Dịch vụ Hàn Kim Loại Tấm Chi Tiết: Từ Phù Hợp Vật Liệu Đến Hoàn Thiện Hoàn Hảo

Hiểu Về Dịch Vụ Hàn Kim Loại Tấm Và Tầm Quan Trọng Công Nghiệp Của Chúng

Bạn đã từng tự hỏi làm thế nào một tấm kim loại phẳng có thể biến thành tấm thân xe bóng bẩy hay vỏ thiết bị y tế chính xác? Đó chính là phép màu của dịch vụ hàn kim loại tấm. Những quy trình chuyên biệt này nối các tấm kim loại mỏng—thường dao động từ 0,5mm đến 6mm độ dày—bằng các kỹ thuật nhiệt và nóng chảy được kiểm soát để tạo ra mọi thứ, từ các hộp thiết bị điện tử phức tạp đến thiết bị công nghiệp chắc chắn.

Không giống như hàn kết cấu xử lý các tấm dày và dầm cho cầu và tòa nhà , hàn kim loại tấm đòi hỏi độ chính xác tuyệt đối. Tại sao? Bởi vì vật liệu mỏng dễ bị ảnh hưởng hơn nhiều. Nếu áp dụng quá nhiều nhiệt, bạn sẽ đốt thủng ngay lập tức. Nếu sử dụng sai kỹ thuật, hiện tượng cong vênh là điều không thể tránh khỏi. Chính sự cân bằng tinh tế này là yếu tố phân biệt một doanh nghiệp hàn chuyên nghiệp với những nỗ lực nghiệp dư.

Điều Gì Làm Cho Hàn Tôn Trở Nên Độc Đáo

Sự khác biệt cơ bản nằm ở việc kiểm soát nhiệt độ. Khi làm việc với vật liệu mỏng, từng độ nhiệt đều rất quan trọng. Những thợ hàn chuyên nghiệp phải kiểm soát lượng nhiệt đưa vào một cách chính xác như phẫu thuật để tránh biến dạng, đồng thời vẫn đảm bảo độ ngấu hoàn toàn. Điều này đòi hỏi thiết bị chuyên dụng, kỹ thuật tinh vi và nhiều năm kinh nghiệm mà chỉ các nhà cung cấp dịch vụ chuyên biệt mới có thể đáp ứng.

Hàn có nguy hiểm khi làm việc với tôn mỏng không? Như bất kỳ quy trình công nghiệp nào, nó tiềm ẩn rủi ro — từ tiếp xúc tia UV đến hít phải khí độc. Những câu hỏi như "hàn có gây ung thư không" và "hàn ảnh hưởng thế nào đến cơ thể bạn" xứng đáng có câu trả lời trung thực: tiếp xúc kéo dài với khói hàn mà không được bảo vệ đúng cách có thể gây ra các vấn đề sức khỏe. Vì vậy, các dịch vụ chuyên nghiệp đầu tư mạnh vào hệ thống thông gió, thiết bị bảo hộ và các quy trình an toàn nhằm bảo vệ cả người lao động lẫn chất lượng sản phẩm.

Nền Tảng Của Lắp Ráp Kim Loại Chính Xác

Hàn kim loại tấm đóng vai trò là nền tảng của sản xuất hiện đại trong hầu hết mọi lĩnh vực. Theo số liệu ngành từ NW Metal Fabricators , gia công kim loại—bao gồm các dịch vụ hàn—đóng một vai trò then chốt trong nhiều ngành công nghiệp nơi độ chính xác và chất lượng là yếu tố hàng đầu.

Dưới đây là những ngành công nghiệp chính phụ thuộc nhiều vào các dịch vụ chuyên biệt này:

- Ngành ô tô: Các bộ phận khung gầm, tấm thân xe, hệ thống xả và các bộ phận động cơ đòi hỏi tiêu chuẩn an toàn và hiệu suất nghiêm ngặt

- Ngành hàng không: Các bộ phận nhẹ nhưng bền cho thân máy bay, bề mặt điều khiển và vỏ động cơ

- Thiết bị y tế: Các thiết bị và hộp chứa bằng thép không gỉ đáp ứng yêu cầu vệ sinh và độ chính xác cao

- Ngành điện tử: Các hộp đựng tùy chỉnh, khung gầm và bộ tản nhiệt cho thiết bị nhạy cảm

- Năng lượng: Khung tấm pin năng lượng mặt trời, các bộ phận tuabin gió và thiết bị phát điện

- Hàng tiêu dùng: Thiết bị gia dụng, đồ nội thất và các sản phẩm gia đình kết hợp giữa chức năng và tính thẩm mỹ

Hiểu được những nguy hiểm khi hàn và thực hiện các biện pháp an toàn phù hợp là yếu tố phân biệt các nhà cung cấp dịch vụ uy tín với những đối thủ còn lại. Khi chúng ta tìm hiểu sâu hơn về các kỹ thuật, vật liệu và tiêu chuẩn chất lượng sắp tới, bạn sẽ có được kiến thức cần thiết để đưa ra quyết định sáng suốt về dự án kim loại tấm tiếp theo của mình.

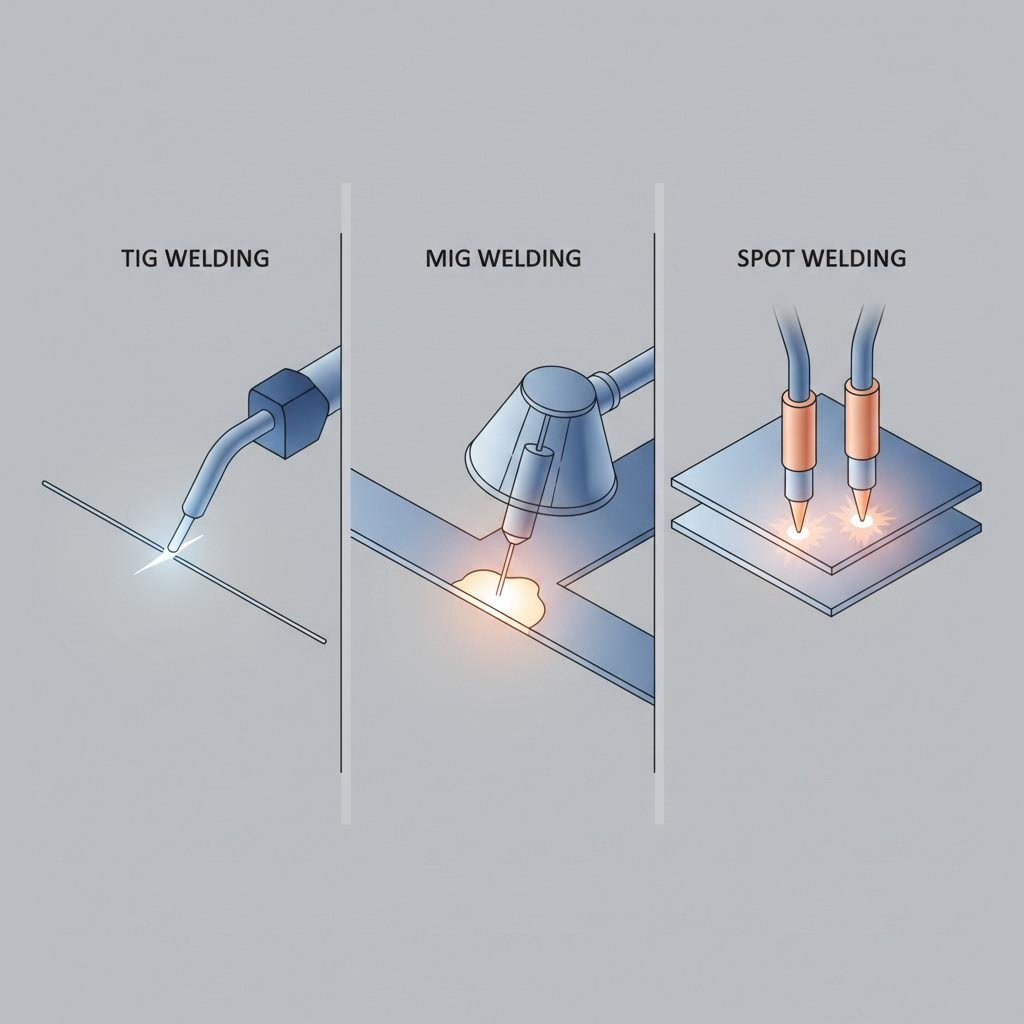

Giải thích các phương pháp hàn TIG, MIG và hàn điểm

Bây giờ bạn đã hiểu tại sao việc hàn kim loại tấm đòi hỏi độ chính xác cao đến vậy, hãy cùng đi sâu vào ba phương pháp chủ lực giúp hiện thực hóa điều đó. Dù bạn đang lên kế hoạch cho hàn kim loại tùy chỉnh cho một mẫu thử duy nhất hay mở rộng quy mô cho sản xuất hàng loạt, việc lựa chọn đúng phương pháp hàn có thể tạo nên sự khác biệt giữa một bề mặt hoàn thiện tuyệt hảo và một thất bại đáng tiếc.

Hãy hình dung như thế này: hàn TIG, MIG và hàn điểm giống như ba công cụ khác nhau trong bộ dụng cụ của một nghệ nhân bậc thầy. Mỗi phương pháp đều vượt trội trong những tình huống cụ thể, và việc biết khi nào nên sử dụng kỹ thuật nào chính là yếu tố phân biệt dịch vụ hàn kim loại tấm chuyên nghiệp với những nỗ lực nghiệp dư.

Hàn TIG cho Công việc Kim loại Tấm Chính xác

Hàn Tungsten Inert Gas—thường được gọi là hàn hồ quang với khí trơ (GTAW)—là tiêu chuẩn vàng khi độ chính xác và tính thẩm mỹ là yếu tố quan trọng nhất. Hãy tưởng tượng việc tạo ra các mối hàn sạch đến mức gần như không cần xử lý sau khi hàn. Đó chính là hàn TIG ở mức hoàn hảo nhất.

Cách thức hoạt động như sau: Một điện cực vonfram không tiêu hao tạo ra hồ quang điện làm nóng chảy kim loại cơ bản của bạn. Đồng thời, thợ hàn dùng một tay đưa thanh que hàn phụ vào vũng hàn trong khi tay kia điều khiển mỏ hàn. Một khí trơ—thường là argon nguyên chất—sẽ bảo vệ toàn bộ quá trình khỏi sự nhiễm bẩn từ môi trường.

Kỹ thuật hàn hai tay này đòi hỏi kỹ năng đáng kể, nhưng kết quả đạt được rất ấn tượng. Hàn TIG mang lại:

- Kiểm soát vượt trội: Thợ hàn có thể điều chỉnh chính xác lượng nhiệt đầu vào, làm cho phương pháp này lý tưởng cho kim loại tấm mỏng mà sẽ bị cháy thủng nếu sử dụng các phương pháp khác

- Tính thẩm mỹ vượt trội: Các mối hàn sạch, không bắn tóe và thường cần ít hoàn thiện—lý tưởng cho các đường nối nhìn thấy được trên đồ nội thất cao cấp hoặc các chi tiết kiến trúc trang trí

- Tính đa dạng của vật liệu: Làm việc hiệu quả với nhôm, titan, thép không gỉ và các hợp kim đặc biệt

- Tính linh hoạt AC/DC: Chế độ dòng xoay chiều xử lý lớp oxit của nhôm, trong khi dòng một chiều vượt trội trên thép

Điểm đánh đổi? Tốc độ. Hàn TIG là phương pháp chậm nhất trong ba phương pháp, do đó phù hợp hơn với công việc chính xác thay vì sản xuất số lượng lớn. Khi bạn cần chất lượng hàn tuyệt hảo trên một chi tiết kiến trúc tùy chỉnh hoặc hộp bao kín chính xác, TIG mang lại kết quả xứng đáng để chờ đợi.

Ứng dụng hàn MIG so với hàn điểm

Trong khi TIG tập trung vào sự tinh tế, thì hàn MIG và hàn điểm ưu tiên hiệu suất—mỗi loại theo một cách thức khác biệt rõ rệt.

Hàn MIG: Phương pháp hàn chủ lực trong sản xuất

Hàn khí trơ kim loại (còn gọi là hàn hồ quang kim loại với khí bảo vệ) sử dụng điện cực dây được cấp liên tục, đảm nhiệm đồng thời hai chức năng là vật dẫn điện và kim loại hàn đắp. Khi dây được cấp qua súng hàn, một hồ quang hình thành giữa đầu dây và vật hàn, làm nóng chảy cả hai kết hợp với nhau trong khi khí bảo vệ che chở vũng hàn.

Phương pháp bán tự động này mang lại những ưu điểm nổi bật trong môi trường sản xuất:

- Tốc độ: Dây hàn được cấp liên tục cho phép thực hiện các mối hàn dài mà không cần dừng lại — lý tưởng cho các cụm lắp ráp lớn

- Khả năng tiếp cận: Dễ học hơn so với hàn TIG, phù hợp với các thợ vận hành có ít kinh nghiệm

- Tính linh hoạt: Xử lý hiệu quả thép cacbon, thép không gỉ và nhôm

- Tính hiệu quả về chi phí: Chi phí thiết bị và nhân công thấp hơn đối với khối lượng công việc lớn

MIG phát huy tốt trên các vật liệu độ dày lớn nơi mà nhiệt lượng đầu vào cao hơn trở thành lợi thế thay vì bất lợi. Đây là phương pháp ưu tiên cho các sản phẩm nội thất công nghiệp như chân bàn hội nghị công nghiệp hoặc các bộ phận cấu trúc yêu cầu các mối nối chắc chắn và đáng tin cậy.

Hàn điểm: Tự động hóa độ chính xác cho các tấm chồng lấn

Hàn điểm tiếp cận theo một cách hoàn toàn khác. Thay vì nóng chảy dọc theo đường nối, phương pháp này sử dụng điện trở để tạo ra các điểm hàn riêng biệt giữa các tấm kim loại chồng lấn. Hai điện cực đồng kẹp chặt các chi tiết kim loại lại với nhau trong khi dòng điện cao chạy qua, tạo ra nhiệt lượng cục bộ mạnh mẽ làm nóng chảy và kết dính các tấm tại đúng vị trí đó.

