mâm xe 'hầu như chưa dùng' nhưng mã ngày lại cho thấy sản phẩm đã sản xuất từ năm năm trước, bạn cần điều tra kỹ hơn.

- Số hiệu phụ tùng không thể xác minh – Khi tìm kiếm số hiệu phụ tùng mà không ra kết quả hoặc thông số không khớp với mâm xe thực tế, rất có thể bạn đang nhìn vào hàng giả.

- Kiểu chữ ghi nhãn không đồng nhất – Mâm đúc chính hãng có kiểu chữ, độ sâu và vị trí đóng dấu nhất quán trên mọi ký hiệu. Dấu đóng không đều hoặc cẩu thả cho thấy sản phẩm không phải do nhà máy sản xuất.

- Mã ngày sản xuất không trùng khớp trong cùng một bộ – Các bộ bánh xe chính hãng từ cùng một lần mua thường có ngày sản xuất tương tự nhau. Những mã ngày khác biệt rõ rệt trên một bộ "ghép đôi" cho thấy đây có thể là hàng giả được lắp ráp hoặc thay thế không đúng nguồn gốc.

- Các ký hiệu bị thay đổi hoặc dập lại – Hãy tìm dấu hiệu của việc mài, hàn hoặc khắc lại xung quanh mã ngày và số phụ tùng. Những đối tượng làm giả đôi khi sửa đổi các ký hiệu để phù hợp với thông số mong muốn.

Các tài liệu tham khảo nhấn mạnh việc kiểm tra các "dấu hiệu nhận biết và mã số thường thấy trên sản phẩm chính hãng", bao gồm các dấu đúc, số phụ tùng và biểu tượng chứng nhận. Nếu các bánh xe thiếu những dấu hiệu này hoặc hiển thị thông tin nhận dạng đã bị thay đổi, cần xem đây là tín hiệu cảnh báo nghiêm trọng về khả năng hàng giả.

Khi đánh giá các lazang đúc đã qua sử dụng, hãy ghi lại tất cả các mã ngày và số phụ tùng trước khi mua. Chụp ảnh rõ ràng và xác minh thông tin thông qua tài liệu của nhà sản xuất hoặc đại lý được ủy quyền. Bước xác minh này chỉ mất vài phút nhưng giúp bạn tránh mua phải những lazang có thể bị hỏng nghiêm trọng hoặc trở nên vô giá trị khi bán lại.

Các ký hiệu sản xuất hoàn thiện bức tranh nhận dạng—nhưng còn các biểu tượng nhà sản xuất và mã riêng theo thương hiệu để phân biệt nhà sản xuất lazang này với nhà sản xuất khác thì sao? Hiểu được các hệ thống này giúp bạn tự tin lựa chọn giữa các tùy chọn OEM và thị trường phụ tùng thay thế.

Biểu Tượng Nhà Sản Xuất Và Mã Riêng Theo Thương Hiệu

Bạn đã giải mã các thông số kích thước, cấp vật liệu và nhãn chứng nhận — nhưng còn những yếu tố thương hiệu xác định nhà sản xuất thực sự của vành xe rèn bạn đang dùng thì sao? Các biểu tượng logo nhà sản xuất và hệ thống mã hóa độc quyền thêm một lớp thông tin nữa trong việc nhận dạng vành, giúp bạn xác minh tính xác thực và hiểu rõ các tiêu chuẩn chất lượng đằng sau sản phẩm mình mua. Dù bạn đang duyệt danh sách các thương hiệu vành hay đánh giá một vành đã qua sử dụng, việc nhận biết các ký hiệu riêng của nhà sản xuất sẽ phân biệt người mua am hiểu với những người bị lừa bởi hàng giả mạo.

Theo StockWheels.com , vành nguyên bản từ nhà máy đôi khi có thể được xác định thông qua logo trên nắp trung tâm — tuy nhiên, ngay cả chi tiết này cũng có thể gây nhầm lẫn vì một số hãng vành tùy chỉnh dán nhãn giả lập giống như nắp trung tâm nguyên bản. Thực tế này làm cho việc hiểu toàn bộ hệ thống ký hiệu trở nên thiết yếu để xác minh chính xác.

Quy ước ghi nhãn OEM so với Hàng thay thế

Các bánh xe của nhà sản xuất thiết bị gốc (OEM) và các bánh xe đúc sau thị trường tuân theo triết lý đánh dấu khác nhau, mặc dù cả hai đều phải tuân thủ các tiêu chuẩn về kích thước và chứng nhận mà chúng ta đã đề cập.