Quy trình này thống trị ngành sản xuất ô tô vì những lý do chính đáng:

- Tốc độ cực nhanh: Mỗi mối hàn chỉ mất vài giây, cho phép tạo hàng ngàn mối nối trên mỗi xe

- Biến dạng tối thiểu: Nhiệt lượng tập trung chỉ ảnh hưởng đến diện tích nhỏ, giữ nguyên hình dạng các tấm vỏ

- Thân thiện với tự động hóa: Các hệ thống hàn điểm bằng robot đảm bảo chất lượng ổn định ở khối lượng khổng lồ

- Tiêu thụ năng lượng thấp: Sinh nhiệt hiệu quả giúp giảm chi phí vận hành

Hạn chế là gì? Hàn điểm chỉ phù hợp với cấu hình các tấm kim loại chồng lấn có độ dày tối đa khoảng 3mm, do đó không thích hợp với các mối nối đối đầu hay vật liệu dày hơn.

So sánh phương pháp toàn diện

Việc lựa chọn giữa ba phương pháp này đòi hỏi phải cân nhắc nhiều yếu tố phù hợp với các yêu cầu cụ thể của dự án bạn. Bảng so sánh dưới đây, dựa trên dữ liệu từ chuyên môn gia công của 3ERP và TORNQVIST Custom Metal Fabricator , phân tích các tiêu chí quyết định chính:

| Tiêu chí | TIG hàn | Phối hàn MIG | Hàn chấm |

|---|---|---|---|

| Phạm vi độ dày vật liệu | 0,5mm - 6mm (vượt trội với vật liệu mỏng) | 1mm - 12mm+ (tốt hơn với vật liệu dày) | 0,5mm - 3mm (chỉ áp dụng với các tấm chồng lấn) |

| Tốc độ hàn | Chậm | Nhanh | Rất nhanh |

| Yêu cầu kỹ năng | Cao (kỹ thuật hai tay) | Trung bình (bán tự động) | Thấp đến Trung bình (thường được tự động hóa) |

| Chất lượng hoàn thiện | Xuất sắc (ít cần xử lý sau) | Tốt (có thể cần làm sạch) | Tốt (có dấu hiệu địa phương hóa) |

| Vật liệu tốt nhất | Thép không gỉ, nhôm, titan, hợp kim đặc biệt | Thép carbon, thép không gỉ, nhôm | Thép ít carbon, thép không gỉ, thép mạ kẽm |

| Ứng Dụng Điển Hình | Các bộ phận hàng không vũ trụ, thiết bị y tế, đồ trang trí, mối hàn nhìn thấy được | Các cụm ô tô, thiết bị công nghiệp, cấu kiện lớn | Tấm thân ô tô, thiết bị gia dụng, vỏ sản xuất hàng loạt |

| Chi phí thiết bị | Trung bình đến Cao | Trung bình | Cao (đối với hệ thống tự động) |

| Tiềm năng tự động hóa | Hạn chế (kỹ năng thủ công là yếu tố then chốt) | Tốt (MIG robot hóa thông thường) | Xuất sắc (dây chuyền hoàn toàn tự động) |

Hãy để ý cách mỗi phương pháp tạo ra phạm vi riêng của nó? Một dự án hàn kim loại tùy chỉnh cho các yếu tố kiến trúc có thể đòi hỏi bề mặt hoàn thiện tinh tế của TIG, trong khi một lô sản xuất hàng ngàn hộp bảo vệ sẽ được hưởng lợi từ tốc độ và độ ổn định của hàn điểm. Việc hiểu rõ những khác biệt này giúp bạn giao tiếp hiệu quả với các đối tác gia công và đưa ra quyết định sáng suốt về yêu cầu dự án của mình.

Tất nhiên, việc lựa chọn phương pháp hàn phù hợp chỉ là một phần của vấn đề. Vật liệu bạn đang nối cũng đóng vai trò quan trọng không kém trong việc xác định kỹ thuật nào — và các thông số cụ thể nào — sẽ mang lại kết quả tối ưu.

Hướng dẫn tương thích vật liệu cho hàn kim loại tấm

Vì vậy, bạn đã chọn được phương pháp hàn phù hợp nhất cho dự án của mình. Nhưng vấn đề nằm ở đây – lựa chọn đó sẽ trở nên vô nghĩa nếu bạn không kết hợp đúng với vật liệu nền của mình. Mỗi loại kim loại mang đến những đặc tính riêng biệt khi hàn, và việc hiểu rõ những điểm khác biệt này chính là ranh giới giữa mối hàn thành công và thất bại tốn kém.

Hãy nghĩ theo cách này: hàn nhôm hoàn toàn khác biệt so với hàn thép, dù cả hai đều là "kim loại". Các đặc tính về nhiệt, hành vi tạo oxit và độ nhạy cảm với nhiễm bẩn khác nhau rất lớn. Hãy cùng phân tích những điều bạn cần biết về từng loại tấm kim loại phổ biến và cách đạt được kết quả hoàn hảo.

Các yếu tố cần xem xét khi hàn tấm nhôm

Nhôm có lẽ là thách thức lớn nhất đối với các dịch vụ hàn kim loại và có lý do tốt. Vật liệu nhẹ này dẫn nhiệt nhanh hơn gấp 5 lần thép, có nghĩa là nhiệt được kiểm soát cẩn thận sẽ nhanh chóng phân tán qua toàn bộ mảnh. Kết quả là gì? Bạn cần điện áp cao hơn đáng kể để đạt được nhiệt hạch, nhưng nhiệt thêm đó làm tăng nguy cơ cháy trên các phần mỏng.

Nhưng tính dẫn nhiệt chỉ là khởi đầu. Nhôm tự nhiên tạo thành một lớp oxit chảy ở nhiệt độ khoảng 3.700 ° Fgần ba lần cao hơn điểm nóng chảy của kim loại cơ bản khoảng 1.200 ° F. Theo Các nguồn lực kỹ thuật của ESAB , lớp oxit này có lỗ và có thể hấp thụ độ ẩm, trở thành một nguồn lỗ chính trong quá trình hàn nếu không được giải quyết đúng cách.

Hàn nhôm có độc hại không? Khi không thực hiện các biện pháp phòng ngừa thích hợp, việc hàn nhôm có thể giải phóng các khí độc hại. Lớp oxit kết hợp với bất kỳ chất bẩn bề mặt nào như chất bôi trơn hoặc dung dịch cắt gọt sẽ tạo ra thêm các mối nguy hiểm từ khói, đòi hỏi phải thông gió đầy đủ và bảo vệ đường hô hấp.

Dưới đây là các loại que hàn và khí bảo vệ thiết yếu cho kim loại tấm nhôm:

- que hàn 4043: Chứa 5% silic — phù hợp tốt với các hợp kim dãy 6xxx, mang lại độ chảy tốt và khả năng chống nứt, nhưng bị tối màu trong quá trình anod hóa

- que hàn 5356: Chứa 5% magiê — mạnh hơn và phù hợp về màu sắc hơn sau khi anod hóa, lý tưởng cho các kim loại nền dãy 5xxx

- que hàn 4643: Được thiết kế đặc biệt cho các ứng dụng xử lý nhiệt sau hàn trên các hợp kim dãy 6xxx

- Khí bảo vệ: Argon tinh khiết (99,99%) dùng cho hàn TIG; argon hoặc hỗn hợp argon-heli dùng cho hàn MIG trên các phần dày hơn

Một yếu tố quan trọng mà nhiều thợ gia công thường bỏ qua: khả năng cấp dây. Như ESAB lưu ý, độ mềm của nhôm khiến nó dễ bị biến dạng trong quá trình cấp dây hàn MIG. Việc sử dụng con lăn dẫn dạng U, ống lót nylon thay vì kim loại và đầu tiếp xúc có kích cỡ phù hợp sẽ ngăn ngừa hiện tượng mài mòn dây, dẫn đến hồ quang không ổn định và nhiễm bẩn.

Các Thực Hành Tốt Nhất Khi Hàn Thép Không Gỉ

Thép không gỉ đòi hỏi sự tôn trọng vì những lý do hoàn toàn khác biệt. Mặc dù nó không có độ dẫn nhiệt cực cao như nhôm , nhưng lại rất nhạy cảm với lượng nhiệt đầu vào quá mức. Tại sao hàn lại có hại cho bạn khi làm việc với thép không gỉ? Hàm lượng crôm mang lại khả năng chống ăn mòn cho thép không gỉ có thể sinh ra khí độc crôm hóa trị sáu—một chất gây ung thư đã biết—khi bị đun nóng quá mức. Thông gió tốt và hệ thống hút khói phải được thực hiện một cách bắt buộc.

Về mặt luyện kim, những nguy cơ lan đến chính vật liệu. Nhiệt độ quá cao gây ra hiện tượng "phân cực", trong đó các carbide crôm hình thành tại các biên giới hạt, làm cạn kiệt vùng xung quanh lượng crôm cần thiết để chống ăn mòn. Điều này tạo ra một vùng yếu dễ bị ăn mòn giữa các hạt—thường không nhìn thấy cho đến khi xảy ra hỏng hóc nghiêm trọng.

Hàn có ảnh hưởng đến sức khỏe khi làm việc với inox không? Ngoài lo ngại về khí thải, bức xạ UV mạnh từ vũng hàn rất phản quang của thép không gỉ làm tăng nguy cơ phơi nhiễm cho mắt và da, do đó việc sử dụng đầy đủ phương tiện bảo hộ cá nhân (PPE) là điều cần thiết.

Dưới đây là những gì bạn cần để hàn thành công các tấm kim loại inox:

- dây hàn 308/308L: Lựa chọn tiêu chuẩn cho inox 304; ký hiệu "L" chỉ hàm lượng carbon thấp nhằm giảm nguy cơ phân cực

- dây hàn 316/316L: Phù hợp với vật liệu nền 316 để tăng khả năng chống ăn mòn trong môi trường biển hoặc hóa chất

- dây hàn 309/309L: Cần thiết khi nối các kim loại khác nhau, ví dụ như inox với thép carbon

- Khí bảo vệ: Argon với 1-2% oxy cho hàn MIG cải thiện độ ổn định hồ quang; argon tinh khiết hoặc hỗn hợp argon-helium cho hàn TIG; hỗn hợp ba thành phần (helium-argon-CO2) cho các ứng dụng cụ thể

- Lửa Thanh: Thiết yếu cho các ứng dụng quan trọng — khí bảo vệ argon phía sau mối hàn ngăn ngừa hiện tượng oxy hóa và hiện tượng "sugaring"

Các thách thức khi hàn vật liệu thép carbon và vật liệu mạ kẽm

Thép carbon nói chung là vật liệu dễ hàn nhất trong các ứng dụng hàn kim loại tấm, nhưng đừng để điều đó khiến bạn chủ quan. Việc chuẩn bị cẩn thận vẫn rất quan trọng, và việc chọn que hàn phải phù hợp với hàm lượng carbon và yêu cầu độ bền của kim loại cơ bản.

Đối với các ứng dụng hàn kim loại tấm bằng thép carbon:

- Que hàn ER70S-3 hoặc ER70S-6: Lựa chọn tiêu chuẩn cho thép mềm; loại S-6 chứa nhiều chất khử ôxy hơn, thích hợp khi hàn qua lớp vảy cán nhẹ

- Khí bảo vệ: hỗn hợp 75% argon/25% CO2 (C25) mang lại khả năng ngấu tốt và văng tóe tối thiểu; hỗn hợp 90/10 hoặc 95/5 argon-CO2 cho mối hàn sạch hơn trên vật liệu mỏng

Thép mạ kẽm gây ra những phức tạp mà nhiều nhà gia công đánh giá thấp. Lớp phủ kẽm bay hơi ở nhiệt độ thấp hơn nhiều so với điểm nóng chảy của thép, tạo ra đồng thời một số vấn đề: rỗ khí do giữ lại khí kẽm, hiện tượng hồ quang không ổn định và lượng khói thải tăng đáng kể. Tại sao việc hàn lại có hại cho bạn khi liên quan đến vật liệu mạ kẽm? Khói kẽm gây ra "sốt kim loại" — một chứng bệnh giống cúm, tuy mang tính tạm thời nhưng cho thấy mức độ tiếp xúc nguy hiểm.

Khi hàn các tấm kim loại mạ kẽm, các dịch vụ chuyên nghiệp áp dụng những chiến lược sau:

- Loại bỏ lớp phủ: Mài hoặc tẩy lớp kẽm bằng hóa chất khỏi khu vực hàn trước khi nối ghép, nếu có thể

- Kỹ thuật điều chỉnh: Tốc độ di chuyển chậm hơn giúp hơi kẽm thoát ra trước khi vũng hàn đông đặc

- Tăng cường thông gió: Hệ thống hút khí thải cục bộ đặt tại vùng hàn là bắt buộc, không phải tùy chọn

- Lựa chọn vật liệu hàn phụ: Dây hàn đồng silic (hàn thiêu kết) đôi khi thay thế hàn nóng chảy, giúp giảm lượng khói thải trong khi vẫn duy trì độ bền mối hàn

Hiểu được các yêu cầu đặc thù của vật liệu chỉ là bước đầu tiên. Trước khi bắt đầu hàn, việc chuẩn bị đúng và các nguyên tắc cơ bản về thiết kế mối nối sẽ quyết định liệu quy trình hàn cùng loại que hàn bạn chọn cẩn thận có thực sự mang lại kết quả như mong đợi hay không.

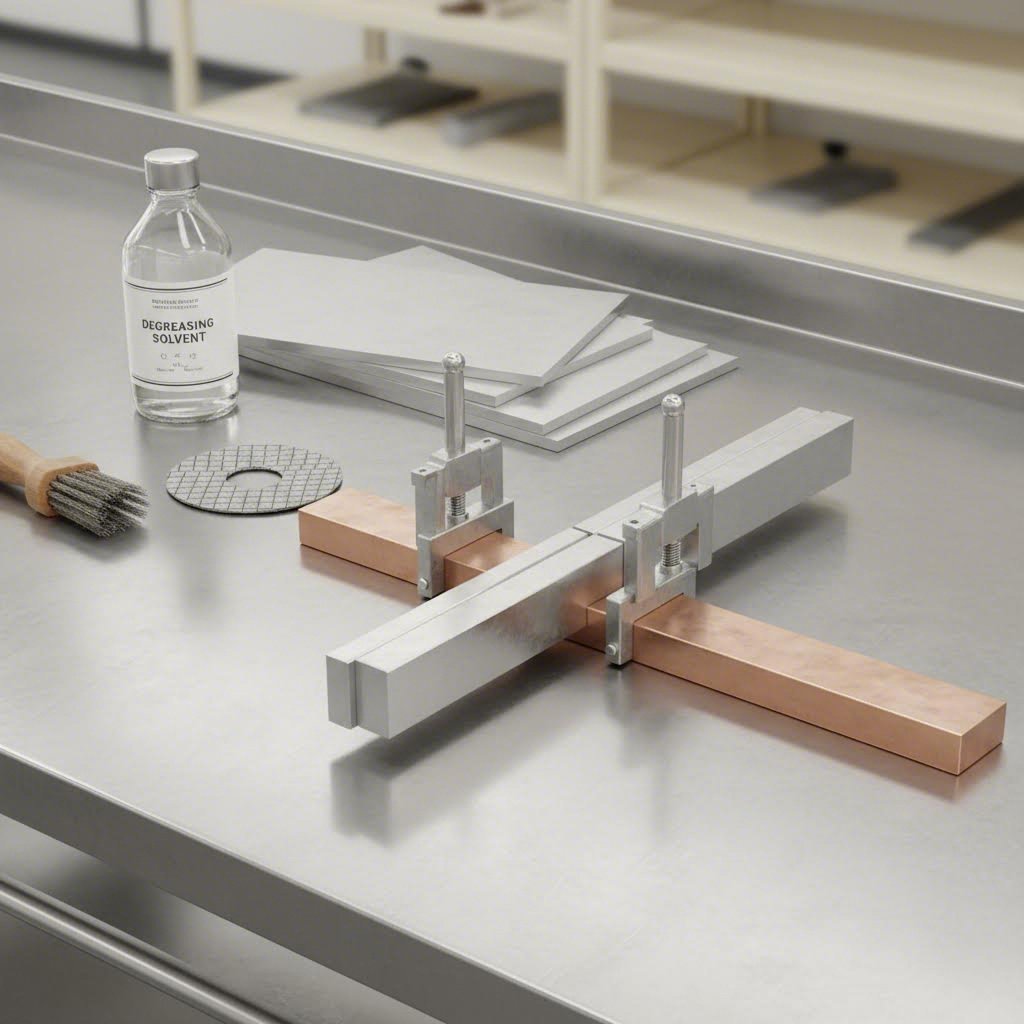

Chuẩn Bị Trước Khi Hàn Và Các Nguyên Tắc Cơ Bản Về Thiết Kế Mối Nối

Bạn đã chọn phương pháp hàn phù hợp. Bạn đã lựa chọn kim loại que hàn và khí bảo vệ phù hợp với vật liệu nền. Nhưng đây là sự thật khó tránh khỏi — tất cả những điều đó đều vô nghĩa nếu công tác chuẩn bị chưa đầy đủ. Trong hàn kim loại tấm, những gì xảy ra trước khi hồ quang được tạo ra thường quyết định thành công hay thất bại nhiều hơn bất cứ yếu tố nào khác.

Hãy nghĩ đến việc sơn một bức tường. Bạn sẽ không thể mong lớp lót bám dính vào bề mặt trần bụi bẩn, có dầu mỡ, đúng không? Nguyên tắc này cũng áp dụng tương tự trong hàn. Theo Người chế tạo , bắt đầu với bề mặt sạch nhất có thể sẽ làm tăng đáng kể khả năng tạo ra mối hàn chắc chắn và đạt chất lượng cao. Hãy cùng phân tích cụ thể những nội dung mà công tác chuẩn bị này bao gồm.

Những Yếu Tố Cơ Bản Của Việc Chuẩn Bị Mặt Bề

Mọi chất bẩn trên bề mặt kim loại tấm của bạn đều là một khuyết tật hàn tiềm tàng đang chờ xảy ra. Gỉ cán, dầu mỡ, rỉ sét, sơn và thậm chí cả dấu vân tay đều có thể gây ra hiện tượng xốp, không hòa nhập hoàn toàn và nứt. Thử thách ở đây là gì? Các vật liệu khác nhau và các quy trình hàn khác nhau đòi hỏi mức độ sạch sẽ khác nhau.

Đối với hàn hồ quang kim loại trong khí bảo vệ (MIG) và hàn hồ quang vonfram trong khí bảo vệ (TIG), yêu cầu chuẩn bị bề mặt rất nghiêm ngặt. Những quy trình này đòi hỏi bề mặt sạch hơn để tạo ra mối hàn chất lượng—nhưng chúng cũng yêu cầu ít làm sạch sau khi hàn hơn. Hàn hồ quang que có thể chấp nhận nhiều tạp chất hơn, mặc dù bạn sẽ phải đánh đổi sự khoan dung đó bằng việc làm sạch giữa các lớp hàn và sau khi hàn nhiều hơn.

Dưới đây là những gì bạn cần chống lại trên các vật liệu khác nhau:

- Thép cán nóng: Lớp gỉ cán dày mà bắt buộc phải được loại bỏ hoàn toàn trước khi hàn

- Nhôm: Lớp oxit cộng với khả năng dễ bị bít bánh trong quá trình mài—yêu cầu sử dụng vật liệu mài được thiết kế để ngăn ngừa tích tụ vật liệu

- Thép không gỉ: Sự nhiễm bẩn bề mặt có thể làm giảm khả năng chống ăn mòn nếu không được xử lý đúng cách

- Thép mạ kẽm: Lớp phủ kẽm cần phải được loại bỏ khỏi các vùng hàn để tránh hiện tượng xốp và vấn đề về khí độc

Phương pháp làm sạch quan trọng không kém gì việc làm sạch. Đối với các chất bẩn nhẹ như rỉ sét, lớp phủ cao su hoặc sơn, thường dùng bàn chải sắt sẽ hiệu quả mà không ảnh hưởng đến kim loại nền. Tuy nhiên, lớp vảy oxit dày từ nhà máy thường yêu cầu dùng đĩa mài hoặc đĩa mài mềm. Điều quan trọng là chọn mức độ mài phù hợp — sử dụng vật liệu mài quá thô có thể làm xước bề mặt hoặc loại bỏ quá nhiều vật liệu, dẫn đến chi tiết thành phẩm nằm ngoài thông số kỹ thuật.

Một đĩa mài mềm hạt 60 thường cung cấp đủ độ mài mòn trong khi cho bề mặt hoàn thiện tốt hơn so với các lựa chọn thô hơn. Đĩa này ít gây xước và undercut hơn, giúp bạn đạt được kết quả mong muốn nhanh hơn với ít lần mài hơn và không để lại đổi màu do nhiệt.

Thiết kế mối nối cho vật liệu tấm mỏng

Cấu hình mối nối quyết định mọi thứ từ khả năng tiếp cận hàn đến nguy cơ biến dạng. Với kim loại tấm, bạn thường làm việc với năm loại mối nối chính, mỗi loại phục vụ cho các ứng dụng cụ thể:

- Mối nối đối đầu: Hai chi tiết được căn chỉnh sát mép cạnh nhau — lý tưởng cho các kết nối phẳng, nhưng đòi hỏi độ chính xác cao khi lắp ráp trên vật liệu mỏng

- Mối nối chồng: Các tấm xếp chồng lên nhau — cấu hình phổ biến nhất cho hàn điểm và các ứng dụng mà độ dày bổ sung của mối nối là chấp nhận được

- Mối nối góc: Gặp vuông góc tại các mép — phổ biến trong các hộp kín và cấu trúc dạng hộp, tương tự như những gì thấy trên tủ kim loại hoặc khung xe

- Mối nối mép: Các tấm song song được nối dọc theo các mép — thường dùng cho các cụm có gờ uốn hoặc các ứng dụng gia cố

- Mối nối kiểu chữ T: Giao vuông góc tạo thành hình chữ T — thường được sử dụng trong các kết cấu và khung đỡ như giá thiết bị hoặc khung hỗ trợ bên trong

Độ dày vật liệu ảnh hưởng trực tiếp đến thiết kế mối nối và việc lựa chọn quy trình. Vật liệu mỏng hơn đòi hỏi dung sai chặt chẽ hơn và kiểm soát nhiệt chính xác hơn. Một khe hở có thể chấp nhận được trên tấm 6mm sẽ trở thành nguy cơ thủng khi hàn trên tấm 1mm. Tương tự, các thông số hàn tạo ra sự nóng chảy hoàn hảo trên vật liệu dày sẽ xuyên thủng hoàn toàn vật liệu mỏng.

Việc cố định trở nên cực kỳ quan trọng khi độ dày vật liệu giảm. Các tấm mỏng có xu hướng dịch chuyển, cong vênh và biến dạng dưới tác động của nhiệt—các phương pháp kẹp dùng cho thép kết cấu sẽ không hiệu quả trong trường hợp này. Nhiều xưởng gia công sử dụng đồ gá chuyên dụng với thanh đồng làm lớp đệm tản nhiệt, giúp hút nhiệt ra khỏi vùng hàn. Những đơn vị khác sử dụng các kết cấu đỡ đồ gá đặc biệt cung cấp sự ổn định tại nhiều điểm trong quá trình hàn.

Dung sai lắp ráp trở nên nghiêm ngặt hơn đáng kể đối với vật liệu mỏng. Khe hở sạch và đồng đều giữa các chi tiết sẽ tạo ra mối hàn chắc chắn và ổn định hơn với lượng kim loại hàn phụ ít hơn — giảm chi phí và tiết kiệm thời gian. Đối với các mối nối đối đầu trên tấm kim loại mỏng, khe hở vượt quá 10% độ dày vật liệu thường gây ra sự cố.

Danh sách kiểm tra chuẩn bị từng bước

Trước khi đốt hồ quang cho bất kỳ dự án nào liên quan đến tấm kim loại, hãy thực hiện tuần tự các bước chuẩn bị hệ thống sau:

- Lập kế hoạch: Xác định yêu cầu về quy trình hàn, chọn phương tiện làm sạch phù hợp nhất với vật liệu của bạn và hiểu rõ yêu cầu về lớp hoàn thiện cuối cùng trước khi bắt đầu bất kỳ công việc vật lý nào

- Cắt và lắp ráp: Thực hiện các đường cắt ban đầu càng sạch, thẳng và đồng đều càng tốt — điều này giúp giảm công đoạn làm sạch sau đó và cải thiện chất lượng mối nối. Sử dụng các công cụ phù hợp với vật liệu và yêu cầu độ chính xác của bạn

- Vát mép (nếu cần): Đối với vật liệu có độ dày trên 3mm hoặc yêu cầu thấu hoàn toàn, hãy tạo các chuẩn bị mép phù hợp. Việc bạn cẩn thận trong việc vát mép sẽ giảm đáng kể công đoạn phía sau

- Loại bỏ gỉ cán và lớp phủ: Mài hoặc tẩy hóa học tất cả các chất bẩn bề mặt trong phạm vi một inch dọc theo mối hàn ở cả hai phía. Bắt đầu bằng các loại mài mòn ít mạnh hơn và chỉ tăng cường khi cần thiết

- Tẩy dầu kỹ lưỡng: Sử dụng acetone hoặc dung môi phù hợp để loại bỏ dầu mỡ, chất làm mát khi cắt và các dư lượng do thao tác. Đảm bảo bay hơi hoàn toàn trước khi hàn

- Loại bỏ lớp oxit: Đối với nhôm, hãy sử dụng bàn chải inox chuyên dụng ngay trước khi hàn. Đối với thép không gỉ, đảm bảo không bị nhiễm thép các bon từ các công đoạn trước đó

- Xác minh độ khít mối ghép: Kiểm tra độ đồng đều của khe hở dọc theo toàn bộ chiều dài mối hàn. Đảm bảo độ căn chỉnh đáp ứng yêu cầu dung sai đối với độ dày vật liệu của bạn

- Định vị các thiết bị cố định và kẹp: Cố định các chi tiết bằng giá đỡ đầy đủ để tránh di chuyển trong quá trình hàn. Đặt các thanh chống lưng hoặc bộ tản nhiệt tại những vị trí cần thiết đối với vật liệu mỏng

- Kiểm tra cuối cùng: Kiểm tra độ sạch, sự căn chỉnh và đồ gá ngay trước khi hàn. Bất kỳ sự chậm trễ nào sau khi làm sạch đều có nguy cơ bị nhiễm bẩn lại

Hãy nhớ—khi chuẩn bị hàn, mục tiêu của bạn là loại bỏ các tạp chất và lớp phủ trên bề mặt mà không làm mất quá nhiều vật liệu nền. Việc mài quá mạnh tay khiến vật liệu mỏng đi hoặc tạo ra các vết xước sẽ làm mất hoàn toàn ý nghĩa của việc chuẩn bị cẩn thận

Ngay cả khi đã chuẩn bị kỹ lưỡng và thiết kế mối nối hoàn hảo, việc hàn kim loại tấm vẫn đặt ra những thách thức riêng biệt, có thể phá hỏng dự án của bạn nếu bạn chưa sẵn sàng xử lý chúng. Việc hiểu cách khắc phục các lỗi thường gặp trước khi chúng xảy ra sẽ tiết kiệm được cả thời gian lẫn vật liệu

Xử lý sự cố thường gặp trong hàn kim loại tấm

Bạn đã làm mọi thứ đúng—lựa chọn phương pháp hàn phù hợp nhất, chọn đúng que hàn tương ứng, và chuẩn bị bề mặt một cách chính xác tuyệt đối. Thế rồi mối hàn bắt đầu bị cong vênh. Hoặc bị cháy thủng. Hoặc xuất hiện những lỗ li ti khó chịu khiến sản phẩm hoàn thiện phải vứt thẳng vào thùng phế liệu

Nghe có vẻ quen thuộc không? Những thách thức này làm phiền ngay cả những thợ gia công giàu kinh nghiệm khi làm việc với vật liệu mỏng. Sự khác biệt giữa các chuyên gia và người nghiệp dư không phải là các chuyên gia không bao giờ gặp sự cố — mà là họ biết chính xác cách ngăn ngừa và khắc phục chúng. Hãy cùng giải mã những lỗi hàn tấm kim loại phổ biến nhất và trang bị cho bạn những giải pháp thực tế thực sự hiệu quả.