Các bánh xe đúc OEM thường hiển thị thương hiệu một cách tinh tế. Bạn sẽ thấy số phụ tùng của hãng ô tô được đóng nổi rõ ràng — thường ở mặt sau nan hoa hoặc bề mặt moay-ơ — trong khi danh tính của nhà sản xuất bánh xe thực tế có thể ít nổi bật hơn. Cách tiếp cận này ưu tiên thương hiệu xe hơn là nhà cung cấp linh kiện. Các tài liệu tham khảo xác nhận rằng việc kiểm tra mặt sau bánh xe để tìm các dấu hiệu OEM sẽ hé lộ thông tin, vì gần như tất cả các vành nguyên bản đều mang số hoặc logo của nhà sản xuất.

Các thương hiệu vành bánh xe trên thị trường sau lại áp dụng cách tiếp cận ngược lại. Các nhà sản xuất bánh xe đúc cao cấp hiển thị rõ ràng logo của họ vì độ nhận diện thương hiệu thúc đẩy doanh số bán hàng. Bạn thường sẽ thấy:

- Logo trên nắp moay-ơ trung tâm Nhãn hiệu thương hiệu dễ nhìn thấy nhất, thường có thiết kế đặc biệt hoặc vòng vòm logo vương miện báo hiệu vị trí cao cấp

- Hình khắc khuôn mặt nói Một số nhà sản xuất khắc tên của họ bằng laser trực tiếp trên bề mặt nhìn thấy được

- Bức mác thùng Tên thương hiệu, tên mô hình và số bộ phận độc quyền trên thùng bên trong

- Bảng số hàng loạt Các thương hiệu cao cấp như BBS và HRE gắn các tấm biển số riêng để xác minh tính xác thực

Khi kiểm tra lốp có logo vương miện hoặc thương hiệu khác, hãy nhớ rằng logo không đảm bảo tính xác thực. Những kẻ làm giả dễ dàng sao chép các yếu tố hình ảnh - đó là hệ thống đánh dấu hoàn chỉnh tiết lộ sự thật.

Hệ thống mã hóa cụ thể cho thương hiệu

Mặc dù tất cả các nhà sản xuất vành đều phải bao gồm các ký hiệu kích thước tiêu chuẩn (kích cỡ, độ dịch chuyển, mẫu bulông) và các chứng nhận phù hợp, nhiều hãng sử dụng hệ thống mã hóa riêng để theo dõi nội bộ và xác định mô hình. Việc hiểu rõ những khác biệt này sẽ giúp bạn nghiên cứu hiệu quả các loại vành từ các thương hiệu vành xe tải khác nhau cũng như các lựa chọn cho xe chở người.

Các dạng ký hiệu phổ biến khác nhau giữa các nhà sản xuất bao gồm:

- Vị trí tên mô hình – Một số thương hiệu đóng nổi tên mô hình (như "TE37" hoặc "RS-GT") một cách rõ ràng; một số khác chỉ sử dụng mã chữ số

- Mã chỉ định lớp hoàn thiện – Các chữ cái hoặc con số biểu thị màu sắc hoặc xử lý bề mặt cụ thể (ví dụ: "MB" là đen mờ, "HP" là bóng cao cấp)

- Ký hiệu trọng lượng – Các nhà sản xuất cao cấp đôi khi đóng nổi trọng lượng từng chiếc vành để tham khảo khi cân bằng

- Dấu gốc xuất xứ – Dòng chữ "Sản xuất tại Nhật Bản", "Đúc tại USA", hoặc các chỉ định tương tự cho biết địa điểm sản xuất

- Các con dấu kiểm soát chất lượng – Chữ viết tắt của nhân viên kiểm tra hoặc mã lô QC đặc thù theo quy trình của nhà sản xuất

Tài liệu tham khảo từ Automator xác nhận rằng mỗi vành đều phải được đánh dấu tên nhà sản xuất để truy xuất nguồn gốc và thương hiệu doanh nghiệp, mã địa điểm sản xuất, số lô phê duyệt và thông số kích thước. Cách tiếp cận chuẩn hóa này có nghĩa là bạn có thể kỳ vọng một số hạng mục đánh dấu nhất định bất kể thương hiệu — mặc dù định dạng cụ thể có thể khác nhau.

Nhận diện các bánh xe không có nhãn hoặc nhãn bị mờ

Việc gặp phải những bánh xe không có, thiếu hoặc khó đọc nhãn mác có ý nghĩa gì? Tình trạng này ngay lập tức làm dấy lên lo ngại về chất lượng và tính xác thực.

Theo StockWheels.com, gần như luôn đúng rằng nếu nắp bánh xe của bạn không có logo OEM VÀ không có bất kỳ dấu dập hay nhãn mác thiết bị gốc nào trên mặt sau vành, thì đó không phải là vành tiêu chuẩn nguyên bản. Nguyên tắc tương tự cũng áp dụng với các vành đúc aftermarket — các nhà sản xuất hợp lệ đầu tư đáng kể vào các hệ thống đánh dấu phù hợp.