Ngăn ngừa hiện tượng cong vênh và biến dạng

Biến dạng có lẽ là thách thức hàn tấm kim loại khó chịu nhất vì nó thường xuất hiện sau khi bạn đã đầu tư nhiều thời gian và vật liệu vào một dự án. Theo Tài liệu kỹ thuật của Lincoln Electric , biến dạng xảy ra do sự giãn nở và co lại của kim loại mối hàn và kim loại cơ bản liền kề trong chu kỳ đốt nóng và làm nguội. Việc thực hiện toàn bộ quá trình hàn ở một phía của chi tiết sẽ gây ra biến dạng nhiều hơn so với việc luân phiên hàn từ phía này sang phía kia.

Dưới đây là những gì xảy ra ở cấp độ phân tử: khi nhiệt độ tăng, giới hạn chảy, độ đàn hồi và độ dẫn nhiệt của tấm thép giảm xuống, trong khi sự giãn nở nhiệt và nhiệt dung riêng lại tăng lên. Những lực cạnh tranh này tạo ra các ứng suất nội bộ làm biến dạng phôi gia công của bạn một cách trực tiếp.

Tin tốt là? Bạn có thể kiểm soát sự biến dạng thông qua việc quản lý nhiệt một cách chiến lược. Hãy cân nhắc những kỹ thuật đã được chứng minh sau:

- Đừng hàn quá mức: Lượng kim loại đưa vào mối hàn càng nhiều thì lực co ngót càng lớn. Hãy xác định kích thước mối hàn phù hợp với yêu cầu của mối ghép—kim loại hàn dư thừa không làm tăng độ bền nhưng lại làm tăng đáng kể sự biến dạng

- Sử dụng phương pháp hàn gián đoạn: Khi không cần thiết về mặt kết cấu phải hàn liên tục, các mẫu hàn gián đoạn có thể giảm lượng kim loại hàn đến 75% đồng thời vẫn đảm bảo đủ độ bền

- Giảm thiểu số lần hàn: Khi lo ngại về biến dạng ngang, việc hàn ít lần hơn với điện cực lớn sẽ tốt hơn so với hàn nhiều lần với điện cực nhỏ—lực co ngót từ mỗi lần hàn có xu hướng cộng dồn

- Cân bằng các mối hàn quanh trục trung hòa: Cân bằng một lực co ngót bằng lực khác bằng cách hàn xen kẽ luân phiên hai bên vật hàn

- Sử dụng kỹ thuật hàn từng đoạn ngược chiều: Di chuyển tổng thể theo một hướng nhất định trong khi mỗi đoạn mối hàn được thực hiện theo hướng ngược lại—kỹ thuật này cho phép các mép được nung nóng giãn nở và co lại đồng đều hơn

Đối với kim loại tấm nói riêng, các đồ gá làm mát bằng nước cực kỳ hữu ích. Các ống đồng được hàn vào các kẹp giữ bằng đồng để tuần hoàn nước trong quá trình hàn, giúp tản nhiệt nhanh khỏi các chi tiết mỏng. Lực cố định từ các kẹp cũng góp phần giảm thiểu chuyển động trong chu kỳ hàn.

Việc điều chỉnh trước hoặc uốn cong trước các bộ phận trước khi hàn có thể khiến sự co ngót hoạt động có lợi thay vì bất lợi. Khi bạn điều chỉnh trước đỉnh rãnh hàn—nơi chứa phần lớn kim loại hàn—mối hàn hoàn chỉnh sẽ dài hơn một chút so với khi hàn trên tấm phẳng. Việc tháo các kẹp sau khi hàn cho phép các tấm trở về trạng thái phẳng, trong khi mối hàn tự giải phóng ứng suất co dãn dọc trục một cách tự nhiên.

Giải quyết các khuyết tật hàn phổ biến

Ngoài biến dạng, hàn kim loại tấm còn gặp nhiều khuyết tật khác có thể làm giảm cả tính thẩm mỹ lẫn độ bền cấu trúc. Việc hiểu rõ các rủi ro hàn liên quan đến vật liệu mỏng sẽ giúp bạn dự đoán trước các vấn đề trước khi chúng xảy ra.

Hiện tượng thủng do nóng chảy là lỗi phổ biến nhất khi hàn vật liệu mỏng. Khi làm việc với các tấm có độ dày dưới 1/8 inch, nhiệt lượng quá mức sẽ làm nóng chảy hoàn toàn vật liệu, tạo thành lỗ thay vì mối nối. Như Capitol Iron Works giải thích, kim loại mỏng có khối lượng nhỏ hơn nên khả năng hấp thụ và tản nhiệt kém, khiến chúng đặc biệt dễ bị ảnh hưởng bởi vấn đề này.

Các chiến lược phòng ngừa bao gồm:

- Sử dụng dòng điện thấp hơn—hầu hết hàn TIG trên kim loại mỏng được thực hiện ở mức 50 ampe hoặc thấp hơn

- Tăng tốc độ di chuyển để hạn chế tập trung nhiệt

- Chọn điện cực và dây hàn có đường kính nhỏ hơn (0,023" đến 0,030" đối với hàn MIG)

- Áp dụng kỹ thuật hàn xung, luân phiên giữa dòng điện cao và thấp

- Đặt các thanh tản nhiệt như đồng hoặc nhôm gần vùng hàn

Độ xốp—những bọt khí nhỏ hoặc lỗ châm kim trong mối hàn—gần như luôn luôn là kết quả của sự giữ khí. Dầu nhiễm bẩn hoặc bảo vệ kém khiến các khí như hydro, oxy và nitơ bị mắc kẹt trong vũng hàn. Việc hàn có gây hại cho bạn khi xuất hiện độ xốp không? Ngoài những lo ngại về kết cấu, sự nhiễm bẩn gây ra độ xốp thường sinh ra khói độc hại. Các triệu chứng do khói hàn từ các mối hàn bị nhiễm bẩn có thể bao gồm kích ứng đường hô hấp và các triệu chứng giống cảm cúm, đặc biệt khi làm việc với các vật liệu có lớp phủ.

Việc khắc phục độ xốp đòi hỏi sự chú ý hệ thống đến độ sạch và bảo vệ. Theo Welding and Welder , các biện pháp phòng ngừa chính bao gồm mài hoặc chải sạch vùng mối nối bằng bàn chải sắt, bảo quản que hàn trong các hộp kín để tránh hút ẩm, duy trì lưu lượng khí phù hợp (thường là 10-20 L/phút đối với argon) và che chắn khỏi gió lùa làm gián đoạn vùng bảo vệ.

Tác động lâu dài của việc hàn khi thường xuyên làm việc với vật liệu bị nhiễm bẩn hoặc thông gió không đầy đủ có thể rất nghiêm trọng. Bệnh hàn và các tác dụng phụ khi hàn thường bắt nguồn từ các thao tác trong xưởng kém hơn là do quy trình hàn – đây cũng là lý do các dịch vụ hàn kim loại tấm chuyên nghiệp đầu tư mạnh vào thiết bị và quy trình phù hợp.

Ma trận Vấn đề - Nguyên nhân - Giải pháp

Bảng dưới đây trình bày các lỗi hàn kim loại tấm phổ biến nhất kèm theo nguyên nhân gốc rễ và các giải pháp thực tiễn:

| Lỗi | Nguyên nhân phổ biến | Phòng ngừa & Giải pháp |

|---|---|---|

| Vênh/biến dạng | Nhiệt lượng đầu vào quá mức; chỉ hàn một phía; quá nhiều đường hàn; cố định chi tiết không tốt | Sử dụng kỹ thuật hàn gián đoạn; kỹ thuật hàn ngược (backstep); cân bằng mối hàn quanh trục trung hòa; sử dụng đồ gá làm mát bằng nước; định hình trước chi tiết trước khi hàn |

| Thủng vật liệu | Cường độ dòng điện quá cao; tốc độ di chuyển quá chậm; điện cực/dây hàn quá lớn; tản nhiệt không đủ | Giảm cường độ dòng điện (dưới 50A đối với hàn TIG mỏng); tăng tốc độ di chuyển; dùng vật tư tiêu hao nhỏ hơn; đặt các thanh dẫn nhiệt bằng đồng; áp dụng kỹ thuật hàn xung |

| Độ xốp | Nhiễm bẩn bề mặt; độ ẩm trong vật liệu hàn; khí bảo vệ không đủ; gió lùa; lưu lượng khí sai | Làm sạch bề mặt kỹ lưỡng; bảo quản vật tư tiêu hao đúng cách; kiểm tra độ tinh khiết và lưu lượng khí (10-20 L/min); che chắn khỏi dòng không khí; kiểm tra chức năng bộ giảm áp |

| Không hòa tan hoàn toàn | Nhiệt lượng không đủ; góc mỏ hàn sai; tốc độ di chuyển quá nhanh; bề mặt bị nhiễm bẩn; đặt que hàn phụ không đúng cách | Điều chỉnh cường độ dòng điện phù hợp với độ dày; giữ góc mỏ hàn 10-15°; kiểm soát tốc độ di chuyển; làm sạch kỹ; nhúng que hàn phụ vào mép trước của vũng hàn |

| Nứt | Giới hạn quá mức; vật liệu que hàn không phù hợp; làm nguội nhanh; nhiễm bẩn; thiết kế mối nối không đúng | Gia nhiệt trước các vật liệu dày hoặc dễ tôi; chọn que hàn phù hợp với kim loại cơ bản; kiểm soát nhiệt độ giữa các lớp hàn; giữ sạch sẽ; cải thiện cấu hình mối nối |

| Tạp chất vonfram | Chiều dài hồ quang quá ngắn; vonfram chạm vào vũng hàn; mài sai cách; điện cực quá lớn so với cường độ dòng điện | Duy trì chiều dài hồ quang 2-5mm; giữ vonfram tránh xa vũng hàn; mài theo hướng dọc; chọn đường kính và loại vonfram phù hợp |

| Oxy hóa/Phai màu | Bảo vệ không đủ; bề mặt bị nhiễm bẩn; nhiệt lượng quá mức; thời gian dòng khí sau hàn không đủ | Kiểm tra độ phủ khí; làm sạch vật hàn và que hàn phụ; giảm lượng nhiệt đưa vào; kéo dài thời gian dòng khí sau hàn (tối thiểu 8-15 giây) |

| Nứt miệng hàn | Ngắt hồ quang đột ngột; lấp đầy miệng hố hàn không đủ; không sử dụng chức năng dốc xuống | Sử dụng cài đặt dốc xuống/lấp đầy miệng hố hàn; kỹ thuật hàn lấp đầy khi kết thúc mối hàn; thêm que hàn phụ trước khi ngắt hồ quang |

Hãy lưu ý có bao nhiêu khuyết tật bắt nguồn từ việc kiểm soát nhiệt độ không tốt? Đó chính là chủ đề trung tâm trong xử lý sự cố hàn kim loại tấm. Khác với hàn các tấm vật liệu dày hơn nơi mà vật liệu có thể hấp thụ và phân bố lại năng lượng nhiệt, vật liệu mỏng đòi hỏi phải luôn chú ý đến lượng nhiệt đưa vào, phân bố nhiệt và tản nhiệt.

Các mẫu hàn gián đoạn cần được đề cập đặc biệt để kiểm soát biến dạng. Thay vì chạy các đường hàn liên tục, bạn hàn theo từng đoạn ngắn với khoảng cách giữa chúng, cho phép làm nguội giữa mỗi mối hàn. Kỹ thuật này phù hợp với cả quy trình hàn MIG và TIG và đặc biệt hiệu quả đối với các mối hàn dài trên vật liệu mỏng. Chìa khóa là sắp xếp xen kẽ các mối hàn dọc theo chi tiết để phân bố nhiệt đều, thay vì tập trung vào một khu vực.

Ngay cả khi kỹ thuật hoàn hảo và không có lỗi nào, cụm hàn của bạn vẫn chưa thực sự hoàn thiện cho đến khi các công đoạn gia công hoàn thiện đúng cách chuyển đổi các mối hàn thô thành kết quả chất lượng chuyên nghiệp.

Các tùy chọn gia công hoàn thiện và xử lý bề mặt sau hàn

Đường hàn của bạn trông chắc chắn. Không có xốp. Không nứt. Biến dạng bằng không. Nhưng điều phân biệt các sản phẩm gia công nghiệp dư với các cụm lắp ráp chuyên nghiệp chính là—những gì xảy ra sau khi ngắt hồ quang. Hoàn thiện sau hàn biến những mối hàn thô thành các bộ phận chức năng, thẩm mỹ và chống ăn mòn, thực sự đáp ứng đúng thông số kỹ thuật của khách hàng.

Theo Người chế tạo , sai sót trong khâu hoàn thiện có thể cực kỳ tốn kém, xét đến toàn bộ giá trị đã được đầu tư vào phôi. Thêm vào đó là vật liệu đắt tiền, nhạy cảm với nhiệt như thép không gỉ, chi phí sửa chữa và phế liệu sẽ còn tăng cao hơn nữa. Hãy cùng tìm hiểu các quy trình hoàn thiện mà các dịch vụ hàn kim loại tấm chuyên nghiệp áp dụng để mang lại kết quả vượt trội.

Mài và đánh bóng các mối hàn

Đầu tiên, hãy làm rõ một quan niệm sai lầm phổ biến. Mài và hoàn thiện không phải là một việc—chúng có mục tiêu cơ bản khác nhau. Mài loại bỏ vật liệu như ba via và phần dư hàn, trong khi hoàn thiện tạo ra độ nhám hoặc hình dạng bề mặt cụ thể trên kim loại. Việc hiểu rõ sự khác biệt này sẽ ngăn ngừa tình huống khó chịu khi mài mạnh tay tạo ra các vết xước sâu, đòi hỏi hàng giờ làm thêm để loại bỏ.