Các bánh xe có dấu hiệu đánh dấu không đầy đủ có thể cho thấy:

- Sản xuất giả mạo – Các bánh xe giả thường thiếu các dấu chứng nhận hợp lệ vì chúng chưa trải qua kiểm tra chính thức

- Hàng nhập khẩu xách tay – Các bánh xe sản xuất cho những thị trường có yêu cầu ít nghiêm ngặt hơn có thể thiếu các chứng nhận cần thiết tại khu vực của bạn

- Bánh xe đã bị thay đổi hoặc tân trang – Mạ crôm, phủ bột hoặc gia công cơ khí có thể che khuất các dấu hiệu gốc, tiềm ẩn việc giấu hư hỏng hoặc tuổi thọ cao

- Sản xuất giá rẻ – Các nhà sản xuất cấp thấp có thể bỏ qua việc đánh dấu đúng cách để giảm chi phí, đây là dấu hiệu phản ánh chất lượng tổng thể kém

Một số dấu hiệu đặc trưng trên vành sau bán hàng được đề cập trong tài liệu tham khảo bao gồm các nhãn "max-load" và "VIA" — điều đáng chú ý là những dấu này thường không xuất hiện trên vành nguyên bản do nhà máy sản xuất. Sự khác biệt này hữu ích khi xác định vành là loại OEM hay vành thay thế sau bán hàng.

Khi đánh giá việc mua bất kỳ bộ bánh xe rèn nào, hãy yêu cầu đảm bảo khả năng nhìn thấy đầy đủ các ký hiệu. Những người bán uy tín sẽ sẵn lòng cung cấp hình ảnh chi tiết về tất cả các khu vực có đóng dấu. Nếu các ký hiệu dường như bị che giấu cố ý, vừa mới thay đổi hoặc đơn giản là không có, hãy coi đây là một dấu hiệu cảnh báo đáng lo ngại, bất kể biểu tượng thương hiệu vành trên nắp trung tâm có ấn tượng đến đâu.

Khi đã hiểu rõ cách nhận biết nhà sản xuất, bạn hiện đã có đủ kiến thức để áp dụng toàn bộ thông tin về các ký hiệu này vào các tình huống mua hàng thực tế — xác minh tính xác thực, xác nhận sự phù hợp và bảo vệ khoản đầu tư của mình trước khi tiền được thanh toán.

Hướng Dẫn Thực Tế Để Xác Minh Tính Xác Thực Của Bánh Xe Rèn

Bạn đã học cách giải mã các thông số kích thước, cấp vật liệu, nhãn chứng nhận và dấu hiệu của nhà sản xuất—giờ là lúc áp dụng kiến thức đó vào thực tế. Dù bạn đang kiểm tra một bộ mâm đúc đã qua sử dụng tại chợ xe hay đánh giá tin đăng trực tuyến từ một người bán nước ngoài, việc có một quy trình xác minh hệ thống sẽ bảo vệ khoản đầu tư và sự an toàn của bạn. Làm thế nào để biết được kích cỡ mâm xe bạn đang có và xác nhận chúng có khớp với những gì người bán tuyên bố hay không? Hãy cùng đi qua từng bước thực tế giúp phân biệt người mua tự tin với những người bị lừa.

Theo Tree Wheels , mâm xe chất lượng kém không chỉ ảnh hưởng đến hiệu suất mà còn tiềm ẩn nguy cơ mất an toàn nghiêm trọng và làm lãng phí hàng nghìn đô la. Quy trình xác minh mà chúng tôi trình bày ở đây sẽ giải quyết từng vấn đề một cách hệ thống, đảm bảo bạn phát hiện ra sự cố trước khi chúng trở thành sai lầm tốn kém.

Danh sách kiểm tra để xác minh khi mua mâm xe đã qua sử dụng

Việc mua bánh xe rèn đã qua sử dụng giúp tiết kiệm đáng kể — nhưng nếu không kiểm tra kỹ lưỡng, khoản tiền tiết kiệm đó có thể nhanh chóng biến mất do chi phí sửa chữa hoặc gây ra các tình huống lái xe nguy hiểm. Trước khi quyết định mua bất kỳ sản phẩm nào, hãy thực hiện quy trình kiểm tra từng bước sau:

- Yêu cầu cung cấp ảnh chụp đầy đủ các ký hiệu – Yêu cầu người bán chụp ảnh tất cả bốn khu vực có ký hiệu: mặt sau nan hoa, bề mặt trong lòng vành, mặt tiếp xúc moay-ơ và khu vực mép vành. Nếu họ do dự hoặc cho rằng các ký hiệu "không quan trọng", hãy coi đây là dấu hiệu cảnh báo.

- Đối chiếu các thông số kích thước – So sánh các thông số được đóng nổi (đường kính, độ rộng, độ dịch chuyển, mẫu bulông) với yêu cầu của xe bạn. Làm cách nào để biết yêu cầu kích thước vành xe của tôi? Hãy kiểm tra sổ tay hướng dẫn sử dụng hoặc bảng thông số nằm trong cánh cửa phía người lái.

- Xác minh các dấu chứng nhận – Xác nhận các chứng nhận phù hợp (DOT cho sử dụng tại Mỹ, JWL/VIA cho vành Nhật Bản, TÜV/ECE cho xe nhập khẩu vào châu Âu) phải có mặt và rõ ràng. Việc thiếu các chứng nhận này có thể cho thấy sản phẩm giả mạo hoặc hàng nhập khẩu qua thị trường xám.

- Giải mã các ký hiệu ngày sản xuất – Tính tuổi của vành từ dấu ngày sản xuất. Những vành trên 10 năm tuổi cần được kiểm tra kỹ lưỡng hơn về hiện tượng mỏi vật liệu, và sự chênh lệch tuổi quá lớn trong một bộ 'đồng bộ' có thể cho thấy đây là bộ vành lắp ráp giả mạo.

- Xác minh số phận hiệu (part number) – Tra cứu cơ sở dữ liệu của nhà sản xuất bằng số phận hiệu được đóng dấu. Nếu thông số không khớp hoặc không có kết quả, rất có thể bạn đang xem xét sản phẩm giả mạo.

- Kiểm tra các ký hiệu cấp vật liệu – Xác nhận sự hiện diện của ký hiệu hợp kim 6061-T6 hoặc tương đương. Những vành không có thông tin về vật liệu có thể sử dụng các hợp kim kém chất lượng hơn, làm ảnh hưởng đến hiệu suất.

- Thực hiện kiểm tra vật lý – Kiểm tra các vết nứt xung quanh lỗ bulông, dùng thước thẳng để kiểm tra độ cong vênh và xác minh khu vực ghế đệm lốp không bị hư hỏng. Theo các chuyên gia trong ngành, lazang đã qua sử dụng cũng nên được kiểm tra áp suất để phát hiện rò rỉ.

- Thực hiện kiểm tra bằng phương pháp gõ – Gõ nhẹ lên lazang bằng một công cụ không gây trầy xước. Lazang rèn chính hãng sẽ phát ra âm thanh rõ ràng, vang như tiếng chuông, trong khi hàng giả thường có âm thanh đục hơn do vật liệu kém chất lượng hoặc hư hỏng ẩn bên trong.

Làm thế nào để kiểm tra độ chính xác kích thước vành? So sánh trọng lượng là một phương pháp xác minh hiệu quả. Hầu hết các nhà sản xuất uy tín đều công bố thông số trọng lượng chính xác của lazang. Nếu bạn có thể sử dụng cân, hãy cân thử các lazang và so sánh với số liệu chính thức — hàng giả thường sử dụng ít vật liệu hơn hoặc hợp kim kém chất lượng, dẫn đến trọng lượng không khớp với thông số công bố.

So sánh các thông số kỹ thuật với yêu cầu xe của bạn

Hiểu cách xác định kích thước vành mà xe của bạn cần là một nửa vấn đề – nửa còn lại là xác nhận rằng các vành bạn đang xem xét thực sự phù hợp với những yêu cầu đó. Quá trình kiểm tra này giúp tránh các vấn đề lắp đặt như cọ sát, xử lý lái khó khăn hoặc nguy cơ mất an toàn.

Bắt đầu bằng việc thu thập thông số kỹ thuật vành xe từ sách hướng dẫn sử dụng hoặc tài liệu của nhà sản xuất. Bạn sẽ cần:

- Dải đường kính và chiều rộng – Hầu hết các xe chấp nhận một dải kích thước (ví dụ: 17x7.5 đến 18x8.5)

- Độ lệch cho phép – Thông thường sai lệch 15-20mm so với vành tiêu chuẩn là chấp nhận được, nhưng điều này phụ thuộc vào từng loại xe cụ thể

- Mẫu bulông (PCD) – Yêu cầu phải khớp chính xác; không có độ linh hoạt nào ở điểm này

- Đường kính lỗ trung tâm – Phải bằng hoặc lớn hơn đường kính trục moay-ơ của xe bạn

- Đánh giá tải – Phải đáp ứng hoặc vượt quá yêu cầu về trọng lượng của xe bạn

Làm thế nào để biết kích thước la-zăng trên những bánh xe bạn đang đánh giá? Tìm dấu kích thước được in ở mặt sau nan hoa – nó hiển thị thông số kỹ thuật đầy đủ theo định dạng tiêu chuẩn. Đối chiếu từng thành phần với yêu cầu của xe trước khi tiếp tục.