Khi mài các mối hàn kim loại tấm, việc chọn lựa bánh mài ảnh hưởng trực tiếp đến hiệu suất và chất lượng cuối cùng. Các bánh mài gốm phù hợp nhất với thép không gỉ và các vật liệu nhạy cảm với nhiệt khác. Tại sao? Hạt mài cực kỳ cứng và sắc bén của chúng mài mòn theo cách đặc biệt—thay vì bị tù, chúng duy trì các cạnh sắc trong quá trình vỡ dần. Điều này có nghĩa là tốc độ loại bỏ vật liệu nhanh hơn, sinh ít nhiệt hơn và giảm nguy cơ biến dạng.

Đây là kỹ thuật quan trọng mà hầu hết các thao tác viên thường làm sai: áp lực và chuyển động. Nếu bạn nghe thấy vòng tua của máy mài giảm nhanh, điều đó có nghĩa là bạn đang ấn quá mạnh. Mục tiêu là duy trì gần với dòng định mức danh định của thiết bị—đối với máy mài 10A, hãy ấn vừa đủ mạnh để tiêu thụ khoảng 10A. Và đừng bao giờ giữ máy tại một vị trí. Hãy luôn di chuyển bánh mài để tránh quá nhiệt, vì hiện tượng này gây ra màu xanh lam đặc trưng cho thấy sự thay đổi tính chất vật liệu.

Góc làm việc rất quan trọng. Với bánh mài loại 27, hãy tiếp cận vật liệu ở góc từ 20 đến 30 độ. Bánh mài loại 29 hoạt động tốt hơn ở khoảng 10 độ. Việc sử dụng góc không đúng có thể dẫn đến nguy cơ làm quá nhiệt các vùng rộng hoặc làm mép bánh mài cắm vào mối hàn đã được hàn cẩn thận của bạn.

Hoàn thiện được thực hiện sau khi mài bằng các chất mài mòn ngày càng mịn hơn. Mỗi bước sẽ thay thế các vết xước sâu từ bước trước bằng những vết xước nhỏ hơn. Bí quyết ngược đời là gì? Đừng bắt đầu với các chất mài mòn quá mạnh trừ khi thực sự cần thiết. Việc bắt đầu với độ nhám 40-grit sẽ tạo ra các vết xước sâu, đòi hỏi nhiều thời gian để loại bỏ. Nếu khách hàng yêu cầu bề mặt hoàn thiện dạng chải No. 4, thì nên bắt đầu với độ nhám trung bình để tiết kiệm hàng giờ công việc về sau.

Đối với các ứng dụng yêu cầu bề mặt bóng gương—ví dụ như các chi tiết kiến trúc tùy chỉnh hoặc các vị trí lắp đặt nổi bật—quy trình hoàn thiện sẽ kéo dài qua các vật liệu không dệt, vải nỉ và các hợp chất đánh bóng. Các dụng cụ điện có tốc độ điều chỉnh được trở nên thiết yếu ở đây, vì các phương tiện hoàn thiện khác nhau yêu cầu số vòng quay khác nhau. Các con lăn không dệt thường chạy ở tốc độ từ 3.000 đến 4.000 vòng/phút, trong khi các đĩa điều chỉnh bề mặt hoạt động ở mức 4.000 đến 6.000 vòng/phút.

Xử lý thụ động để bảo vệ thép không gỉ

Nếu bạn đang làm việc với thép không gỉ, thì công đoạn thụ động hóa không phải là tùy chọn—mà là bắt buộc. Theo Tulsa Welding School , thụ động hóa mối hàn sử dụng axit nitric hoặc axit xitric để loại bỏ sắt tự do khỏi bề mặt, tạo thành một lớp oxit bảo vệ chống lại sự ăn mòn.

Tại sao thép không gỉ cần được xử lý này sau khi hàn? Crom trong thép không gỉ hình thành một lớp oxit crom mỏng khi tiếp xúc với oxy—đó chính là yếu tố giúp nó "không gỉ". Tuy nhiên, quá trình hàn làm phá vỡ lớp bảo vệ tự nhiên này. Nhiệt độ cao, tạp chất và việc đưa kim loại phụ vào đều làm suy giảm lớp thụ động, khiến một số khu vực trở nên dễ bị rỉ sét dù vật liệu có danh tiếng chống ăn mòn tốt.

Quy trình thụ động hóa bao gồm ba bước chính:

- Làm sạch: Dung dịch kiềm loại bỏ các chất gây nhiễm bẩn, sau đó rửa bằng nước

- Ngâm axit: Chi tiết ngâm trong bồn axit nitric hoặc axit xitric từ 20-30 phút, hòa tan sắt tự do nhưng giữ nguyên crom

- Thử nghiệm: Các bài kiểm tra phun muối, buồng độ ẩm hoặc dung dịch sunfat đồng để xác minh mức độ thụ động hóa đạt yêu cầu

Đối với các ứng dụng quan trọng, làm sạch điện hóa cung cấp một phương pháp thay thế. Kỹ thuật viên sử dụng bàn chải nối với hệ thống làm sạch điện hóa để làm sạch bề mặt mối hàn, đảm bảo loại bỏ hoàn toàn các chất gây nhiễm bẩn. Phương pháp này đặc biệt hữu ích trong sản xuất cầu thang kim loại, cầu thang kim loại được gia công, và các kết cấu kiến trúc khác nơi mà cả tính thẩm mỹ lẫn khả năng chống ăn mòn lâu dài đều quan trọng.

Lớp phủ Bảo vệ cho Các Bộ phận Hàn

Ngoài xử lý thụ động, các lớp phủ bảo vệ giúp kéo dài tuổi thọ của các bộ phận tấm kim loại hàn trong môi trường khắc nghiệt. Theo Dulux Protective Coatings , hệ thống lớp phủ trên khu vực hàn phải tương thích với phần thép xung quanh để đảm bảo bảo vệ chống ăn mòn liên tục—bất kỳ khoảng trống hay điểm yếu nào cũng sẽ làm giảm hiệu quả bảo vệ của toàn bộ bộ phận.

Dưới đây là các lựa chọn lớp phủ chính cùng với ứng dụng phù hợp của chúng:

- Sơn Tĩnh Điện: Bột khô được phủ tĩnh điện và đóng rắn dưới nhiệt độ—độ bền cao, dải màu sắc đa dạng, thân thiện với môi trường và không chứa hợp chất hữu cơ bay hơi (VOC). Lý tưởng cho đồ nội thất trong nhà, các hộp bao che và các chi tiết yêu cầu lớp hoàn thiện đồng đều. Đặc biệt phù hợp với sản xuất cầu thang thép và các ứng dụng cầu thang thép chế tạo.

- Hệ thống Sơn Ướt: Các lớp phủ lỏng truyền thống bao gồm lớp sơn lót, lớp trung gian và lớp phủ bề mặt. Mang lại sự linh hoạt tối đa trong thi công và sửa chữa tại hiện trường. Lớp sơn lót cần phủ chồng lên lớp phủ bên cạnh còn nguyên vẹn một khoảng 25-50mm để đảm bảo bảo vệ liên tục.

- Sơn Lót Giàu Kẽm: Bảo vệ bằng cơ chế điện hóa khi kẽm bị ăn mòn theo cách hy sinh để bảo vệ nền thép. Thiết yếu cho các ứng dụng kết cấu ngoài trời và môi trường biển.

- Mạ điện: Phủ các lớp kim loại mỏng (crom, niken, kẽm) thông qua quá trình điện hóa. Cung cấp khả năng chống ăn mòn vượt trội và lớp hoàn thiện trang trí cho các chi tiết chính xác.

- Phủ kẽm nóng: Việc nhúng vào kẽm nóng chảy tạo ra lớp phủ dày và bền. Phù hợp nhất cho các ứng dụng ngoài trời dạng kết cấu yêu cầu bảo vệ trong nhiều thập kỷ.

- Phủ điện (Electrocoating): Lớp phủ được điện phân bám đều lên các khu vực khuất và bề mặt bên trong. Đây là tiêu chuẩn ngành công nghiệp ô tô để đảm bảo độ phủ toàn diện.

Chiến lược hoàn thiện tốt nhất là gì? Theo các phương pháp tốt nhất trong ngành, làm sạch bằng phun mài, sơn lót và sơn phủ tại xưởng—sau đó hàn, mài, sơn lót điểm các mối hàn và sơn hoàn thiện tại hiện trường—sẽ mang lại hiệu suất và chất lượng bề mặt vượt trội đồng thời giảm thiểu chi phí.

Việc hoàn thiện đúng cách sẽ biến những mối hàn đạt yêu cầu thành sản phẩm cuối cùng xuất sắc. Nhưng làm thế nào để bạn kiểm tra rằng nhà cung cấp dịch vụ hàn kim loại tấm của bạn duy trì các tiêu chuẩn chất lượng mà các quy trình hoàn thiện này đòi hỏi? Điều đó đòi hỏi sự hiểu biết về các chứng nhận và tiêu chuẩn ngành phân biệt các đơn vị gia công có đủ điều kiện với phần còn lại.

Chứng nhận Chất lượng và Tiêu chuẩn Ngành

Bạn đã nắm vững các phương pháp hàn, tính tương thích vật liệu và kỹ thuật hoàn thiện. Nhưng đây là câu hỏi phân biệt những nhà gia công đáng tin cậy với những lựa chọn rủi ro: làm thế nào bạn biết một nhà cung cấp dịch vụ hàn kim loại tấm thực sự có thể đáp ứng đúng những gì họ cam kết? Câu trả lời nằm ở các chứng chỉ và tiêu chuẩn—những bằng chứng được ngành công nghiệp công nhận, chứng minh quy trình, nhân sự và hệ thống chất lượng của doanh nghiệp đáp ứng các yêu cầu nghiêm ngặt từ bên thứ ba.

Hãy xem các chứng chỉ như bản sơ yếu lý lịch của một nhà gia công, được xác minh bởi các kiểm toán viên độc lập chứ không phải tự tuyên bố. Khi bạn đang tìm nguồn cung các bộ phận quan trọng cho các ứng dụng ô tô, hàng không vũ trụ hoặc kết cấu, những chứng nhận này không chỉ đơn thuần là biểu tượng tiếp thị hấp dẫn—chúng chính là bảo đảm rằng các mối hàn sẽ hoạt động đúng như thông số kỹ thuật, tài liệu có thể truy xuất nguồn gốc và các hệ thống quản lý chất lượng thực sự vận hành hiệu quả.

Hiểu về Chứng chỉ Hàn

Trước khi đi vào các tiêu chuẩn cụ thể, hãy làm rõ sự phân biệt mà nhiều người mua hay nhầm lẫn. Theo Steel Joist Institute , chứng nhận và trình độ không phải là hai thuật ngữ thay thế được cho nhau—chúng mang ý nghĩa khác biệt trong ngành hàn.

Trình độ ám chỉ bài kiểm tra thực tế chứng minh thợ hàn có thể thực hiện công việc chất lượng. Nó thể hiện rằng một thợ hàn cá nhân biết cách thực hiện các mối hàn cụ thể một cách hiệu quả và an toàn ở các vị trí hoặc quy trình nhất định. Chứng nhận là tài liệu chính thức ghi nhận trình độ đó—giúp khả năng đã được chứng minh trở nên hợp lệ và có thể truy xuất nguồn gốc.

Tại sao điều này quan trọng đối với dự án của bạn? Việc duy trì trình độ và tuân thủ các tiêu chuẩn trình độ giúp đảm bảo chất lượng ổn định. Việc lệch khỏi các yêu cầu kỹ thuật có thể tiềm ẩn nguy hiểm tùy thuộc vào những tiêu chuẩn nào bị bỏ qua. Khi đánh giá các nhà thầu kim loại tấm thương mại, việc hiểu họ có duy trì trình độ hiện hành cho thợ hàn—chứ không chỉ đơn thuần là các chứng nhận trong quá khứ—sẽ cho bạn biết nhiều hơn rất nhiều về năng lực thực tế.

Theo các tiêu chuẩn AWS D1.1 và D1.3, chứng chỉ thợ hàn có hiệu lực vô thời hạn, miễn là thợ hàn đã sử dụng quy trình hàn trong vòng sáu tháng gần nhất. Chứng chỉ sẽ hết hiệu lực nếu nhà thầu không thể xác minh rằng thợ hàn đã thực hành quy trình được chứng nhận trong khoảng thời gian đó. Điều này có nghĩa là các cơ sở gia công uy tín liên tục giám sát và kiểm tra lại nhân sự hàn thay vì dựa vào các tài liệu đã lỗi thời.

Quy trình kiểm tra bao gồm việc hàn các mẫu thử mà các thanh tra sau đó kiểm tra bằng các phương pháp phá hủy và không phá hủy. Kiểm tra bằng mắt được thực hiện ở mọi giai đoạn, nhưng các thử nghiệm cơ học—bao gồm thử uốn và thử kéo—sẽ phá hủy các mẫu để xác minh chất lượng mối hàn. Theo Westmoreland Mechanical Testing & Research , chế độ kiểm tra phá hủy này đảm bảo rằng khi các quy trình được sử dụng trong sản xuất, các mối hàn sẽ chịu được trong điều kiện thực tế.

AWS D1.1 và D1.3: Nền tảng của hàn kết cấu

Các mã trong bộ D1 của Hiệp hội Hàn Mỹ (American Welding Society) tạo thành nền tảng cho các tiêu chuẩn hàn kết cấu tại Hoa Kỳ. Việc hiểu rõ mã nào áp dụng cho dự án của bạn sẽ ngăn ngừa những hiểu lầm tốn kém và đảm bảo các yêu cầu chất lượng phù hợp.

Mã hàn kết cấu AWS D1.1 – Thép bao gồm các vật liệu dày 1/8 inch (3mm) trở lên. Tiêu chuẩn toàn diện này đề cập mọi khía cạnh, từ yêu cầu thiết kế đến các phương pháp gia công và quy trình kiểm tra đối với thép cacbon và thép hợp kim thấp trong các ứng dụng kết cấu. Nếu bạn đang gia công các bộ phận nặng cho nhà cửa, cầu hay thiết bị công nghiệp, D1.1 có khả năng là tài liệu điều chỉnh chính.