Đối với người mua tìm kiếm sự đảm bảo bổ sung, Bác sĩ Vành xe khuyên nên tra cứu mã VIN hoặc liên hệ đại lý để có thông tin chính xác về la-zăng, sau đó xác minh rằng sản phẩm tiềm năng phải khớp đúng các thông số này. Bước kiểm tra bổ sung này giúp phát hiện những vấn đề tương thích tinh vi mà kiểm tra bằng mắt thường có thể bỏ sót.

Tại Sao Tiêu Chuẩn Chất Lượng Nhà Sản Xuất Quan Trọng

Tất cả kiến thức về các ký hiệu đều trở nên ít ý nghĩa nếu bản thân những chiếc la-zăng đến từ các nhà sản xuất hay cắt giảm chi phí. Tài liệu tham khảo nhấn mạnh rằng các chứng nhận như JWL, VIA, TÜV và IATF 16949 cho thấy cam kết của một công ty đối với chất lượng và an toàn – và những chứng nhận này không phải là lựa chọn tùy chọn đối với những người mua nghiêm túc.

Theo Flexiforge Wheel, chứng nhận IATF 16949:2016 rất quan trọng đối với các nhà sản xuất vành cung cấp cho các hãng ô tô lớn, bao gồm toàn bộ quy trình sản xuất và đảm bảo tiêu chuẩn chất lượng cao ở mọi giai đoạn. Chứng nhận này tập trung vào cải tiến liên tục và phòng ngừa lỗi — chính xác những gì bạn mong đợi từ các thành phần trực tiếp ảnh hưởng đến an toàn của bạn.

Làm thế nào để xác định yêu cầu kích thước la-zăng của bạn và tìm nguồn cung cấp vành đáp ứng đáng tin cậy các yêu cầu đó? Hãy làm việc với các nhà sản xuất duy trì các quy trình kiểm soát chất lượng nghiêm ngặt và tạo ra các dấu hiệu rõ ràng, có thể truy xuất được. Các nhà sản xuất được chứng nhận IATF 16949 như Công nghệ kim loại Shaoyi (Ningbo) đảm bảo các thành phần rèn của họ đi kèm tài liệu hợp lệ và đáp ứng đúng thông số kỹ thuật thông qua đội ngũ kỹ thuật nội bộ và hệ thống chất lượng toàn diện. Mức độ kỷ luật sản xuất này tạo ra các dấu hiệu trên vành rõ ràng, chính xác, giúp việc xác minh trở nên dễ dàng.

Môi trường sản xuất thực tế tiết lộ nhiều điều về chất lượng. Các tài liệu tham khảo lưu ý rằng khi đến thăm một nhà sản xuất vành xe, cần thận trọng nếu bạn chỉ thấy các máy CNC, khu vực sơn và các trạm kiểm tra cơ bản — điều này cho thấy nhiều quy trình quan trọng có thể đã được gia công ngoài, dẫn đến nguy cơ mất kiểm soát chất lượng và độ chính xác của các ký hiệu.

Các Dấu Hiệu Cảnh Báo Cần Tránh Xa

Đôi khi quyết định mua hàng tốt nhất chính là không mua gì cả. Dựa trên kiến thức về đánh dấu mà bạn đã tích lũy được, hãy lưu ý những dấu hiệu cảnh báo sau đây cho thấy việc mua bánh xe không đáng để chấp nhận rủi ro:

- Người bán từ chối cung cấp ảnh chụp các ký hiệu – Người bán hợp pháp sẽ không có gì phải giấu

- Các dấu chứng nhận bị thiếu hoặc không rõ ràng – Điều này cho thấy sản phẩm có thể là hàng giả hoặc vành được sản xuất cho các thị trường ít nghiêm ngặt về quy định

- Các số hiệu phụ tùng không khớp với cơ sở dữ liệu của nhà sản xuất – Dấu hiệu mạnh mẽ cho thấy vành xe là hàng giả

- Trọng lượng không khớp với thông số kỹ thuật công bố – Hàng giả thường sử dụng ít vật liệu hơn để giảm chi phí

- Mã ngày trong một bộ không khớp nhau – Gợi ý đây là hàng giả được lắp ráp thay vì bộ chính hãng đồng bộ