Mã hàn kết cấu AWS D1.3 – Thép tấm cụ thể đề cập đến các vật liệu dày 3/16 inch (5mm) và mỏng hơn — trùng lắp trực tiếp với độ dày thông thường của tôn tấm. Viện Kết cấu Thép (Steel Joist Institute) lưu ý rằng có sự trùng lắp cố ý khoảng 1/16 inch giữa hai mã này nhằm giúp các nhà gia công duy trì làm việc theo một tiêu chuẩn duy nhất bất cứ khi nào có thể.

Sự khác biệt chính giữa các mã này phản ánh sự tinh tế khi hàn các vật liệu dày và mỏng. Cách một thợ hàn thiết kế mối hàn trên tấm dày về cơ bản khác biệt so với thiết kế cho các tấm kim loại mỏng. D1.3 bao gồm các quy định về các kỹ thuật như hàn góc vát mép mở rộng và hàn góc nối chồng, vốn đặc biệt phổ biến trong các ứng dụng kim loại tấm.

Một điểm phân biệt quan trọng: D1.1 cung cấp Các Thông số Kỹ thuật Quy trình Hàn (WPS) đã được "tiền công nhận" cho các cấu hình mối nối thông dụng. Nếu các nhà gia công tuân thủ nghiêm ngặt các thông số tiền công nhận này, họ có thể không cần thực hiện kiểm tra đánh giá đối với các quy trình cụ thể đó. Tuy nhiên, nếu vượt ra ngoài các điều kiện tiền công nhận—sử dụng vật liệu không liệt kê hoặc các kỹ thuật mới—thì yêu cầu phải đánh giá đầy đủ quy trình kèm theo kiểm tra được ghi chép tài liệu.

IATF 16949: Chất lượng xuất sắc trong ngành ô tô

Khi liên quan đến các bộ phận ô tô, IATF 16949 trở thành tiêu chuẩn vàng. Theo hướng dẫn chứng nhận của Xometry, khuôn khổ này tóm lược thông tin từ tiêu chuẩn ISO 9001 thành các hướng dẫn đặc biệt hữu ích cho các nhà sản xuất ô tô và nhà cung cấp của họ.

Điều gì khiến IATF 16949 khác biệt so với các hệ thống quản lý chất lượng nói chung? Tiêu chuẩn này tập trung mạnh vào việc tạo ra sự nhất quán, an toàn và chất lượng trong các sản phẩm ô tô thông qua các yêu cầu riêng biệt theo ngành. Chứng nhận này bao gồm một loạt chủ đề ấn tượng như:

- An toàn sản phẩm: Các quy trình được tài liệu hóa đảm bảo các bộ phận hàn không bị lỗi theo cách có thể gây nguy hiểm cho người ngồi trong xe

- Ngăn ngừa khuyết tật: Các phương pháp tiếp cận hệ thống nhằm loại bỏ các vấn đề về chất lượng trước khi chúng xảy ra

- Giảm thiểu biến động: Các kiểm soát quy trình thống kê đảm bảo đầu ra ổn định

- Quản lý chuỗi cung ứng: Yêu cầu mở rộng kỳ vọng về chất lượng xuống cả các nhà cung cấp cấp dưới

Chứng nhận IATF 16949 mang tính chất nhị phân—một công ty hoặc là đáp ứng các yêu cầu hoặc là không. Không có chứng nhận từng phần hay các cấp độ khác nhau. Khi được cấp, điều này chứng tỏ tổ chức đã thể hiện được năng lực và cam kết trong việc hạn chế khuyết tật, giảm thiểu lãng phí và nỗ lực bị phung phí trong suốt quá trình sản xuất.

Mặc dù không bắt buộc về mặt pháp lý, các nhà cung cấp và OEM thường sẽ không hợp tác với các đối tác chưa được chứng nhận. Nếu dự án hàn kim loại tấm của bạn tham gia vào chuỗi cung ứng ô tô, việc làm việc với các nhà cung cấp đã được chứng nhận IATF 16949 không phải là lựa chọn—mà là điều bắt buộc.

ISO 9001: Quản lý Chất lượng Toàn diện

ISO 9001 là nền tảng cơ bản cho nhiều tiêu chuẩn chuyên biệt theo ngành, bao gồm cả IATF 16949. Khung hệ thống quản lý chất lượng (QMS) được công nhận trên toàn thế giới này ghi nhận các trách nhiệm, quy trình và thủ tục cần thiết để đạt được các mục tiêu chất lượng trong mọi ngành nghề.

Đối với các dịch vụ hàn kim loại tấm, chứng nhận ISO 9001 cho thấy nhà cung cấp đã thiết lập:

- Các chính sách và mục tiêu chất lượng được tài liệu hóa

- Các vai trò và trách nhiệm được xác định rõ trong toàn bộ tổ chức

- Các quy trình được kiểm soát đối với các hoạt động then chốt

- Các phương pháp tiếp cận hệ thống để đo lường và cải thiện hiệu suất

- Tập trung vào khách hàng được tích hợp vào quá trình ra quyết định

Không giống như các tiêu chuẩn chuyên biệt như AWS D1.3, ISO 9001 không quy định các yêu cầu kỹ thuật hàn cụ thể. Thay vào đó, tiêu chuẩn này đảm bảo các hệ thống quản lý bao quanh các quy trình kỹ thuật vận hành hiệu quả. Một nhà gia công có thể tạo ra các mối hàn hoàn hảo nhưng vẫn không đạt ISO 9001 nếu hồ sơ tài liệu, hồ sơ đào tạo hoặc quy trình hành động khắc phục không đáp ứng tiêu chuẩn.

Tài liệu PQR: Chứng minh năng lực quy trình

Bên cạnh các chứng nhận cấp độ doanh nghiệp, từng quy trình hàn riêng lẻ cần được đánh giá thông qua kiểm tra có tài liệu hóa. Hồ sơ Đánh giá Quy trình Hàn (PQR) đóng vai trò bằng chứng chính thức rằng một quy trình hàn cụ thể tạo ra các mối hàn đạt tiêu chuẩn về chất lượng và an toàn.

Dưới đây là cách hệ thống hoạt động: Một nhà chế tạo phát triển Đặc tả Quy trình Hàn (WPS) mô tả chính xác cách thực hiện một mối hàn cụ thể — bao gồm vật liệu, vị trí, điện áp, tốc độ di chuyển và các biến số khác. WPS này phải được hỗ trợ bởi một PQR ghi lại việc thực hiện một mối hàn thử nghiệm theo các thông số đó, tiếp theo là các bài kiểm tra nghiêm ngặt để xác minh kết quả.

Việc kiểm tra thường bao gồm:

- Kiểm tra kéo: Kéo các mẫu cho đến khi đứt để xác minh độ bền đạt yêu cầu

- Kiểm tra uốn: Uốn các mẫu để phát hiện các khuyết tật hoặc độ giòn

- Kiểm tra va đập: Thử nghiệm rãnh chữ V Charpy để đánh giá độ dai trong các ứng dụng nhiệt độ thấp

- Kiểm tra độ cứng: Xác minh các tính chất của mối hàn và vùng ảnh hưởng nhiệt nằm trong phạm vi chấp nhận được

- Phân tích hóa học: Xác nhận thành phần kim loại mối hàn khi hàm lượng hợp kim có ý nghĩa quan trọng

Tại sao tài liệu PQR lại quan trọng? Việc có quy trình hàn được chứng nhận đảm bảo mối hàn đạt được độ bền, độ dẻo và độ dai cần thiết cho ứng dụng cụ thể. Nhiều ứng dụng — bao gồm các thiết bị chịu áp lực, đường ống dẫn và kết cấu thép — yêu cầu pháp lý về việc hàn phải được thực hiện theo quy trình đã được chứng nhận. PQR mang lại sự tin cậy rằng các mối hàn sẽ không bị phá hủy trong quá trình sử dụng.

Ma trận so sánh chứng chỉ

Việc lựa chọn các chứng chỉ phù hợp cho dự án của bạn đòi hỏi phải hiểu rõ từng tiêu chuẩn bao gồm những nội dung gì và áp dụng ở đâu. Bảng dưới đây so sánh các chứng chỉ chính liên quan đến dịch vụ hàn kim loại tấm:

| Chứng nhận/Tiêu chuẩn | Phạm vi | Yêu cầu Chính | Các ứng dụng chính |

|---|---|---|---|

| AWS D1.1 | Hàn kết cấu thép có độ dày từ 1/8" trở lên | Kiểm tra chứng nhận thợ hàn; Tài liệu WPS/PQR; Kiểm tra bằng mắt và cơ học; Quy trình tiền chứng nhận hoặc đã được chứng nhận | Nhà ở, cầu, thiết bị nặng, công trình công nghiệp |

| AWS D1.3 | Hàn kết cấu thép tấm có độ dày từ 3/16" trở xuống | Kiểm tra thợ hàn theo từng bảng tính; cấu hình mối nối được điều chỉnh; chứng nhận cho các kỹ thuật hàn vật liệu mỏng | Các cụm kết cấu tấm kim loại, hộp bao che, chi tiết kết cấu nhẹ, hệ thống HVAC |

| IATF 16949 | Hệ thống quản lý chất lượng ô tô | Kiểm toán nội bộ và bên ngoài; hệ thống phòng ngừa khuyết tật; kiểm soát chuỗi cung ứng; cải tiến liên tục; tập trung vào an toàn sản phẩm | Các bộ phận ô tô, chi tiết khung gầm, cụm thân xe, hệ thống truyền động |

| ISO 9001 | Hệ thống quản lý chất lượng chung | Quy trình được tài liệu hóa; đánh giá của ban lãnh đạo; lấy khách hàng làm trung tâm; hệ thống hành động khắc phục; kiểm toán nội bộ | Tất cả các ngành công nghiệp—sản xuất, dịch vụ và hơn thế nữa |

| ASME Section IX | Hàn bình chịu áp lực và đường ống | Kiểm tra PQR bắt buộc đối với mọi quy trình; không có tùy chọn WPS được tiền chứng nhận; theo dõi toàn diện các biến số | Lò hơi, thiết bị chịu áp lực, hệ thống đường ống, ứng dụng hạt nhân |

| ITAR | Kiểm soát xuất khẩu trong lĩnh vực quốc phòng và hàng không vũ trụ | Đăng ký với DDTC; xử lý dữ liệu kiểm soát; truy cập hạn chế; tài liệu tuân thủ | Các bộ phận quân sự, hệ thống quốc phòng, các bộ phận hàng không vũ trụ bị kiểm soát |

Hãy lưu ý cách các chứng nhận khác nhau giải quyết các mối quan tâm khác nhau như thế nào? Các mã AWS tập trung vào năng lực kỹ thuật hàn, trong khi các tiêu chuẩn ISO và IATF đề cập đến các hệ thống quản lý. ITAR hoàn toàn không liên quan đến chất lượng hàn — nó quy định việc kiểm soát xuất khẩu đối với các mặt hàng liên quan đến quốc phòng. Việc hiểu rõ những điểm khác biệt này sẽ giúp bạn đặt ra những câu hỏi phù hợp khi đánh giá các đối tác gia công tiềm năng.

Các nhà thầu cơ khí kim loại thương mại phục vụ nhiều ngành công nghiệp thường duy trì đồng thời nhiều chứng chỉ. Một nhà cung cấp ô tô có thể sở hữu các chứng nhận IATF 16949, ISO 9001 và AWS D1.3 — mỗi chứng nhận đáp ứng các yêu cầu khách hàng và quy định pháp lý khác nhau. Việc đầu tư để duy trì nhiều chứng nhận cho thấy cam kết nghiêm túc về chất lượng trong mọi ứng dụng.

Các chứng nhận cung cấp sự đảm bảo tối thiểu, nhưng chúng chỉ là một yếu tố khi lựa chọn đối tác gia công phù hợp. Việc xác định khi nào cần dịch vụ chuyên nghiệp — so với khi nào cách tiếp cận tự làm (DIY) có thể chấp nhận được — đòi hỏi phải đánh giá trung thực các yêu cầu và năng lực cụ thể của dự án bạn.

Lựa chọn giữa Dịch vụ Hàn Tự Làm và Dịch vụ Chuyên Nghiệp

Vì vậy, bạn đã tìm hiểu về các phương pháp hàn, tính tương thích vật liệu, kỹ thuật xử lý sự cố và các chứng nhận chất lượng. Giờ đây là câu hỏi thực tế mà mọi dự án đều phải đối mặt: bạn có nên tự thực hiện công việc hàn này hay nên sử dụng dịch vụ hàn kim loại tấm chuyên nghiệp?

Đây không phải là quyết định đơn giản chỉ có hai lựa chọn. Câu trả lời phụ thuộc vào sự tương tác phức tạp của nhiều yếu tố—độ phức tạp của dự án, khả năng tiếp cận thiết bị, các yếu tố an toàn, yêu cầu về chất lượng và các yêu cầu chứng nhận cụ thể theo ngành. Hãy cùng xây dựng một khuôn khổ ra quyết định giúp bạn đưa ra lựa chọn phù hợp với tình huống cụ thể của mình.

Đánh giá Yêu cầu Dự án của Bạn

Trước khi đầu tư vào thiết bị hoặc liên hệ với các xưởng gia công, hãy đánh giá trung thực những gì dự án của bạn thực sự đòi hỏi. Theo Ace Welding Supply , việc hiểu rõ giới hạn của bản thân là rất quan trọng—thực hiện các công việc sửa chữa phức tạp mà không có đủ kinh nghiệm có thể dẫn đến hỏng hóc kết cấu và nguy cơ mất an toàn.

Hãy bắt đầu với những câu hỏi cơ bản sau:

- Tầm quan trọng về kết cấu là gì? Một chiếc ghế hàn trang trí hoặc những chiếc ghế đẩu độc đáo cho xưởng gia đình bạn sẽ có mức độ rủi ro hoàn toàn khác so với các bộ phận ô tô chịu tải

- Độ dày và loại vật liệu là gì? Hàn tấm nhôm mỏng đòi hỏi kỹ năng cao hơn nhiều so với hàn thép carbon

- Chất lượng bề mặt hoàn thiện chấp nhận được là như thế nào? Các mối nối nhìn thấy được trên đồ nội thất yêu cầu tiêu chuẩn khác biệt so với các khớp nối kết cấu ẩn

- Có yêu cầu chứng chỉ không? Các tiêu chuẩn riêng theo ngành có thể yêu cầu quy trình được chứng nhận và thợ hàn đã được cấp chứng chỉ

- Thời gian biểu của bạn là gì? Đường cong học việc tốn thời gian—các chuyên gia sẽ hoàn thành nhanh hơn khi tiến độ gấp rút

Đối với người mới bắt đầu đang cân nhắc cách khởi nghiệp hàn hoặc chỉ đơn giản là thực hiện các dự án tại nhà, một số công việc sửa chữa nhất định có thể thực hiện an toàn nếu được chuẩn bị đúng cách. Theo hướng dẫn của ngành, những nhiệm vụ đơn giản bao gồm sửa chữa dụng cụ làm vườn bị hỏng, các đồ dùng gia đình nhỏ hoặc các chi tiết kim loại trang trí. Hàn điểm – tạm thời nối các mảnh lại trước khi hàn hoàn thiện – là cách luyện tập tuyệt vời để phát triển kỹ năng kiểm soát và độ chính xác mà không chịu áp lực.

Nhưng đây là thực tế: nếu dự án của bạn liên quan đến các bộ phận kết cấu quan trọng, các thiết bị chịu áp lực, hoặc các ứng dụng mà sự cố có thể gây nguy hiểm cho con người, thì chuyên môn của thợ hàn chuyên nghiệp là bắt buộc. Chi phí do một mối hàn bị hỏng nghiêm trọng gây ra còn lớn hơn rất nhiều so với khoản tiết kiệm từ việc tự làm.

Các Lưu ý về Đầu tư Thiết bị

Kinh tế học của thiết bị hàn cần được phân tích cẩn thận. Theo hướng dẫn giá của SSIMDER, chi phí thiết bị thay đổi đáng kể tùy theo khả năng:

| Loại thiết bị | Khoảng giá | Ứng dụng tốt nhất |

|---|---|---|

| Máy hàn MIG | $100 - $1.500 | Tôn tấm mỏng đến trung bình; phù hợp với người làm nghề tại nhà đến sản xuất chuyên nghiệp |

| Máy hàn TIG | $1.000 - $5.000 | Công việc chính xác trên inox, nhôm, hợp kim đặc biệt; các dự án chuyên nghiệp và phức tạp |

| Thiết bị an toàn | 100 - 500+ USD | Mũ bảo hiểm, găng tay, mặt nạ phòng độc, quần áo chống cháy—bắt buộc đối với mọi công việc hàn |

| Vật tư tiêu hao | Chi phí phát sinh | Điện cực, dây hàn, khí bảo vệ—được bổ sung thường xuyên tùy theo mức độ sử dụng |

| Phụ kiện | 50 - 500 USD | Xe đẩy hàn, búa đục, bánh mài, kẹp, đồ gá |

Ngoài chi phí ban đầu, cần xem xét chu kỳ làm việc—thời gian thiết bị có thể hoạt động ở công suất tối đa trước khi quá nhiệt. Môi trường sản xuất đòi hỏi các máy móc có chu kỳ làm việc cao hơn so với việc sử dụng thỉnh thoảng trong sở thích. Ngoài ra, độ dày vật liệu ảnh hưởng đến yêu cầu công suất; vật liệu dày hơn cần máy có cường độ dòng điện cao hơn.

Lời khuyên thực tế? Bắt đầu với một mẫu cơ bản nếu bạn đang học. Một máy hàn MIG chất lượng ở mức giá khoảng 300-500 đô la Mỹ có thể xử lý hiệu quả nhiều dự án tại nhà. Bạn có thể nâng cấp sau này khi kỹ năng và độ phức tạp của dự án tăng lên. Nhưng hãy nhớ — những máy hàn rẻ tiền, chất lượng thấp sẽ dẫn đến sự thất vọng và lãng phí tiền bạc. Hãy ưu tiên các thương hiệu uy tín được biết đến với độ tin cậy.

Đối với các dự án chỉ làm một lần hoặc nhu cầu sử dụng thỉnh thoảng, việc tính toán chi phí thường nghiêng về dịch vụ chuyên nghiệp. Tại sao phải đầu tư hơn 2.000 đô la Mỹ cho thiết bị hàn TIG, đào tạo và vật tư tiêu hao để hàn một chiếc ghế trong khi một thợ gia công có thể hoàn thành nhanh hơn và tốt hơn?

Khi Dịch Vụ Chuyên Nghiệp Là Thiết Yếu

Một số ứng dụng nhất định đòi hỏi bắt buộc phải có dịch vụ hàn kim loại tấm chuyên nghiệp. Không có lượng video hướng dẫn trên YouTube hay luyện tập trên kim loại phế liệu nào có thể thay thế cho chuyên môn đã được chứng nhận trong những trường hợp này:

Ứng dụng ô tô

Các bộ phận xe—khung gầm, hệ thống treo, các chi tiết cấu trúc—vận hành trong điều kiện chịu tải cực lớn và liên quan đến an toàn. Như chúng ta đã đề cập trước đó, chứng nhận IATF 16949 không chỉ được ưu tiên trong chuỗi cung ứng ô tô; mà thường là bắt buộc. Các nhà sản xuất OEM và nhà cung cấp cấp một sẽ không chấp nhận các bộ phận từ nguồn chưa được chứng nhận, bất kể chất lượng bề ngoài như thế nào.

Đây là nơi các nhà sản xuất như Công nghệ kim loại Shaoyi (Ningbo) thể hiện giá trị của họ. Với chứng nhận IATF 16949, khả năng tạo mẫu nhanh trong 5 ngày và các hệ thống sản xuất hàng loạt tự động hóa, họ đáp ứng được yêu cầu về đảm bảo chất lượng cho các ứng dụng ô tô. Hỗ trợ DFM (Thiết kế để Sản xuất) toàn diện cùng thời gian báo giá trong vòng 12 giờ giúp tối ưu hóa chuỗi cung ứng cho các bộ phận khung gầm, hệ thống treo và cấu trúc, nơi các cụm kim loại tấm chính xác đóng vai trò then chốt.

Yêu cầu của ngành hàng không vũ trụ

Theo NASA-STD-5006A , hàn hàng không vũ trụ đòi hỏi độ chính xác cực kỳ nghiêm ngặt. Tiêu chuẩn này phân loại các mối hàn thành ba nhóm dựa trên mức độ quan trọng:

- Loại A (Quan trọng): Sự cố gây mất hệ thống, các thành phần chính, điều khiển hoặc tổn thất nhân sự—yêu cầu kiểm tra bằng mắt, kiểm tra kích thước, bề mặt và thể tích

- Loại B (Bán thiết yếu): Sự cố làm giảm hiệu suất nhưng không gây nguy hiểm cho nhân viên—yêu cầu kiểm tra bằng mắt, kiểm tra kích thước và bề mặt

- Loại C (Không thiết yếu): Sự cố không ảnh hưởng đến hiệu suất hệ thống hay gây nguy hiểm cho nhân viên—yêu cầu kiểm tra bằng mắt và kiểm tra kích thước

Mọi mối hàn hàng không vũ trụ đều yêu cầu các quy trình được chứng nhận, được tài liệu hóa trong Các Đặc tả Quy trình Hàn (WPS), đi kèm bởi Hồ sơ Đánh giá Quy trình (PQR). Thợ hàn phải được chứng nhận cho các quy trình cụ thể, và thiết bị phải được hiệu chuẩn và kiểm tra chấp nhận trước khi gia công các bộ phận dùng trên phương tiện bay. Các phương pháp tự chế đơn giản là không thể đáp ứng được những yêu cầu này.

Ứng dụng Kiến trúc và Cấu trúc

Các quy chuẩn xây dựng và yêu cầu kỹ thuật kết cấu đòi hỏi phải tuân thủ AWS D1.1 hoặc D1.3 đối với các mối hàn chịu lực. Dù đang chế tạo ghế công xôn, thiết kế ghế công xôn cho không gian thương mại hay hệ thống hỗ trợ kết cấu, các quy trình được chứng nhận và thợ hàn có đủ điều kiện đều đảm bảo sự tuân thủ pháp lý và độ bền vững về mặt kết cấu.

Các yếu tố liên quan đến bảo hiểm và trách nhiệm pháp lý làm tăng thêm những yêu cầu này. Nếu một mối hàn tự làm bị đứt gãy và gây ra chấn thương hoặc thiệt hại tài sản, việc thiếu tài liệu chứng nhận và đủ điều kiện sẽ dẫn đến rủi ro pháp lý nghiêm trọng.

Tiêu chí lựa chọn dịch vụ chuyên nghiệp

Khi sử dụng dịch vụ chuyên nghiệp là lựa chọn đúng đắn, bạn nên chọn nhà cung cấp tốt nhất như thế nào? Hãy dùng các tiêu chí sau để đánh giá các đối tác gia công tiềm năng:

- Các chứng chỉ liên quan: Xác minh chứng nhận AWS phù hợp với vật liệu và ứng dụng của bạn; xác nhận ISO 9001 hoặc IATF 16949 về quản lý chất lượng; kiểm tra đăng ký ITAR đối với các công việc liên quan đến quốc phòng

- Chuyên môn về Vật liệu: Đảm bảo kinh nghiệm với các hợp kim cụ thể của bạn—hàn nhôm đòi hỏi kỹ năng khác biệt so với hàn thép không gỉ hoặc các vật liệu đặc chủng

- Khả năng thiết bị: Xác nhận các quy trình hàn phù hợp và năng lực đáp ứng quy mô dự án của bạn—từ số lượng mẫu thử đến sản lượng sản xuất hàng loạt

- Tài liệu chất lượng: Yêu cầu tài liệu WPS/PQR mẫu; kiểm tra khả năng kiểm định bao gồm phương pháp trực quan, đo kích thước và kiểm tra không phá hủy (NDT)

- Thời gian hoàn thành: Đánh giá tốc độ tạo mẫu và thời gian sản xuất so với tiến độ dự án của bạn

- Hỗ trợ DFM: Tìm kiếm nhà cung cấp có thể đưa ra phản hồi thiết kế nhằm tối ưu khả năng chế tạo và giảm chi phí

- Khả năng hoàn thiện: Xác nhận dịch vụ mài, đánh bóng, thụ động hóa và phủ lớp trong nội bộ hoặc được quản lý nếu cần thiết

- Khả năng phản hồi trong giao tiếp: Thời gian phản hồi báo giá cho thấy mức độ phản ứng tổng thể—phản hồi báo giá trong 12 giờ cho thấy sự tập trung nghiêm túc vào khách hàng

Chiếc ghế hàn bạn đang chế tạo để sử dụng cá nhân sẽ có yêu cầu khác biệt so với ghế hàn sản xuất hàng loạt để phân phối thương mại. Hãy lựa chọn nhà cung cấp có năng lực phù hợp với nhu cầu thực tế của dự án, thay vì đặt yêu cầu quá cao hoặc quá thấp.

Ra quyết định cuối cùng

Dưới đây là khung quyết định thực tiễn:

Tự làm là phù hợp khi:

- Các dự án không mang tính kết cấu và có hậu quả thấp nếu xảy ra lỗi

- Bạn có đầy đủ thiết bị và biện pháp an toàn

- Có thời gian để học hỏi và luyện tập

- Chi phí vật liệu cho phép sai sót trong quá trình phát triển kỹ năng

- Không yêu cầu chứng chỉ hoặc kiểm tra bởi bên thứ ba

Dịch vụ chuyên nghiệp là cần thiết khi:

- Độ bền kết cấu hoặc an toàn phụ thuộc vào chất lượng mối hàn

- Yêu cầu bắt buộc phải có chứng nhận ngành hoặc tuân thủ quy chuẩn

- Tiến độ dự án không cho phép thời gian học việc

- Chi phí vật liệu cao và việc sửa chữa lại không được chấp nhận

- Khối lượng sản xuất vượt quá khả năng thực tế của công việc tự làm (DIY)

- Yêu cầu thiết bị hoặc quy trình chuyên dụng

Thực hiện phân tích lợi ích - chi phí một cách trung thực. Chi phí vật liệu, thiết bị và các sai sót tiềm tàng—kể cả giá trị thời gian—cần được cân nhắc so với giá dịch vụ chuyên nghiệp. Với các dự án nhỏ hơn, tự làm thường tiết kiệm chi phí. Với các công việc lớn hơn, phức tạp hơn hoặc yêu cầu chứng nhận, đầu tư vào dịch vụ chuyên nghiệp sẽ ngăn ngừa các lỗi tốn kém và đảm bảo kết quả đạt yêu cầu.

Nếu bạn quyết tâm phát triển kỹ năng hàn, hãy cân nhắc tham gia khóa đào tạo chính thức. Các trường cao đẳng cộng đồng và trường kỹ thuật cung cấp các khóa học thực hành với sự hướng dẫn từ những thợ hàn giàu kinh nghiệm. Các bài hướng dẫn trực tuyến có thể hỗ trợ nhưng không thể thay thế việc học tập có cấu trúc với thiết bị phù hợp và sự giám sát đúng đắn.

Hãy nhớ — thực hành làm nên hoàn hảo. Hãy bắt đầu với những dự án nhỏ để xây dựng sự tự tin trước khi đảm nhận những công việc thách thức hơn. Theo thời gian, ranh giới giữa những gì bạn có thể tự xử lý và những gì cần sự trợ giúp của chuyên gia sẽ thay đổi khi kỹ năng của bạn phát triển.

Dù bạn chọn con đường tự làm (DIY) hay hợp tác với các thợ gia công chuyên nghiệp, bước cuối cùng vẫn giống nhau: đảm bảo rằng bạn đã lựa chọn phương pháp phù hợp với yêu cầu cụ thể và kỳ vọng về chất lượng cho dự án của mình.

Lựa chọn Đối tác Hàn Kim loại Tấm Phù hợp

Bạn đã đi qua các phương pháp hàn, khoa học vật liệu, kỹ thuật khắc phục sự cố, quy trình hoàn thiện và các yêu cầu chứng nhận. Giờ đây là lúc quyết định — chuyển tất cả kiến thức đó thành hành động bằng cách chọn đối tác gia công sẽ hiện thực hóa dự án của bạn.