- Giá dường như tốt đến mức khó tin – Các bánh xe rèn cao cấp có giá cao tương xứng; các mức giảm giá sâu đáng làm dấy lên nghi ngờ

- Các dấu hiệu nhận biết cho thấy dấu hiệu bị sửa đổi – Các khu vực bị mài, đóng lại mã hoặc bị che khuất cho thấy khả năng gian lận

Các tài liệu tham khảo xác nhận rằng những bánh xe được quảng cáo là "rèn" đôi khi thực chất là sản phẩm đúc chất lượng thấp hơn với giá bị thổi phồng. Kỹ năng kiểm tra dấu hiệu của bạn giúp bạn tránh được sự lừa dối này bằng cách vạch ra câu chuyện sản xuất thực sự phía sau bất kỳ bánh xe nào.

Với phương pháp kiểm tra hệ thống này, bạn đã sẵn sàng đánh giá tự tin các bánh xe rèn—biết chính xác cần kiểm tra gì, tìm ở đâu và khi nào nên từ chối. Bước cuối cùng là hiểu rõ những dấu hiệu nào quan trọng nhất và cách áp dụng kiến thức này để bảo vệ lâu dài cho khoản đầu tư và sự an toàn của bạn.

Làm Chủ Các Nhãn Hiệu Trên Vành Đúc Để Ra Quyết Định Thông Minh Hơn

Bạn đã tìm hiểu toàn bộ các yếu tố liên quan đến nhãn hiệu trên vành đúc — từ thông số kích thước, cấp vật liệu, đến tem chứng nhận và mã nhà sản xuất. Giờ là lúc tổng hợp lại những kiến thức này thành hướng dẫn thực tiễn mà bạn có thể áp dụng mỗi khi đánh giá vành đúc. Việc hiểu được những gì vành xe đang 'nói' với bạn thông qua các ký hiệu không chỉ đơn thuần là kiến thức kỹ thuật — mà còn là kỹ năng kết hợp giữa bảo vệ tài chính và đảm bảo an toàn.

Dù bạn đang mua bộ vành cao cấp đầu tiên hay bổ sung thêm vào bộ sưu tập hiện có, thì thói quen kiểm tra các ký hiệu ngay từ bây giờ sẽ đồng hành cùng bạn trong nhiều năm tới. Hãy làm rõ những điểm then chốt giúp phân biệt người mua hàng am hiểu với những người phải trả giá đắt để học bài học kinh nghiệm.

Các Ký Hiệu Cần Thiết Luôn Phải Kiểm Tra

Không phải tất cả các ký hiệu đều có mức độ quan trọng như nhau khi đánh giá bánh xe đúc. Một số ký hiệu tiết lộ thông tin an toàn quan trọng, trong khi những ký hiệu khác chỉ cung cấp xác minh bổ sung. Hãy ưu tiên thời gian kiểm tra của bạn vào những yếu tố bắt buộc sau:

- Thông số kích thước (kích cỡ, độ dịch chuyển, mẫu bulông) – Những thông số này xác định xem bánh xe có khớp vật lý với phương tiện của bạn hay không. Thông số sai có thể gây ma sát, vấn đề về xử lý lái và hư hại các bộ phận liên quan.

- Dấu chứng nhận (DOT, JWL, VIA, TÜV, ECE) – Những dấu này chứng minh rằng các phòng thí nghiệm độc lập đã kiểm tra và xác nhận độ bền cấu trúc. Sản phẩm thiếu chứng nhận cho thấy đây là hàng chưa được kiểm định hoặc hàng giả.

- Ký hiệu cấp vật liệu (6061-T6 hoặc tương đương) – Những ký hiệu này xác nhận thành phần hợp kim nhôm và chế độ xử lý nhiệt, từ đó xác định các đặc tính vận hành.

- Mã ngày sản xuất và số phụ tùng – Những mã này xác minh tuổi đời sản phẩm, hỗ trợ yêu cầu bảo hành và cho phép tra cứu cơ sở dữ liệu nhà sản xuất để xác thực nguồn gốc.

- Xác định nhà sản xuất – Các nhà sản xuất hợp pháp tự hào hiển thị nhãn hiệu và các dấu hiệu kiểm soát chất lượng của họ; việc thiếu hoặc che giấu thông tin nhận diện cần phải cảnh giác.

Khi kiểm tra các loại vành bánh xe khác nhau, hãy nhớ rằng ý nghĩa của vành hợp kim không chỉ dừng lại ở vẻ ngoài. Những ký hiệu được đóng trên bề mặt kim loại đại diện cho các tiêu chuẩn sản xuất, quy trình thử nghiệm và cam kết về chất lượng, những yếu tố này ảnh hưởng trực tiếp đến độ an toàn khi lái xe của bạn. Kích thước vành xe được giải thích qua các ký hiệu sẽ cho bạn biết bộ phận đó có phù hợp với phương tiện của bạn hay không—hay là nên nằm trong gara của người khác.