Việc lựa chọn nhà cung cấp sai sẽ làm lãng phí thời gian, tiền bạc và nguyên vật liệu. Đối tác phù hợp sẽ cung cấp các bộ phận chất lượng đúng tiến độ và dự đoán các vấn đề trước khi chúng xảy ra. Theo Metal Works Inc., đối tác không phù hợp có thể làm chậm quá trình đưa sản phẩm ra thị trường, ngăn cản bạn hoàn thành dự án và tiến tới các sáng kiến tiếp theo. Hãy cùng tìm hiểu những yếu tố nào tạo nên sự khác biệt giữa các dịch vụ hàn kim loại tấm xuất sắc so với các lựa chọn trung bình.

Các yếu tố chính trong việc lựa chọn nhà cung cấp dịch vụ

Không phải cơ sở gia công nào cũng có thể đáp ứng được yêu cầu cụ thể của bạn — ngay cả khi quảng cáo của họ cho thấy điều ngược lại. Gia công kim loại bao gồm nhiều dịch vụ chuyên biệt, từ cắt laser và mài đến các công đoạn hoàn thiện như lắp ráp và sơn. Mỗi công đoạn đều đòi hỏi thiết bị chuyên dụng, nhân sự tay nghề cao và diện tích nhà xưởng phù hợp.

Dưới đây là những tiêu chí cần đánh giá khi xem xét các đối tác tiềm năng:

- Chuyên môn về thiết kế và hỗ trợ DFM: Một số nhà sản xuất thiếu năng lực kỹ thuật để định hướng các quyết định quan trọng về vật liệu, điều chỉnh thiết kế nhằm thuận tiện sản xuất hoặc tối ưu hóa chi phí mà không làm giảm chất lượng. Các nhà cung cấp đưa ra phản hồi toàn diện về Thiết kế Dành cho Sản xuất sẽ phát hiện sự cố từ sớm — trước khi chúng trở thành những vấn đề sản xuất tốn kém

- Năng lực nội bộ: Nếu các bộ phận kim loại của bạn cần cắt laser, hàn và các dịch vụ thứ cấp như sơn hoặc lắp ráp, việc thuê ngoài từng công đoạn cho các cơ sở khác nhau sẽ làm tăng chi phí, kéo dài tiến độ và dẫn đến sự biến động về chất lượng. Hãy tìm các đối tác có thể thực hiện toàn bộ quy trình gia công nội bộ

- Độ hiện đại của thiết bị: Thiết bị lỗi thời sẽ kéo dài thời gian thực hiện dự án và có thể ảnh hưởng đến chất lượng. Các cơ sở tiên tiến duy trì thiết bị không quá năm năm tuổi và ứng dụng robot cùng tự động hóa để nâng cao độ chính xác. Dù bạn cần một vòm công nghiệp cho ứng dụng kiến trúc hay một cầu thang kim loại tùy chỉnh để lắp đặt thương mại, thiết bị hiện đại đều đảm bảo kết quả nhất quán

- Khả năng hoàn thành nhanh: Thời gian đưa sản phẩm ra thị trường ảnh hưởng trực tiếp đến lợi nhuận của bạn. Chế tạo mẫu nhanh trong thời gian chỉ từ một đến ba ngày, kết hợp với quy trình vận chuyển đáng tin cậy, giúp các dự án tiếp tục tiến triển thay vì bị đình trệ trong hàng đợi sản xuất

Các xưởng gia công ở các khu vực và quy mô khác nhau có sự khác biệt lớn về những khả năng này. Đừng mặc định—hãy xác minh thông qua tham quan cơ sở, kiểm tra tham chiếu và đánh giá mẫu sản phẩm.

Từ Thiết Kế đến Giao Hàng

Hiểu rõ toàn bộ vòng đời dự án giúp bạn đánh giá xem một đối tác tiềm năng có thể đáp ứng các yêu cầu của bạn từ khâu ý tưởng đến hoàn thiện hay không. Theo Benchmark Steel , từ giai đoạn thiết kế ban đầu đến giao hàng cuối cùng, quá trình gia công là một nỗ lực tỉ mỉ và được phối hợp chặt chẽ, trong đó mỗi bước đều đóng vai trò quan trọng.

Dưới đây là hình ảnh vòng đời gia công chuyên nghiệp:

- Tư vấn thiết kế: Các kỹ sư cộng tác sử dụng phần mềm CAD tiên tiến để phát triển các bản vẽ kỹ thuật chính xác, xem xét khả năng chịu tải, điều kiện môi trường và các yêu cầu cụ thể của dự án, đồng thời tối ưu hóa bố trí để giảm thiểu lãng phí

- Lựa chọn vật liệu: Các mác thép phù hợp hoặc hợp kim nhôm được lựa chọn dựa trên các tính chất yêu cầu—khả năng chống ăn mòn, độ bền kéo, độ linh hoạt—phù hợp vật liệu với nhu cầu ứng dụng

- Cắt và chuẩn bị: Các phương pháp cắt laser, cắt plasma hoặc cắt bằng tia nước đạt được kích thước chính xác với các cạnh mịn, trong khi đánh dấu và ghi nhãn giúp đảm bảo độ chính xác khi lắp ráp

- Tạo hình và Hàn: Các thiết bị uốn tôn và máy cán định hình các bộ phận, tiếp theo là quá trình hàn chuyên nghiệp sử dụng các quy trình đã được chứng nhận phù hợp với yêu cầu vật liệu và ứng dụng của bạn

- Hoàn thiện và Kiểm tra: Xử lý bề mặt bảo vệ khỏi sự ăn mòn trong khi kiểm soát chất lượng nghiêm ngặt—kiểm tra kích thước, thử nghiệm độ bền, kiểm tra trực quan—đảm bảo từng chi tiết đáp ứng đúng thông số kỹ thuật

- Tổ chức giao hàng: Đóng gói đúng cách ngăn ngừa hư hỏng trong quá trình vận chuyển, trong khi lập kế hoạch logistics đảm bảo thời gian giao hàng đúng hạn và sản phẩm sẵn sàng sử dụng ngay lập tức

Điều gì giúp tối ưu hóa toàn bộ quy trình này? Hỗ trợ DFM toàn diện kết hợp với thời gian phản hồi báo giá nhanh chóng. Khi các nhà sản xuất phản hồi trong vòng 12 giờ thay vì vài ngày, bạn có thể nhanh chóng điều chỉnh thiết kế, so sánh các phương án một cách hiệu quả và duy trì đà thực hiện dự án. Các nhà cung cấp như Công nghệ kim loại Shaoyi (Ningbo) điển hình cho cách tiếp cận này — cung cấp chất lượng đạt chứng nhận IATF 16949 cho các bộ phận khung gầm ô tô, hệ thống treo và các cấu kiện chịu lực, đồng thời hỗ trợ tạo mẫu nhanh trong 5 ngày và hỗ trợ DFM toàn diện nhằm tối ưu khả năng chế tạo ngay từ đầu.

Khi lựa chọn đối tác hàn kim loại tấm, hãy ưu tiên những nhà cung cấp có chứng chỉ phù hợp với yêu cầu ngành của bạn, chuyên môn đã được chứng minh về các hợp kim cụ thể, trang thiết bị hiện đại đáp ứng được khối lượng sản xuất của bạn, và khả năng giao tiếp phản hồi nhanh để dự án luôn tiến triển chứ không bị đình trệ trong hàng đợi.

Các bước tiếp theo của bạn

Với kiến thức từ hướng dẫn này, bạn đã sẵn sàng để đưa ra các quyết định sáng suốt về nhu cầu hàn kim loại tấm của mình. Dù bạn đang gia công các bộ phận ô tô yêu cầu chứng nhận IATF 16949, các chi tiết kiến trúc đòi hỏi độ chính xác về thẩm mỹ, hay thiết bị công nghiệp nơi độ bền kết cấu là yếu tố hàng đầu, việc lựa chọn nhà cung cấp phù hợp với các yêu cầu của bạn sẽ đảm bảo kết quả thành công.

Hãy bắt đầu bằng việc xác định các yêu cầu bắt buộc của dự án—vật liệu, chứng chỉ, tiến độ, tiêu chuẩn chất lượng. Sau đó đánh giá các đối tác tiềm năng dựa trên những tiêu chí này thay vì chỉ dựa vào giá cả. Đối tác gia công phù hợp không chỉ đơn thuần thực hiện theo thông số kỹ thuật của bạn; họ còn cải thiện thiết kế của bạn, dự đoán trước các thách thức trong sản xuất và cung cấp các bộ phận vượt quá mong đợi.

Hành trình từ tấm kim loại thô đến sản phẩm hoàn thiện bao gồm vô số quyết định, mỗi quyết định đều ảnh hưởng đến chất lượng cuối cùng. Bằng việc hiểu rõ các phương pháp hàn, tính tương thích vật liệu, yêu cầu chuẩn bị, kỹ thuật xử lý sự cố, các lựa chọn hoàn thiện và các chứng nhận chất lượng, bạn đã có nền tảng vững chắc để tự tin đưa ra những quyết định này — dù là tự thực hiện dự án hay hợp tác với các dịch vụ hàn kim loại tấm chuyên nghiệp chia sẻ cam kết của bạn về sự xuất sắc.

Các câu hỏi thường gặp về dịch vụ hàn kim loại tấm

1. Công việc kim loại tấm có giá bao nhiêu?

Chi phí gia công kim loại tấm thường dao động từ 4 đến 48 USD mỗi foot vuông, tùy thuộc vào loại vật liệu, độ dày, mức độ phức tạp và yêu cầu tùy chỉnh. Dịch vụ hàn làm tăng chi phí gia công cơ bản tùy theo độ phức tạp của mối nối, phương pháp hàn được sử dụng (hàn TIG đắt hơn hàn MIG do tốn nhiều nhân công) và các chứng nhận yêu cầu. Đối với các ứng dụng trong ngành ô tô hoặc hàng không vũ trụ yêu cầu tuân thủ IATF 16949 hoặc AWS D1.3, hãy dự kiến mức giá cao hơn để phản ánh các quy trình đảm bảo chất lượng nghiêm ngặt liên quan.

2. Loại hàn nào tốt nhất cho kim loại tấm?

Phương pháp hàn tối ưu phụ thuộc vào ứng dụng cụ thể của bạn. Hàn TIG vượt trội trong công việc chính xác trên các vật liệu mỏng dưới 3mm, mang lại tính thẩm mỹ và độ kiểm soát tốt hơn — lý tưởng cho thép không gỉ và nhôm. Hàn MIG cung cấp tốc độ sản xuất nhanh hơn đối với vật liệu dày hơn và khối lượng công việc lớn. Hàn điểm thống trị trong sản xuất ô tô đối với các cấu hình tấm chồng lên nhau, mang lại tốc độ cực nhanh với độ biến dạng tối thiểu. Loại vật liệu, độ dày, yêu cầu bề mặt hoàn thiện và khối lượng sản xuất đều ảnh hưởng đến lựa chọn tốt nhất.

3. TIG hay MIG tốt hơn cho kim loại tấm?

Cả hàn TIG và hàn MIG đều tạo ra các mối hàn kim loại tấm chất lượng cao, nhưng chúng phục vụ các mục đích khác nhau. Hàn TIG mang lại độ kiểm soát vượt trội và bề mặt hoàn thiện sạch hơn, làm cho nó lý tưởng cho các mối nối nhìn thấy được, vật liệu mỏng dưới 1mm và các ứng dụng yêu cầu ít xử lý sau khi hàn. Hàn MIG cung cấp tốc độ nhanh hơn và thao tác dễ dàng hơn, phù hợp hơn với vật liệu dày (trên 1mm), môi trường sản xuất và các ứng dụng mà hình dạng mối hàn không quá quan trọng. Nhiều thợ gia công chuyên nghiệp sử dụng cả hai phương pháp tùy theo yêu cầu cụ thể của từng dự án.

4. Dịch vụ hàn kim loại tấm nên có những chứng nhận gì?

Các chứng nhận yêu cầu phụ thuộc vào ngành của bạn. AWS D1.3 bao gồm hàn thép tấm cấu trúc cho vật liệu dày 3/16 inch và mỏng hơn. IATF 16949 là bắt buộc đối với chuỗi cung ứng ô tô, đảm bảo ngăn ngừa khuyết tật và duy trì chất lượng ổn định. ISO 9001 cung cấp xác minh hệ thống quản lý chất lượng cơ bản. Đối với các ứng dụng hàng không vũ trụ, hãy tìm các cơ sở đáp ứng yêu cầu NASA-STD-5006A với kiểm tra PQR được tài liệu hóa. Công việc liên quan đến quốc phòng yêu cầu đăng ký ITAR. Luôn xác minh trình độ thợ hàn hiện hành cùng với các chứng nhận công ty.

5. Làm thế nào để tôi tránh biến dạng khi hàn kim loại tấm mỏng?

Việc ngăn ngừa cong vênh đòi hỏi phải quản lý nhiệt một cách chiến lược. Các kỹ thuật chính bao gồm sử dụng các mẫu hàn gián đoạn thay vì các đường hàn liên tục, các trình tự hàn từng bước ngược để phân bố nhiệt đều, và cân bằng mối hàn quanh trục trung hòa bằng cách luân phiên hai bên. Các đồ gá đồng làm mát bằng nước loại bỏ nhanh chóng nhiệt lượng khỏi các bộ phận mỏng. Điều chỉnh trước hoặc uốn cong trước các chi tiết trước khi hàn để tận dụng lực co ngót theo hướng có lợi. Tránh hàn quá mức—lượng kim loại hàn dư thừa làm tăng đáng kể biến dạng mà không gia tăng độ bền. Việc cố định đúng cách với kẹp chặt đầy đủ cũng giúp giảm thiểu chuyển động trong suốt chu kỳ hàn.

Sản xuất với số lượng nhỏ, tiêu chuẩn cao. Dịch vụ tạo nguyên mẫu nhanh của chúng tôi giúp việc kiểm chứng trở nên nhanh chóng và dễ dàng hơn —

Sản xuất với số lượng nhỏ, tiêu chuẩn cao. Dịch vụ tạo nguyên mẫu nhanh của chúng tôi giúp việc kiểm chứng trở nên nhanh chóng và dễ dàng hơn —