Các dấu chứng nhận không mang tính trang trí—đó là minh chứng cho thấy các phòng thí nghiệm kiểm định độc lập đã xác nhận độ bền cấu trúc của vành xe trong điều kiện khắc nghiệt. Những vành xe thiếu các chứng nhận phù hợp có thể đã bỏ qua các bài kiểm tra nghiêm ngặt nhằm bảo vệ bạn trong từng dặm đường di chuyển.

Kiến Thức Của Bạn Về Các Ký Hiệu Trên Vành Xe Trong Hành Động

Những kỹ năng xác minh mà bạn đã phát triển sẽ thay đổi cách tiếp cận khi mua bánh xe rèn. Thay vì chỉ dựa vào lời khẳng định của người bán hay vẻ ngoài hấp dẫn, giờ đây bạn đánh giá bánh xe dựa trên các bằng chứng có thể kiểm chứng được đóng trực tiếp lên chính kim loại.

Áp dụng kiến thức này bằng cách:

- Yêu cầu hiển thị đầy đủ các ký hiệu – Yêu cầu ảnh chụp tất cả bốn khu vực ký hiệu trước mọi giao dịch mua. Những người bán do dự thường có điều gì đó cần giấu giếm.

- Đối chiếu từng thông số kỹ thuật – So sánh các ký hiệu đóng trên bánh xe với yêu cầu xe của bạn và cơ sở dữ liệu nhà sản xuất. Sự khác biệt sẽ cho thấy hàng giả hoặc sản phẩm không tương thích.

- Xem việc thiếu giấy chứng nhận là yếu tố loại trừ – Thiếu dấu chứng nhận nghĩa là không có xác nhận độc lập về hiệu suất an toàn. Rủi ro này không đáng để đánh đổi dù với bất kỳ mức giảm giá nào.

- Xác minh chất lượng sản xuất thông qua các ký hiệu loại vành – Các bánh xe rèn cao cấp thể hiện hệ thống ký hiệu đồng nhất, chuyên nghiệp, phản ánh tính kỷ luật trong quy trình sản xuất tổng thể.

Sự bảo vệ tài chính mà kiến thức này mang lại là rất lớn. Những bánh xe giả mạo bị hỏng nghiêm trọng có thể gây ra tai nạn, làm mất hiệu lực bảo hiểm và để lại cho bạn những sản phẩm vô giá trị. Các bánh xe có thông số kỹ thuật không chính xác sẽ tạo ra vấn đề lắp ráp, đòi hỏi phải sửa chữa tốn kém. Việc hiểu biết về các loại vành cũng như các ký hiệu liên quan sẽ ngăn ngừa những sai lầm tốn kém này.

Vượt ra ngoài các giao dịch mua cá nhân, kiến thức về ký hiệu của bạn còn liên quan đến chất lượng sản xuất trên diện rộng. Theo các tiêu chuẩn ngành, các chứng nhận như IATF 16949 cho thấy sự cam kết của một công ty đối với chất lượng và an toàn trong toàn bộ quá trình sản xuất. Các nhà sản xuất đầu tư vào hệ thống chứng nhận và kiểm soát chất lượng phù hợp sẽ tạo ra các ký hiệu đồng nhất, có thể truy xuất được, giúp việc xác minh trở nên đơn giản và dễ dàng.

Các công ty như Công nghệ kim loại Shaoyi (Ningbo) minh chứng cho cách tiếp cận này — chứng nhận IATF 16949 và đội ngũ kỹ thuật nội bộ của họ đảm bảo các thành phần rèn có đầy đủ tài liệu phù hợp với các thông số kỹ thuật chính xác. Khi bạn mua bánh xe từ những nhà sản xuất có quy trình ghi mã minh bạch và hệ thống chất lượng nghiêm ngặt, việc xác minh trở thành quá trình xác nhận thay vì điều tra.

Mỗi chiếc bánh xe rèn đều kể một câu chuyện qua các ký hiệu trên bề mặt. Giờ đây, bạn đã có kiến thức để đọc trọn vẹn câu chuyện đó — hiểu rõ các thông số về kích thước, thành phần vật liệu, trạng thái chứng nhận, lịch sử sản xuất và danh tính nhà sản xuất. Sự hiểu biết toàn diện này bảo vệ khoản đầu tư của bạn, đảm bảo độ vừa khít chính xác và quan trọng nhất là giữ an toàn cho bạn trong mọi chuyến đi. Lần tới khi nhìn thấy một bộ bánh xe rèn, bạn sẽ thấy được chất lượng đã được kiểm định bên dưới lớp hoàn thiện bóng bẩy — hoặc nhận ra những dấu hiệu cảnh báo mà người khác bỏ lỡ.

Câu hỏi thường gặp về ký hiệu bánh xe rèn

1. Làm cách nào để phân biệt bánh xe rèn và bánh xe đúc?

Vành đúc thường nhẹ hơn 25-30% so với vành đúc cùng kích thước do cấu trúc nhôm đặc hơn. Hãy tìm các ký hiệu cấp vật liệu như 6061-T6 trên vành đúc, điều mà vành đúc thông thường hiếm khi có. Vành đúc cũng đi kèm các dấu chứng nhận đầy đủ (JWL, VIA, TÜV) phản ánh các tiêu chuẩn kiểm tra nghiêm ngặt. Kiểm tra bằng cách gõ nhẹ cũng hữu ích—vành đúc thật tạo ra âm thanh rõ ràng, vang như tiếng chuông, trong khi vành đúc thông thường nghe đục hơn.

2. Cách đọc các ký hiệu trên vành xe?

Các ký hiệu trên vành tuân theo định dạng tiêu chuẩn như 18x8.5J ET35 5x114.3. Số đầu tiên chỉ đường kính (18 inch), tiếp theo là độ rộng (8.5 inch). Chữ cái J chỉ loại mép vành, ET35 cho biết độ dịch chuyển tính bằng milimét, và 5x114.3 biểu thị mẫu bulông (5 bulông, đường kính 114.3mm). Kiểm tra khu vực phía sau chấu để tìm dấu kích thước, bề mặt trong lòng vành để tìm mã ngày sản xuất, và bề mặt lắp trung tâm để biết thông tin nhà sản xuất.

3. Dấu chứng nhận DOT và JWL trên vành xe có ý nghĩa gì?

Các dấu DOT cho biết sự tuân thủ các tiêu chuẩn an toàn của Bộ Giao thông Vận tải Hoa Kỳ, bắt buộc để được phép lưu hành hợp pháp trên đường tại Mỹ. Chứng nhận JWL (Japan Light Alloy Wheel) xác nhận vành đã vượt qua các bài kiểm tra về mỏi uốn, mỏi hướng tâm, va chạm và độ tròn. Chứng nhận VIA bổ sung thêm các bài kiểm tra nghiêm ngặt hơn so với yêu cầu của JWL. Những dấu này chứng minh rằng các phòng thí nghiệm độc lập đã xác minh tính toàn vẹn cấu trúc — các vành không có chúng có thể là hàng giả chưa được kiểm định.

4. Làm cách nào để xác minh vành rèn thật hay giả?

Tra cứu chéo số hiệu phụ tùng thông qua cơ sở dữ liệu của nhà sản xuất — hàng giả thường không trả về kết quả nào. Kiểm tra kiểu chữ ghi nhãn có đồng nhất hay không, vì các la-zăng chính hãng luôn có độ sâu và vị trí chữ in đều nhau. Xác minh các mã ngày sản xuất phải phù hợp trong bộ lắp đặt tương ứng, cân trọng lượng la-zăng so với thông số công bố (hàng giả thường có trọng lượng khác), và xác nhận tất cả các dấu chứng nhận đều hiện diện và rõ ràng. Các nhà sản xuất đạt chứng nhận IATF 16949 như Shaoyi đảm bảo các thành phần rèn có thể truy xuất nguồn gốc và được tài liệu hóa đầy đủ.

5. ET offset nghĩa là gì và tại sao nó quan trọng?

ET (Einpresstiefe) đo khoảng cách tính bằng milimét giữa bề mặt lắp ráp moay-ơ và đường tâm của la-zăng. Độ lệch dương (ET35, ET45) đưa la-zăng vào phía trong, phổ biến trên các xe hiện đại. Độ lệch âm đẩy la-zăng ra ngoài, thường dùng trên xe tải và xe địa hình. Sai lệch độ offset sẽ gây cọ lốp, mài mòn bạc đạn nhanh hơn và làm giảm khả năng điều khiển. Hầu hết các xe cho phép sai lệch 15-20mm so với thông số tiêu chuẩn.

Sản xuất với số lượng nhỏ, tiêu chuẩn cao. Dịch vụ tạo nguyên mẫu nhanh của chúng tôi giúp việc kiểm chứng trở nên nhanh chóng và dễ dàng hơn —

Sản xuất với số lượng nhỏ, tiêu chuẩn cao. Dịch vụ tạo nguyên mẫu nhanh của chúng tôi giúp việc kiểm chứng trở nên nhanh chóng và dễ dàng hơn —